Patents

Literature

159 results about "Nanoporous silicon" patented technology

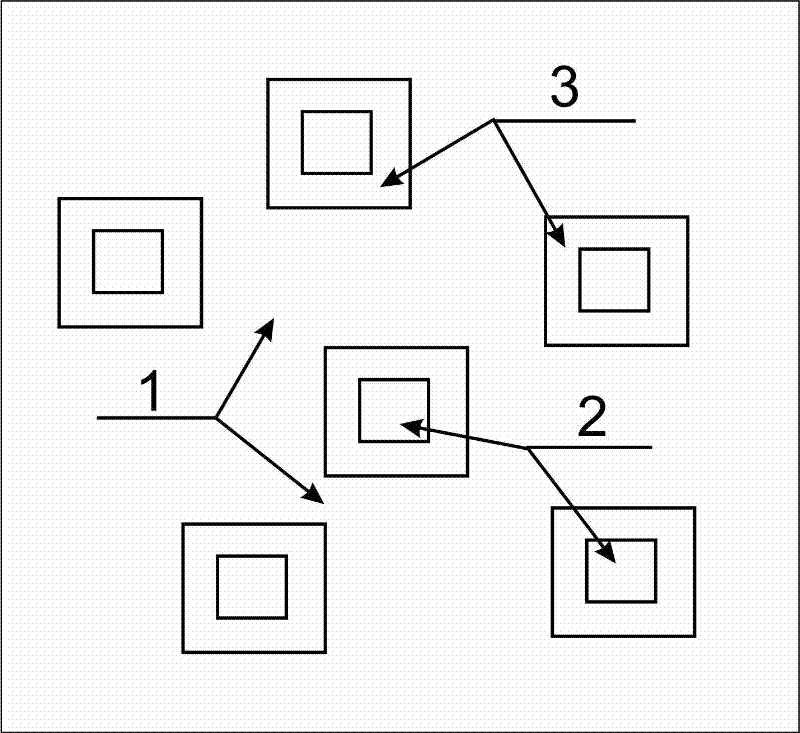

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoporous silicone resins having low dielectric constants

InactiveUS6541107B1Group 4/14 element organic compoundsDead plant preservationOrganic solventCarbon–carbon bond

Nanoporous silicone resins and silicone resin films having low dielectric constants and a method for preparing such nanoporous silicone resins. The silicone resin comprises the reaction product of a mixture comprising(A) 15-70 mol % of a tetraalkoxysilane described by formula where each R1 is an independently selected alkyl group comprising 1 to about 6 carbon atoms,(B) 12 to 60 mol % of a hydrosilane described by formula where each X is an independently selected hydrolyzable substituent,(C) 15 to 70 mole percent of an organotrialkoxysilane described by formula where R2 is a hydrocarbon group comprising about 8 to 24 carbon atoms or a substituted hydrocarbon group comprising a hydrocarbon chain having about 8 to 24 carbon atoms and each R3 is an independently selected alkyl group comprising 1 to about 6 carbon atoms; in the presence of(D) water,(E) hydrolysis catalyst, and(F) organic solvent for the reaction product.The silicone resin is cured and heated in an inert atmosphere at a temperature sufficient to effect thermolysis of carbon-carbon bonds of the R2 groups thereby forming a nanoporous silicone resin.

Owner:DOW CORNING CORP

Nanoporous silicone resins having low dielectric constants and method for preparation

InactiveUS6313045B1NanotechSemiconductor/solid-state device manufacturingOrganic solventCarbon–carbon bond

Owner:DOW CORNING CORP

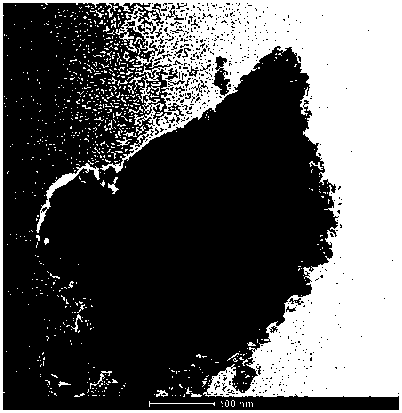

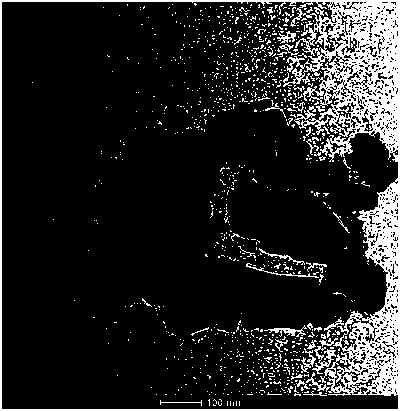

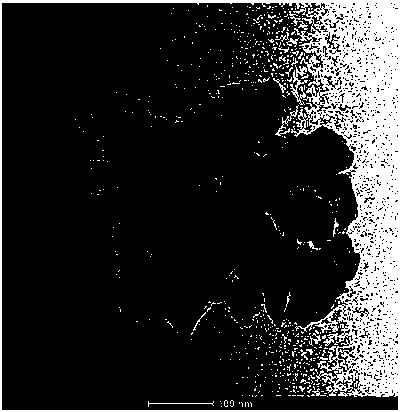

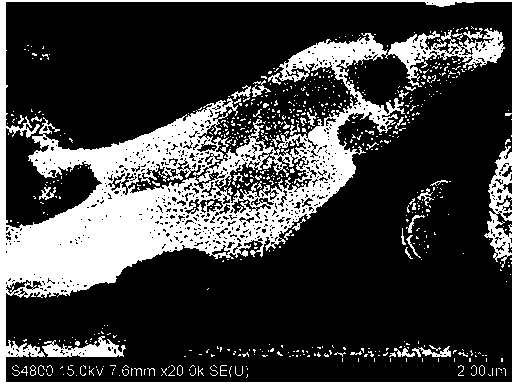

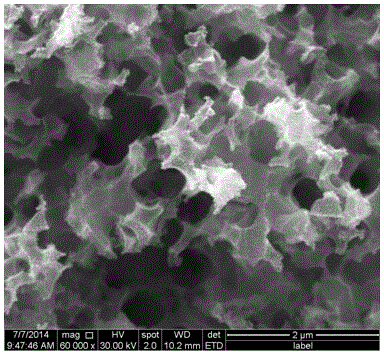

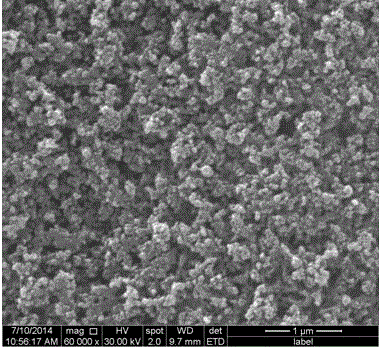

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

InactiveCN102759520AQuick checkIncrease surface areaRaman scatteringChemical vapor depositionCadmium Cation

The invention provides a preparation method of an active radical with a surface-enhanced Raman scattering (SERS) effect, belongs to the technical field of spectrum detection, and relates to the preparation technology of the SERS active radical, which is rapid, has high sensitivity and performs a low trace detection function. The preparation method is characterized in that firstly, a nano porous silicon columnar array with a large specific surface area is prepared by utilizing a hydrothermal etching technology; afterwards, a nanowire structure of an II-VI group compound semiconductor (such as zinc oxide, titanium dioxide, cadmium sulfide, cadmium selenide, cadmium telluride, and the like) by utilizing a chemical vapor deposition method; and finally, nano particles of precious metal (such as gold, silver, copper and the like) are finally prepared on the nanowire structure by using a chemical reduction method, so as to obtain an active radical material. The preparation method has a wide application prospect in the aspects of clinical biomolecular fast recognition, trace chemical substance detection, biological sample analysis, and the like. The preparation method has the advantages that the preparation process of each material is simple, the condition is mild and the repetition rate reaches 100 percent.

Owner:BEIJING UNIV OF CHEM TECH

Method for making nanoporous silicone resins from alkylydridosiloxane resins

InactiveUS6143360ALow dielectric constantPretreated surfacesSemiconductor/solid-state device manufacturingPolymer chemistryCarbon atom

A method for preparing a nanoporous silicone resin which can be used to form low dielectric constant films useful for electrical insulating coatings on electronic devices comprising (A) contacting a hydridosilicon containing resin with a 1-alkene comprising about 8 to 28 carbon atoms in the presence of a platinum group metal-containing hydrosilation catalyst effecting formation of an alkylhydridosiloxane resin where at least 5 percent of silicon atoms are substituted with at least one group comprising about 8 to 28 carbon atoms and at least 45 percent of silicon atoms are substituted with at least one hydrogen atom and (B) heating the alkylhydridosiloxane resin of step (A) at a temperature sufficient to effect curing and thermolysis of alkyl groups comprising about 8 to 28 carbon atoms from the silicon atoms thereby forming a nanoporous silicone resin.

Owner:DOW CORNING CORP

Method for making nanoporous silicone resins from alkylhydridosiloxane resins

InactiveUS6184260B1Pretreated surfacesSemiconductor/solid-state device manufacturingPolymer chemistryCarbon atom

A method for preparing a nanoporous silicone resin which can be used to form low dielectric constant films useful for electrical insulating coatings on electronic devices comprising (A) contacting a hydridosilicon containing resin with a 1-alkene comprising about 8 to 28 carbon atoms in the presence of a platinum group metal-containing hydrosilation catalyst effecting formation of an alkylhydridosiloxane resin where at least 5 percent of silicon atoms are substituted with at least one group comprising about 8 to 28 carbon atoms and at least 45 percent of silicon atoms are substituted with at least one hydrogen atom and (B) heating the alkylhydridosiloxane resin of step (A) at a temperature sufficient to effect curing and thermolysis of alkyl groups comprising about 8 to 28 carbon atoms from the silicon atoms thereby forming a nanoporous silicone resin.

Owner:DOW CORNING CORP

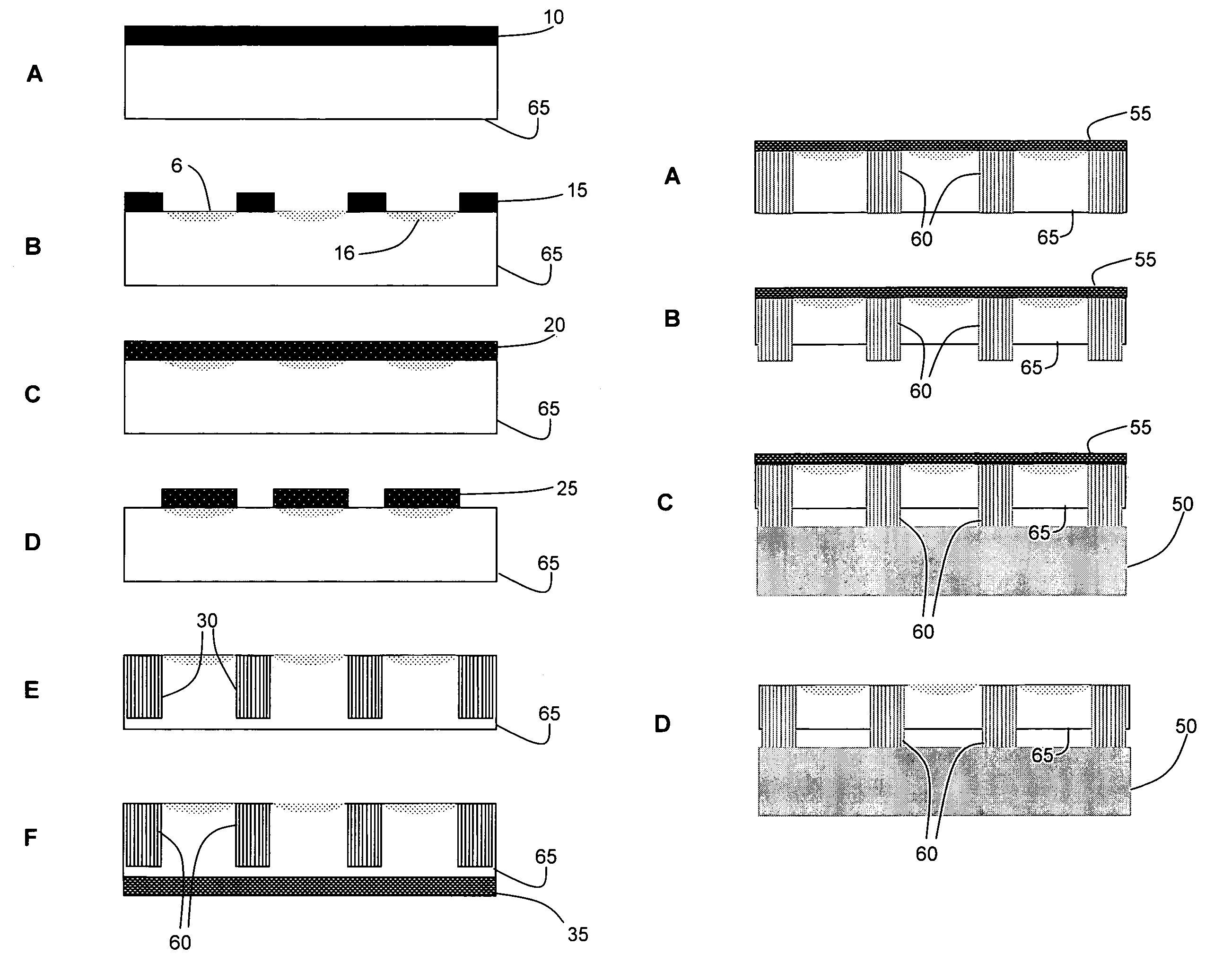

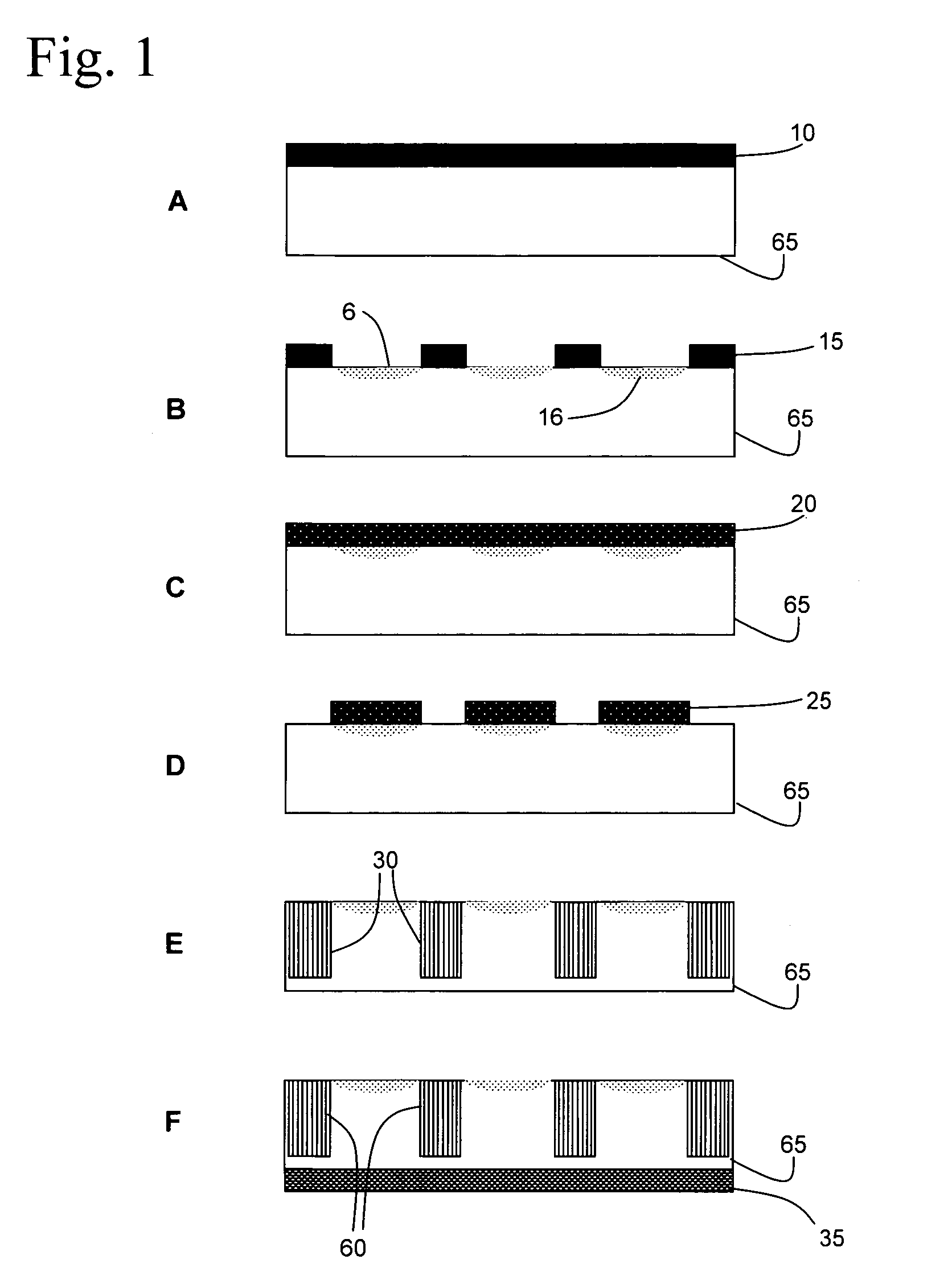

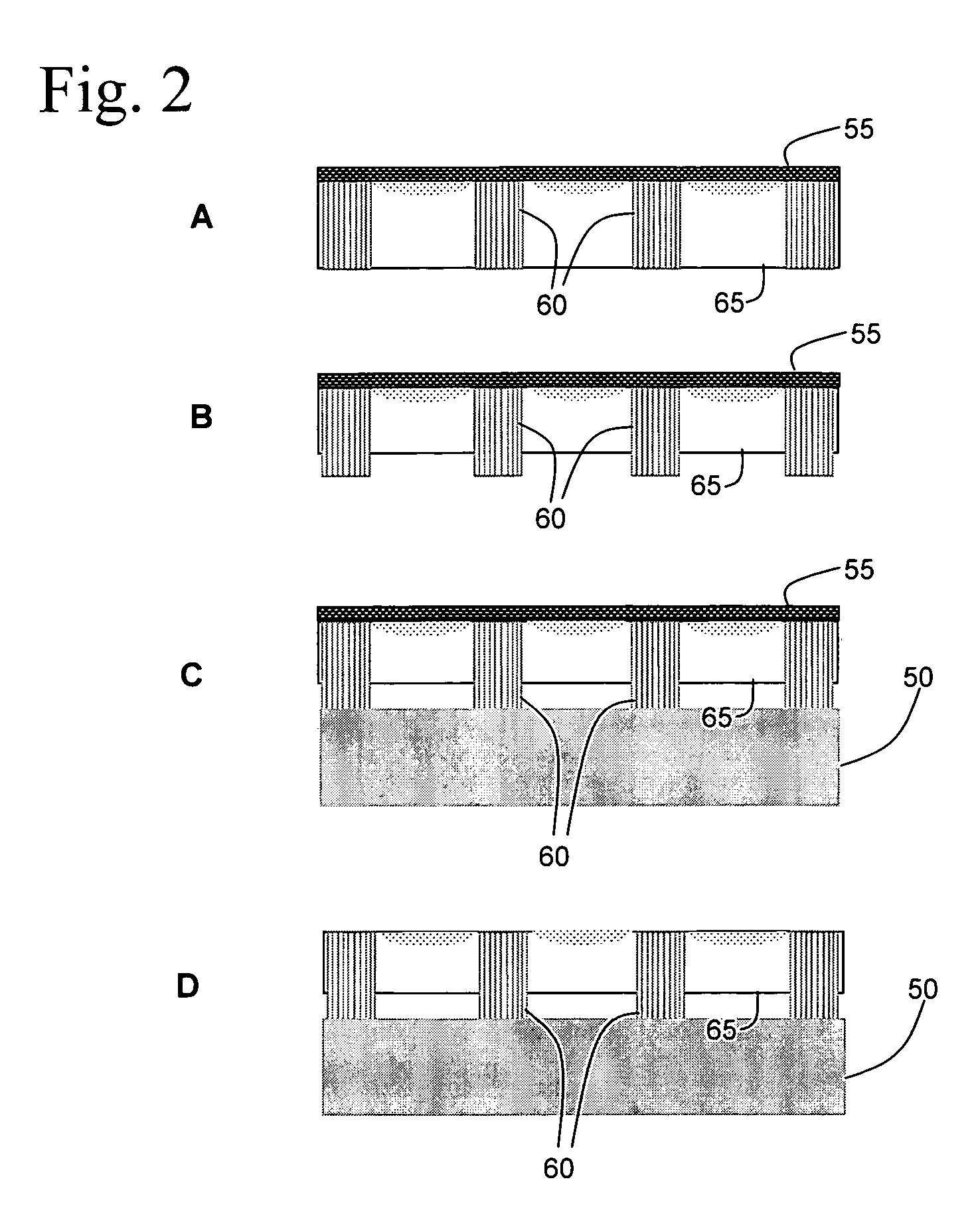

Method for the assembly of nanowire interconnects

ActiveUS7112525B1High aspect ratioLower the volumeNanotechSolid-state devicesNanowireNanoporous silicon

