Patents

Literature

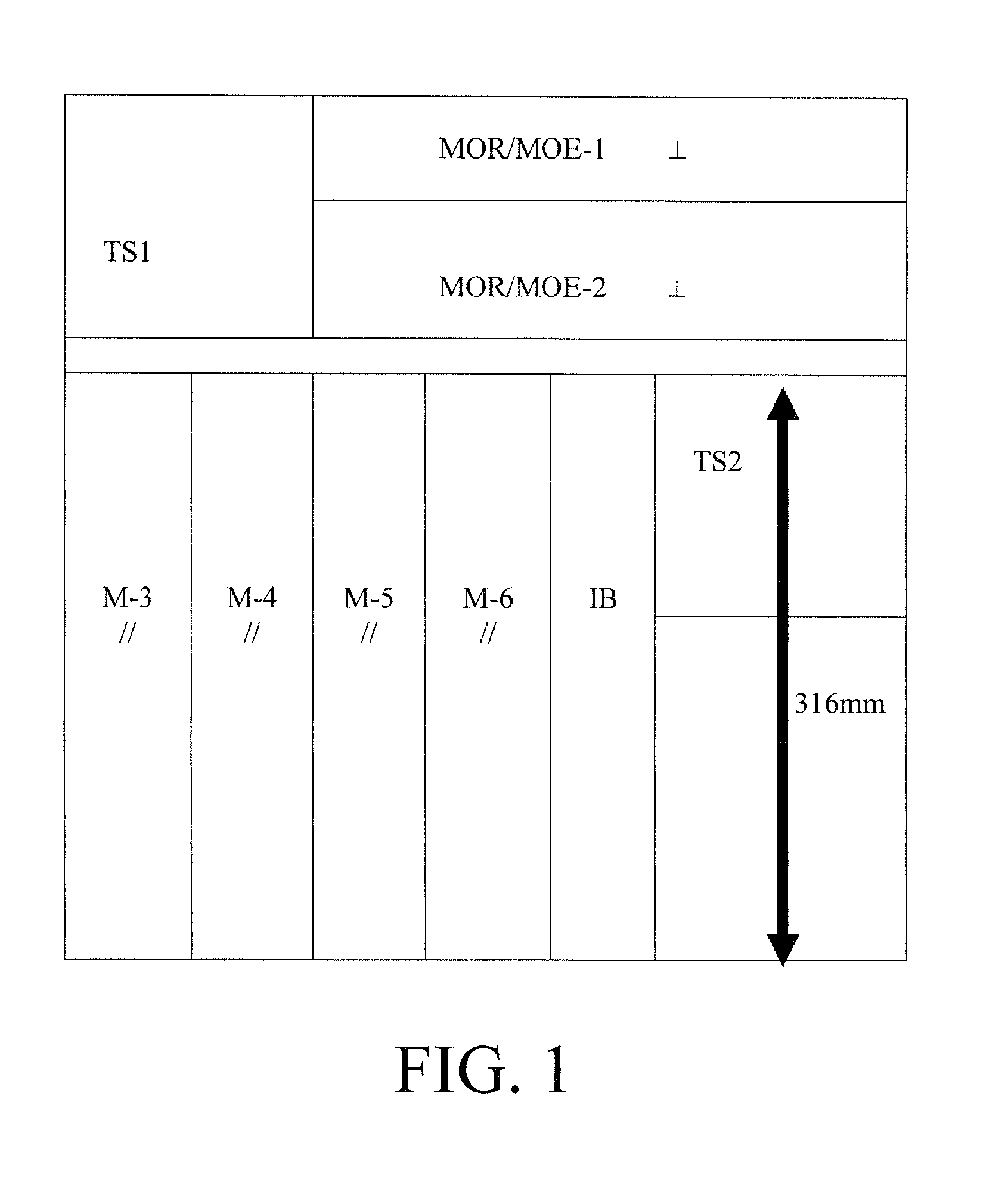

76 results about "Composite lumber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite lumber is a material that is a mixture of wood fiber, plastic, and some type of binding agent. These ingredients are put together to form a material that is denser, stronger, and heavier than wood alone, a wood-plastic composite.

Wood Adhesives Containing Reinforced Additives for Structural Engineering Products

The present disclosure relates to additives used in conjunction with adhesives to give enhanced performance. Engineered composite wood materials and methods of making such materials are also provided by the subject application. A reinforced adhesive includes an adhesive and an additive material comprising nanoscopic and microscopic materials.

