Precise high-efficiency polishing method and device for curved surface parts

A technology of curved surface parts and polishing devices, which is applied in the field of precision ultra-precision machining, can solve the problems of low processing efficiency, poor processing consistency, complex processing equipment and high cost, and achieve the effect of simple manufacturing and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

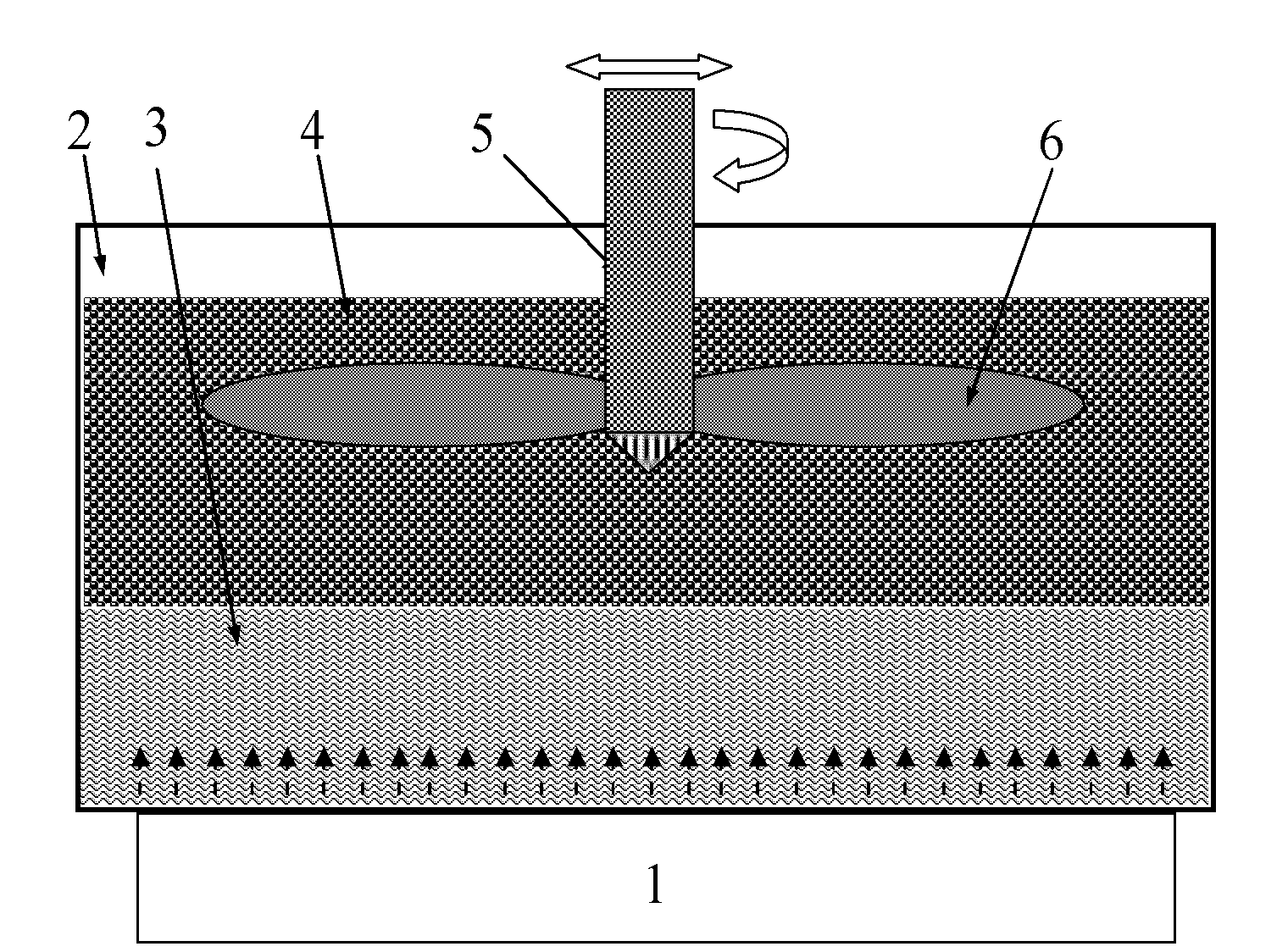

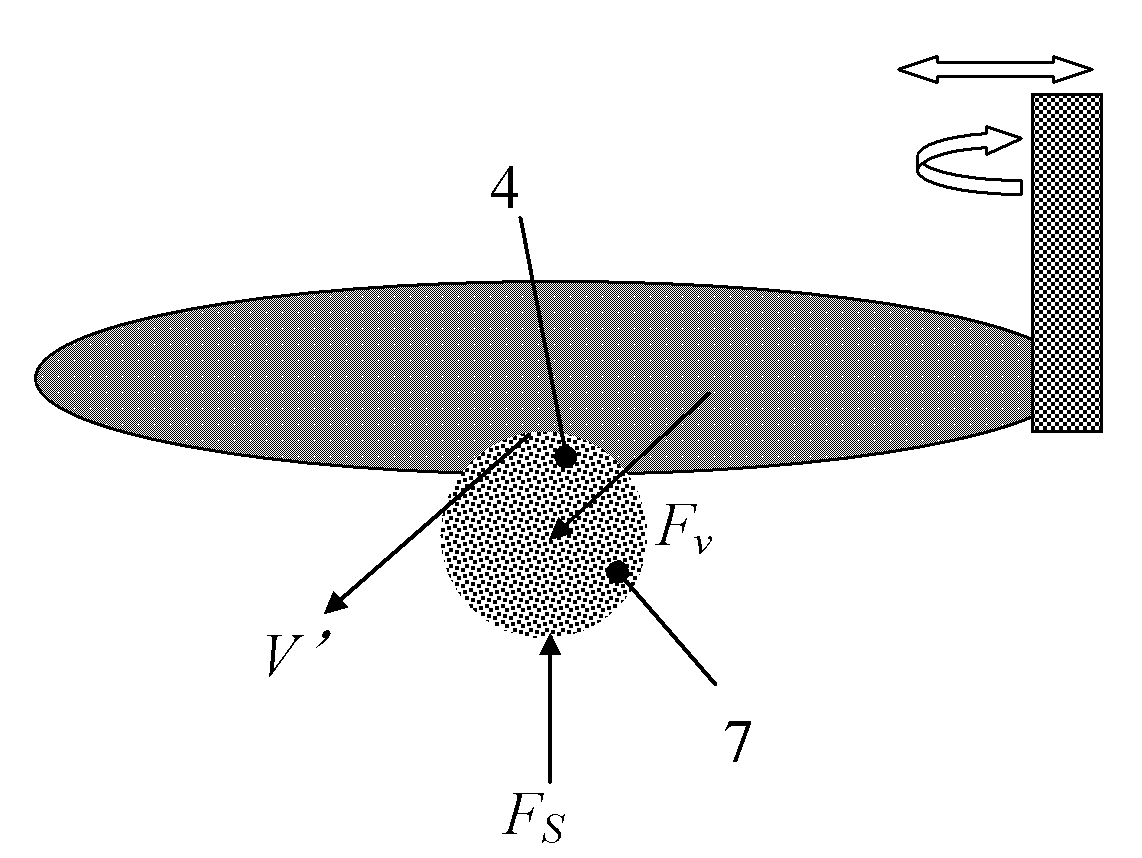

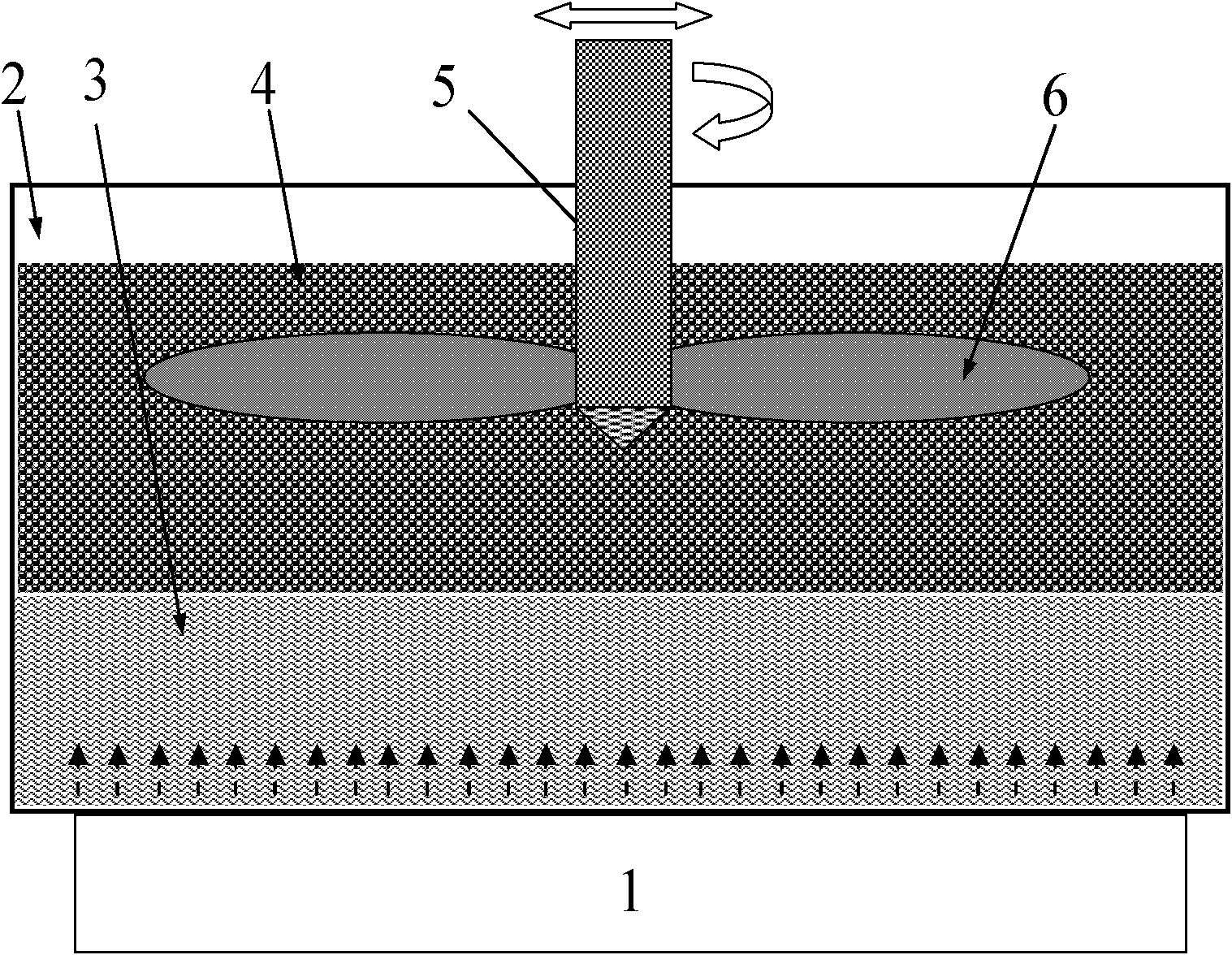

[0034] see figure 1 and figure 2 , a precision and high-efficiency polishing method for special-shaped complex molds. The polishing equipment for realizing the polishing method is mainly composed of a polishing tank 2, an ultrasonic generator 1, a workpiece clamping device 5, and a large number of porous