Patents

Literature

46results about How to "The distribution ratio is scientific and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane resin mortar for cement base material repairing

The invention relates to a polyurethane resin mortar composition for cement base material repairing, which comprises raw materials A, B and C, wherein the raw material A comprises the following materials in parts by weight: 100 parts of polyalcohol, 5-60 parts of plasticizer, 0.01-3 parts of catalyst, 0-2 parts of defoaming agent, 0-30 parts of chain extender or crosslinking agent, 0-3 parts of coupling agent and 0-10 parts of stabilizer; the raw material B is isocyanate or prepolymer thereof; the raw material C is solid filler; and the mass ratio of the three raw materials A, B and C is 10:(1-30):(10-200). The composition is used as the repairing material for concrete structures of ballastless tracks and cement asphalt mortar, and has the advantages of high curing speed, good low-temperature curing property, high ductility and the like.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

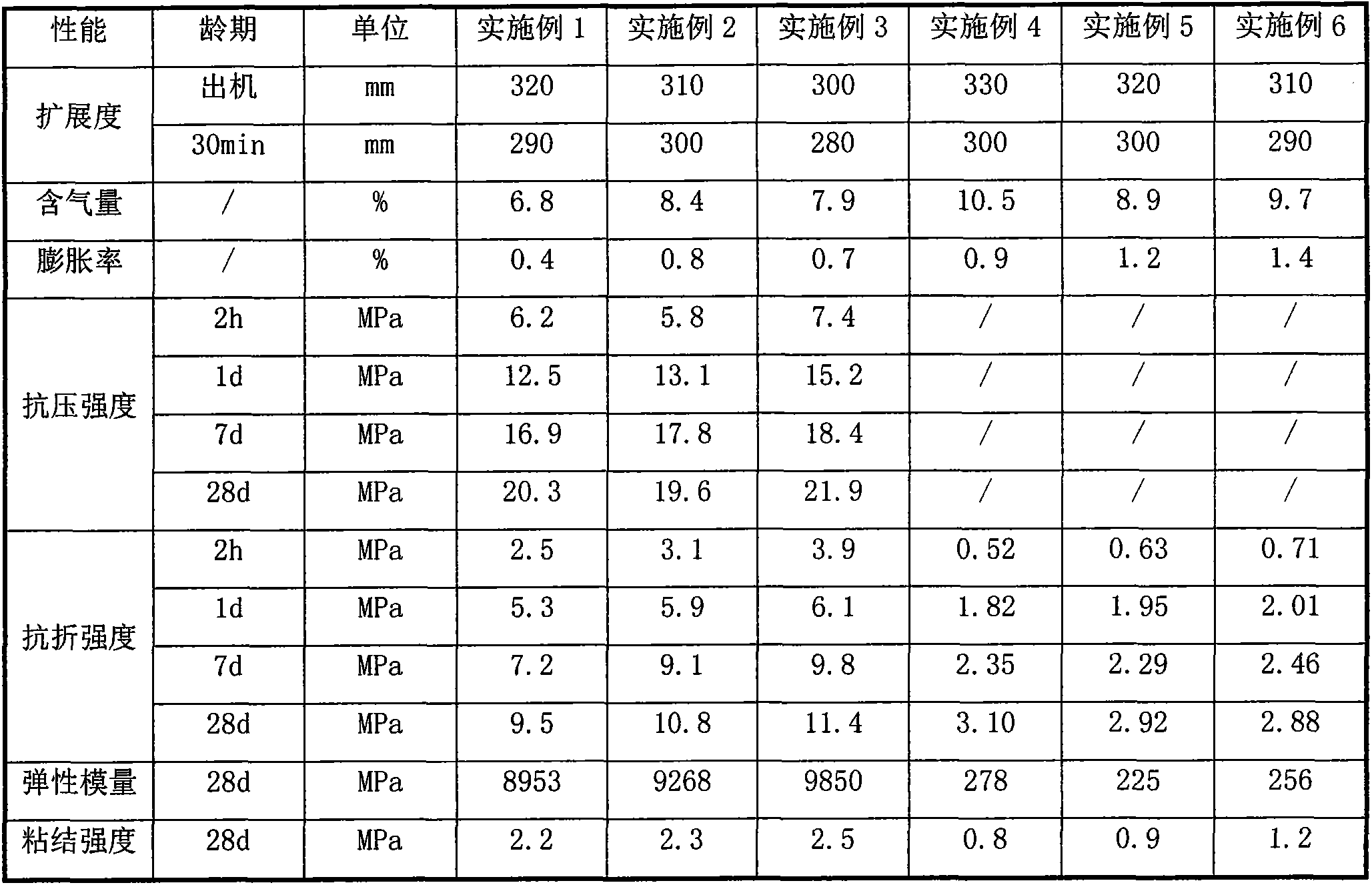

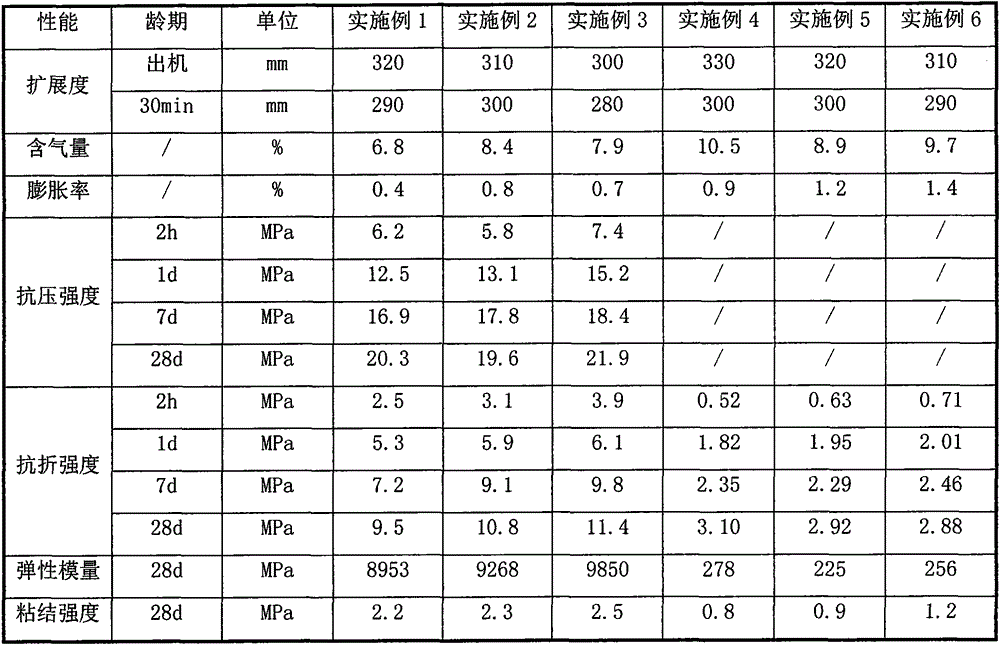

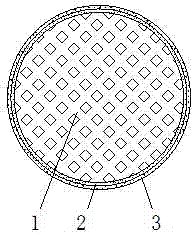

Polymer cement mortar for slab ballastless track of high-speed railway

