Cured track bed sinking repairing high-viscosity vibration attenuation polyurethane repairing material

A repair material, polyurethane technology, applied in the direction of track, road, track maintenance, etc., can solve the problems of aggravated railway transportation and line maintenance, increased maintenance and repair workload, poor maintainability of ballastless track, etc., to achieve strong deformation ability , high dimensional stability, good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

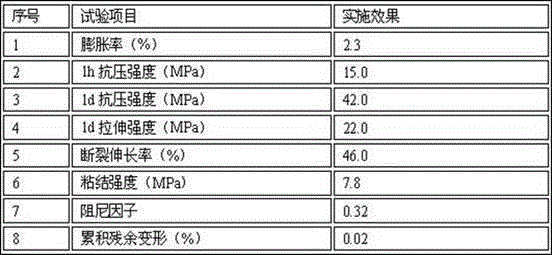

[0024] Specific embodiment 1 is as shown in table 1.

[0025] Concrete specimens were cored and cut to size φ For a sample of 50mm×25mm, place the two samples in the middle, the distance between the samples is 20mm, seal the surrounding of the sample with kraft paper and wide tape, leave a grouting hole in the upper part, and use an electric stirrer to mix A component and B component The components were mixed at high speed and poured into the cavity. After 1 day, the mold was demoulded, and the metal side head was pasted on the outside of the concrete sample. The electronic universal testing machine was used to test the bonding performance of the polyurethane repair material and the concrete material. The tensile rate was 10mm / min. In the anti-fatigue performance test, the maximum load is 0.3MPa, the minimum load is 0.03MPa, and the loading frequency is 5HZ. Use a vernier caliper to measure the thickness of the sample before and after loading, and calculate the accumulated r...

specific Embodiment 2

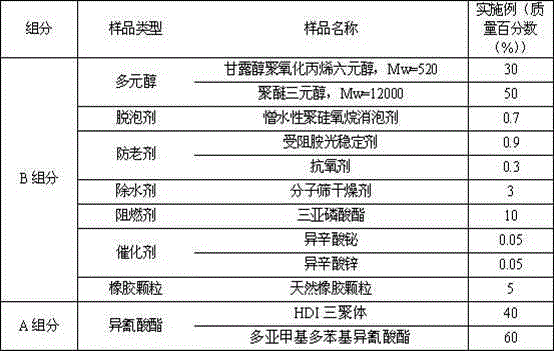

[0032] Specific embodiment 2 is as shown in table 3.

[0033] Table 3 specific embodiment 2

[0034]

[0035] Note: Mw in the table represents the average molecular weight of the compound.

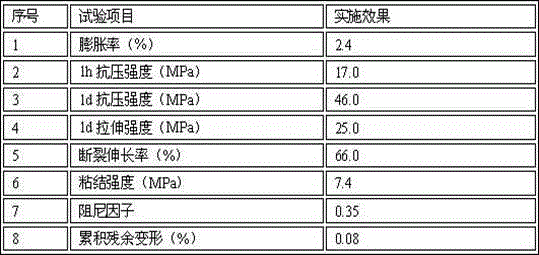

[0036] Specific embodiment 2 test method is identical with the test method of embodiment 1, and implementation effect is shown in Table 4.

[0037] The performance of the polyurethane repair material that table 4 produces according to specific embodiment 2

[0038]

specific Embodiment 3

[0040] Specific embodiment 3 is as shown in table 5.

[0041] Table 5 specific embodiment 3

[0042]

[0043] Note: Mw in the table represents the average molecular weight of the compound.

[0044] Test method is identical with the test method of embodiment 1, and implementation effect is shown in Table 6.

[0045] Table 6 is according to the performance of the polyurethane repairing material that concrete embodiment 3 produces

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com