Polymer composite material with adjustable work function, and preparation method and application thereof

A composite material with adjustable work function technology, which is applied in the fields of application, sustainable manufacturing/processing, household appliances, etc., can solve the problems of low efficiency and inappropriate preparation methods, improve interface contact performance, reduce process requirements, and reduce raw materials Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] An aspect of the embodiments of the present invention also provides a method for preparing the polymer composite material, comprising: uniformly mixing at least a conductive polymer and an organic dopant in a solvent to form the polymer composite material.

[0048] Another aspect of the embodiments of the present invention also provides a composite ink, which includes the polymer composite material with adjustable work function.

[0049] In some embodiments, the polymer composite material can also be combined with other inks to form the composite ink.

[0050] Correspondingly, another aspect of the embodiments of the present invention also provides a method for preparing the composite ink, which includes: dissolving or dispersing the organic dopant in a solvent, and then mixing it with a conductive polymer solution or dispersion to prepare Obtain the composite ink.

[0051] Furthermore, in some embodiments, the composite ink can also be prepared by mixing the organic d...

Embodiment 1

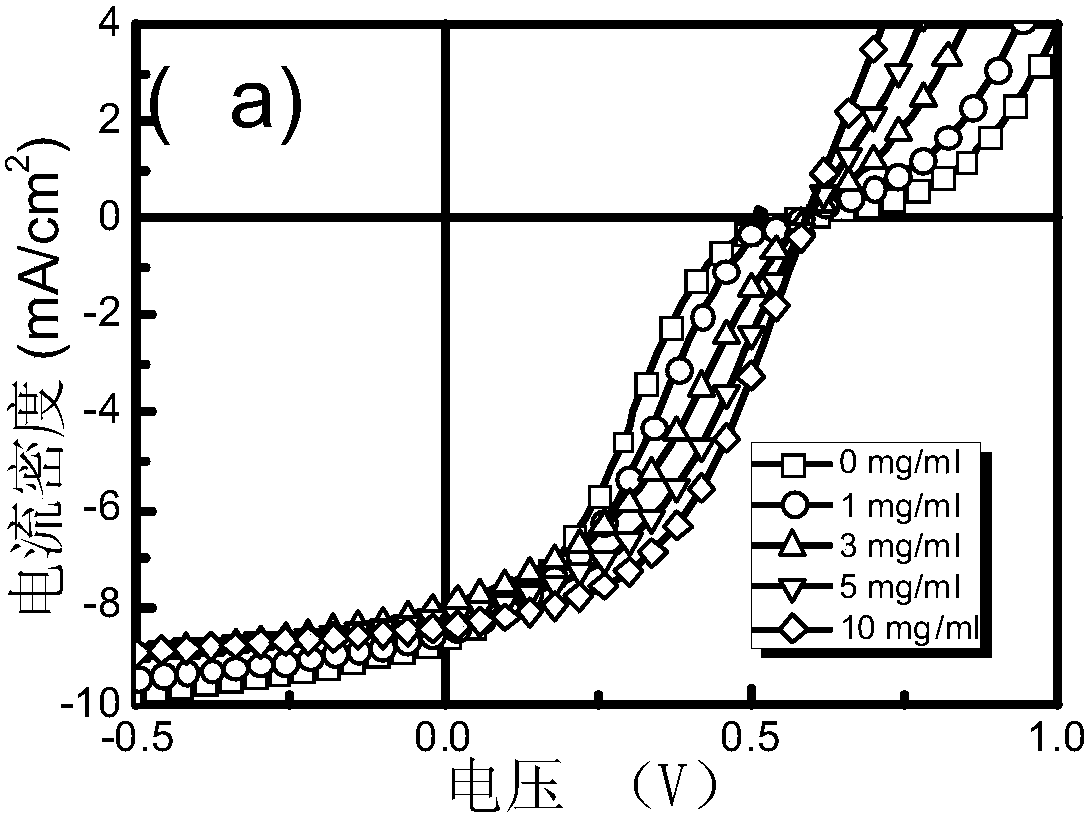

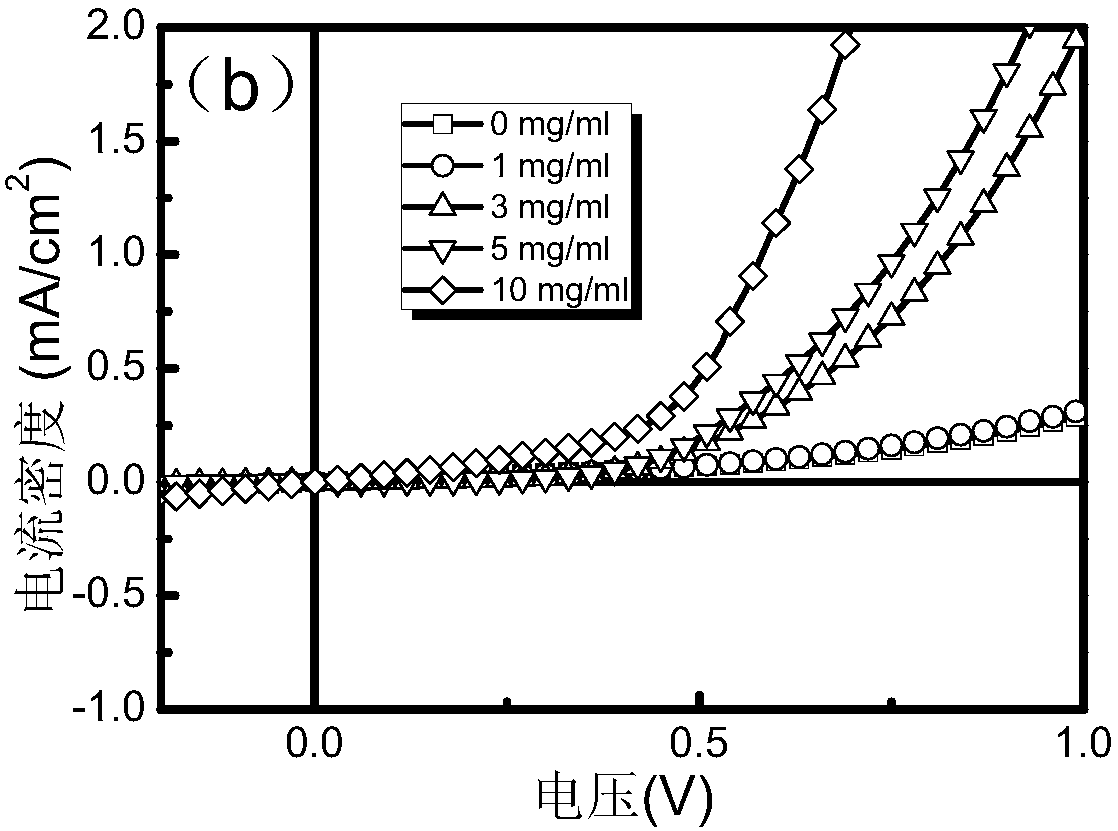

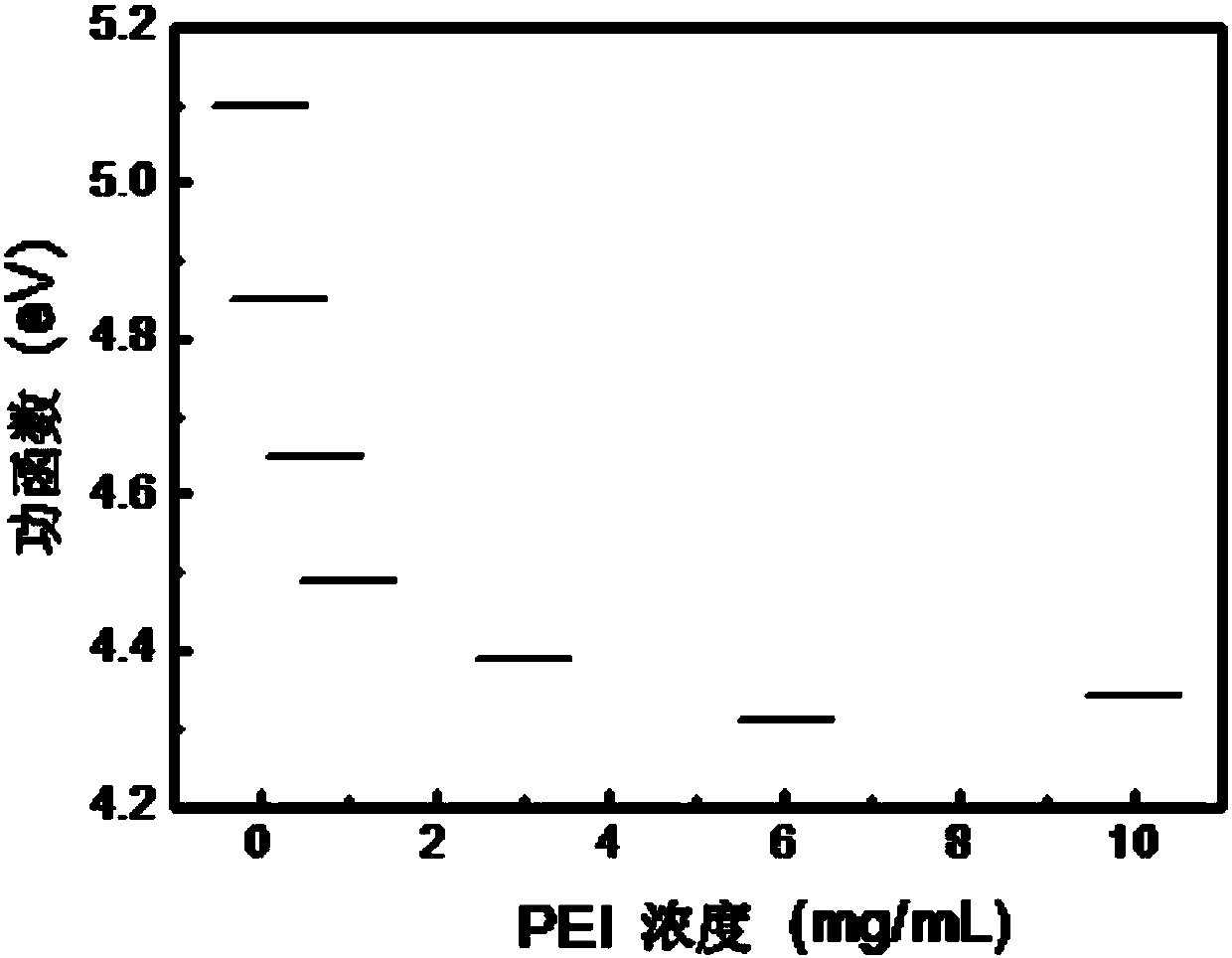

[0087] Example 1: Preparation of PEDOT:PSS:PEI composite and its application as a cathode interface layer in organic solar cells

[0088] 1. The preparation process of PEDOT:PSS:PEI composite ink includes:

[0089] (1) Preparation of PEI ink: Take 2mg of PEI in 1mL of deionized water, stir magnetically for 2 hours to obtain PEI solution;

[0090] (2) Mix PEDOT:PSS and PEI solutions according to the volume ratio of 8:1, and mix them ultrasonically for 0.5 hours to obtain PEDOT:PSS:PEI composite ink.

[0091]2. The preparation process of the corresponding PEDOT:PSS:PEI composite film includes: coating the PEDOT:PSS:PEI composite ink on the base material by general methods such as spin coating and doctor blade coating, and forming the composite film after drying.

[0092] 3. The preparation process of the inverted device with PEDOT:PSS:PEI composite film as the cathode modification layer includes: the structure of the inverted device includes ITO cathode, PEDOT:PSS:PEI composite...

Embodiment 2

[0093] Example 2: Preparation of PEDOT:PSS:PEI composite with ammonia as a stabilizer and its application in organic solar cells as a cathode interface layer

[0094] The PEDOT:PSS:PEI composite film provided in Example 1 has shown the advantage of adjustable work function, but the stability of this type of ink is not ideal, and it will appear delamination after being placed in the air for several hours. In Example 2, on the basis of Example 1, ammonia water is introduced as the stabilizer of the ink. On the basis of retaining the adjustable work function of the composite ink, a stable composite ink that can be placed for a long time is obtained. The following are the specific details of this embodiment:

[0095] (1) Configuration of PEI ink containing ammonia water stabilizer: take 5 mg of PEI in 1 mL of deionized water, and stir magnetically for 2 hours to obtain a PEI solution. Add 200 microliters of 40% ammonia water to 1 mL of PEI solution, and then magnetically stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com