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

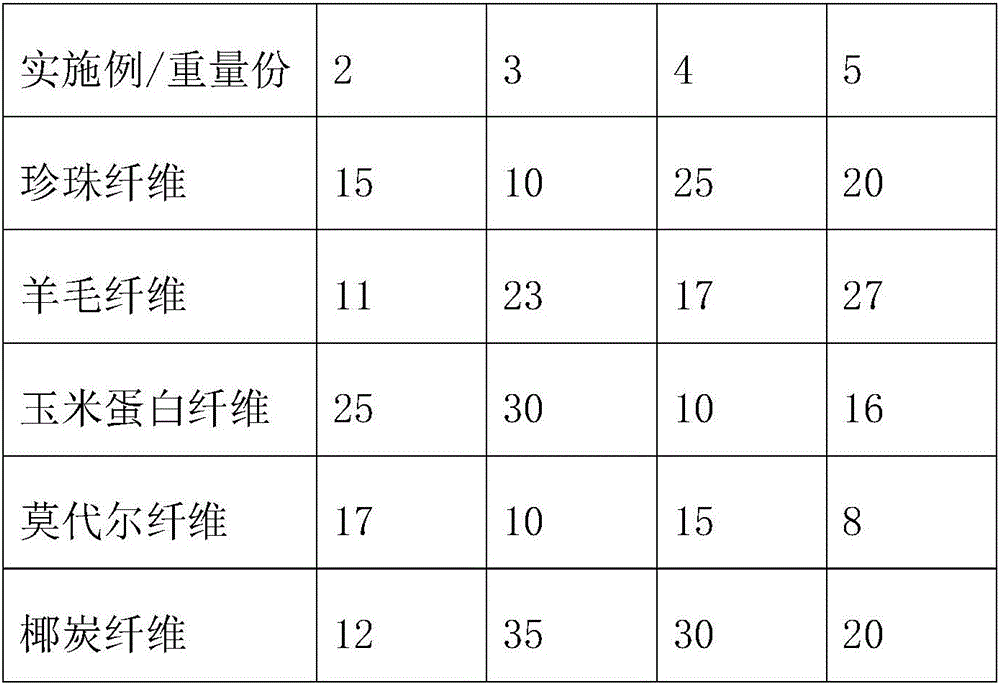

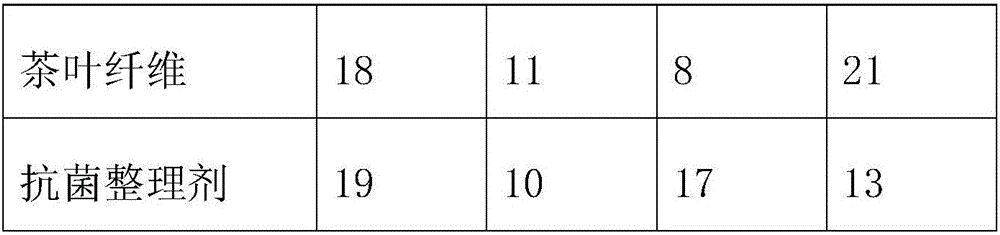

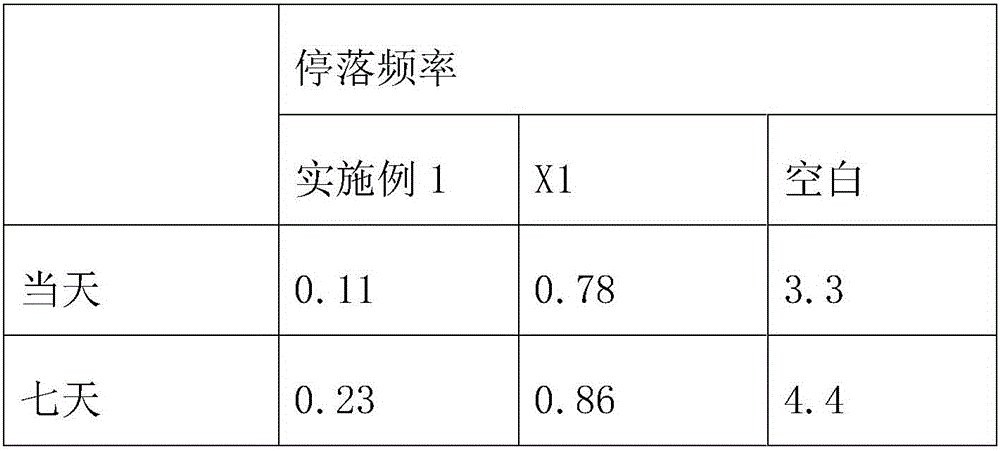

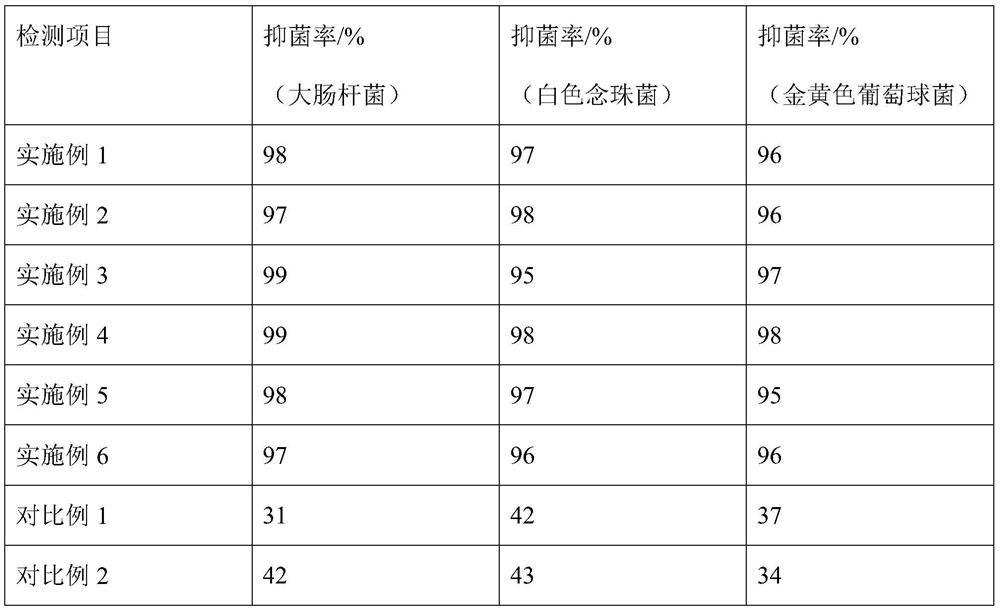

Novel antibacterial fabric and preparation method thereof

ActiveCN106435944AThe distribution ratio is scientific and reasonableWith mosquito repellentCarbon fibresWarp knittingFlame resistanceWool fiber

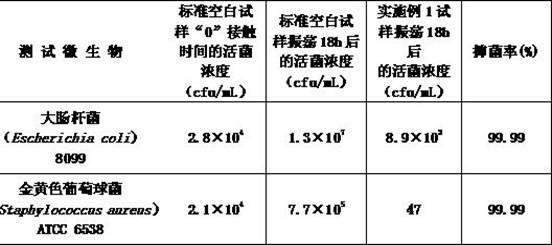

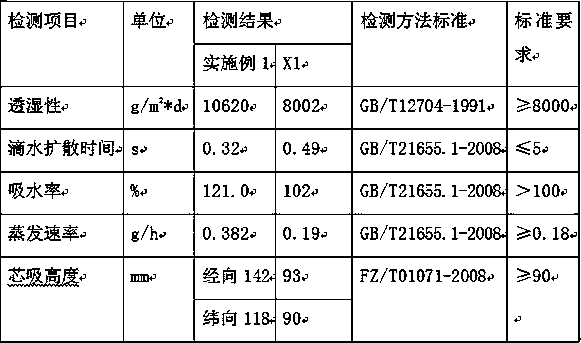

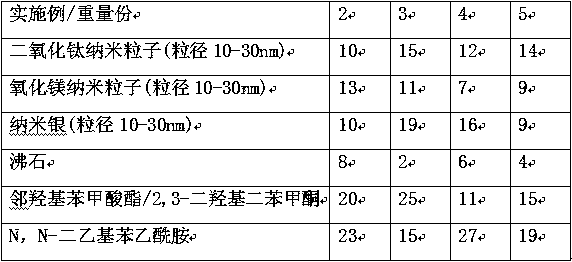

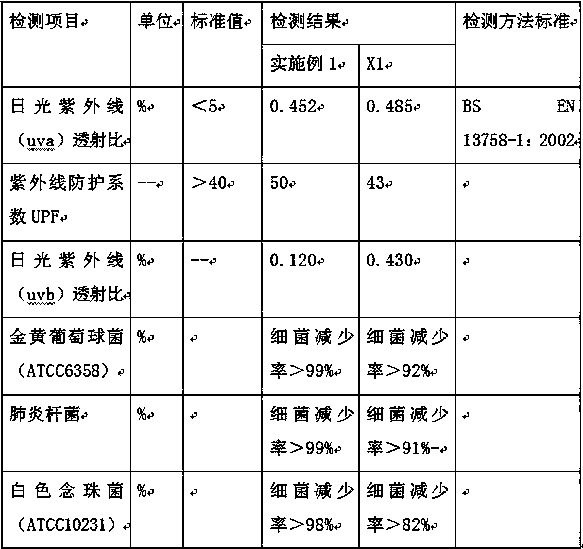

The invention discloses a novel antibacterial fabric and a preparation method thereof and belongs to the field of functional textiles. The novel antibacterial fabric comprises, by weight, 10-25 parts of pearl fiber, 11-27 parts of wool fiber, 10-30 parts of corn protein fiber, 8-17 parts of modal fiber, 12-35 parts of coconut charcoal fiber, 8-21 parts of tea fiber and 10-19 parts of antibacterial finishing agent. The novel antibacterial fabric has the functions of comfort, bacterium prevention, mosquito dispelling, moisture conduction, sweat permeability, warmth keeping and the like. Meanwhile, the fabric also has good flame resistance, high crease elasticity and high breaking strength.