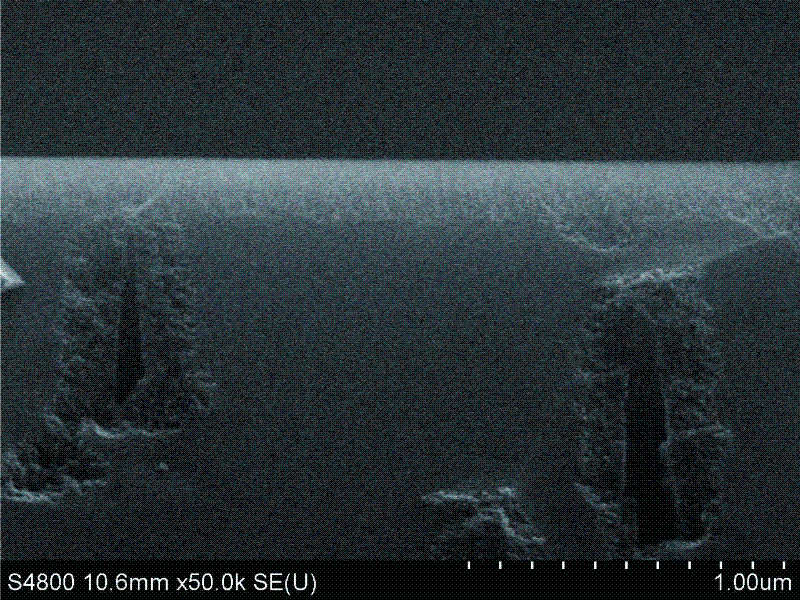

The present invention provides a method for the synthesis of nanowires in a silicon nanoporous template by electrodeposition and a novel technique for the integration of nanowires to transduction surfaces. In accordance with the present invention, a method for the fabrication of nanowire interconnects is provided. The method includes the steps of fabricating substantially vertical nanowires in a selectively passivated nanoporous silicon template, backetching the silicon template to expose the nanowires, eutectically bonding the exposed nanowires to a receiving silicon wafer, and etching the silicon template to produce substantially freestanding nanowire interconnects in contact with the receiving silicon wafer.

Owner:UNIV OF SOUTH FLORIDA

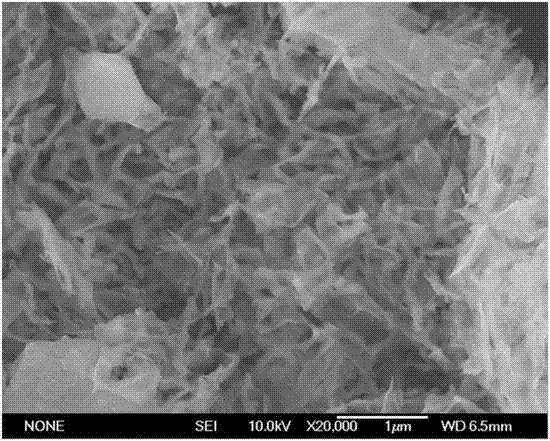

Preparation method for nanoporous silicon

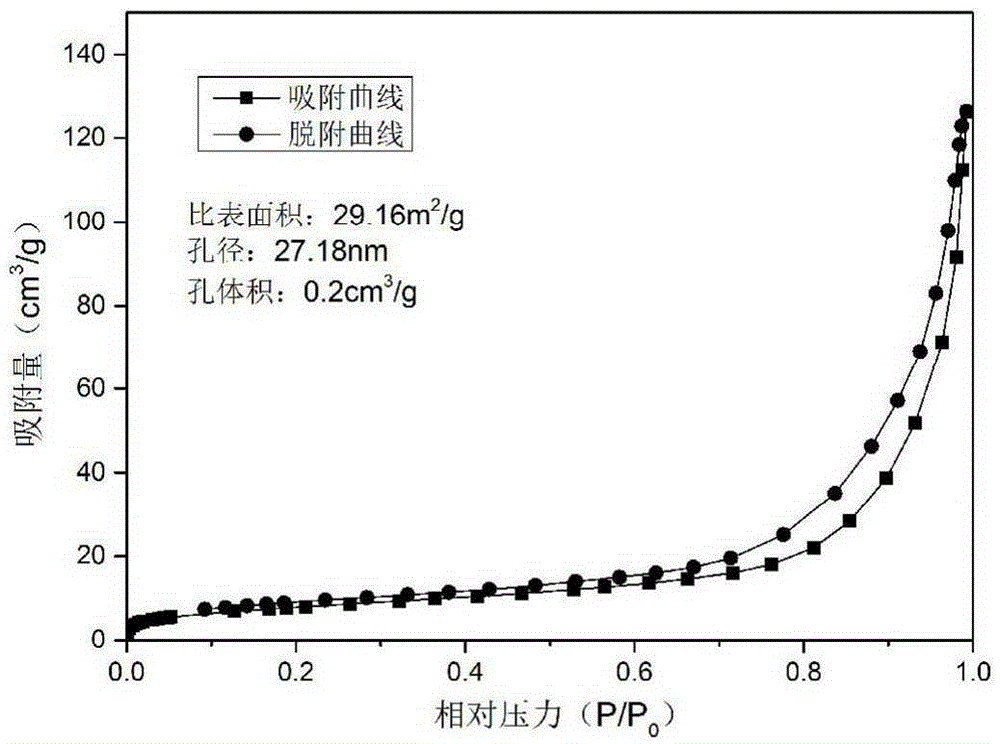

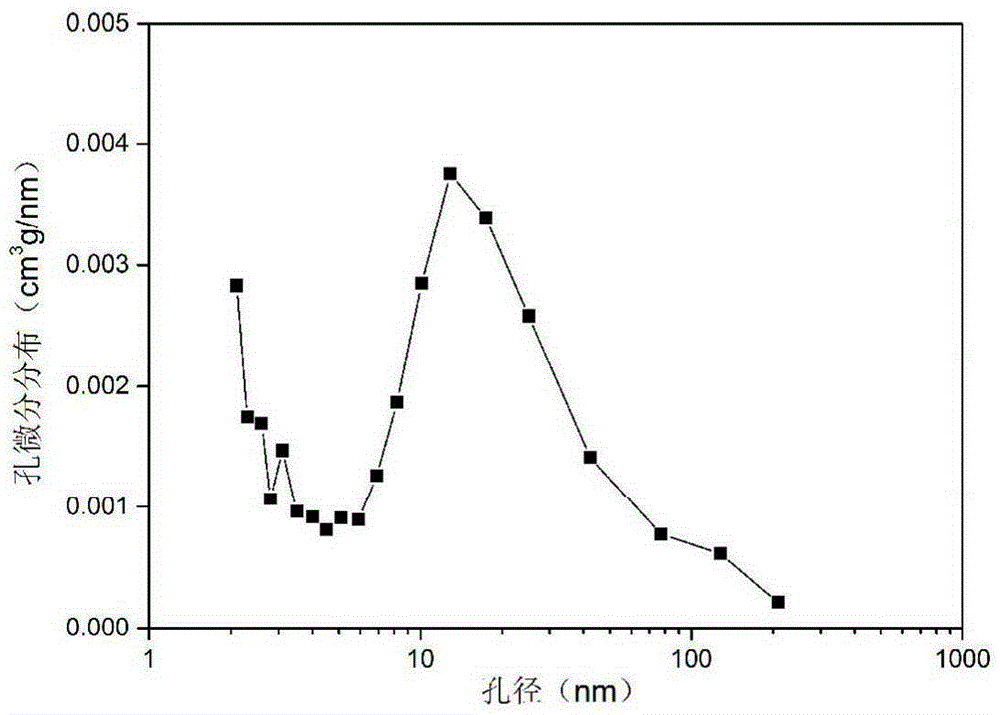

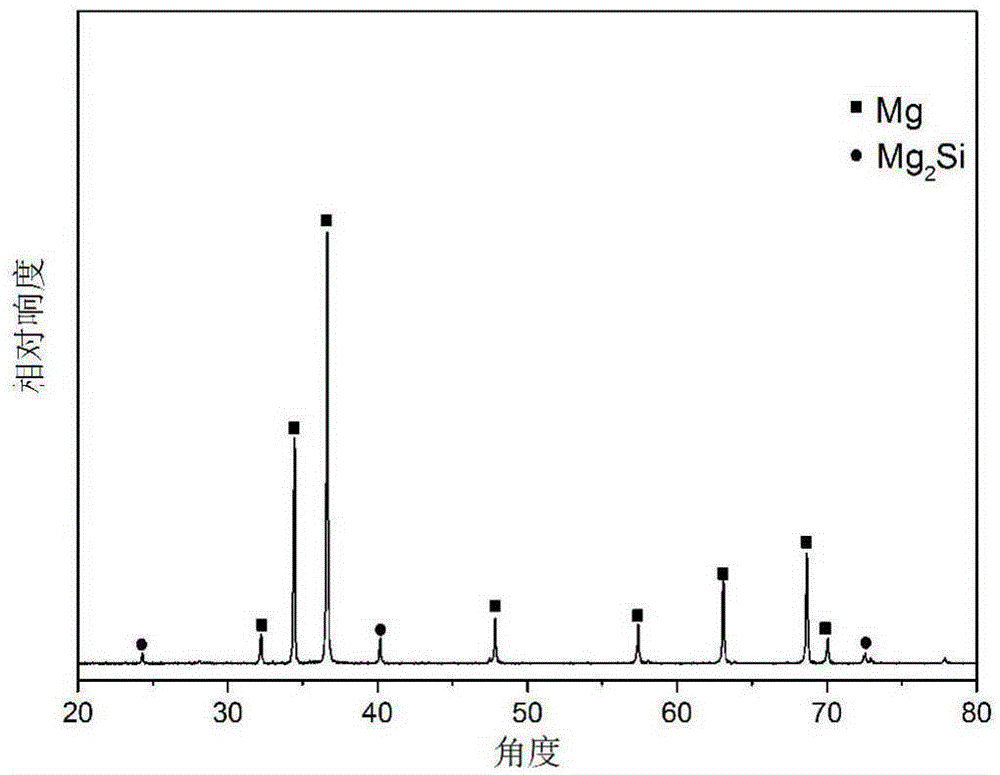

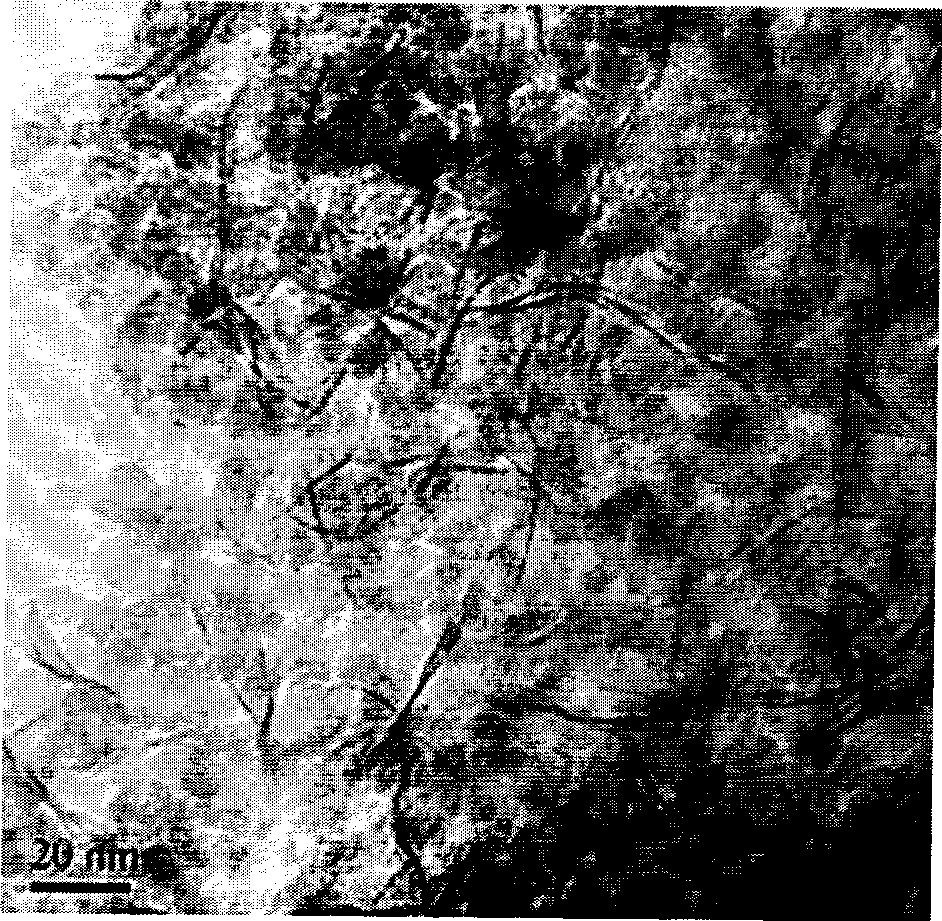

InactiveCN105399100ALarge specific surface areaUniform pore size distributionMaterial nanotechnologySilicon compoundsMg compositeCentrifugation

The invention provides a method for preparing nanoporous silicon with industrial silica powder as a raw material. Silica powder and magnesium powder are subjected to alloying treatment, a precursor Mg2Si / Mg composite material is prepared, then dealloying treatment is carried out, finally the prepared product is subjected to acid pickling, centrifugation and drying, and nanoporous silicon is prepared. The method can raise the utilization rate of industrial silica powder, achieves resource utilization of silica powder, raises the additional value of silica powder, and has characteristics of wide raw material sources, low cost and simple technology operation. The prepared nanoporous silicon has characteristics of uniform pore size distribution, large specific surface area and the like, and has wide application prospects.

Owner:SOUTHEAST UNIV

Nickel-based catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444737AHigh mechanical strengthHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNanowire

The invention discloses a nickel-based catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance nickel nanowire as an active component, and nano-particles of MgO or CaO or ZrO2 or TiO2 or CeO2 or compound nano-particles thereof as an adjuvant. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, nickel nitrate or magnesium nitrate or calcium nitrate or zirconium nitrate or cerous nitrate or complex nitrate thereof and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, and limits the selectivity of byproducts CH4 and CO at a lower level. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

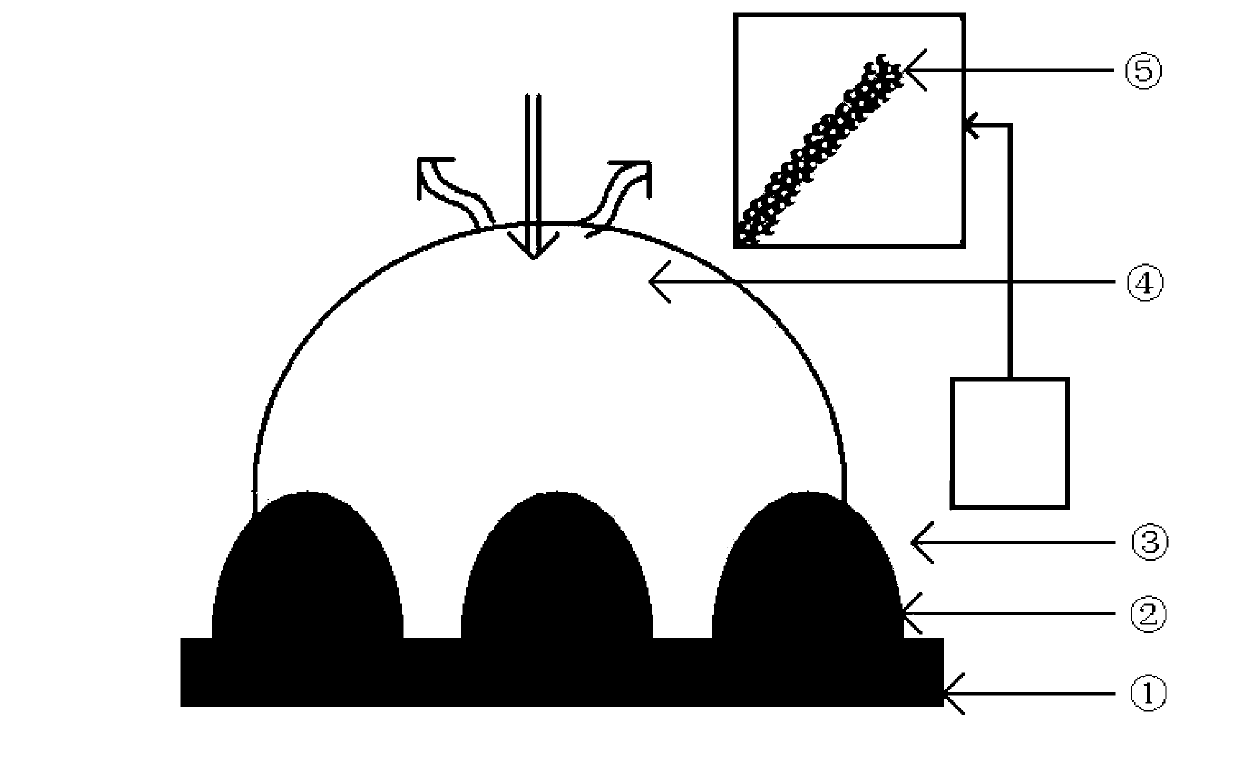

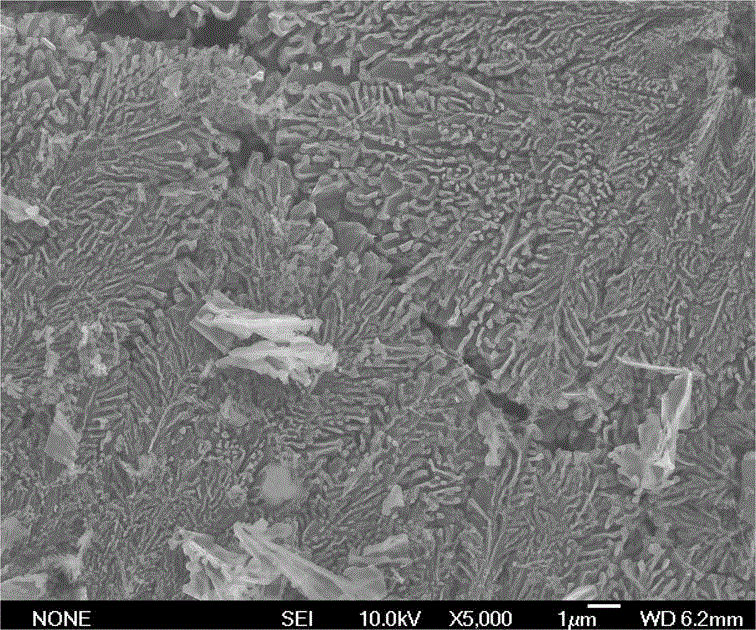

Metal catalytic texturing method for decreasing reflectance of polycrystalline silicon wafer cut with diamond wire