Owner:UNIV OF TENNESSEE RES FOUND

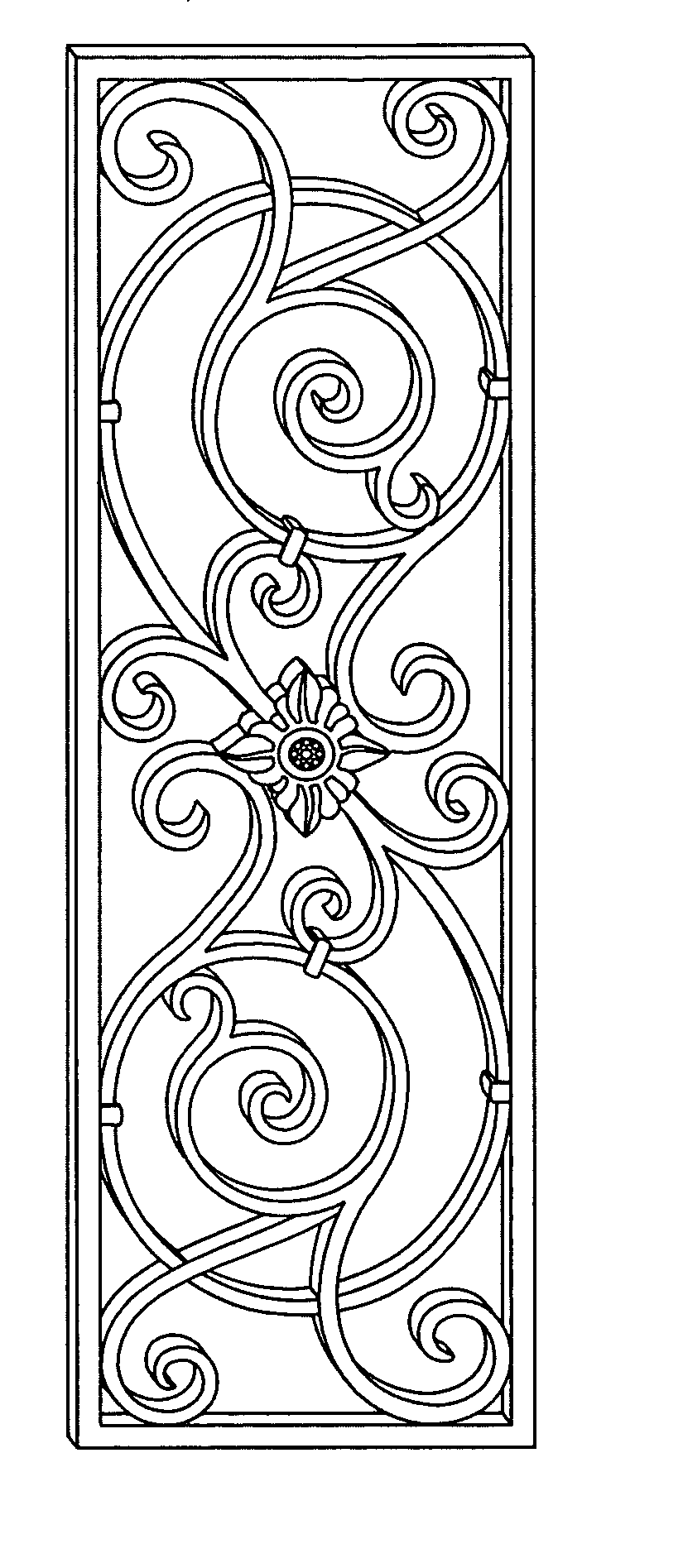

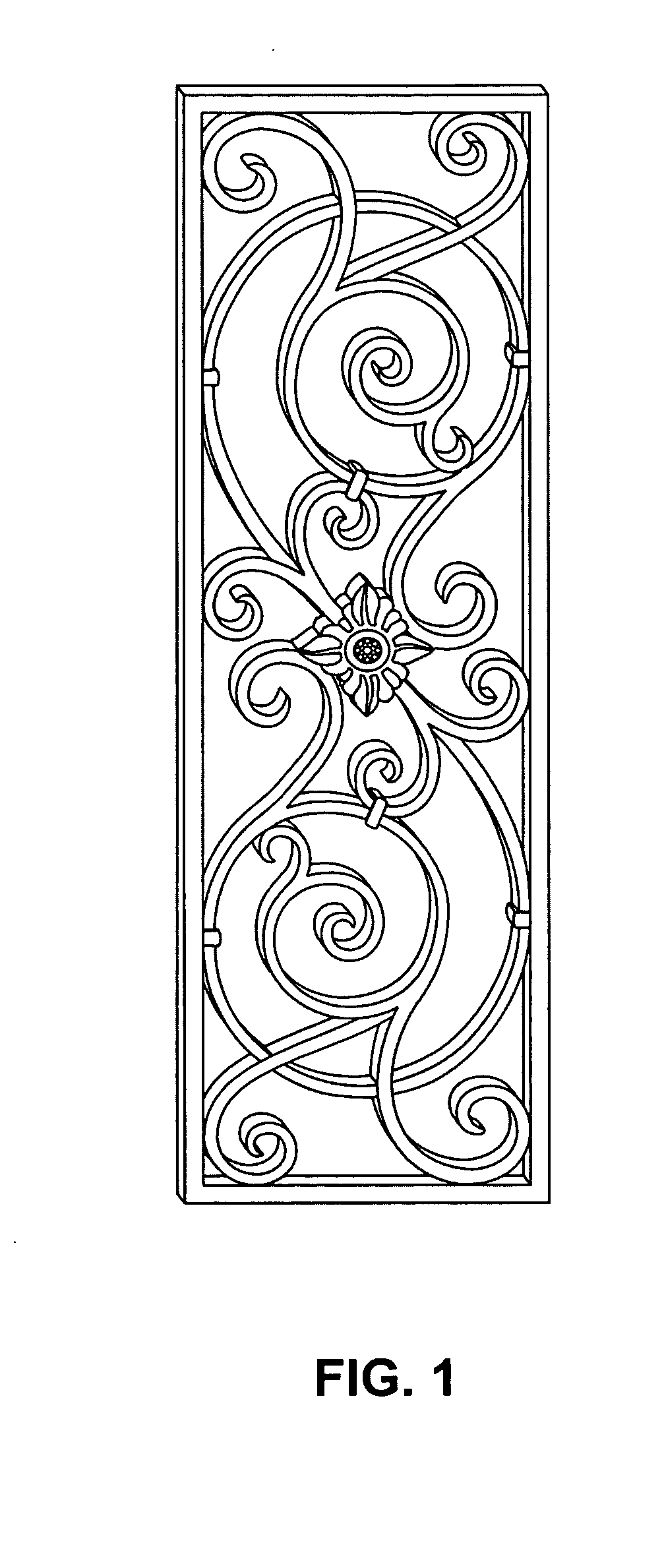

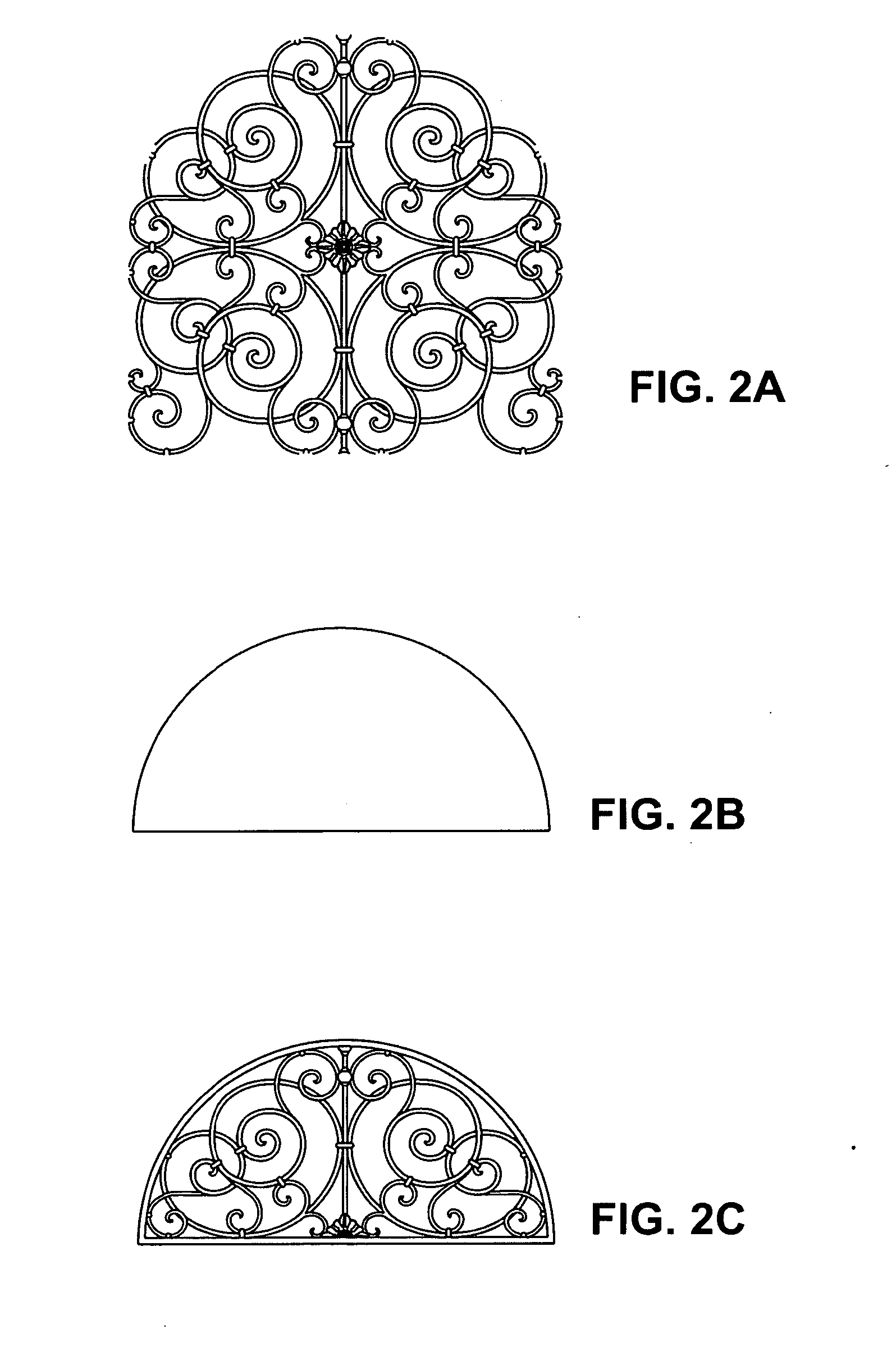

Decorative lattice structure and methods for manufacturing and installing same

InactiveUS20070000195A1High cost lookLow mass production costCovering/liningsFixed grillesFiberMass customization

A decorative lattice that simulates the look and feel of decorative ironwork by combining carving techniques and coating techniques is described. The decorative latticework is made of a sheet material such as a composite wood / fiber board material. The decorative lattice is suitable for a mass customization manufacturing processes.

Owner:LUNA PIENA

Plant fiber polymerization wood and method for manufacturing same

The invention relates to artificial composite wood, in particular to a plant fiber polymer wood and a method for making the same. The plant fiber polymer wood is made form the following materials in percentage by weight: 50 to 85 percent of plant fiber powder, 10 to 45 percent of plastic resin, 0.5 to 1.5 percent of coupling agent, 2 to 5 percent of foaming agent, 0.5 to 1.5 percent of blowing promoter, 1 to 2 percent of plasticizer, 0.5 to 1 percent of nucleating agent, and 0.5 to 3 point of lubricating agent, wherein the plant fiber powder is one or a plurality of kinds selected form wood meal, powdered rice hull, powdered straw( corn stalk, sorghum stalk, wheat straw, straw, sunflower stalk, egg plant stalk, bean stalk, haulm, hemp stalk and other crop stalks), brushwood powder, weed powder, and peanut and seed shell powder. The artificial composite wood has the characteristics o saving wood material, allowing for recycling, contributing to environment protection, along with high strength, low cost, long service life. The process is simple, scientific and reasonable.