Owner:BEIJING SUKENO RISHENG SOCKS

Water-soluble PU nubuck low-temperature foamex for synthetic leather

InactiveCN101666039ALow costThe ratio is scientific and reasonableFibre treatmentSolventWater soluble

The invention discloses water-soluble PU nubuck low-temperature foamex for synthetic leather, prepared by the following raw materials in percentage by weight: 30-40 percent of water-soluble polyurethane, 40-50 percent of water, 2-10 percent of low-temperature nubuck foam powder, 2-5 percent of organosilicon levelling agent, 2-5 percent of organosilicon antifoaming agent and 0.5-2 percent of water-soluble polyurethane thickener. The mixture ratio of each component of the water-soluble PU nubuck low-temperature foamex for synthetic leather is scientific and reasonable, and the components mutually coordinate and jointly act. The nubuck low-temperature foamex has the advantages of good film reforming property and firm adhesion, and coating is resistant to solvent, cold, hydrolysis and thermalageing. The original effect of the leather surface of a finished product prepared from the water-soluble PU nubuck low-temperature foamex can not be influenced; after the leather surface is treated bythe foamex, low-temperature foaming is carried out to produce nubuck leather, and therefore, the effect of the leather surface is unique; moreover, the synthetic leather has exquisite texture, good air permeability and excellent resultant effect of hand feeling, water proofing, adhesion and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Antibacterial moisture-transfer chinlon 6 and preparation method thereof

ActiveCN102677215AReduce contentStrong ability to load copper ionsBiocideFilament forming substance formingPolyamideMoisture absorption

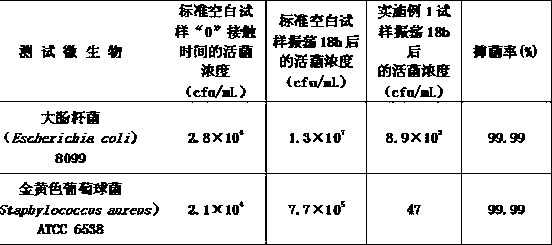

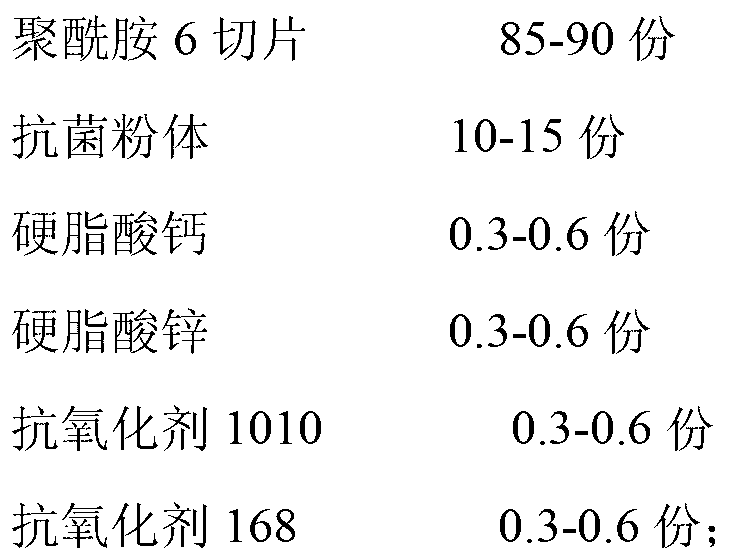

The invention discloses antibacterial moisture-transfer chinlon 6 comprising antibacterial master batches, polyamide 6 chips and calcium stearate, wherein the weight ratio of the antibacterial master batches to the polyamide 6 chips to the calcium stearate is (7-10) to (95-100) to (0.1-0.3). The antibacterial moisture-transfer chinlon 6 provided by the invention adopts nano porous bergmeal to carry cuprous oxide and has the characteristic of high copper ion carrying capacity, thereby not only saving the production cost and reducing the content of inorganic particles in melt, but also improving the stability of the spinning process; the antibacterial moisture-transfer chinlon 6 is scientific and reasonable in component proportion and can resist various bacteria, thereby having the advantages that the antibacterial range is high and the antibacterial ratio is above 99 the antibacterial moisture-transfer chinlon 6 has excellent moisture absorption and sweat discharging functions and a wide application range; and the operability of a preparation method is strong, the process is reasonable, the production efficiency is high, and industrialized production can be realized.

Owner:TAICANG HONGYI CHEM FIBER

Electrolytic solution used for molybdenum gate screen electrolytic polishing and preparation method and application thereof

InactiveCN101864590AThe ratio is scientific and reasonableStrong maneuverabilityPhosphoric acidChemistry

The invention discloses an electrolytic solution used for molybdenum gate screen electrolytic polishing and a preparation method thereof, and application thereof to the molybdenum gate screen electrolytic polishing process. The electrolytic solution consists of the following raw materials: 400 to 450 ml of phosphoric acid, 150 to 200 ml of sulfuric acid, 40 to 60 g of nickel sulfate and 150 to 200 ml of water. Experiment researches show that each ingredient of the electrolytic solution has scientific and reasonable proportion, and can be perfectly used for the electrolytic polishing process of molybdenum gate screens and the like. The molybdenum gate screen electrolytic polishing method of the invention has the advantages of strong operability and good electrolytic polishing effect, and can perfectly remove the burr on the surface of the molybdenum gate screens particularly under the preferable process parameter conditions such as the electrolytic voltage, the time, the temperature and the like, so the quality of the molybdenum gate screens can be improved, the striking rate is obviously reduced after the molybdenum gate screens are assembled to traveling wave tubes, and the performance of the traveling wave tubes is improved.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Water PU cracking resin for synthesizing leather

The invention discloses water PU cracking resin for synthesizing leather, which comprises following materials in percentage by weight: 60-70 percent of water polyurethane resin, 20-35 percent of water, 0.3-2 percent of organic silicon flatting agent and 0.5-4 percent of water polyurethane thickener. The water PU cracking resin for synthesizing leather uses water as solvent to replace dimethyl formamide and butanone and other toxic solvents, thereby achieving the non-inflammable, safe, environmental-protection and cost-saving performance. In addition, the cracking resin has the advantages of good film forming, firm bonding, solvent-resist, cold resist, hydrolysis-resist and heat aging-resist performances, and the like. Finished products made by using the cracking resin have the advantages of excellent cracking effect, better real leather quality, fine and smooth texture, good air permeability, and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

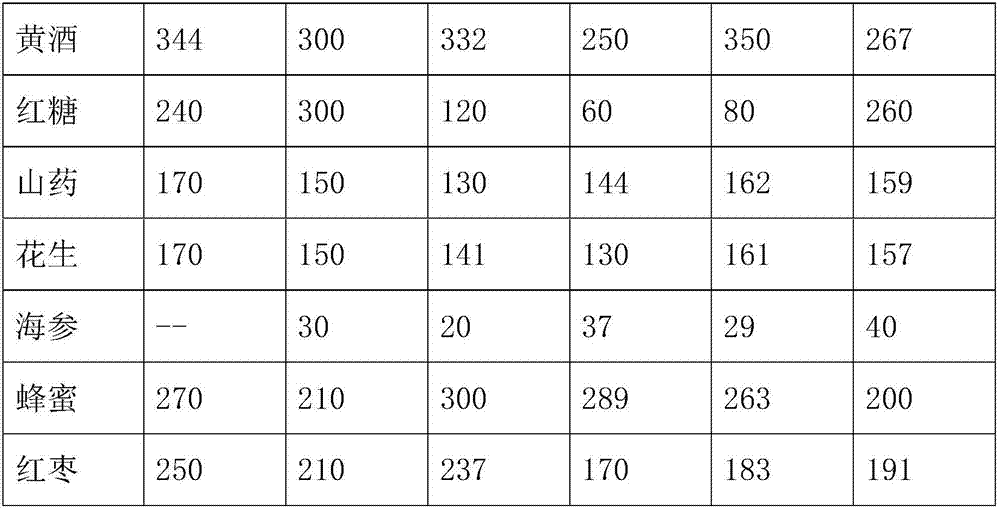

Copper alloy bar for high-strength corrosion-resistant wear-resistant valve element and preparation method thereof