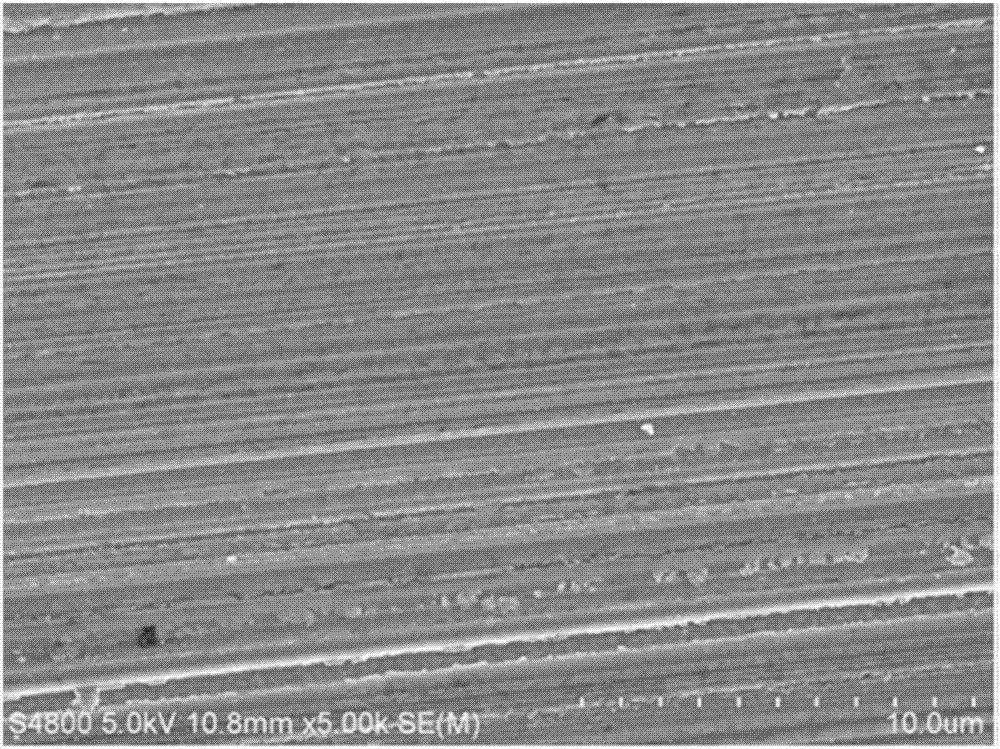

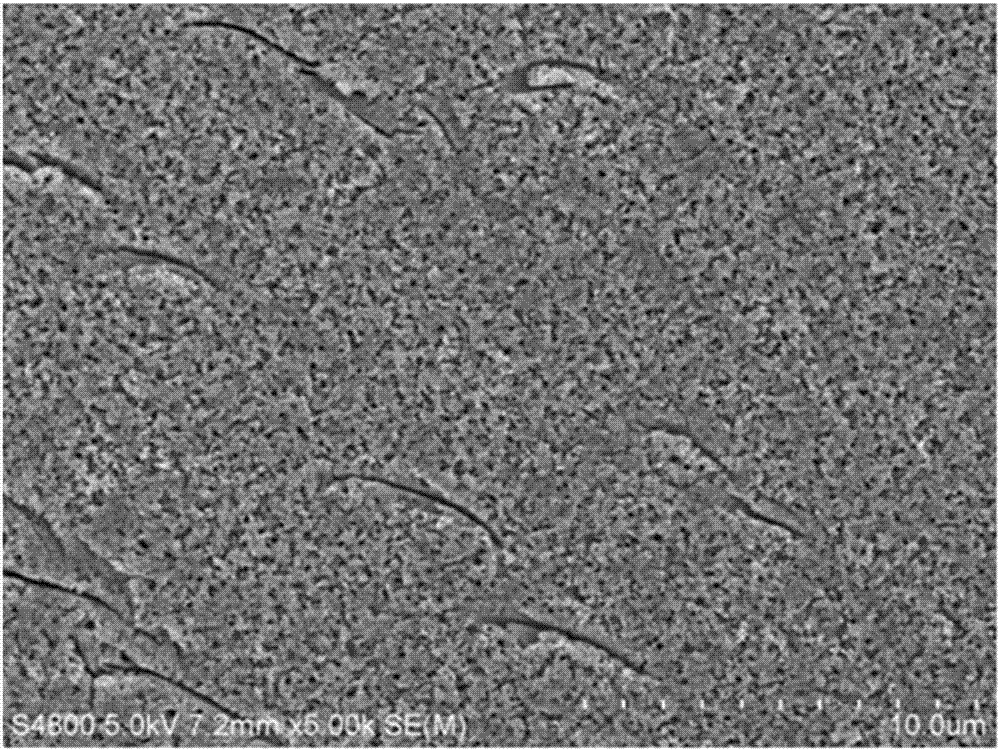

InactiveCN107268087AImprove surface reactivitySimple processAfter-treatment detailsEtchingNanoporous silicon

The invention relates to a metal catalytic etching method for decreasing a reflection rate of a polycrystalline silicon wafer cut with a diamond wire. The method comprises the following steps: soaking a polycrystalline silicon wafer cut with a diamond wire in an alkaline solution, and removing a mechanically damaged layer on the surface of the silicon wafer in an etching manner; and integrally treating the treated polycrystalline silicon wafer by virtue of metal catalysis, chemical etching and silver plating and hole digging, and forming a nano porous silicon structure on the surface of the polycrystalline silicon wafer; soaking the polycrystalline silicon wafer treated in the step II in a second mixed solution, performing the etching treatment, so that a honeycomb-shaped suede-like structure is formed on the surface of the silicon wafer; alkaline washing and desilverizing the polycrystalline silicon wafer treated by the last step in an alkaline mixed solution; and cleaning the treated polycrystalline silicon wafer successively with an acid mixed solution and deionized water, and finally drying. By adopting the method, cut marks of the diamond wire can be eliminated, the reflection rate of the polycrystalline silicon etched surface can be effectively decreased to 15 percent, the compatibility with a conventional etching process is good, and the conversion efficiency of a solar cell can be increased.

Owner:NANJING NAXIN NEW MATERIAL

Nano-porous silica lithium battery anode material and preparation method and application thereof

InactiveCN104701491AHigh porosityResistance to volume expansionMaterial nanotechnologyNegative electrodesFluorescenceSlurry

