Polyurethane patching material used for settlement repairing of ballastless track structure for high-speed railway

A ballastless track and repair material technology, applied in the field of polyurethane foam, can solve the problems of heavy equipment weight, uncontrollable line shape, and difficult construction on the track, and achieve high dimensional stability, fast strength development speed, and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

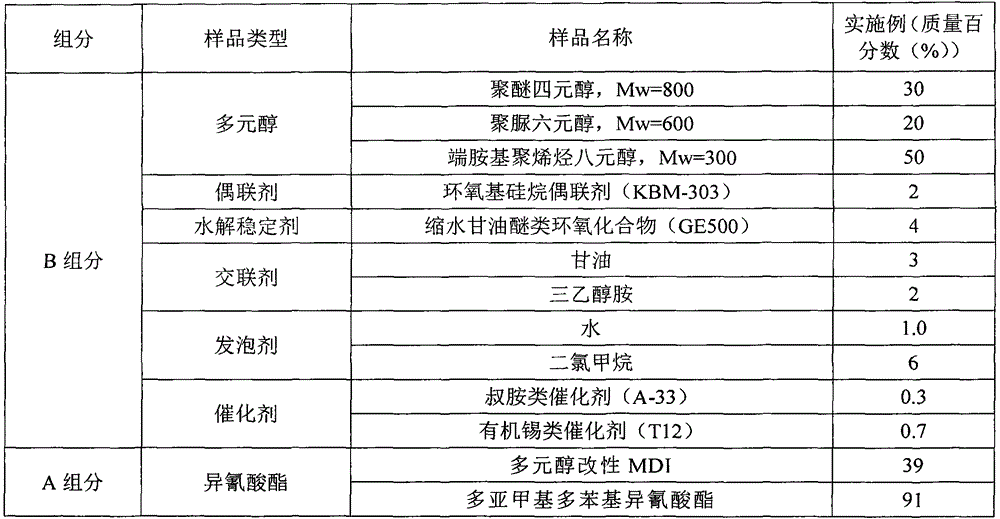

[0022] Specific embodiment 1 is as shown in table 1.

[0023] Table 1 Specific embodiment 1

[0024]

[0025] Note: Mw in the table represents the average molecular weight of the compound.

[0026] Use a high-pressure foaming agent to mix components A and B through high-pressure collision and inject them into a steel round mold with a cover on the top and the cover can move upward freely. The amount of polyurethane slurry injected is 1 / 4 of the volume of the round mold, with a cover The round mold is placed between the upper and lower pressure plates of the electronic universal testing machine, and the electronic universal testing machine is used to test the expansion force of the material after grouting. In the anti-fatigue performance test, the maximum load is 0.3MPa, the minimum load is 0.03MPa, and the loading frequency is 5HZ. Use a vernier caliper to measure the thickness of the sample before and after loading, and calculate the accumulated residual deformation after...

specific Embodiment 2

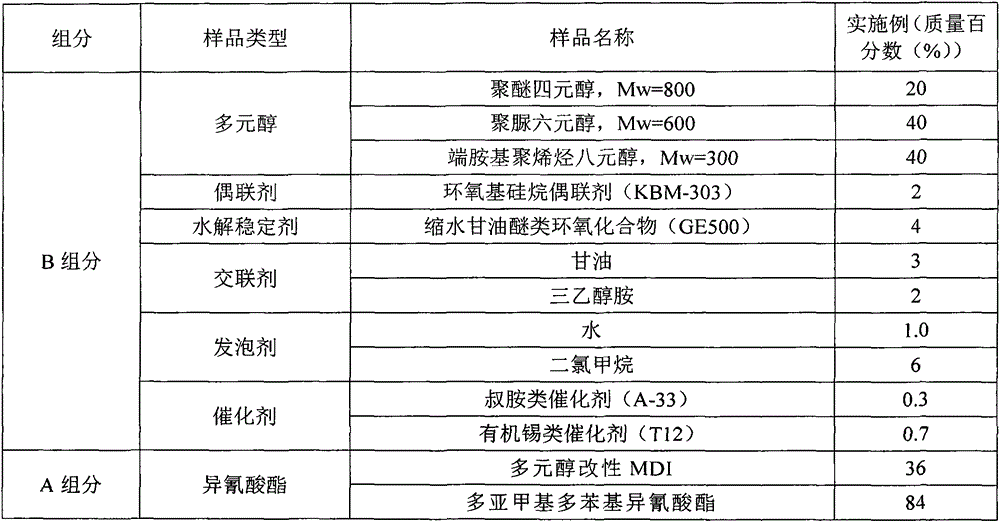

[0030] Specific embodiment 2 is as shown in table 3.

[0031] Table 3 Specific embodiment 2

[0032]

[0033] Note: Mw in the table represents the average molecular weight of the compound.

[0034] Specific embodiment 2 test method is identical with the test method of embodiment 1, and implementation effect is shown in Table 4.

[0035] Table 4 The performance of the polyurethane repair material produced according to specific embodiment 2

[0036] serial number

specific Embodiment 3

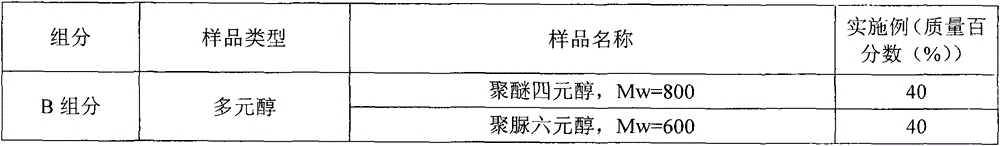

[0038] Specific embodiment 3 is as shown in table 5.

[0039] Table 5 Specific embodiment 3

[0040]

[0041]

[0042] Note: Mw in the table represents the average molecular weight of the compound.

[0043] Test method is identical with the test method of embodiment 1, and implementation effect is shown in Table 6.

[0044] Table 6 is according to the performance of the polyurethane repairing material that concrete embodiment 3 produces

[0045] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com