Novel antibacterial fabric and preparation method thereof

A kind of antibacterial fabric, a new type of technology, applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles, etc., can solve the problems of mosquito repellent performance, flame retardant performance and anti-wrinkle performance, and achieve good antibacterial performance. Flammability, simple preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. To prepare the masterbatch of antibacterial finishing agent:

[0030] (1) Take 13 parts of titanium dioxide; 10 parts of magnesium oxide; 13 parts of nano silver; 5 parts of zeolite; 17 parts of o-hydroxybenzoate; a mixture;

[0031] (2) Take polyethylene terephthalate of 9 times the weight of the first mixture, blend with the first mixture, extrude with a screw extruder, cut into pellets, and prepare an antibacterial masterbatch, which is used for later use. The temperature is 250-270°C, and the screw rotation speed is 100-200rpm.

[0032] 2. Preparation of new antibacterial fabrics:

[0033] Take 17 parts of pearl fibers in the following parts by weight; 20 parts of wool fiber / chitin fiber / milk fiber; 21 parts of soybean protein fiber / corn protein fiber / peanut protein fiber; 13 parts of modal fiber; 25 parts of coconut charcoal fiber; 15 parts of tea fiber parts; 15 parts of antibacterial finishing agent, add 110 parts of water, mix and stir evenly, and then dr...

Embodiment 2-5

[0037] The preparation method of embodiment 2-5 is with embodiment 1, and the proportioning ratio of each component is as follows:

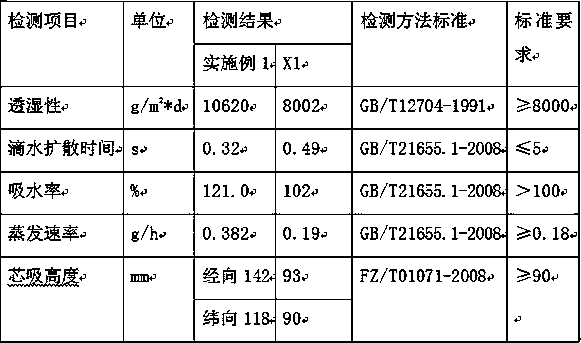

[0038] The distribution ratio of each component of the antibacterial agent in the embodiment 2-5 is shown in the following table 1:

[0039] Table 1 The proportion of each component of the antibacterial agent in Examples 2-5

[0040]

[0041] The distribution ratio of each component of the novel antibacterial fabric in the embodiment 2-5 is shown in the following table 2:

[0042] Table 2 The distribution ratio of each component of the novel antibacterial fabric in Examples 2-5

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com