Owner:吕铁铮 +1

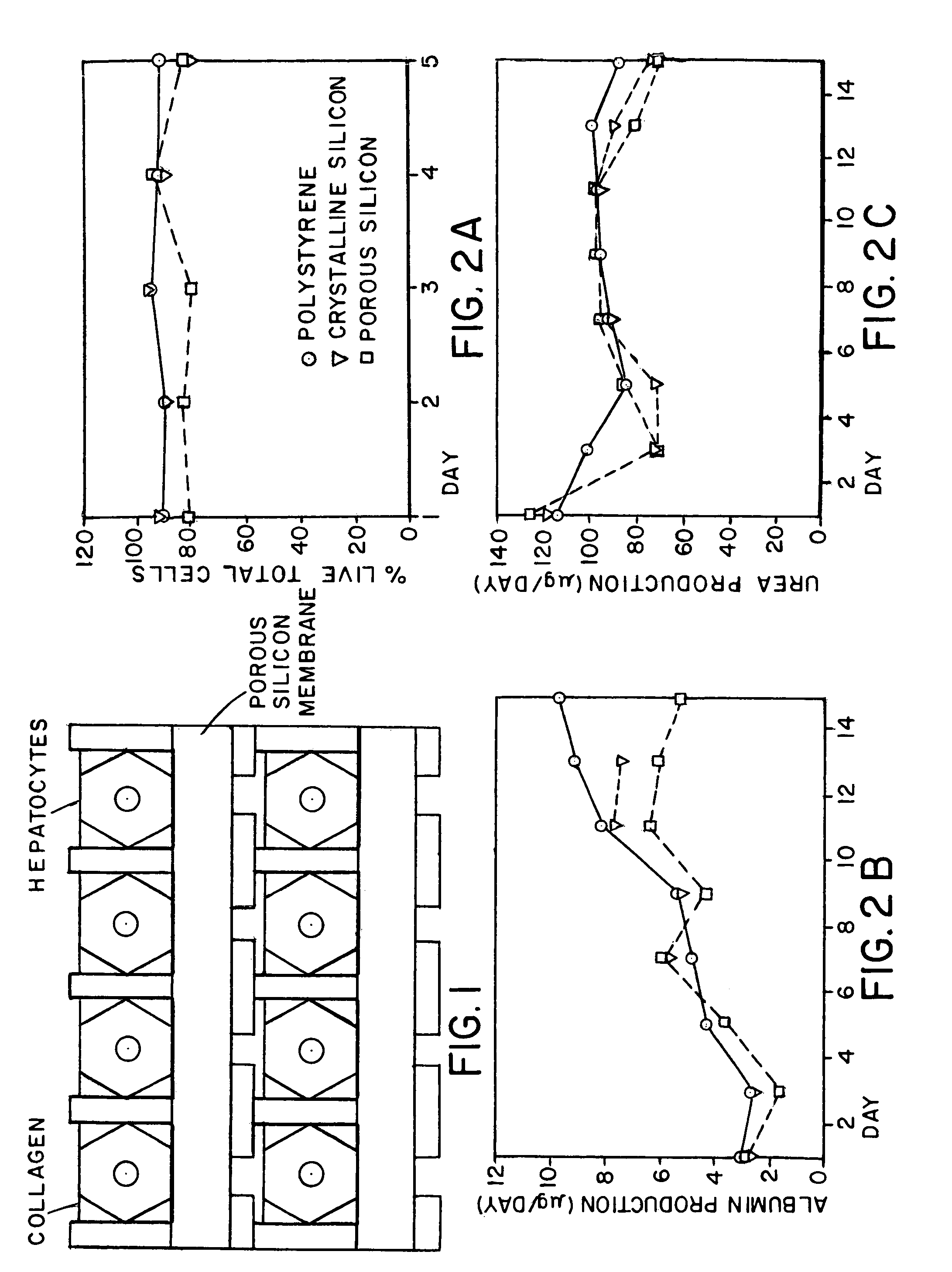

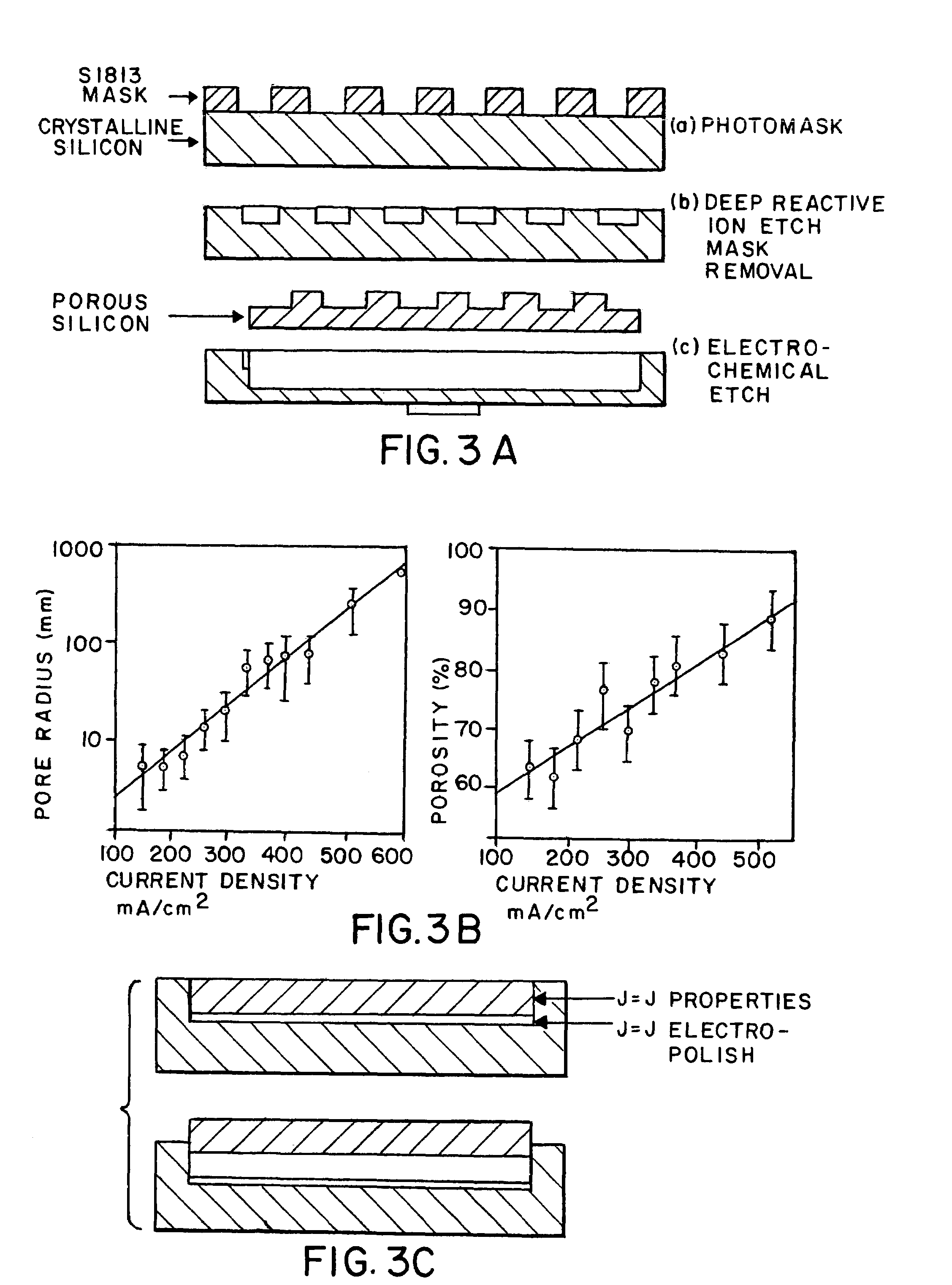

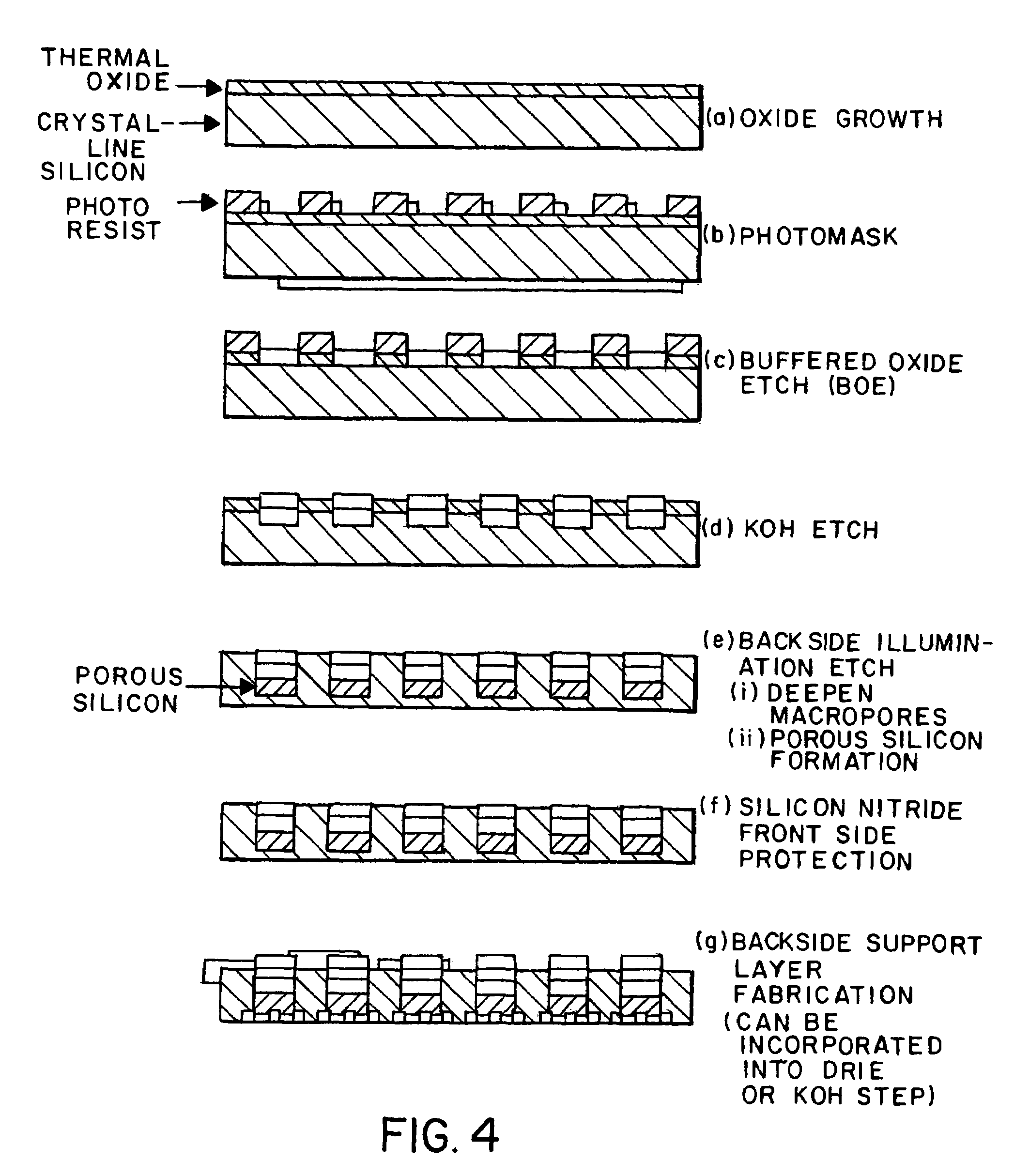

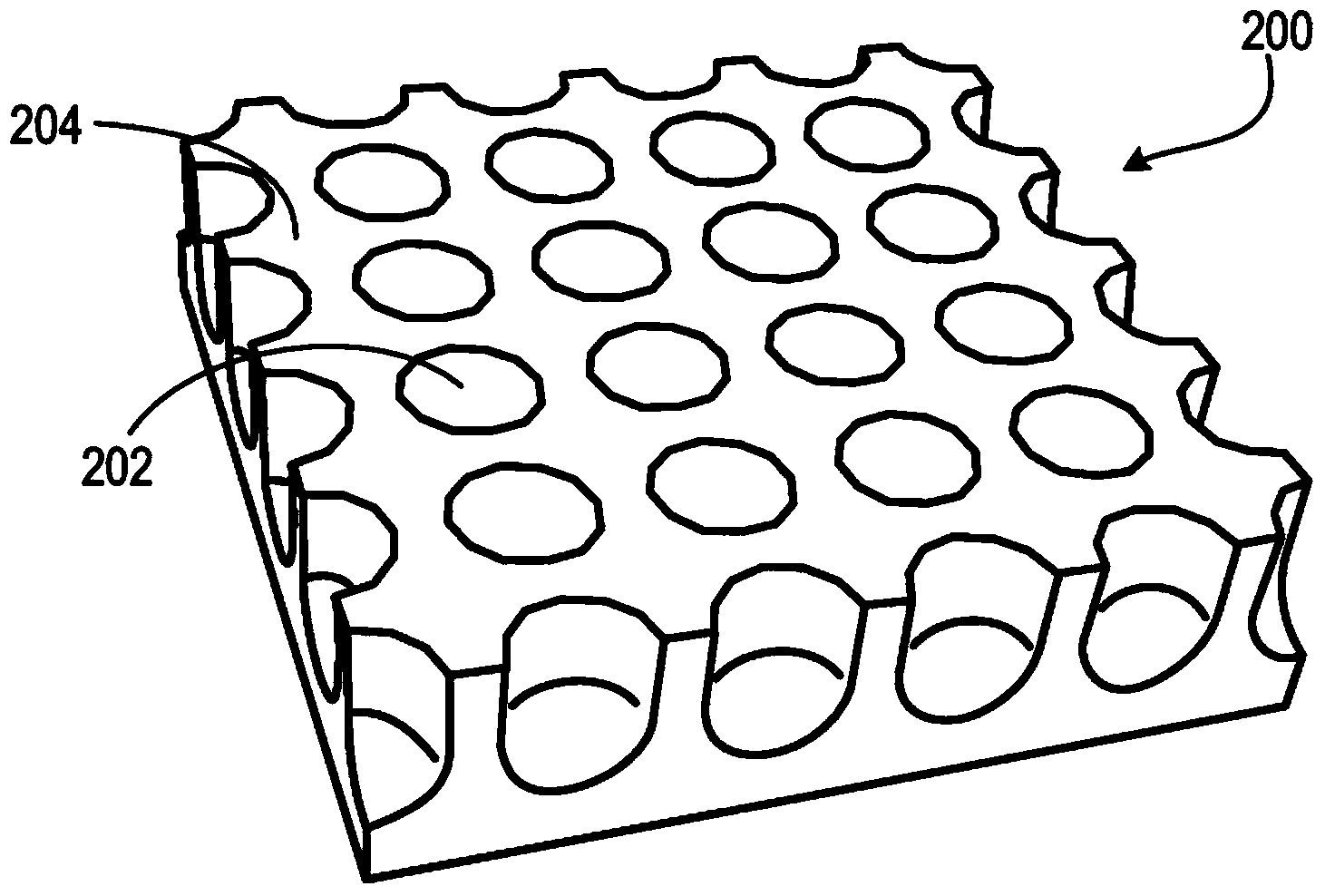

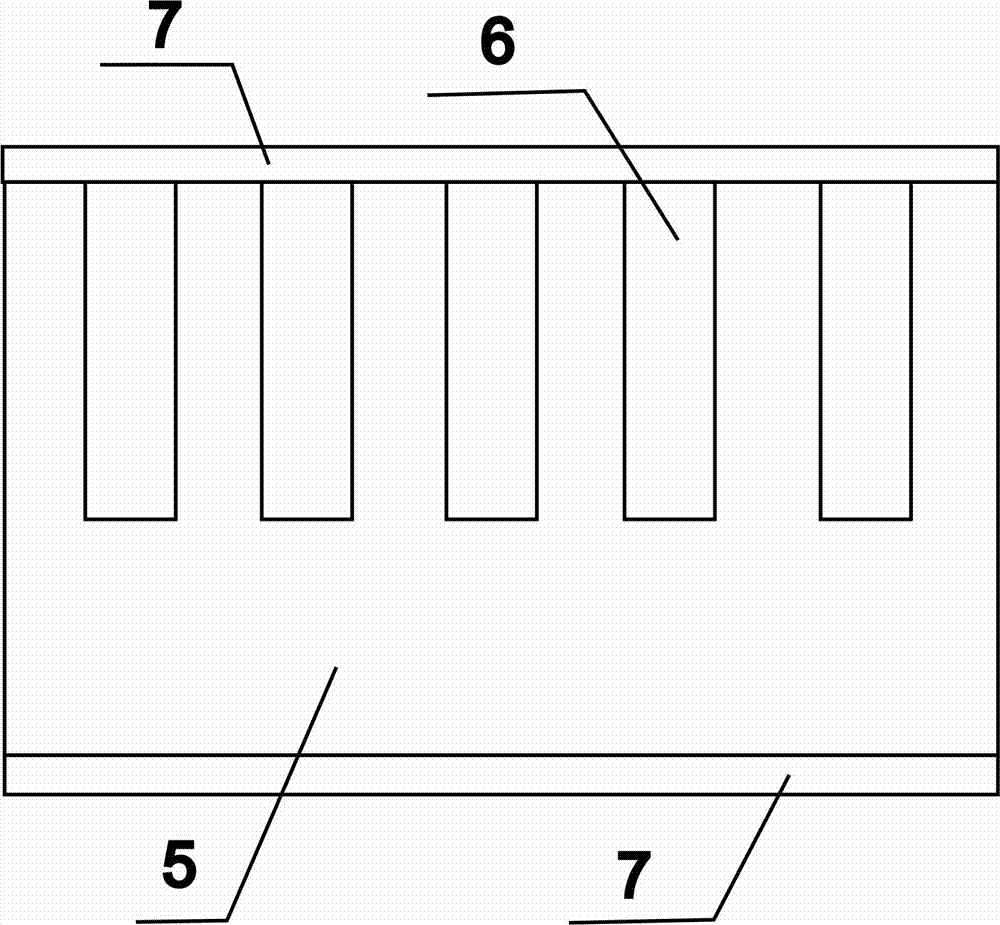

Method of screening compounds using a nanoporous silicon support containing macrowells for cells

InactiveUS7312046B2Improve consistencyRigorously control the environment of the cellBioreactor/fermenter combinationsCompound screeningCell adhesionPerfusion

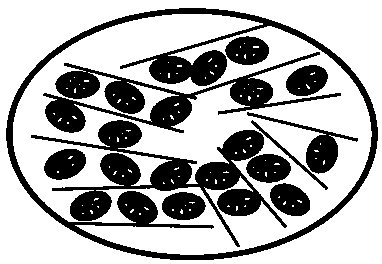

A nanoporous silicon support comprising a plurality of macropores is provided to function as a bioreactor for the maintenance of cells in culture in a differentiated state. Each cell or group of cells is grown in an individual macropore and is provided with nutrients by means such as perfusion of the nanoporous silicon support with fluid. The macropores may be between 0.2 and 200 microns and be coated with a substance that promotes cell adhesion. The support containing cells may be used to used to test compounds for biological activity, metabolism, toxicity, mutagenicity, carcinogenicity or to characterize novel or unknown comounds. The supports are sufficiently robust that they may be assembled into larger reactors to simulate organ function or be used for the production of biomolecules.

Owner:RGT UNIV OF CALIFORNIA

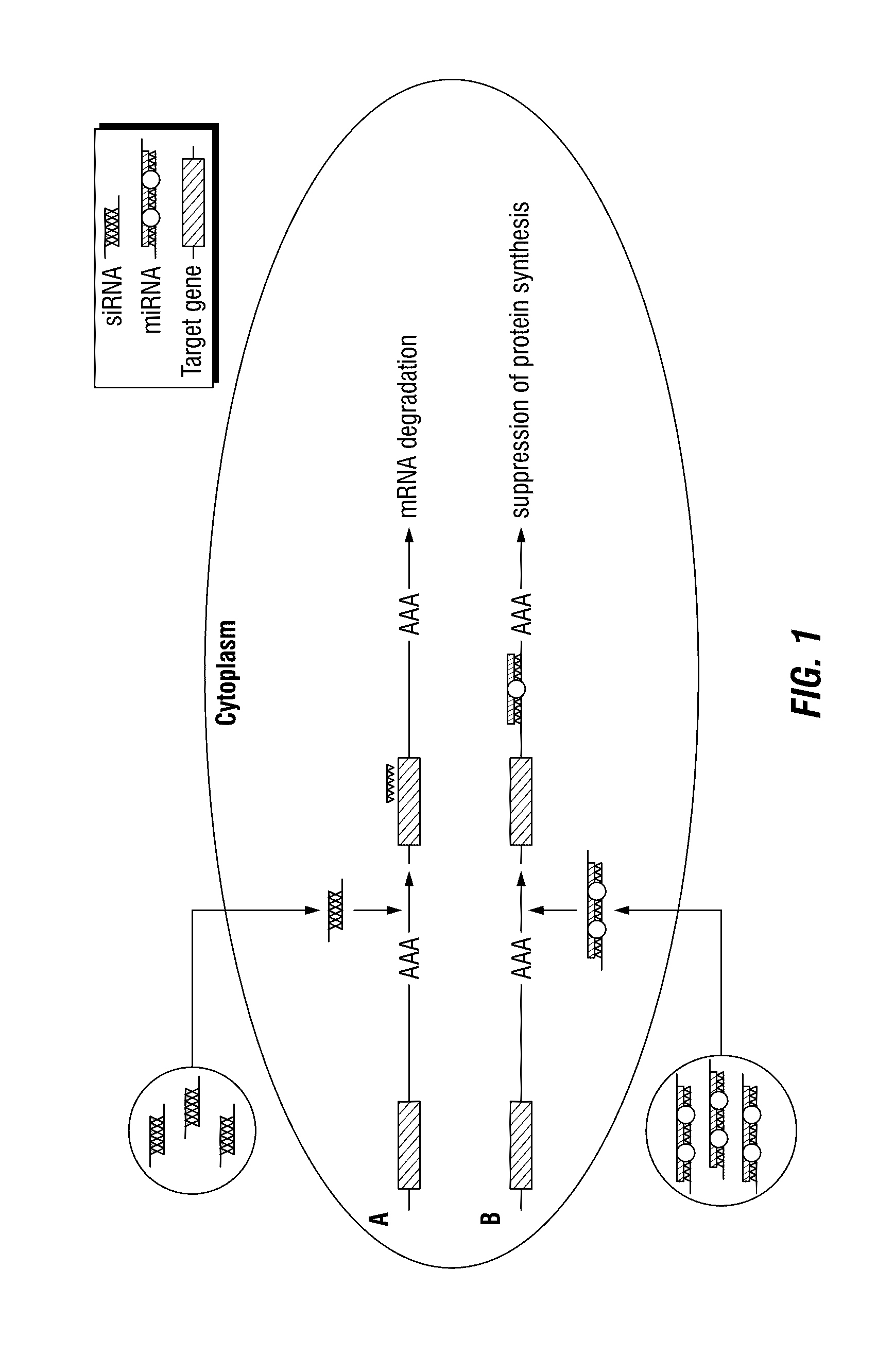

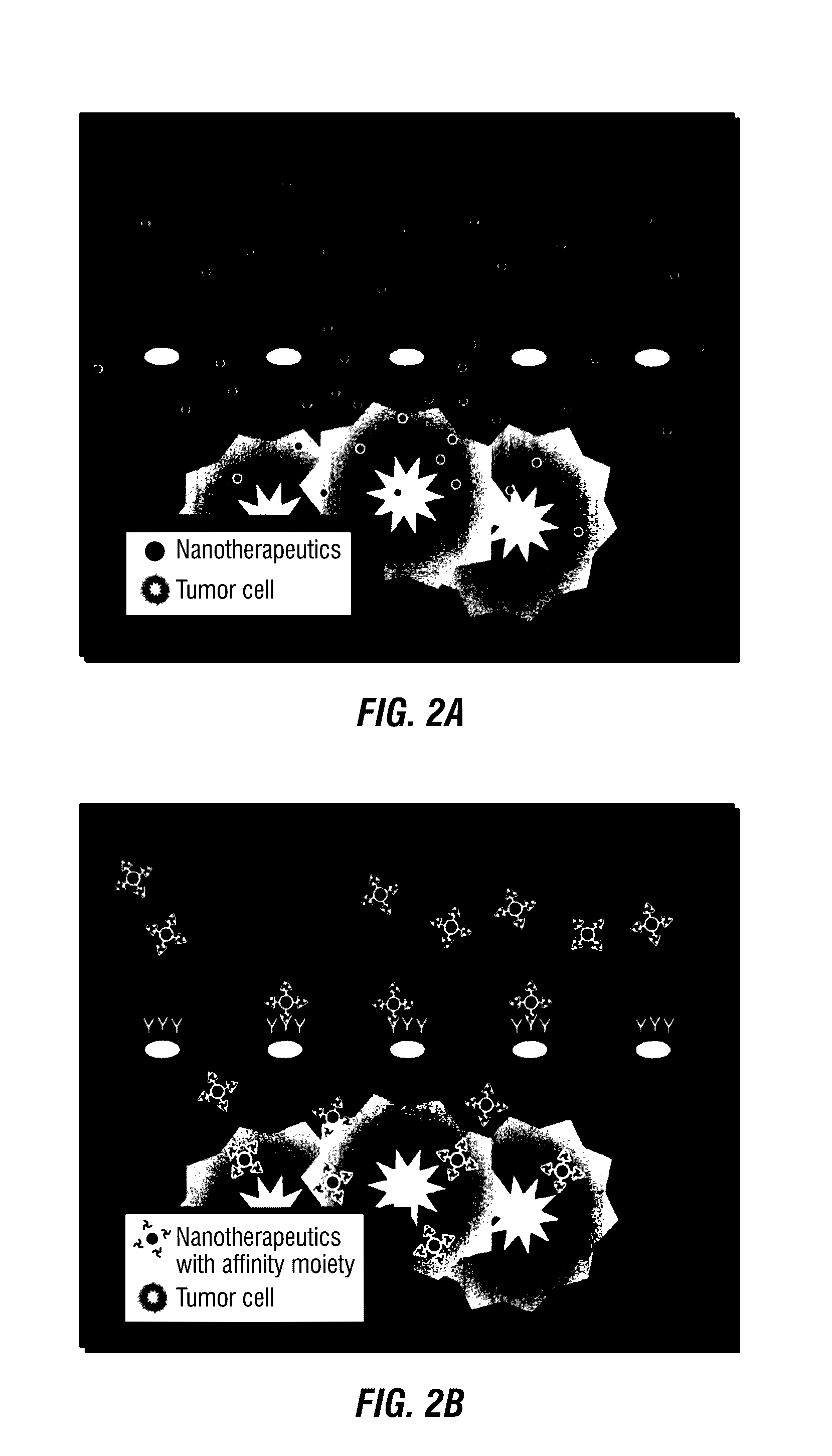

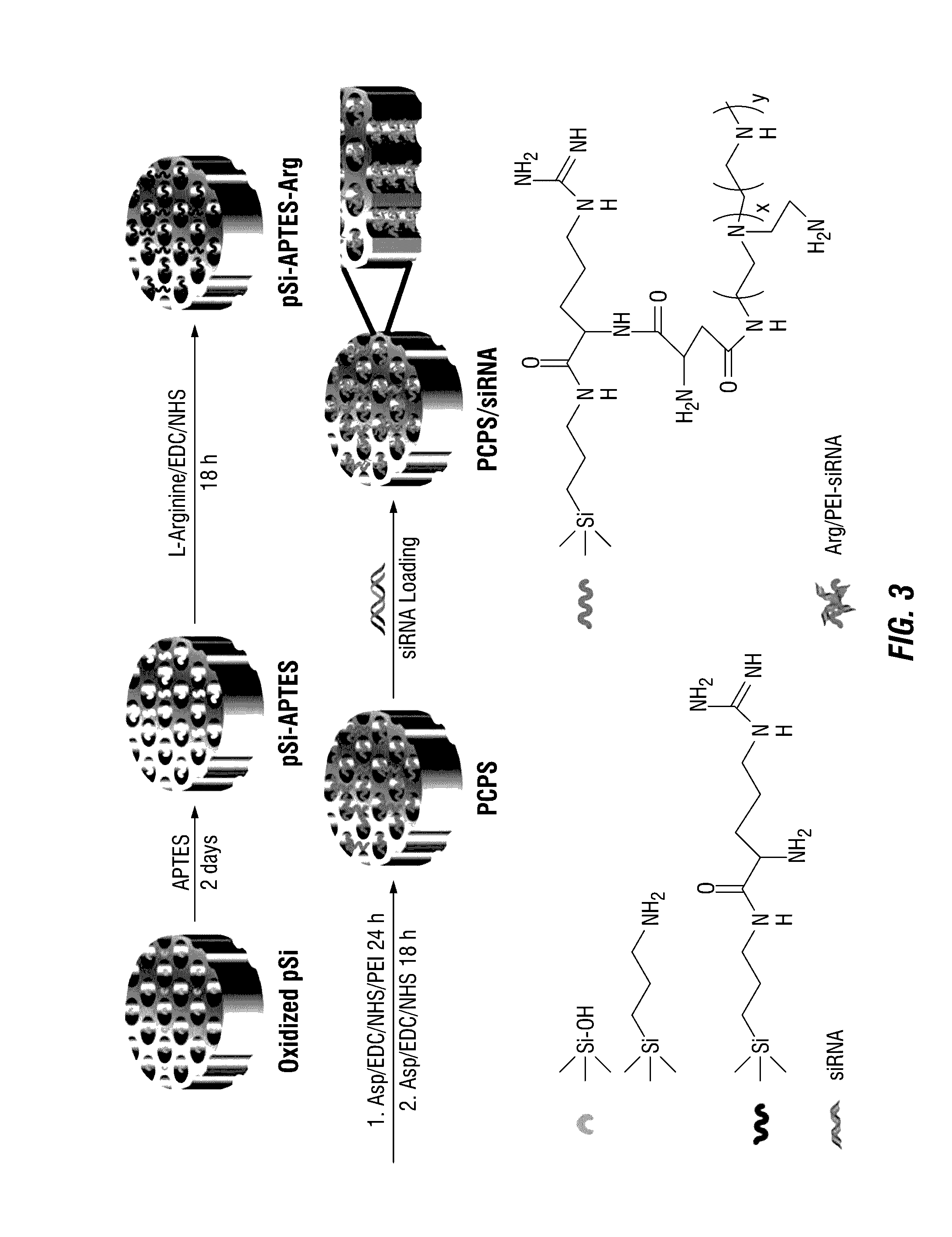

Polycation-functionalized nanoporous silicon carrier for systemic delivery of gene silencing agents

InactiveUS20160369269A1Reduce the amount requiredLess toxicityOrganic active ingredientsSpecial deliveryNanoporous siliconCell organisation

Disclosed are methods and compositions containing functionalized nanoporous silicon particles, useful in a variety of diagnostic and / or therapeutic regimens for delivery of genetic constructs to one or more cells, tissues, and / or organs of interest. Also provided are methods for introducing into selected host cells one or more selected nucleic acid molecules. The present disclosure is also directed to a method of treating a tumor, comprising the step of administering to an individual one or more of the compositions and formulations thereof as described herein.

Owner:THE METHODIST HOSPITAL

Nanoporous silicon/carbon composite material and preparation method thereof

InactiveCN103337612ASimple processEasy to operateMaterial nanotechnologyCell electrodesCarbon compositesNano structuring

The invention relates to a nanoporous silicon / carbon composite material and a preparation method thereof, and aims at providing a method of preparing the nanoporous silicon / carbon composite material through corrosion to a multicomponent alloy. The material prepared by the method can be used as a nano-structured bulk material, easily shows high performance and stability, and is suitable for large-scale production. The objective of the invention is to provide the nanoporous silicon / carbon composite material prepared by following technical schemes, and the preparation method employ a free corrosion method. The nanoporous silicon / carbon composite material and the preparation method have advantages of simple operation, controllable and adjustable structure and component, high yield, no target material loss, and suitability for large-scale production.

Owner:UNIV OF JINAN

Recording sheet for ink jet printing

InactiveUS20070196596A1Improve image qualityGood ink absorptionMaterial nanotechnologyThermographyNanoporous siliconEngineering

A recording sheet for ink jet printing is described, which consists of a support having coated onto said support at least two ink-receiving layers, wherein the ink-receiving layer situated next to the support contains nanoporous silicon dioxide with a positively charged surface and at least one binder and the ink-receiving layer situated further away from the support contains nanocrystalline, nanoporous aluminium oxide or aluminium oxide / hydroxide and at least one binder and, optionally, nanoporous silicon dioxide with a positively charged surface.

