Patents

Literature

41results about How to "Meet the needs of the job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

No-co ferrous alloy powder composition for sealing face of nuclear power valve

InactiveCN101797643AMeet the needs of the jobExtended service lifeMetallic material coating processesNuclear powerSulfur

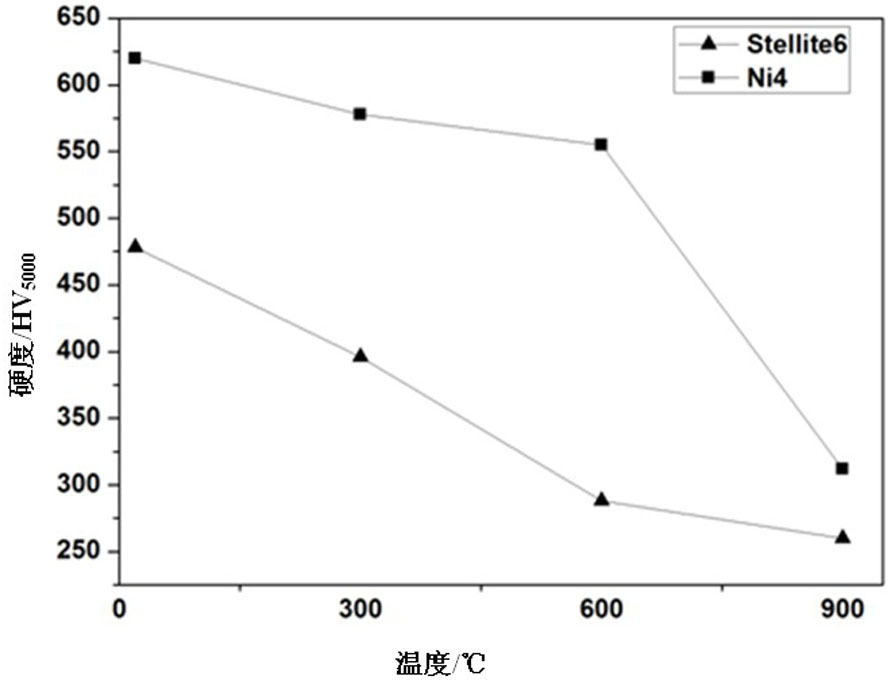

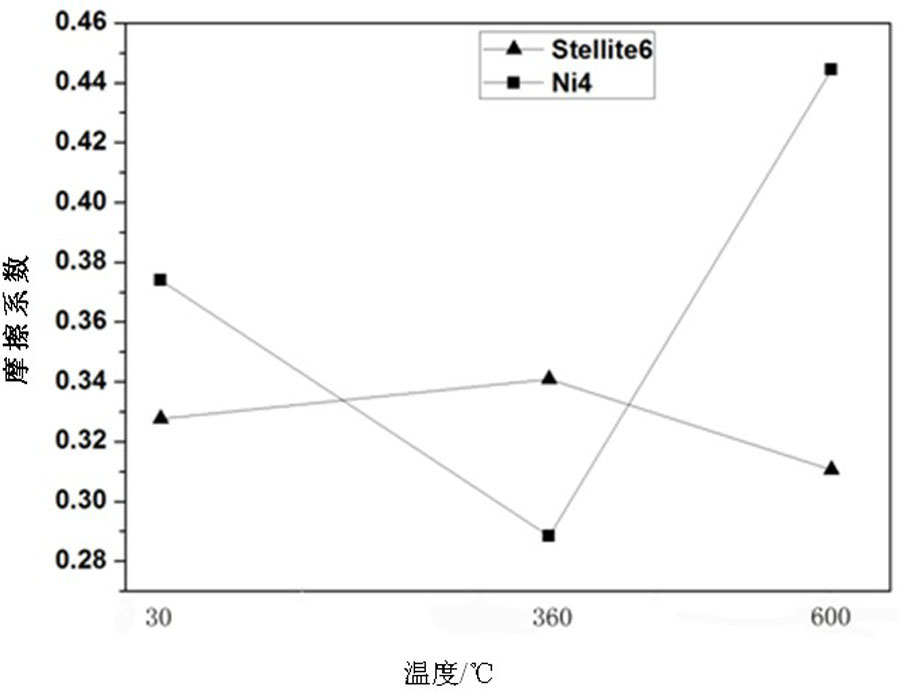

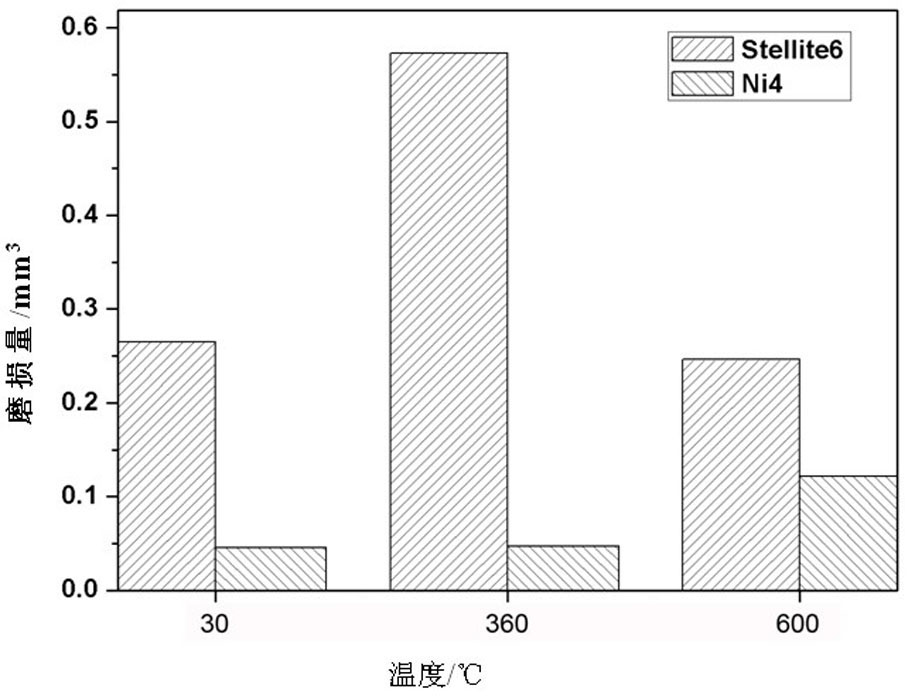

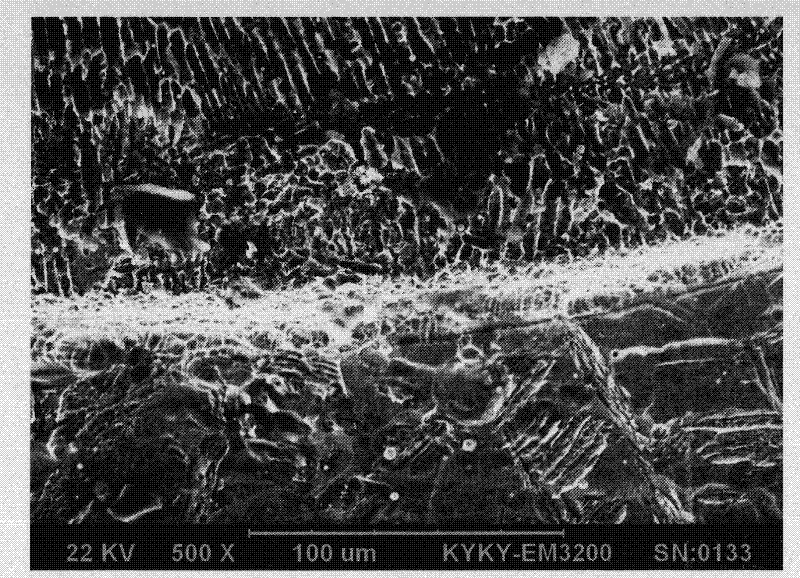

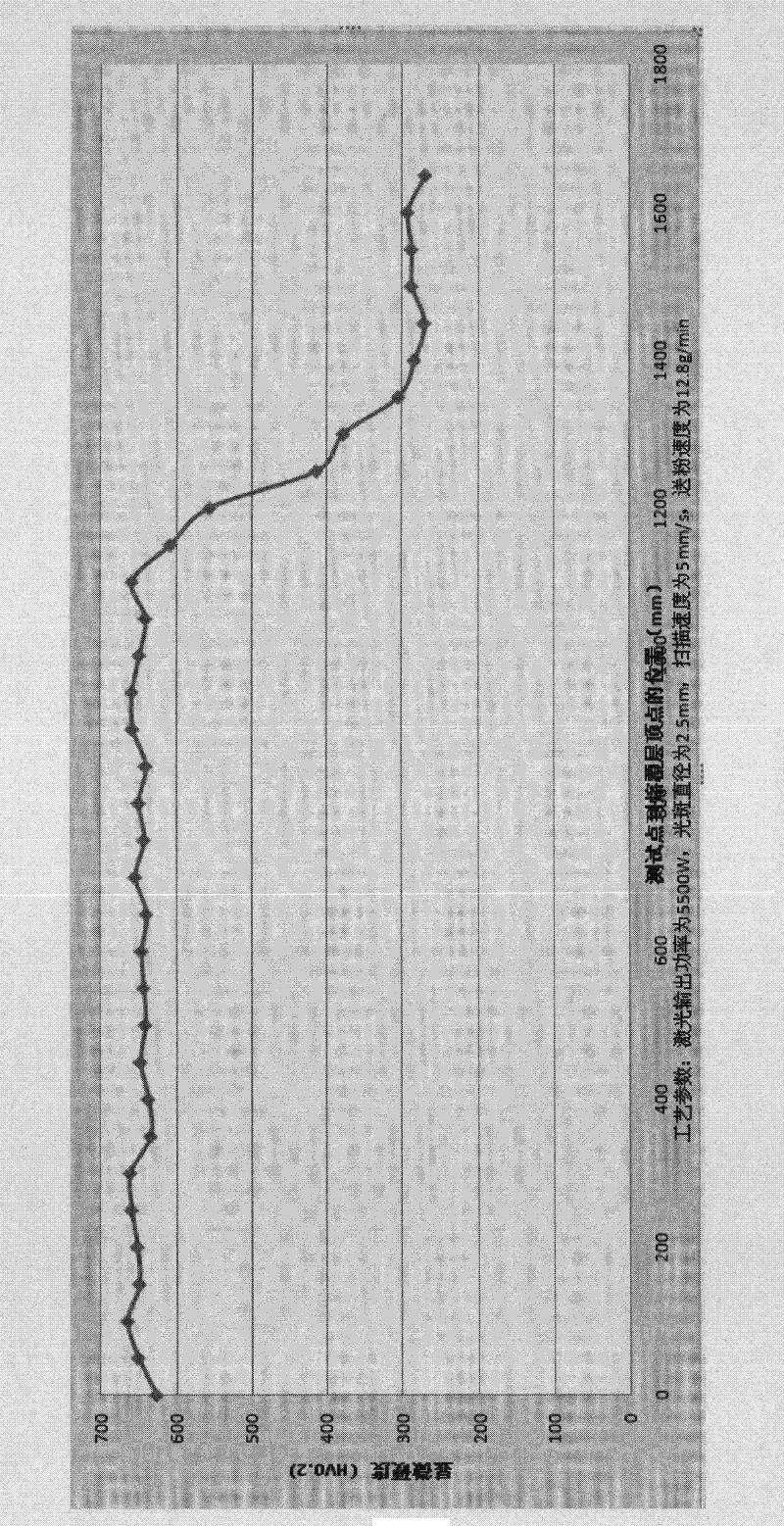

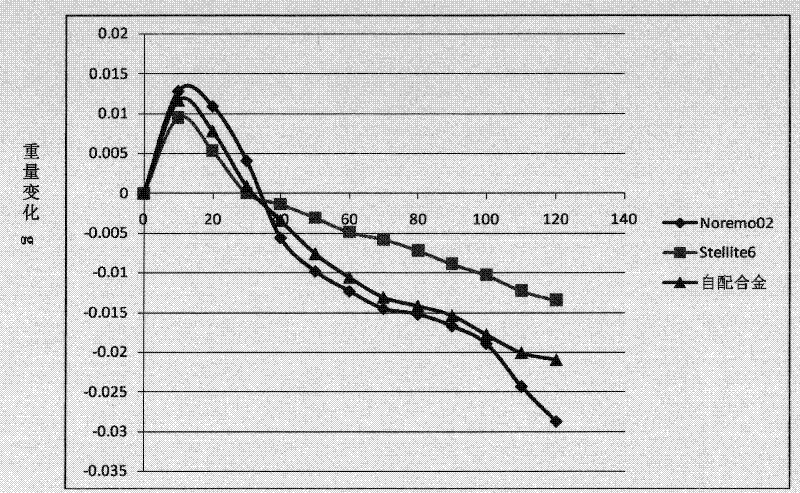

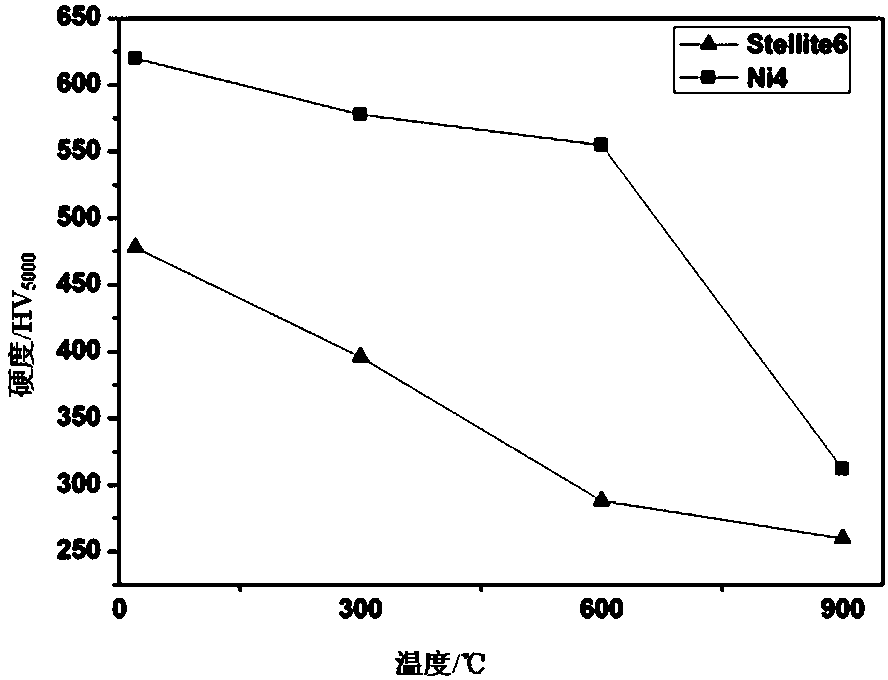

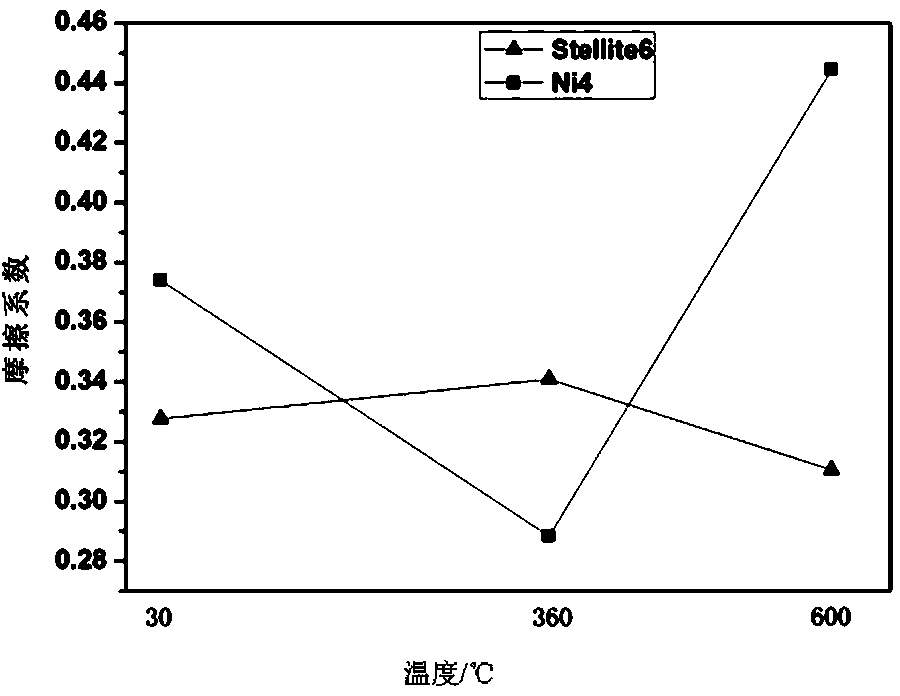

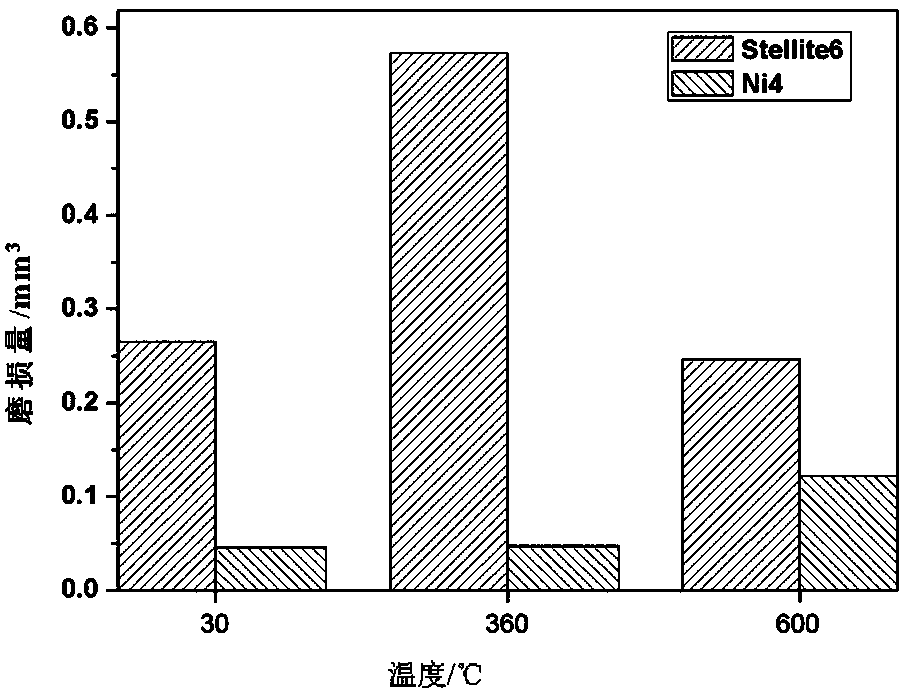

The invention belongs to the field of alloy material, relating to no-co ferrous alloy, in particular to no-co ferrous alloy for enhancing material of the sealing face of a nuclear power valve. The no-co ferrous alloy powder composition contains the following ingredients by weight percent: 20.5%-21.5% of Cr, 3.0%-3.5% of Ni, 3.0%-3.5% of Mn, 2.0%-2.5% of Si, 0.9%-1.0% of C, 1.5%-2.0% of Mo, 0.7%-1.2% of W, 0.3%-0.5% of V, P is less than or equal to 0.02%, S is less than or equal to 0.02%, 0.5%-1.0% of Y and the balance of Fe. The no-co ferrous alloy powder composition contains no noble metal of Co, at the same time, since laser cladding technology is adopted to prepare the coating, the microhardness of the cladding layer is 1.6-1.8 times of that the stainless steel matrix. The no-co ferrous alloy powder composition has excellent high-temperature abrasion performance and high-temperature corrosion resistance, so the no-co ferrous alloy powder composition can prolong the service life of the valve.

