Patents

Literature

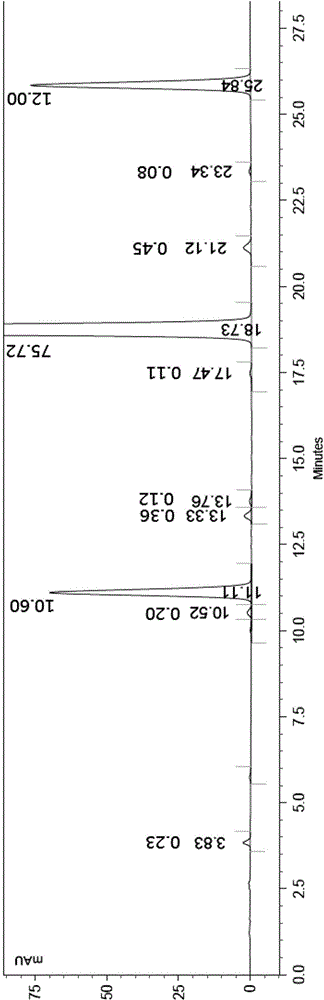

183 results about "Phenyl isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenyl isocyanate is an organic compound typically abbreviated PhNCO. The molecule consists of a phenyl ring attached to the isocyanate functional group. It is a colourless liquid that reacts with water. Phenyl isocyanate has a strong odor and tearing vapours, therefore it is therefore handled with care.

Phenyl isocyanate-based urethane acrylates, processes for producing and methods of using the same

ActiveUS20100036013A1High refractive indexImproved DE valueCarbamic acid derivatives preparationMirrorsHydrogenUrethane acrylate

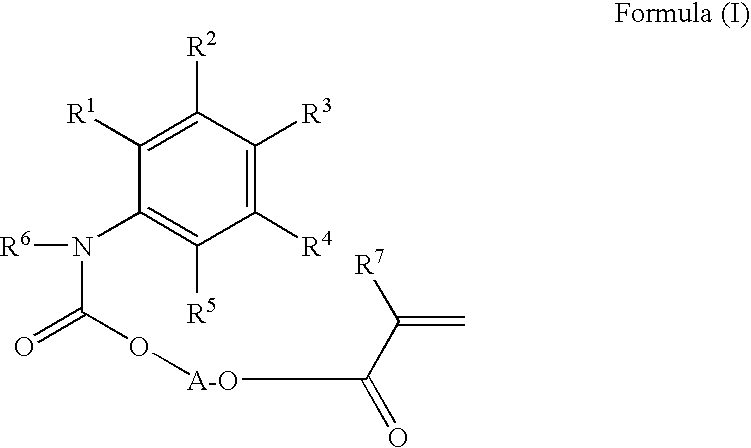

Urethane acrylates of the general Formula (I), corresponding salts, solvates or solvates of a salt thereof:wherein R1, R2, R3, R4 and R5 each independently represent a substituent selected from the group consisting of hydrogen, halogens, C1-6-alkyls, trifluoromethyl, C1-6-alkylthios, C1-6-alkylselenos, C1-6-alkyltelluros, and nitro groups, with the proviso that at least one of R1, R2, R3, R4 and R5 is not hydrogen; R6 and R7 each independently represent a substituent selected from the group consisting of hydrogen and C1-6-alkyls; and A represents a saturated or unsaturated or linear or branched C1-6-alkyl radical or a polyalkylene oxide radical having 2-6 ethylene oxide or propylene oxide units; processes for producing and methods of using the same.

Owner:COVESTRO DEUTSCHLAND AG

Polyurethane patching material used for settlement repairing of ballastless track structure for high-speed railway

ActiveCN104693413AThe distribution ratio is scientific and reasonableImprove performanceCross-linkPolyolefin

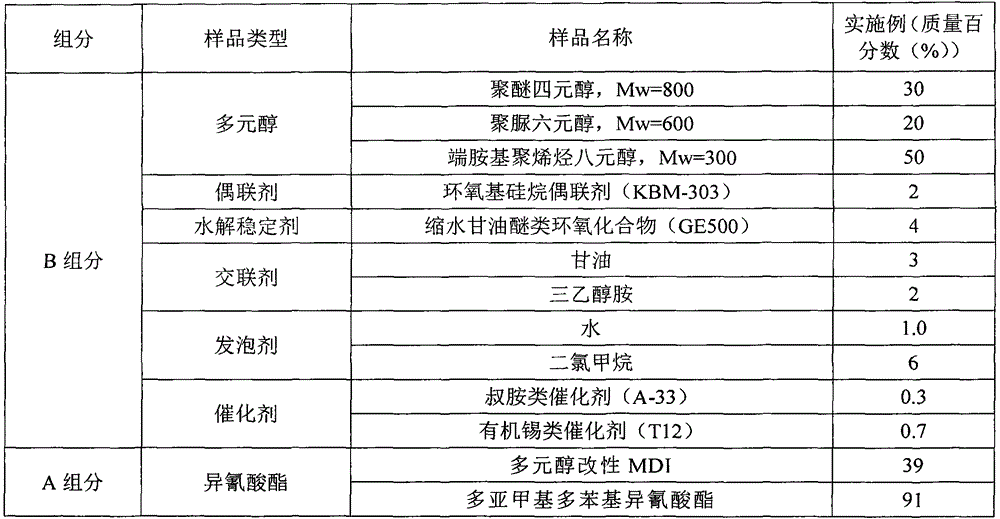

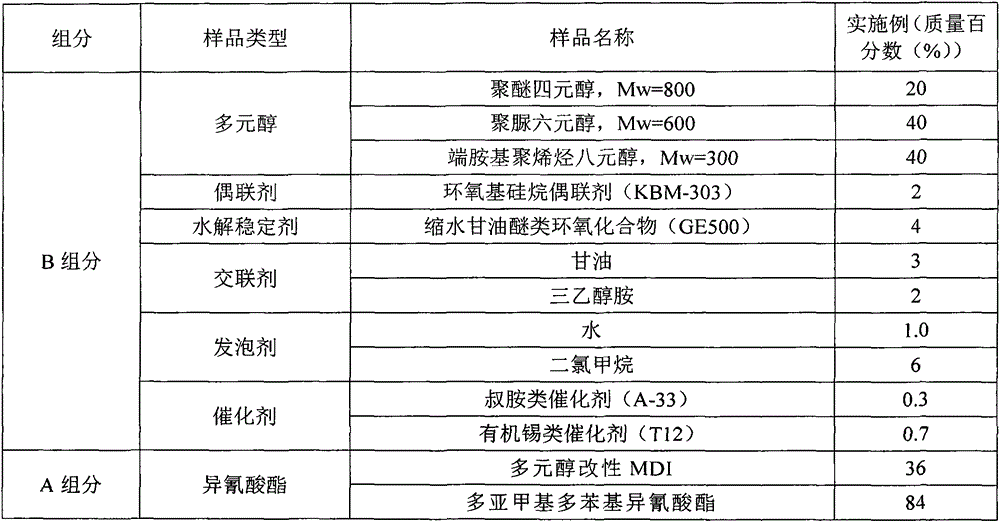

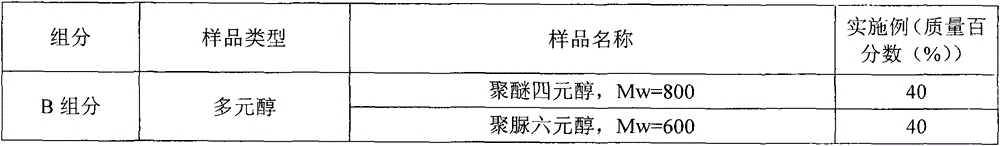

The invention relates to a polyurethane patching material used for settlement repairing of a ballastless structure for a high-speed railway. The polyurethane patching material is formed by hybrid reaction of an A component material and a B component material by a high-pressure impact. The volume ratio of the A component and the B component is 1:1-1:1.8. The A component is a mixture formed by polyhydric alcohol modified diphenylmethane diisocyanate and multi-methylene multi-phenyl isocyanate. The viscosity of the A component ranges from 100 mPa.s to 200 mPa.s at the 25 DEG C temperature. The B component is a mixture formed by polyhydric alcohol, a coupling agent, a hydrolytic stabilizing agent, a cross-linking agent, a foam stabilizing agent, a catalyst agent and a foaming agent. The viscosity of the B component ranges from 150 mPa.s to 300 mPa.s at the 25 DEG C temperature. The B component is characterized in that at least a part of end amido polyolefin polyhydric alcohol with 8 functionalities is in the polyhydric alcohol, and the content of the end amido ranges from 60%-80%. According to the polyurethane repairing material, the chemical reaction speed is high, the expansibility is high, the mechanical strength is high, the binding power is high, the size stability is high, the anti-hydrolysising property is good, and the deformation of accumulated residues is low. The polyurethane repairing material can be used for the settlement repairing of the ballastless structure for the high-speed railway, and can also be used for the pavement structure repairing of an expressway and the settlement repairing of an industrial building terrace.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

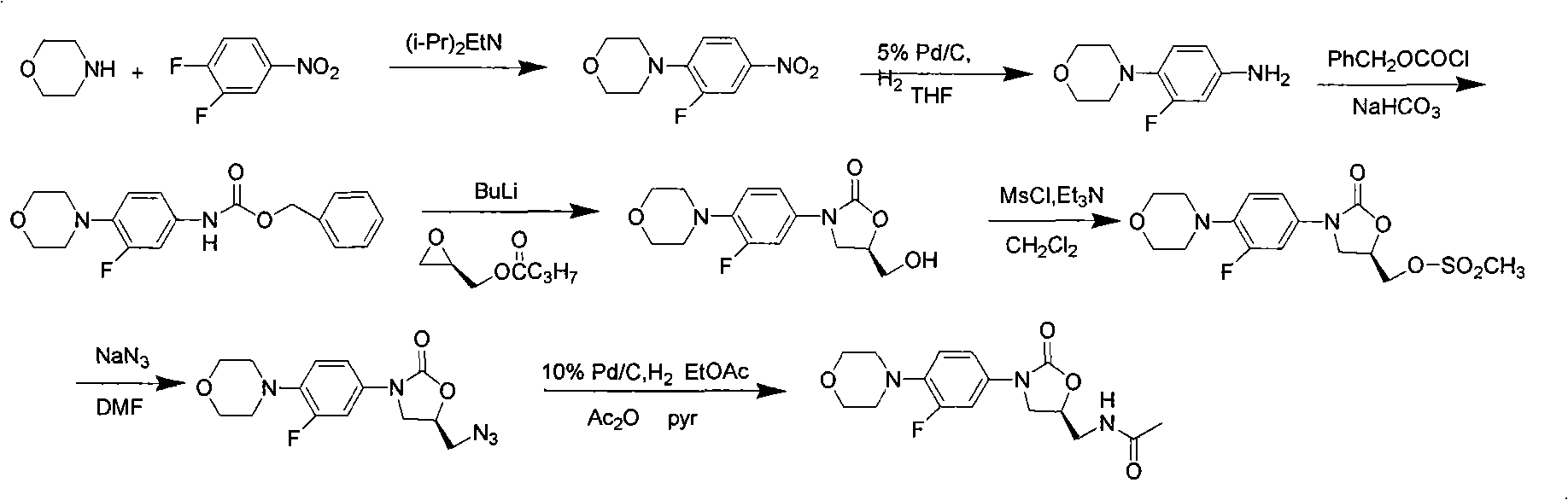

Novel preparation method of netaglinide oxazolone

InactiveCN101638392AAtom utilization is highHigh stereoselectivityAntibacterial agentsOrganic chemistryEpoxyMorpholine

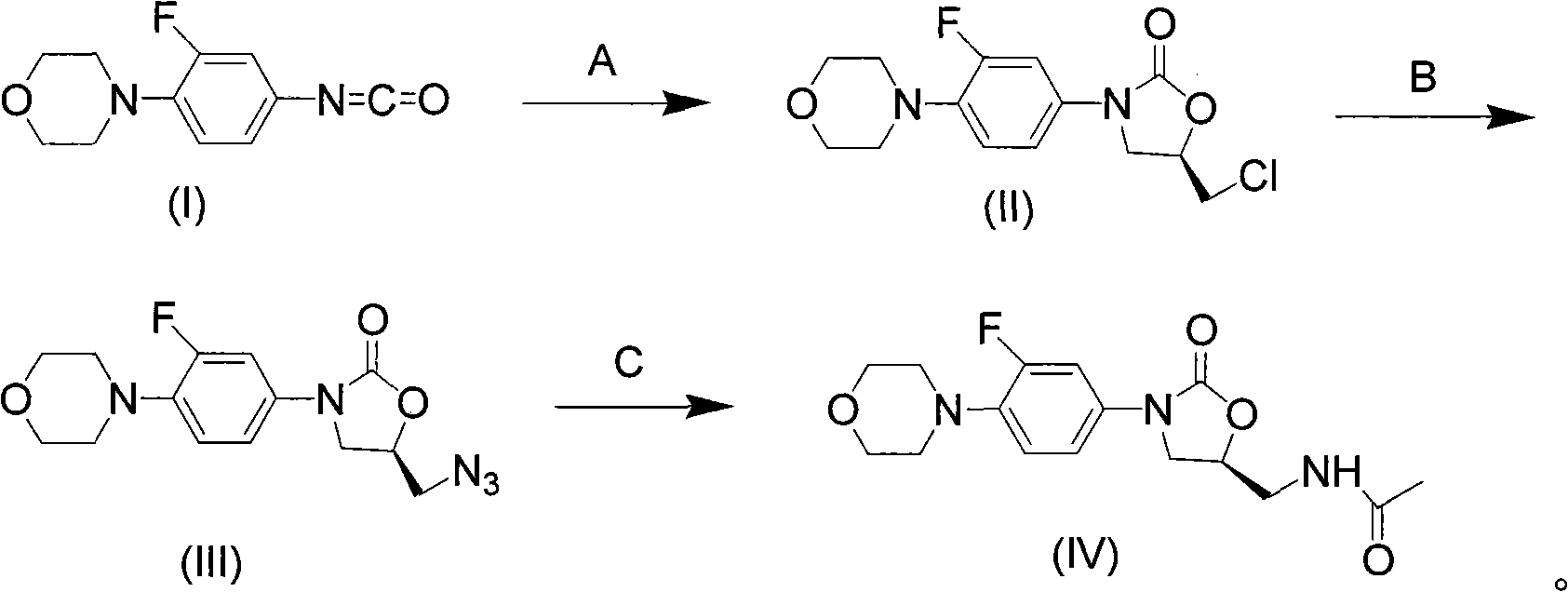

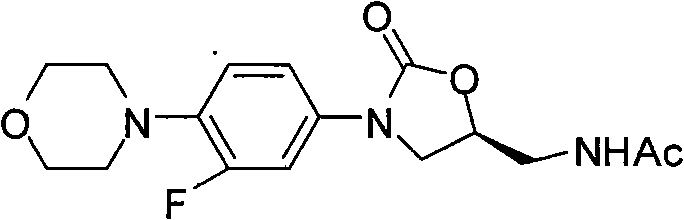

The invention discloses a novel preparation method of netaglinide oxazolone shown in the formula (IV), which comprises the following steps: under the action of a catalyst A, enabling 3-fluorine-4-morpholine phenyl isocyanate shown in the formula (I) to react with (R)-epoxy chloropropane to obtain a compound (II), wherein the catalyst A is magnesium diiodide, magnesium dibromide, magnesium dichloride, magnesium perchlorate or magnesium trifluoromethanesulfonic acid; enabling the compound (II) to react with sodium azide to obtain a compound (III); reducing the compound (III) by hydrogenation, and then, acetylating the reduced compound (III) to obtain the compound (IV). In the invention, the low-cost and environment-friendly catalyst (Lewis acid magnesium) is used for catalyzing the cycloaddition reaction of the (R)-epoxy compound and the isocyanate to establish a mother nucleus structure of the netaglinide oxazolone by one step, thus the prepared netaglinide oxazolone has high stereoselectivity, does not need rigorous operation conditions, such as low temperature, no water, no oxygen and the like, has the advantages of moderate reaction conditions, simple and convenient operation, high utilization ratio of atoms, environment protection, low production cost and the like, and is suitable for industrialized production.

