Lithium secondary battery, solid electrolyte composite material for same and method for preparing solid electrolyte composite material

A solid electrolyte and lithium secondary battery technology, applied in the field of material chemistry, can solve the problems of complex preparation process and high energy consumption, and achieve the effects of simple preparation process, high ion conductivity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

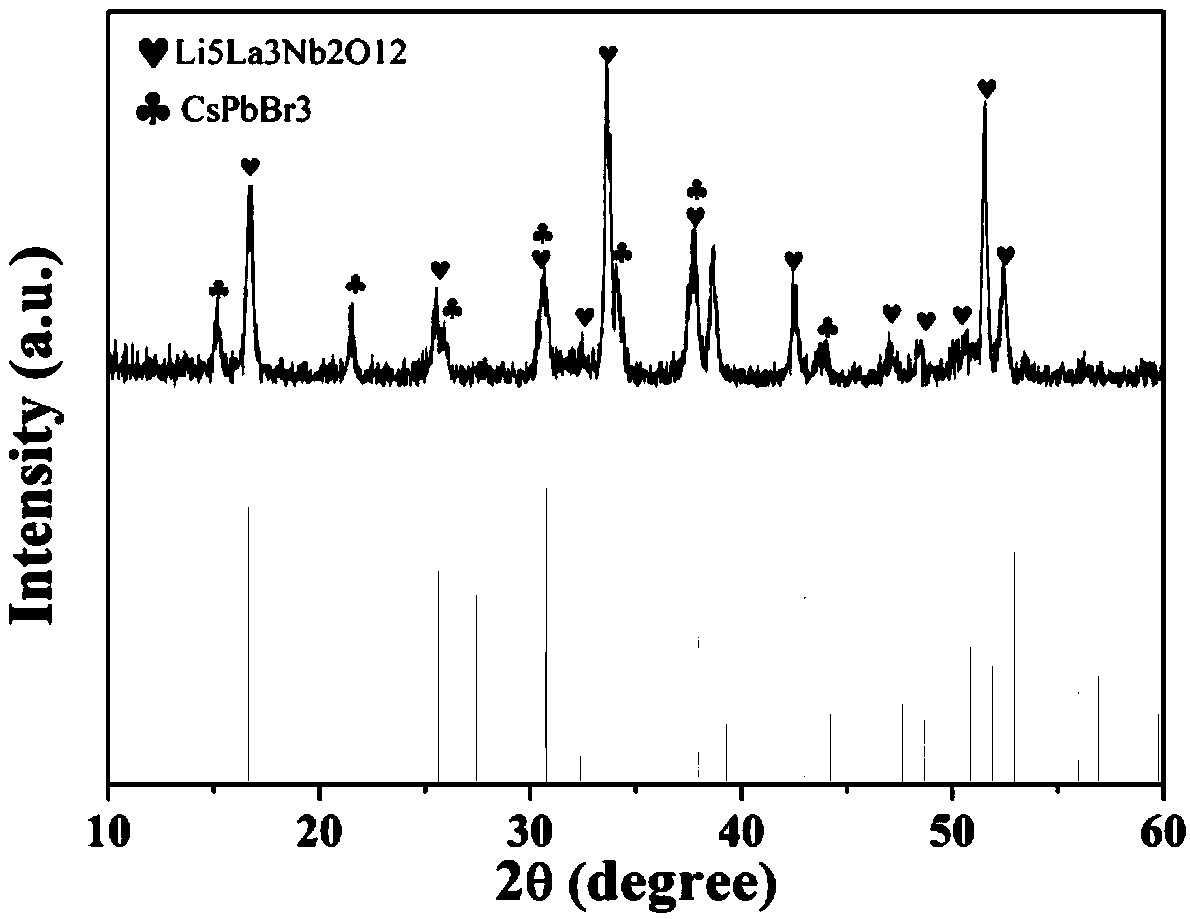

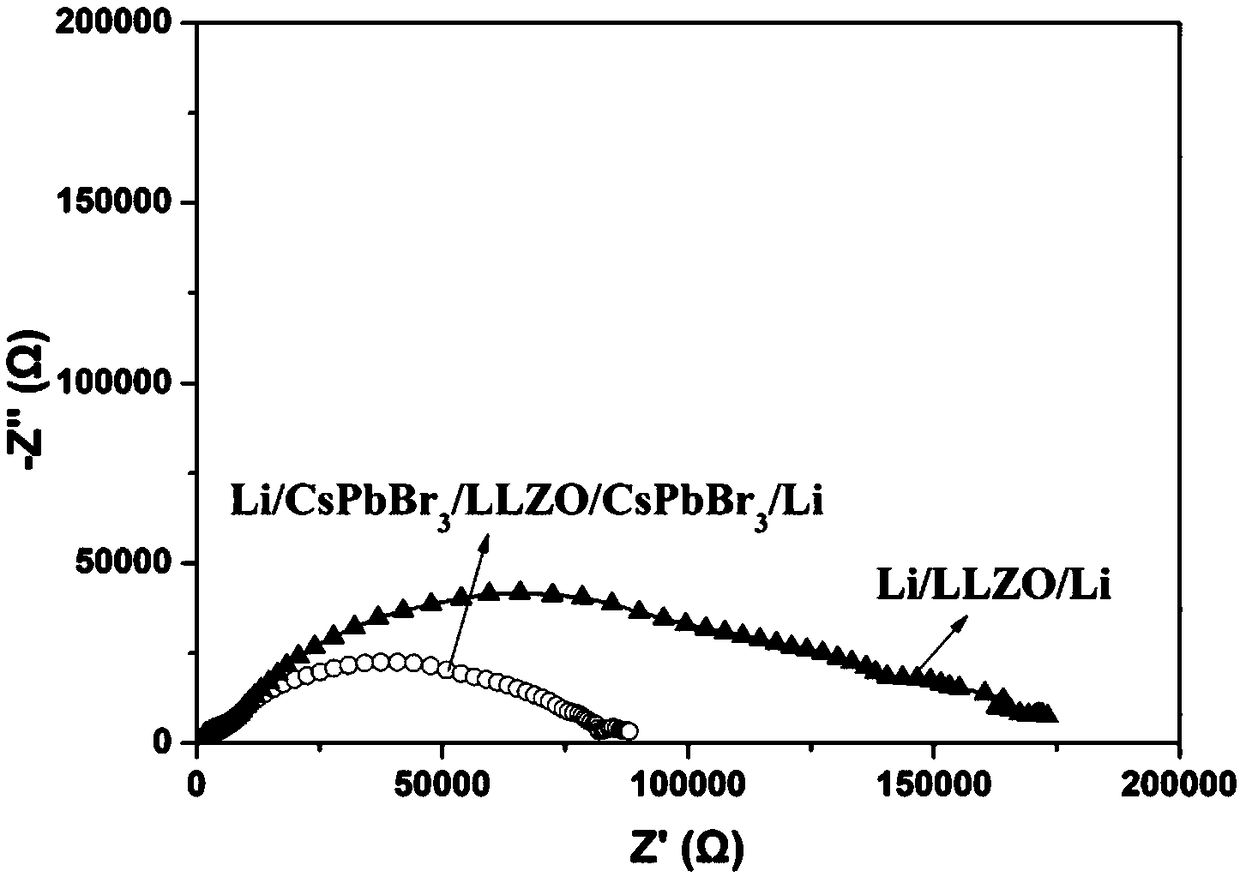

[0046] Weigh the raw materials lithium hydroxide, lanthanum oxide and zirconia according to the stoichiometric molar ratio (14:3:4), then use isopropanol as the ball milling solvent and zirconia balls as the ball milling medium for 12 hours, and dry to obtain a uniform mixture. raw materials. Then the raw material after ball milling was put into a tubular atmosphere furnace, calcined at 800°C for 12 hours and then cooled naturally; the calcined sample was taken out and pressed into a disc with a diameter of 13.5 mm by a manual dry press molding machine. The pressure used is 2-4 MPa, and the holding time is 2-3 minutes. The pellets were placed in a porcelain boat and calcined in a tubular atmosphere furnace at 1200 °C in air for 36 hours, and then cooled naturally to prepare garnet-type Li 7 La 3 Zr 2 o 12 .

[0047] Prepare 1M PbBr 2 N,N-dimethylformamide (DMF) solution and 0.07 M CsBr in methanol solution, 40 μl of PbBr 2 The solution was spin-coated on a piece of 500m...

Embodiment 2

