Low voltage load test device

A technology for testing devices and low-voltage loads, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as easy electric shock burns, safety accidents, high risks, etc., and achieve reliable production quality, high production efficiency, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

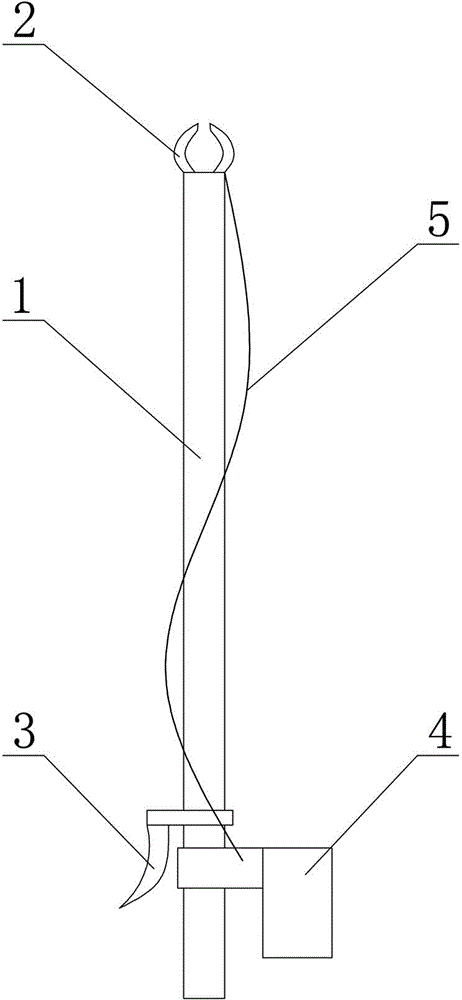

[0016] Such as figure 1 Shown, a kind of low-voltage load test device comprises a 2-meter-long insulating rod 1, a clamp-type current transformer 2 arranged at the top of the insulating rod, an ammeter 4 arranged at the lower end of the insulating rod 1, and an ammeter 4 arranged at the insulating rod 1. The handbrake 3 at the lower end, the handbrake 3 is connected to the clamp current transformer 2 to control its opening and closing through the handbrake line, and the clamp current transformer 2 is connected to the ammeter 4 through the current secondary line 5, and the clamp current transformer 2 is connected to the current secondary line 5. The transformer 2 and the ammeter 4 are respectively the clamp current transformer part and the ammeter part of the clamp ammeter.

[0017] When working, the operator holds the lower end of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com