Owner:ZHEJIANG UNIV OF TECH

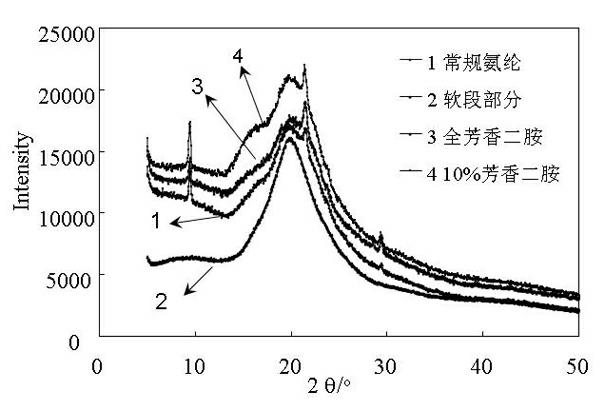

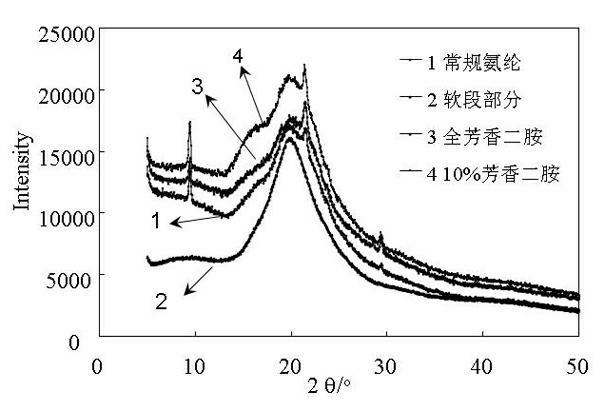

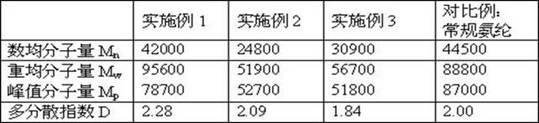

Preparation method of heat resistant spandex fiber

ActiveCN102220653AImprove heat resistanceGood lifting effectMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of heat resistant spandex fiber, belonging to the technical field of polymer textile material and preparation thereof; the preparation method comprises the following steps of: (1) mixing polyoxytetramethylene and 4,4'-methylenebis(phenyl isocyanate) according to a mole ratio of 1 / 1.4 to 1 / 2.5 for reaction to obtain a prepolymer; (2) adding non-protonicpolar solvent to the prepolymer prepared in the step (1) so that the prepolymer is dissolved in the non-protonic polar solvent to obtain prepolymer solution; (3) adding a chain extender in the prepolymer solution obtained in the step (2) to obtain spandex spinning fluid with a molecular weight of 20-300 thousands after polymerization reaction, wherein the chain extender is aromatic diamine or themixture of aromatic diamine and aliphatic diamine; (4) using the spandex spinning fluid prepared in the step (3) to obtain the heat resistant spandex fiber with a solution spinning method. Compared with conventional spandex, the product has obviously improved resistance to heat; moreover, the viscosity stability of the polymer is good.

Owner:ZHEJIANG KAIPUTE SPANDEX +1

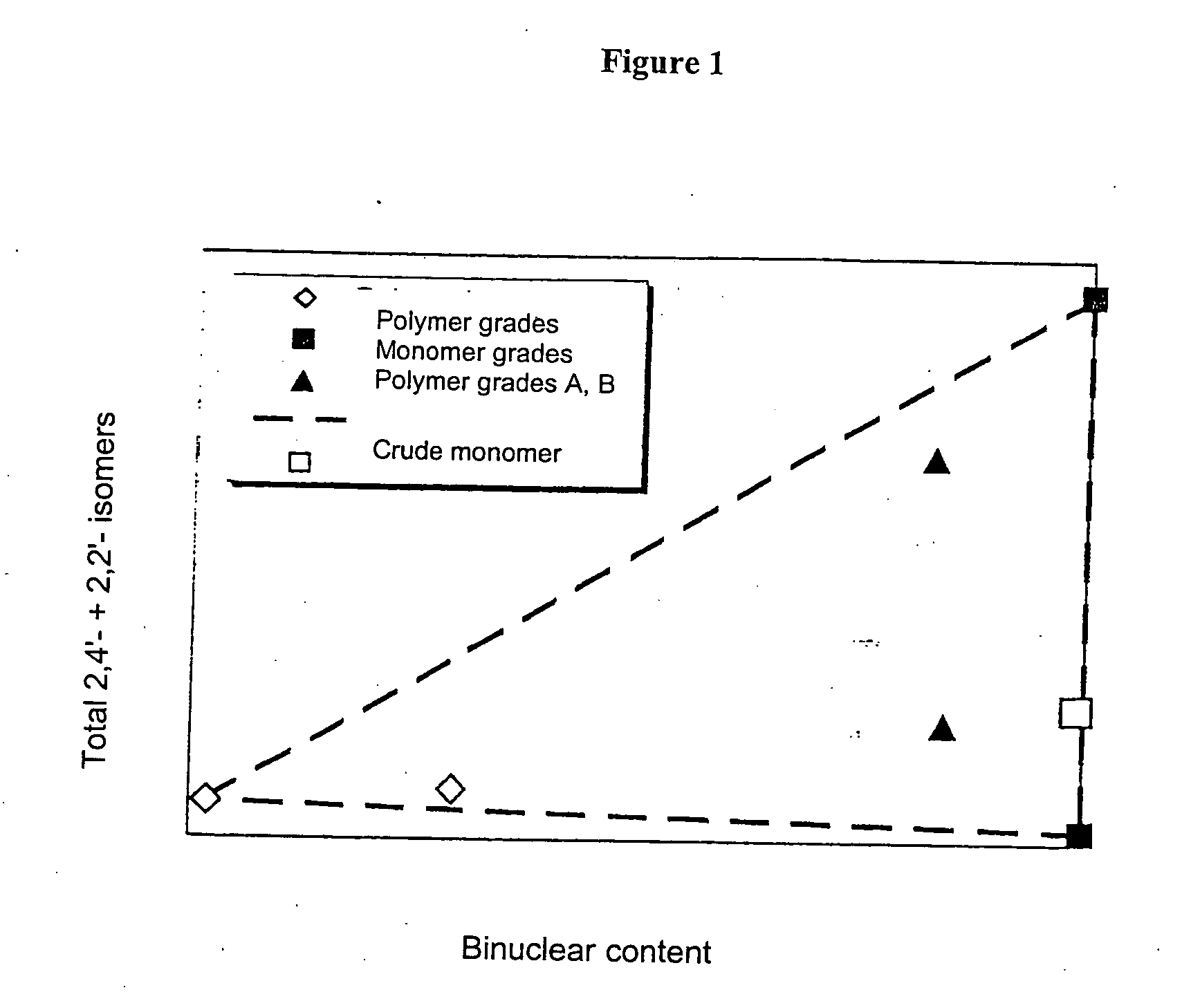

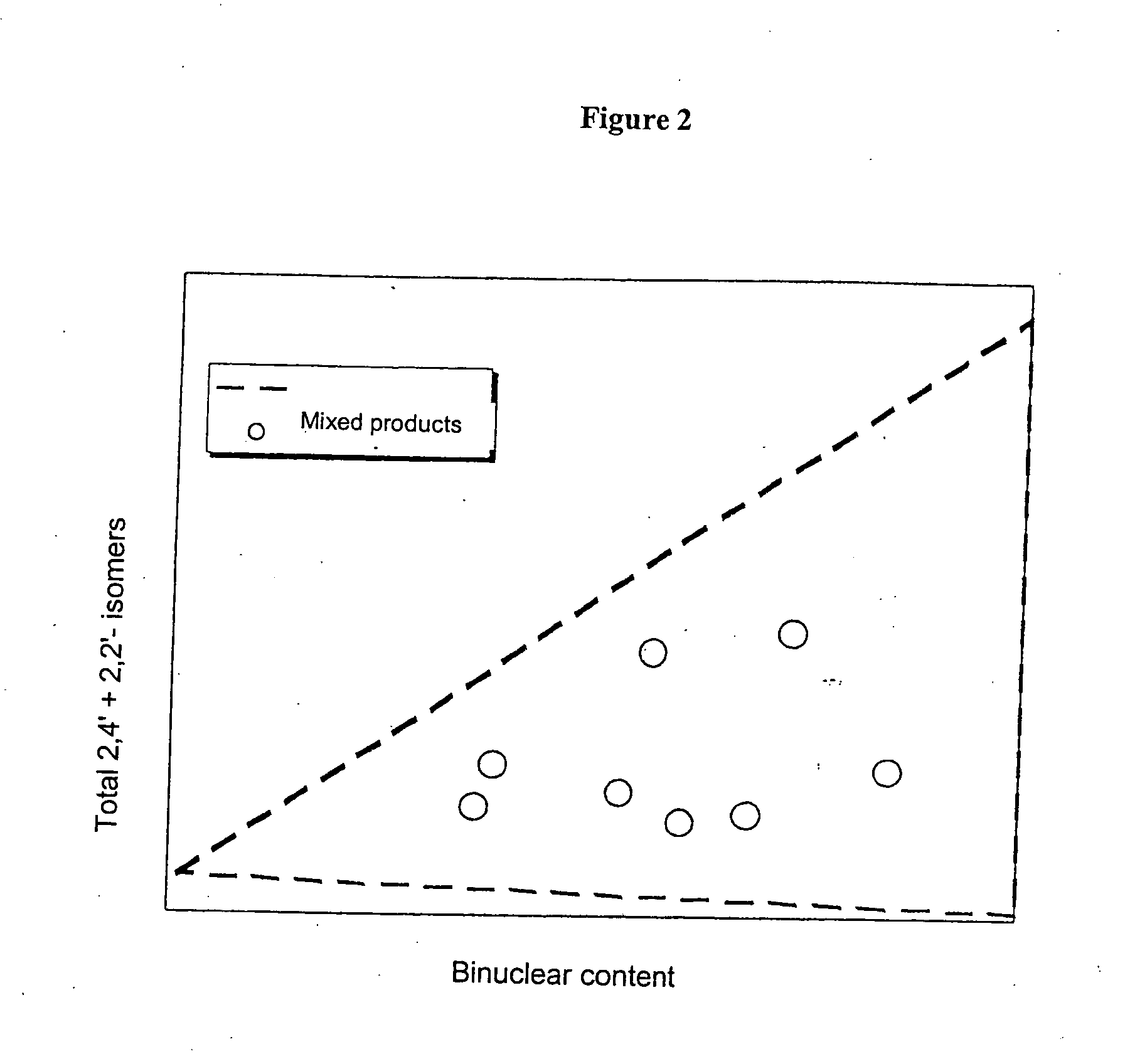

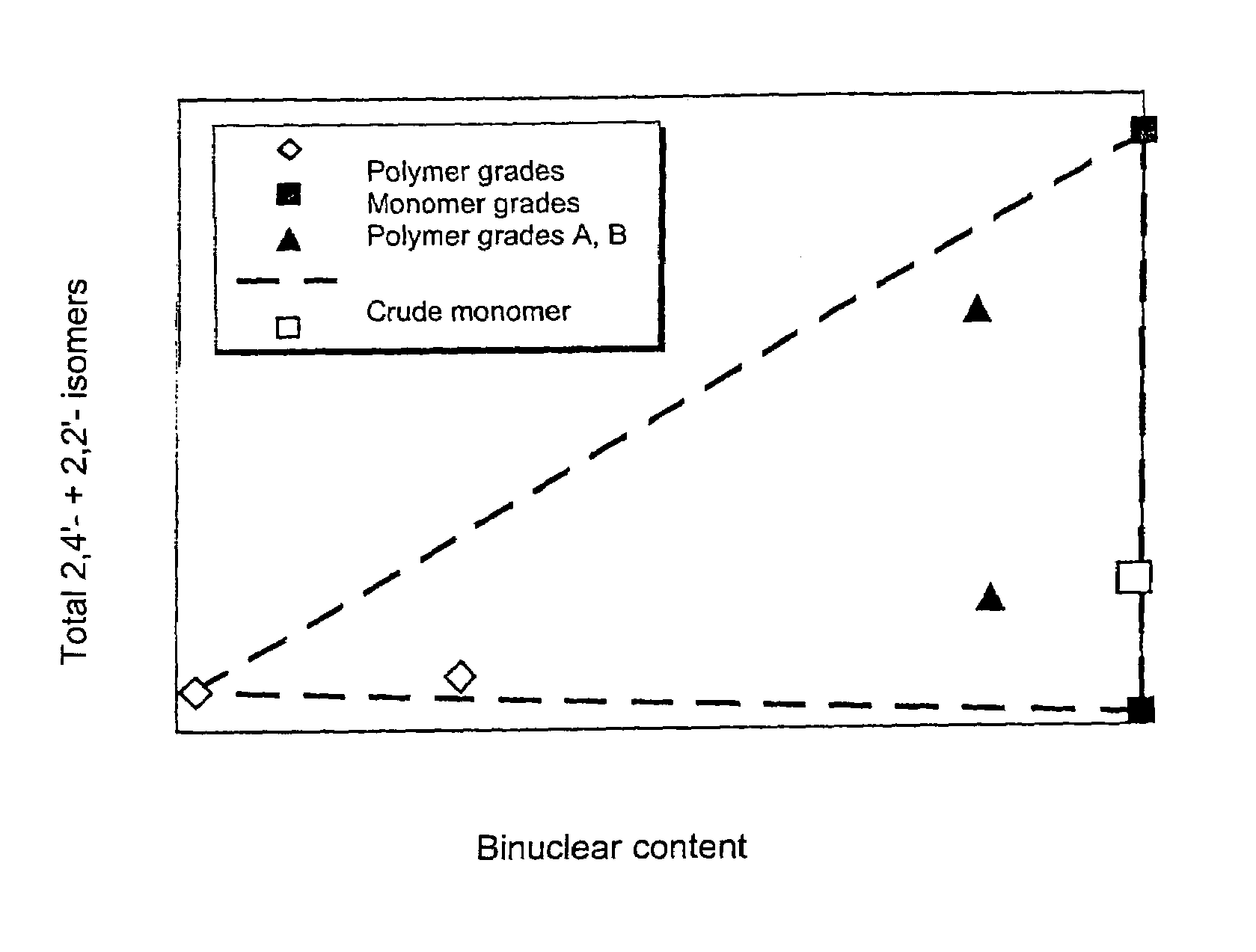

Production of mixtures of diisocyanates and polyisocyanates from the diphenylmethane series with high contents of 4,4'-methylenediphenyl diisocyanate and 2,4'-methylenediphenyl diisocyanate

ActiveUS20050020797A1Simple processLow component requirementsOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