The invention provides a copper alloy bar for a high-strength corrosion-resistant wear-resistant valve element. The cooper alloy bar is characterized in that the copper alloy bar comprises, by weight,0.04-0.2% of Si, 0.25-0.6% of Mn, 0.1-0.4% of Sn, 0.06-0.2% of Ni, 0.7-1.3% of A1, 0.1-0.25% of Fe, 83-87% of Cu, 0.01-0.1% of lanthanum and strontium rare earth, and the balance Zn and inevitable trace impurities. The preparation method comprises the following steps of burdening and smelting; refining and removing impurities; degassing; adding lanthanum and strontium rare earth; carrying out horizontal continuous casting; drawing and extending a casting blank; peeling twice; and carrying out light pressing and straightening to obtain a finished product. The copper alloy component is scientific and reasonable in component ratio, and the prepared copper alloy has good machining performance and casting performance; and meanwhile, the alloy is high in strength and good in corrosion resistance and wear resistance, and can be applied to the manufacturing of the valve element of ocean engineering; the preparation process is simple and easy to operate; and the horizontal continuous casting is adopted, so that cracks caused by thermal stress are avoided, and the hot extrusion cracking problem of the casting blank is solved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

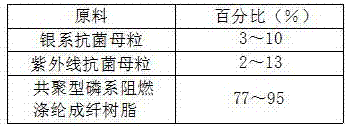

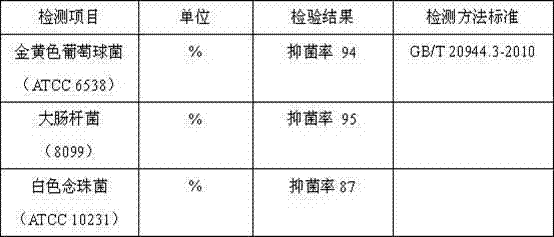

Uvioresistant, antibacterial, inflaming retarding and moisture wicking polyester fiber

InactiveCN102534852AAntibacterialHas antibacterial propertiesFilament/thread formingMonocomponent polyesters artificial filamentPolyesterYarn

The invention discloses uvioresistant, antibacterial, inflaming retarding and moisture wicking polyester fiber, which is manufactured by the following raw materials, by weight, 5-10 parts of silver antibacterial master batch, 6-12 parts of uvioresistant master batch and 80-89 parts of copolymerization phosphorus inflaming retarding dacron fiber forming resin, wherein the fiber section is an irregular section. The distribution ratio of components of the polyester fiber is reasonable and scientific, the silver antibacterial master batch, the uvioresistant master batch and the copolymerization phosphorus inflaming retarding polyester fiber forming resin which have antibacterial effect are organically and scientifically combined and prepared to obtain pre-oriented yarn and undergo texturing so as to produce low stretch yarn, the permanently antibacterial, uvioresistant, inflaming retarding and moisture wicking multifunctional polyester fiber is obtained, and the application range of the polyester fiber is wide.

Owner:WUJIANG SANHUI TEXTILE

Water-based PU matte surface color fixing finishing agent for synthetic leather

The invention discloses a water-based PU matte surface color fixing finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 50 to 60 parts of water, 3 to 6 parts of modified organic silicon polymer, 1 to 2 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 2 to 3 parts of modified organic silicon matting agent. For the water-based PU matte surface color fixing finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface color fixing finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface color fixing effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Novel antibacterial fabric and preparation method thereof

ActiveCN106435944BThe distribution ratio is scientific and reasonableWith mosquito repellentCarbon fibresWarp knittingWool fibreAnti bacterial

The invention discloses a novel antibacterial fabric and a preparation method thereof, belonging to the field of functional textiles. The new antibacterial fabric of the present invention comprises the following parts by weight: 10-25 parts of pearl fiber; 11-27 parts of wool fiber; 10-30 parts of zein fiber; 8-17 parts of modal fiber; 12-35 parts of coconut charcoal fiber; 8-21 parts of fiber; 10-19 parts of antibacterial finishing agent. The novel antibacterial fabric provided by the invention not only has the functions of comfort, antibacterial, mosquito repellent, moisture conduction and perspiration, and warmth retention, but also has good flame retardancy, high wrinkle resistance elasticity and high fracture resistance.

Owner:BEIJING SUKENO RISHENG SOCKS

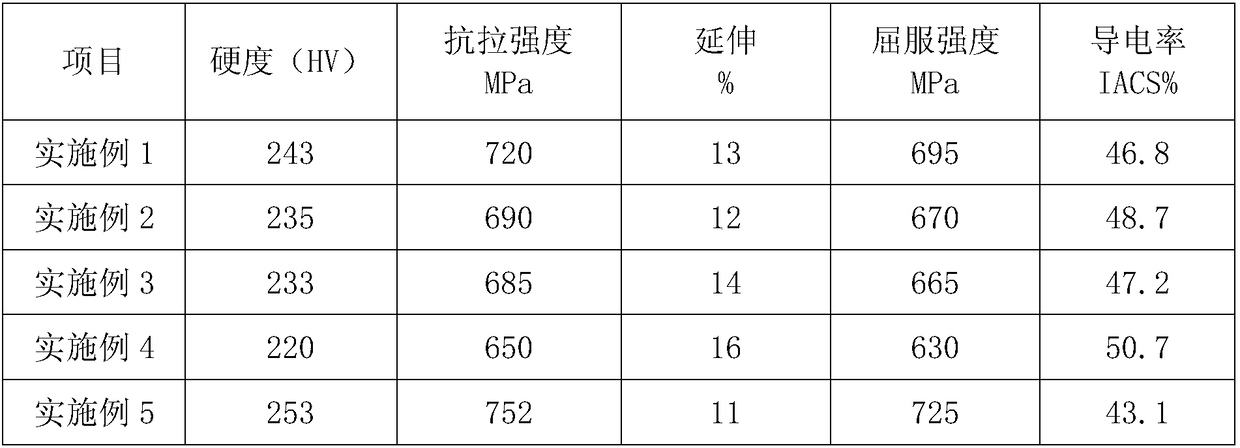

Ageing strengthening copper alloy strip and preparing method thereof

The invention relates to an ageing strengthening copper alloy strip. The copper alloy strip is composed of components including, by weight, 0.4%-1.3% of Si, 2%-4.5% of Ni, 0.06%-0.2% of Cr, 0.2%-0.8%of Zn, 0.05%-0.2% of Mg and the balance copper and inevitable trace impurities. Preparing steps include that burdening and smelting are carried out; Mg is added for deoxygenation treatment; when the temperature of a holding furnace reaches the casting temperature being 1220 DEG C-1300 DEG C, and a horizontal continuous casting red ingot casting technology is adopted; face milling, rough rolling and solution treatment are carried out; intermediate rolling is carried out after surface washing; second solid solution is carried out; finished product finish rolling is carried out after surface washing; finished product aging is carried out; surface washing and surface grinding polishing are carried out; and finished stripping, checking and packaging are carried out. The ageing strengthening copper alloy strip has the good processability and casting performance, has the advantages of high strength, high elasticity, high conductivity, excellent resistance to high temperatures and good stressrelaxation resistance and is an ideal material for a lead frame, and the preparing technology is simple.