[0053]The raw materials lithium hydroxide, lanthanum oxide and zirconium oxide are according to the stoichiometric molar ratio (14:3:4), and then use isopropanol as the ball milling solvent, and the zirconia balls are used as the ball milling medium for ball milling for 12 hours, and then dry to obtain a uniformly mixed raw material . Then the raw material after ball milling was put into a tubular atmosphere furnace, calcined at 800°C for 12 hours and then cooled naturally; the calcined sample was taken out and pressed into a disc with a diameter of 13.5 mm by a manual dry press molding machine. The pressure used is 2-4 MPa, and the holding time is 2-3 minutes. The pellets were calcined in a porcelain boat at 1200 °C in air for 36 hours, and then cooled naturally to prepare garnet-type Li 7 La 3 Zr 2 o 12 .

[0054] Weigh the same molar amount of PbBr 2 and CsBr powder dissolved in DMF to obtain 0.48M concentration of CsPbBr 3 DMF solution. Then, to 1mL CsPbBr 3 Add 3...

Embodiment 3

[0060] Weigh the raw materials lithium hydroxide, lanthanum oxide and zirconia according to the stoichiometric molar ratio (14:3:4), then use isopropanol as the ball milling solvent and zirconia balls as the ball milling medium for 12 hours, and dry to obtain a uniform mixture. raw materials. Then the raw material after ball milling was put into a tubular atmosphere furnace, calcined at 800°C for 12 hours and then cooled naturally; the calcined sample was taken out and pressed into a disc with a diameter of 13.5 mm by a manual dry press molding machine. The pressure used is 2-4 MPa, and the holding time is 2-3 minutes. The pellets were placed in a porcelain boat and calcined in a tubular atmosphere furnace at 1200 °C in air for 36 hours, and then cooled naturally to prepare garnet-type Li 7 La 3 Zr 2 o 12 .

[0061] Prepare 1M PbBr 2 N,N-dimethylformamide (DMF) solution and 0.07 M CsBr in methanol solution, 40 μl of PbBr 2 The solution was spin-coated on a piece of 500m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com