Cobalt-free nickel-based alloy

A base alloy, cobalt-nickel technology, applied in metal processing equipment, metal material coating technology, coating and other directions, can solve the problems of the threat of maintenance personnel, increase the maintenance time, increase the difficulty and cost of nuclear fuel shielding, and achieve wear resistance. Excellent, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of cobalt-free nickel-based alloy powder, according to weight percentage, each component and its content are:

[0044] Carbon (C): 1.0%, Chromium (Cr): 25%, Tungsten (W): 4.2%, Silicon (Si): 2.5%, Aluminum (Al): 7%, Molybdenum (Mo): 4.5%, Boron ( B): 0.8%, yttrium oxide (Y 2 o 3 ): 5%, the rest is nickel (Ni), the nickel-chromium alloy powder mixture is obtained by mechanical ball milling, the powder particle size reaches 200-300 mesh, and dried;

[0045] Use ether to dissolve methyl cellulose as a binder, mix it with the above powder mixture to form a paste, and evenly pre-coat a layer of ring-shaped pre-coating with a thickness of 2.0mm on the sealing surface of the nuclear power valve of the stainless steel substrate, and dry it in the oven medium drying;

[0046] (2) Place the nuclear power valve to be processed on the laser processing machine tool, and guide the laser working head directly above the target area;

[0047] (3) On the nuclear power...

