Aluminate for assembling barium-tungsten cathode of diode and preparation method thereof

A barium tungsten cathode and aluminate technology, which is applied in the field of diodes, can solve the problems of traveling wave tubes such as high requirements for diodes, poor anti-poisoning performance, low aluminate yield and pass rate, etc. The effect of strong poisoning performance and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Aluminate for assembly of barium tungsten cathode in diode, which is composed of the following molar fractions of raw materials:

[0054] Barium carbonate 5.8mol, calcium carbonate 1.2mol, aluminum hydroxide 4.0mol.

[0055] 2, the preparation method of the aluminate that barium tungsten cathode is assembled in the diode, it comprises the following steps:

[0056] (1) Barium carbonate, calcium carbonate and aluminum hydroxide were placed in a 160°C oven and baked for 24 hours, then accurately weighed barium carbonate 214.62g, calcium carbonate 22.52g and aluminum hydroxide 58.5 (the molar ratio was 5.8:1.2: 4.0) Put it into a ball mill jar, add 500ml of distilled water, and then put 8 agate balls with a diameter of 25mm, 14 agate balls with a diameter of 15mm, and 25 agate balls with a diameter of 10mm in the ball mill jar, and place them after sealing. Grind on a planetary ball mill with a rotation speed of 180 rpm for 4 hours, then pour the ball-milled powder into...

Embodiment 2

[0060] 1. Aluminate for assembly of barium tungsten cathode in diode, which is composed of the following molar fractions of raw materials:

[0061] Barium carbonate 5.6mol, calcium carbonate 1.4mol, aluminum hydroxide 4.0mol.

[0062] 2, the preparation method of the aluminate that barium tungsten cathode is assembled in the diode, it comprises the following steps:

[0063] (1) Place barium carbonate, calcium carbonate and aluminum hydroxide in an oven at 160°C for 24 hours, then accurately weigh 5.6 mol of barium carbonate, 1.4 mol of calcium carbonate and 4.0 mol of aluminum hydroxide and put them into a ball mill, add 500ml of distilled water, and then put 8 agate balls with a diameter of 25mm, 14 agate balls with a diameter of 15mm, and 25 agate balls with a diameter of 10mm in the ball mill jar, and place them on a planetary ball with a speed of 180 rpm after sealing. Grind on a ball mill for 4 hours, then pour the ball-milled powder into a porcelain plate, place it in a...

Embodiment 3

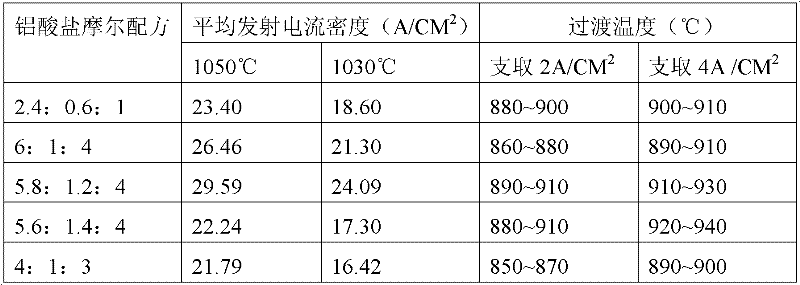

[0066] Example 3 Aluminate stability, consistency, anti-poisoning performance and service life test

[0067] 1. According to the method of Example 1 and Example 2, 4 batches of aluminate were prepared and loaded into tubes, and the stability and consistency of the emission performance were tested. The specific experimental results are shown in Table 7. And 4 batches of aluminates were tested for anti-poisoning performance (re-exposed the cathode of the secondary tube after the exhaust test to the atmosphere, and then tested after the secondary sealing and exhaust, and tested the change of the emission performance of the cathode after the above process. Measuring the anti-poisoning performance of aluminate) The specific experimental results are shown in Table 8.

[0068] Table 7 Emission stability and consistency test results of different batches of aluminates

[0069]

[0070] Table 8 Test results of anti-poisoning properties of different batches of aluminates

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com