Owner:JINTIAN COPPER GROUP CORP NINGBO

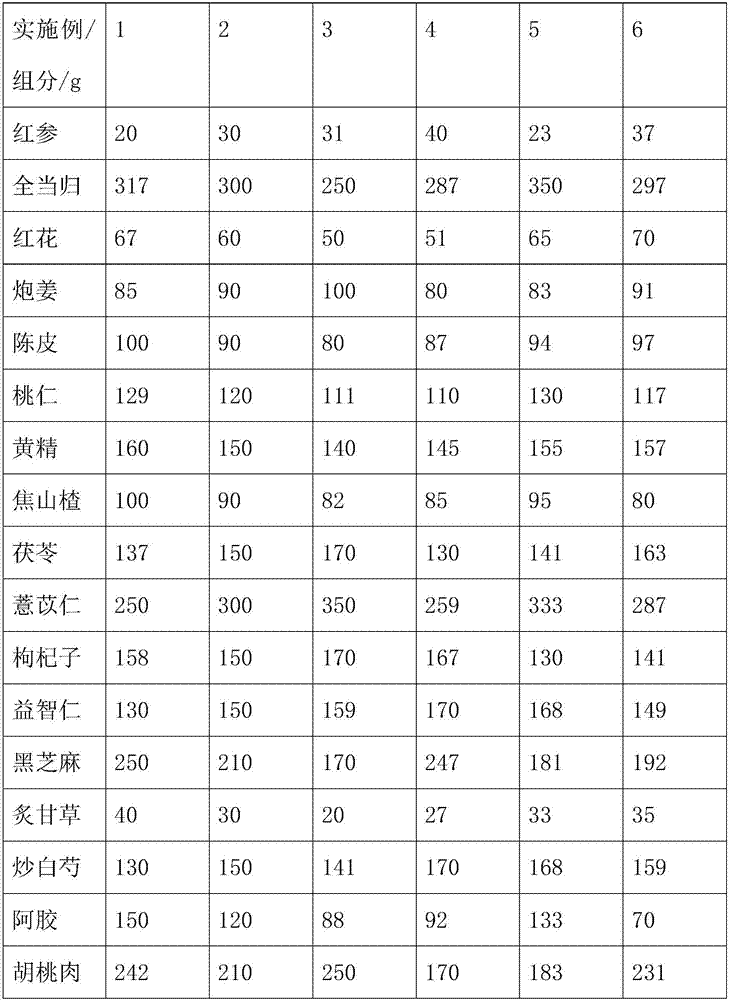

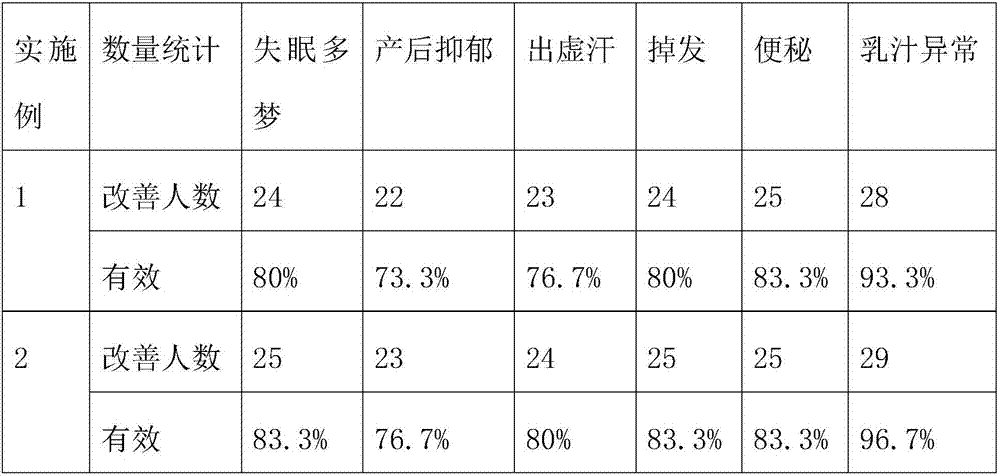

Postpartum conditioning composition and preparation method thereof

InactiveCN107096007AGood effectImprove postpartum deficiencyOrganic active ingredientsSexual disorderPericarpium citri reticulataeLycium chinense

The invention discloses a postpartum conditioning composition and a preparation method thereof and belongs to the technical field of traditional Chinese medicine processing. The composition is prepared from the following raw materials in parts by weight: 20-40 parts of red ginseng, 250-350 parts of all angelica sinensis, 50-70 parts of flowers carthami, 80-100 parts of baked ginger, 80-100 parts of pericarpium citri reticulatae, 110-130 parts of peach kernels, 140-160 parts of sealwort, 80-100 parts of scorched hawthorns, 130-170 parts of poria cocos, 250-350 parts of semen coicis, 130-170 parts of fruits of Chinese wolfberries, 130-170 parts of bitter cardamom, 170-250 parts of semen sesami nigrum, 20-40 parts of honey-fried licorice roots, 130-170 parts of parched white peony roots, 70-150 parts of colla corii asini, 170-250 parts of walnut meat, 250-350 parts of yellow rice wine, 60-300 parts of brown sugar, 130-170 parts of Chinese yam, 130-170 parts of peanuts, 210-300 parts of honey and 170-250 parts of red dates. The composition disclosed by the invention is obvious in effects of improving weakness, extravasated blood, constipation and abnormal milk after delivery, recovering beauty of healthy shaping and activating and tendering skin.

Owner:山西中唐慈幼生物科技有限公司

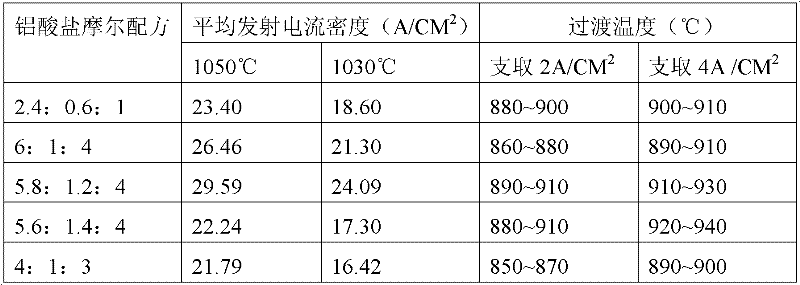

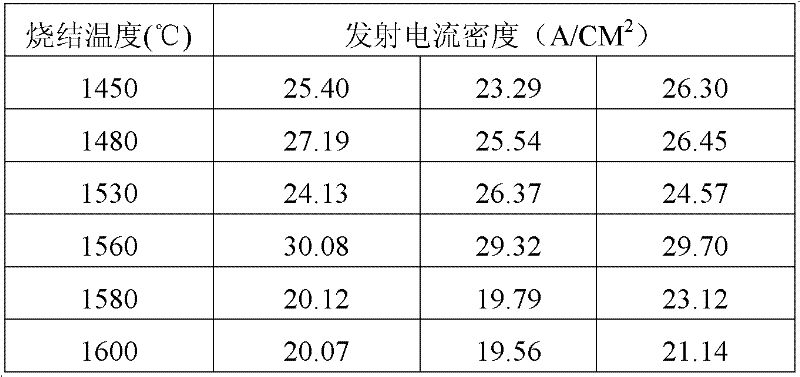

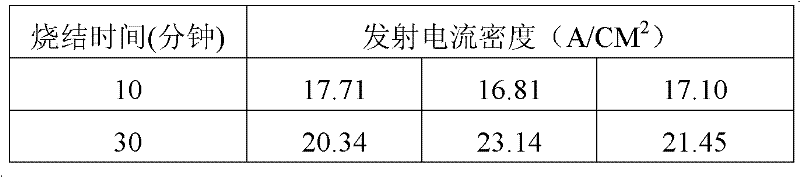

Aluminate for assembling barium-tungsten cathode of diode and preparation method thereof

InactiveCN102241412ASolution to short lifeGood launch performanceAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateAluminium hydroxide

The invention discloses aluminate for assembling barium-tungsten cathode of diode and a preparation method thereof. The aluminate is formed by 5.6 to 5.8 moles of barium carbonate, 1.2 to 1.4 moles of calcium carbonate and 4.0 moles of aluminium hydroxide. Experiment study indicates that the mixing ratio of the components is reasonable, that the prepared aluminate has high emission performance and high anti-poisoning performance, and that the service life of the assembled cathode is long. The preparation method of the aluminate has high operability and reasonable process design; and particularly, under optimal pressing mode, sintering temperature, sintering heat-preservation time, sintering atmosphere and the like, the preparation method can prepare the aluminate which has high emission performance and long service life and can meet requirements for high-standard traveling-wave diode cathode assembly.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Composite solid-solid phase change heat storage material and preparation method thereof

InactiveCN107828382AThe distribution ratio is scientific and reasonableImprove thermal stabilityHeat-exchange elementsRelease timeHeat storage material

The invention relates to a phase change heat storage material, and particularly discloses a composite solid-solid phase change heat storage material and a preparation method thereof. The phase changeheat storage material is prepared from the following components in parts by weight: 90-95 parts of Ba(OH)2.8H2O, 5-8 parts of expanded graphite and 1-2 parts of KH2PO4. The components of the materialare blended scientifically and reasonably, an inorganic phase change temperature ranges from 78 DEG C to 80 DEG C, latent heat of phase change ranges from 230 kJ / kg to 270 kJ / kg, and the shortcomingsof low heat conduction, leakage, phase separation, excessive cold and the like of a single phase change material can be overcome effectively; and the thermal stability and long-time stability of the material are good. Compared with pure substances, the phase change heat storage material has the advantages that the heat storage time can be shortened by 42.6-45.5%, the heat release time can be shortened by 52.4-55.1%, and liquid is not generated in a phase change process.