Embodiment 2

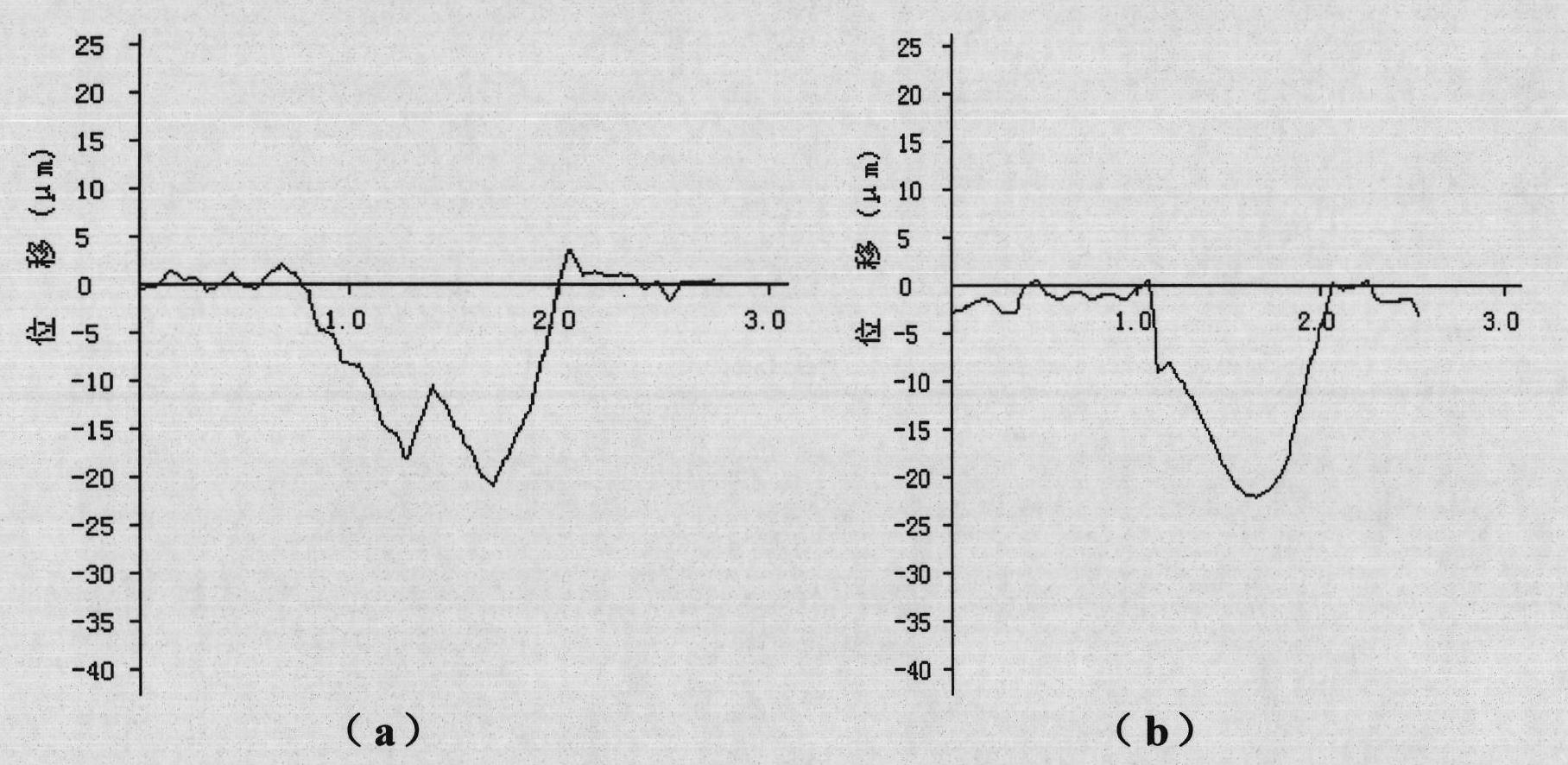

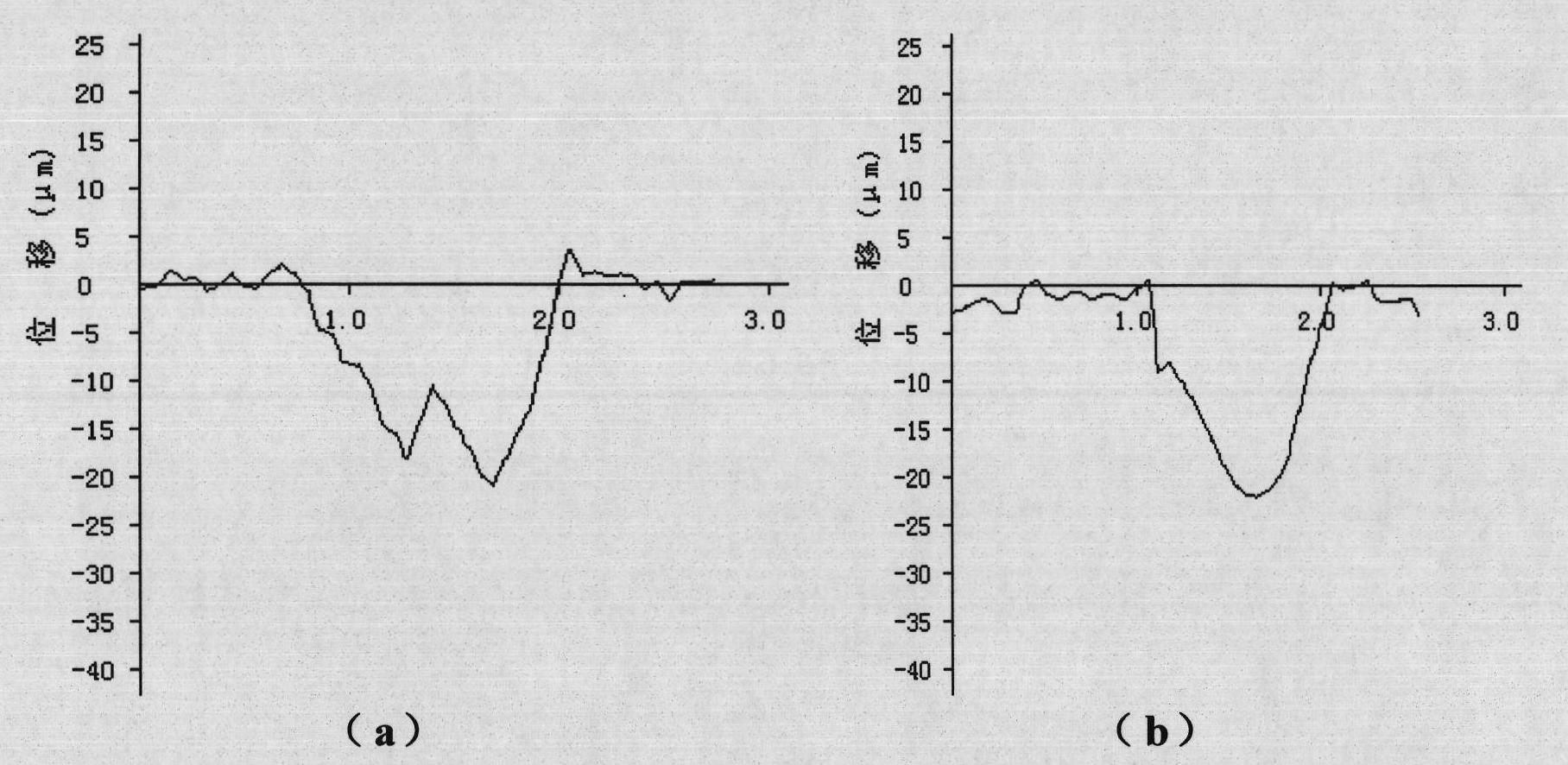

[0050] Carry out high-temperature wear test to the sealing face coating obtained in embodiment one (high-temperature wear test method is referred to L.Dubourg, D.Ursescu, et al..Laser Cladding of MMC coatings on aluminum substrate: influence of composition and microstructure on mechanicalproperties[J]. Wear, 258(1-2): 1745-1754.), friction and wear test conditions: rotation speed v = 200r / min, load F = 500g, friction track radius r = 6mm, temperature rises from normal temperature to 360°C in the first 5 minutes , and then continue to keep warm for 120min, and the grinding ball is a SiN ball with a diameter of 6mm, without lubrication.

[0051] The result is as figure 2 Shown, embodiment one gained sealing surface coating and Stellite06 wear volume are respectively 0.682mm 3 and 0.6465mm 3 .

Embodiment 3

[0053] (1) Preparation of cobalt-free nickel-based alloy powder, according to weight percentage, each component and its content are:

[0054] Carbon (C): 1.2%, Chromium (Cr): 27%, Tungsten (W): 5.8%, Silicon (Si): 2.8%, Aluminum (Al): 10.0%, Molybdenum (Mo): 6.0%, Boron ( B): 0.8%, yttrium oxide (Y 2 o 3 ): 2.0%, and the rest is nickel (Ni). Mix and prepare the required mixed powder with a stirring ball mill. The particle size of the powder is 200-300 mesh, and dry in an oven;

[0055] (2) Place the nuclear power valve to be processed on the laser processing machine tool, and guide the laser working head directly above the target area;

[0056] (3) On the nuclear power valve sealing surface of the 1Cr18Ni9Ti austenitic stainless steel substrate, a laser with a power of 6000W is used to irradiate the surface of the substrate to form a molten pool, and the prepared alloy powder is synchronously fed in. The powder carrier gas is nitrogen, and the nitrogen is simultaneously As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com