Owner:SUZHOU UNIV

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

Cobalt-free nickel-based alloy

InactiveCN101838758AReduce usageAvoid CoMetallic material coating processesLaser beam welding apparatusAlloy coatingCobalt

The invention discloses cobalt-free nickel-based alloy powder. The cobalt-free nickel-based alloy powder comprises the following components in percentage by weight: 1.0 to 1.2 percent of carbon (C), 24.0 to 28.0 percent of chromium (Cr), 4.0 to 6.0 percent of wolfram (W), 2.4 to 2.8 percent of silicon (Si), 6.0 to 10.0 percent of aluminum (Al), 4.0 to 6.0 percent of molybdenum (Mo), 0.8 to 1.0 percent of boron, 1.0 to 5.0 percent of yittrium oxide (Y2O3) and the balance of nickel (Ni). The alloy coating prepared by combining the formula of the cobalt-free nickel-based alloy powder with the laser cladding process has a compact structure and no defects, can be well and metallurgically combined with a nuclear valve substrate and has high wear resistance at a high temperature, so that the cobalt-free nickel-based alloy powder is particularly suitable for a nuclear valve sealing face and meets the requirements of the valve working in a nuclear environment.

Owner:SUZHOU UNIV +1

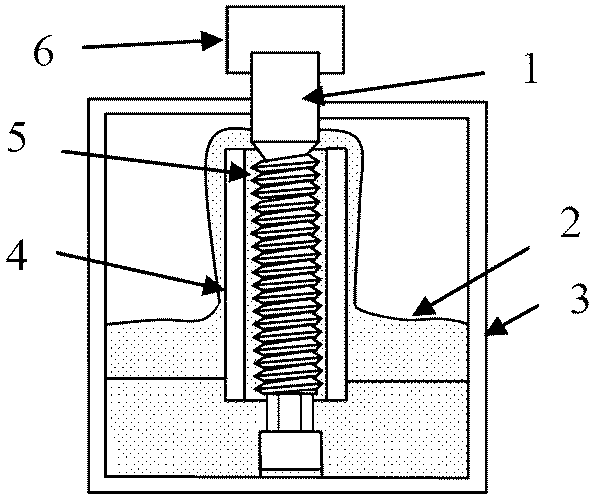

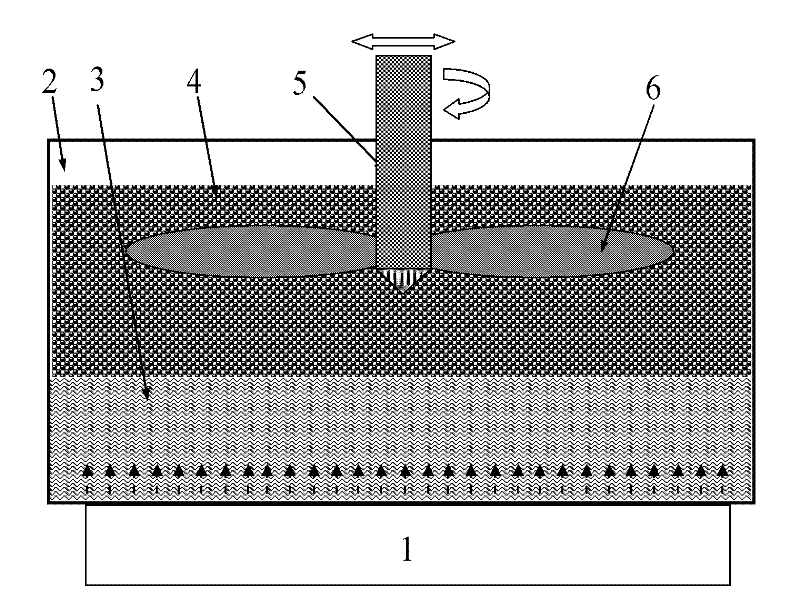

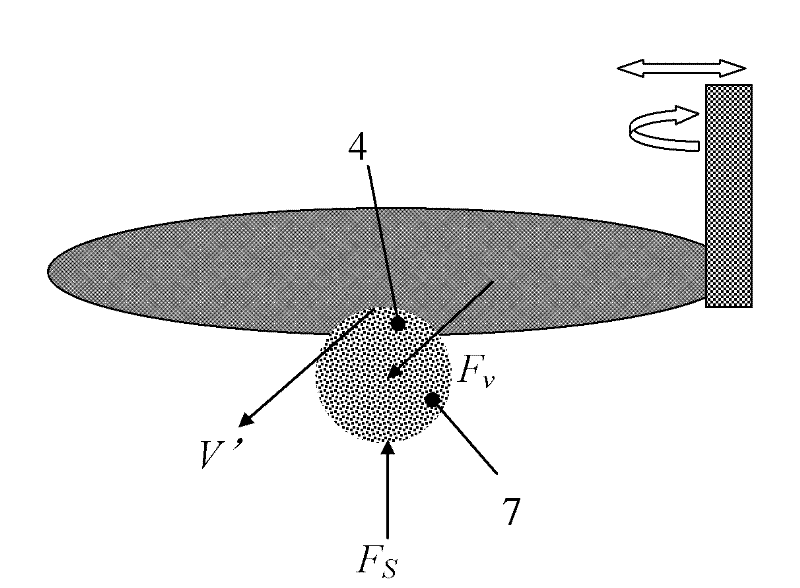

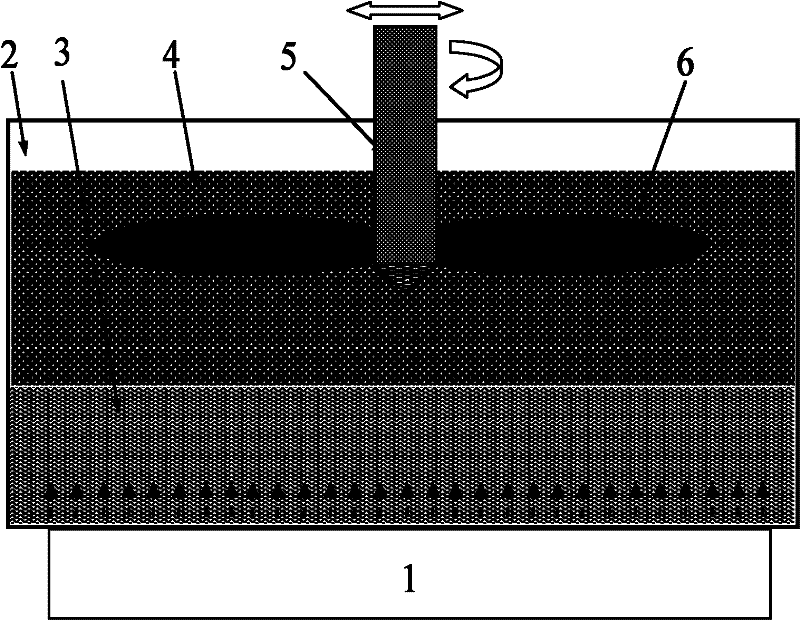

Precise high-efficiency polishing method and device for curved surface parts

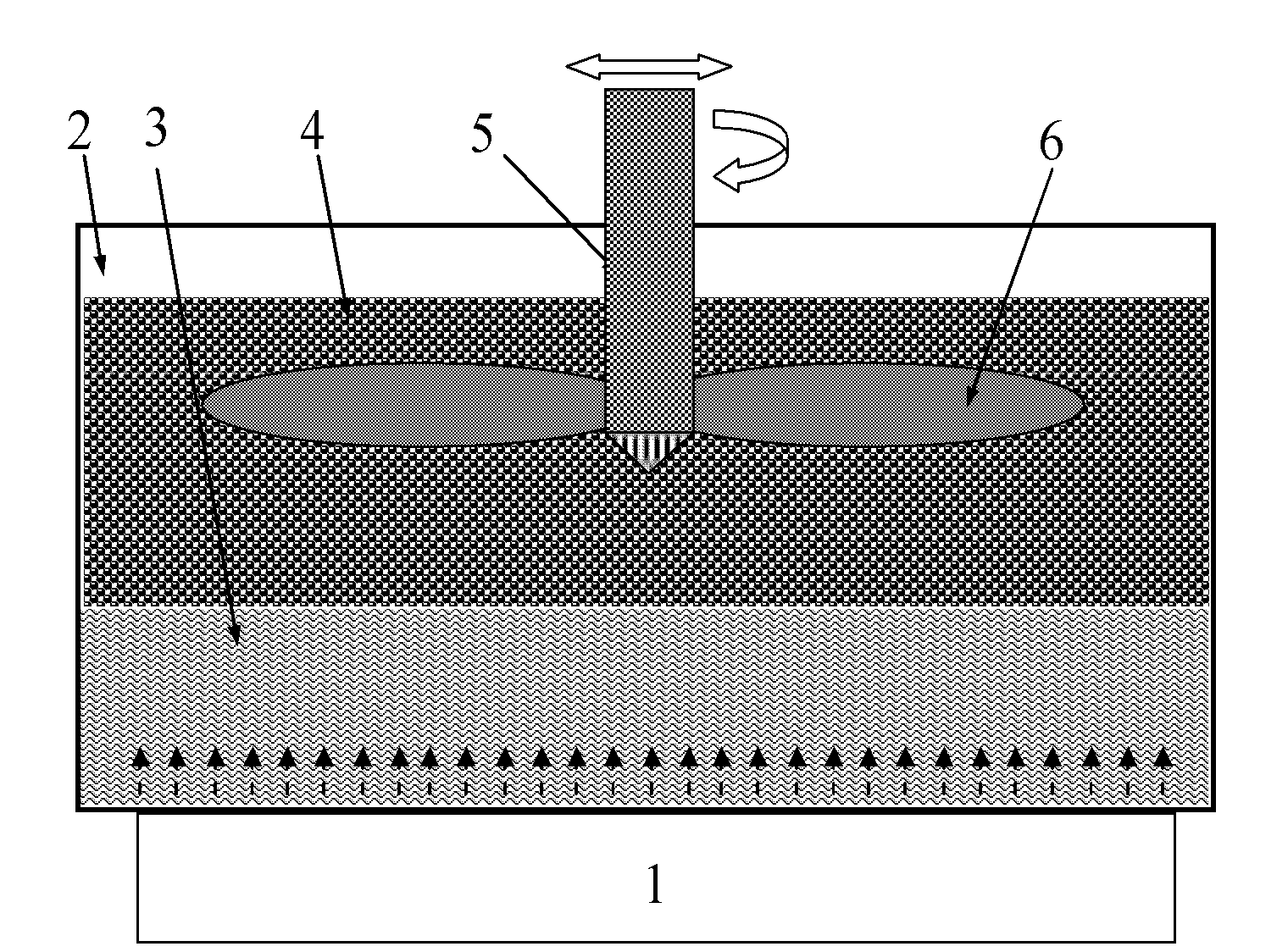

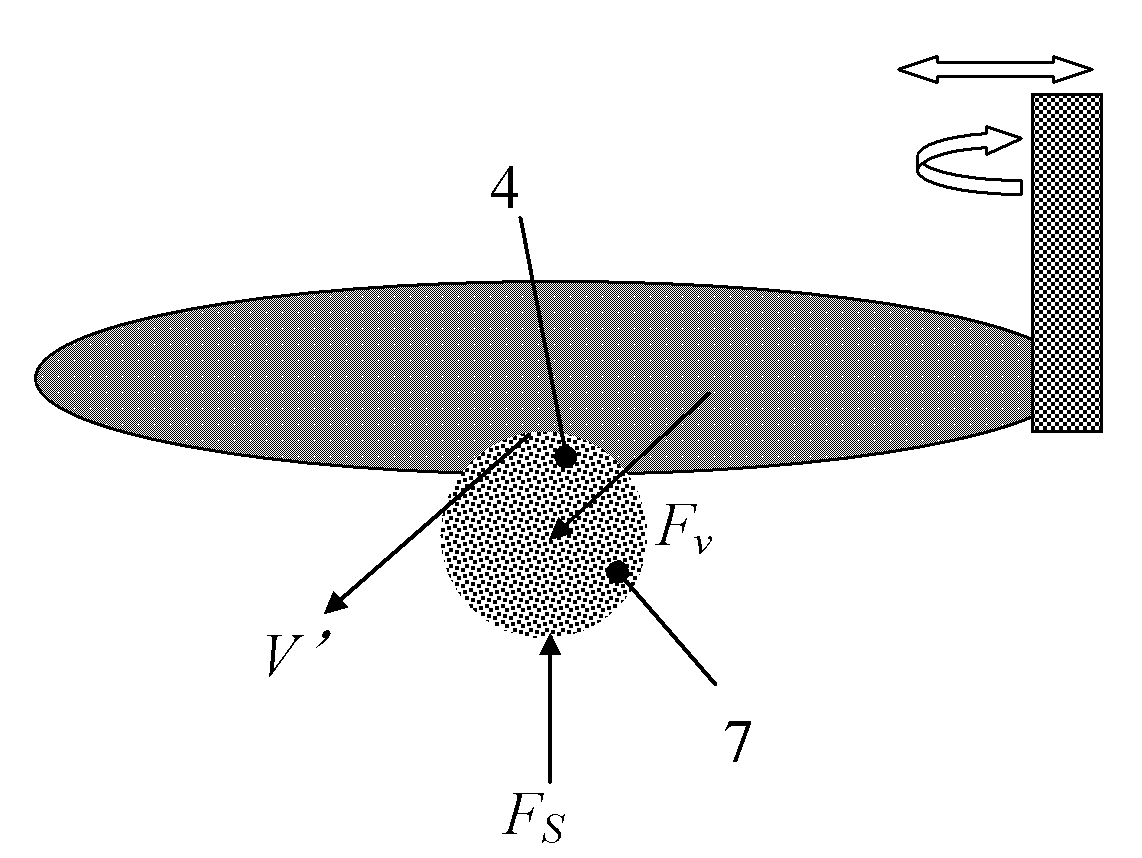

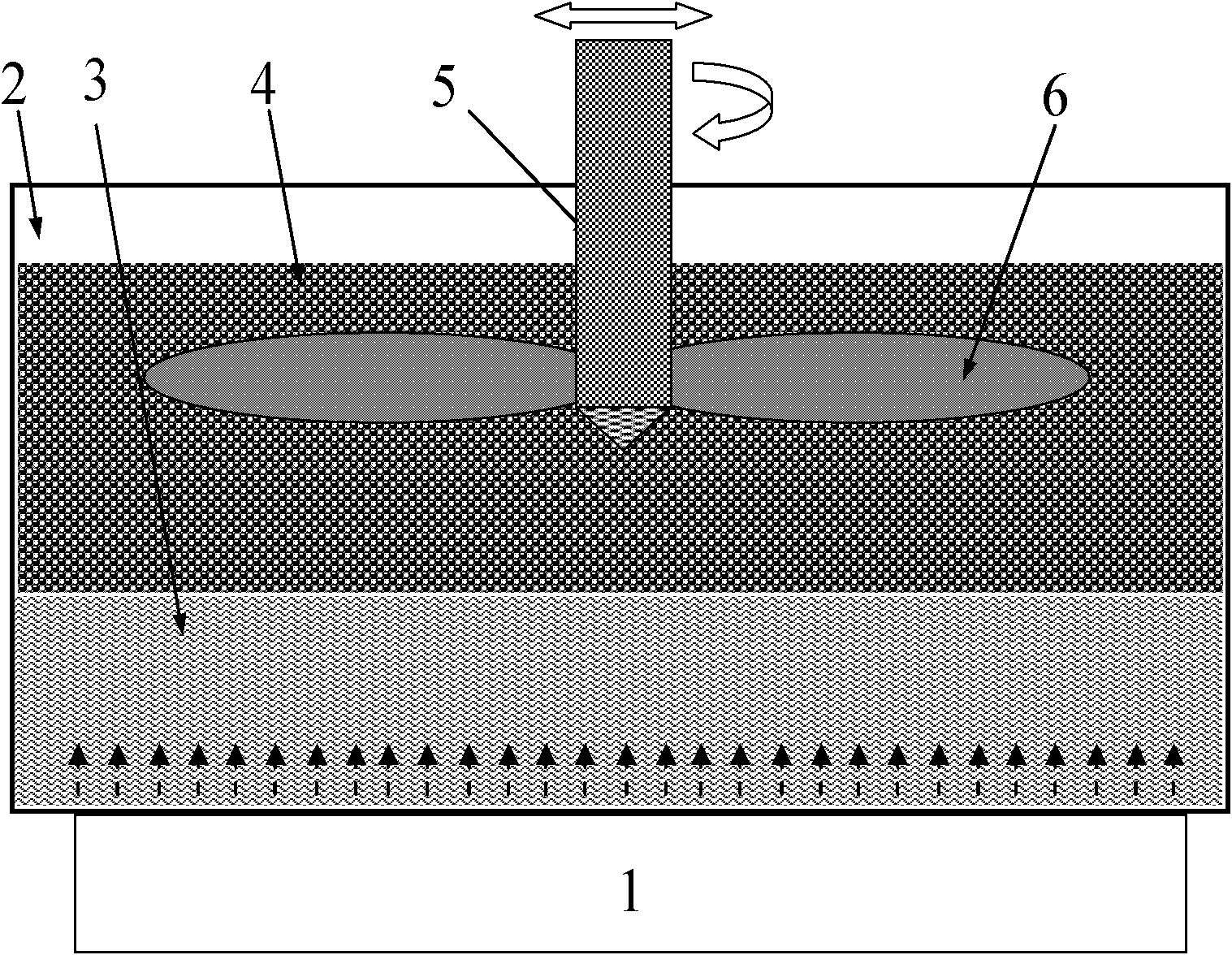

The invention discloses a precise high-efficiency polishing method and a precise high-efficiency polishing device for curved surface parts. The method comprises the following steps of: making numerous porous microspheres adsorbed with abrasive grains suspended in polishing solution; arranging a workpiece to be polished on a workpiece clamping device, immersing the workpiece to be polished in the polishing solution in a polishing tank, and rotating the workpiece clamping device to drive the workpiece to be polished to move under the action of a driving force; and starting an ultrasonic generator positioned at the bottom of the polishing solution and polishing the workpiece to be polished under the combined action of an ultrasonic exciting acting force and a viscous force of the polishing solution. The precise high-efficiency polishing device for the curved surface parts is characterized in that: the polishing solution is accommodated in the polishing tank; the porous microspheres are adsorbed with the abrasive grains; the upper part of the polishing tank is provided with the rotatable clamping device for clamping the workpiece to be polished; and the bottom of the polishing tank is provided with the ultrasonic generator. The processing accuracy and processing efficiency are high by adopting the method and the device; and the method and the device have the advantages of simple structure of processing equipment and low cost.

Owner:吴寿麟

Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

InactiveCN102534606AMeet the needs of the jobGood high temperature performanceMetallic material coating processesPowder mixtureNuclear power

The invention discloses a nickel-base alloy coating for a sealing surface of a nuclear power valve, and is characterized in that the nickel-base alloy coating is prepared according to a method of conducting laser-cladding on nickel-base alloy powder. The nickel-base alloy powder comprises the following constituents by weight percent: 20.0 to 24.0 percent of Cr, 4.0 to 4.2 percent of Si, 3.0 to 3.5 percent of P, 3.0 to 3.2 percent of Mo, 8.0 to 8.5 percent of Fe, 1.0 to 1.2 percent of C, 0.8 to 1.0 percent of yttrium oxide, and Ni in balancing amount. The laser-cladding process adopts a synchronous powder feeding method and a pre-coating method. The nickel-base alloy powder mixture contains no noble metal Co, thereby particularly meeting requirements on valves under nuclear environments; and due to the formulation design of the mixture, and the advantage of the laser-cladding technology in coating preparing, the coating on the sealing surface has a favorable high-temperature property.

