Copper alloy bar material for high-strength corrosion-resistant and wear-resistant valve parts and preparation method thereof

A copper alloy and corrosion-resistant technology, which is applied in the field of copper alloy bars for high-strength, corrosion-resistant and wear-resistant valve parts and their preparation, can solve the problems of unsatisfactory corrosion-resistant and wear-resistant properties, and achieve scientific and reasonable composition ratio and enhanced strength. and hardness, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

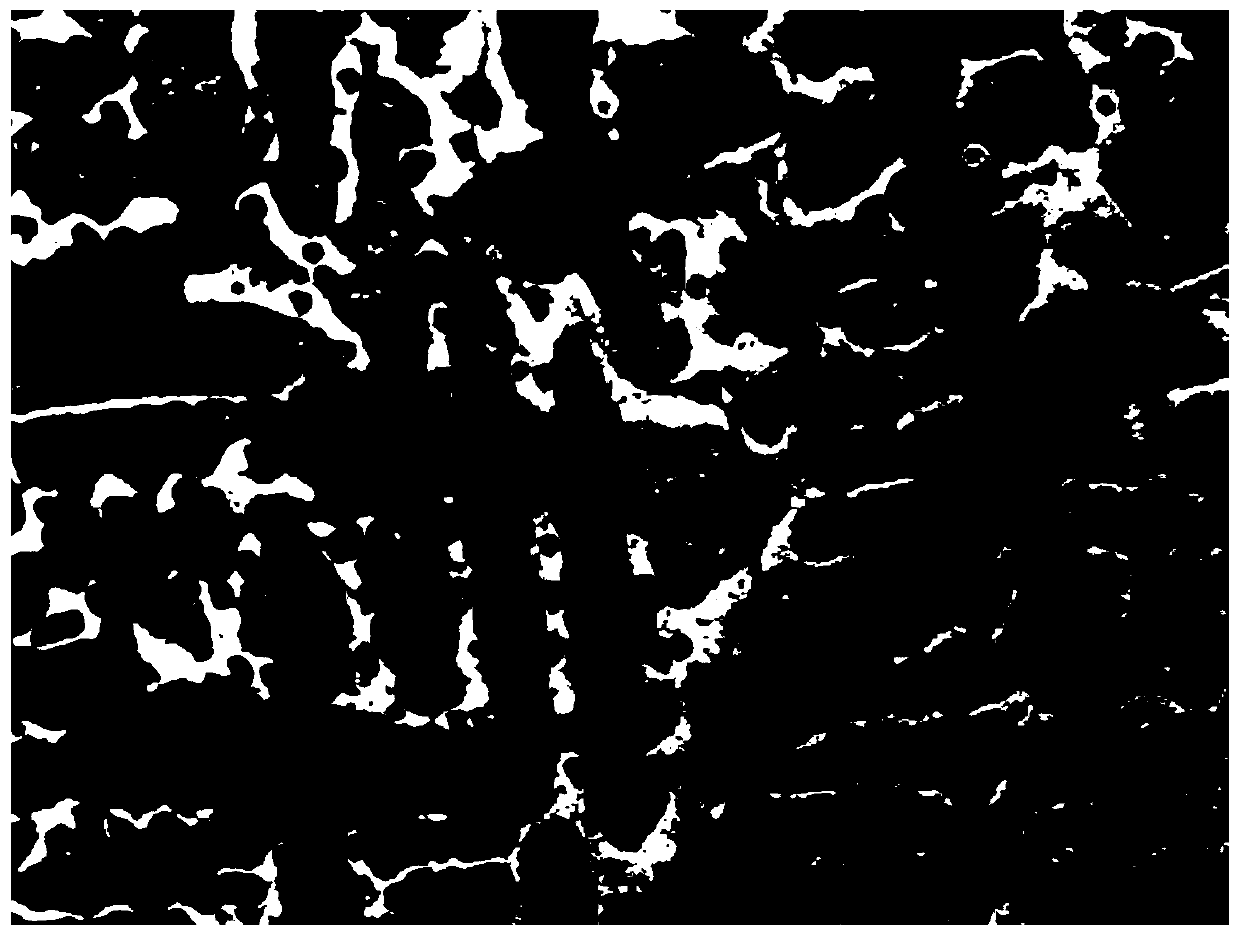

Image

Examples

Embodiment 1

[0027] A method for preparing copper alloy rods for high-strength corrosion-resistant and wear-resistant valve parts. The steps are: adding raw materials to a smelting furnace to heat up and melt them. After all the melts are melted, the temperature of the melt is controlled at 1170° C. to remove impurities and gas by blowing and stirring. Add the slag-removing refining agent through the refining degasser, the blowing pressure of the degasser is controlled at 0.25MPa, the graphite rotor speed is controlled at 350r / min, the flow rate is 10L / min, the blowing gas is nitrogen, and the slag-removing refining agent is blown into 0.25% of the weight of molten copper. After standing still for 7 minutes, remove the slag.

[0028] Add 0.05% of melt weight lanthanum and strontium rare earth for refining treatment, the ratio of lanthanum and strontium is 5:3, the temperature of the melt is controlled at 1170°C, and it is transferred to the holding furnace after standing still for 5 minute...

Embodiment 2

[0035] A method for preparing copper alloy rods for high-strength corrosion-resistant and wear-resistant valve parts. The steps are: adding raw materials to a melting furnace to heat up and melt them. Add the slag-removing refining agent through the refining degasser, the blowing pressure of the degasser is controlled at 0.25MPa, the graphite rotor speed is controlled at 320r / min, the flow rate is 10L / min, the blowing gas is nitrogen, and the slag-removing refining agent is blown into The amount is 0.25% of the weight of the copper liquid. After standing still for 8 minutes, remove the slag.

[0036] Add 0.06% of melt weight lanthanum and strontium rare earth for refining treatment, the ratio of lanthanum and strontium is 5:3, control the temperature at 1180°C, and start to transfer to the holding furnace after standing still for 5 minutes.

[0037] When the temperature of the holding furnace reaches the casting temperature of 1195°C, horizontal continuous casting is used to ...

Embodiment 3

[0042] A method for preparing copper alloy rods for high-strength corrosion-resistant and wear-resistant valve parts. The steps are: adding raw materials to the melting furnace to heat up and melt, and after all the melts are melted, the temperature of the melt is controlled at about 1165°C to carry out blowing and stirring to remove impurities and degassing . Add the slag-removing refining agent through the refining degasser, the blowing pressure of the refining degasser is controlled at 0.25MPa, the graphite rotor speed is controlled at 350r / min, the flow rate is 10L / min, the blowing gas is nitrogen, and blown into the slag-removing refining agent The amount is 0.25% of the weight of the copper liquid. After standing still for 8 minutes, remove the slag.

[0043]Add 0.07% of melt weight lanthanum and strontium rare earth for refining treatment, the ratio of lanthanum and strontium is 5:3, control the temperature at 1175°C, and start to transfer to the holding furnace after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com