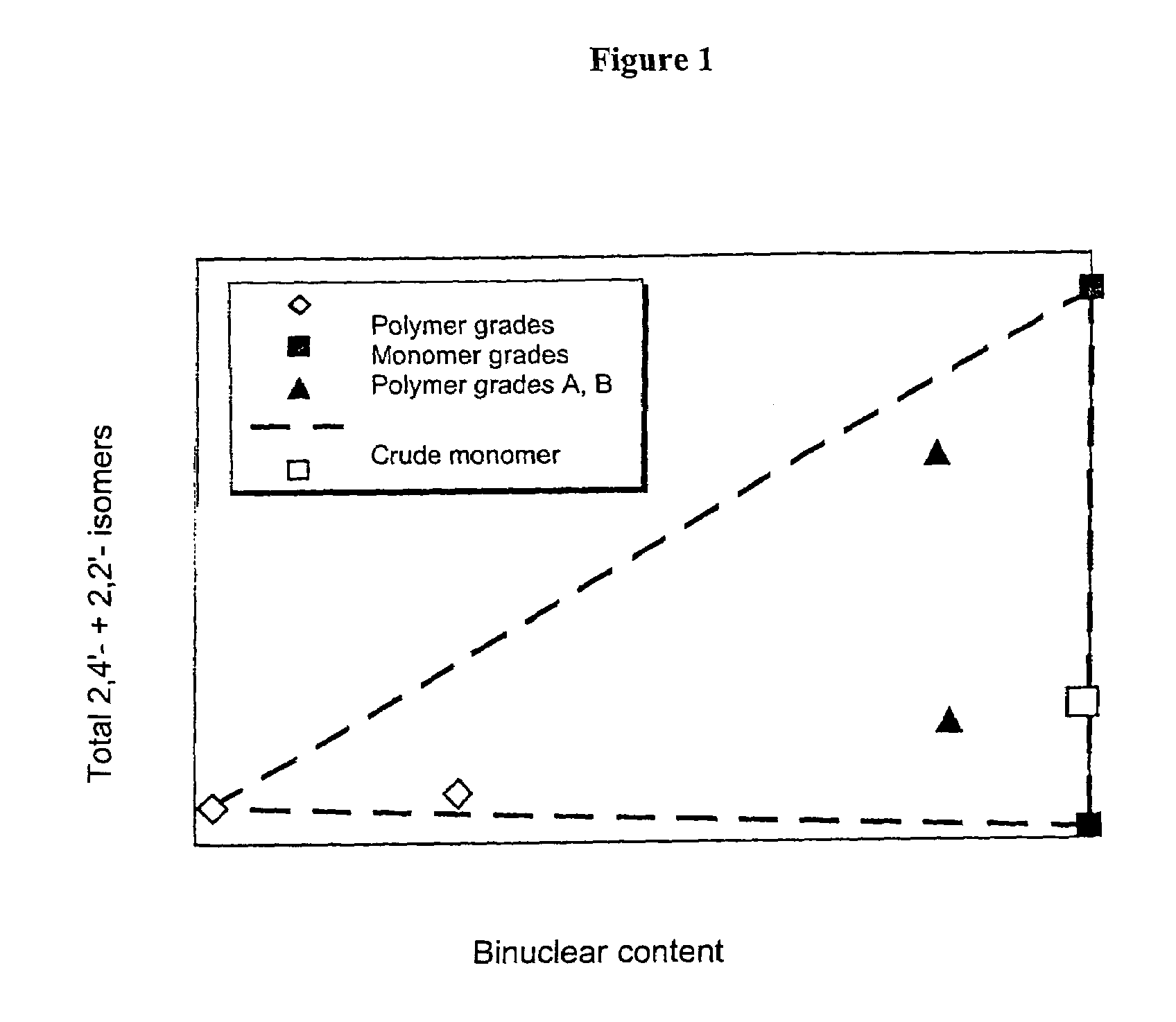

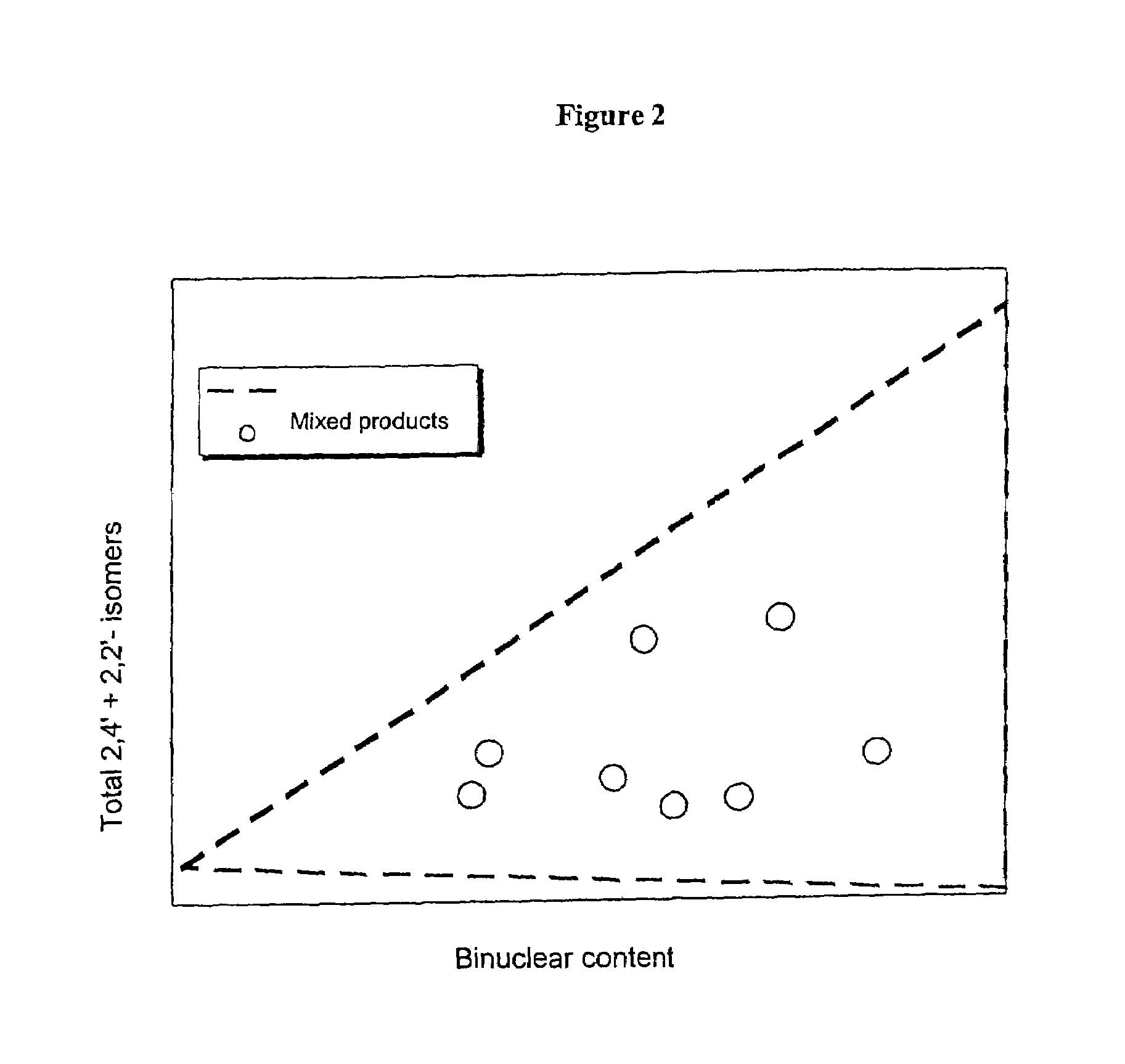

A fraction of diisocyanates of the diphenylmethane series containing at least 95 wt. % binuclear methylenediphenyl diisocyanate is obtained by a) reacting aniline and formaldehyde in the presence of an acid catalyst to produce diamines and polyamines of the diphenylmethane series containing binuclear methylenediphenyl diamine, b) phosgenating the diamines and polyamines produced in a), optionally in the presence of a solvent, to produce a crude diisocyanate and polyisocyanate, and c) separating a fraction containing at least 95 wt. % binuclear methylenediphenyl diisocyanate with a 4,4′-MDI content of over 60 wt. %, a 2,4′-MDI content of 4 to 35 wt. % and a 2,2′-MDI content of 0.01 to 10 wt. %, relative to the mass of the fraction, and a maximum of 20 ppm phenyl isocyanate and optionally a maximum of 50 ppm solvent from the crude diisocyanate and polyisocyanate produced in b) in a single distillation step with optional upstream and / or downstream separation of low-boiling components.

Owner:COVESTRO DEUTSCHLAND AG

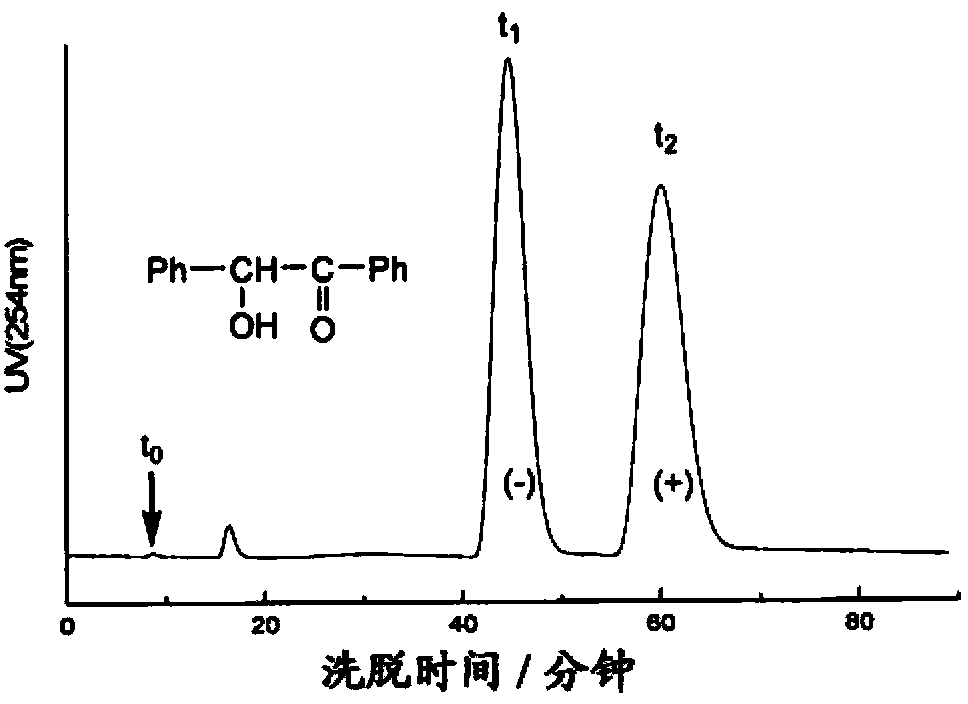

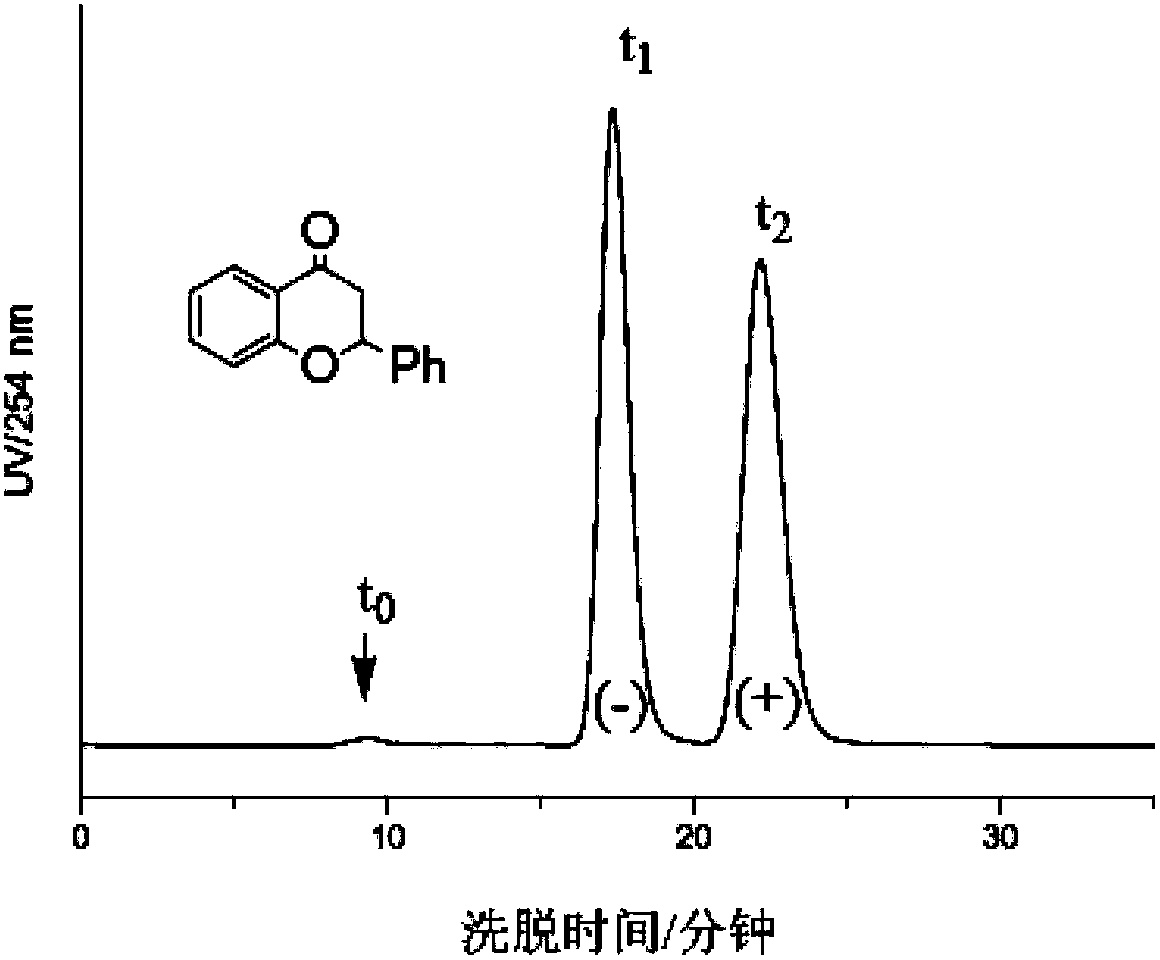

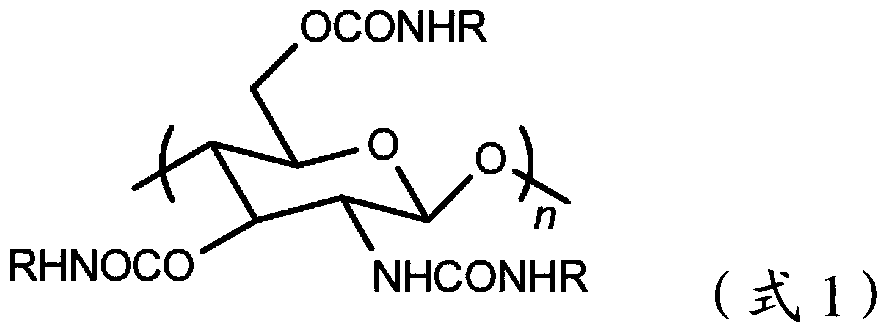

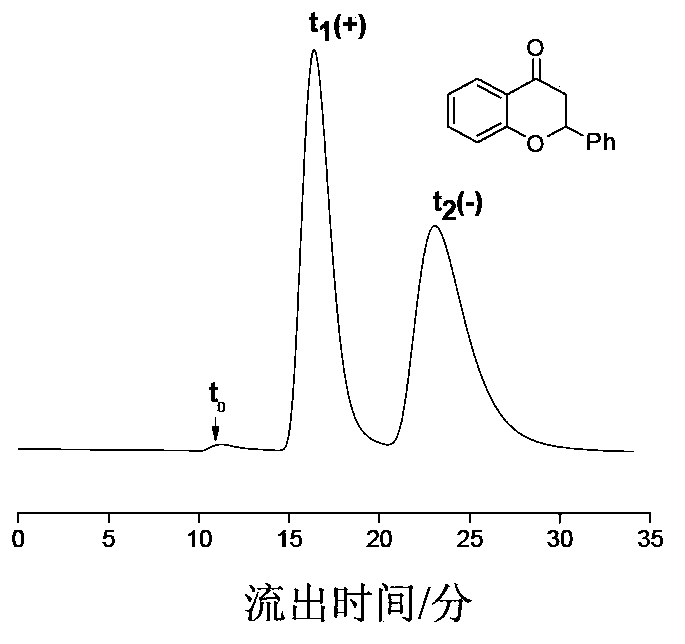

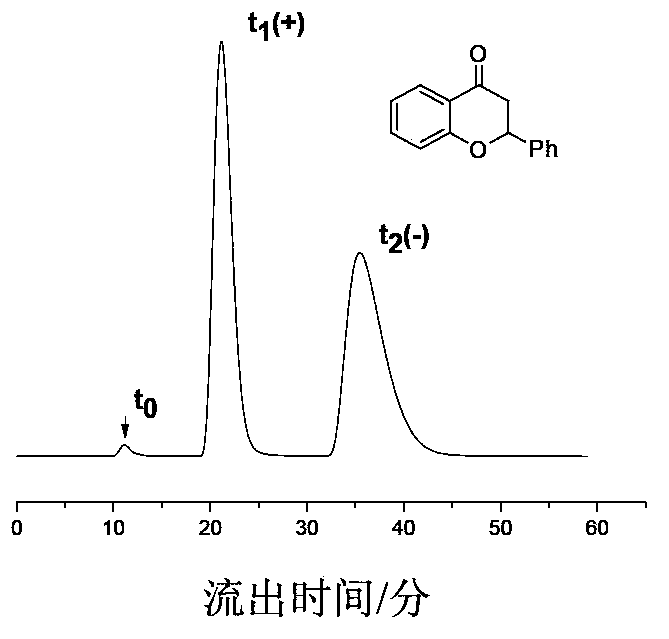

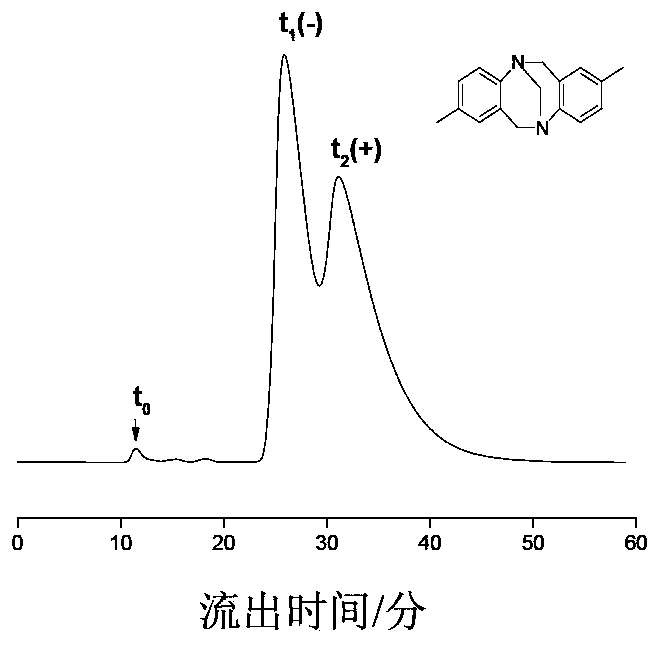

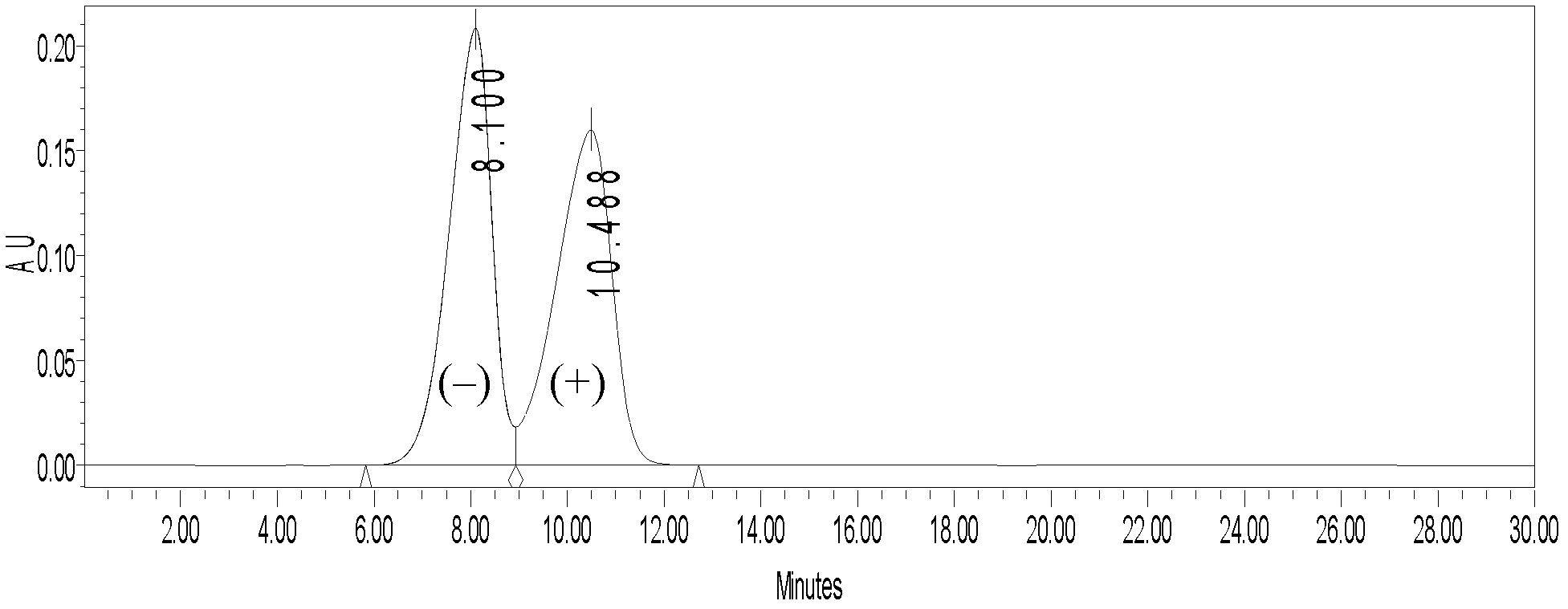

Chitosan carbanilate-carbamido derivative preparation method

ActiveCN104250312AImprove solubilitySmall structureOther chemical processesCarbamateChitosan phenylcarbamate

The invention provides a novel chitosan carbanilate-carbamido derivative synthetic method, the method employs chitosan and phenyl isocyanate with different groups to react, and then the hydroxy and amino on chitosan can be completely conversed to the chitosan carbanilate-carbamido derivative of carbamate and carbamido. According to the invention, a coating process is employed to prepare the derivative to a chiral stationary phase, and high performance liquid chromatography is used for resolution of various enantiomers, and the chiral stationary phase has high chiral identification capability.