Owner:WIFAG POLYTPE HLDG AG

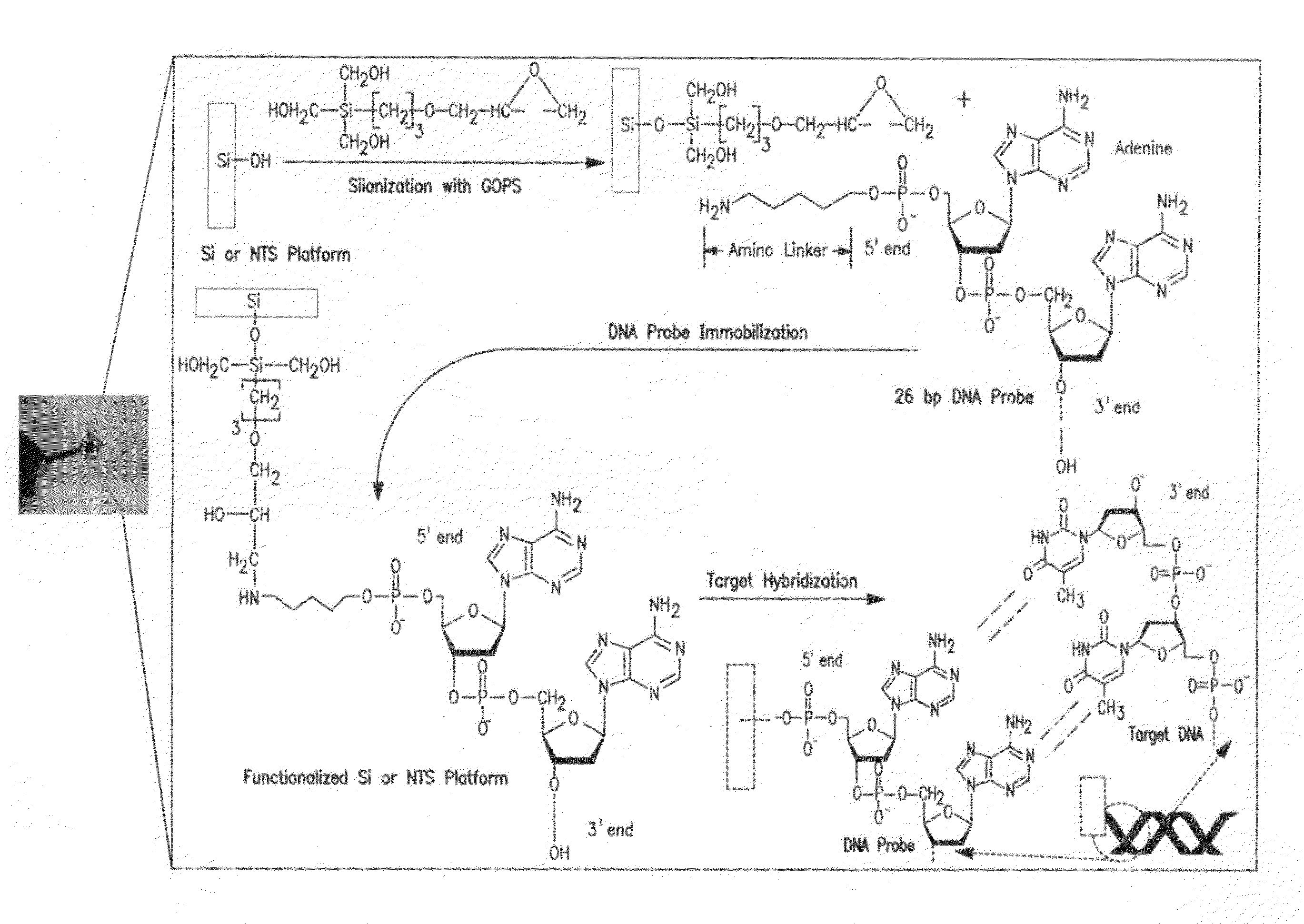

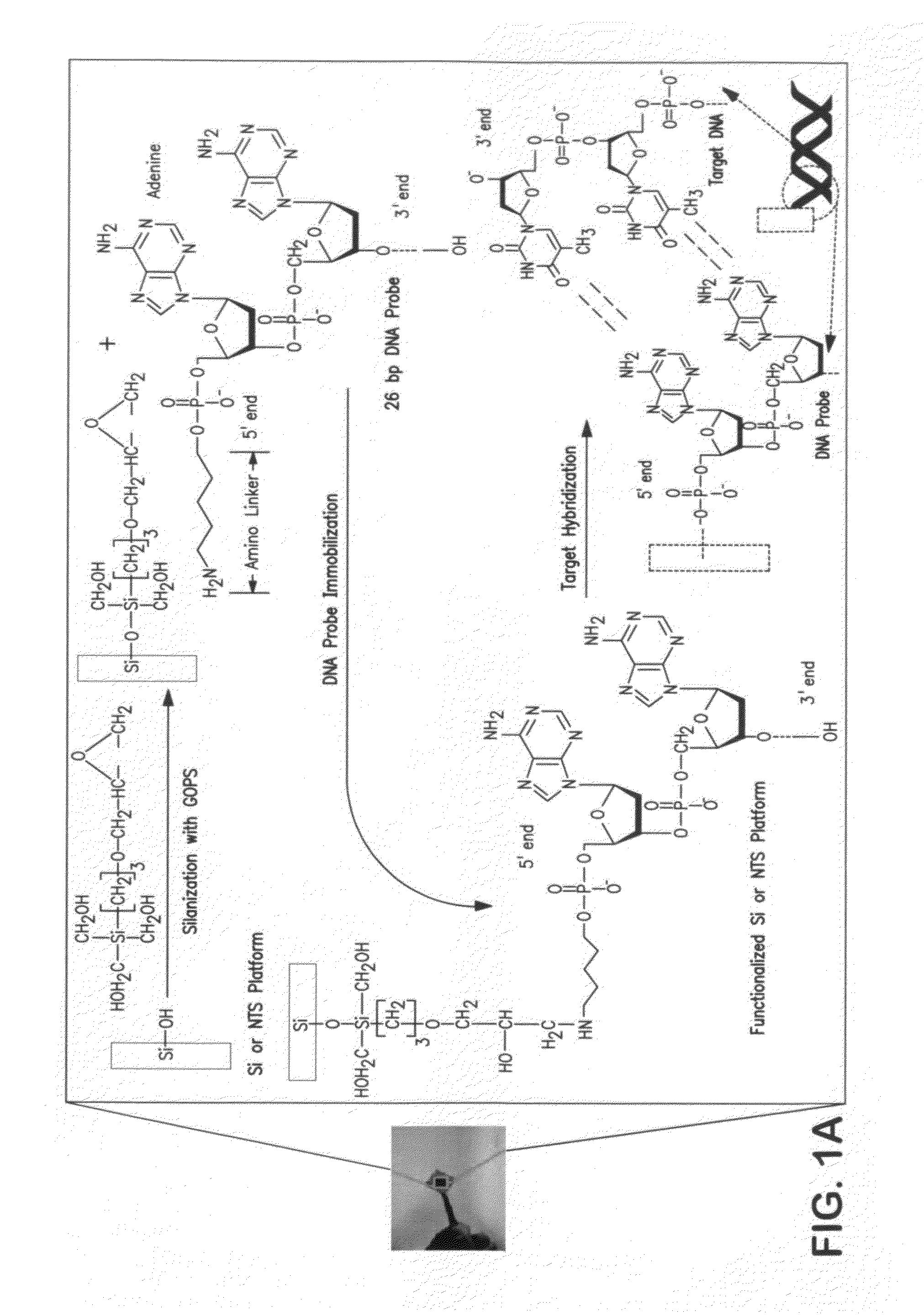

Nanoporous silicon-based electrochemical nucleic acid biosensor

InactiveUS20090050492A1Immobilised enzymesBioreactor/fermenter combinationsMicroorganismNanoporous silicon

A method and biosensor device for detecting single strand target nucleic acid by cyclic voltammetry is described. A porous silicon chip is linked to bound DNA probe complementary to the target nucleic acid. The device is particularly useful for detecting microorganisms and viruses that may be pathogenic or cancer genes, however any target nucleic acid can be detected by using a specific DNA probe.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

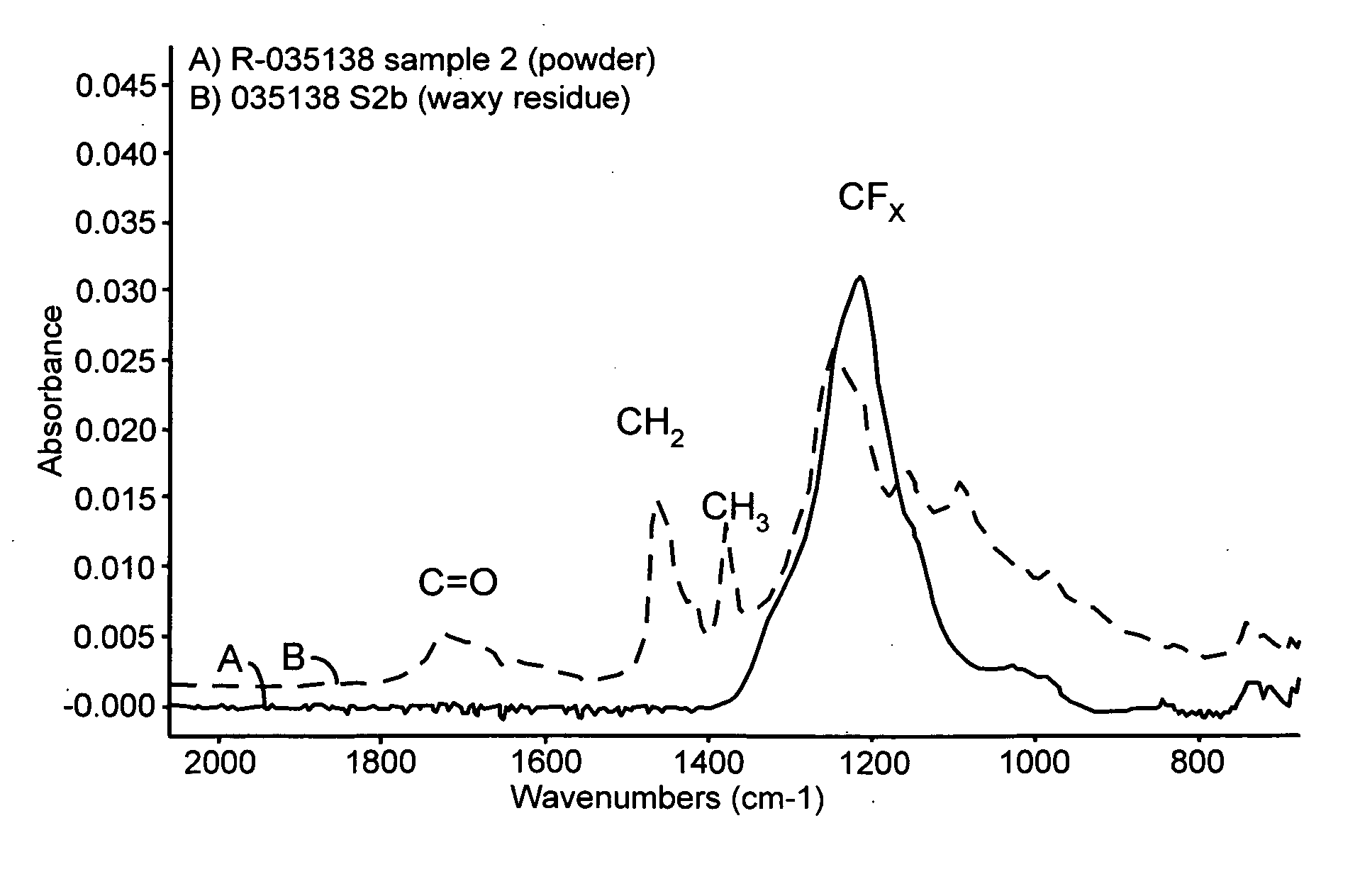

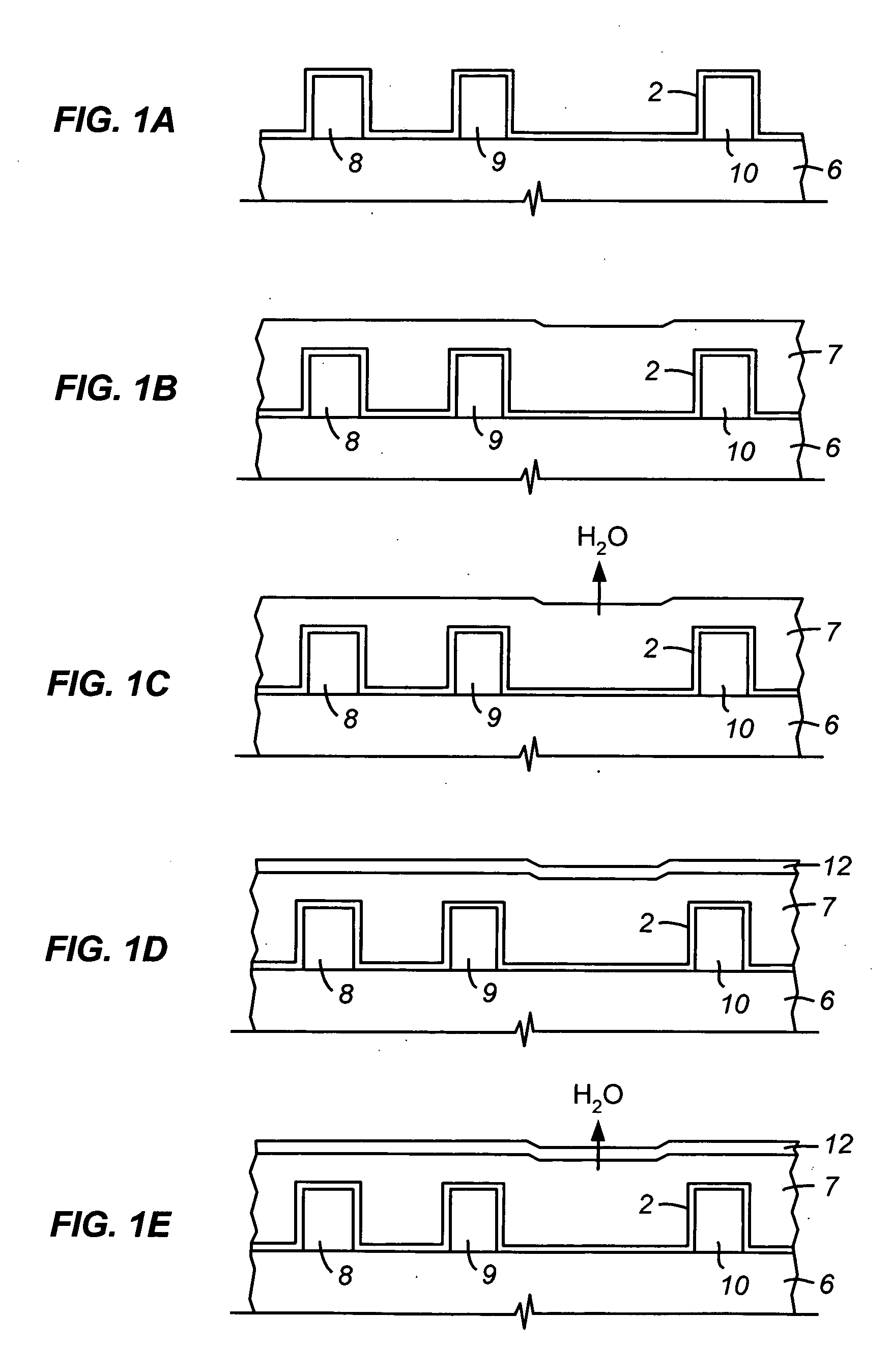

Formation of low K material utilizing process having readily cleaned by-products

InactiveUS20060160374A1Easy to disassembleSolid-state devicesSemiconductor/solid-state device manufacturingFuranCyclopentene

Nano-porous low dielectric constant films are deposited utilizing materials having reactive by-products readily removed from a processing chamber by plasma cleaning. In accordance with one embodiment, an oxidizable silicon containing compound is reacted with an oxidizable non-silicon component having thermally labile groups, in a reactive oxygen ambient and in the presence of a plasma. The deposited silicon oxide film is annealed to form dispersed microscopic voids or pores that remain in the nano-porous silicon. Oxidizable non-silicon components with thermally labile groups that leave by-products readily removed from the chamber, include but are not limited to, limonene, carene, cymene, fenchone, vinyl acetate, methyl methacrylate, ethyl vinyl ether, tetrahydrofuran, furan, 2,5 Norbornadiene, cyclopentene, cyclopentene oxide, methyl cyclopentene, 2-cyclopentene-1-one, and 1-butene.

