Micro tritium battery and preparation method of micro tritium battery

A battery and miniature technology, which is used in the fields of obtaining electric energy from radioactive sources, nuclear engineering, and the application of radioactive source radiation. It can solve the problems of small tritium gas adsorption, energy consumption, and small tritium adsorption, so as to improve protection and safety. , Reduce the size of the radioactive source, and be conducive to the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned miniature tritium battery, the silicon wafer is an n-type silicon wafer of 1 ~ 100Ωcm, comprising the following steps:

[0041] Step 1, structure preparation, install the cleaned silicon wafer in the electrochemical etching tank, the etching solution is mixed with hydrofluoric acid and organic solvent at a volume ratio of 1:1~1:1.5, and the concentration of hydrofluoric acid is 40%~50 %, the organic solvent is one of methanol, ethanol, and isopropanol, the power supply voltage is set at 40-70 V and the current is set at 20-60 mA / cm 2 , the etching time is 1-10 min, and then ion beam sputtering is performed on the etched surface to remove the corroded layer on the surface, and a porous silicon structure is produced;

[0042] Step 2, pn junction preparation, porous silicon structure doping with boron doping 10 on the corrosion surface 16 ~10 20 cm -3 and the other side doped with phosphorus 10 16 ~10 20 cm -3 ;

[004...