Owner:TIANJIN RUIKUN TECH

A kind of polymer cement mortar used for filling layer of high-speed railway slab ballastless track

ActiveCN104030644BAchieve expansibilityAchieve low shrinkage and micro-expansion propertiesPolymer scienceRepair material

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

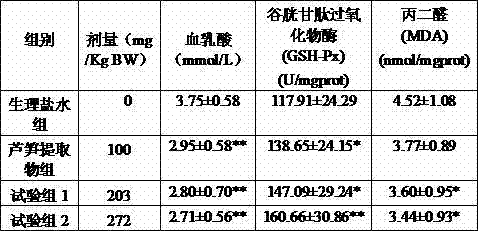

Preparation method of functional health food

A preparation method of a functional health food. The method employs asparagus, soy isolated protein and soy lecithin as raw materials to prepare the functional health food; and the raw materials can also be added with jujube or the root of kudzu vine to prepare the functional health food. The functional health food provided by the invention has functions of enhancing immunity, resisting fatigue, reducing blood lipid and assisting protection on chemical liver injury.

Owner:NANCHANG UNIV

High-fullness high-distinctness thermosetting acrylic resin and preparation method thereof

InactiveCN103342783AThe ratio is scientific and reasonableImproves image clarity and fullnessPrepolymerButyl acrylate

The invention discloses a high-fullness high-distinctness thermosetting acrylic resin which is prepared from the following raw materials in parts by weight: 15-25% of prepolymer, 15-25% of styrene, 8-20% of n-butyl acrylate, 5-10% of butyl acrylate, 0.1-0.5% of tert-butyl peroxybenzoate and 25-37% of dimethylbenzene. The high-fullness high-distinctness thermosetting acrylic resin disclosed by the invention is composed of the raw materials selected from abundant experiments according to the optimal proportion, and the component proportion is scientific and reasonable. The property detection result indicates that the thermosetting acrylic resin has the characteristics of high gloss, high hardness, high distinctness, high fullness and the like, and can be widely used in the fields of automobiles, electric appliances, mechanics, architecture and the like.

Owner:无锡市南雅化工有限公司

High-strength terylene flame-retarding composite yarn and preparation method of same

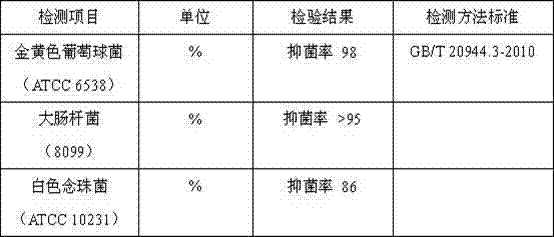

InactiveCN107502987AAntibacterial hasFlame retardantElectroconductive/antistatic filament manufactureFlame-proof filament manufactureYarnFiber

The present invention disclosed a high -strength polyester flame -retardant composite wire and its preparation process, including the body, including the body and the outer core, and the outer surface of the body is painted from the inside to the outside.The base composite coating, which is composed of silver antibacterial mother grains, anti -ultraviolet maternal particles, and co -concentrated phosphorus -based flame retardant polyester resin. The percentage of the ingredients is 3 % to 10 % of the silver antibacterial mother particles.The polyester fiber provided by the present invention is scientific and reasonable in each group. Through scientifically, the silver -based antibacterial mother grains, anti -ultraviolet mother grains, and co -concentration phosphorus are combined with flame retardant polyester resin to prepare to get pre -removal -oriented wires, and then go through through it.Add bullet deformation to produce low -bullet polyester deformation wires, and then enter the mixed spinning box spinning after measuring pump measuring pump meters to obtain a permanent antibacterial, ultraviolet and flame -retardant multi -functional polyesterFiber makes the application range of polyester fibers wider.

Owner:常州亿达化纤有限公司

Antibacterial and anti-ultraviolet fiber

InactiveCN102560730AImprove antibacterial propertiesThe composition ratio is scientific and reasonableMonocomponent polyesters artificial filamentArtifical filament manufactureMasterbatchFiber

The invention discloses an antibacterial and anti-ultraviolet fiber, which is prepared from the following raw materials, by weight, 5-15 parts of anti-ultraviolet masterbatch, 10-15 parts of silver antibacterial masterbatch, and 70-85 parts of terylene fiber forming resin. According to the present invention, the silver antibacterial masterbatch with the antibacterial effect, the anti-ultraviolet masterbatch with the antibacterial effect, and the terylene fiber forming resin are subjected to scientific and organic combination to obtain the multifunctional terylene fiber with the antibacterial effect and the anti-ultraviolet effect, and the application range is wide.

Owner:WUJIANG SANHUI TEXTILE

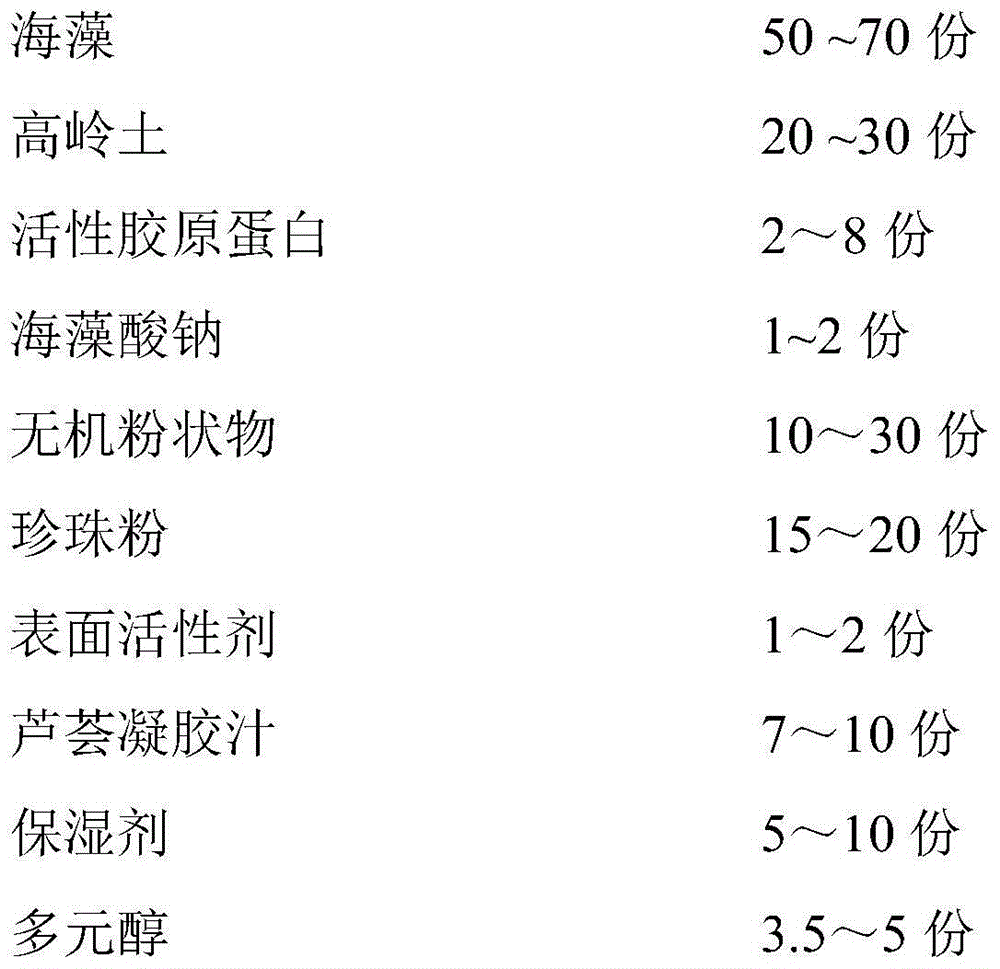

Preparation method of skin whitening, wrinkle removing and elastic repairing mask and mask product

InactiveCN104546664AAntibacterial and anti-inflammatoryAntioxidantCosmetic preparationsToilet preparationsWrinkle skinCaprylyl Glycol

