Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

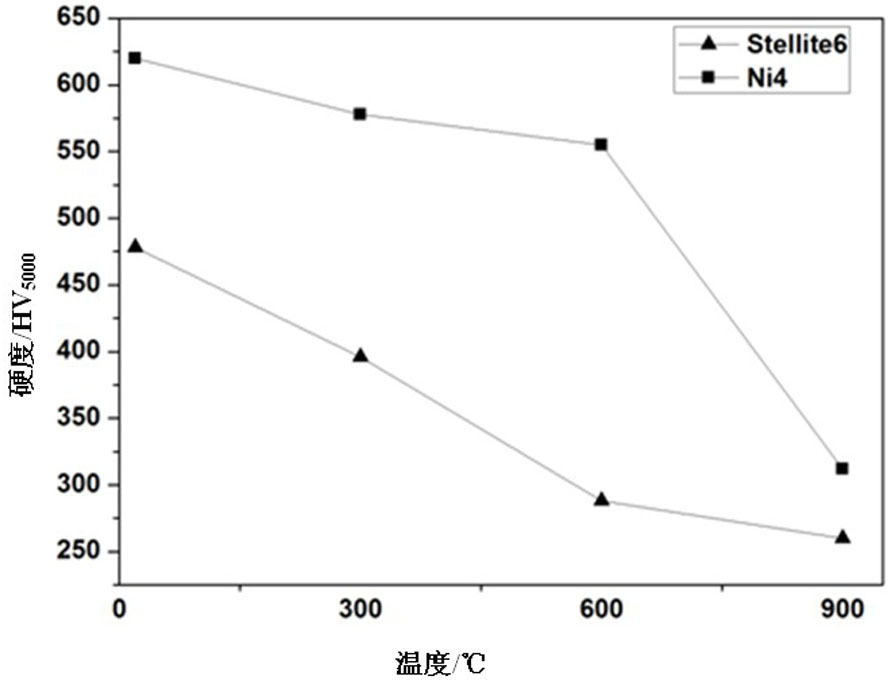

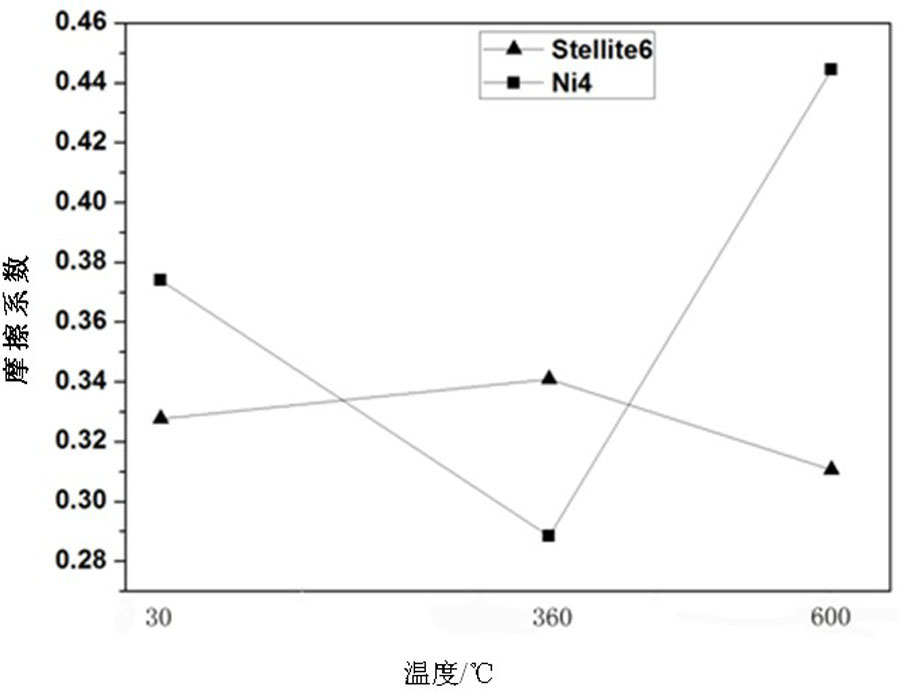

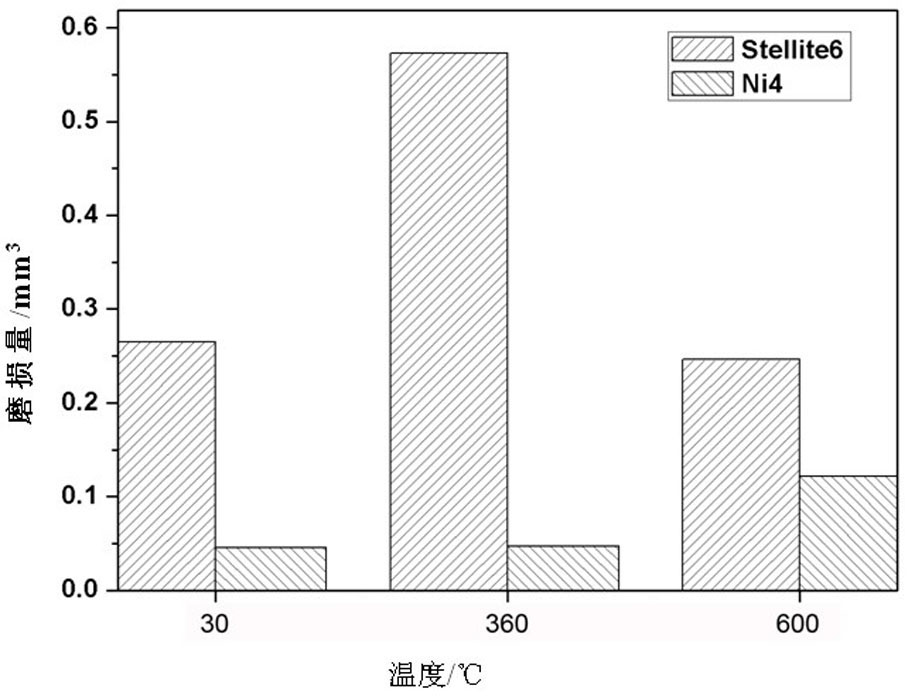

A nickel-based alloy, valve sealing technology, applied in metal material coating process, coating and other directions, can solve the problems of few special material systems for laser cladding, lack of serialized special powder materials, increasing the difficulty and cost of nuclear shielding, etc. To achieve the effect of short thermal action time, high hardness and toughness, and high joint surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A nickel-based alloy coating for the sealing surface of a nuclear power valve is prepared from a nickel-based alloy powder material through laser cladding treatment. The composition of the nickel-based alloy powder material is calculated as:

[0037] Chromium (Cr): 20.0-24.0%, Silicon (Si): 4.0-4.2%, Boron (B): 3.0-3.5%, Molybdenum (Mo): 3.0-3.2%, Iron (Fe): 8.0-8.5%, Carbon (C): 1.0-1.2%, yttrium oxide (Y 2 o 3 ) 0.8 to 1.0%, and the rest is nickel.

[0038] Among them, the content of the required carbon element can be completely composed of external chromium carbide (Cr 3 C 2 ) The carbon element in the element is provided; at the same time, the chromium carbide (Cr 3 C 2 ) also provides part of the chromium element, and the remaining chromium element is provided by the addition of fine pure chromium metal.

[0039] The particle size of the finally obtained nickel-based alloy powder is 200-300 mesh.

[0040]The preparation method of the present em...

Embodiment 2

[0063] Embodiment 2: A nickel-based alloy coating used for the sealing surface of nuclear power valves is prepared by laser cladding from nickel-based alloy powder materials, and the composition of the nickel-based alloy powder materials is calculated as:

[0064] Chromium: 13.5-16.2%, silicon: 4.0-4.2%, boron: 3.0-3.5%, molybdenum: 3.0-3.2%, iron: 8.0-8.5%, chromium carbide: 7.5-9%, yttrium oxide 0.8-1.0%, The rest is nickel.

[0065] Its preparation method comprises the following steps:

[0066] (1) Obtain the nickel-based alloy powder material described in claim 1 or 2 with a mechanical mixing method, and the powder particle size is 200~300 orders;

[0067] (2) dissolving the silicic acid resin material with ethanol as an adhesive, blending with the nickel-based alloy powder material, coating the sealing surface of the nuclear power valve as a pre-coat, and baking and drying;

[0068] (3) The power density is 136~181J / mm 2 The laser irradiates the pre-laid coating, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com