Embodiment 1

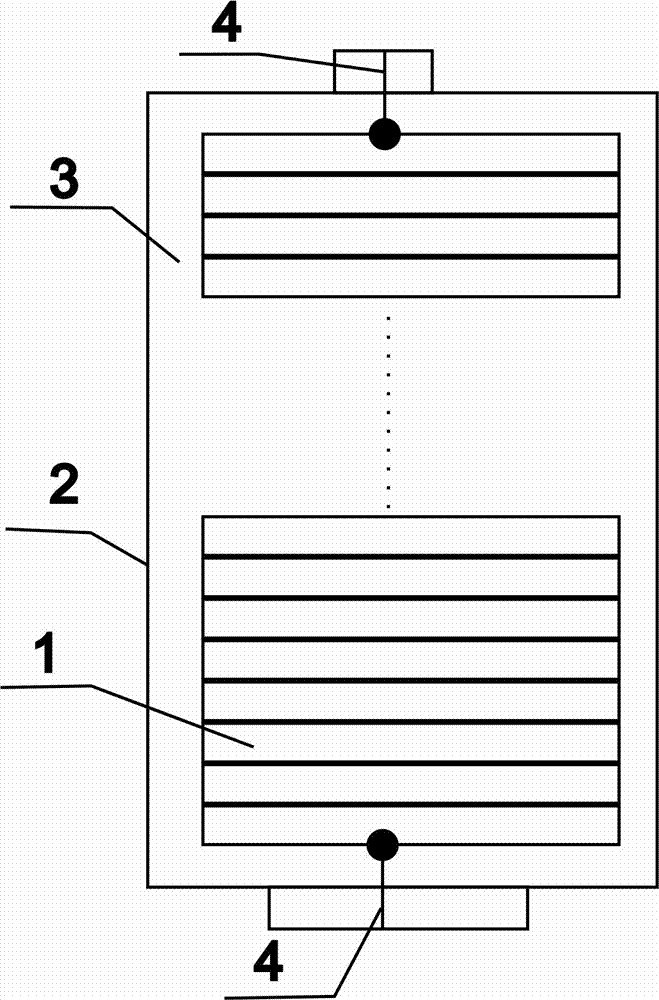

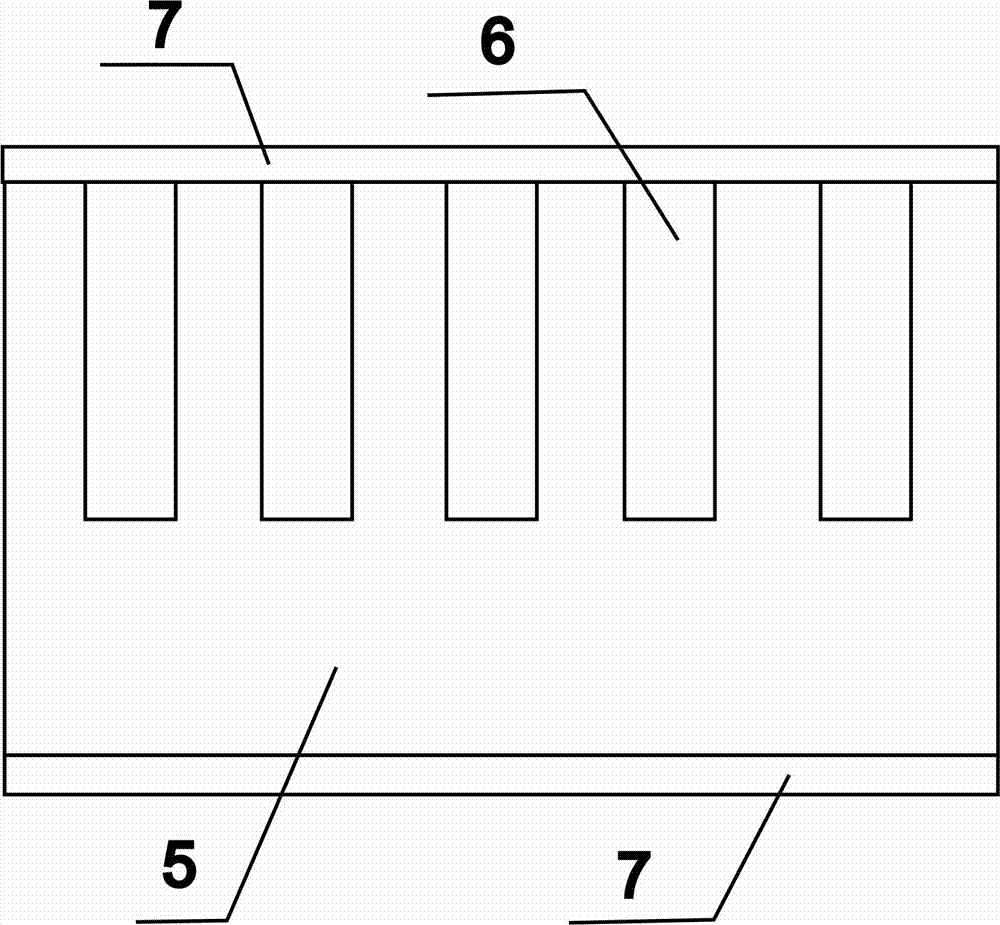

[0055] The micro tritium battery includes several layers of tritium battery cells 1, casing 2, protective material 3 and external electrodes 4, and the tritium battery cells include single crystal silicon 5, columnar tritiated nanoporous silicon 6 embedded in single crystal silicon and located in the single crystal The surface electrodes 7 on both sides of the silicon are sequentially connected to the tritium battery unit 1 through the contact of the surface electrodes 7 .

[0056] The protective material 3 is a tritium-proof polyvinyl chloride composite material, forming a sealed space, and the joint is sealed with an O-ring made of polytetrafluoroethylene. The shell 2 is stainless steel, and the surface electrode 7 is a gold film with a thickness of 100nm. The resistivity of monocrystalline silicon 5 is 1~5Ωcm, and nanoporous silicon is a sponge-like structure composed of silicon nanocrystals and nanopores below 5nm. Columnar tritiated nanoporous silicon 6: height 1 μm, spa...

Embodiment 2

[0064] The micro tritium battery includes several layers of tritium battery cells 1, casing 2, protective material 3 and external electrodes 4, and the tritium battery cells include single crystal silicon 5, columnar tritiated nanoporous silicon 6 embedded in single crystal silicon and located in the single crystal The surface electrodes 7 on both sides of the silicon are sequentially connected to the tritium battery unit 1 through the contact of the surface electrodes 7 .

[0065] The protective material 3 can be polytetrafluoroethylene, and forms a sealed space, and the connection is sealed with an O-ring made of neoprene. The shell 2 is stainless steel, and the surface electrode 7 is an aluminum film with a thickness of 500nm. The resistivity of monocrystalline silicon 5 is 80~100Ωcm, and nanoporous silicon is a sponge-like structure composed of silicon nanocrystals and nanopores below 5nm. Columnar tritiated nanoporous silicon 6: 60 μm in height, 1 to 2 μm in pitch, and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com