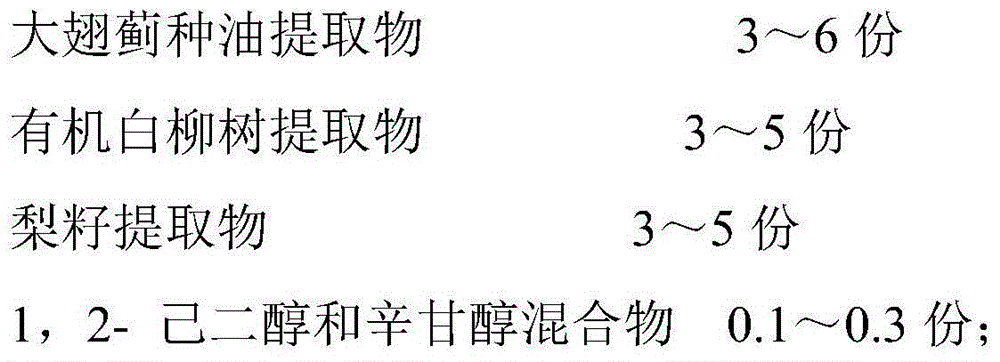

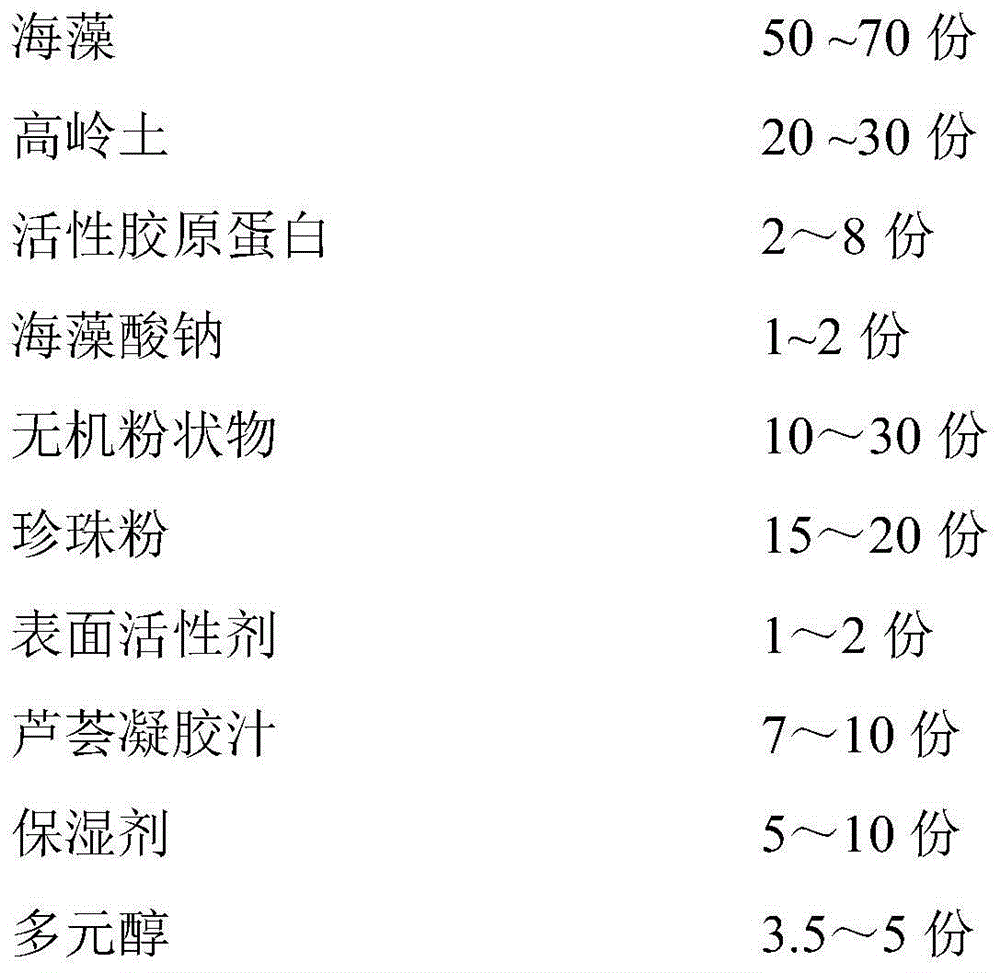

The invention discloses a skin whitening, wrinkle removing and elastic repairing mask which comprises components in parts by weight as follows: a component A: 50-70 parts of algae, 20-30 parts of kaolin, 2-8 parts of active collagen, 1-2 parts of sodium alginate, 10-30 parts of inorganic powder, 15-20 parts of pearl powder, 1-2 parts of a surfactant, 7-10 parts of aloe gel juice, 5-10 parts of a moisturizer and 3.5-5 parts of polyhydric alcohol; a component B: 3-6 parts of an onopordum acanthium seed oil extract, 3-5 parts of an organic white willow extract, 3-5 parts of a pear seed extract as well as 0.1-0.3 parts of a 1,2-hexanediol and caprylyl glycol mixture. The invention further discloses a preparation method of the skin whitening, wrinkle removing and elastic repairing mask. According to the skin whitening, wrinkle removing and elastic repairing mask, the algae and the active collagen are added, so that supplement of collagen lost by the skin is promoted, sodium alginate in the algae has an obvious skin moisturizing effect as well as antibacterial and sun-resistant functions.

Owner:东莞市高明企业服务有限公司

Immunity-improving and body-function-enhancing health-care product

The invention discloses an immunity-improving and body-function-enhancing health-care product prepared from, by weight: 3-15 parts of seabuckthorn fruit, 4-16 parts of spiral algae, 2-8 parts of pollen, and 8-24 parts of hawthorn fruit. With the immunity-improving and body-function-enhancing health-care product provided by the invention, body functions can be regulated from various respects. As a result of various functional experiments, the health-care product provided by the invention assists in improving various immunity indexes, and has an excellent body-immunity-improving function. The product is especially suitable for sub-health populations of the modern society with fast pace. The raw materials are green and environment-friendly. The product has no chemical additive, and causes lower toxic and side effects. The product is safer.

Owner:SUZHOU GULI BIOTECH

Antibacterial moisture-transfer chinlon 6 and preparation method thereof

ActiveCN102677215BReduce contentStrong ability to load copper ionsBiocideFilament forming substance formingPolyamideMoisture absorption

Owner:TAICANG HONGYI CHEM FIBER

Glass mould material and preparation method thereof

InactiveCN104233037AThe distribution ratio is scientific and reasonableImprove wear resistanceGlass blowing apparatusIron powderTitanium

The invention discloses a glass mould material and a preparation method thereof. The glass mould material comprises the following components in part by weight: 30-50 parts of graphite, 0.6-0.88 part of copper, 3-5 parts of silicon, 10-15 parts of tungsten powder, 0.5-0.98 part of titanium, 0.012-0.335 part of molybdenum and 30-35 part of iron powder. The invention further discloses a preparation method of the glass mould material. The glass mould material benefits as follows: the glass mould material is scientific and reasonable in component matching; through addition of titanium and copper, the wear resistance and the hardness are greatly improved; the glass mould material is more stable in performance; the service life of the glass mould material is prolonged; the preparation method is simple in process and the components are easy to obtain, so that the manufacturing cost is greatly reduced.

Owner:KUNSHAN BOJIAN PRECISION MOLD

Copper alloy bar material for high-strength corrosion-resistant and wear-resistant valve parts and preparation method thereof

The invention provides a copper alloy bar for a high-strength corrosion-resistant wear-resistant valve element. The cooper alloy bar is characterized in that the copper alloy bar comprises, by weight,0.04-0.2% of Si, 0.25-0.6% of Mn, 0.1-0.4% of Sn, 0.06-0.2% of Ni, 0.7-1.3% of A1, 0.1-0.25% of Fe, 83-87% of Cu, 0.01-0.1% of lanthanum and strontium rare earth, and the balance Zn and inevitable trace impurities. The preparation method comprises the following steps of burdening and smelting; refining and removing impurities; degassing; adding lanthanum and strontium rare earth; carrying out horizontal continuous casting; drawing and extending a casting blank; peeling twice; and carrying out light pressing and straightening to obtain a finished product. The copper alloy component is scientific and reasonable in component ratio, and the prepared copper alloy has good machining performance and casting performance; and meanwhile, the alloy is high in strength and good in corrosion resistance and wear resistance, and can be applied to the manufacturing of the valve element of ocean engineering; the preparation process is simple and easy to operate; and the horizontal continuous casting is adopted, so that cracks caused by thermal stress are avoided, and the hot extrusion cracking problem of the casting blank is solved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Antibacterial fabric and preparation method thereof

InactiveCN112900078AThe ratio is scientific and reasonableSimple structureWeft knittingCarbon fibresChemistryCotton fibre

The invention discloses an antibacterial fabric and a preparation method thereof, and relates to the technical field of fabric preparation equipment. The fabric comprises the following raw materials of wool fibers, soybean protein fibers, bamboo charcoal fibers, chitin fibers, coconut carbon fibers, cotton fibers and modal fibers. An antibacterial finishing agent is composed of the following raw materials of nano silver, water-soluble chitosan, aloe powder, menthol, camphor, a traditional Chinese medicine extracting solution, ethyl p-hydroxybenzoate and dimethyl dioctadecyl ammonium bromide. The antibacterial finishing agent in the novel antibacterial fabric provided by the invention is scientific and reasonable in component proportion; through the synergistic interaction of the ethyl p-hydroxybenzoate, the menthol, the camphor and the traditional Chinese medicine extracting solution, the novel antibacterial fabric provided by the invention has the functions of comfort, antibiosis, itching relieving, moisture conduction, sweat release, heat preservation and the like; the antibacterial fabric is simple in structure, low in cost, wide in raw material source, very excellent in antibacterial effect and long in antibacterial time, and has a broad-spectrum antibacterial effect; and the preparation method is simple, convenient and easy to operate.