Owner:SUZHOU UNIV

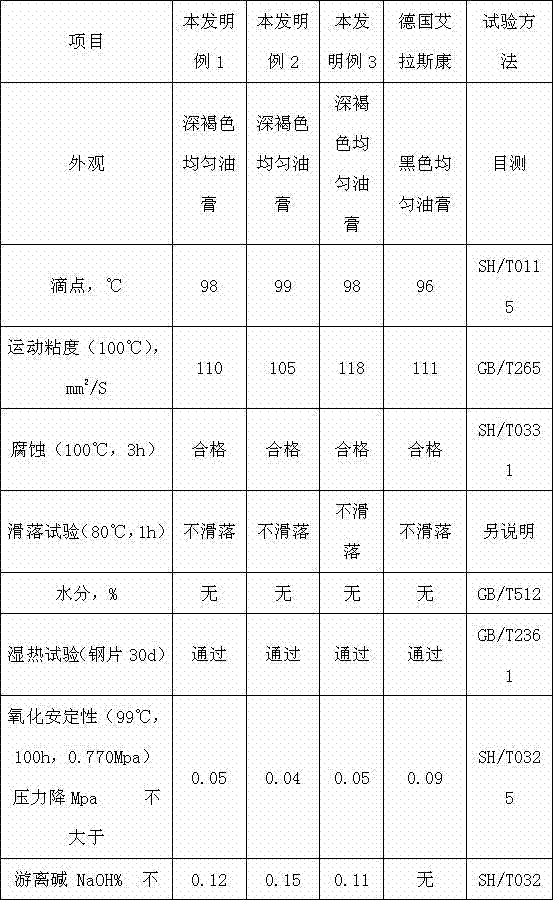

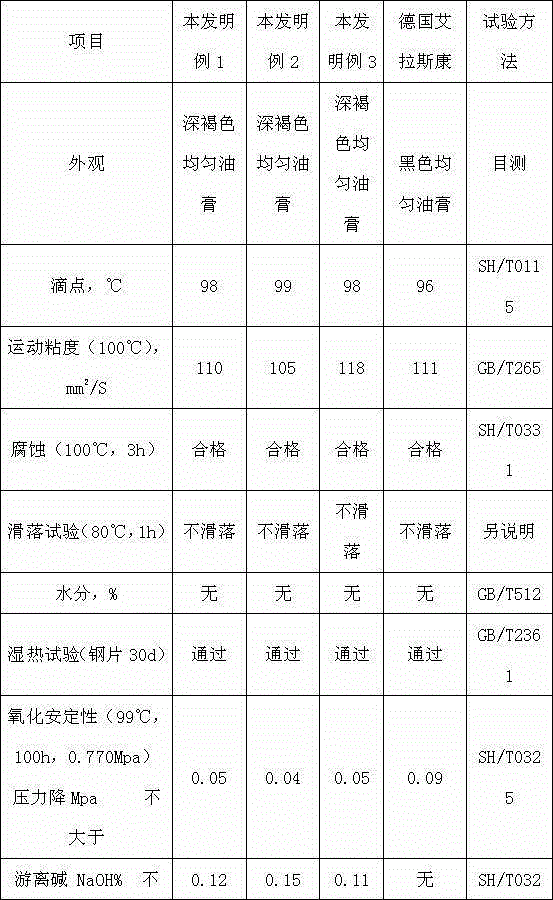

Anti-oxidant and wear-resistant surface protection grease for steel wire ropes

The invention relates to anti-oxidant and wear-resistant surface protection grease for steel wire ropes. The surface protection grease consists of the following components in percentage by weight: 12-16 percent of palm wax, 17-20 percent of Duroc slack wax, 17-21 percent of naphthenic base extract oil, 22-26 percent of paraffin base high-viscosity oil, 2-5 percent of zinc dialkyl dithiophosphate, 1-4 percent of diphenylamine, 6-10 percent of polyisobutene, 7-11 percent of ethylene-propylene copolymer and 0.1-1 percent of calcium sulfonate. Compared with the prior art, the surface protection grease has the advantages of high dropping point, no softening or drain on hot weather, quick coagulation during coating, no waste of raw materials, no pollution on the operation environment (including use), high moving viscosity, high adhesion to the surfaces of steel ropes, and avoidance of the phenomenon of falling in a strong shocking state at a high temperature during operation. The more outstanding characteristic is that the neutral and weakly acid states of the conventional final products (including imported Elaskon) are turned into a weakly alkaline (NaOH is not more than 0.15 percent) state in which metals can pass a corrosion test. As the formation of acid substances can be neutralized effectively, SH / T0325 oxidation stability test and SH / T0332 corrosion test are passed excellently, the service lives of steel wire ropes are prolonged, and the production, storage and use environments are purified.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

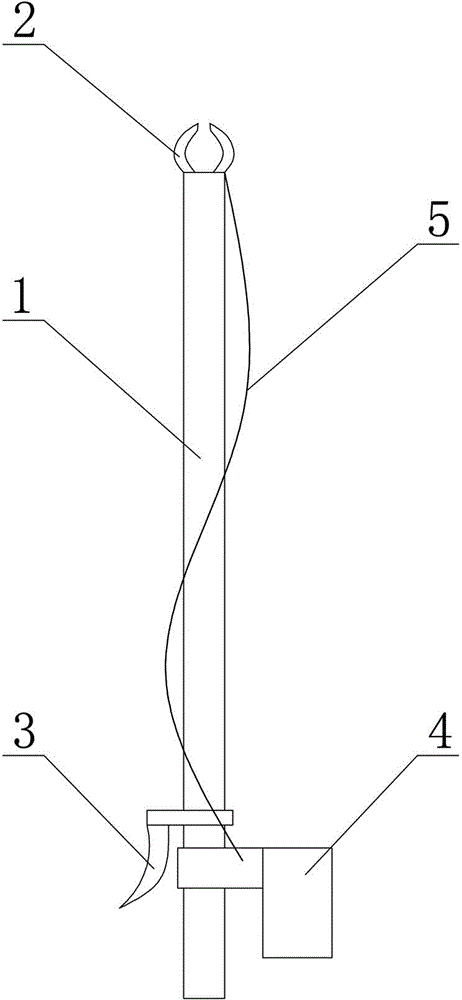

Method and device for carrying out polishing through flowing of viscoelasticity abrasive materials with spiral complex curved surfaces

InactiveCN104029109AReduce consumptionEasy maintenance and operationEdge grinding machinesPolishing machinesMechanical equipmentEngineering

The invention provides a method and device for carrying out polishing through flowing of viscoelasticity abrasive materials with spiral complex curved surfaces and belongs to the field of mechanical equipment. The device comprises a machined screw rod, the abrasive materials, a sealing box, a fixing die, a gap and a screw rod drive device. One end of the machined screw rod is connected with the screw rod drive device, the other end of the machined screw rod is immersed into the abrasive materials, the screw rod drive device is installed on the upper portion of the sealing box, the fixing die is installed in the sealing box through a supporting rod, the abrasive materials are the viscoelasticity abrasive materials, and the fixing die is a tubular hollow die. When the screw rod drive device drives the machined screw rod to rotate at a high speed, the abrasive materials move upwards along the spiral surfaces; meanwhile, under restraining of the fixing die, the abrasive materials extrude the surface of the screw rod, polish the surface of the screw rod, and flow back to the sealing box after reaching the top end of the fixing die, so that polishing of a circulating type is achieved; according to the method and the device, the screw rod can be polished efficiently with high quality and uniformity.

Owner:ZHEJIANG OCEAN UNIV

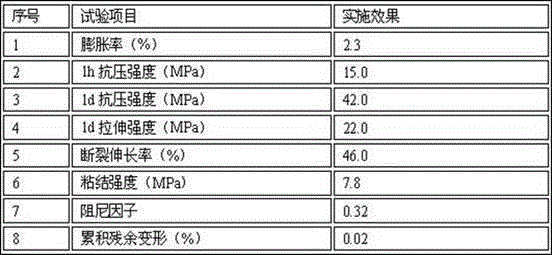

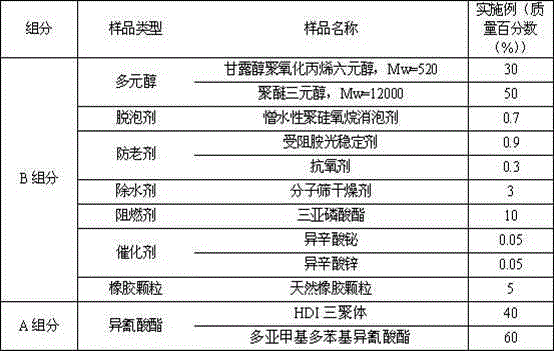

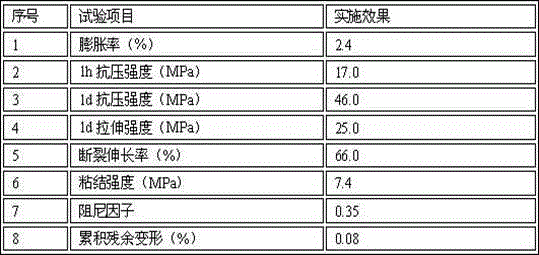

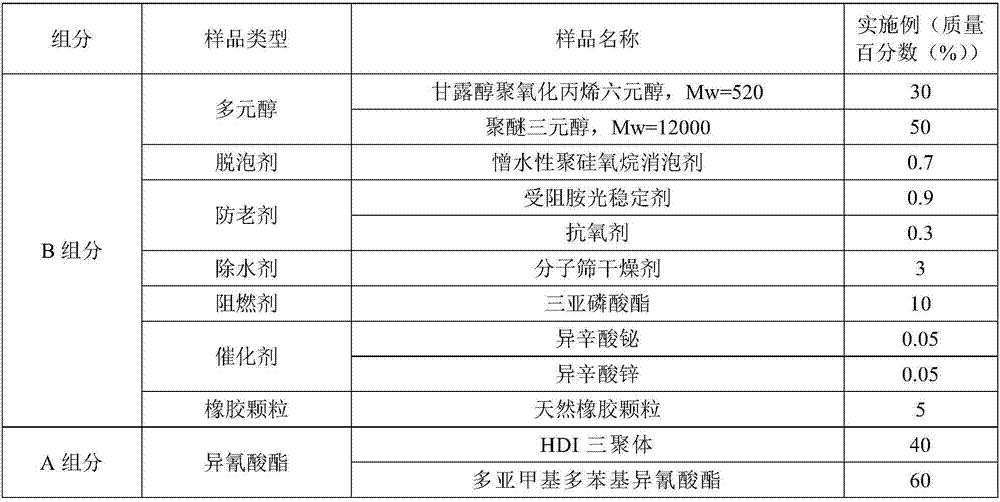

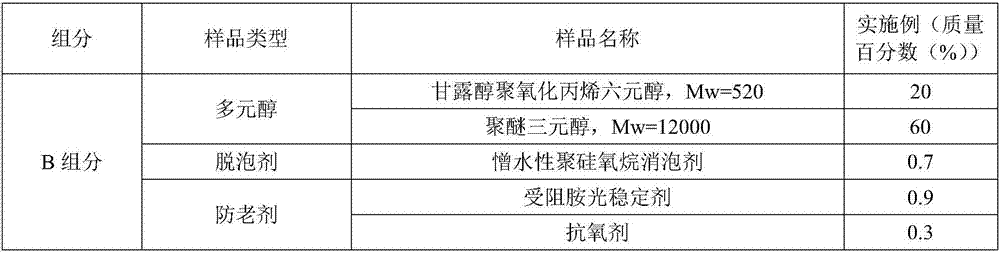

Cured track bed sinking repairing high-viscosity vibration attenuation polyurethane repairing material

