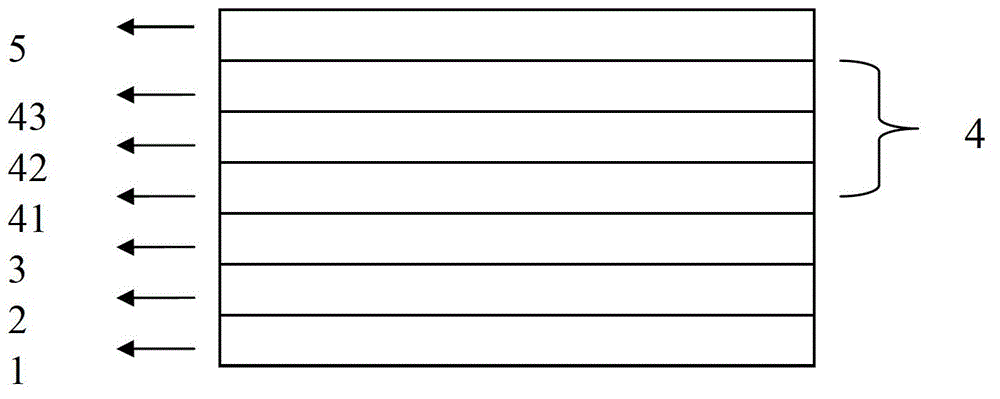

Inverted polymer solar cell of Ag nano particle compounded cavity transmission layer and fabrication method

A technology of hole transport layer and silver nanoparticles, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low efficiency of solar cells, achieve the effects of increasing optical distance, enhancing light absorption capacity, and improving interface contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

