Anti-oxidant and wear-resistant surface protection grease for steel wire ropes

A technology of steel wire rope and protective grease, applied in the directions of base materials, thickeners, additives, etc., can solve the problems of poor oxidation inhibition and neutralization properties, easy softening in working and storage states, poor adhesion, etc., to ensure long-term Safe use, good economic and social benefits, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

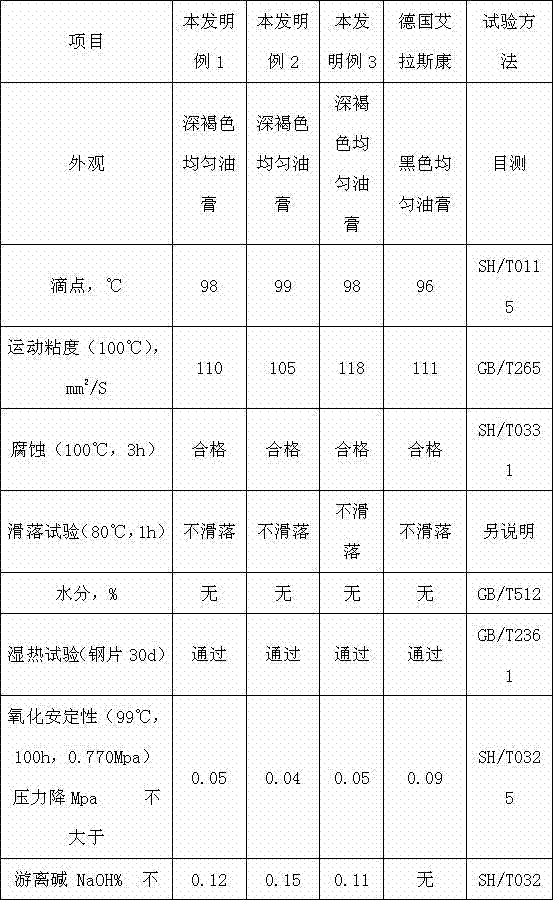

Examples

preparation example Construction

[0028] The preparation process of the anti-oxidation and wear-resistant surface grease for steel wire ropes in the present invention is to put cycloalkyl oil and paraffin-based high-viscosity oil into the reaction kettle, stir and heat up to 110°C, and dehydrate after stirring slowly

[0029] Put into palm wax, Duroc pine wax in the process, heat up to 130 ℃, cool down.

[0030] During the cooling process, put in zinc dialkyldithiophosphate, diphenylamine, polyisobutylene, ethylene-propylene copolymer, calcium sulfonate, homogenize at 100°C (±5°C), degas, and pack.

Embodiment 1

[0031] Example 1 : Steel wire rope anti-oxidation and wear-resistant surface grease, according to weight percentage, its components are as follows: Palm wax 12.8%, Duroc pine wax 20%, naphthenic oil 19%, paraffin-based high-viscosity oil 25%, dialkyl di Zinc thiophosphate 3%, diphenylamine 3%, polyisobutylene 10%, ethylene-propylene copolymer 7%, calcium sulfonate 0.2%.

Embodiment 2

[0032] Example 2 : Steel wire rope anti-oxidation wear-resistant surface grease, according to weight percentage, its components are as follows: Palm wax 14%, Duroc pine wax 19%, naphthenic oil 17.5%, paraffin-based high-viscosity oil 26%, dialkyl two Zinc thiophosphate 5%, diphenylamine 1%, polyisobutylene 8%, ethylene-propylene copolymer 9%, calcium sulfonate 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com