Owner:APPLIED MATERIALS INC

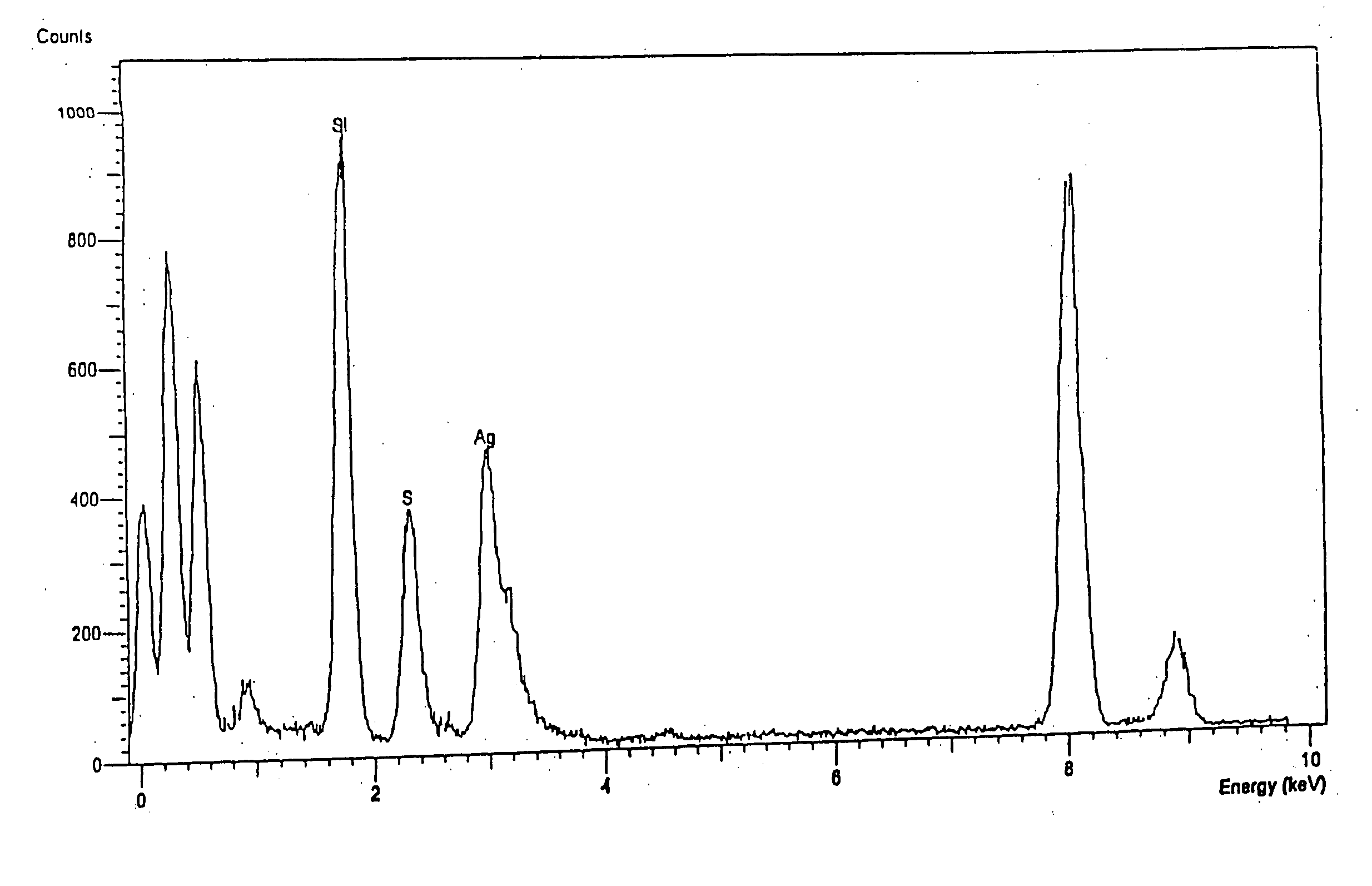

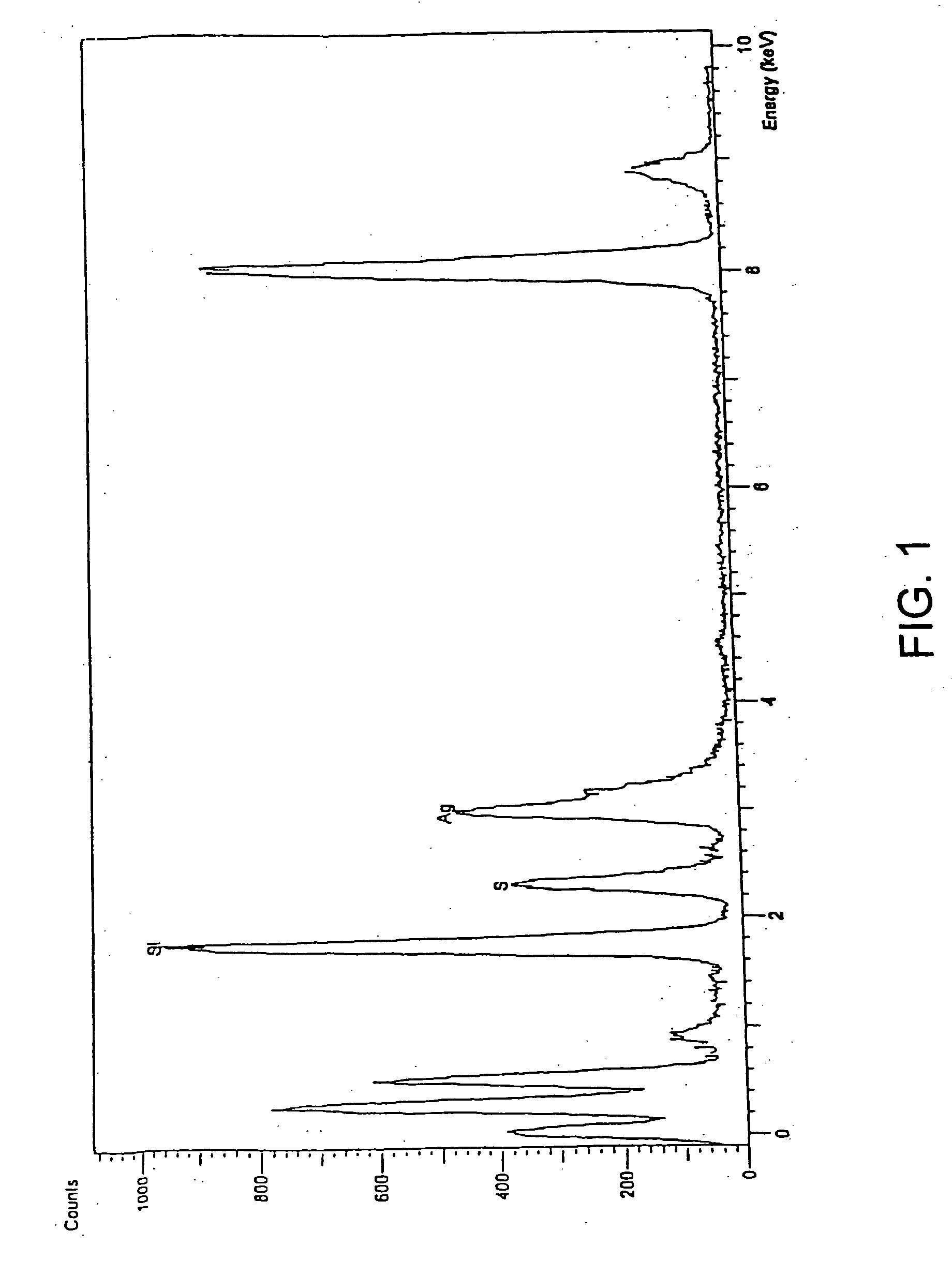

Nano porous silicon alloy material and preparation method thereof

The invention relates to a nano porous silicon alloy material and a preparation method thereof and provides a method for preparing a nano porous silicon alloy material by corroding multi-element alloy. As a nano-structured bulk material, the material prepared by using the method is high in performance and stability and is suitable for large-scale production. According to the technical scheme, the nano porous silicon alloy material comprise silicon and silver or one of 3d elements, wherein the 3d elements comprise Cu, Zn, Co, Ni and Fe; and the preparation method of the nano porous silicon alloy material is a free corrosion method. The nano porous silicon alloy material and the preparation method thereof have the beneficial effects that operation is simple, structural components are controllable and adjustable, yield is high, no target material loss is generated, and large-scale production is easily realized.

Owner:UNIV OF JINAN

Preparation method of lithium ion battery nanoporous silicon negative electrode material

ActiveCN110350181AEfficient purificationOvercome volumeSecondary cellsNegative electrodesMicro nanoEtching

The invention relates to a preparation method of lithium ion battery nanoporous silicon negative electrode material, and belongs to the technical field of new energy materials and electrochemistry. The silicon material crushed and finely ground into the micro-nano silicon powder in the protective gas atmosphere, and then crushing pretreatment is performed and the metal nanoparticles on the surfaceof the silicon powder are washed away and dried so as to obtain the nano silicon powder; one-step or two-step metal nanoparticle assisted chemical etching is performed on the nano silicon powder, solid-liquid separation and drying are performed so as to obtain nanoporous silicon / metal composite material; or a detergent is applied to remove the metal nanoparticles on the surface of the nanoporoussilicon, solid-liquid separation and drying are performed so as to obtain the nanoporous silicon; and the nanoporous silicon / metal composite material or the nano-porous silicon is oxidized so as to obtain an oxidized nano-porous silicon / metal composite material or oxidized nano-porous silicon, and the nanoporous silicon / metal composite material, the nanoporous silicon, the oxidized nanoporous silicon / metal composite material or the oxidized nanoporous silicon are the lithium ion battery nanoporous silicon negative electrode material.

Owner:KUNMING UNIV OF SCI & TECH

Porous silicon-carbon composite material for lithium ion battery and preparation method of material

InactiveCN106450246ARich sourcesLow priceCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a porous silicon-carbon composite material for a lithium ion battery and a preparation method of the material. According to the preparation method, CMC (sodium carboxy methyl cellulose) serves as template agents and enwrapping agents, a porous silicon-carbon material is prepared by the aid of microwave drying technologies, the porous silicon-carbon material and graphite materials are composited to obtain the porous silicon-carbon composite material, the porous silicon-carbon composite material is used for negative electrode materials of the lithium ion battery, the graphite materials are one or more in mesocarbon micro-beads, natural graphite and artificial graphite, porous silicon is carbon-coating nano-scale porous silicon, porous characteristics of the porous silicon are beneficial to absorption and storage of electrolyte solution, a space for volume expansion is provided in the charge and discharge process of the silicon materials, the porous silicon is the nano-scale porous silicon, so that volume effect of silicon particles is relieved, and the porous silicon-carbon composite material has the advantages of high reversible capacity, good circulation performance and excellent rate performance.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

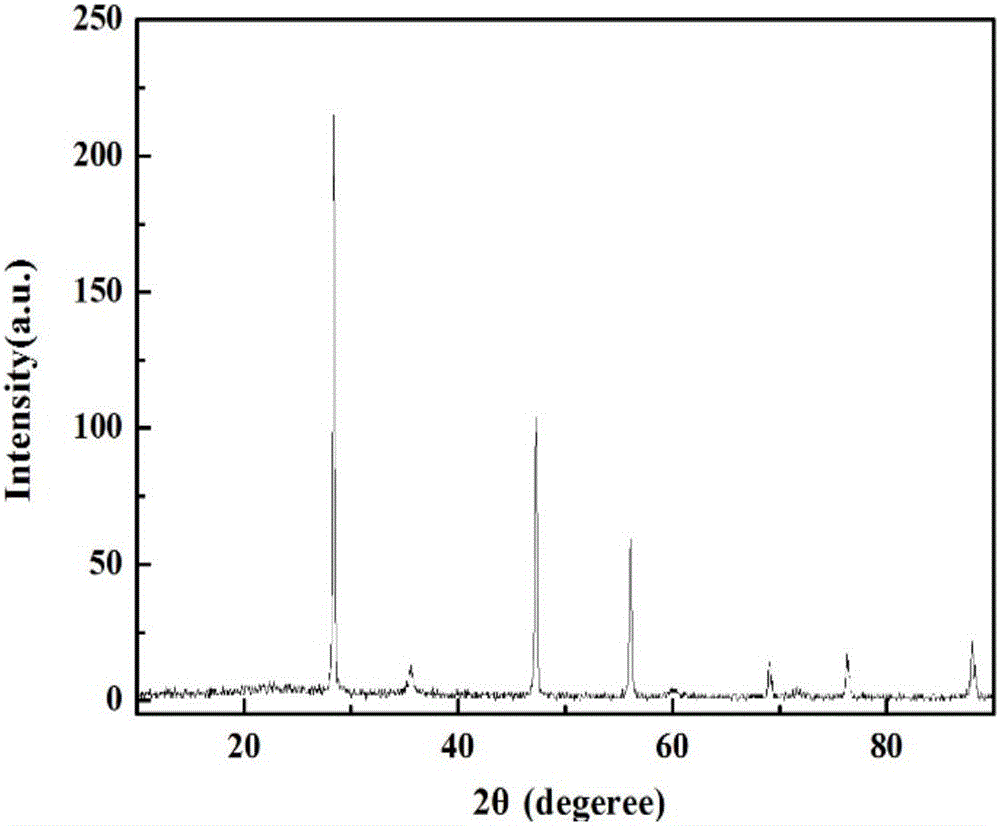

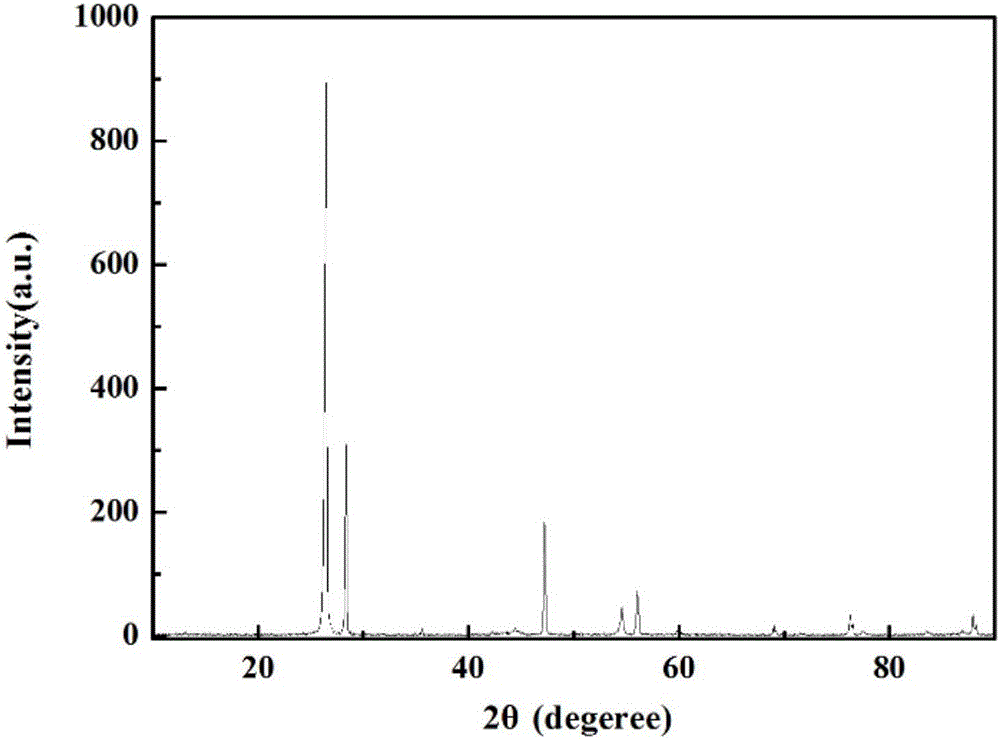

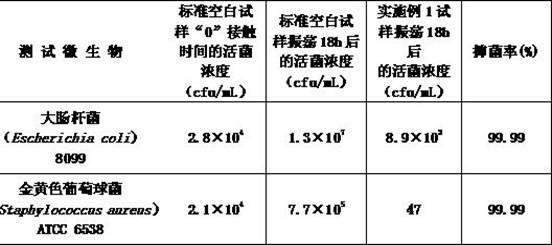

Antibacterial moisture-transfer chinlon 6 and preparation method thereof

ActiveCN102677215AReduce contentStrong ability to load copper ionsBiocideFilament forming substance formingPolyamideMoisture absorption

The invention discloses antibacterial moisture-transfer chinlon 6 comprising antibacterial master batches, polyamide 6 chips and calcium stearate, wherein the weight ratio of the antibacterial master batches to the polyamide 6 chips to the calcium stearate is (7-10) to (95-100) to (0.1-0.3). The antibacterial moisture-transfer chinlon 6 provided by the invention adopts nano porous bergmeal to carry cuprous oxide and has the characteristic of high copper ion carrying capacity, thereby not only saving the production cost and reducing the content of inorganic particles in melt, but also improving the stability of the spinning process; the antibacterial moisture-transfer chinlon 6 is scientific and reasonable in component proportion and can resist various bacteria, thereby having the advantages that the antibacterial range is high and the antibacterial ratio is above 99 the antibacterial moisture-transfer chinlon 6 has excellent moisture absorption and sweat discharging functions and a wide application range; and the operability of a preparation method is strong, the process is reasonable, the production efficiency is high, and industrialized production can be realized.

Owner:TAICANG HONGYI CHEM FIBER

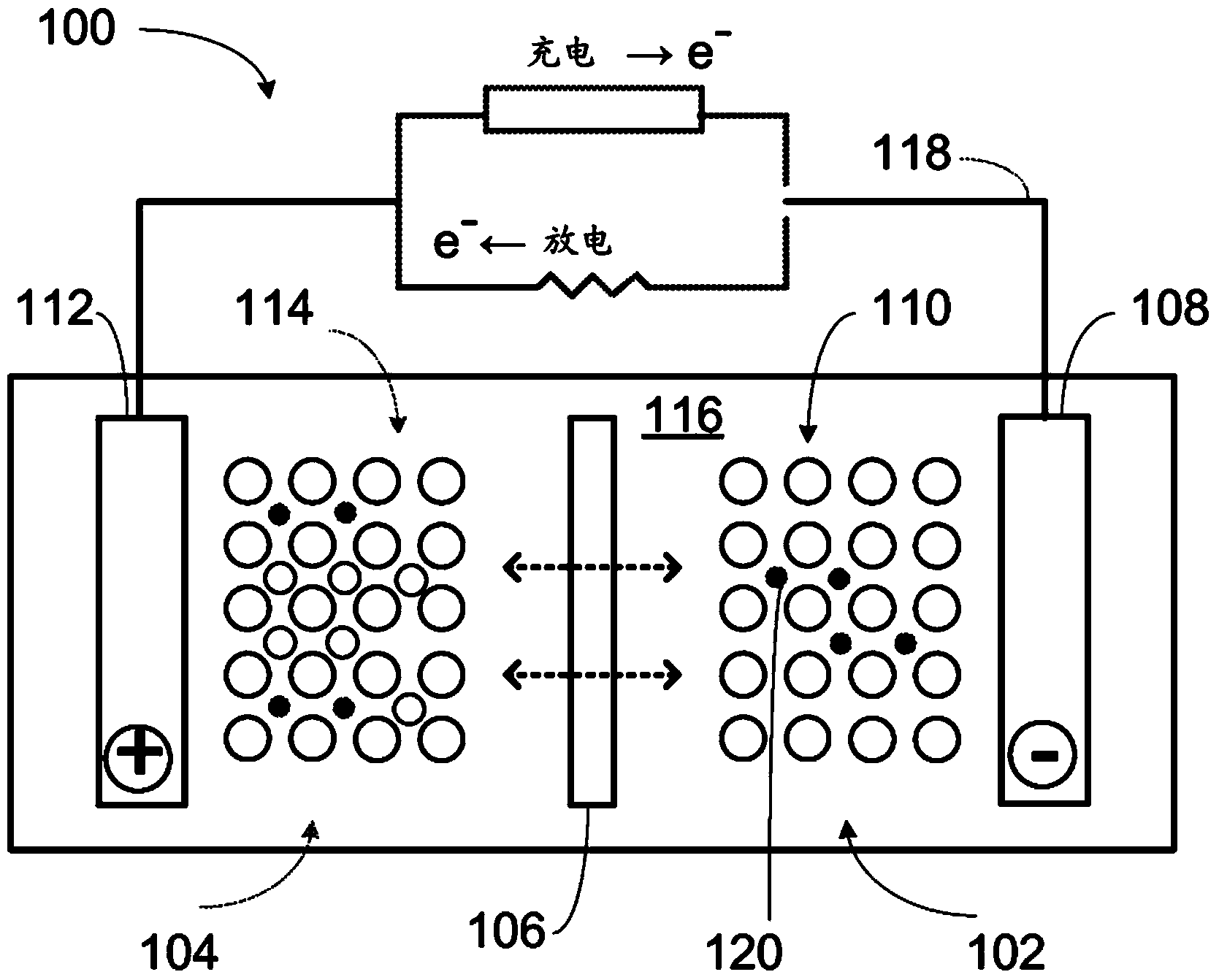

Nanoporous silicon and lithium ion battery anodes formed therefrom

An electrode for a lithium ion battery, the electrode including nanoporous silicon structures, each nanoporous silicon structure defining a multiplicity of pores, a binder, and a conductive substrate. The nanoporous silicon structures are mixed with the binder to form a composition, and the composition is adhered to the conductive substrate to form the electrode. The nanoporous silicon may be, for example, nanoporous silicon nanowires or nanoporous silicon formed by etching a silicon wafer, metallurgical grade silicon, silicon nanoparticles, or silicon prepared from silicon precursors in a plasma or chemical vapor deposition process. The nanoporous silicon structures may be coated or combined with a carbon-containing compound, such as reduced graphene oxide. The electrode has a high specific capacity (e.g., above 1000 mAh / g at current rate of 0.4 A / g, above 1000 mAh / g at a current rate of 2.0 A / g, or above 1400 mAh / g at a current rate of 1.0 A / g).

