High-strength waterproof material for high-speed railways and preparation method thereof

A waterproof material and high-strength technology, applied in fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem that the bonding strength is difficult to meet the design requirements, the infiltration and spreading process is short, and the adhesion of the lower cladding material is weakened. Requirements and other issues to achieve excellent physical and mechanical properties, outstanding chemical resistance, excellent tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] High-strength high-speed iron waterproof material, the mass ratio of component A and component B is 1:1. A component raw materials (parts by weight): 100 parts of polyether DL-2000D, 5 parts of dioctyl phthalate, 14 parts of bis(4-isocyanate phenyl) methane, 10 parts of graphene / methanesulfonic acid solution, 6 parts of triphenyl phosphate. Component B raw materials (parts by weight): 66 parts of amino-terminated polyether, 30 parts of amine chain extender.

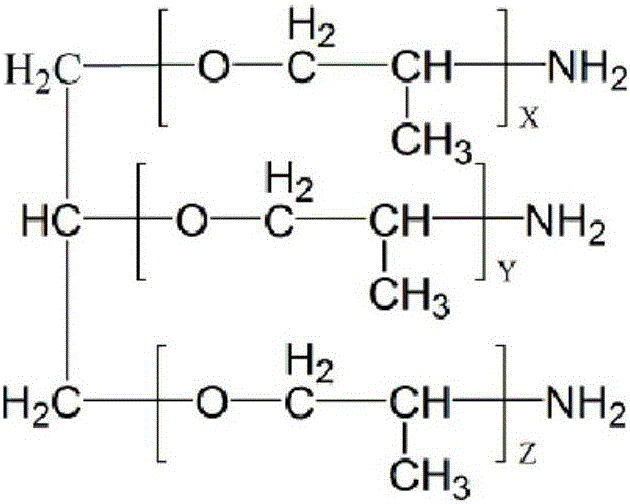

[0047] The amino-terminated polyether is obtained by uniformly mixing amino-terminated polyether T5000, amino-terminated polyether T3000 and amino-terminated polyether T403 in a mass ratio of 1:1:1.

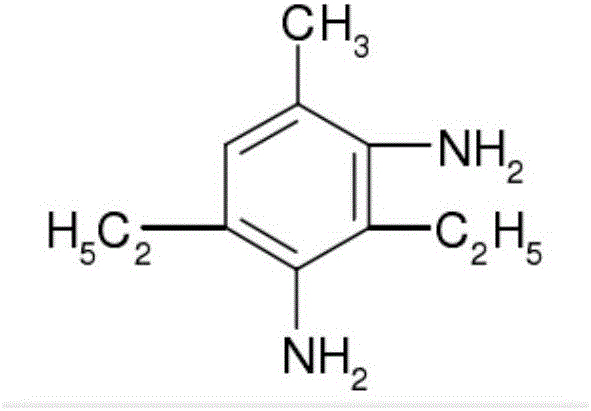

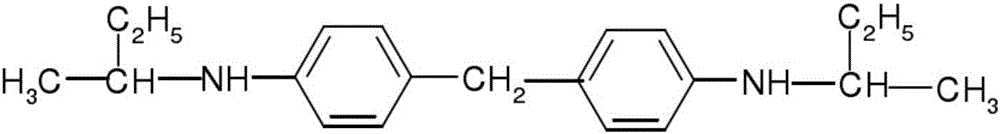

[0048] The amine chain extender consists of 3,5-diethyl-2,4-toluenediamine, 4,4′-bis-sec-butylaminodiphenylmethane, 3,5-dimethylthio-2,4 Toluenediamine is obtained by stirring and mixing uniformly according to the mass ratio of 1:1:1.

[0049] Preparation of high-strength high-speed iron waterproof material:

[00...

Embodiment 2

[0054] It is basically the same as Example 1, except that the amino-terminated polyether is obtained by stirring and mixing the amino-terminated polyether T3000 and the amino-terminated polyether T403 at a mass ratio of 1:1. . Obtain the high-strength high-speed iron waterproof material of embodiment 2.

Embodiment 3

[0056] It is basically the same as Example 1, except that the amino-terminated polyether is obtained by stirring and mixing the amino-terminated polyether T5000 and the amino-terminated polyether T403 at a mass ratio of 1:1. . Obtain the high-strength high-speed iron waterproof material of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com