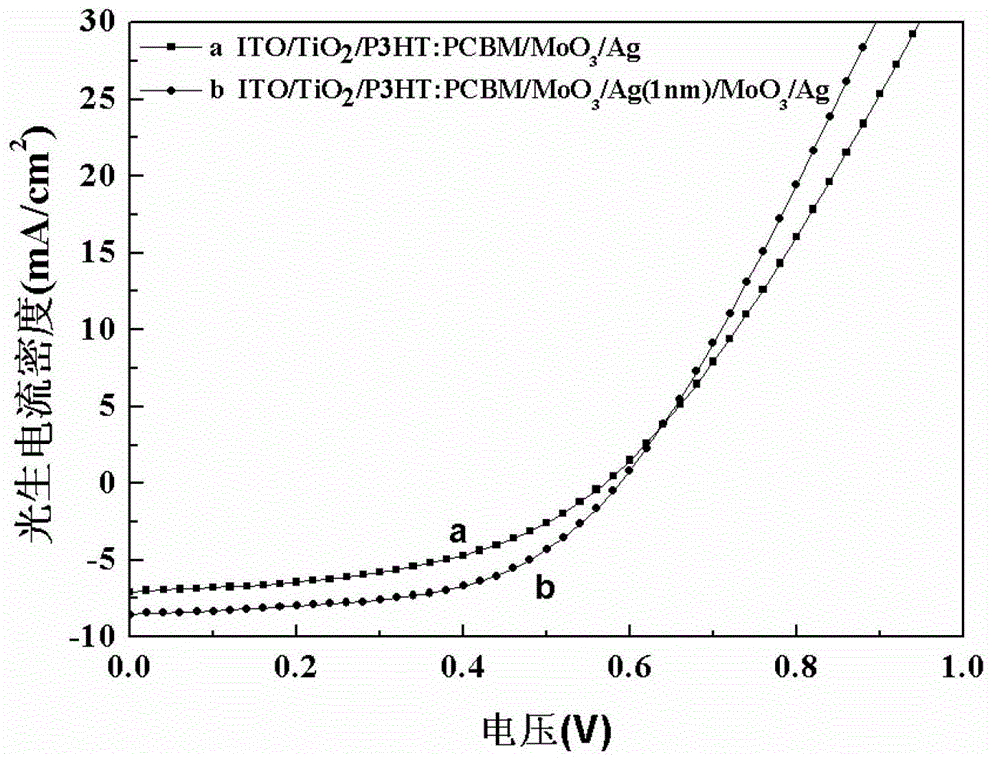

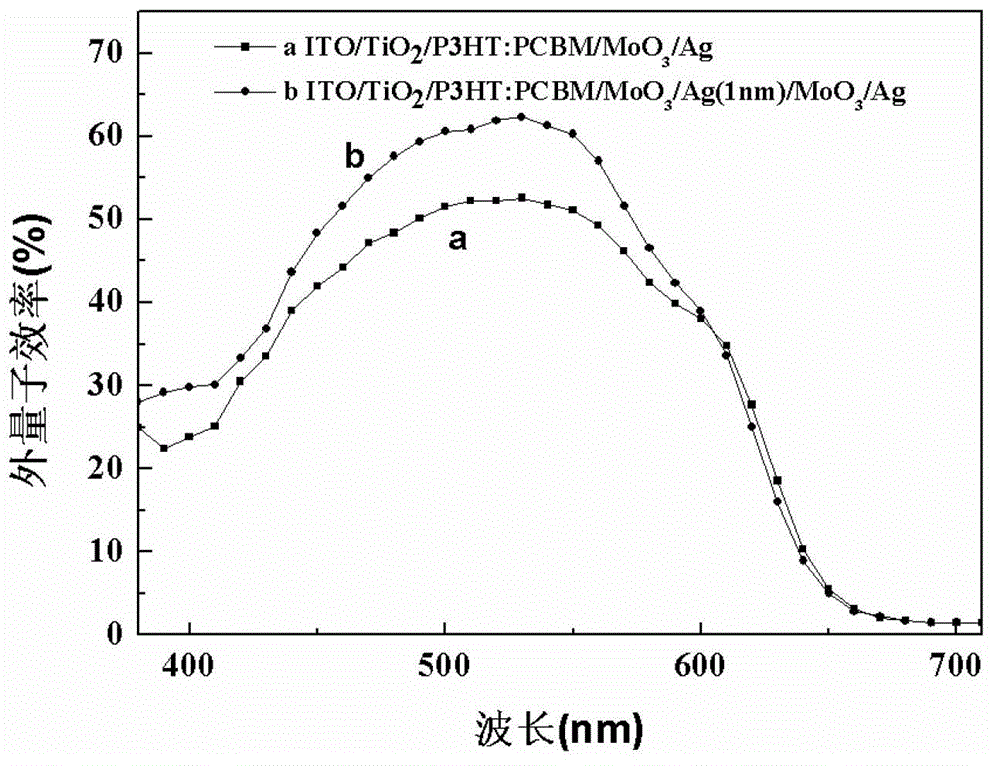

Examples

Embodiment 1

[0024] 1. The ITO glass was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried with nitrogen;

[0025] 2. At room temperature, drop the mixed solution of 20ml ethanol, 5ml deionized water, and 1ml hydrochloric acid with a concentration of 0.2mol / l into the solution containing 5ml tetrabutyl titanate, 40ml ethanol, and 3ml acetylacetone , and accompanied by vigorous stirring for 1 hour, left to age for 48 hours, and then obtained TiO 2 Sol.

[0026] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 1000rpm and spin-coated for 20s, and sintered in a muffle furnace at 450°C for 1.5 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer.

[0027] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:0.8 and a concentration of 10 mg / ml on the ITO / nc-TiO 2 , the thickness of the active layer is 100nm; then put it on the hot stage in the glove box, anneal the active...

Embodiment 2

[0030] 1. The ITO glass was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried with nitrogen;

[0031] 2. At room temperature, drop the mixed solution of 30ml ethanol, 10ml deionized water, and 2ml hydrochloric acid with a concentration of 0.25mol / l into the solution containing 10ml tetrabutyl titanate, 60ml ethanol, and 5ml acetylacetone , and accompanied by vigorous stirring for 3 hours, left to age for 48h, and then obtained TiO 2 Sol.

[0032] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 3000rpm and spin-coated for 20s, and sintered in a muffle furnace at 450°C for 2 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer.

[0033] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:0.9 and a concentration of 12 mg / ml on the ITO / nc-TiO 2 , the thickness of the active layer is 70nm; then put it on the hot stage in the glove box, anneal the active lay...

Embodiment 3

[0036] 1. The ITO glass was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried with nitrogen;

[0037] 2. At room temperature, drop the mixed solution of 40ml ethanol, 15ml deionized water, and 3ml hydrochloric acid with a concentration of 0.3mol / l into the solution containing 20ml tetrabutyl titanate, 80ml ethanol, and 10ml acetylacetone , and accompanied by vigorous stirring for 5 hours, left to age for 48h, and then obtained TiO 2 Sol.

[0038] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 5000rpm and spin-coated for 20s, and sintered in a muffle furnace at 450°C for 3 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer.

[0039] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:1 and a concentration of 15 mg / ml on the ITO / nc-TiO 2 , the thickness of the active layer is 50nm; then put it on the hot stage in the glove box, anneal the active layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com