Owner:仇付莲

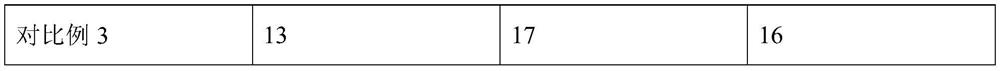

Traditional Chinese medicine compound preparation for treating diabetes as well as preparation method and application thereof

ActiveCN107213204AThorough and effective extractionEasy to useMetabolism disorderUrinary disorderMulti linkICAM-1

The invention relates to a traditional Chinese medicine compound preparation for treating diabetes as well as a preparation method and application thereof. The traditional Chinese medicine compound preparation is prepared from the following raw materials in parts by weight: 6-18 parts of astragalus, 6-18 parts of mulberries, 5-15 parts of folium mori and 5-15 parts of lotus leaves. The preparation method of the traditional Chinese medicine compound preparation comprises the following steps: decocting, filtering and concentrating so as to obtain a concentrated solution for later use; extracting and performing vacuum concentration so as to obtain a concentrated solution for later use; and preparing the decocted concentrated solution and the extracted concentrated solution as well as pharmaceutically acceptable carriers into oral liquid, granules, capsules, tablets and other dosage forms. Due to the multi-link and multi-target comprehensive effects, the traditional Chinese medicine compound preparation provided by the invention achieves the aims of lowering the blood sugar and blood fat and content of BUN and SCr, reducing expressions of NF-kB and ICAM-1 in renal tissues, improving the insulin sensitivity index and finally improving the diabetic renal functions in the aspect of treating diabetes.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

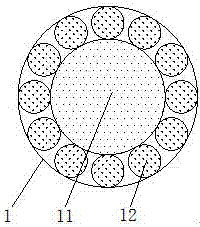

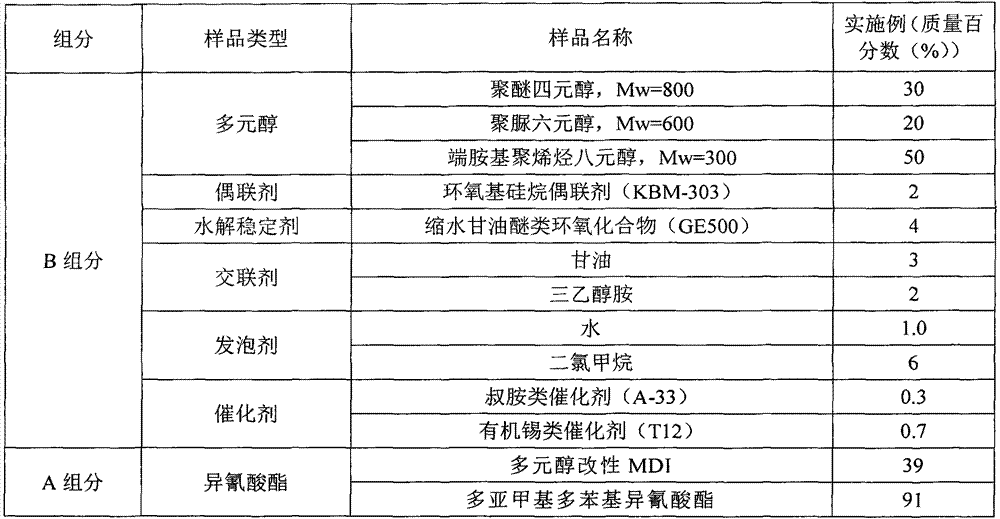

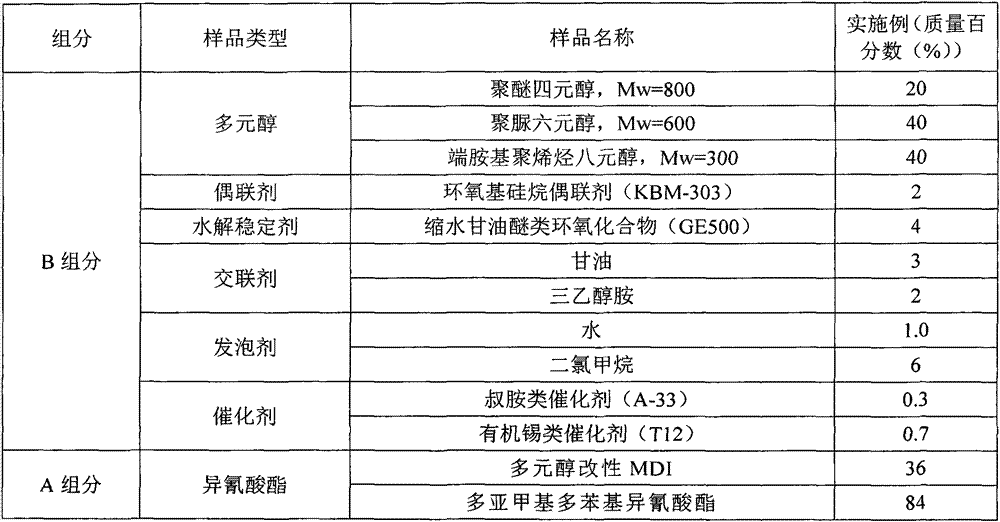

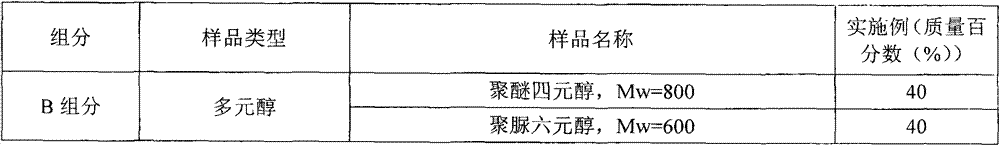

A polyurethane repair material for settlement repair of ballastless track structure of high-speed railway

ActiveCN104693413BThe distribution ratio is scientific and reasonableImprove performanceCross-linkPolyolefin

The invention relates to a polyurethane patching material used for settlement repairing of a ballastless structure for a high-speed railway. The polyurethane patching material is formed by hybrid reaction of an A component material and a B component material by a high-pressure impact. The volume ratio of the A component and the B component is 1:1-1:1.8. The A component is a mixture formed by polyhydric alcohol modified diphenylmethane diisocyanate and multi-methylene multi-phenyl isocyanate. The viscosity of the A component ranges from 100 mPa.s to 200 mPa.s at the 25 DEG C temperature. The B component is a mixture formed by polyhydric alcohol, a coupling agent, a hydrolytic stabilizing agent, a cross-linking agent, a foam stabilizing agent, a catalyst agent and a foaming agent. The viscosity of the B component ranges from 150 mPa.s to 300 mPa.s at the 25 DEG C temperature. The B component is characterized in that at least a part of end amido polyolefin polyhydric alcohol with 8 functionalities is in the polyhydric alcohol, and the content of the end amido ranges from 60%-80%. According to the polyurethane repairing material, the chemical reaction speed is high, the expansibility is high, the mechanical strength is high, the binding power is high, the size stability is high, the anti-hydrolysising property is good, and the deformation of accumulated residues is low. The polyurethane repairing material can be used for the settlement repairing of the ballastless structure for the high-speed railway, and can also be used for the pavement structure repairing of an expressway and the settlement repairing of an industrial building terrace.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Plaster mold

The invention relates to a plaster mold, which comprises the following components by weight part: 10-15 parts of carbon fiber, 5-10 parts of rosin, 1-3 parts of transformer oil, 5-10 parts of rare earth, 8-12 parts of tungsten powder, 4-8 parts of adhesive, 1-3 parts of magnesium and 3-5 parts of quartz sand. The plaster mold has the advantages that the composition proportion is scientific and reasonable, fine seam can not be generated during a usage process, service life is greatly prolonged, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com