T beam sling and hoisting method thereof

A hoisting method and technology of a hoisting tool are applied in the field of bridge construction auxiliary equipment, which can solve problems such as difficulty in penetrating the hoisting ring, overturning of the beam body, increase in working time and labor intensity, etc. The effect of reducing the risk of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

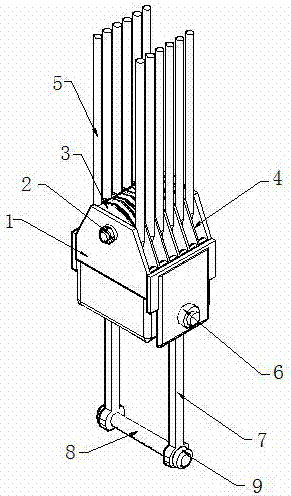

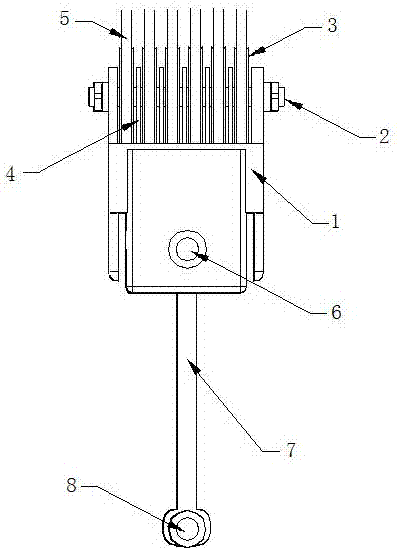

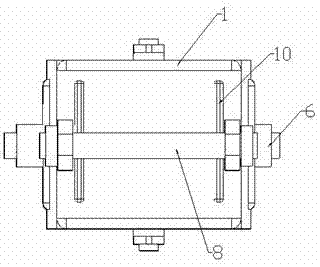

[0037] Such as Figure 1-3 As shown, the T-beam spreader of the present invention includes a body 1, the top and bottom of which are open, and the upper part of the body 1 is equipped with a sheave set composed of a plurality of winding sheaves 3 through a fixed shaft 2, each winding A steel wire rope 5 is wound on the sheave 3, and a plurality of baffles 4 are welded and fixed at equal distances on the body 1 to separate each winding sheave 3; the left and right ends of the lower part of the body 1 are fixed with two Each steel boom 7, the installation shaft 6 is positioned at the inner side of two steel booms 7, each is fixed with the spacer 10 that is used to limit the lateral movement of the steel boom 7, and the bottom of each steel boom 7 has a bolt hole 701 A bearing pin 8 passes through the bolt holes 701 on the two steel suspension arms 7 and is threaded with a safety nut 9 at both ends of the bearing pin 8 and on the outside of the steel suspension arms 7 .

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com