The invention relates to a high-viscosity vibration attenuation polyurethane repairing material for sinking repairing of a polyurethane cured track bed of a high speed railway or a heavy haul railway. The high-viscosity vibration attenuation polyurethane repairing material consists of a component A and a component B which are mixed and stirred together mechanically, wherein the mass ratio of the component A to the component B is (1:0.9)-(1:1.5); the component A is a mixture of an HDI tripolymer and polymethylene polyphenyl isocyanate ester; the mass ratio of the HDI tripolymer to polymethylene polyphenyl isocyanate ester is (3:7)-(6:4); the content of -NCO is 27-29%; and the component B consists of polyhydric alcohol, a catalyst, a defoaming agent, a moisture scavenger, an anti-aging agent, a flame retardant and rubber granules. The high-viscosity vibration attenuation polyurethane repairing material is characterized in that the polyhydric alcohol is a mixture which consists of 6-functionality-degree mannitol poly(propylene oxide polyol) and 3-functionality-degree high molecular weight polyether polyol with the molecular weight of 12000. According to the polyurethane repairing material provided by the invention, the volume expansion ratio is 1-3%, the compressive strength of 1 hour is greater than or equal to 12MPa, the adhesion strength is greater than or equal to 6MPa, the damping factor is 0.25-0.40, the accumulated residual deformation is less than or equal to 0.5% after 5 million times of fatigue loading, and the polyurethane repairing material can be applied to polyurethane cured track bed sinking repairing and railway ballast cured track bed sinking repairing as well.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

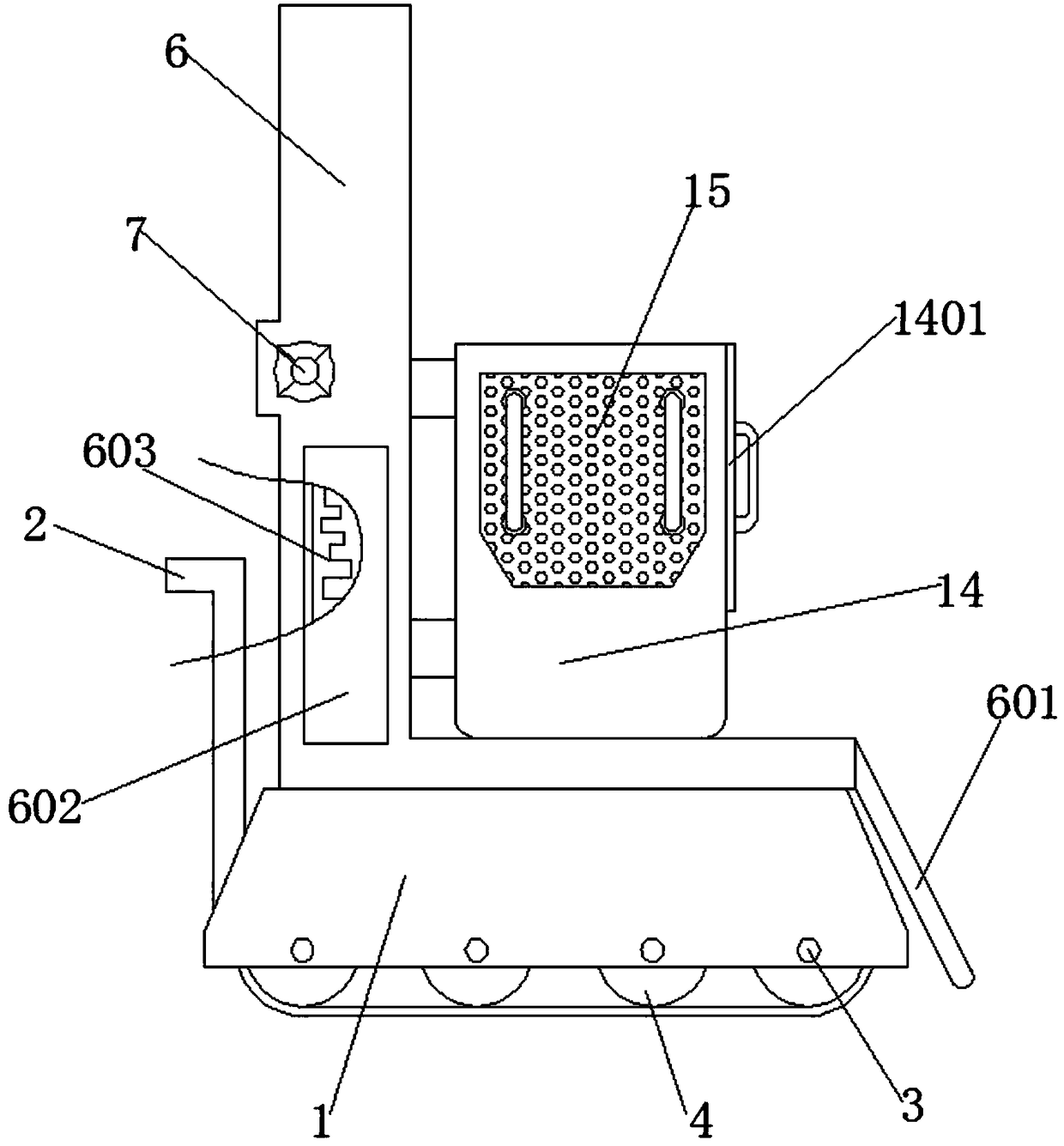

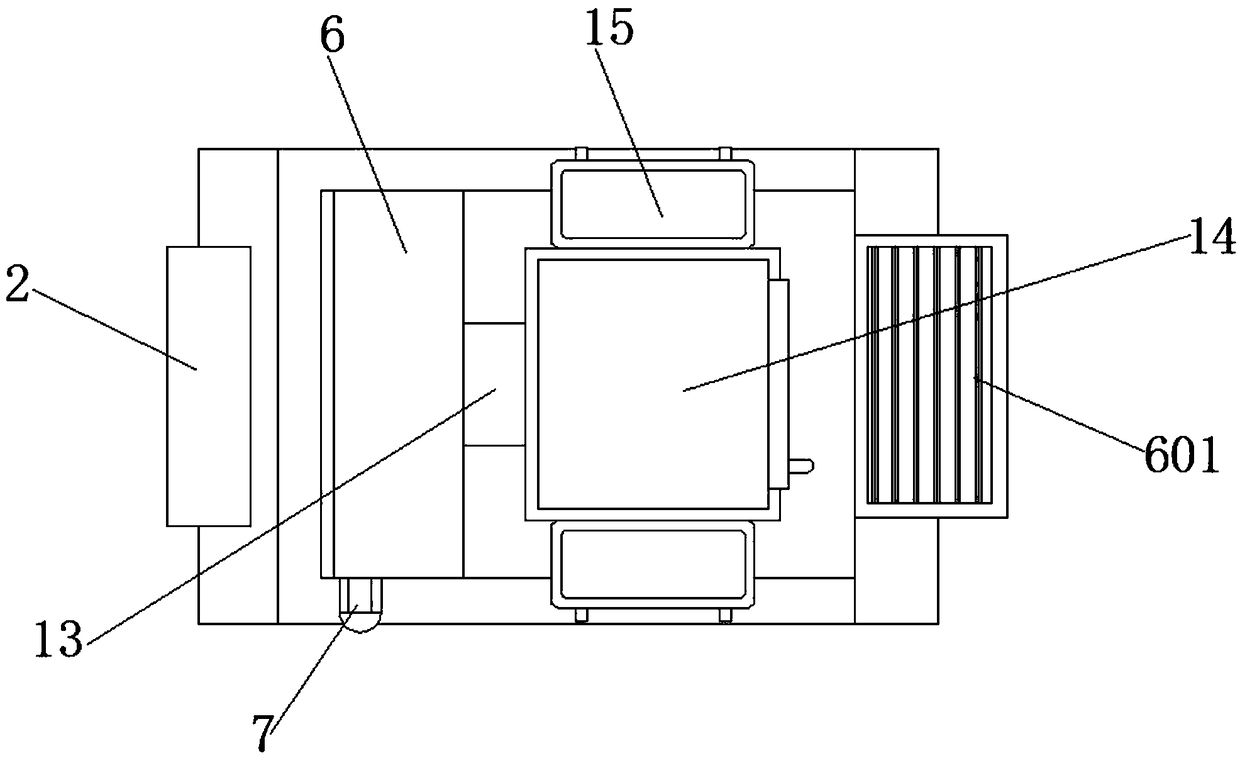

Agricultural multifunctional elevation type work platform

The invention discloses an agricultural multifunctional elevation type work platform. The agricultural multifunctional elevation type work platform comprises a base, a suspension bar, a fixing shaft,wheels, crawler belts, a fixing base, a motor, a rotating shaft, gears, a rack plate, a yield hole, a connecting plate, an elevating chamber and a collecting basket. The agricultural multifunctional elevation type work platform is skillful in design and powerful in functionality; by means of the suspension bar, the agricultural multifunctional elevation type work platform can be conveniently fixedand mounted onto a tractor and then be driven by the tractor to move; through cooperation of a lifting mechanism, workers can conveniently work on high fruit trees. Therefore, the agricultural multifunctional elevation type work platform reduces the labor intensity for the workers, greatly meets the working demands in orchards and facilitates industrial promotion and application.

Owner:宁波暴雪信息技术开发有限公司

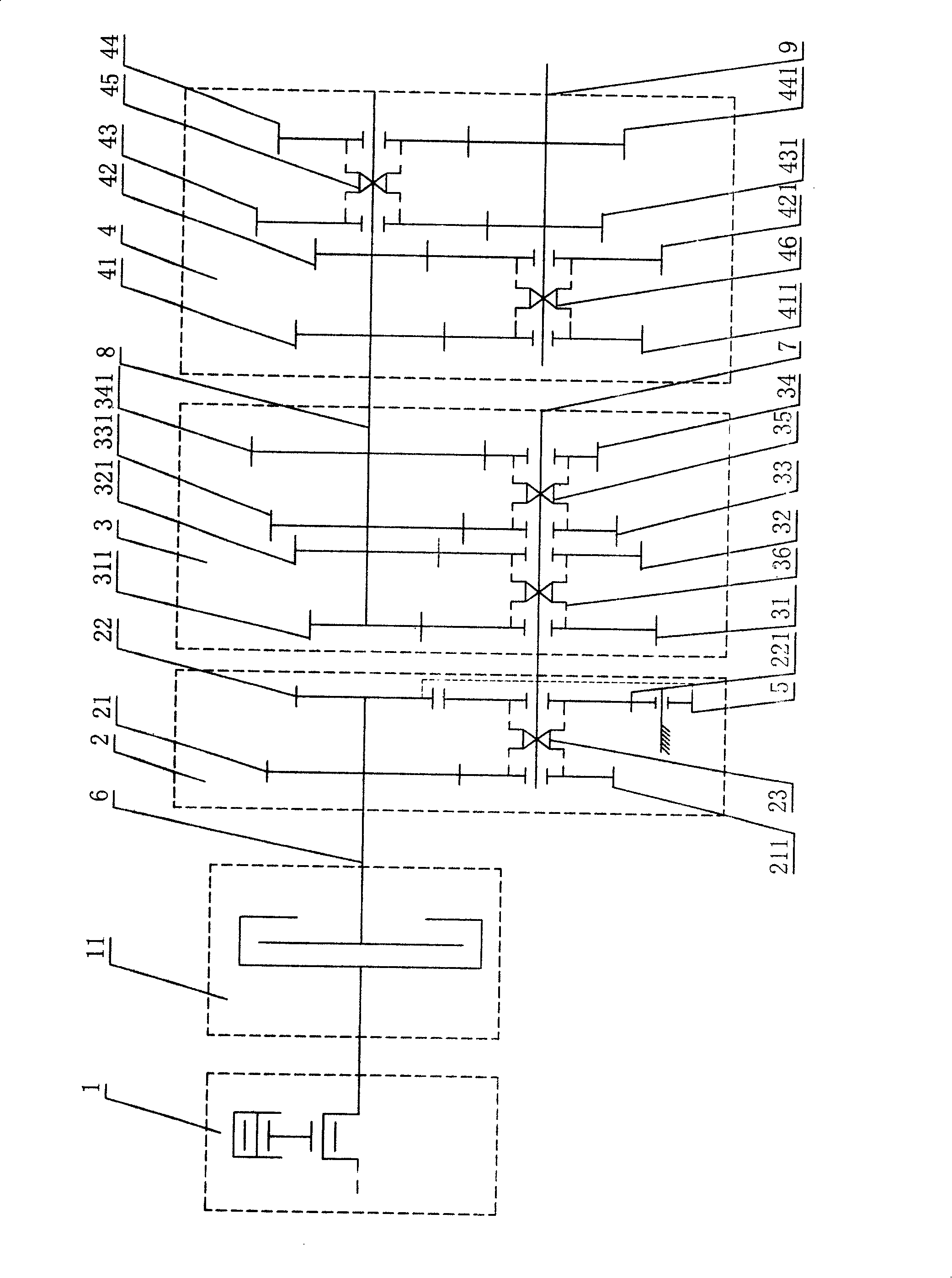

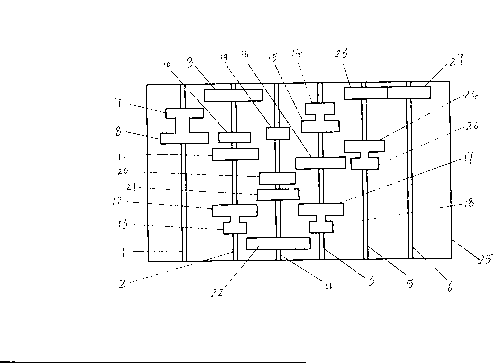

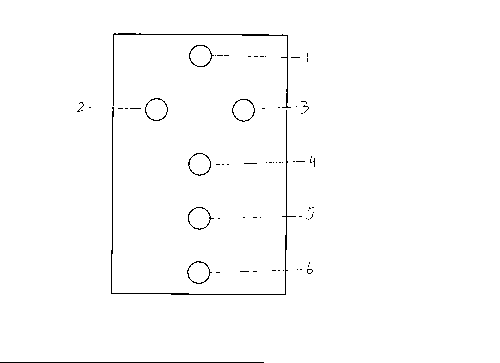

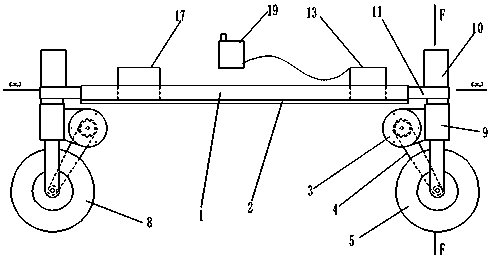

Multi-stage transmission device of tractor

The invention discloses a tractor multi-section speed change gear, comprising a gearbox which adjusts the rotation speed which is output by the power device of the tractor under the control of an operation device; an input shaft, a first shaft, a second shaft and an output shaft are arranged in parallel in the gearbox body; the gearbox comprises a shift speed change gear which is connected with the power device of the tractor through the input shaft, a main speed change gear which is connected with the shift speed change gear through the first shaft, and an auxiliary speed change gear which is connected with the main speed change gear,by the second shaft. The gears which are provided by the invention meet the operation requirement of the tractor under various environments, furthermore, the gear shifting operation stroke is small, and the operation is convenient.