Owner:DAICEL CHEM IND LTD

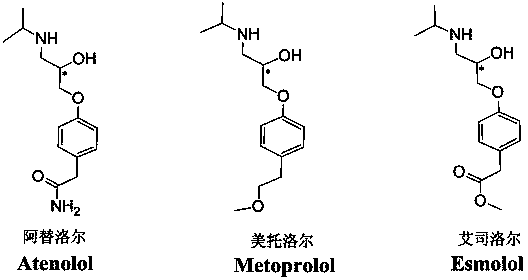

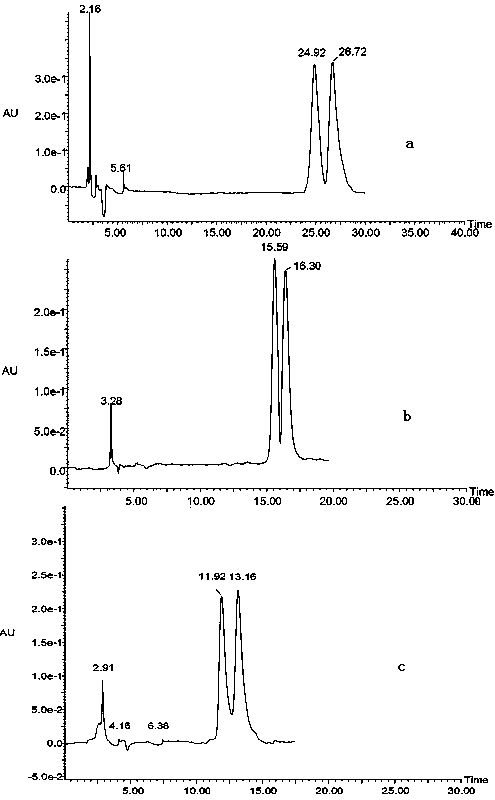

Preparation method of immobilized beta-cyclodextrin derivative type chiral stationary phase

InactiveCN103406113ASimple manufacturing methodMild reaction conditionsOther chemical processesSilanesSilicon oxygen

The invention provides a preparation method of an immobilized beta-cyclodextrin derivative type chiral stationary phase. The preparation method comprises the following steps: reacting isocyanate propyl triethoxy silane with beta-cyclodextrin; performing derivatization modification on a hydroxyl group on a beta-cyclodextrin glucose unit by using phenyl isocyanate to obtain a beta-cyclodextrin derivative; coating the beta-cyclodextrin derivative bonded with a small amount of silane coupling agent on the surface of aminopropyl silica gel, and performing condensation in ethanol / aqueous solution in the presence of trimethylchlorosilane by using the silane coupling agent in the beta-cyclodextrin derivative molecules to finally obtain the immobilized beta-cyclodextrin derivative type chiral stationary phase, wherein the phenylcarbamate beta-cyclodextrin derivative molecules are connected by using a silicon-oxygen-silicon bond to form an inclusion netlike structure which covers the surface of the aminopropyl silica gel. The preparation method has the characteristics of simplicity, few steps and high bonding efficiency, can be applied to the normal-phase high-performance liquid chromatographic condition, and has the advantages of high chromatographic column stability and high chiral separation capacity.

Owner:三亚哈尔滨工程大学南海创新发展基地

Process for production of wood composites using mixed PMDI/solid novolac resin binder

InactiveCN1330668AImprove water resistanceLess tendency to stick to platenPolyureas/polyurethane adhesivesWood veneer joiningMethylene diisocyanateComposite lumber

This invention relates to a process for the production of composite wood products. This process comprises a) applying a binder composition to wood particles, and b) molding or compressing the wood particles treated with the binder to form a composite wood product. Suitable binder compositions comprise a polymethylene poly(phenyl isocyanate) and a solid novolac resin.

Owner:HEXION SPECIALTY CHEM INC

Decorative molded foams with good impact resistance and fire retardant properties

This invention relates to fire-resistant, flexible, molded, medium density polyurethane foams. These foams typically have a density of from 10 to 30 pcf. The foams are the reaction product of a) at least one polyester polyol, b) at least one highly branched polyether polyol, c) at least one chain extender, d) a polymethylene poly(phenyl isocyanate), an isocyanate group containing prepolymer based on a polymethylene poly(phenyl isocyanate), or mixtures thereof, e) a solid flame retardant and f) water. This invention also relates to a process for preparing these polyurethane foams in open molds.

Owner:BAYER MATERIALSCIENCE AG

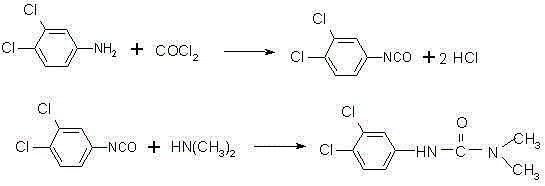

Method for preparing weedicide diuron

InactiveCN102617407AThe synthesis process is reasonableLow costUrea derivatives preparationOrganic compound preparationEvaporationPhosgene

The invention provides a method for preparing weedicide diuron. The method is characterized in that aromatic compound solvents are added in a reaction kettle, cooling and phosgene introduction are carried out, less dimethylformamide is added, 3, 4-dichloro phenylamine solution is dripped, and cocatalyst triethylene-diamine is added after the dripping completion; the temperature is raised to 80 to 100 DEG C, and the stirring is carried out under the heat insulation condition; solution consisting of 3, 4-dichloro phenyl isocyanate and the aromatic compound solvents is obtained through the reaction; and partial solvents are removed through evaporation, then, 40-percent dimethylamine is dripped, and dinitramine is prepared. Because the catalyst dimethylformamide and the cocatalyst triethylene-diamine are used in the reaction in the method provided by the invention, so the total yield of the synthesized dinitramine is higher than 91 percent, and the purity of the dinitramine raw medicine is higher than 99 percent. The synthesis process provided by the invention is more reasonable, the cost is low, the quality is high, a better environment-friendly effect is realized, the safety is higher, the international standard is reached, and the method is more suitable for industrialized production.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD

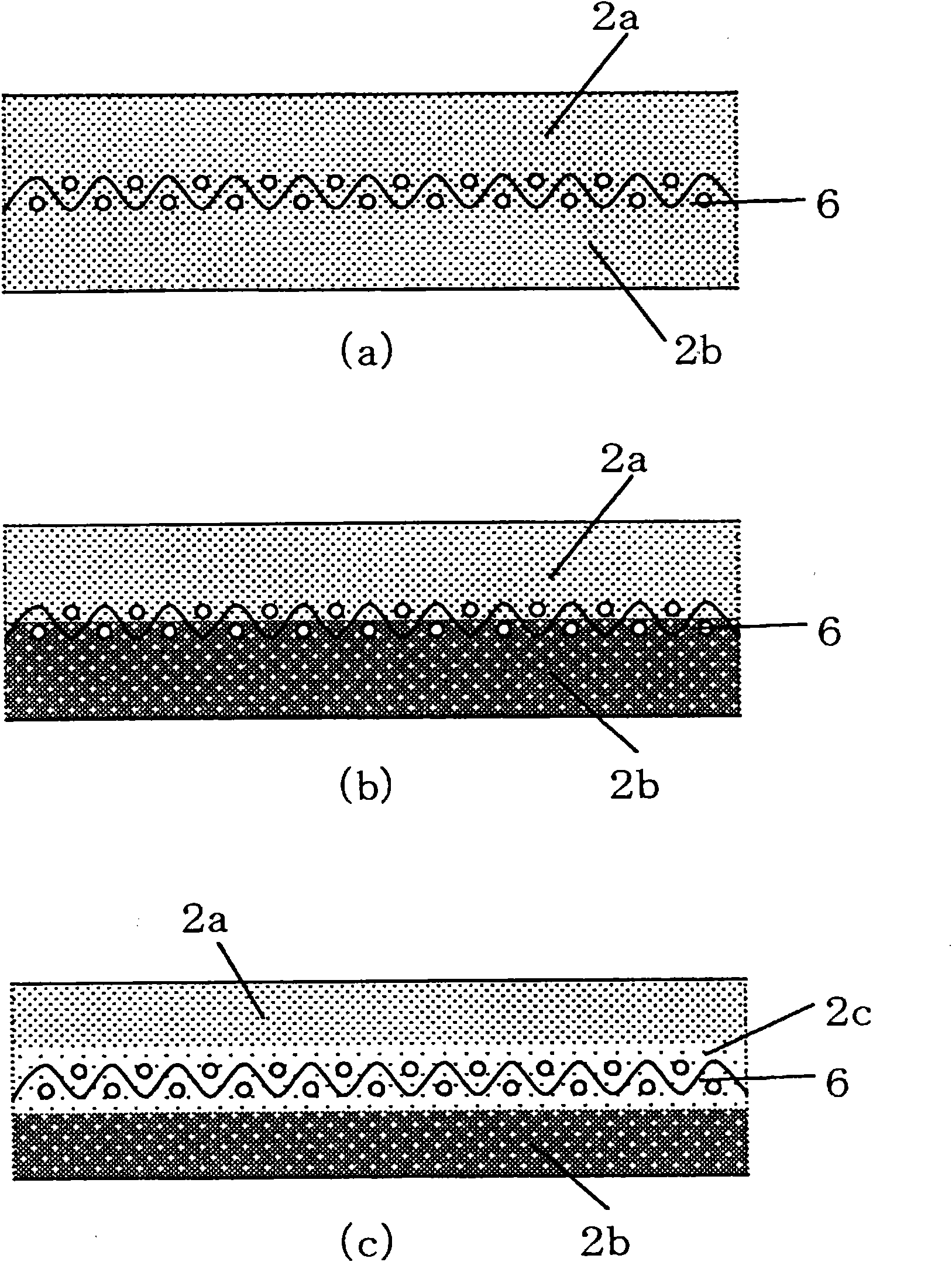

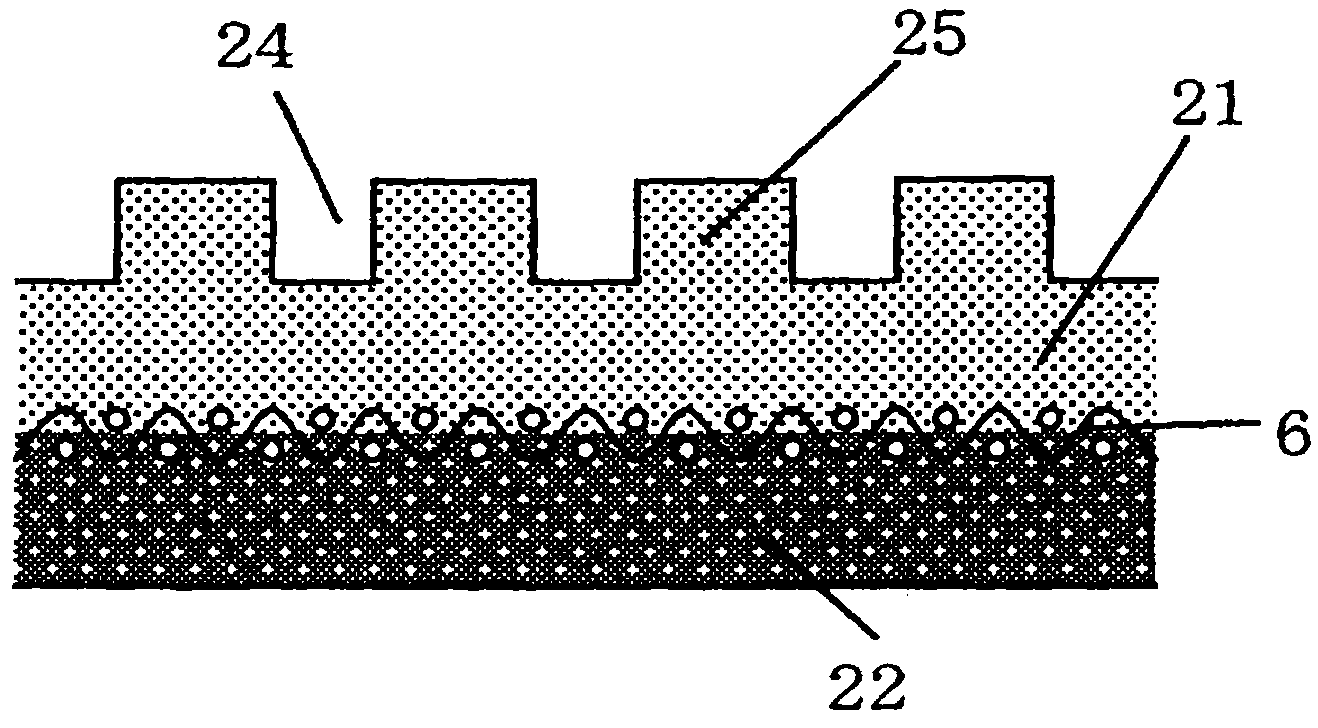

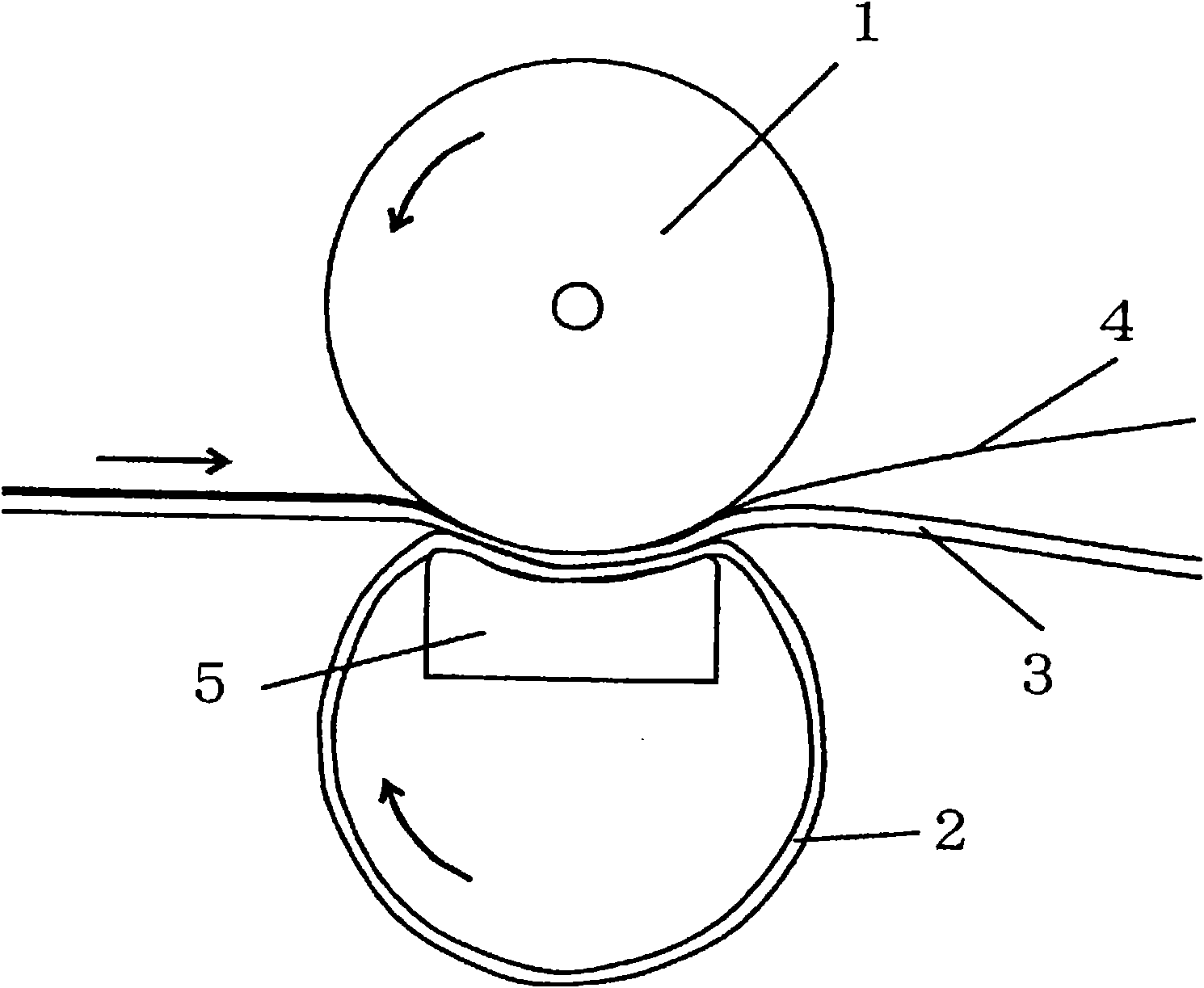

Shoe press belt for papermaking

ActiveCN101939483AExcellent mechanical propertiesIncreased durabilityPaper/cardboardPress sectionFiberCarbamate

