Antibacterial fabric and preparation method thereof

A kind of antibacterial fabric and fabric technology, applied in textile, biochemical fiber treatment, fabric, etc., can solve the problems of antibacterial, antiviral and antipruritic treatment in the budding state, and achieve excellent antibacterial effect, scientific and reasonable proportion, and long antibacterial time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

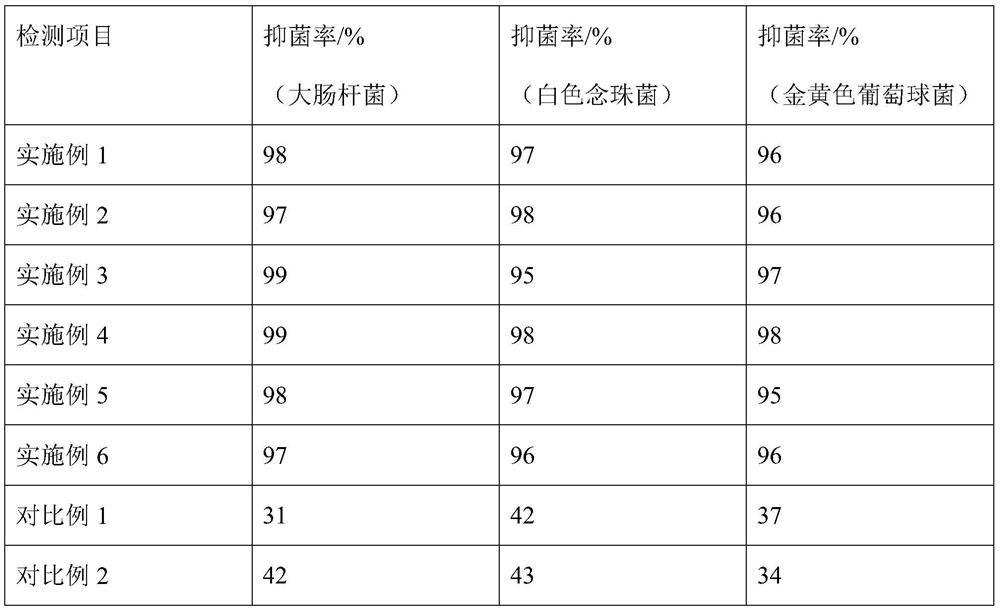

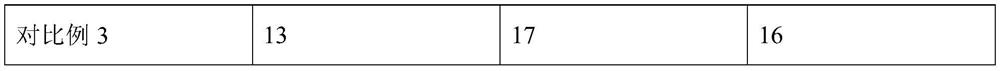

Examples

Embodiment 1

[0027] Take 16 parts of wool fiber, 12 parts of soybean protein fiber, 8 parts of bamboo charcoal fiber, 4 parts of chitin fiber, 10 parts of coconut charcoal fiber, 14 parts of cotton fiber, 9 parts of modal fiber and antibacterial finishing agent at 40 ℃, add dispersant , binder, softening agent, add 120 parts of water, mix and stir evenly, and then air-dry and form, the antibacterial finishing agent is made up of the raw material of following parts by weight: 8 parts of nano-silver, 1 part of water-soluble chitosan, 0.5 parts of aloe powder 4 parts, 4 parts of mint ice, 8 parts of camphor, 7 parts of Chinese medicine extract, 0.2 part of ethyl p-hydroxybenzoate, 3 parts of dioctadecyldimethylamine bromide, the Chinese medicine extract includes 10 parts of Coptidis Rhizoma, 5 parts of Folium Folium, 6 parts of Bezoar, 4 parts of White Poria, 3 parts of Honeysuckle, 2 parts of Angelica, and 4 parts of Wasabi, put Coptis Folium, Folium Bezoar, Bezoar, White Poria, Honeysuckle, ...

Embodiment 2

[0029] Take 18 parts of wool fiber, 14 parts of soybean protein fiber, 9 parts of bamboo charcoal fiber, 5 parts of chitin fiber, 11 parts of coconut charcoal fiber, 16 parts of cotton fiber, 10 parts of modal fiber and antibacterial finishing agent at 45 ℃, add dispersant , binder, softener, add 130 parts of water, mix and stir evenly, and then air-dry and form, the antibacterial finishing agent is made up of the raw material of following weight parts: 9 parts of nano-silver, 2 parts of water-soluble chitosan, aloe vera powder 1 5 parts, 5 parts of mint ice, 9 parts of camphor, 8 parts of Chinese medicine extract, 0.3 part of ethyl p-hydroxybenzoate, 4 parts of dioctadecyldimethylamine bromide. 6 parts of Folium Folium, 7 parts of Bezoar, 5 parts of White Poria, 4 parts of Honeysuckle, 3 parts of Angelica, and 5 parts of Wasabi, put Coptis Folium, Folium Bezoar, Bezoar, White Poria, Honeysuckle, Angelica, and Wasabi in water according to the corresponding mass fractions Decoc...

Embodiment 3

[0031] Take 20 parts of wool fiber, 16 parts of soybean protein fiber, 10 parts of bamboo charcoal fiber, 6 parts of chitin fiber, 12 parts of coconut charcoal fiber, 18 parts of cotton fiber, 11 parts of modal fiber and antibacterial finishing agent at 50 ℃, add dispersant , binder, softening agent, add 140 parts of water, mix and stir evenly, and then air-dry and shape, the antibacterial finishing agent is made up of the raw material of following parts by weight: nano-silver 11 parts, water-soluble chitosan 3 parts, aloe vera powder 1.2 parts 6 parts, 6 parts of mint ice, 10 parts of camphor, 10 parts of Chinese medicine extract, 0.4 part of ethyl p-hydroxybenzoate, 5 parts of dioctadecyldimethylamine bromide, the Chinese medicine extract includes 12 parts of Coptidis Rhizoma, 7 parts of Folium Folium, 8 parts of Bezoar, 6 parts of White Poria, 5 parts of Honeysuckle, 4 parts of Angelica, and 6 parts of Wasabi. Put Coptis Folium, Folium Bezoar, Bezoar, White Poria, Honeysuckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com