Owner:UNIV OF SOUTHERN CALIFORNIA

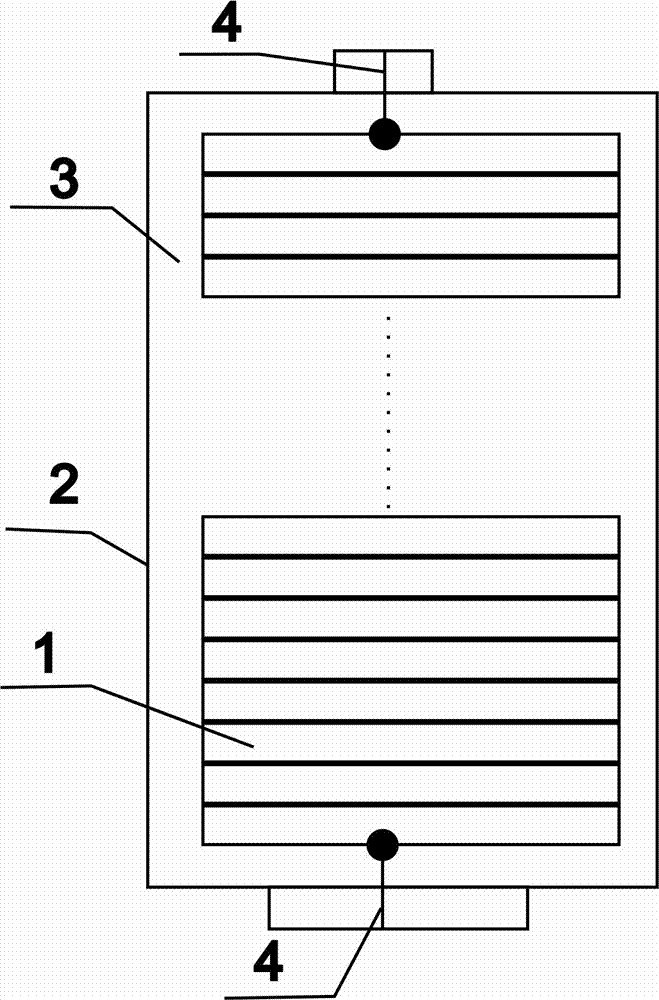

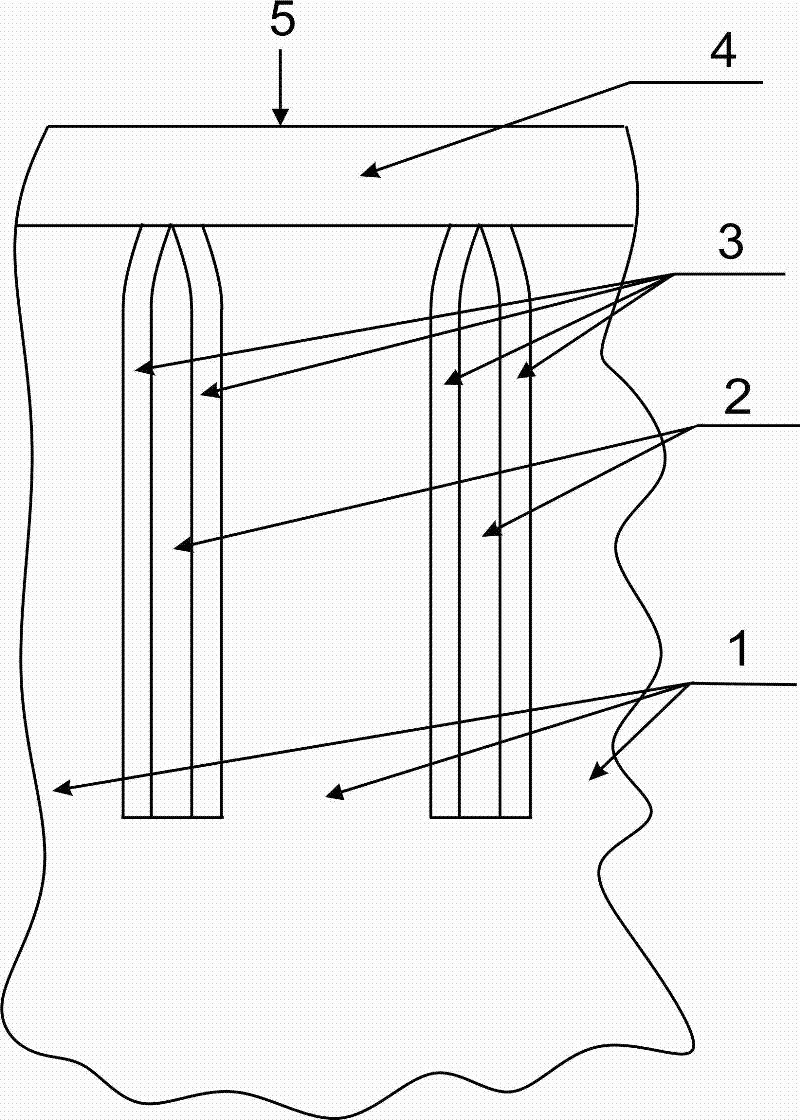

Micro tritium battery and preparation method of micro tritium battery

InactiveCN102737747AGuaranteed normal transmissionSmall sizeRadiation electrical energyNanoporous siliconEngineering

The invention discloses a micro tritium battery. The micro tritium battery is composed of a plurality of layers of tritium battery units, a protecting material, a housing and an electrode, wherein the tritium battery unit is composed of monocrystalline silicon and tritiated nano porous silicon in the monocrystalline silicon; according to the tritium battery unit, the adsorption of a radioactive source can be reduced, and the utilization efficiency of the monocrystalline silicon can be improved. According to the method of the micro tritium battery, the steps of etching the monocrystalline silicon through electrochemistry, doping, absorbing tritium, depositing electrode, manufacturing a protective housing, etc. are adopted; and the preparation method is simple and safe.

Owner:SICHUAN UNIV

Method for preparing nano porous silicon by utilizing doped silicon particles

ActiveCN103985848AIncrease concentrationHigh hole densityCell electrodesSecondary cellsHydrofluoric acidReaction temperature

The invention discloses a method for preparing nano porous silicon by utilizing doped silicon particles. The method comprises the following steps: selecting silicon particles with a certain doping concentration, washing with hydrofluoric acid, then enabling the silicon particles to react in a solution which is prepared by selecting nitrate, hydrofluoric acid and oxidant with assistance of ultrasonic process centrifugally washing the silicon particles, and finally washing the silicon particles by using dilute nitric acid to obtain the three-dimensional nano porous silicon. The optimal process parameters such as best constitution of chemical etching corrosive agent, volume ratio and specific concentration of a reaction reagent, reaction time, reaction temperature, ultrasonic frequency, processing time and the like are screened out through a great number of experiments, and the prepared high-purity three-dimensional doped porous silicon is regular in pore shape, uniform in distribution and applicable to the fields such as lithium batteries, solar batteries, semiconductors and sensors. The method is strong in process maneuverability, low in cost, high in yield and applicable to industrialized mass production.

Owner:南京卓胜自动化设备有限公司

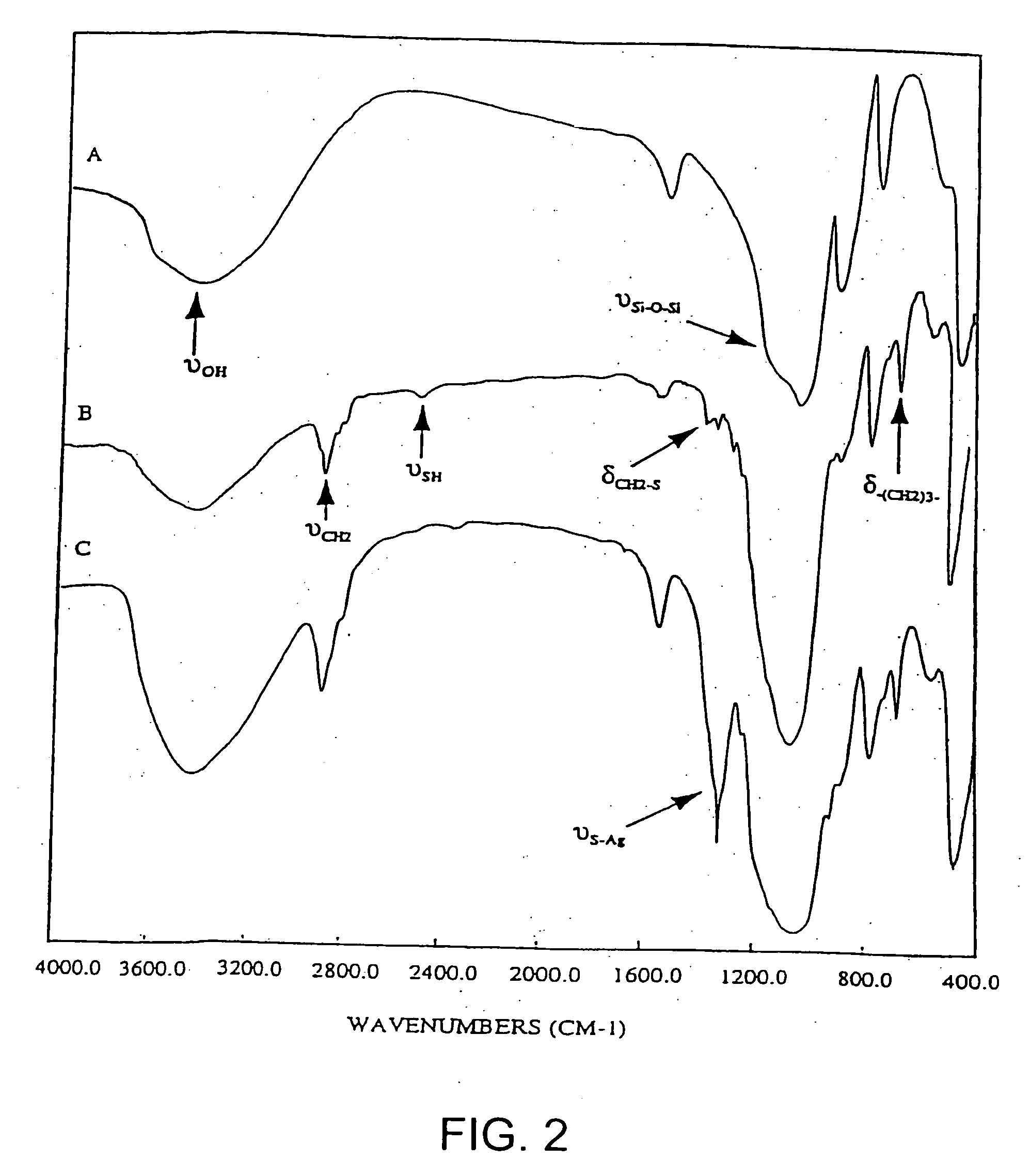

Ion separation using a surface-treated xerogel

InactiveUS20070122333A1Preserves porosityPrevent shrinkageSilicaOther chemical processesSilica gelSilicon dioxide

Amorphous, nanoporous silica gel having an open channel structure may be surface modified at higher loading of surface modifying ligands, e.g., 7.5 mmole per gram, than known nanoporous silica gels. In one embodiment, an amorphous silica gel has a bimodal pore size distribution of pores at about 10 nanometers and at about 10 microns, and a bulk density of about 0.2 to about 0.25 g / ml. Surface modification with functionalized ligand groups, effective for selective adsorption or reaction catalysis, is achieved by gelling silica sol solution to form a wet silica gel, maintaining the gel at a relatively low elevated temperature in a moist state to obtain a wet nanoporous silica gel having a plurality of open channels within the gel structure and silanol groups on the surface and reacting the surface silanol groups with the ligand group to introduce the functionalized group. The surface modifying reaction may be carried out concurrently with the gelling of a silica precursor in an aqueous alcoholic medium. 3-mercaptopropyltrialkoxysilane is an exemplary ligand introducing compound. The chemically surface modified gel may be used, for example, to remove or concentrate metallic substances in a liquid, or to separate two or more metallic impurities from a mixture thereof, or for cleanup of oil or chemical contaminants from the surface of a body of water.

Owner:IND SCI & TECH NETWORK INC

Method for preparing nano-porous silicon from Cu nano-particles by two-step auxiliary etching

InactiveCN104576353APorosity adjustableReduce manufacturing costSemiconductor/solid-state device manufacturingEtchingSurface oxidation

The invention relates to a method for preparing nano-porous silicon from Cu nano-particles by two-step auxiliary etching and belongs to the technical field of preparation of nano-materials. The method comprises the following steps: firstly, pre-treating a silicon chip; performing surface oxidation treatment on the pre-treated silicon chip by using a physical or chemical method to form an oxidation layer; preparing a deposition solution and an etching solution; placing the silicon chip with the oxidation layer in the deposition solution for chemical deposition, taking out the silicon chip, placing the silicon chip in the etching solution, completely etching the silicon chip, then soaking the silicon chip into nitric acid, washing the silicon chip by using a great amount of deionized water, and then blow-drying the silicon chip by nitrogen to obtain the nano-porous silicon. The method offers a great help to the improvement of the surface area and the reaction activity of the nano-porous silicon, the surface reflectivity of the nano-porous silicon is greatly reduced, and the method has broad application prospect in the fields of nano-sensors and nano-catalysis.

Owner:KUNMING UNIV OF SCI & TECH

Novel porous silicon and a preparation method thereof

InactiveCN102400217ADoes not affect productionEasy to integratePolycrystalline material growthAfter-treatment detailsMicro nanoHydrofluoric acid

The invention discloses novel porous silicon and a preparation method thereof. The porous silicon has a structure that cylindrical nanometer porous silicon is formed in a low-doped and N-shape monocrystalline silicon film base, and closes straight hole cavities, and the surface is nanometer porous silicon. The invention employs an electrochemical corrosion method, where the structure of the novel porous silicon is made by controlling the mixture solution proportioning and the voltage and current of a dc source in a mixture solution of hydrofluoric acid and an organic solvent. The novel porous silicon structure and the preparation method provide a new technological approach and method for the integration of a silicon-based micro nano device with a sensor, a self-destructing chip, a luminescent device, etc.

Owner:SICHUAN UNIV

Silicon/expanded graphite/amorphous carbon composite material and preparation method thereof

InactiveCN109638269AImprove cycle performanceImprove conductivityCell electrodesSupercritical dryingCarbon composites

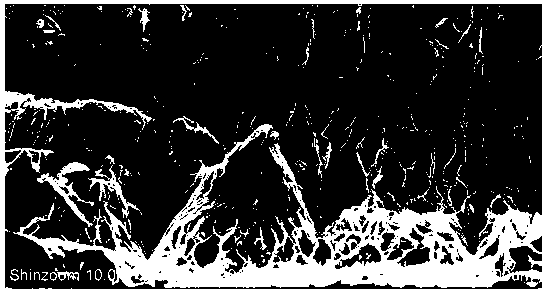

The invention provides a preparation method of a silicon / expanded graphite / amorphous carbon composite material. The preparation method comprises the following steps: mixing tetraethoxysilane, absoluteethyl alcohol and deionized water, dropwise adding an oxalic acid solution and ammonia water to form an alcohol gel, aging, carrying out supercritical drying to obtain a SiO2 aerogel blocky solid, mixing the SiO2 aerogel blocky solid with magnesium powder, heating in an argon atmosphere, cooling, then putting into an HCl solution and an HF solution, soaking, cleaning and drying to obtain nano-porous silicon. Then mixing the nano-porous silicon with the expanded graphite in ethanol, stirring, impregnating, filtering, and finally coating in a protective atmosphere to obtain the silicon / expandedgraphite / amorphous carbon composite material. According to the invention, the problem of poor cycle performance caused by a huge volume effect of the silicon negative electrode in the prior art is solved.

Owner:HUNAN SHINZOOM TECH

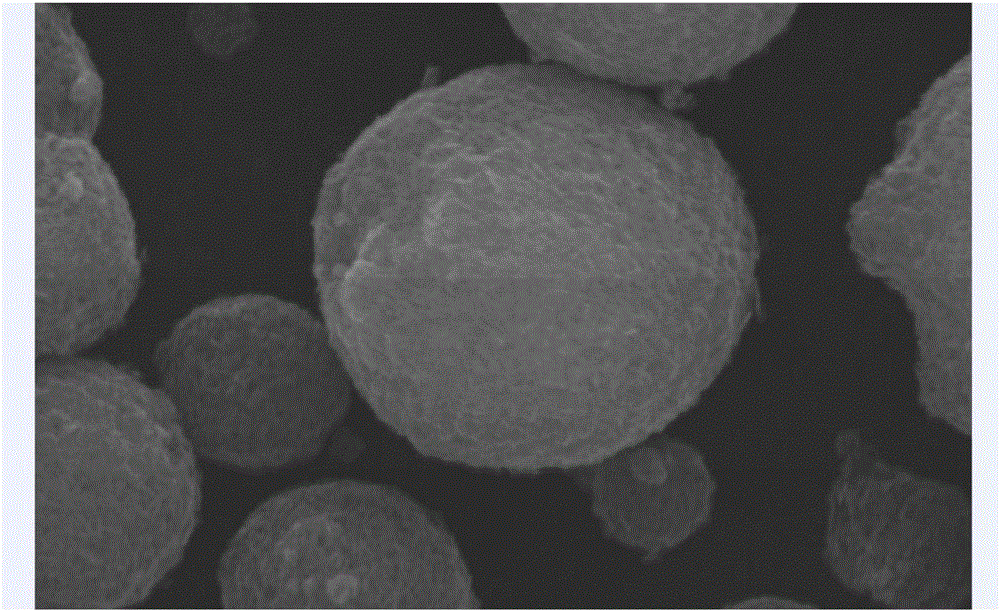

Method for preparing doping porous silicon ball

InactiveCN103979487AAchieving controllable equipmentEasy to operateNanostructure manufactureReaction temperatureOperability

The invention discloses a method for preparing a doping porous silicon ball. The method includes the steps that a silicon ball with certain doping content is selected, after being washed by hydrofluoric acid, the silicon ball is immersed in solutions formed by nitrate and hydrofluoric acid, after ultrasonic processing is carried out, the silicon ball is immersed in solutions prepared by the hydrofluoric acid and oxidizing agents and reacts at a certain temperature for a certain time period, then the silicon ball is washed in a centrifugal mode, and ultimately the nano porous silicon ball is prepared after nitric acid washing and other post-processing procedures. The best variety and the best concentration of reaction solutions, the optimum proportion of components, the best reaction temperature, the best reaction time, best ultrasonic frequency and best ultrasonic processing time are screened out through a large quantity of experiments. According to the whole preparation method, process design is reasonable, operability is high, production cost is low, production efficiency is high, and large-scale industrial production can be achieved. According to the high-purity doping porous silicon ball prepared in the method, the shapes of holes are regular, the holes are uniformly distributed and honeycomb-shaped, the shape of the silicon ball is regular, and the method can be widely used in the field of lithium batteries, solar batteries, semi-conductors, sensors and the like.