A belt for papermaking shoe presses is provided which comprises a reinforcing fibrous base (6) and a polyurethane layer (2) united therewith, the reinforcing fibrous base (6) having been embedded in the polyurethane layer (2). The belt includes a polyurethane layer obtained by curing a mixture comprising: a urethane prepolymer obtained by reacting a polyisocyanate compound selected among p-phenylene diisocyanate, 4,4'-methylenebis(phenyl isocyanate), and tolylene diisocyanate with a polyol compound selected among polypropylene glycol, polytetramethylene glycol, and a polycarbonate diol; a hardener selected among an aliphatic diol compound, hydroquinone bis-ss-hydroxyethyl ether, and organic polyamine compound; and an aliphatic triol compound. Due to this layer, the shoe press belt for papermaking is excellent in wearing resistance and flexing fatigue resistance.

Owner:ICHIKAWA ELECTRIC CO LTD

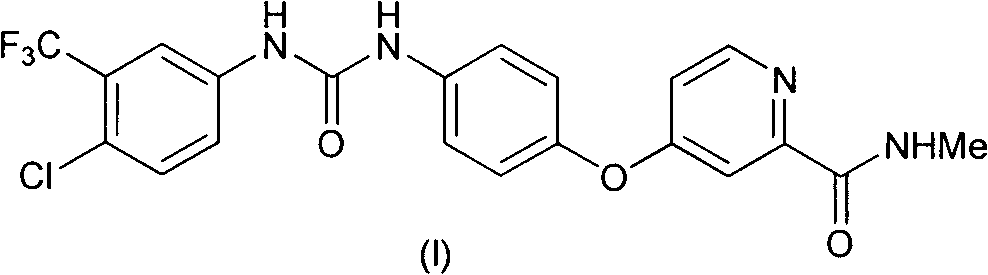

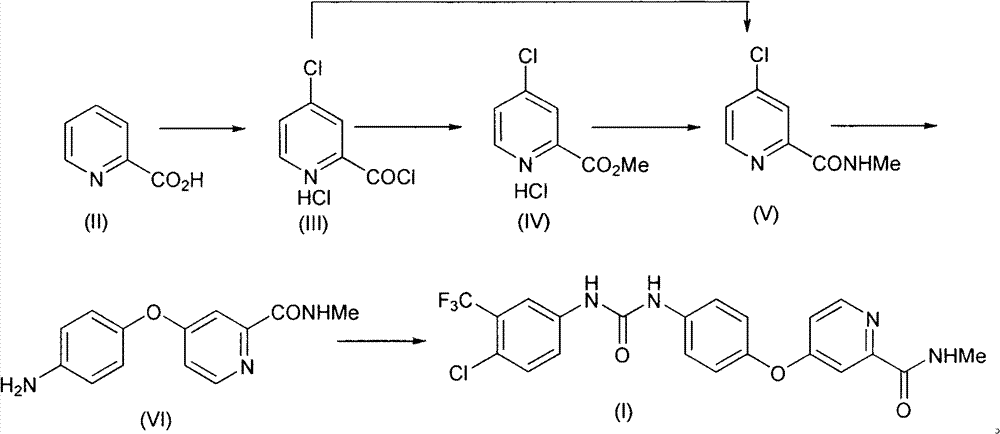

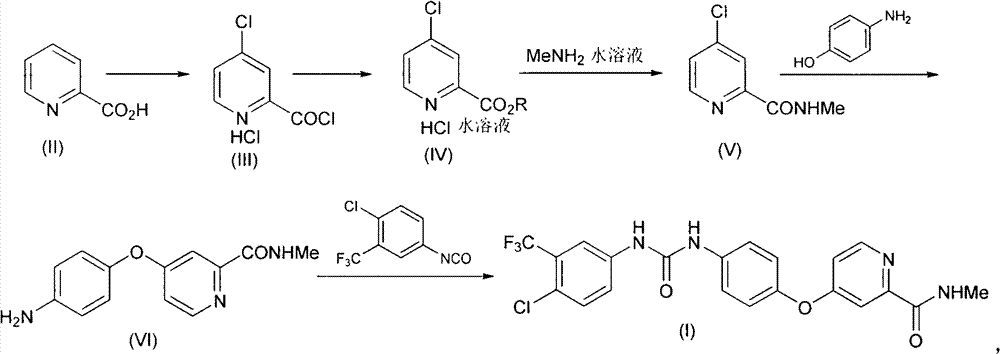

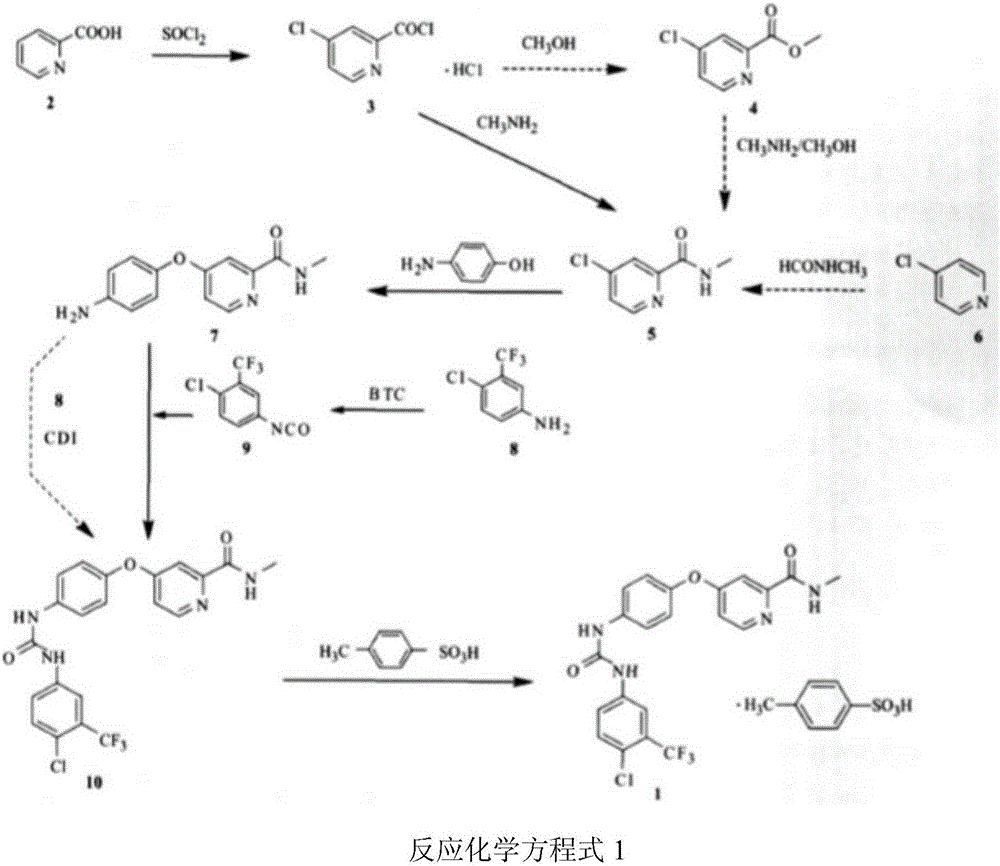

Method for preparing sorafenib

The invention discloses a method for preparing sorafenib. 2-picolinic acid is subjected to chlorination, esterification and methylamination to form a key intermediate, namely 4-chloropyridine-N-methyl-2-formamide, the intermediate and p-aminophenol are subjected to coupled reaction under alkaline condition, and a reaction product is reacted with 4-chloro-3-trifluoromethyl phenyl isocyanate to form a target compound.