Owner:LOVOL HEAVY IND

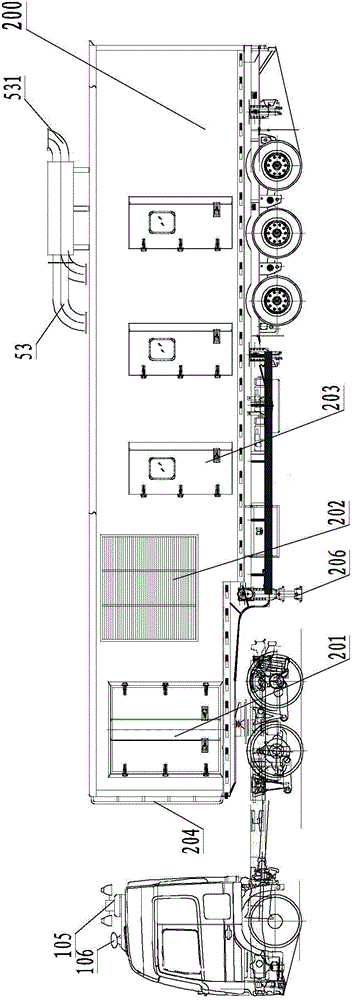

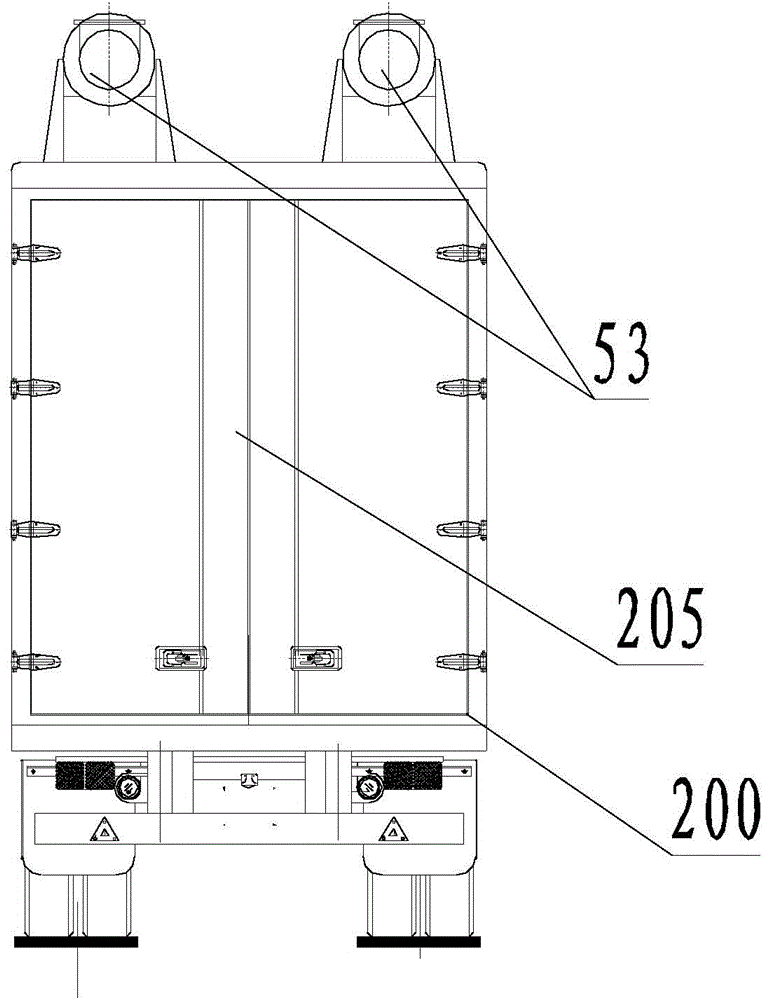

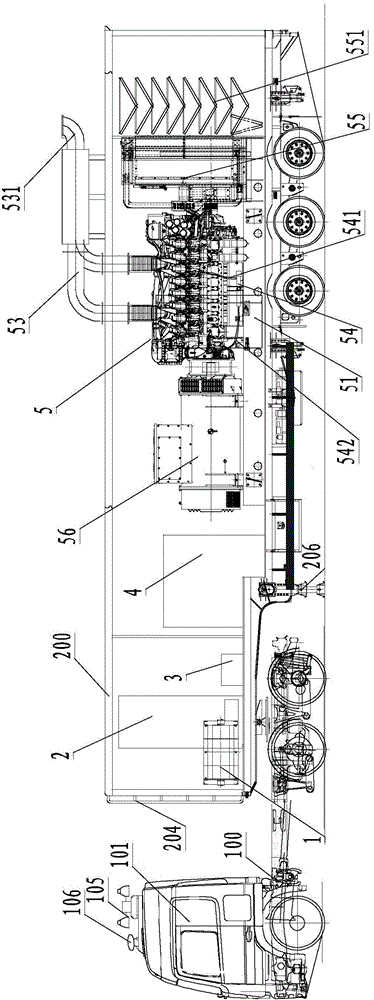

Emergent mobile power van for offshore nuclear station

InactiveCN104908629AMeet the needs of the jobEasy maintenanceBatteries circuit arrangementsMachines/enginesFuel tankHigh voltage

The invention discloses an emergent mobile power van for an offshore nuclear station. The emergent mobile power van comprises a van body and a mobile power case, wherein the front part of the van body is provided with a driving cab; the front part of the mobile power case is connected with the back part of the van body; a cable hoist, a control case a high voltage switch cabinet, an oil tank and a diesel oil generating unit are disposed in the mobile power case; the cable hoist, the control case and the high voltage switch cabinet are all arranged on the front end of the mobile power case and connected with the diesel oil generating unit; the oil tank is placed in the middle part of the mobile power case and communicated with the diesel oil generating unit; the diesel oil generating unit is placed on the back part of the mobile power case; and gaps for maintenance are preserved between the oil tank and the cable hoist, the control case and the high voltage switch cabinet, and between the diesel oil generating unit and the oil tank. The technical effects of the emergent mobile power van for the offshore nuclear station are that power can be supplied to the offshore nuclear station for emergent maintenance; and the power van can be easily maintained and meets requirements for offshore nuclear station work.

Owner:SHANGHAI COOLTECH POWER

Coating containing trace photoinitiator and solidifying method thereof

InactiveCN102304318AShort curing timeImprove efficiencyPretreated surfacesPolyester coatingsAir atmospherePolyester

The invention relates to a coating containing trace photoinitiator. According to the invention, the main components of the coating are unsaturated polyester resin or acrylic acid type oligomer, acrylic acid monoester and polyester compounds as well as the photoinitiator, wherein the mass percentage of the photoinitiator is 0.1%-1%. The invention also provides a solidifying method of the coating. The solidifying method comprises the following steps: covering the coating on a substrate by using printing, spreading, roller painting and combination processes; irradiating the coating with ultraviolet light; and enabling the substrate to pass through a self-shielding electron accelerator which is located in the air atmosphere at the linear speed of 1-10 m / s, wherein the electron accelerator generates a low-energy electron beam to irradiate the coating so that the coating can be instantly solidified. The coating has the advantages that no odor emerges in the production process, trace residue of the photoinitiator in the coating can meet the requirement of food package, cost is low, and production efficiency is high; and the solidifying method is suitable for solidifying production of all-color coatings.

Owner:HUBEI ERAY NUCLEAR TECH

Precise high-efficiency polishing method and device for curved surface parts

The invention discloses a precise high-efficiency polishing method and a precise high-efficiency polishing device for curved surface parts. The method comprises the following steps of: making numerous porous microspheres adsorbed with abrasive grains suspended in polishing solution; arranging a workpiece to be polished on a workpiece clamping device, immersing the workpiece to be polished in the polishing solution in a polishing tank, and rotating the workpiece clamping device to drive the workpiece to be polished to move under the action of a driving force; and starting an ultrasonic generator positioned at the bottom of the polishing solution and polishing the workpiece to be polished under the combined action of an ultrasonic exciting acting force and a viscous force of the polishing solution. The precise high-efficiency polishing device for the curved surface parts is characterized in that: the polishing solution is accommodated in the polishing tank; the porous microspheres are adsorbed with the abrasive grains; the upper part of the polishing tank is provided with the rotatable clamping device for clamping the workpiece to be polished; and the bottom of the polishing tank isprovided with the ultrasonic generator. The processing accuracy and processing efficiency are high by adopting the method and the device; and the method and the device have the advantages of simple structure of processing equipment and low cost.

Owner:吴寿麟

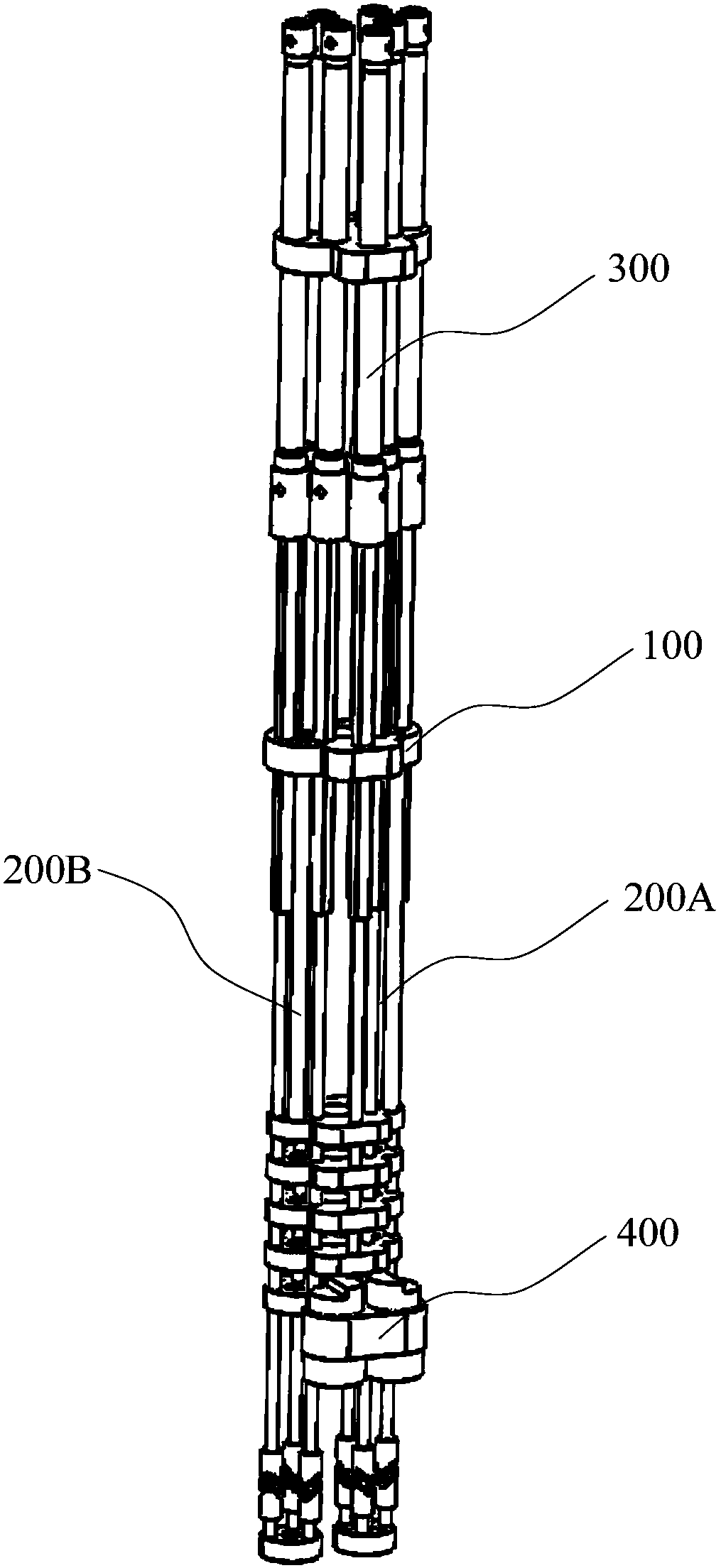

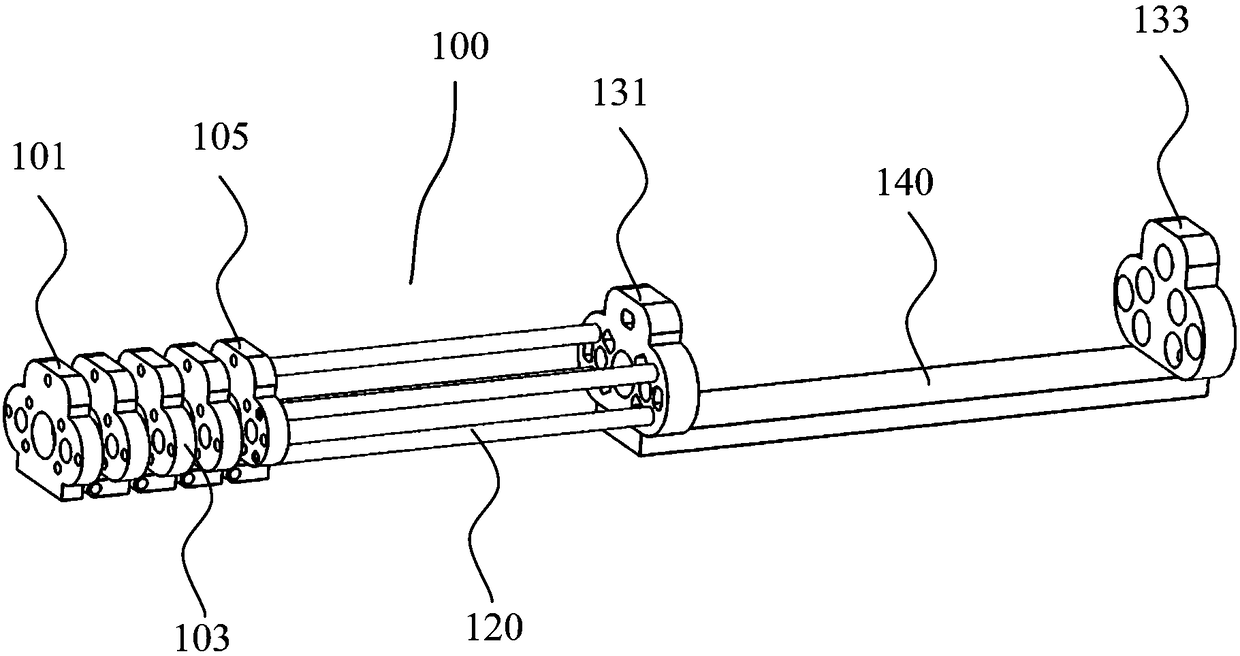

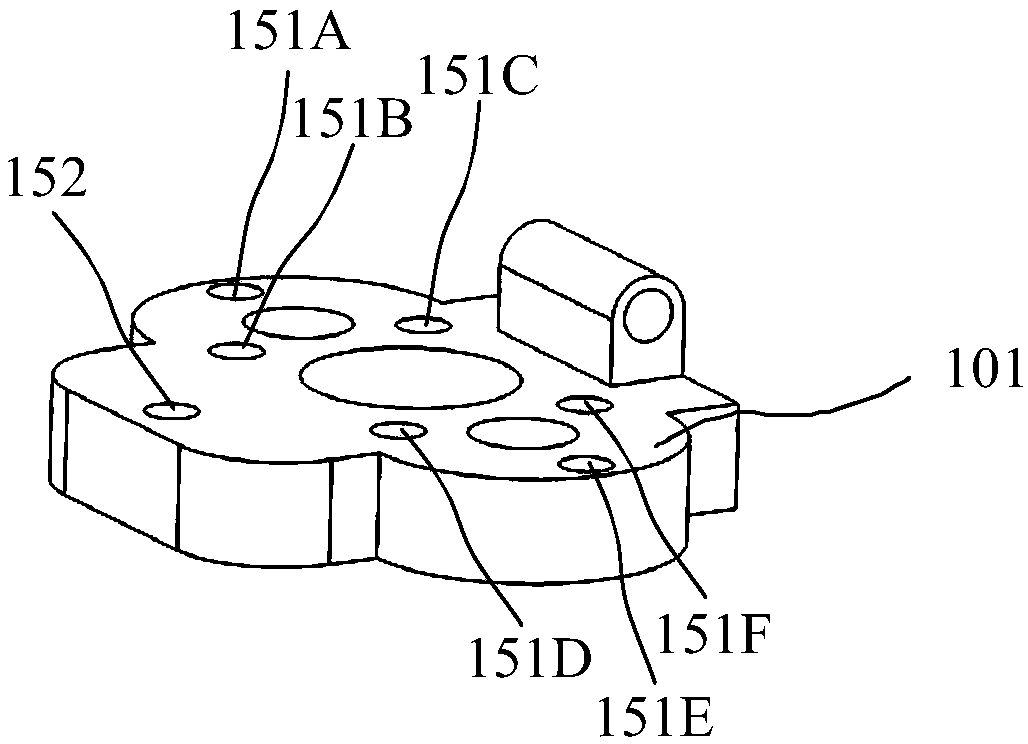

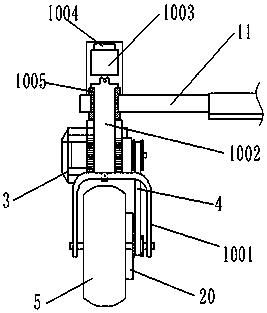

Surgery operating arm and surgery robot

The invention discloses a surgery operating arm. The surgery operating arm comprises a bracket assembly, at least one movement assembly, a bending drive assembly and an endoscope. The bracket assemblycomprises a front supporting seat, a rear supporting seat and a bending assembly connected to the front supporting seat through a supporting rod, wherein the bending assembly comprises a rear end member, an intermediate member and a front end member, the rear end member is connected to the supporting rod, and the intermediate member and the front end member are pivotally connected to the rear endmember in sequence; each movement assembly comprises a plurality of transmission assemblies arranged in parallel; elastic lead screws of the transmission assemblies can slidably run through first through holes form in the front end member, the intermediate member and the rear end member respectively; a drive rope of the bending drive assembly can slidably run through second through holes formed in the front end member and the intermediate member respectively and is fixedly connected to the rear end member; the drive rope is suitable for the relative rotation of the front end member, intermediate member and rear end member, thereby promoting the elastic lead screws to perform elastic deformation. The surgery operation arm has the advantages of being convenient to operate and high in precision.