Owner:JILIN ZISEN DECORATION MATERIALS

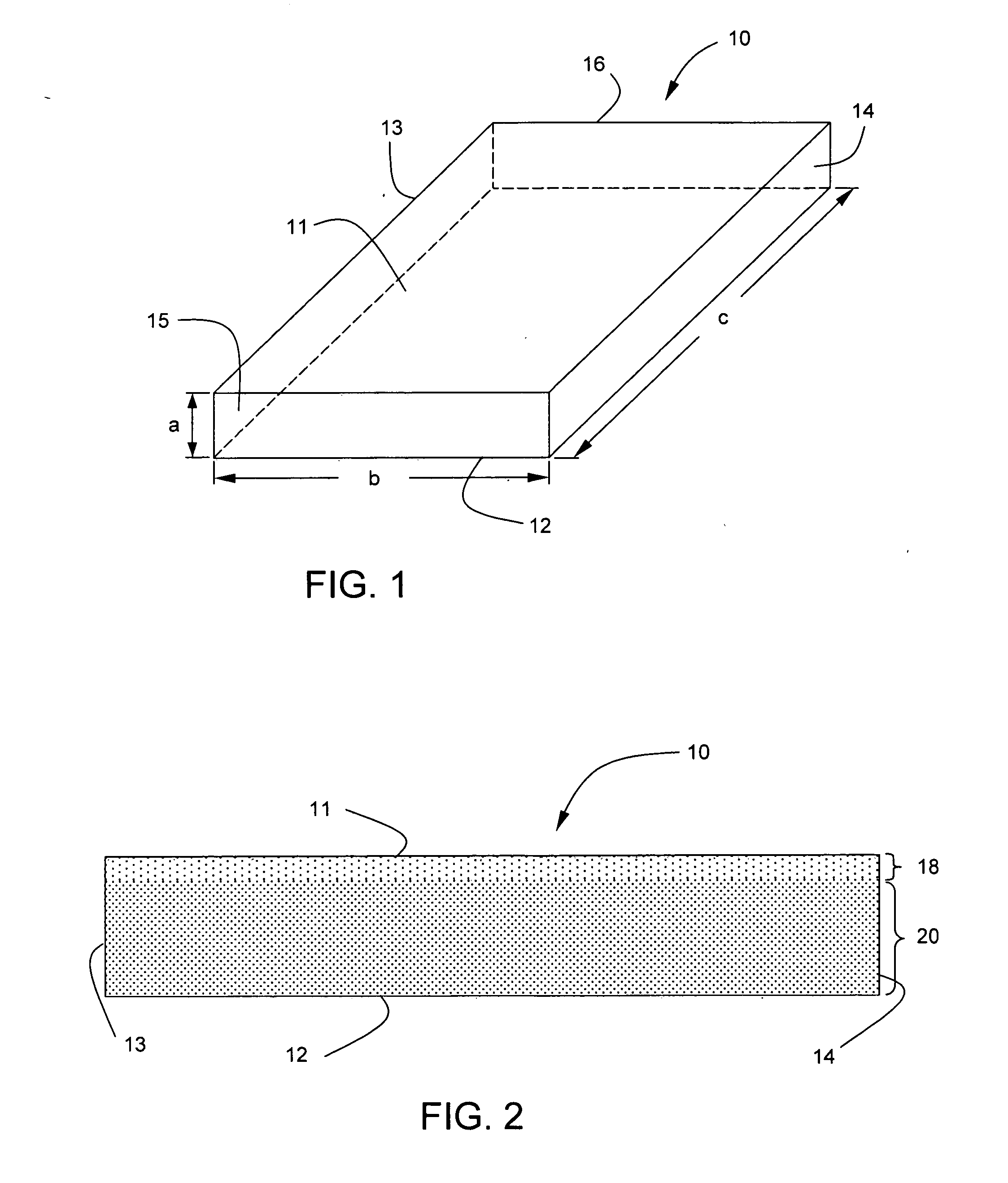

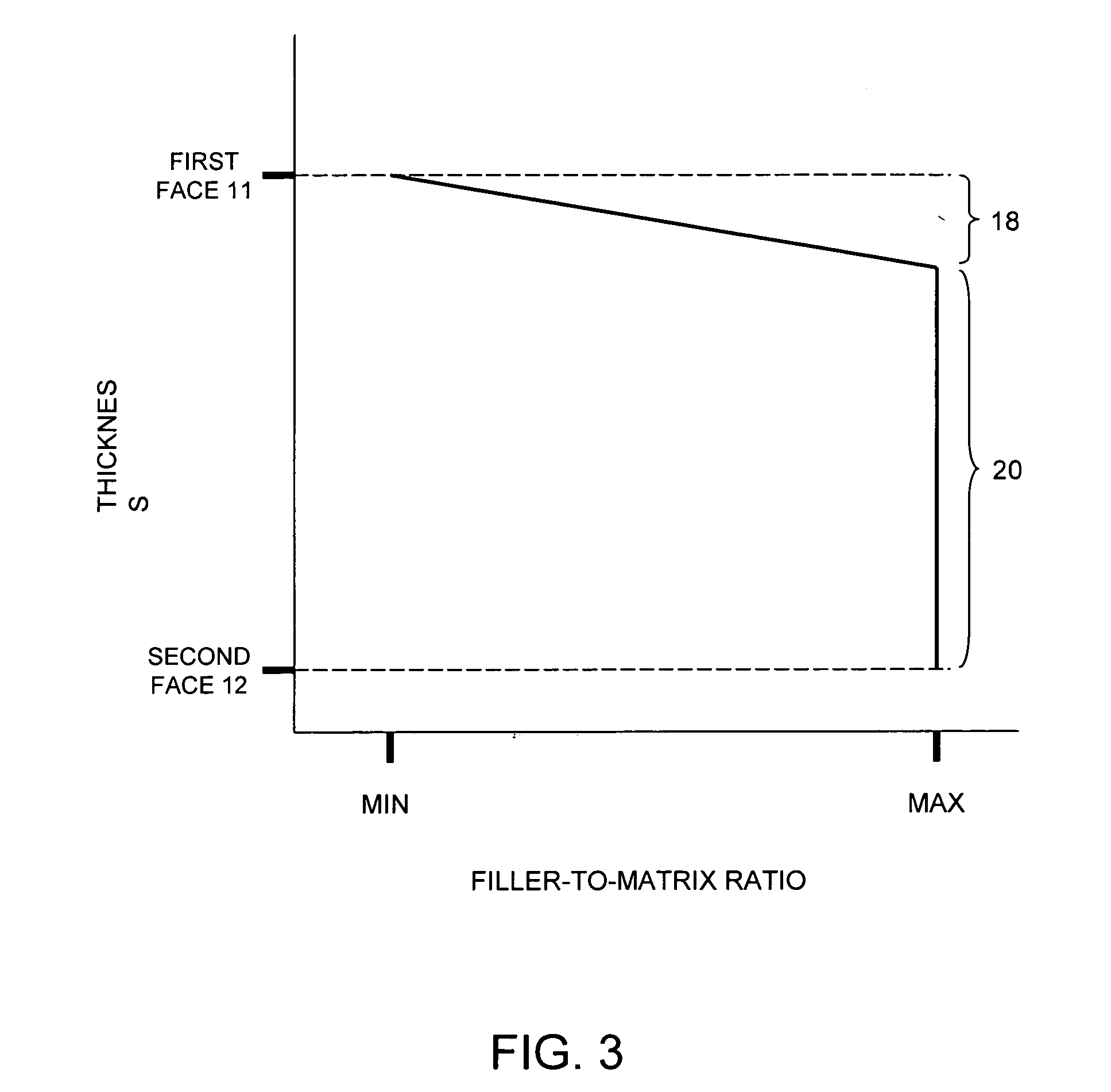

Composite wood replacement article and method of making same

ActiveUS20070104930A1Easy to understandLayered productsThin material handlingFilling materialsVolumetric Mass Density

A composite article includes a matrix having first and second opposing surfaces defining a transverse dimension and a filler material embedded in the matrix. The filler material presents a density gradient in the transverse dimension wherein a minimum filler density is at the first surface. In one embodiment, the composite article is a non-laminated article defining first and second regions wherein the first region encompasses the first surface. The first region has a filler-to-matrix ratio that varies along the transverse dimension, the filler-to-matrix ratio being at a minimum at the first surface. The first region can include one or more additives. A method for forming a composite article includes injecting first and second compositions into a die head at different points so as to produce a partially mixed composition that is discharged from the die head. The second composition contains less filler material than the first composition.

