Method and device for carrying out polishing through flowing of viscoelasticity abrasive materials with spiral complex curved surfaces

A technology for complex curved surfaces and polishing devices, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of high cost and poor polishing effect, and achieve low cost, high productivity, and uniform distribution of polishing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

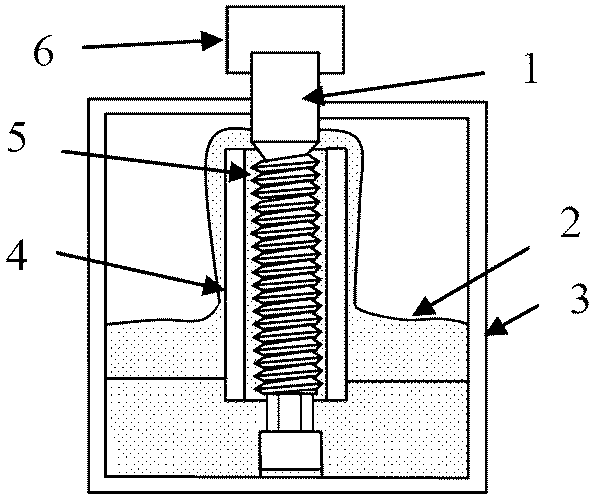

[0020] A viscoelastic abrasive flow polishing device with a spiral complex curved surface, comprising a processed screw 1, abrasive materials 2, a sealed box 3, a fixed mold 4, a gap 5 and a screw driving device 6, one end of the processed screw 1 and the screw driving device 6 The other end is immersed in the abrasive 2, the screw drive device 6 is installed on the upper part of the sealed box 3, the fixed mold 4 is installed inside the sealed box 3 through the pole to realize positioning, the abrasive 2 is viscoelastic abrasive, the fixed mold 4 is a tubular hollow mold for placing the processed screw 1.

[0021] The abrasive material 2 is composed of a high viscosity solution and a mixed solution added with fine abrasive grains to form a viscoelastic abrasive material.

[0022] The length of the fixed mold 4 is greater than the length of the helical surface of the processed sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com