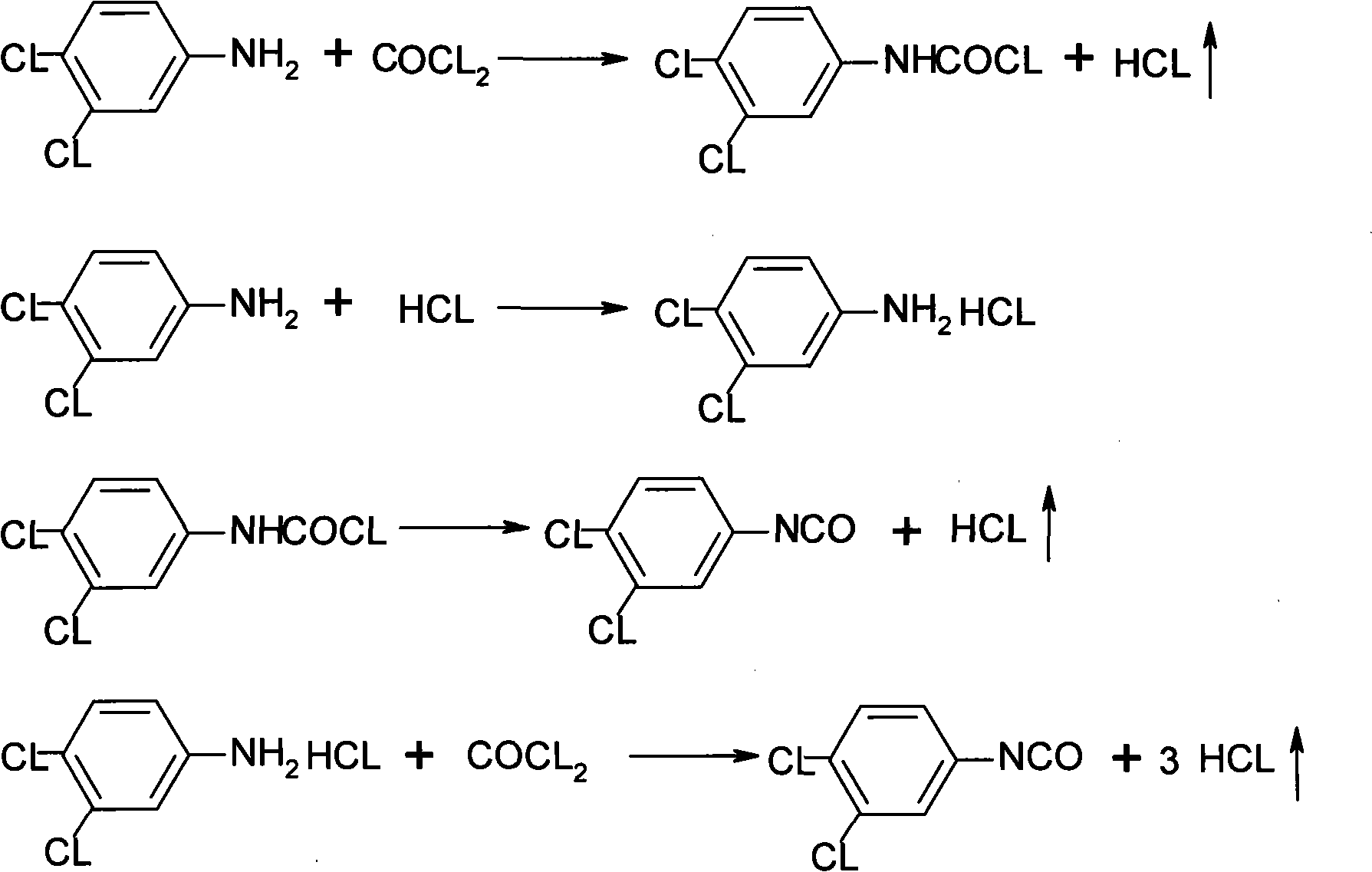

Preparation for 3, 4-dichloro phenyl isocyanate

A technology of phenyl dichloroisocyanate and dichloroaniline, applied in 3 fields, can solve problems such as low product content and low yield, and achieve the effects of reducing side reactions, reducing the occurrence of side reactions, and providing product conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In a 500L dissolution kettle, add 100 kg of xylene and 50 kg of 3,4-dichloroaniline, start stirring, open the steam valve, slowly raise the temperature to 40°C, and then stir for 30 minutes to 1 hour until the solid 3,4- After the dichloroaniline is completely dissolved, it is pumped into the high-level metering tank. In a 500L reaction kettle, add 215 kg of xylene and lower the temperature at the same time. Pass 10 kg of phosgene through the phosgene introduction tube. When the temperature drops to -5°C, start to add 3,4-dichloroaniline solution dropwise for 2 hours. After dripping, stir for another 1.5 hours, raise the temperature to 130°C at a heating rate of 20°C / hour, then add phosgene until the material is in a clear and transparent state, stop passing through the phosgene, drive the phosgene with nitrogen for 1 hour, and rectify to obtain the pure product 56.6 kg, the product purity is 98.5%, based on 3,4-dichloroaniline, the total yield of 3,4-dichloroisocyanate...

Embodiment 2

[0033] In a 500L dissolution kettle, add 110 kg of chlorinated benzene and 55 kg of 3,4-dichloroaniline, start stirring, open the steam valve, slowly raise the temperature to 50°C, and stir for another 30 minutes to 1 hour, until the solid 3,4 - After the dichloroaniline is completely dissolved, pour it into the high metering tank. In the 500L reaction kettle, add 240 kg of chlorinated benzene, and at the same time lower the temperature, pass 10 kg of phosgene through the phosgene introduction tube, and when the temperature drops to -5 °C, start to drop 3,4-dichloroaniline solution, 1.8 After hours of dripping, stir for another 1.5 hours, raise the temperature to 125°C at a heating rate of 20°C / hour, then add phosgene until the material is clear and transparent, stop passing through the phosgene, drive the phosgene with nitrogen for 1 hour, and rectify to obtain the pure product 62.3 kg, the product purity is 98.7%, based on 3,4-dichloroaniline, the total yield of 3,4-dichloro...

Embodiment 3

[0035] In a 500L dissolution kettle, add 120 kg of o-dichlorobenzene and 60 kg of 3,4-dichloroaniline, start stirring, open the steam valve, slowly raise the temperature to 55°C, and then stir for 30 minutes to 1 hour until the solid is 3, After 4-dichloroaniline is completely dissolved, put it into the high-level metering tank. In a 500L reaction kettle, add 250 kg of o-dichlorobenzene, while lowering the temperature, pass 12 kg of phosgene through the phosgene introduction tube, and when the temperature drops to 0°C, start to add 3,4-dichloroaniline solution dropwise, 1.6 After hours of dripping, stir for another 1.5 hours, raise the temperature to 135°C at a heating rate of 20°C / hour, then add phosgene until the material is in a clear and transparent state, stop passing through the phosgene, drive the phosgene with nitrogen for 1 hour, and rectify to obtain the pure product 68.6 kg, the product purity is 98.7%, based on 3,4-dichloroaniline, the total yield of 3,4-dichlorois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com