Owner:BARRETTE OUTDOOR LIVING INC

Wood bunch recombining material and producing method thereof

InactiveCN101104286ALow technical requirementsReduce investmentDomestic articlesFlat articlesFiberVolumetric Mass Density

Disclosed is a wood bunch composite lumber, whose cross section is square, round or elliptical shaped, wherein the wood fiber is vertically arranged; the appearance of the cross section is a congregated section of numerous wood bunches, showing the combining color of the natural wood color and the color of the glue; the density is 0.7-1.1g / cm3; the static bending strength is 30-40MPa; the elasticity modulus is 5000 -11000MPa; the nail-holding ability is 1100-2000N. The production of the composite lumber includes the following procedures: material selection, wood-bunch preparation, desiccantion, gluing, measuring, assembling, mould packing, cold pressing, thermal initiated solidification, cooling and mould removal. The composite lumber can be applied directly to the architectural ornament industry, the sawed floor board and the furniture faceplate and so on. The invention has advantages that the raw materials adopted can make comprehensive use of the lumber resources; the material quality of the product is even; the structure and the nature of the lumber can basically be kept unchanged; the lumber is material-saving, stable and easy for secondary production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

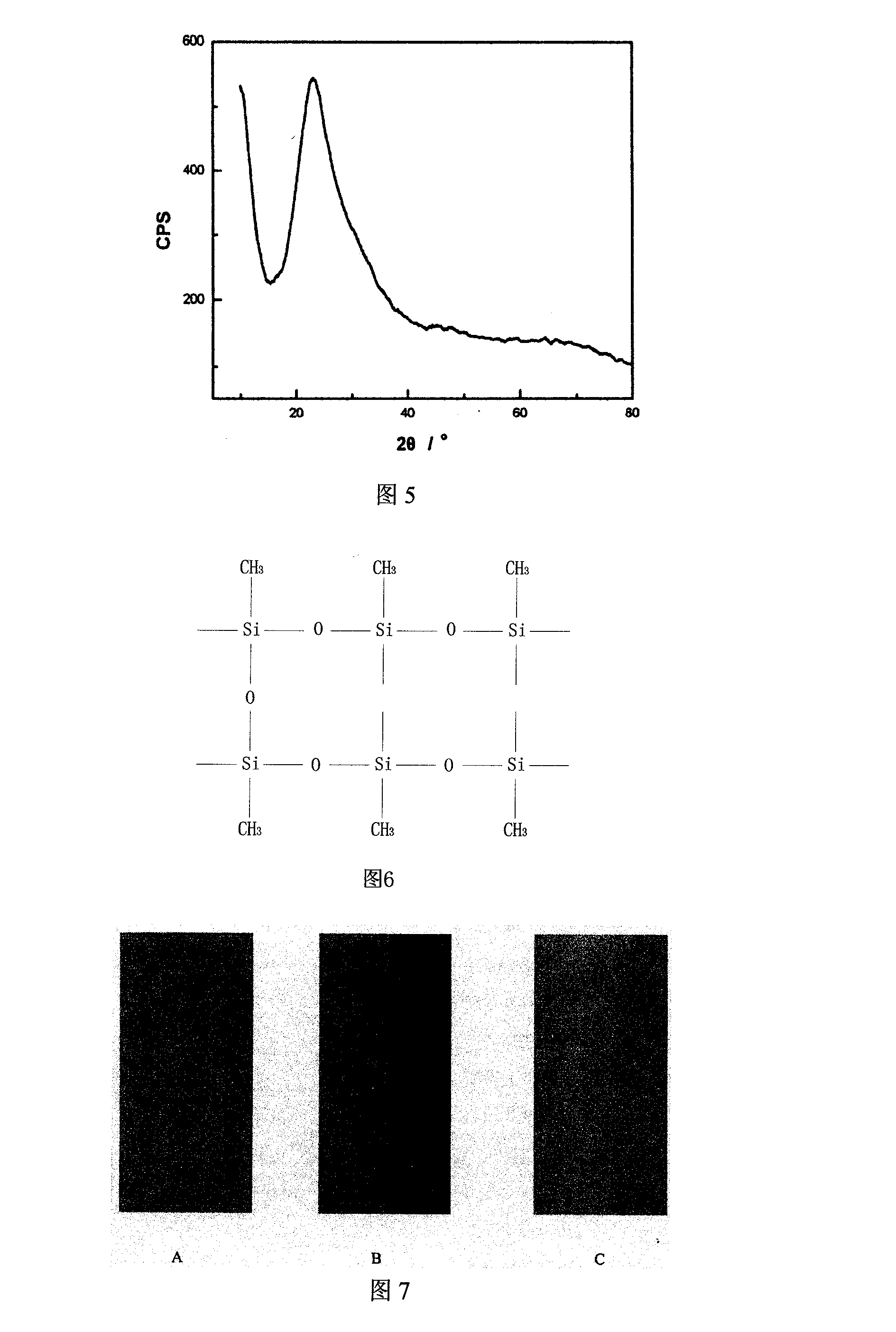

Core-shell type multifunctional composite wood precursor solution and its preparation method

InactiveCN101100079AChange structureChange propertiesWood impregnation detailsFireproofingDouble bond

The present invention is core-shell type multifunctional compound timber precursor liquid and its preparation process, and belongs to the field of building material technology. Nanometer inorganic particle is first surface modified and then is emulsion polymerized together with organic monomer containing double bond to prepare the core-shell type compound timber precursor liquid. The core-shell type multifunctional compound timber precursor liquid is applied in dipping timber for preparing compound timber. The core-shell type multifunctional compound timber precursor liquid has the high strength, high heat stability and high wear resistance of inorganic matter as well as high flexibility and less deformation of organic matter, and the timber modified with the precursor liquid has raised hardness and strength, enhanced fireproofing performance and corrosion resistance, and high endurance.