Owner:SHANGHAI AOBO PHARMTECH INC LTD

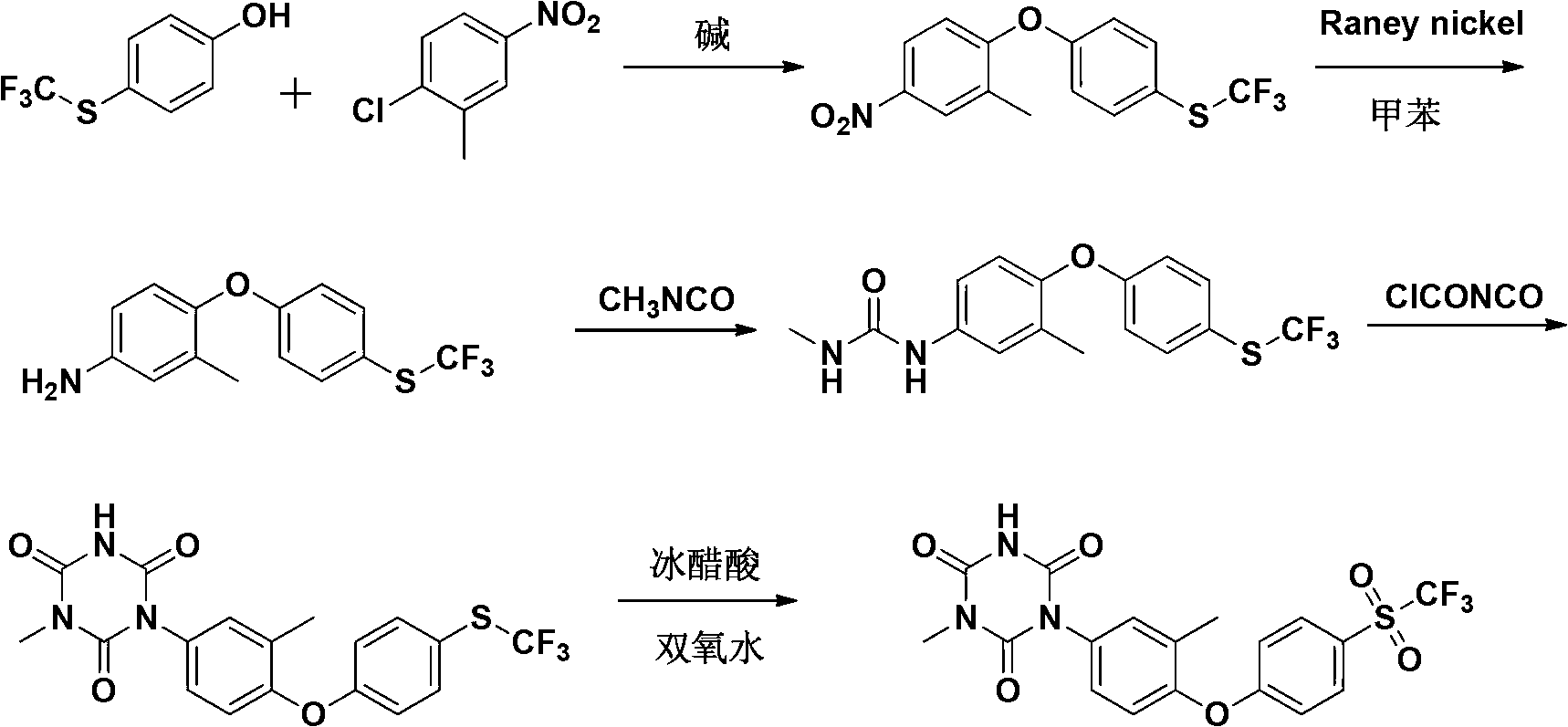

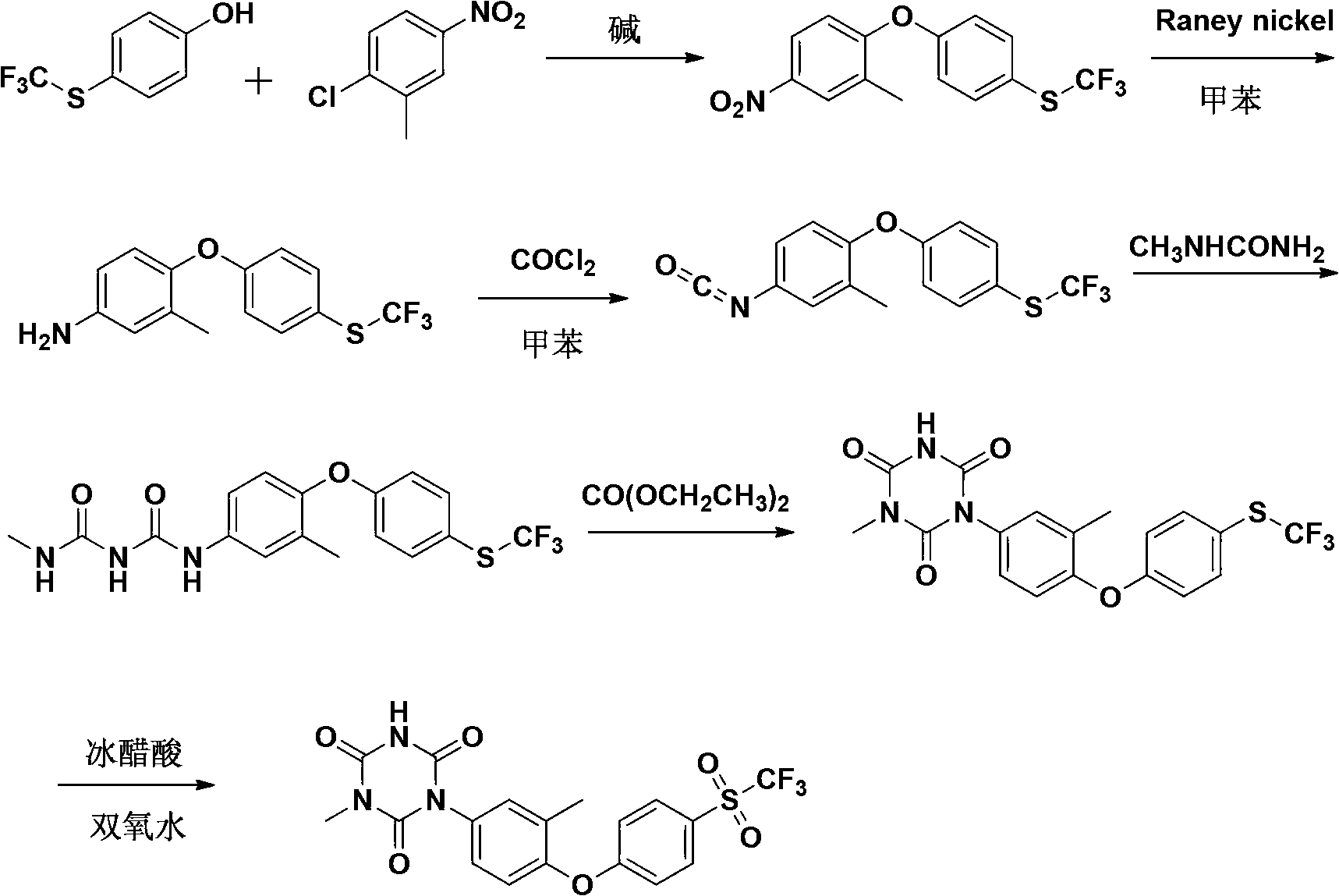

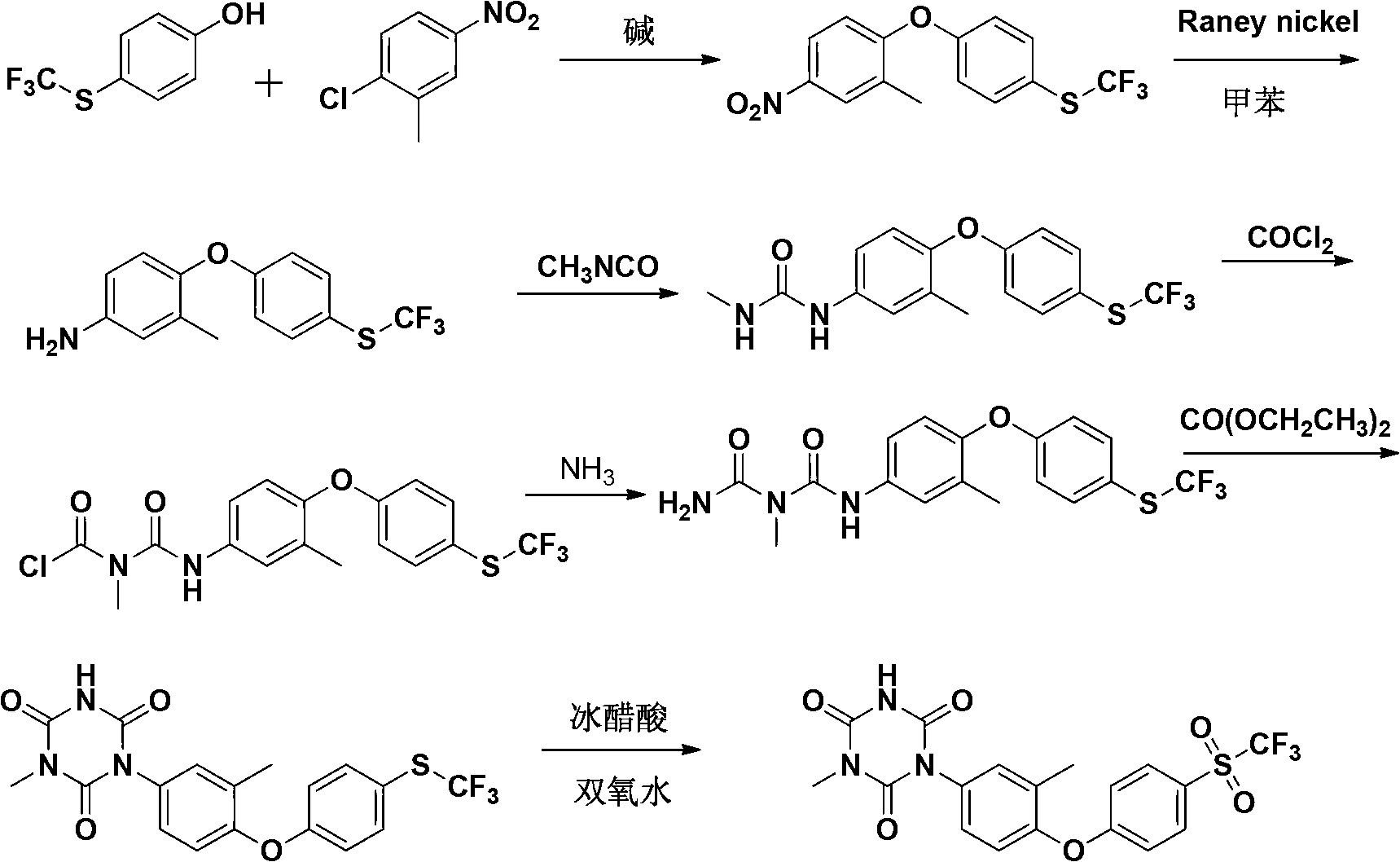

Preparation method of ponazuril

InactiveCN102936227AOperational securityRaw materials are easy to getOrganic chemistryCoccidiosisNitrobenzene

The invention relates to a preparation method of ponazuril which is an anti-coccidiosis drug. The method includes syntheses of 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-nitrobenzene, 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-aniline, 3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-phenyl isocyanate, 1-[3-methyl-4-(4-phenoxy trifluoromethyl sulfide)-m-methylphenyl]-1,3,5-triazine-2,4,6-trione and ponazuril. Dangerous articles such as raney nickel, methyl isocyanate, chloroformylisocyanate, phosgene, triphosgene and hydrazine hydrate are not used during the reaction processes, and the operation is safe and reliable; raw materials are easy to obtain, the production cost and pollution are low, and the production process is environment-friendly; and the preparation method is simple, special equipment is not needed, a total yield of ponazuril product can reach above 60%, and large-scaleindustrial production is facilitated.

Owner:QILU ANIMAL HEALTH PROD +1

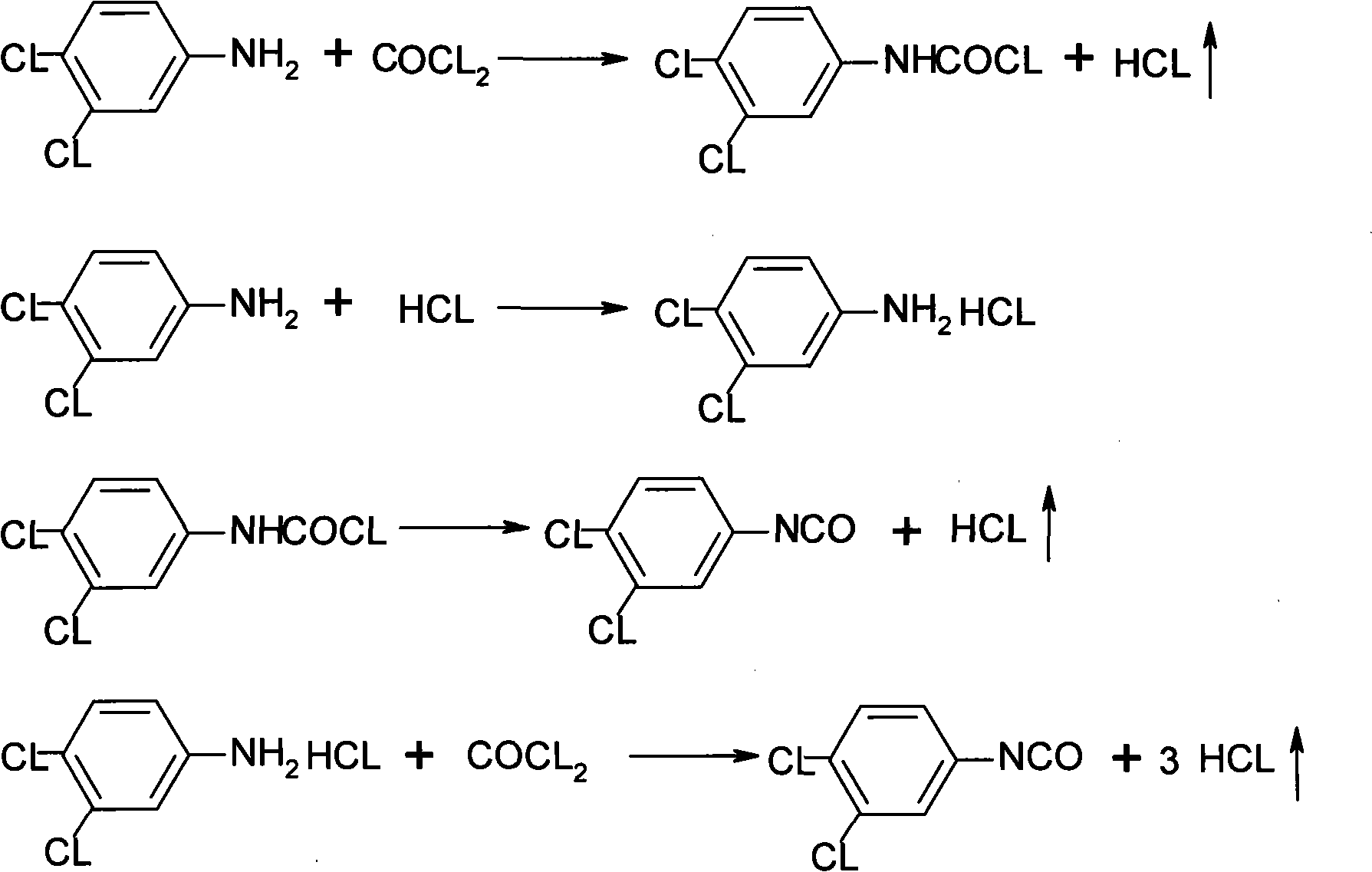

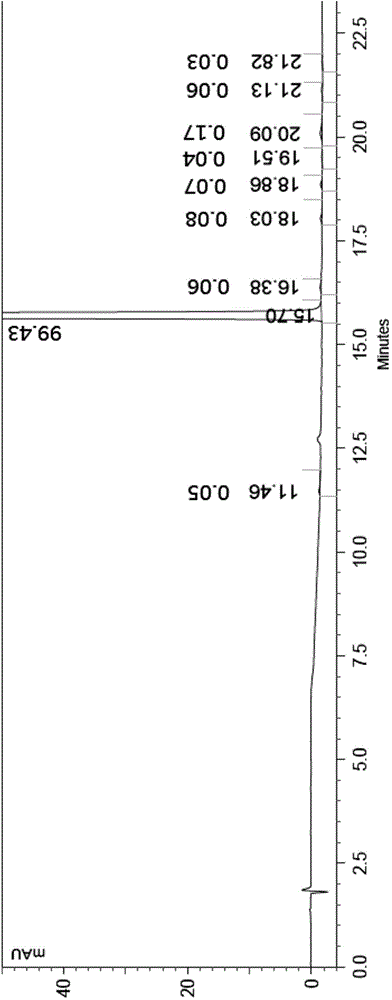

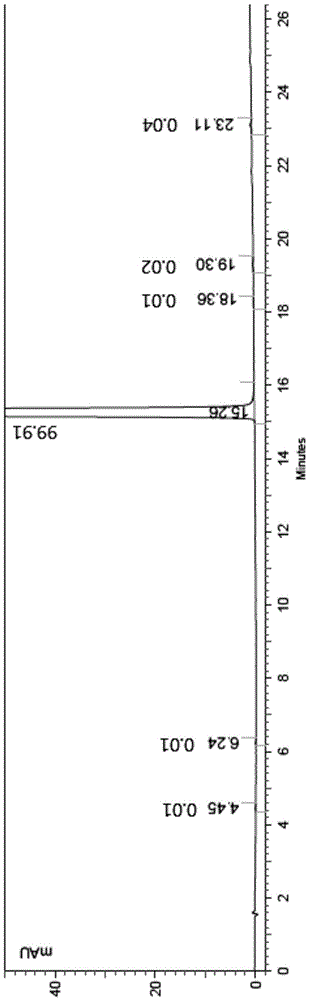

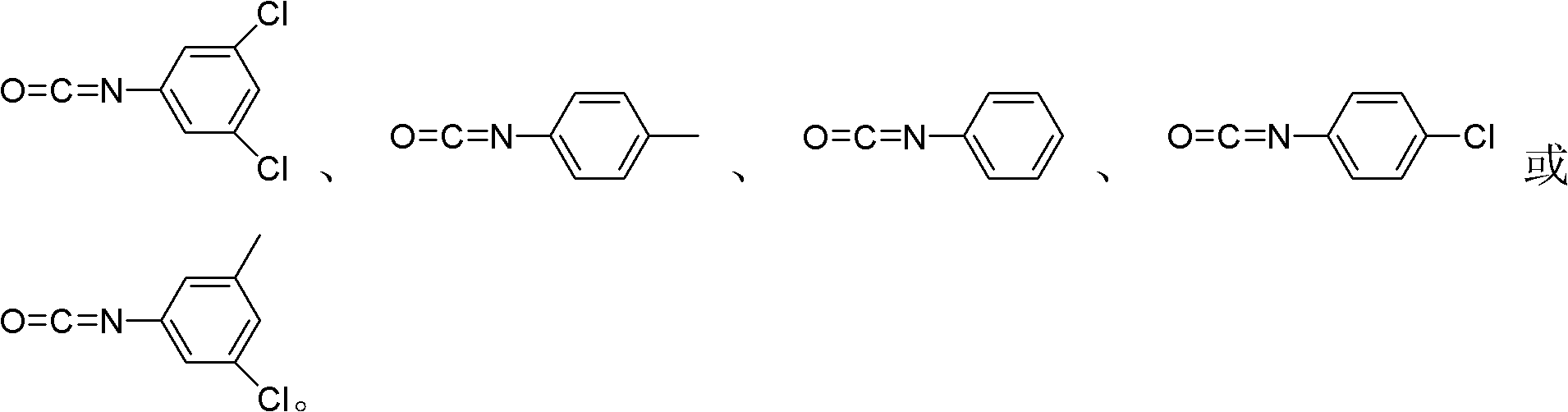

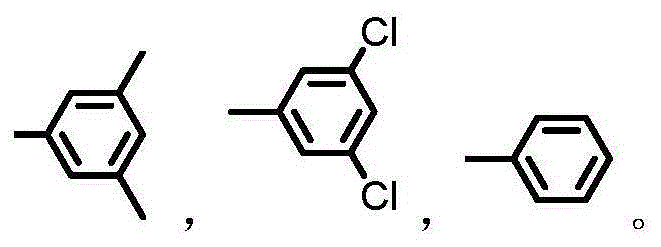

Preparation for 3, 4-dichloro phenyl isocyanate

ActiveCN101274904AReduce the temperatureLess side effectsIsocyanic acid derivatives preparationOrganic compound preparationChemical reactionOrganic solvent

The invention discloses a method for preparing 3, 4-dichloro phenyl isocyanate. The method takes 3, 4-dichloroaniline as raw material and xylene, or benzene chloride, o (p) dichlorobenzene and other organic solvents which do not react chemically with phosgene as a reaction solvent, goes through two steps of phosgenation reaction under low temperature and high temperature and distillation to obtain products with purity over 98 percent. The technique of two steps of phosgenation reaction under low temperature and high temperature can effectively reduce side reaction and improve reaction efficiency; the total yield of the invention achieves over 97 percent calculated by 3, 4-dichloroaniline.

Owner:JIANGSU ANPON ELECTROCHEM

Production of mixtures of diisocyanates and polyisocyanates from the diphenylmethane series with high contents of 4,4'-methylenediphenyl diisocyanate and 2,4'-methylenediphenyl diisocyanate

ActiveUS7038002B2Simple processLow proportionOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

A fraction of diisocyanates of the diphenylmethane series containing at least 95 wt. % binuclear methylenediphenyl diisocyanate is obtained bya) reacting aniline and formaldehyde in the presence of an acid catalyst to produce diamines and polyamines of the diphenylmethane series containing binuclear methylenediphenyl diamine,b) phosgenating the diamines and polyamines produced in a), optionally in the presence of a solvent, to produce a crude diisocyanate and polyisocyanate, andc) separating a fraction containing at least 95 wt. % binuclear methylenediphenyl diisocyanate with a 4,4′-MDI content of over 60 wt. %, a 2,4′-MDI content of 4 to 35 wt. % and a 2,2′-MDI content of 0.01 to 10 wt. %, relative to the mass of the fraction, and a maximum of 20 ppm phenyl isocyanate and optionally a maximum of 50 ppm solvent from the crude diisocyanate and polyisocyanate produced in b) in a single distillation step with optional upstream and / or downstream separation of low-boiling components.

