Multi-stage transmission device of tractor

A technology of speed change device and tractor, which is applied in transmission device, gear transmission device, mechanical equipment and other directions, can solve the problems of many internal gears in the gearbox, huge box body of the gearbox, and large operating stroke, etc., and achieves a small operating stroke. , the effect of reducing the volume and changing the speed compactly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

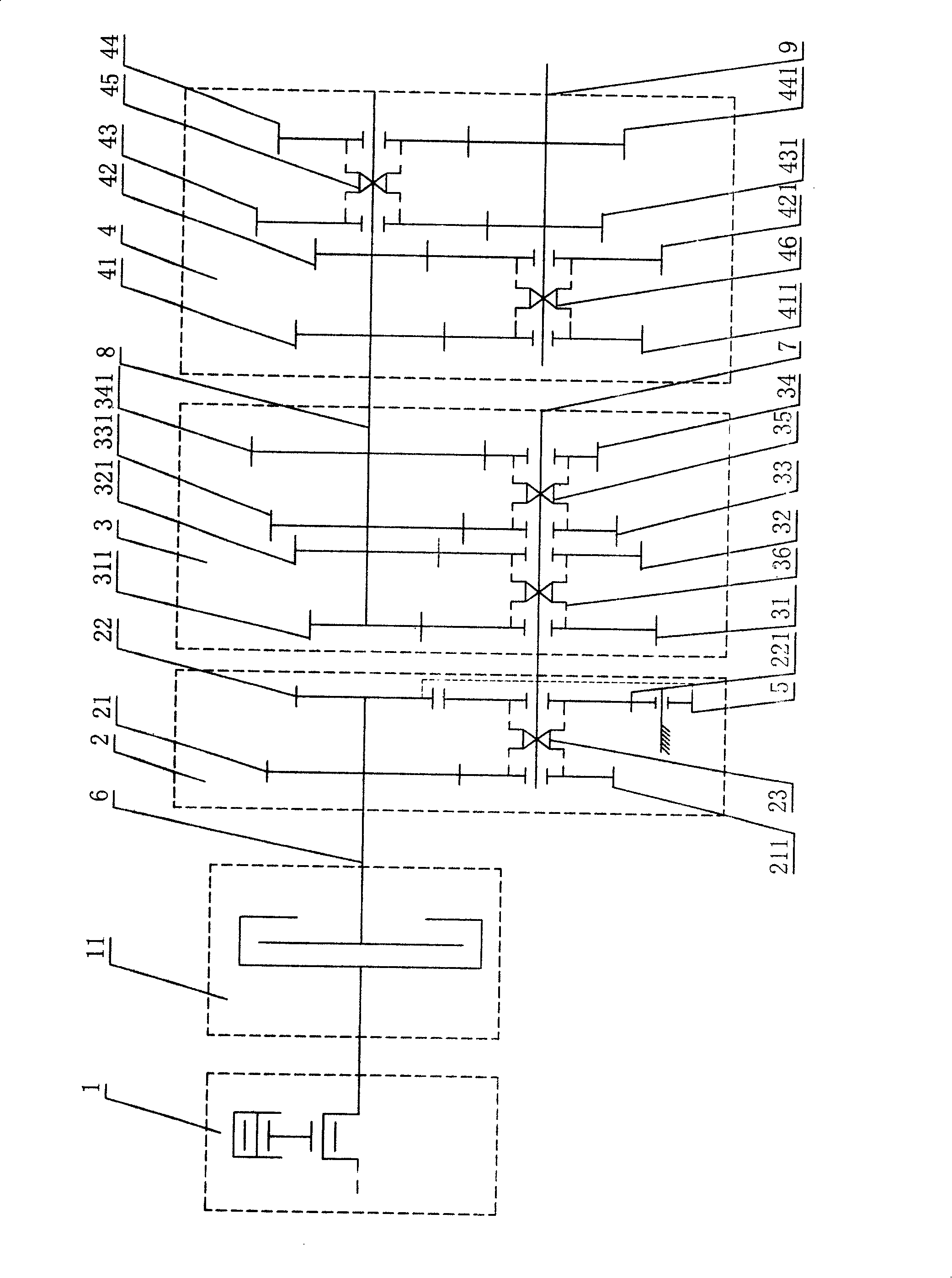

[0012] As shown in the accompanying drawings, the multi-stage transmission device of the tractor includes a power device composed of an engine assembly 1 and a clutch assembly 11 arranged on the tractor body, a gearbox connected to the clutch assembly 11, and a gearbox operating device. Under the control of the operating device, the rotation speed output by the tractor can be reversed and adjusted up and down. An input shaft 6, a first shaft 7, a second shaft 8 and an output shaft 9 are arranged in parallel in the gearbox case. The gearbox includes a shifting transmission device 2 capable of reversing and adjusting the rotational speed, a main transmission device 3 and an auxiliary transmission device 4 for adjusting the rotational speed at high and low speeds, and the shifting transmission device 2 communicates with the power unit of the tractor through an input shaft 6 The output of the clutch assembly 11 is connected to adjust the rotation speed output by the clutch assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com