Owner:NAT UNIV OF SINGAPORE +1

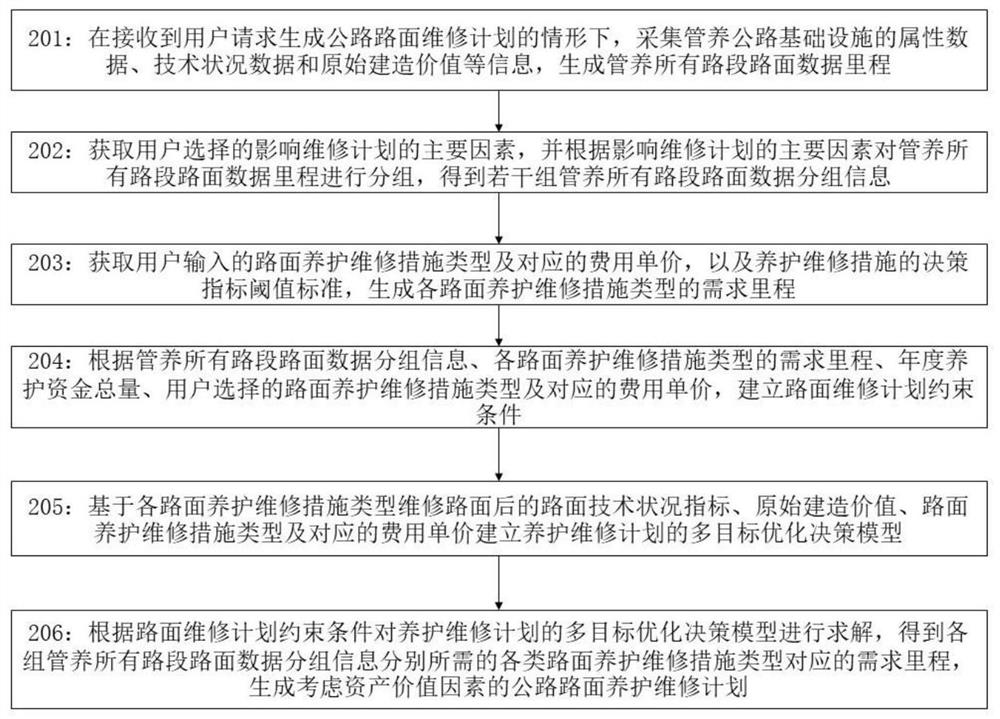

Method and device for generating highway pavement maintenance plan

ActiveCN112330516AImprove scienceImprove practicalityData processing applicationsInternal combustion piston enginesPavement maintenanceMaintenance planning

The invention discloses a method and a device for generating a highway pavement maintenance plan, belongs to the technical field of highway management, and particularly relates to a method for generating a highway pavement maintenance plan, which comprises the following steps: establishing a relationship between a technical condition of infrastructure and a pavement asset value; and introducing multi-objective constraints including asset value factors of original construction values, pavement maintenance measure types and corresponding cost unit prices and pavement technical condition indexes,solving the multi-objective optimization decision model to obtain required maintenance mileage corresponding to each pavement maintenance measure type, and generating a highway pavement maintenance plan. According to the invention, the scientificity and practicability of maintenance plan making are greatly improved, on the basis of meeting the industry management requirements, the work requirements of maintenance management are better met, the use benefits of maintenance funds are effectively improved, and the modeling method has the advantages of being low in calculation intensity and high in adaptability; and the invention is suitable for popularization and application in traffic transportation competent departments and highway management institutions at all levels.

Owner:交科院检测技术(北京)有限公司

Low voltage load test device

The invention provides a low voltage load test device. The low voltage load test device comprises an insulating rod, a clamp-shaped current transformer which is arranged at the top of the insulating rod, an ammeter which is arranged on the lower end of the insulating rod, and a handbrake which is arranged on the lower end of the insulating rod. The handbrake is connected with the clamp-shaped current transformer through a handbrake line to control the clamp-shaped current transformer to switch on and off. The clamp-shaped current transformer is connected with the ammeter through a current secondary line. The low voltage load test device has the advantages of scientific design, high work efficiency and high safety coefficient.

Owner:STATE GRID CORP OF CHINA +1

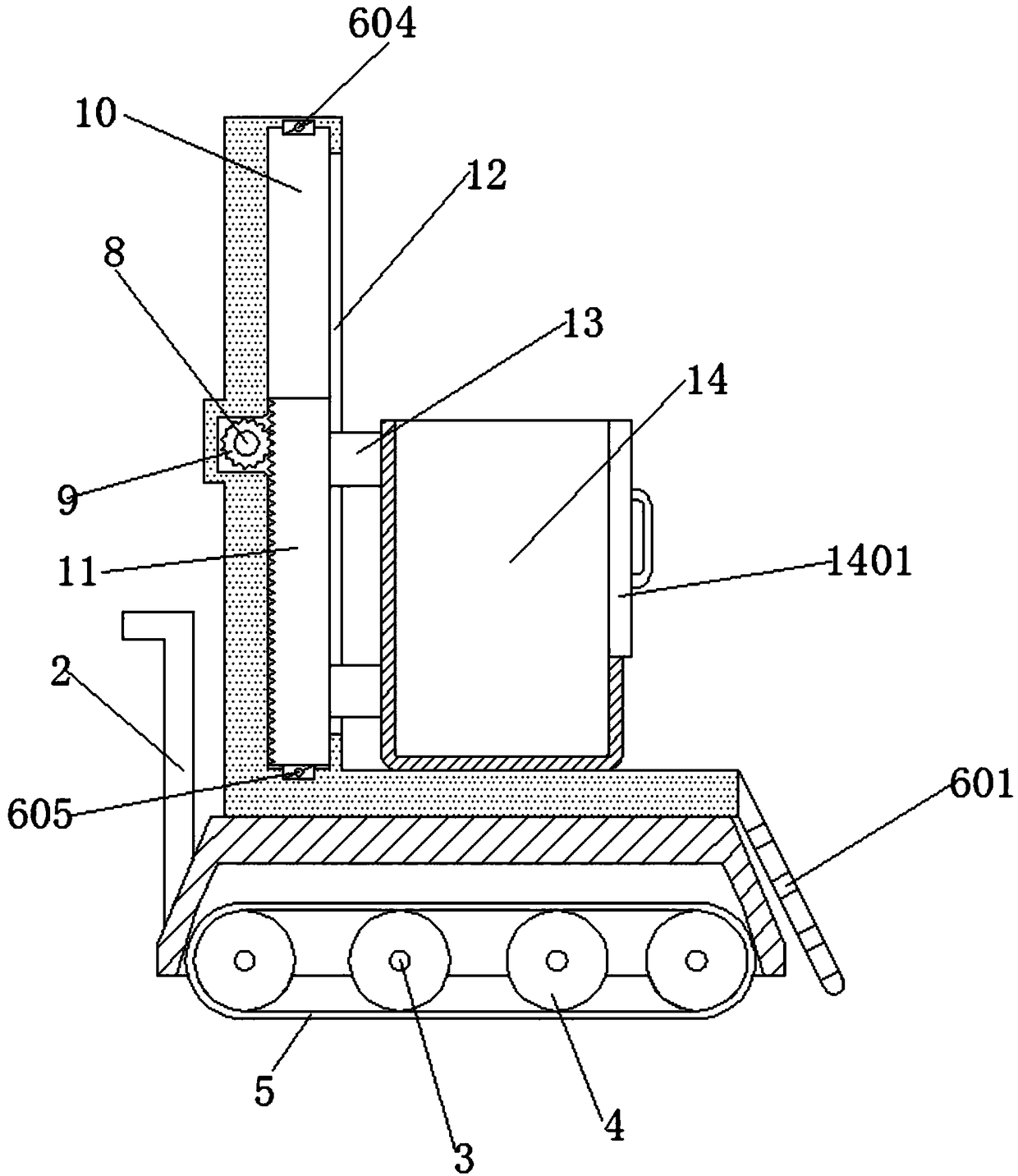

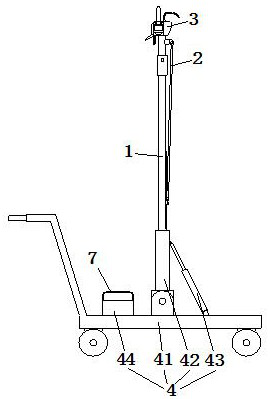

Orchard multifunctional lifting operation platform

InactiveCN109650299AConvenient dropEasy to pick and storeLifting devicesPicking devicesDrive motorOrchard

The invention discloses an orchard multifunctional lifting operation platform. The orchard multifunctional lifting operation platform comprises a chassis, a driving motor, a driving rotating shaft, adriving rotating wheel, a crawler belt, a fixed base, a first stepping motor, a first rotating shaft, a gear, a rack plate, a trigger plate, a sliding groove, a first travel switch, a second travel switch, a connecting plate, a connecting frame, a storage basket, a deflector, a second stepping motor, a second rotating shaft, a maneuvering desk, a connecting sleeve, a reinforcing sleeve and a softcushion. The orchard multifunctional lifting operation platform is ingenious in structure and powerful in function, firstly, through an electric driving mechanism, the platform can move in an orchard;secondly, through cooperation with a lifting mechanism, staff can pick and store fruits of different heights conveniently; and finally, through the platform, the orchard operation demands are greatlymet, and application and popularization in the industry are facilitated.

Owner:安化盛鼎农业科技发展有限公司

No-co ferrous alloy powder composition and its uses

InactiveCN101797643BMeet the needs of the jobExtended service lifeMetallic material coating processesNuclear powerManganese

The invention belongs to the field of alloy material, relating to no-co ferrous alloy, in particular to no-co ferrous alloy for enhancing material of the sealing face of a nuclear power valve. The no-co ferrous alloy powder composition contains the following ingredients by weight percent: 20.5%-21.5% of Cr, 3.0%-3.5% of Ni, 3.0%-3.5% of Mn, 2.0%-2.5% of Si, 0.9%-1.0% of C, 1.5%-2.0% of Mo, 0.7%-1.2% of W, 0.3%-0.5% of V, P is less than or equal to 0.02%, S is less than or equal to 0.02%, 0.5%-1.0% of Y and the balance of Fe. The no-co ferrous alloy powder composition contains no noble metal of Co, at the same time, since laser cladding technology is adopted to prepare the coating, the microhardness of the cladding layer is 1.6-1.8 times of that the stainless steel matrix. The no-co ferrous alloy powder composition has excellent high-temperature abrasion performance and high-temperature corrosion resistance, so the no-co ferrous alloy powder composition can prolong the service life of the valve.

Owner:SUZHOU UNIV

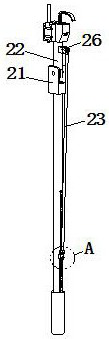

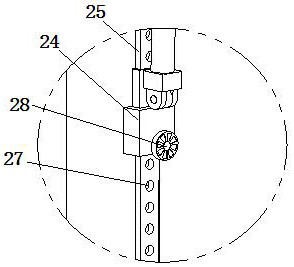

Plum blossom trimming mechanical arm

ActiveCN111802116AImprove applicabilitySimple structureCuttersMotor driven pruning sawsAgricultural engineeringStructural engineering

The invention discloses a plum blossom trimming mechanical arm, and relates to the technical field of mechanical arms. The mechanical arm comprises an extension rod, an angle adjusting mechanism, a trimming mechanism and a moving mechanism, the angle adjusting mechanism is arranged on the extension rod, the trimming mechanism is arranged on the angle adjusting mechanism and comprises a trimming conversion assembly, a first trimming assembly, a second trimming assembly and a limiting assembly, the trimming conversion assembly is arranged at the upper end of the angle adjusting mechanism, the first trimming assembly and the second trimming assembly are arranged on the two sides of the trimming conversion assembly respectively, the limiting assembly is arranged between the first trimming assembly and the second trimming assembly, and the lower end of the extension rod is fixedly connected to the moving mechanism. The mechanical arm has multiple working modes, the first pruning assembly and the second pruning assembly are arranged to prune branches of different sizes, the applicability of the mechanical arm is improved, and due to the arrangement of the limiting assembly, potential safety hazards in the pruning process can be avoided, and the pruning accuracy is improved.

Owner:莱州市宏顺文化产业有限公司

Anti-oxidation and wear-resistant surface protection grease for steel wire rope

An antioxidation and wear-resistant surface protection grease for a steel wire rope, which comprises the following components in percentage by weight: 12%-16% of a palm wax, 17%-20% of a Duroc slack wax, 17%-21% of a cycloalkyl extract oil, 22%-26% of a paraffinic high-viscosity oil, 2%-5% of zinc dialkyl dithiophosphate, 1%-4% of diphenylamine, 6%-10% of polyisobutene, 7%-11% of an ethylene-propylene copolymer and 0.1%-1% of calcium sulfonate. The protection grease has a high kinematic viscosity and a strong adhesion to the surface of a steel rope, and prolongs the service life of the steel wire rope.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

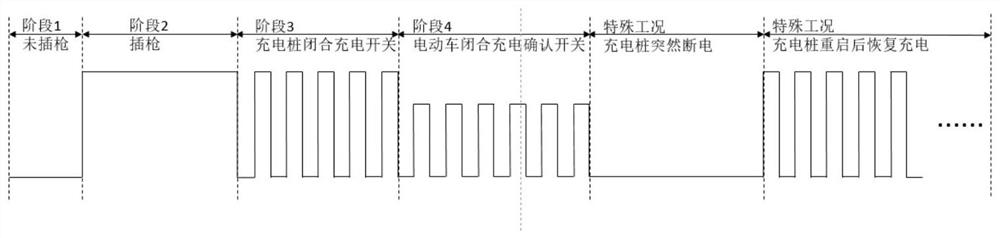

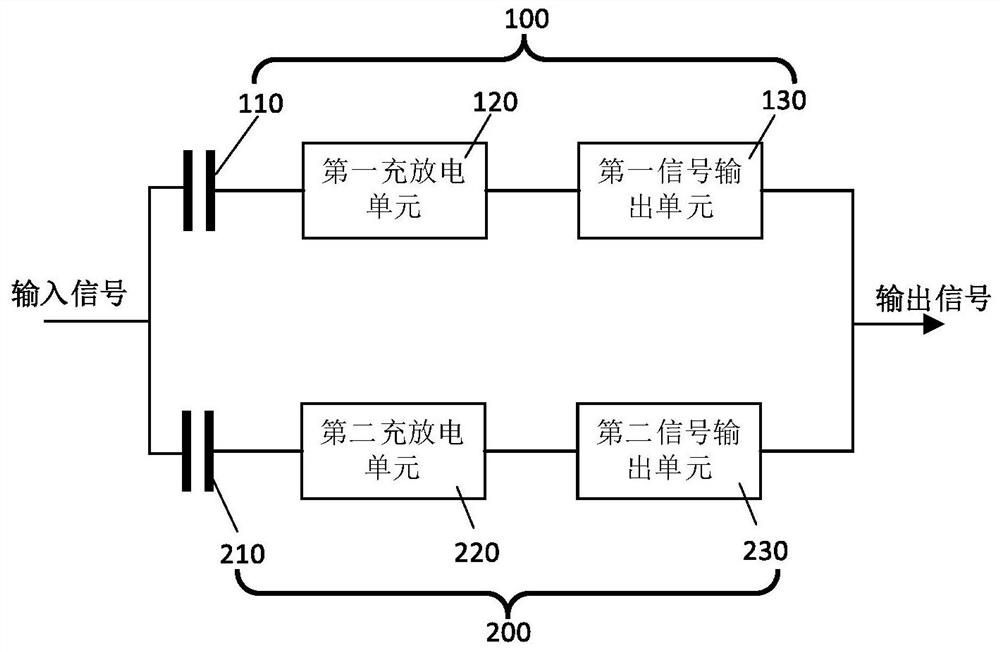

Wake-up signal generating circuit and vehicle charging system

The invention provides a wake-up signal generating circuit and a vehicle charging system.The signal triggering circuit comprises a first triggering module and a second triggering module, and when the first triggering module receives a falling edge signal, the time interval between the falling edge signal and a previous rising edge signal is larger than a first preset duration, the first triggering module outputs the pulse signal of the first level, and under other conditions, the second level is output; and when the second trigger module receives a rising edge signal, the time interval between the rising edge signal and the last falling edge signal is greater than a second preset duration, the second triggering module outputs the pulse signal of the first level, and in other cases, the second triggering module outputs the second level. Through the configuration, the wake-up signal is output at a proper time, the actual working requirement of the controller is met, and the problems that a charging wake-up circuit in the prior art cannot completely realize a better expected output signal scheme and cannot wake up the controller or enable the controller not to enter a sleep state under a specific working condition are solved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Transmission box

InactiveCN103185112AIncrease the number ofMeet the needs of the jobToothed gearingsDrive shaftEngineering

The invention provides a transmission box, which comprises a box body internally provided with one input shaft and five driven shafts, and is characterized in that two toggling gears are arranged on the input shaft, three fixed gears and two toggling gears are arranged on the second driven shaft, five toggling gears are arranged on the third driven shaft, four fixed gears are arranged on the fourth driven shaft, one fixed gear and two toggling gears are arranged on the fifth driven shaft, and a fixed input gear is arranged on a sixth driven shaft. The transmission box is provided with three main advancing gears and two main backing gears and additionally provided with 24 secondary advancing gears and 8 secondary backing gears, so the number of the gears is greatly increased, needs of the machine during operation are met, and the functions of saving more energy source, environmental protection and improving work efficiency are achieved.