Owner:COVESTRO DEUTSCHLAND AG

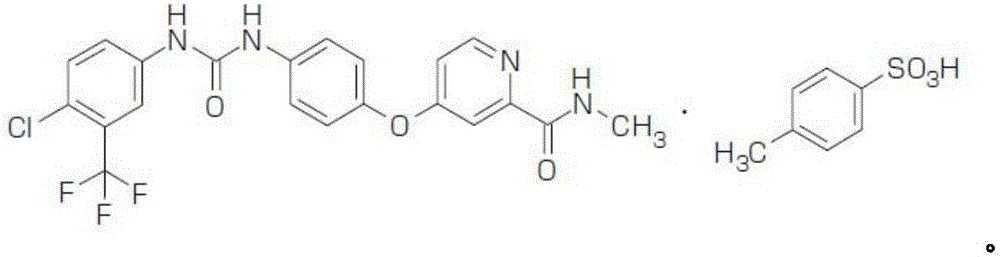

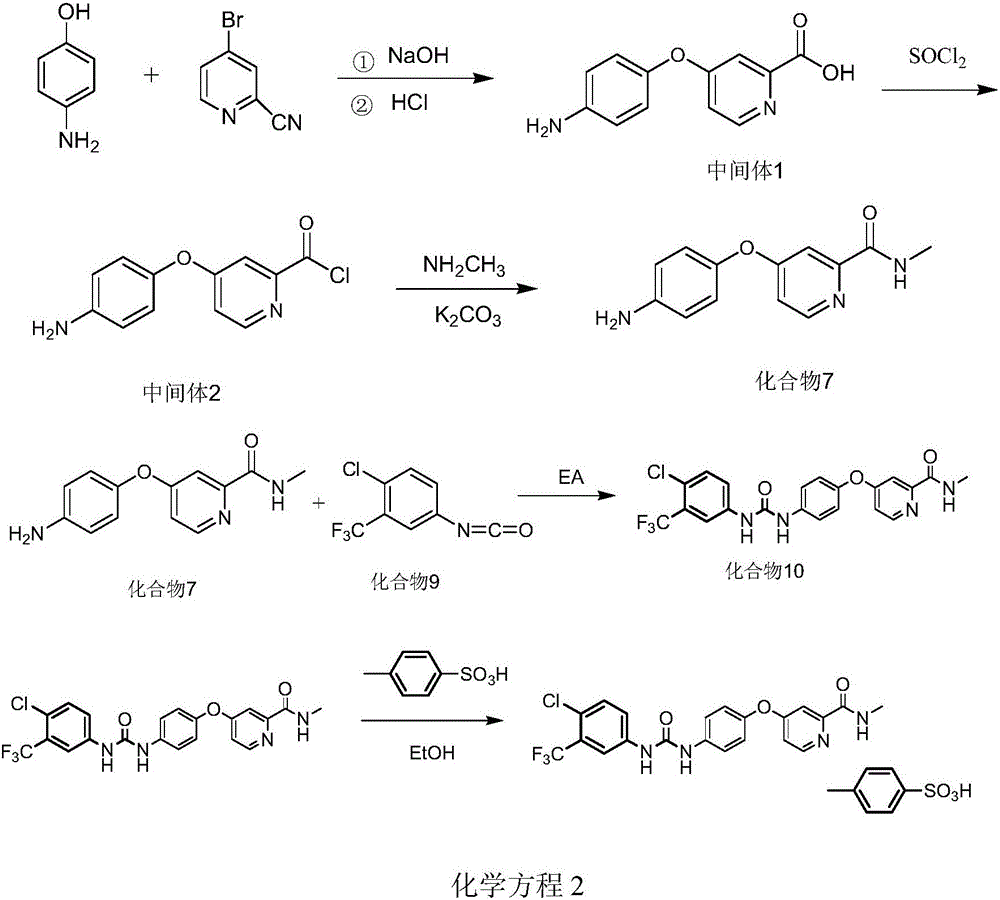

Method for preparing sorafenib tosylate

ActiveCN105801475AHigh yieldThe reaction steps are simpleOrganic chemistry methodsP-AminophenolP-Toluenesulfonic acid

The invention discloses a method for preparing sorafenib tosylate. The method comprises the following steps: reacting p-aminophenol with 4-bromo-2-cyanopyridine in the presence of sodium hydroxide, and then obtaining 4-(4-aminophenoxy)-2-(formic acid) pyridine after acidification; after carrying out a substitution reaction with thionyl chloride, reacting with methylamine in the presence of potassium carbonate to obtain 4-(4-aminophenoxy)-2-(methyl carbamyl) pyridine; after carrying out direct condensation with a 4-chlorine-3-(trifluoromethyl) phenyl isocyanate compound, salifying with p-toluenesulfonic acid to obtain sorafenib tosylate. The 4-bromo-2-cyanopyridine is used as a starting raw material to prepare the 4-(4-aminophenoxy)-2-(formic acid) pyridine, the steps of subsequent reaction are simplified, the steps of whole reaction are simple, and the yield of product is high.

Owner:JINAN LIMIN PHARMA

Deuterated bisarylurea compound and preparation method thereof, and application of compound in preparation of antitumor drug

ActiveCN105348186ATherapeuticHave kidney cancerOrganic chemistry methodsAntineoplastic agentsTreatment effectP-Aminophenol

The invention provides a deuterated bisarylurea compound and a preparation method thereof, and application of the compound in preparation of an antitumor drug. The compound has a structure as shown in a general formula (I). The preparation method comprises the following steps: with methyl 4-chloropyridine-2-formate as a raw material, sucjecting methyl 4-chloropyridine-2-formate and methylamine or deuterated methylamine to a substitution reaction; then subjecting a product obtained in the previous step to condensation with p-aminophenol or deuterated p-aminophenol; and reacting a product obtained in the previous step with 4-chloro-3-(trifluoromethyl)phenyl isocyanate or deuterated 4-chloro-3-(trifluoromethyl)phenyl isocyanate so as to prepare the deuterated bisarylurea compound. Experiment results show that the deuterated bisarylurea compound provided by the invention has tumor treatment effect. The invention also provides application of the compound to research and development of the antitumor drug.

Owner:MARINE BIOMEDICAL RES INST OF QINGDAO CO LTD

High-strength waterproof material for high-speed railways and preparation method thereof

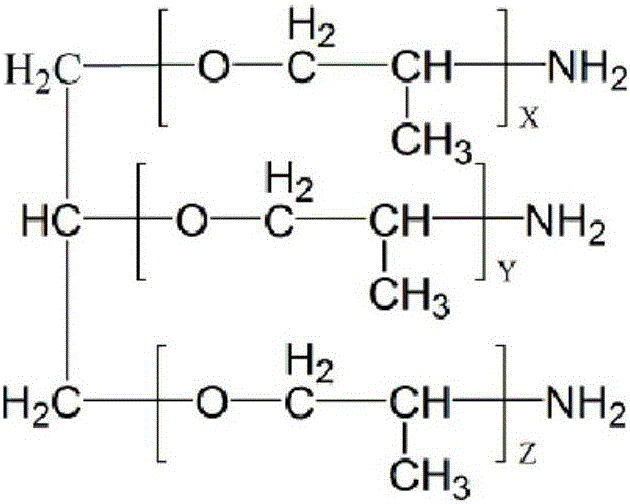

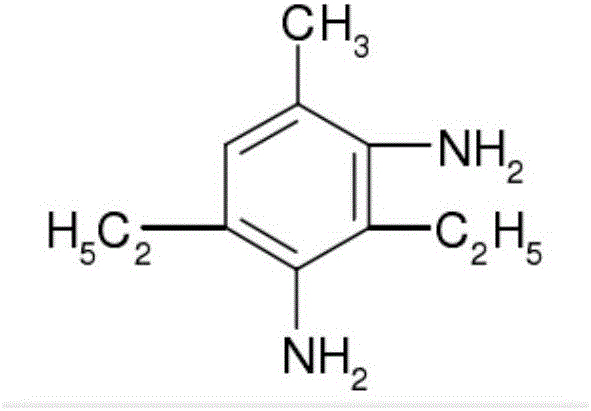

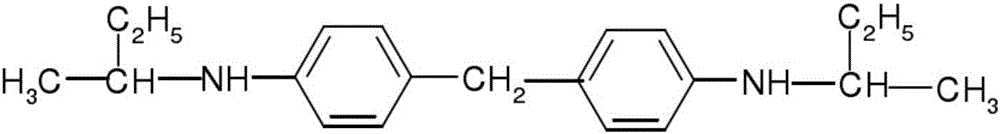

InactiveCN106118431AHigh strengthGood physical and mechanical propertiesFireproof paintsPolyurea/polyurethane coatingsTemperature resistanceMechanical property

The invention discloses a high-strength high-speed iron waterproof material and a preparation method thereof. The high-strength high-speed iron waterproof material includes component A and component B, and component A is prepared from the following raw materials in parts by weight: polyether polyol 95‑105 parts, 1‑10 parts of plasticizer, 10‑20 parts of bis(4‑isocyanatophenyl) methane, 3‑30 parts of graphene / methanesulfonic acid solution, 5‑50 parts of additives; component B It is prepared from the following raw materials in parts by weight: 50-80 parts of amino-terminated polyether, and 20-40 parts of amine chain extender. The present invention optimizes the type and amount of amino-terminated polyether and amine chain extender suitable for high-strength high-speed iron waterproof materials through reasonable proportioning, and has excellent physical and mechanical properties, temperature resistance, weather resistance, chemical medium resistance and Outstanding wear resistance, convenient construction and high efficiency.

Owner:上海基典防水科技有限公司

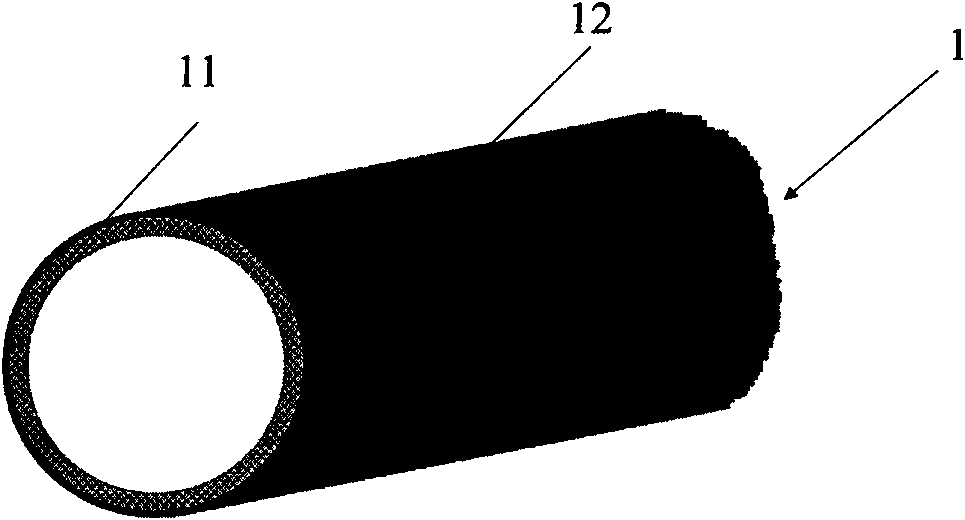

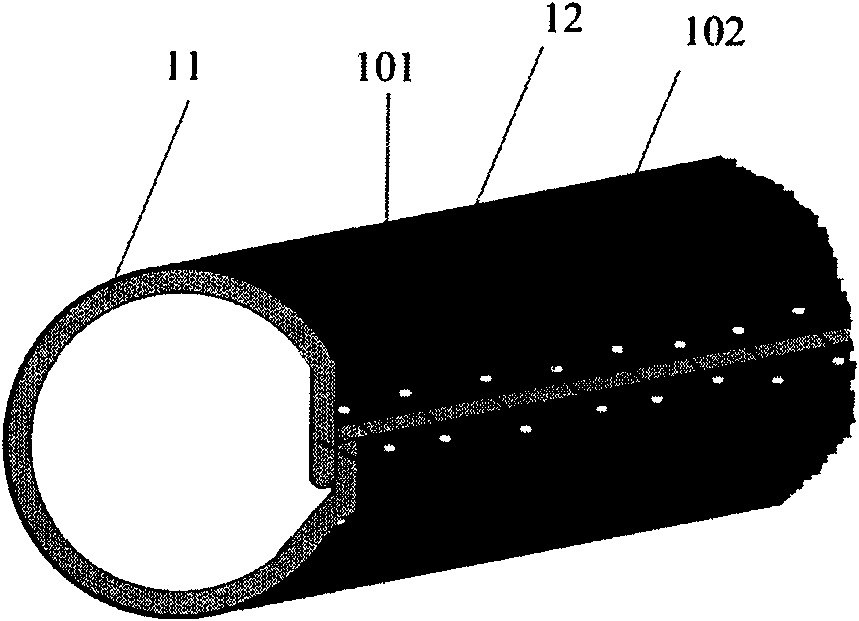

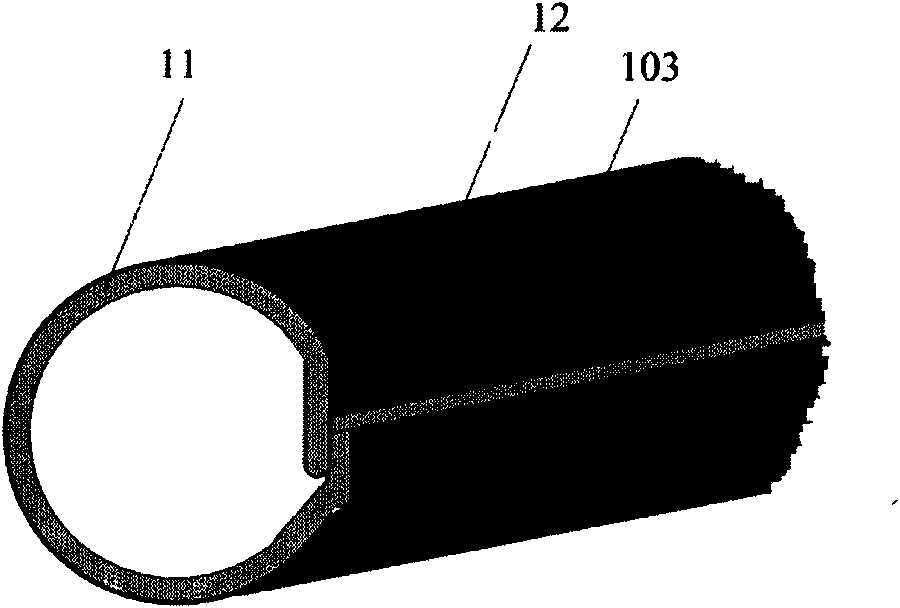

Lining material for repairing pipelines and manufacturing method thereof

InactiveCN101613954ASimple processSeamlessSynthetic resin layered productsPipe elementsEngineeringVolumetric Mass Density

The invention relates to a lining material for repairing pipelines and a manufacturing method thereof, the lining material comprises tubular textile base fabric and a coating layer on the outside surface of the base fabric. The lining material is characterized in that the tubular base fabric is an once forming integral tubular woven fabric, the warp yarn thereof is industrial zero twist or weak twist filament yarns with the number of 800-1200tex; the weft yarn thereof is zero twist or weak twist combined filament yarns of industrial polyester filament yarn (PFY) and polyester low stretch yarn, and the number of the combined weft yarn is 800-1200tex; the wrap density and the weft density are both 40-60 roots / 10cm; the coating layer adopts polyester polyurethane resin, comprising the following components by quality ratio: poly tetramethylene adipate diol: 1,4-butanediol: 4-phenyl isocyanate is 100:5-10: 60-80. The manufacturing method is applicable to the lining material of the invention and adopts the following processes: raw materials -> doubling -> rewinding -> weaving -> laminating -> products.

Owner:BEIJING TIANHUAN GAS

A composite foaming insulating material and a preparing method thereof

A composite foaming insulating material and a preparing method thereof are disclosed. The insulating material is prepared from following raw materials by weight: 90-380 parts of low-hydroxyl-value polyether polyol, 5-105 parts of high-hydroxyl-value polyether polyol, 1-5 parts of a surfactant, 20-200 parts of waste tyre rubber powder the particle size of which is 60-200 meshes, 40-176 parts of 4,4'-methylenebis(phenyl isocyanate) and 35-155 parts of a foaming agent. The insulating material is polyurethane flexible foam with good mechanical and insulating properties. Synthesis of the polyurethane flexible foam is free of catalysts, simple in method, easy to operate and low in cost. Experiments prove that the waste tyre rubber powder and a polyurethane material which are added are matched, a thermal insulating property of the polyurethane flexible foam is effectively enhanced, a heat conductivity coefficient of products is lower than 0.035 W / (m.K), and the volume density is less than 70 Kg / m3. The composite foaming insulating material is used for building walls and floors, and can play good roles of insulating and reducing noise.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of urea compound

The invention relates to a preparation method of a urea compound, belongs to the technical field of pharmacy and in particular relates to a preparation method of sorafenib. The preparation method comprises the following steps: forming a mixed solution by using 4-(4-aminophenoxy)-N-methyl-2-pyridinecarboxamide solids, a solvent and water; stirring, and then removing a water layer; and reacting with 4-chloro-3-trifluoromethyl-phenyl isocyanate to prepare a target product namely sorafenib. According to the preparation method, a reactant is mixed with water to remove alkali and avoid the generation of impurities, thereby obtaining a high-purity product; and the preparation method is simple to operate and easy to control, and is suitable for industrial production.