Owner:YANCHENG INST OF TECH

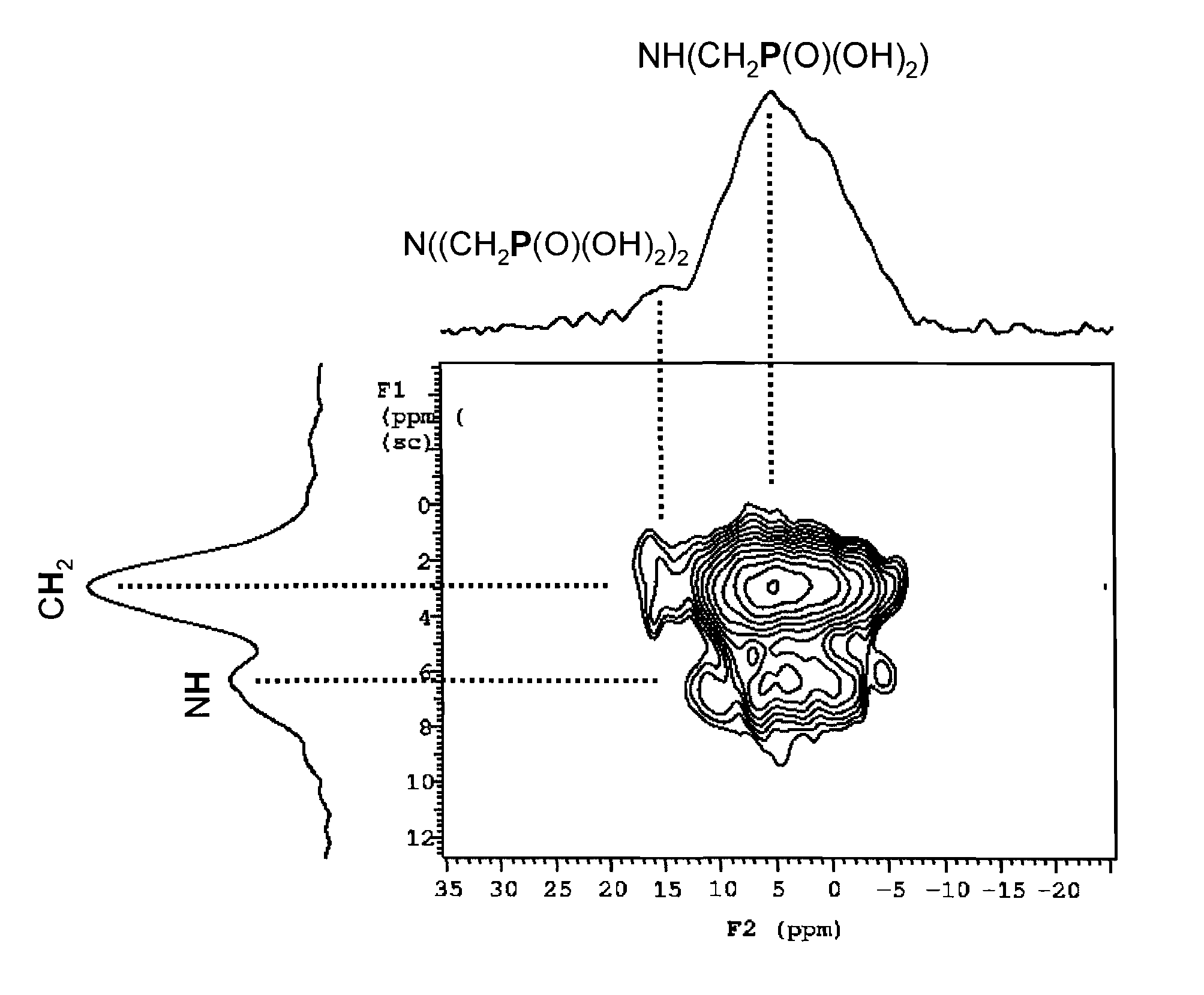

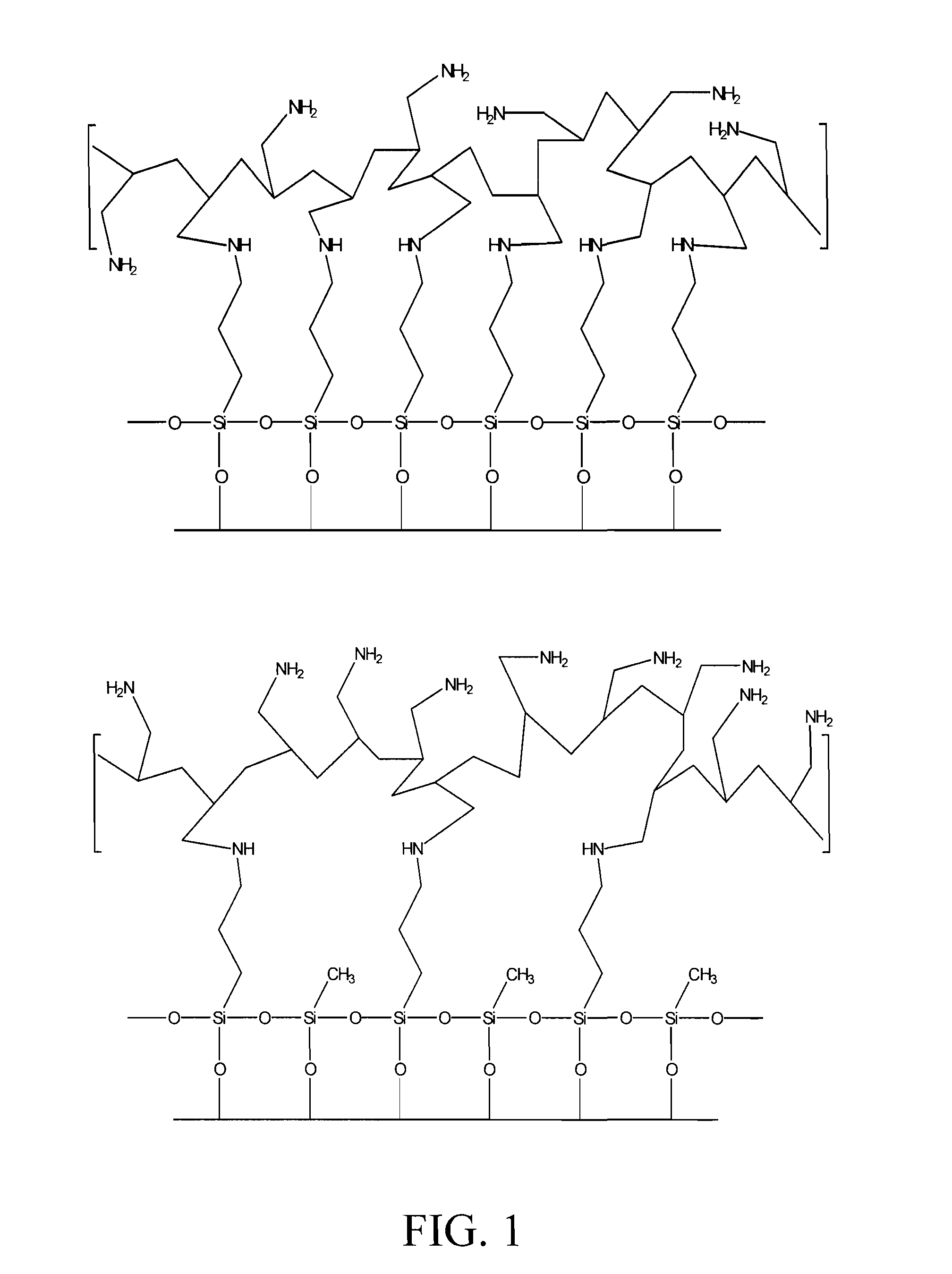

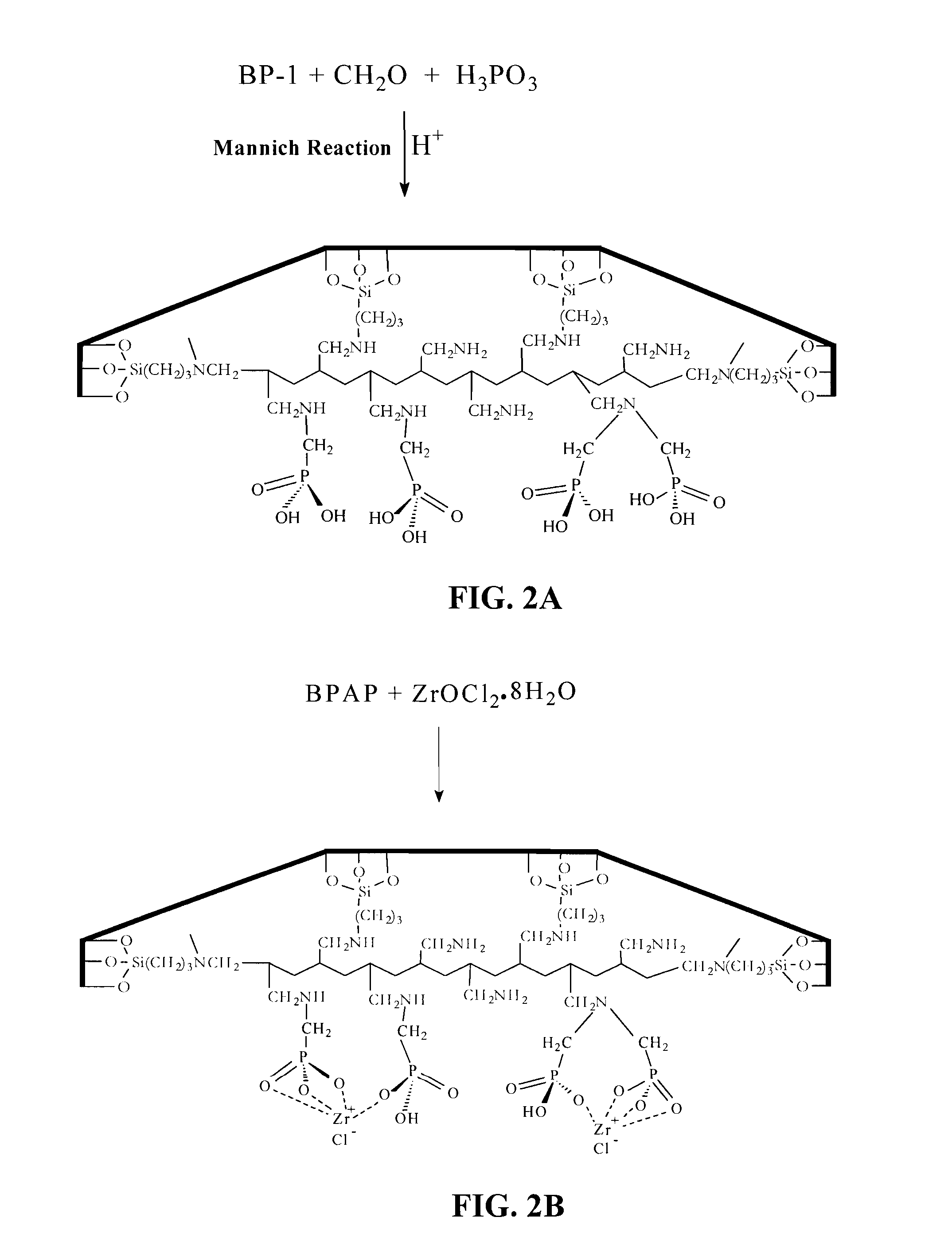

Nanoporous Silica Polyamine Composites with Surface-Bound Zirconium (IV) and Methods of Use

Silica polyamine composites (SPC) made from silanized amorphous nano-porous silica gel and poly(allylamine) (BP-1) were functionalized with phosphorus acid using the Mannich reaction, resulting in a phosphonic acid modified composite (BPAP). Zirconium (IV) was immobilized on BPAP. Arsenate anions strongly adsorbed on the ZrBPAP composite in the pH range 2 to 8, while arsenite only adsorbed well at pH 10. Regeneration of the resin was carried out successfully for As(V) and As(III) using 2M-H2SO4. Four adsorption / desorption cycles were performed for As(V) at pH 4 without significant decrease in the uptake performance. ZrBPAP capture capacity and kinetics for arsenate were tested for longevity over 1000 cycles with only a marginal loss of performance.

Owner:UNIVERSITY OF MONTANA

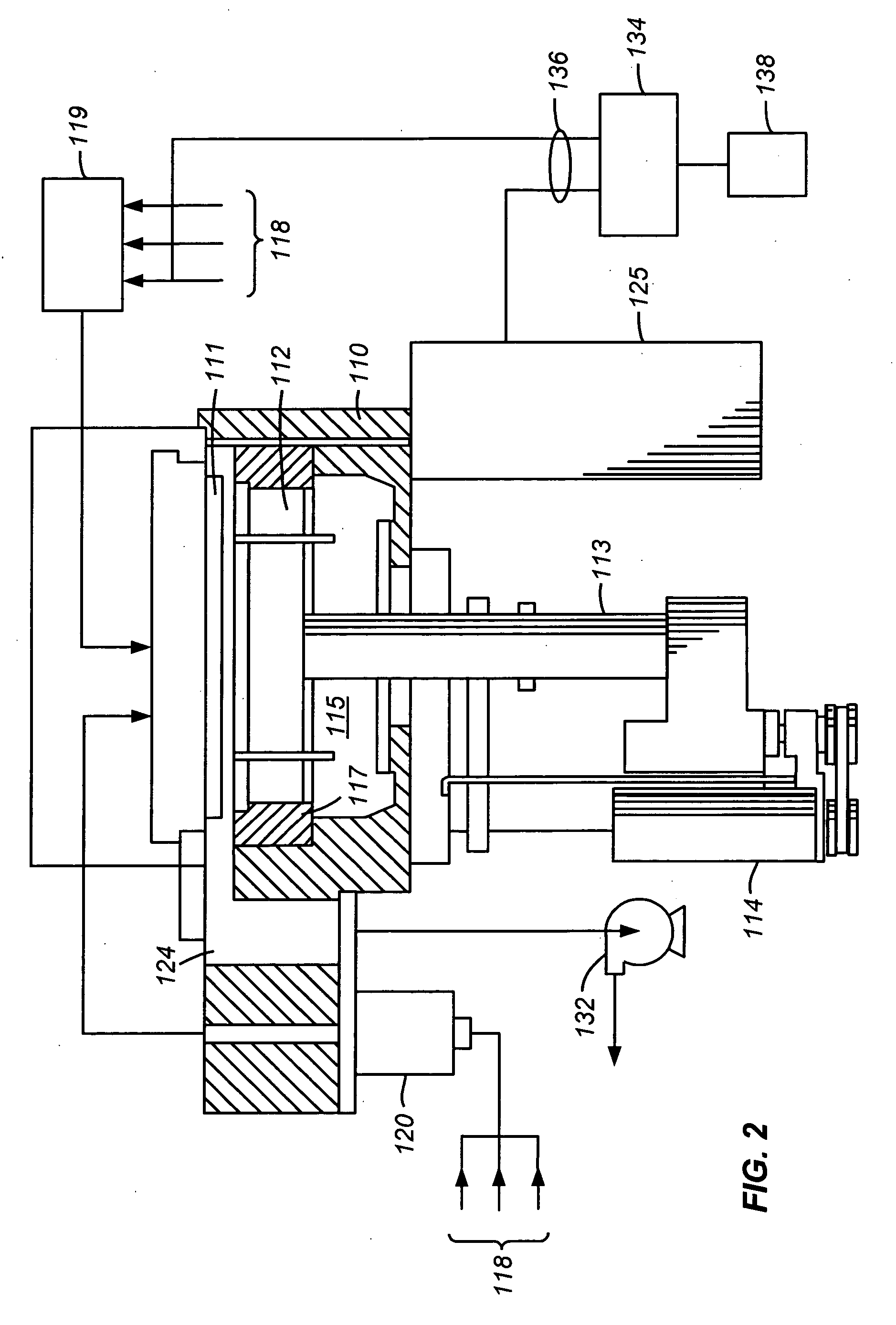

Processes and apparatuses for producing porous materials

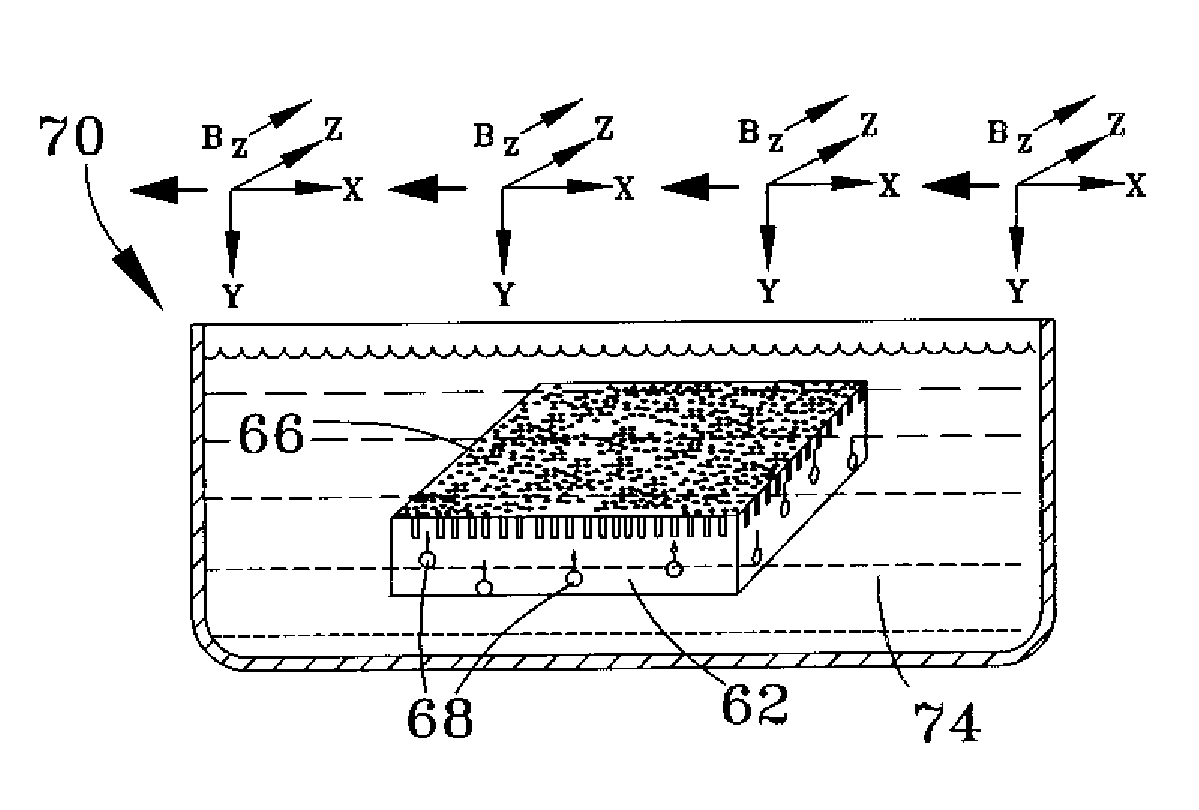

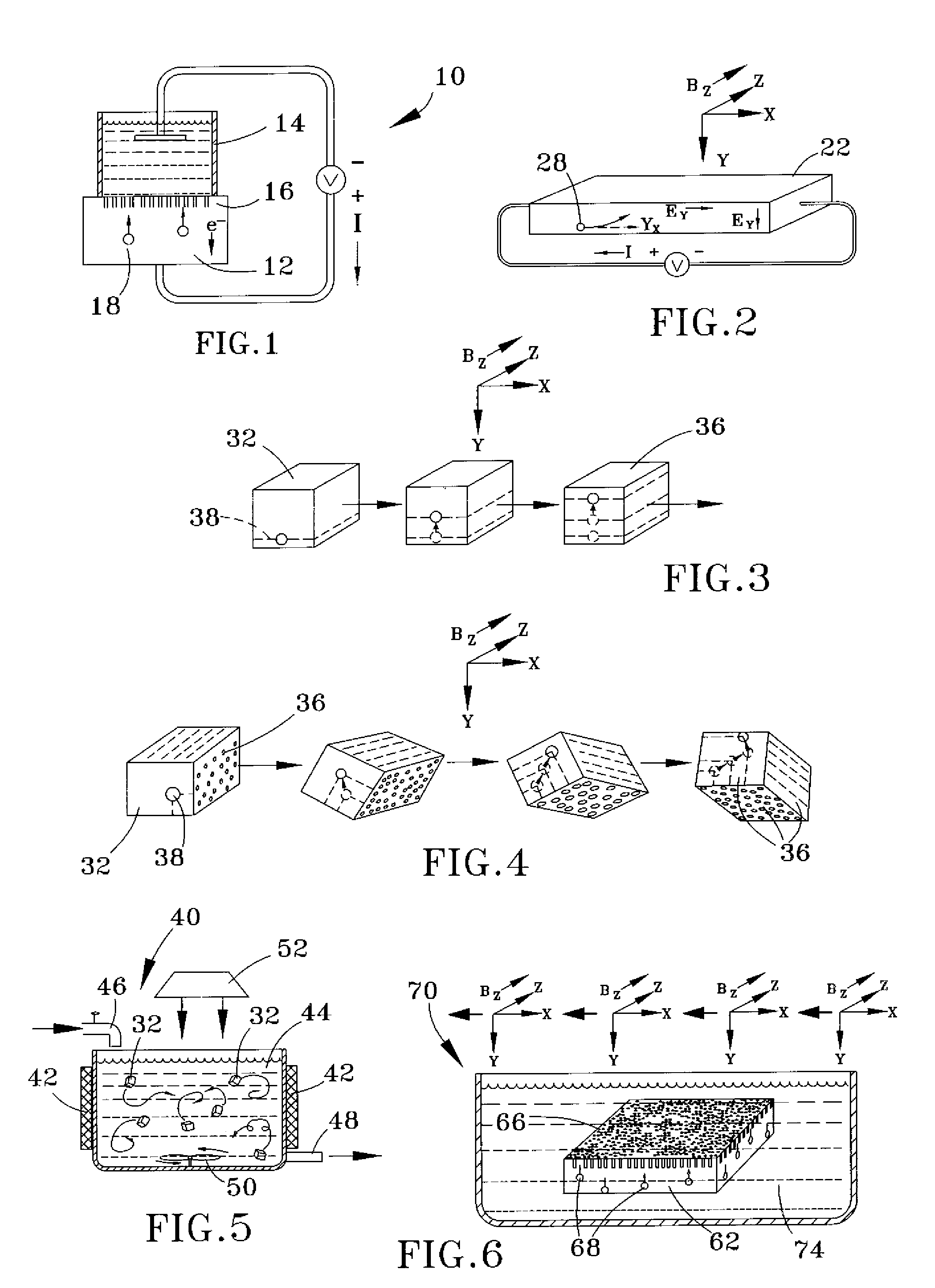

ActiveUS20080277380A1High porosityOptimize npSi formationReversible hydrogen uptakePaper/cardboard articlesHydrogenCharge carrier

Processes and apparatuses for producing a porous material, such as nano-porous silicon (npSi) media suitable for storage and retrieval of elemental hydrogen. Processes of this invention generally entail applying a magnetic field to a substrate that contains charge carriers and is in contact with an etchant, and then etching the substrate with the etchant while relative movement occurs between the substrate and the magnetic field. During etching, the charge carriers move relative to the substrate and the magnetic field, and porosity forms at surfaces of the substrate contacting the etchant.

Owner:INDIANA UNIV RES & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com