Owner:侯福新

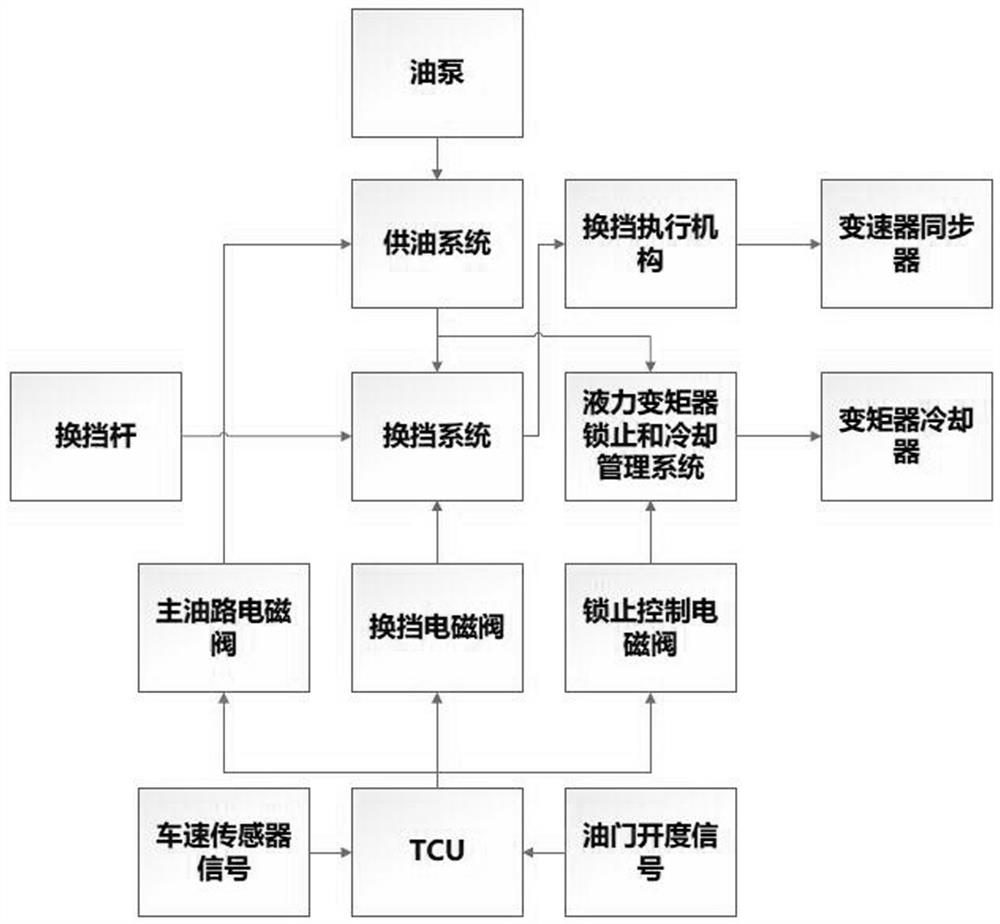

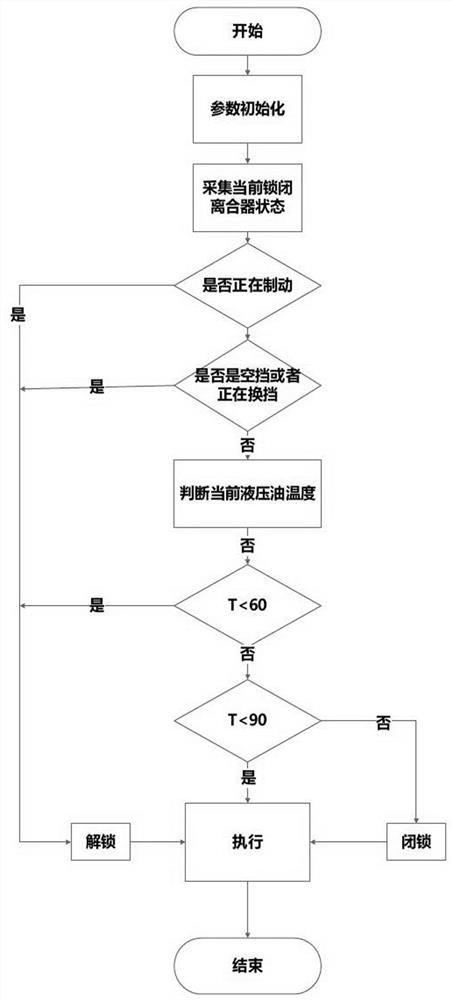

Control system and control method of fluid coupling type transmission

InactiveCN111810630AActively adjust the operating statusMeet the needs of the jobGearing controlFluid couplingDriver/operator

The invention provides a control system and a control method of a fluid coupling type transmission. The control system comprises an automatic transmission electronic control system and an automatic transmission hydraulic system; the automatic transmission hydraulic system comprises an oil pump, an oil supply system, a shifting system and a hydraulic torque converter locking and cooling managementsystem, and the automatic transmission electronic control system comprises a sensor, a TCU and a solenoid valve. In the invention, the control system and a control strategy of the fluid coupling typetransmission can realize real-time communication of an engine and a transmission, guarantee that engine input revolving speed, torque and transmission gear satisfy needs of vehicle operations, meanwhile, also can actively adjust a transmission operating state according to will of a driver, and guarantee that the automatic transmission can work according to preset optimal control rules under any working condition, thereby, can achieve optimal shifting quality and transmission efficiency.

Owner:HENAN UNIV OF SCI & TECH

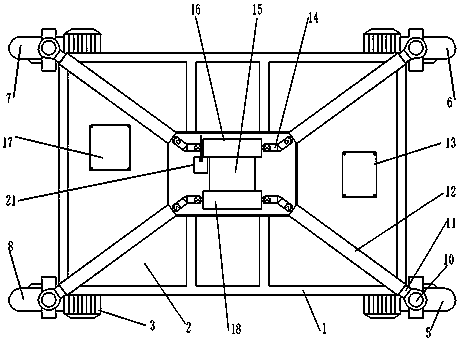

Motor wheel track adjusting mechanism and its control method

The invention discloses a motor vehicle wheel distance adjusting mechanism. The motor vehicle wheel distance adjusting mechanism comprises a vehicle frame, and is characterized in that a wheel distance adjusting motor is mounted in the center of the vehicle frame and comprises double output shafts, the two ends of each output shaft are provided with a reduction box R and a reduction box L correspondingly, each reduction box comprises a worm and gear mechanism with double output shafts, one of the output shafts of each reduction box is provided with an encoder B, the output shafts of the reduction boxes are connected with the rear ends of screw and nut mechanisms through universal joints correspondingly, the front ends of the four screw and nut mechanisms are mounted at the four corners ofthe vehicle frame correspondingly, the screw and nut mechanisms are provided with retractable frames, the front ends of the four retractable frames are provided with steering executing mechanisms correspondingly, wheels are mounted on the steering executing mechanisms, wheel driving motors are further mounted on the steering executing mechanisms, a bottom plate is mounted at the bottom of the vehicle frame, and a power system and a control system are mounted on the bottom plate. The motor vehicle wheel distance adjusting mechanism has the characteristics of being simple in structure, reasonable in design, wide in application, high in practicability and the like.

Owner:柳州市孚桂智能科技有限公司

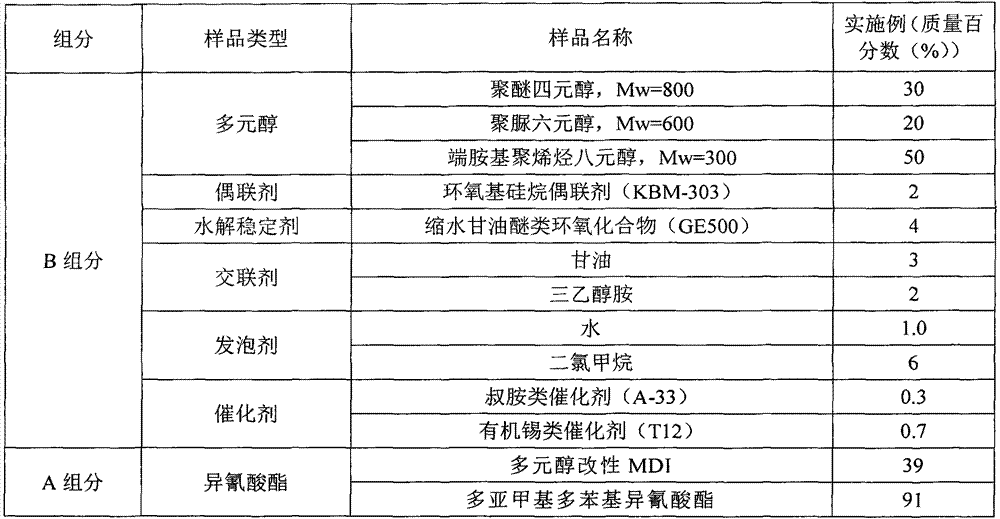

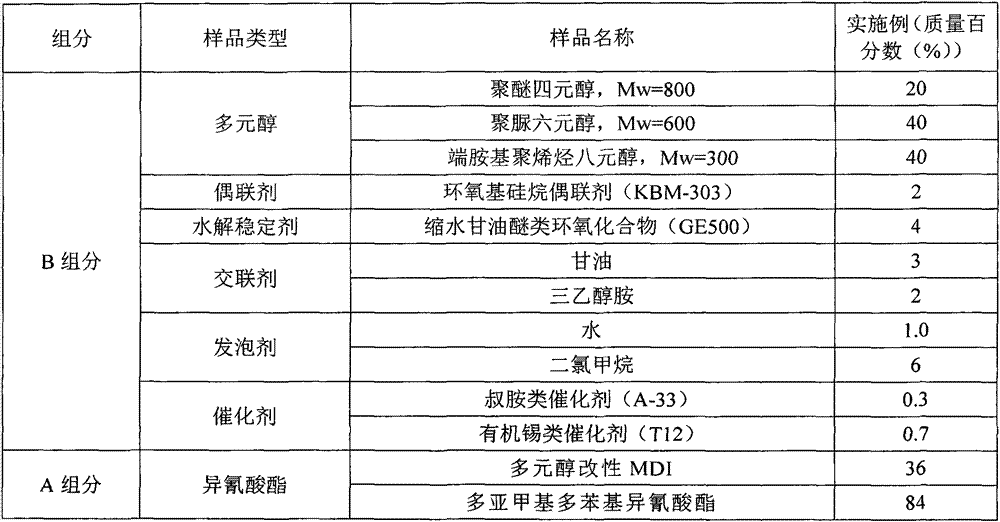

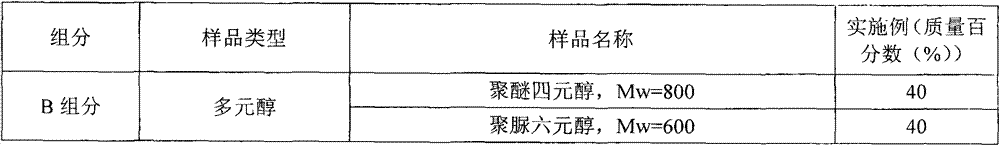

A polyurethane repair material for settlement repair of ballastless track structure of high-speed railway

ActiveCN104693413BThe distribution ratio is scientific and reasonableImprove performanceCross-linkPolyolefin

The invention relates to a polyurethane patching material used for settlement repairing of a ballastless structure for a high-speed railway. The polyurethane patching material is formed by hybrid reaction of an A component material and a B component material by a high-pressure impact. The volume ratio of the A component and the B component is 1:1-1:1.8. The A component is a mixture formed by polyhydric alcohol modified diphenylmethane diisocyanate and multi-methylene multi-phenyl isocyanate. The viscosity of the A component ranges from 100 mPa.s to 200 mPa.s at the 25 DEG C temperature. The B component is a mixture formed by polyhydric alcohol, a coupling agent, a hydrolytic stabilizing agent, a cross-linking agent, a foam stabilizing agent, a catalyst agent and a foaming agent. The viscosity of the B component ranges from 150 mPa.s to 300 mPa.s at the 25 DEG C temperature. The B component is characterized in that at least a part of end amido polyolefin polyhydric alcohol with 8 functionalities is in the polyhydric alcohol, and the content of the end amido ranges from 60%-80%. According to the polyurethane repairing material, the chemical reaction speed is high, the expansibility is high, the mechanical strength is high, the binding power is high, the size stability is high, the anti-hydrolysising property is good, and the deformation of accumulated residues is low. The polyurethane repairing material can be used for the settlement repairing of the ballastless structure for the high-speed railway, and can also be used for the pavement structure repairing of an expressway and the settlement repairing of an industrial building terrace.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

A high-bonding vibration-absorbing polyurethane repair material for settlement repair of solidified ballast bed

ActiveCN105255159BImprove adhesionIncrease dampingTrack maintainenceDamping factorPolyurethane adhesive

The invention relates to a high-bonding and vibration-absorbing polyurethane repairing material used for repairing the settlement of polyurethane solidified ballast beds of high-speed railways or heavy-duty railways. The material is made by mechanical mixing and stirring of component A and component B. The mass ratio of component A to component B is 1:0.9~1:1.5; component A is HDI trimer and polymethylene A mixture of polyphenylisocyanates, the mass ratio of the two is 3:7~6:4, and the -NCO content is 27%~29%; B component is polyol, catalyst, defoamer, water remover, anti-aging agent It is composed of agent, flame retardant and rubber particles, and is characterized in that the polyol is a mixture of 6-functionality mannitol polyoxypropylene polyol and 3-functionality high molecular weight polyether polyol with a molecular weight of 12,000. The polyurethane repair material prepared according to the present invention has a volume expansion rate of 1% to 3%, a 1h compressive strength ≥ 12MPa, a bond strength ≥ 6MPa, and a damping factor of 0.25 to 0.40; after 5 million times of fatigue loading, the accumulated residual deformation is ≤ 0.5%, this material can be used for settlement repair of polyurethane cured ballast bed, and can also be used for repair of ballast glue cured ballast bed settlement.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

InactiveCN102534606BMeet the needs of the jobImprove high temperature performanceMetallic material coating processesPowder mixtureNuclear power

The invention discloses a nickel-base alloy coating for a sealing surface of a nuclear power valve, and is characterized in that the nickel-base alloy coating is prepared according to a method of conducting laser-cladding on nickel-base alloy powder. The nickel-base alloy powder comprises the following constituents by weight percent: 20.0 to 24.0 percent of Cr, 4.0 to 4.2 percent of Si, 3.0 to 3.5 percent of P, 3.0 to 3.2 percent of Mo, 8.0 to 8.5 percent of Fe, 1.0 to 1.2 percent of C, 0.8 to 1.0 percent of yttrium oxide, and Ni in balancing amount. The laser-cladding process adopts a synchronous powder feeding method and a pre-coating method. The nickel-base alloy powder mixture contains no noble metal Co, thereby particularly meeting requirements on valves under nuclear environments; and due to the formulation design of the mixture, and the advantage of the laser-cladding technology in coating preparing, the coating on the sealing surface has a favorable high-temperature property.

Owner:SUZHOU UNIV

Cobalt-free nickel-based alloy

InactiveCN101838758BReduce usageAvoid CoMetallic material coating processesLaser beam welding apparatusAlloy coatingCobalt

The invention discloses cobalt-free nickel-based alloy powder. The cobalt-free nickel-based alloy powder comprises the following components in percentage by weight: 1.0 to 1.2 percent of carbon (C), 24.0 to 28.0 percent of chromium (Cr), 4.0 to 6.0 percent of wolfram (W), 2.4 to 2.8 percent of silicon (Si), 6.0 to 10.0 percent of aluminum (Al), 4.0 to 6.0 percent of molybdenum (Mo), 0.8 to 1.0 percent of boron, 1.0 to 5.0 percent of yittrium oxide (Y2O3) and the balance of nickel (Ni). The alloy coating prepared by combining the formula of the cobalt-free nickel-based alloy powder with the laser cladding process has a compact structure and no defects, can be well and metallurgically combined with a nuclear valve substrate and has high wear resistance at a high temperature, so that the cobalt-free nickel-based alloy powder is particularly suitable for a nuclear valve sealing face and meets the requirements of the valve working in a nuclear environment.