Owner:SUNSHINE LAKE PHARM CO LTD

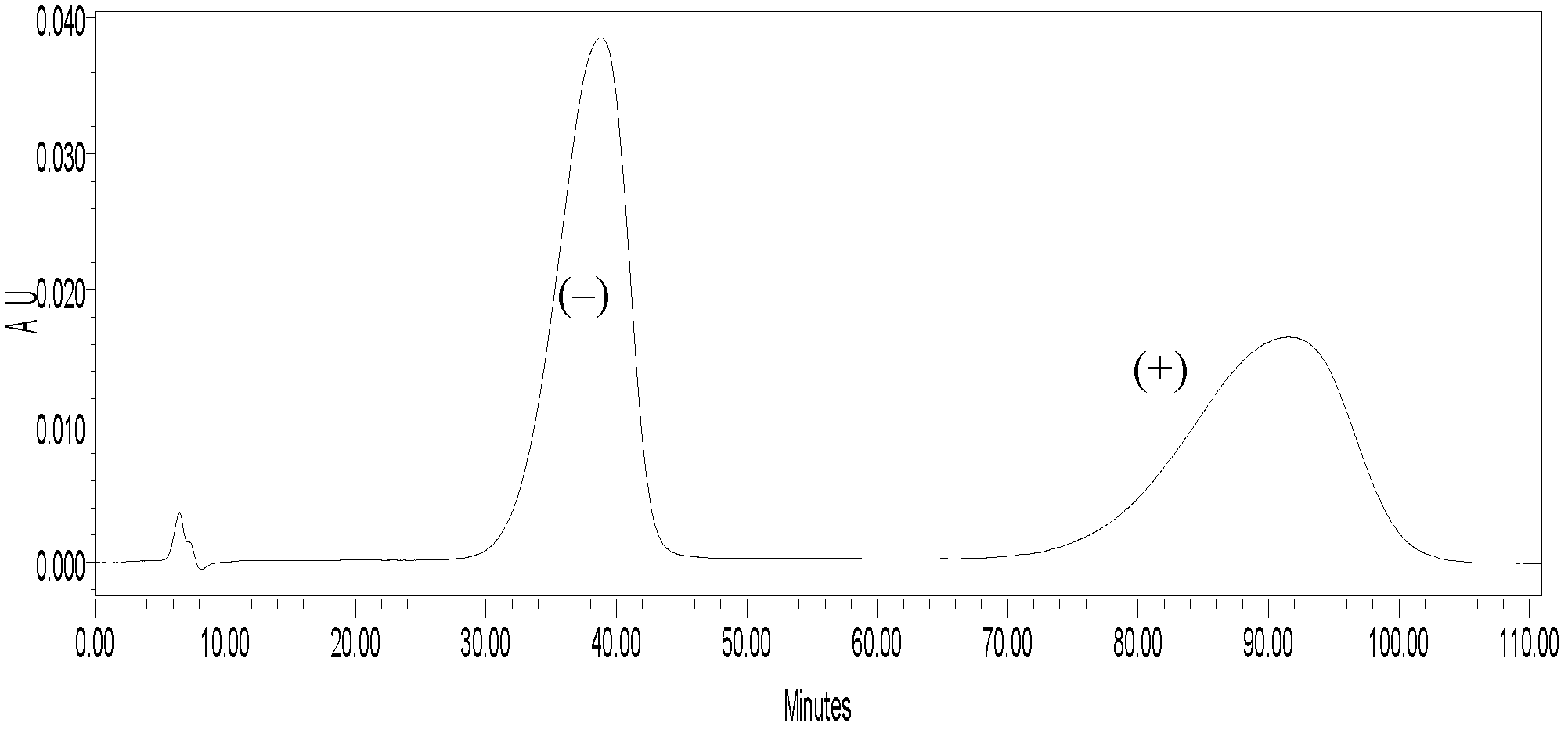

Hybridization chirality stationary phase based on cellulose derivative and preparation method thereof

ActiveCN102553550AHigh content of derivativesEasy to operateOther chemical processesChromatographic separationCross-link

The invention discloses a preparation method of a hybridization chirality stationary phase based on cellulose derivative, which cross-links non-replaced or replaced phenyl isocyanate cellulose derivative with silane coupling agents to prepare hybridization chirality silicon ball stationary phase in a sol-gel method and is simple in operation and easy to control. The prepared cellulose derivative of the hybridization chirality stationary phase is high in content, has good chirality resolution capability and mechanical strength, is good in solvent resistant property, has strong loading capability and is suitable for preparing chromatograph chairality stationary phase.

Owner:ZHEJIANG UNIV

Anti-skid natural rubber material for sneaker soles and preparation method thereof

InactiveCN109181025AReduce the free volume of molecular chainsSmall free volumeSolesRubber materialPolymer science

The invention belongs to the technical field of sneaker materials, and provides an anti-skid natural rubber material for sneaker soles and a preparation method thereof. The method comprises the following steps: modifying precipitated white carbon black filler with phenyl isocyanate, modifying graphene oxide filler with carboxy nitrile rubber, adding C5 petroleum resin into crude rubber of naturalrubber, and performing mixing, mill-running and vulcanizing to prepare the anti-skid natural rubber material. Compared with a traditional method, the anti-skid natural rubber material has the advantages that the inorganic filler has good dispersibility and cannot be easily agglomerated; the rubber material has relatively high dry friction coefficient and wet friction coefficient, the anti-skid performance is remarkably improved, and the abrasion resistance is improved to a certain extent, so that the anti-skid natural rubber material can be used as a sole material of high-grade sneakers.

Owner:蔡杰

Halogen-free environment-friendly polyurethane oil paint and preparation method thereof

ActiveCN104610525ASolve the problem of difficult flame retardantHigh oxygen indexFireproof paintsPolyurea/polyurethane coatingsHigh pressureSolvent

The invention discloses a preparation method of a halogen-free environment-friendly polyurethane oil paint. The preparation method comprises the following steps: performing refluxing catalytic hydrogenation reduction on a phosphatizing agent and a nitrobenzene derivative in an organic solvent with the presence of a metal catalyst to obtain a phosphatized aniline derivative, dropwise adding trichloromethyl chloroformate, mixing and stirring uniformly at room temperature, reacting continuously for 2-4 hours to obtain phosphatized phenyl isocyanate, stirring the phosphatized phenyl isocyanate and an alcoholic compound for 3 hours with the presence of a polymerization catalyst, adding an amine compound, stirring continuously for 2 hours, performing vacuum dewatering on a reaction mixture to obtain flame-retardant polyurethane resin, adding a curing agent and a solvent, and reacting to obtain the halogen-free environment-friendly polyurethane oil paint. The invention further discloses the halogen-free environment-friendly polyurethane oil paint. The halogen-free environment-friendly polyurethane oil paint is an expansive environment-friendly flame-retardant polyurethane oil paint with a phosphorous-nitrogen synergistic effect. In the production process of a flame retardant, raw materials are cheap and easily obtained; the preparation method is free of a high-heat and high-pressure process, and simple to operate, and energy consumption in the production process is low; the whole production process is saves energy and is environment-friendly.

Owner:安徽科赛富新材料科技有限公司

Method for preparing thidiazuron

ActiveCN101386601ALow priceEase of industrial productionPlant growth regulatorsOrganic chemistryButanoneThiadiazoles

The invention disclosed a method for preparing Thidiazuron. The method comprises the following steps: (1) adding a reactant of 5-amino-1, 2, 3-thiadiazole to a butanone solvent while stirring, keeping stirring the mixed solution until the 5-amino-1, 2, 3-thiadiazole is completely dissolved; (2) adding reactants of phenyl isocyanate and a triethylamine catalyst to the solution obtained in the step (1), so that the 5-amino-1, 2, 3-thiadiazole has catalytic synthesis reaction with the phenyl isocyanate, and then filtering the reactant after the reaction is complete to obtain a filter cake which is the Thidiazuron finished product. With the method, the yield of the Thidiazuron can be more than 92 percent and the purity can be more than 98 percent; besides, the used butanone solvent has low price and easy reclaiming, and is applicable to industrial production.

Owner:江苏省农用激素工程技术研究中心有限公司 +1

Polyamide film with electrochromism performance, and preparation method and application thereof

InactiveCN104844813AHas electrochromic propertiesImprove high temperature resistanceChemical recyclingTenebresent compositionsSolubilityOrganic solvent

The invention discloses a polyamide film with the electrochromism performance, and a preparation method and application thereof, relates to the polyamide film, and the preparation method and the application thereof, and aims to solve the problems of low solubility of polyamide in an organic solvent, difficulty in film forming and low heat stability in the prior art. The structural formula of the polyamide film with the electrochromism performance is shown as follows. The preparation method comprises the following steps: 1, synthesizing an N,N'-di(alpha-naphthyl)-N,N'-di(4-phenyl isocyanate) biphenyl monomer; 2, performing polymerization reaction; 3, performing curing and film-forming to obtain the polyamide film with the electrochromism performance. According to the invention, the polyamide film with the electrochromism performance can be obtained.

Owner:HEILONGJIANG UNIV

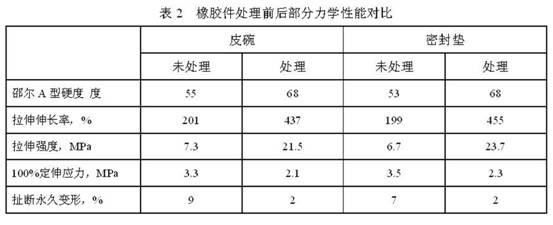

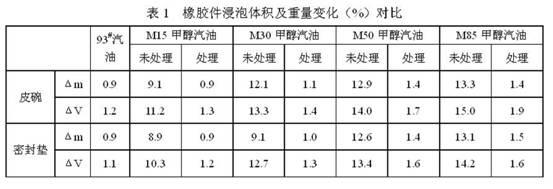

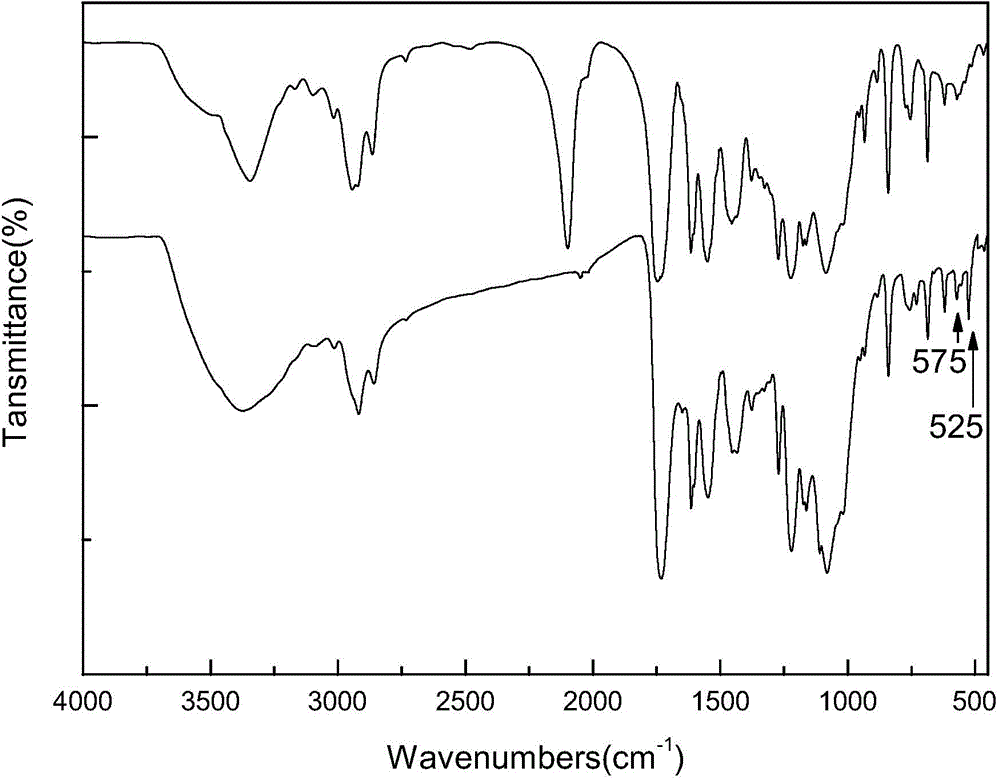

Rubber swelling inhibitor

ActiveCN102492501ADecreased ability to absorb methanolImprove stabilityLiquid carbonaceous fuelsFuel additivesMorpholinePhosphate

The invention relates to a rubber swelling inhibitor, which is used for inhibiting the swelling of the ordinary rubber and solves the technical problem of the swelling of rubber pieces of an automobile oil supply system, which is caused by methanol gasoline. The rubber swelling inhibitor is prepared from the following raw materials in part by weight: 4 to 18 parts of 2,6-dimethyl morpholine, 6 to 21 parts of tris(2-chloroethyl) phosphate, 0 to 5 parts of N-ethyl morpholine, 6 to 26 parts of dicumyl peroxide, 3 to 21 parts of 2,4,6-trichloro-phenyl isocyanate, 10 to 40 parts of No.120 solvent gasoline, 3 to 12 parts of sodium dibutyl dithiocarbamate, 2 to 9 parts of bis(N,N-diamyl dithiocarbamate)zinc, 5 to 11 parts of stearic acid, 8 to 23 parts of bis(2-ethylhexyl) phthalate, 7 to 17 parts of hexyl alcohol and 0 to 7 parts of butyl acetate. The rubber swelling inhibitor is appropriate in cost, and easy to produce, can inhibit the swelling of the ordinary rubber by the methanol gasoline effectively, and also has a certain corrosion-inhibiting and protective effect on metal parts of an engine. In addition, pollution discharge of tail gas of vehicles is reduced, and the discharge of major pollutants is far below the national standard.

Owner:CRPC INNOVATION ENERGY

Hybrid phenol-formaldehyde and isocyanate based resins

InactiveCN1455720APolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesCardboardPhenol

Hybrid resins formed of an acylated phenol-formaldehyde (PF) resin and a polymeric phenyl isocyanate (pMDI) resin have extended shelf stability, yet cure at a rate faster than any of its components when used in conventional flakeboard, strandboard or other board making processes.

Owner:BAYER AG +1

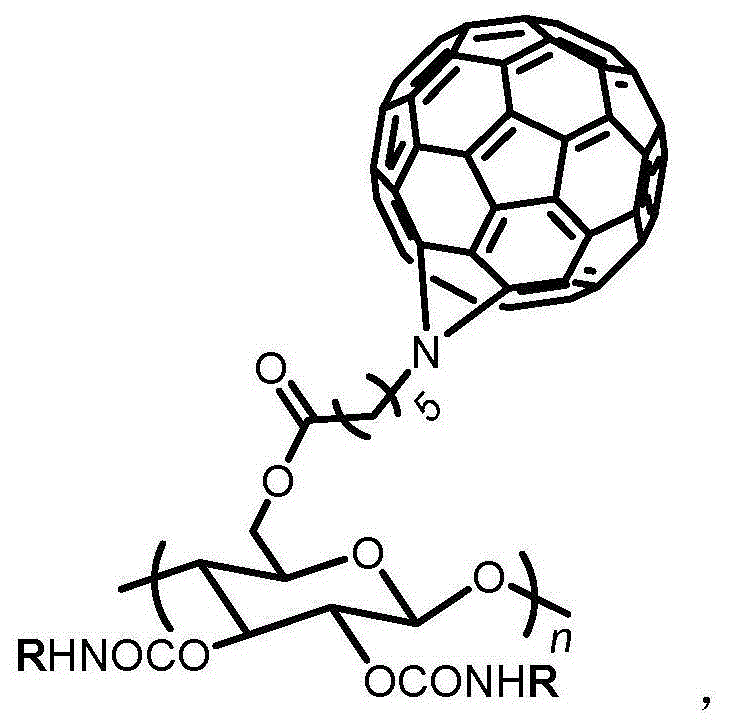

Fullerene cellulose derivative used as chiral stationary phase material and preparation method of fullerene cellulose derivative

The invention relates to a fullerene cellulose derivative used as a chiral stationary phase material and a preparation method of the fullerene cellulose derivative and belongs to the technical field of organic polymer materials. A nonpolar solvent is required by using an existing cellulose derivative as the chiral stationary phase material. The preparation method provided by the invention is characterized by comprising the following steps: bonding a triphenylchloromethane protective group to 6-hydroxyl of cellulose; derivatizing 2, 3-hydroxyls of cellulose by virtue of one of 3, 5-dimethyl phenyl isocyanate, 3, 5-dichlorophenyl isocyanate and phenyl isocyanate; removing the triphenylchloromethane protective group by using hydrochloric acid; replacing the 6-hydroxyl of cellulose by using 6-bromohexanoic acid through esterification reaction; carrying out nucleophilic substitution on sodium azide and 6-bromine; and carrying out addition reaction on fullerene and azido to obtain the fullerene cellulose derivative used as the chiral stationary phase material. The structural formula of the derivative is shown in the description.

Owner:CHANGCHUN UNIV OF SCI & TECH

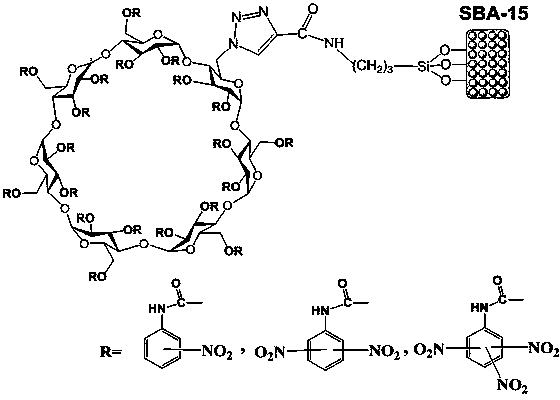

Preparation method of nitrophenylcarbamate full-derived beta-cyclodextrin bonded ordered mesoporous SBA-15 chiral stationary phase

InactiveCN103881107AHigh bonding capacitySimple methodOther chemical processesBond orderN dimethylformamide

The invention relates to a preparation method of a bonded SBA-15 silica gel chiral stationary phase. The preparation method comprises the major steps of firstly, preparing an azido-containing beta-cyclodextrin ligand from beta-cyclodextrin in an anhydrous solvent, secondly, preparing alkynyl-containing bonded ordered mesoporous SBA-15 silica gel from 3-aminopropyltriethoxysiloxane and propynoic acid, thirdly, bonding the azido-containing beta-cyclodextrin to the surface of the SBA-15 silica gel by virtue of a click reaction by taking anhydrous N,N-dimethylformamide as a solvent and CuI(PPh3) as a catalyst, and fourthly, modifying the product of the third step by using a nitro-containing phenyl isocyanate with anhydrous N,N-dimethylformamide as a solvent, and reacting to obtain the nitrophenylcarbamate full-derived beta-cyclodextrin bonded SBA-15 silica gel chiral stationary phase. The preparation method is simple and convenient, low in cost and wide in applicability.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com