polyurethane balls 4 distributed in the polishing liquid. . The ultrasonic generator 1 is installed at the bottom of the polishing tank 2 . The polishing liquid 3 in the described polishing tank 2 contains abrasive material 7 (~20%wt) of relatively high concentration and numerous porous polyurethane balls 4, and described workpiece clamping device 5 is positioned at the top of polishing tank 2, under driving force Different motion modes can be realized under the action of the

[0035]The special-shaped complex mold 6 to be polished is installed on the workpiece holding device 5, and the special-shaped complex mold 6 is immersed in the polishing liquid 3 in the polishing ta...

Embodiment 2

[0041] see figure 1 and figure 2 , the precise and efficient polishing method of the automobile wheel hub, in the polishing equipment for realizing the described polishing method, it is mainly composed of a polishing tank 2, an ultrasonic generator 1, a workpiece clamping device 5 and numerous porous polyurethane balls 4 distributed in the polishing liquid. The ultrasonic generator 1 is installed at the bottom of the polishing tank 2 . The polishing solution 3 in the polishing tank 2 contains a relatively high concentration of abrasives 7 (~20%wt) and numerous porous polyurethane balls 4, and has relatively high viscosity. The workpiece clamping device 5 is located above the polishing tank 2, and can realize different movement modes under the action of the driving force.

[0042] Install the automobile wheel hub to be polished on the workpiece holding device 5, immerse the wheel hub in the polishing liquid 3 in the polishing tank 2, under the action of the driving force, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com