Owner:SUZHOU UNIV +1

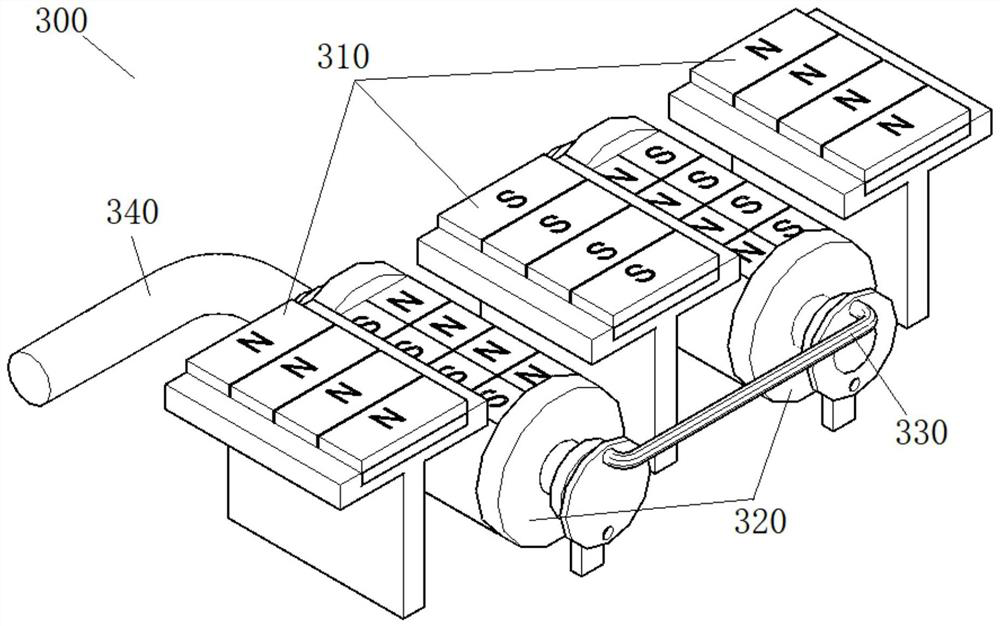

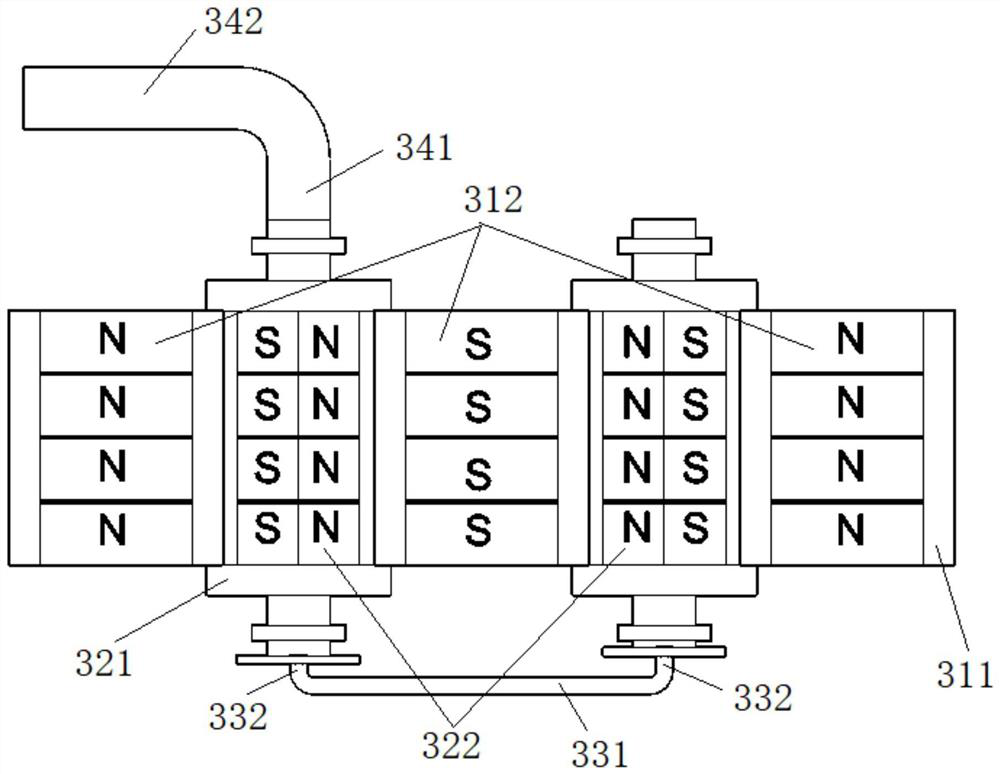

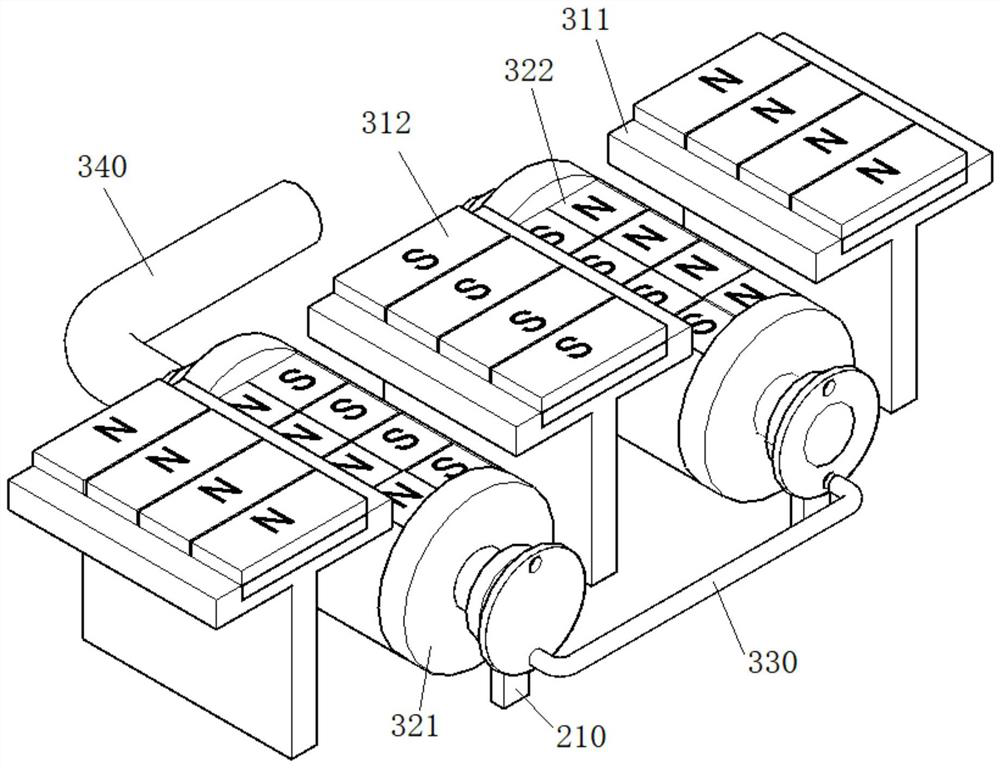

Magnetic glove

ActiveCN113951589AConvenient for climbing operationsMeet the needs of the jobGlovesApparatus for overhead lines/cablesMagnetic polesEngineering

The invention relates to the technical field of gloves, in particular to a magnetic glove which comprises a glove body, a box body and a magnetic device. The magnetic device comprises a driver, a connecting rod mechanism, fixed magnet sets and switching magnet groups; the number of the fixed magnet sets is at least three. Each fixed magnet set comprises a bracket and a first magnet; the upper magnetic pole of the first magnet in the middle is opposite to the upper magnetic poles of the first magnets on the two sides in magnetism; a switching magnet group is arranged between every two adjacent fixed magnet sets; the switching magnet group comprises rotary drums and a second magnet; the driver is connected with the rotary drums; the two rotary drums are rotationally arranged in the box body, and the two rotary drums are in swing connection through a connecting rod mechanism; when the glove body is in a magnetic force release state, the left magnetic pole and the right magnetic pole of the second magnet on each switching magnet group are identical to the upper magnetic poles of the first magnets on the two adjacent sides in magnetism. The technical problem that climbing is inconvenient in the prior art is effectively solved.

Owner:GUANGDONG POWER GRID CO LTD +1

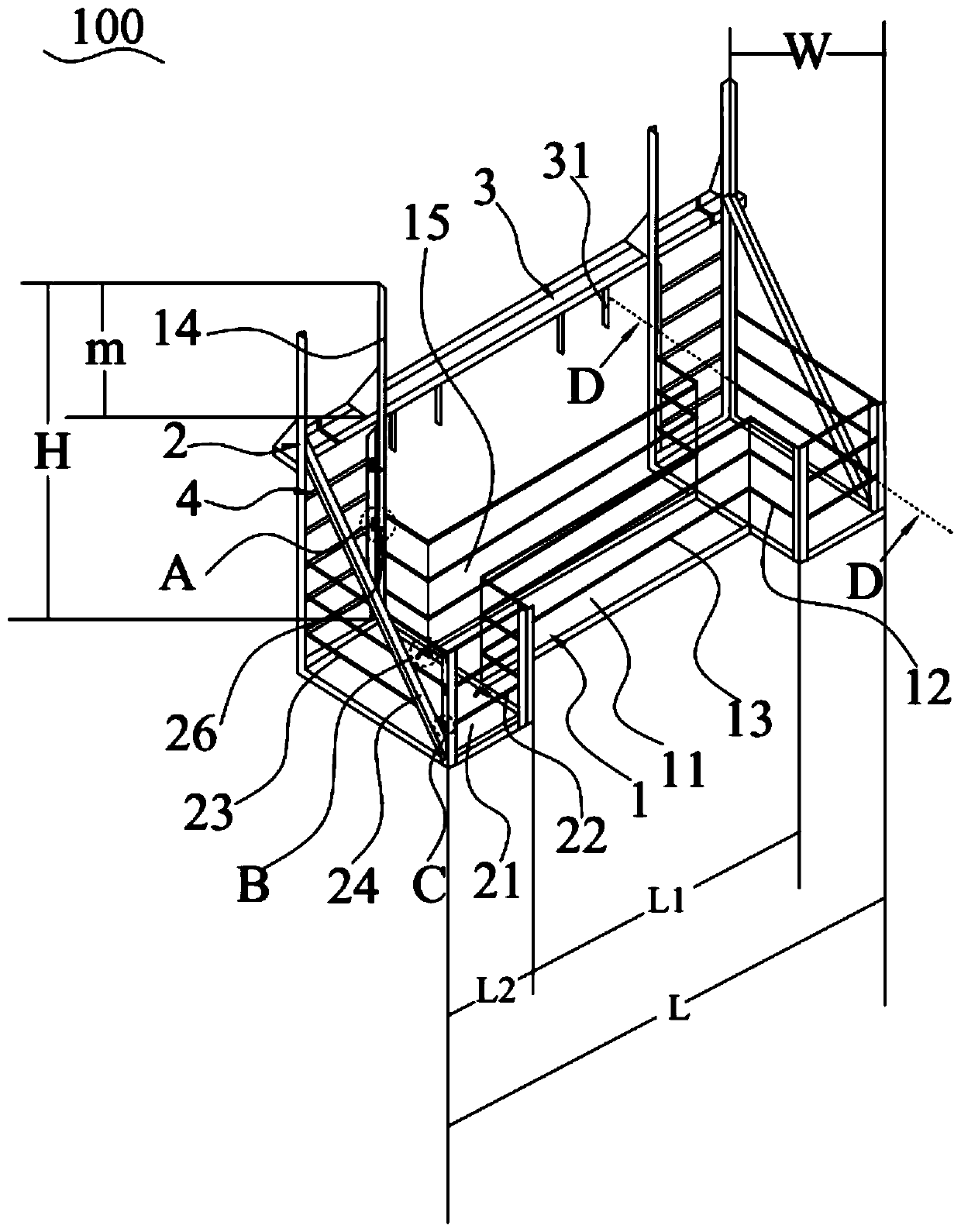

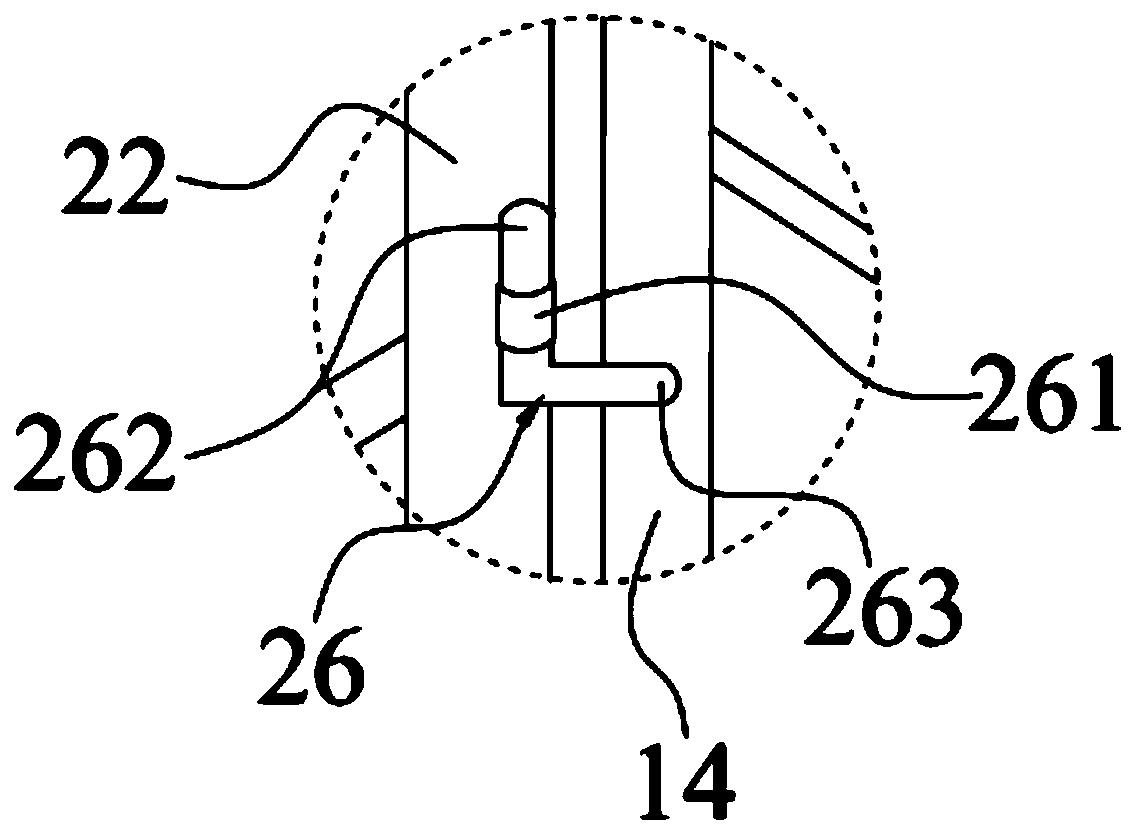

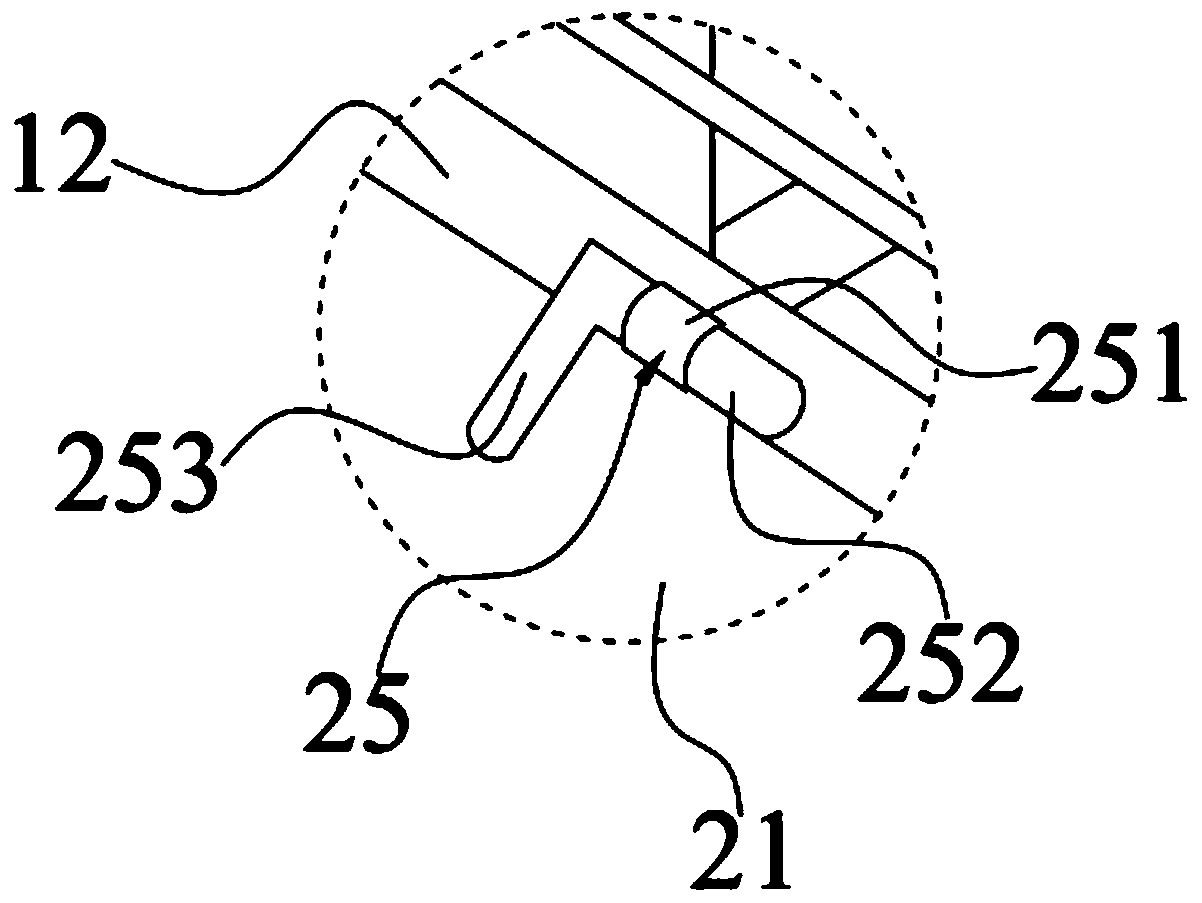

A method of using an arch rib high-altitude folding work platform

ActiveCN108589533BReduce volumeSave workBridge erection/assemblyArch-type bridgeOperations managementCollision probability

The invention discloses a using method of an arch rib high-altitude folding type operation platform. The using method comprises the following steps that the arch rib high-altitude folding type operation platform is provided; the arch rib high-altitude folding type operation platform in a folded state is fixed to an arch rib; the arch rib fixedly provided with the arch rib high-altitude folding type operation platform is hoisted to the preset height in a wrapped mode; the arch rib high-altitude folding type operation platform is unfolded at the high altitude; and the arch rib high-altitude folding type operation platform is detached. The using method of the arch rib high-altitude folding type operation platform has the advantages that no redundant working cable is occupied, and the collision probability of the operation platform and a buckle cable is decreased.

Owner:广西公路检测有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com