n-type Mg-Sb based room temperature thermoelectric material and preparation method thereof

A thermoelectric material and technology of electrical materials, which are applied in the field of n-type Mg-Sb-based room temperature thermoelectric materials and their preparation, can solve the problem of limiting the service temperature range and application fields of materials, thermoelectric figure of merit and mechanical properties are not ideal, limiting thermoelectricity Device diversity and other issues, to achieve the effect of low cost, strong controllability and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above n-type Mg-Sb based room temperature thermoelectric material, comprising the following steps:

[0031] S1 according to the general chemical formula Mg3+δ mn x Sb 2-y-z Bi y A z Select a single material with a purity ≥ 99% as a raw material, weigh the ingredients in an argon atmosphere with an oxygen content of less than 1ppm, and then place them in a planetary ball mill, and add a certain amount of stainless steel balls to the ball mill to utilize the stainless steel in the ball mill. The impact energy of the ball makes the above raw materials pulverized and mixed, and the powder Mg is initially synthesized. 3+δ mn x Sb 2-y-z Bi y A z Mutually.

[0032] In this step, the stainless steel balls and raw materials added to the ball mill are protected by argon gas when they are rotating in the ball mill, so as to prevent the powder from oxidation.

[0033] In order to further change the grain size,...

Embodiment 1

[0042] Prepare as follows:

[0043] S1 selects flaky Mg (purity 99.8%), granular Sb (purity 99.999%), Bi (purity 99.999%), Te (purity 99.999%), powdery Mn (purity 99.95%) as raw materials, according to the general formula Mg 3+δ mn x Sb 2-y-z Bi y Te z The stoichiometric ratio (where δ=-0.1, x=0.1, y=0.5, z=0.01, that is, the general chemical formula is Mg 2.9 mn 0.1 Sb 1.49 Bi 0.5 Te 0.01 ), weigh the ingredients in a vacuum drying oven with an argon atmosphere with an oxygen content of less than 1ppm, and put stainless steel balls with a diameter of 6mm and 20mm into a planetary ball mill at a ratio of 10:1, and pass through argon Gas protection to prevent powder oxidation, the ball to material weight ratio is 20:1. The operating speed of the planetary ball mill is 500r / min, and the ball milling time is 7.5h.

[0044] S2 Take the powder obtained in the above steps out of a vacuum drying oven with an argon atmosphere with an oxygen content of less than 0.1ppm, weigh...

Embodiment 2

[0053] Prepare as follows:

[0054] S1 uses flake Mg (purity 99.8%), granular Sb (purity 99.999%), Bi (purity 99.999%), Te (purity 99.999%), powdered Mn (purity 99.95%) as raw materials, according to Mg 3+δ mn x Sb 2-y-z Bi y Te z Stoichiometric ratio (δ=0.1x=0.2, y=0.3, z=0.05, that is, the general chemical formula is Mg 3.1 mn 0.2 Sb 1.65 Bi 0.3 Te 0.05 ), weigh the ingredients in an argon atmosphere vacuum drying oven with an oxygen content of less than 1ppm, and put stainless steel balls with a diameter of 6mm and 20mm into the ball mill according to the ratio of 10:2, and pass through the argon protection , to prevent powder oxidation, the ball to material weight ratio is 15:1. The running speed of the ball mill is 400r / min, and the ball milling time is 10h.

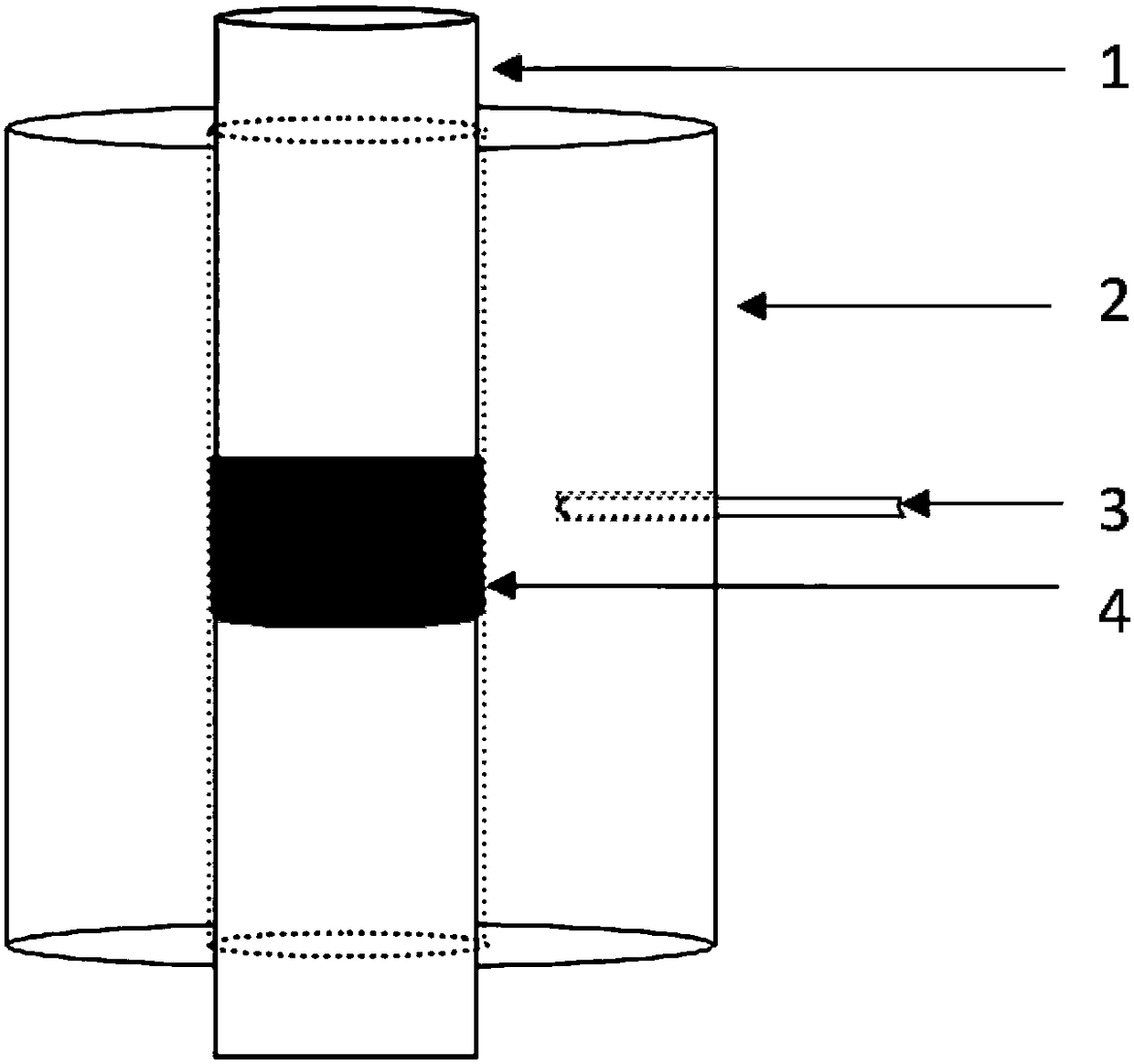

[0055] S2 Take out the powder obtained in the above steps in a vacuum drying oven with an argon atmosphere with an oxygen content of less than 0.1ppm, weigh them separately and put them in figure 1 In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com