Owner:BEIJING PEIER MAOSEN TECH PROMOTION

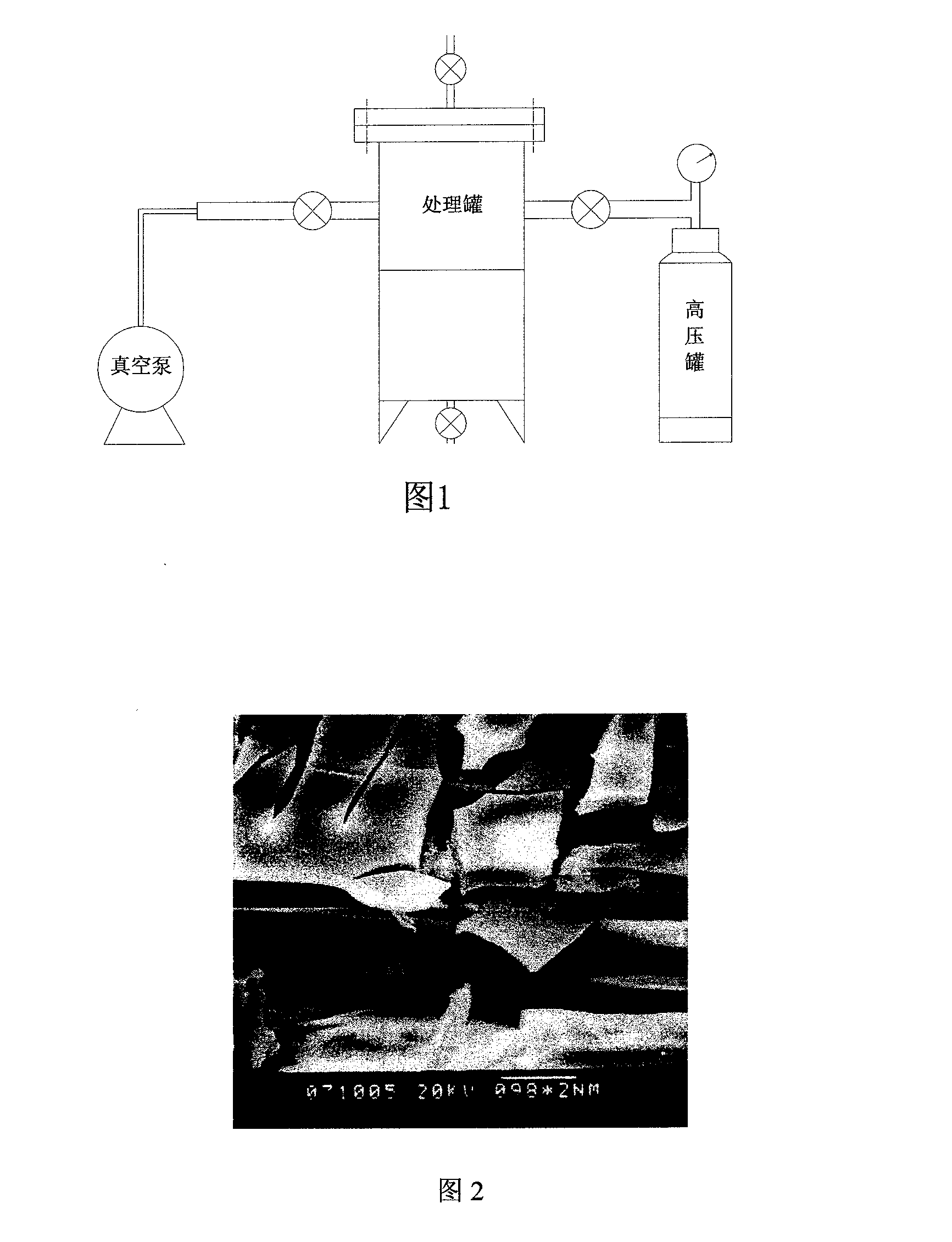

Method for preparing ceramic composite wood

InactiveCN101164744AIncrease profitOvercome the shortcoming of serious volatile lossWood treatment detailsPolymerisation impregnationCeramic compositePositive pressure

The present invention discloses a preparation method of vitrified composite wood material. Said preparation method includes the following steps: (1), preparing MTES-TEOS sol; (2), making the wood material to be treated undergo the process of negative pressure and positive pressure treatment in a treatment tank and impregnating the wood material to be treated with the sol prepared in step 1 in the process of negative pressure treatment; and (3), making the above-mentioned wood material undergo the process of ageing treatment in the room, then making gel treatment in the drying oven so as to obtain the invented vitrified composite wood material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Cold curable isocyanate adhesives with reduced foaming

InactiveUS20050010013A1ViscosityLow composition viscosityPolyureas/polyurethane adhesivesAdhesiveComposite lumber

Moisture activated polyisocyanate adhesives comprising isocyanate terminated prepolymers that provide rapid curing at relatively low temperatures. The adhesives have reduced tendency toward foaming and exhibit excellent gap filling characteristics. The adhesive compositions are suitable for use as wood adhesives, and are especially suitable for engineered composite lumber applications.

