Carbon-coated foamed aluminium compound and preparation method thereof, current collector and filtering material

A foamed aluminum and composite technology, applied in the field of materials, can solve the problems of uncontrollable activity, poor mechanical strength, narrow electrochemical window, etc., and achieve the effect of improving interface contact effect, improving mechanical strength, and reducing contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

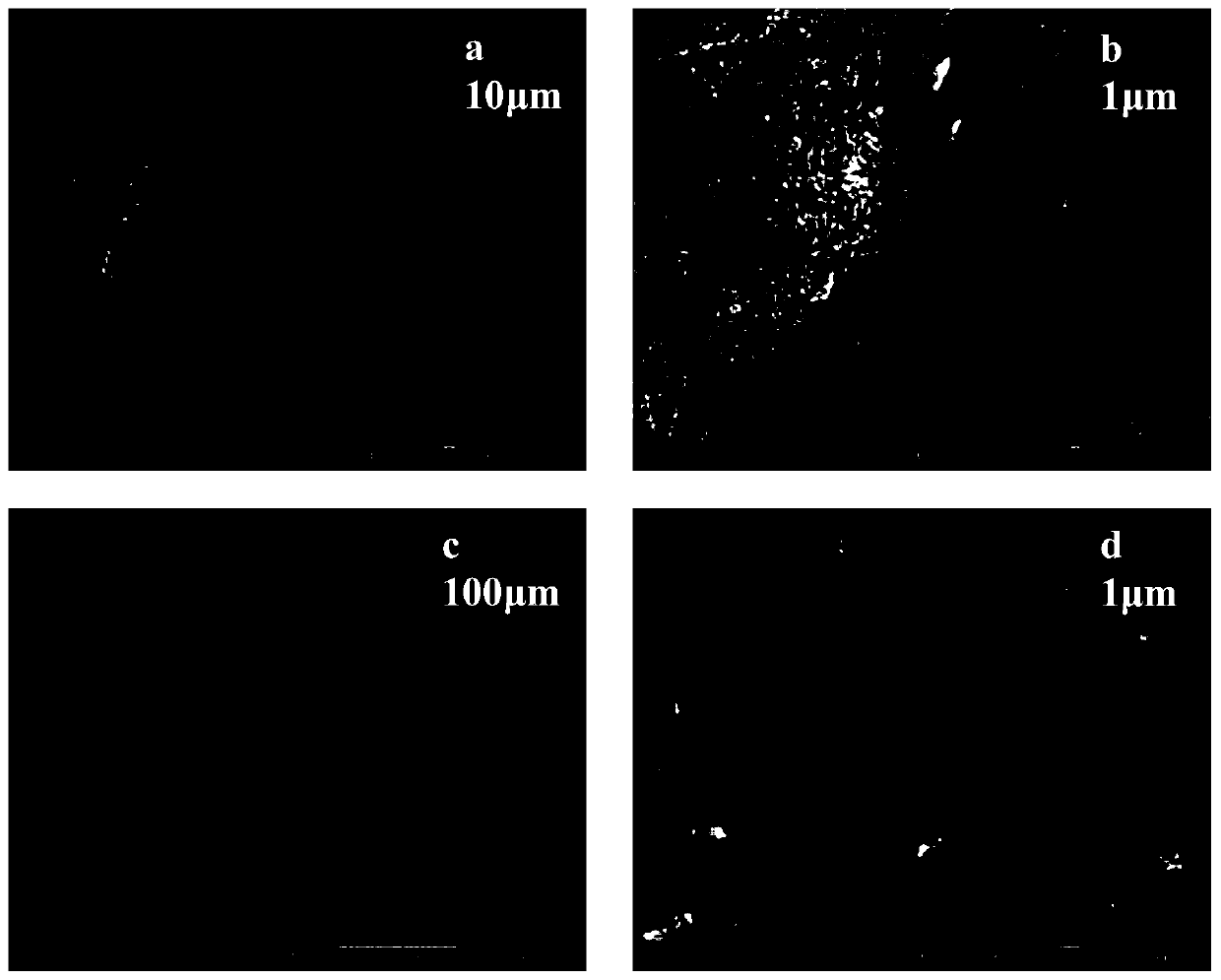

[0045] see figure 1 and figure 2 , the present invention relates to a kind of preparation method of carbon-covered aluminum foam composite, comprising the following steps:

[0046]The aluminum foam is treated at 300-700°C with a carbon source, or a gas containing a carbon source and a nitrogen source for 0.1-3 hours to form a uniform and dense carbon layer on the surface of the aluminum wire skeleton; then a weak oxidant is passed through at 500- Treat at 600°C for 1-24 hours to create pores in the carbon layer to obtain a composite in which the microporous carbon layer is coated on the surface of foamed aluminum (such as figure 1 As shown, the coated carbon layer has a microporous structure, and the rest is tightly coated);

[0047] in,

[0048] The carbon source is CO, C 1 -C 9 Hydrocarbon, C 1 -C 6 One or more of alcohols, ethers, ketones or esters; when the gas containing carbon sources and nitrogen sources is introduced, the nitrogen sources are one or more of org...

Embodiment 1

[0058] Put aluminum foam particles with a diameter of 0.2 mm and a porosity of 50% into a reaction furnace, and at 550° C., feed gas containing carbon source and nitrogen source (C 5 -C 9 Hydrocarbon, ammonia, and hydrogen, the mixture of argon, volume fraction is respectively 87%, 3%, 5%, 5%) After 2 hours, stop passing through carbon source and nitrogen source. Cool down to 500°C and pass H 2 O for 24 hours, at room temperature, under the protection of nitrogen, the resulting product was taken out to obtain a foamed aluminum-carbon composite with a dense carbon-coated layer of microporous structure. The thickness of the carbon layer is 300 nm. In this product, SP 2 The carbon mass fraction of hybridization is 80%, and the rest is SP 3 hybridized carbon. The pore volume of the carbon layer is 2ml / g.

[0059] Compared with non-carbon-coated products (wall thickness of hollow aluminum wire is 7-100 μm, porosity 85-99%, tensile strength 0.4-2MPa, compressive strength 1-3.5...

Embodiment 2

[0061] Put the foamed aluminum block with a length, width and height of 2-200mm and a porosity of 80% into the reaction furnace, and feed the carbon source and nitrogen source gas at 600°C (C 1 -C 4 Hydrocarbon, C 1 -C 7 Organic amines, C 3 -C 6 The mixture of ketone, hydrogen and argon, the volume fractions are respectively 20%, 10%, 40%, 25%, 5%) for 2 hours, and then the carbon source and nitrogen source are stopped. Maintain 600°C with CO 2 After 1 hour, the resulting product was taken out under nitrogen protection at room temperature to obtain a foamed aluminum-carbon composite with a dense carbon-coated layer with a microporous structure. The thickness of the carbon layer is 20 nm. In this product, SP 2 Hybridized carbon mass fraction is 88%, the rest is SP 3 hybridized carbon. The pore volume of the carbon layer is 0.3ml / g.

[0062] Compared with the above-mentioned non-carbon-coated products, the tensile and compressive strengths of the carbon-coated aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com