Antibacterial and anti-ultraviolet fiber

An ultraviolet type, anti-ultraviolet technology, applied in the field of polyester fiber, can solve the problems of human health hazards, peculiar smell, poor hygiene and cleaning function, etc., and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

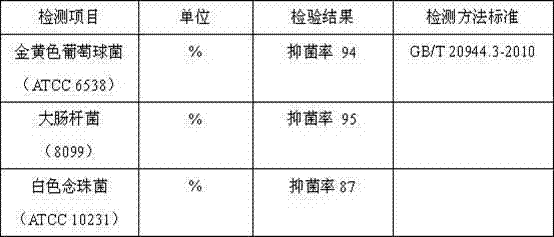

Embodiment 1

[0018] 1. An antibacterial and anti-ultraviolet fiber, which is made of the following raw materials in parts by weight: 15 kg of anti-ultraviolet masterbatch, 15 kg of silver-based antibacterial masterbatch, and 85 kg of polyester fiber-forming resin.

[0019] 2. Preparation of antibacterial and anti-ultraviolet fibers:

[0020] (1) Take the anti-ultraviolet agent of 12% by weight and the polyethylene terephthalate of 88% by weight, blend, extrude with screw extruder, pelletize, make anti-ultraviolet masterbatch, standby , wherein the blending temperature is 200~250°C, and the screw speed is 150~250rpm;

[0021] (2) Take 10-20% by weight of nano-silver ions and nano-carrier silicon dioxide 0 and blend with 80-90% by weight of polyethylene terephthalate, extrude with a screw extruder, and pelletize , to prepare silver-based antibacterial masterbatches for future use, wherein the blending temperature is 200~250°C, and the screw speed is 120~250rpm;

[0022] (3) get the anti-ul...

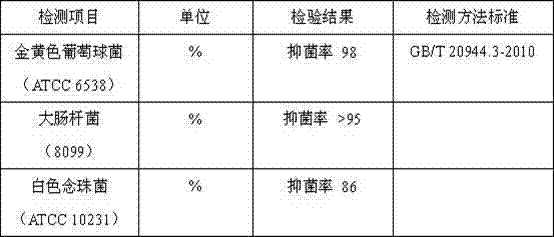

Embodiment 2

[0036] 1. A kind of antibacterial and anti-ultraviolet type fiber, it is made up of the raw material of following weight: 6 kilograms of anti-ultraviolet masterbatches, 10 kilograms of silver series antibacterial masterbatches, and 70 kilograms of polyester fiber-forming resins.

[0037] 2. Preparation of antibacterial and anti-ultraviolet fibers:

[0038] (1) Take the anti-ultraviolet agent of 12% by weight and the polyethylene terephthalate of 88% by weight, blend, extrude with screw extruder, pelletize, make anti-ultraviolet masterbatch, standby , wherein the blending temperature is 200~250°C, and the screw speed is 150~250rpm;

[0039] (2) Take 10% by weight of nano-silver ions and nano-carrier silicon dioxide and blend with 90% by weight of polyethylene terephthalate, extrude with a screw extruder, and pelletize to obtain silver-based Antibacterial masterbatch, spare, where the blending temperature is 200~250℃, and the screw speed is 120~250rpm;

[0040] (3) get the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com