Owner:HUNTSMAN INT LLC

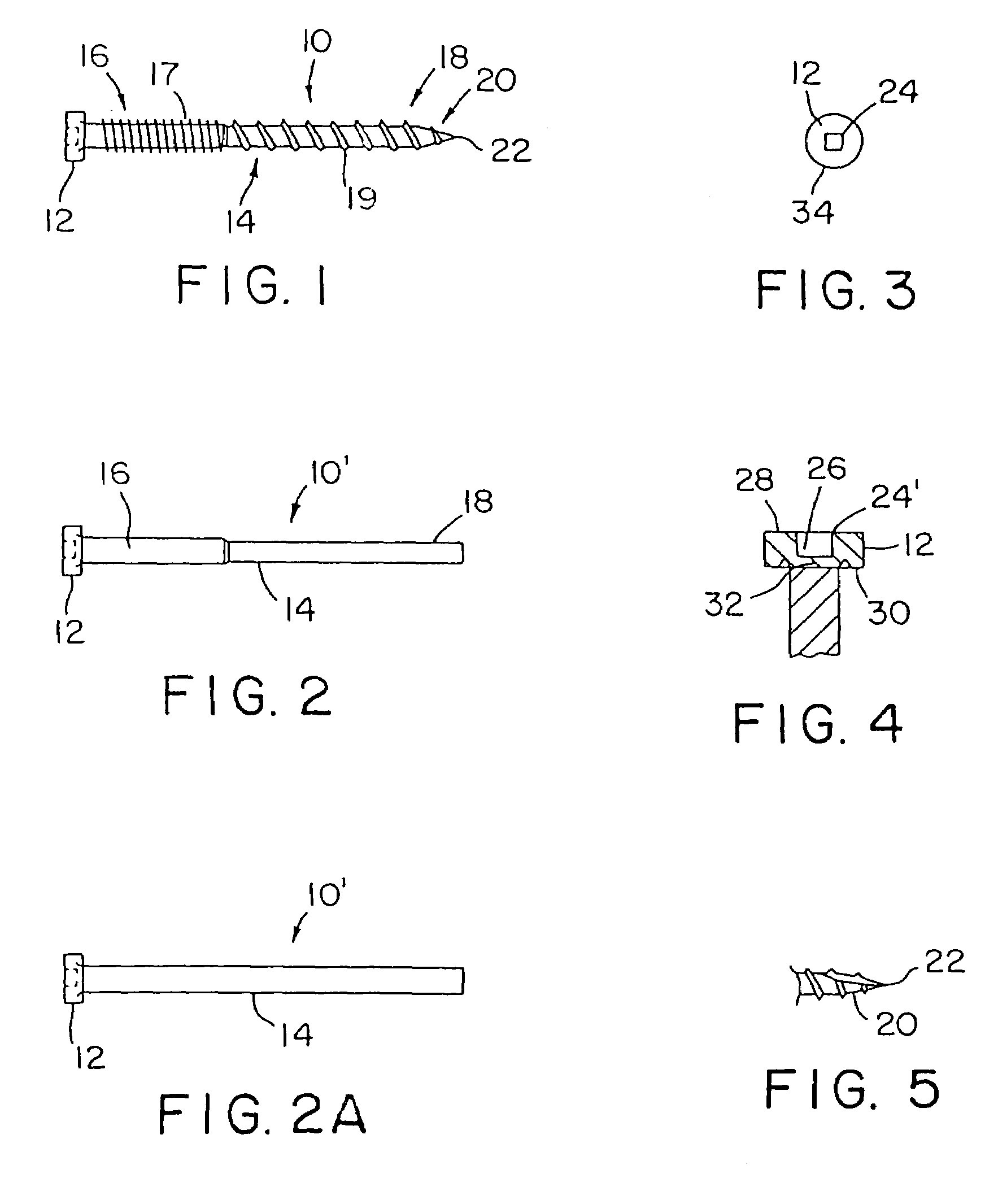

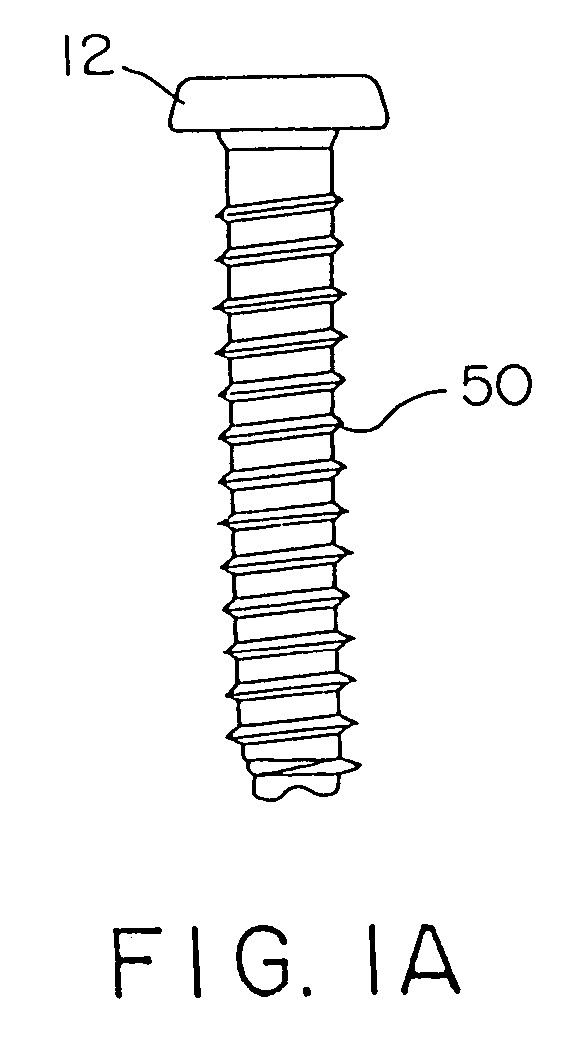

