Antibacterial moisture-transfer chinlon 6 and preparation method thereof

An antibacterial and nylon technology, applied in the field of nylon fiber, can solve the limited problems, and achieve the effects of reasonable process, improved stability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

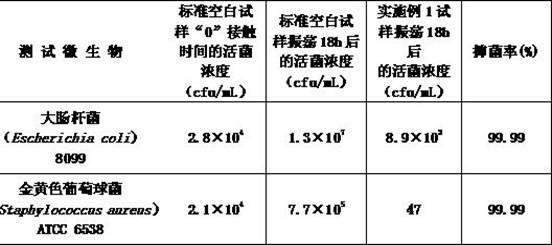

Examples

Embodiment 1

[0034] An antibacterial and moisture-conducting nylon 6, the antibacterial and moisture-conducting nylon 6 is composed of antibacterial masterbatch, polyamide 6 slices and calcium stearate, and the weight ratio between each component is antibacterial masterbatch: polyamide 6 slices: stearic acid Calcium=8.5:97.5:0.2.

[0035] Described antibacterial masterbatch is made by following weight component blending:

[0036] Polyamide 6 slices 87.5 kg

[0037] Antibacterial powder 12.5 kg

[0038] Calcium stearate 0.45 kg

[0039] Zinc stearate 0.45 kg

[0040] Antioxidant 1010 0.45 kg

[0041] Antioxidant 168 0.45 kg.

[0042] The preparation method of the above-mentioned antibacterial and moisture-conducting nylon 6 comprises the following steps:

[0043](1) First, heat the deionized water to boil or pass nitrogen gas to remove the oxygen in the water, then add cuprous chloride to prepare a saturated cuprous chloride solution. In parts by weight, place 13.5 kg of nanoporous d...

Embodiment 2

[0053] An antibacterial and moisture-conducting nylon 6, the antibacterial and moisture-conducting nylon 6 is composed of antibacterial masterbatch, polyamide 6 slices and calcium stearate, and the weight ratio between each component is antibacterial masterbatch: polyamide 6 slices: stearic acid Calcium = 7:95:0.1.

[0054] Described antibacterial masterbatch is made by following weight component blending:

[0055] Polyamide 6 slices 85 kg

[0056] Antibacterial powder 10 kg

[0057] Calcium stearate 0.3 kg

[0058] Zinc stearate 0.3 kg

[0059] Antioxidant 1010 0.3 kg

[0060] Antioxidant 168 0.3 kg.

[0061] The preparation method of the above-mentioned antibacterial and moisture-conducting nylon 6 comprises the following steps:

[0062] (1) First, heat the deionized water to boil or pass nitrogen gas to remove the oxygen in the water, then add cuprous chloride to prepare a saturated cuprous chloride solution. In parts by weight, place 0.7 kg of nanoporous diatomite w...

Embodiment 3

[0072] An antibacterial and moisture-conducting nylon 6, the antibacterial and moisture-conducting nylon 6 is composed of antibacterial masterbatch, polyamide 6 slices and calcium stearate, and the weight ratio between each component is antibacterial masterbatch: polyamide 6 slices: stearic acid Calcium=10:100:0.3.

[0073] Described antibacterial masterbatch is made by following weight component blending:

[0074] Polyamide 6 slices 90 kg

[0075] Antibacterial powder 15 kg

[0076] Calcium stearate 0.6 kg

[0077] Zinc stearate 0.6 kg

[0078] Antioxidant 1010 0.6 kg

[0079] Antioxidant 168 0.6 kg.

[0080] The preparation method of the above-mentioned antibacterial and moisture-conducting nylon 6 comprises the following steps:

[0081] (1) First, heat the deionized water to boil or pass nitrogen gas to remove the oxygen in the water, then add cuprous chloride to prepare a saturated cuprous chloride solution. In parts by weight, 2 kg of nanoporous diatomite with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com