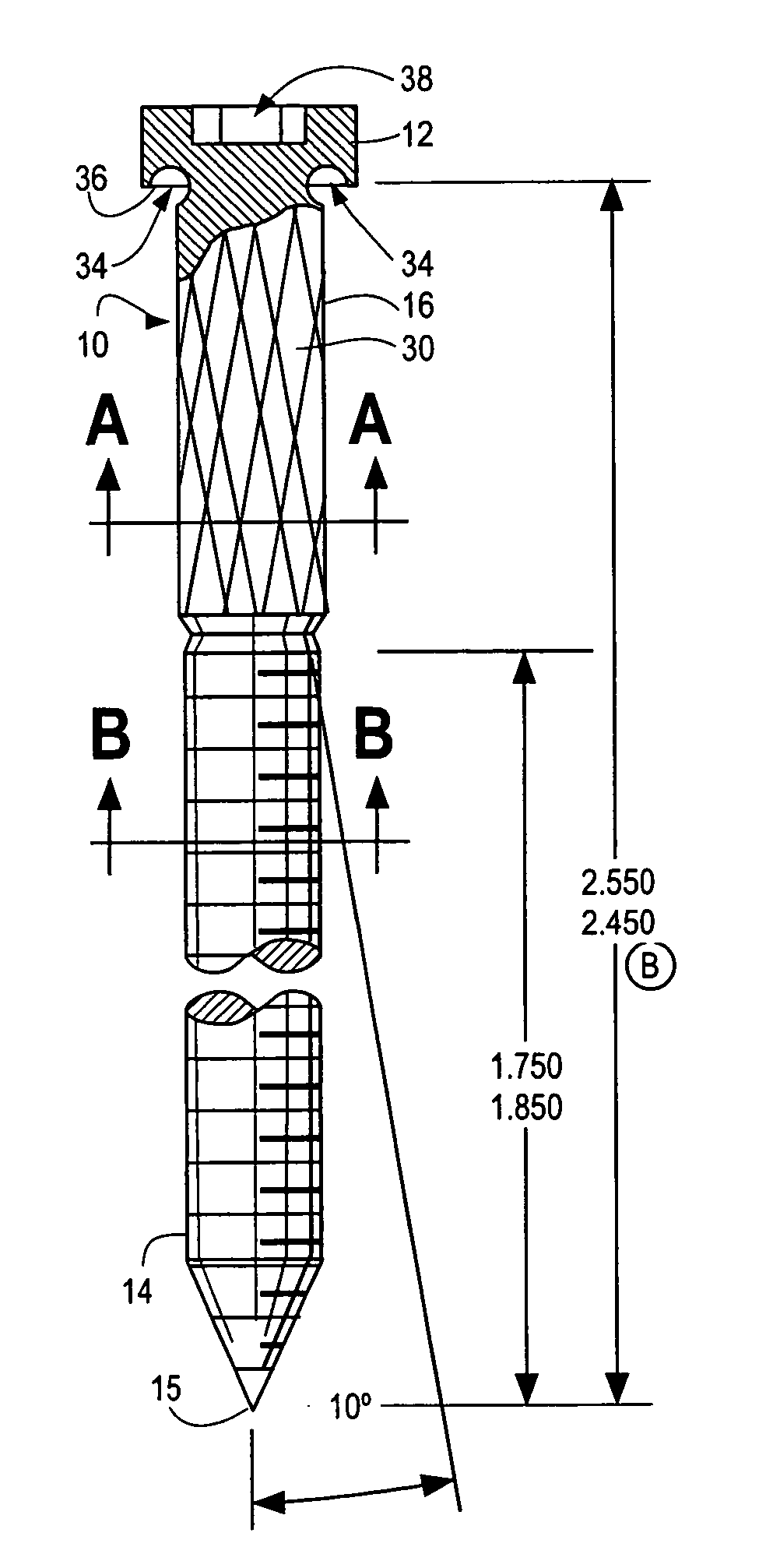

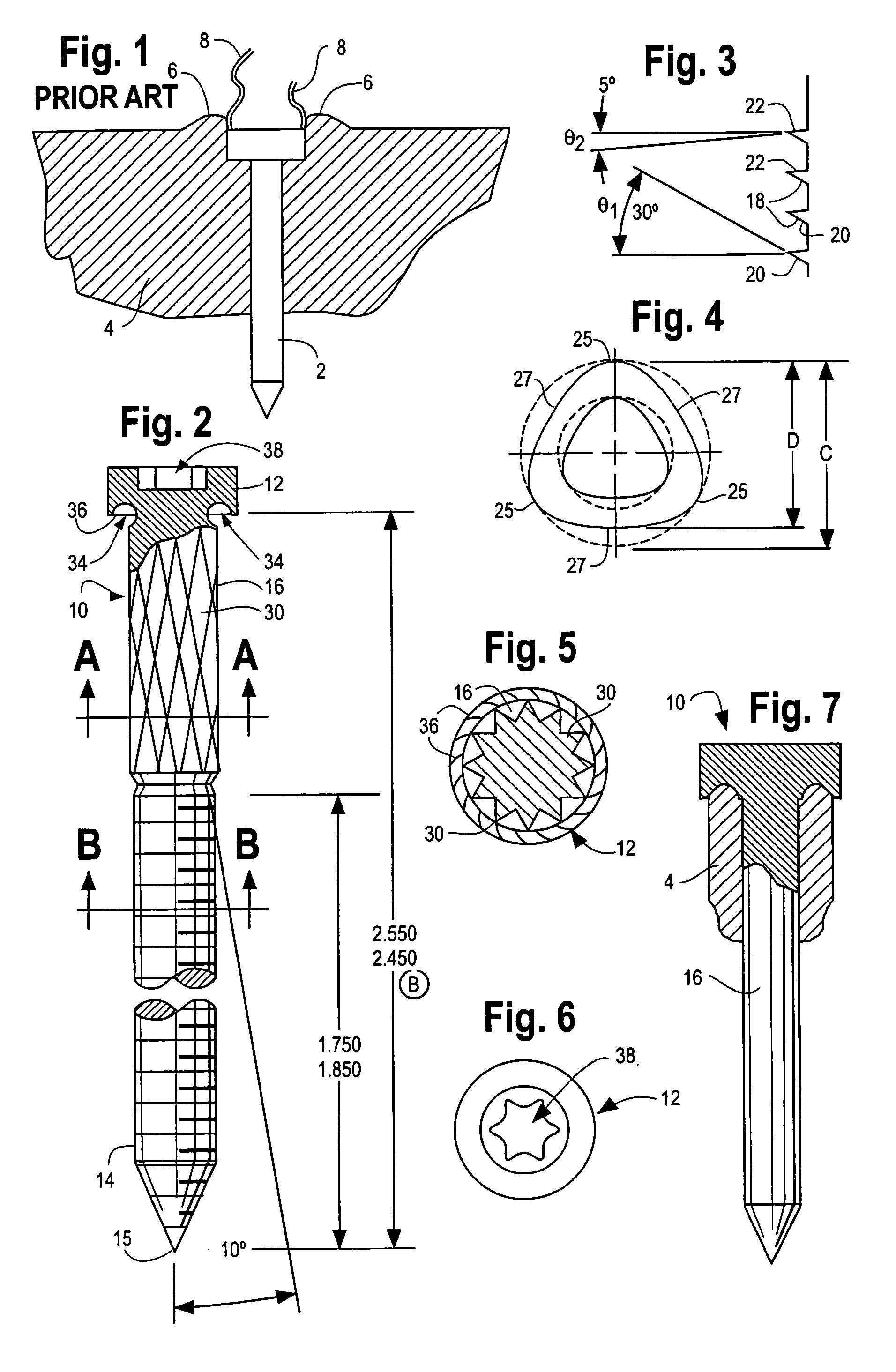

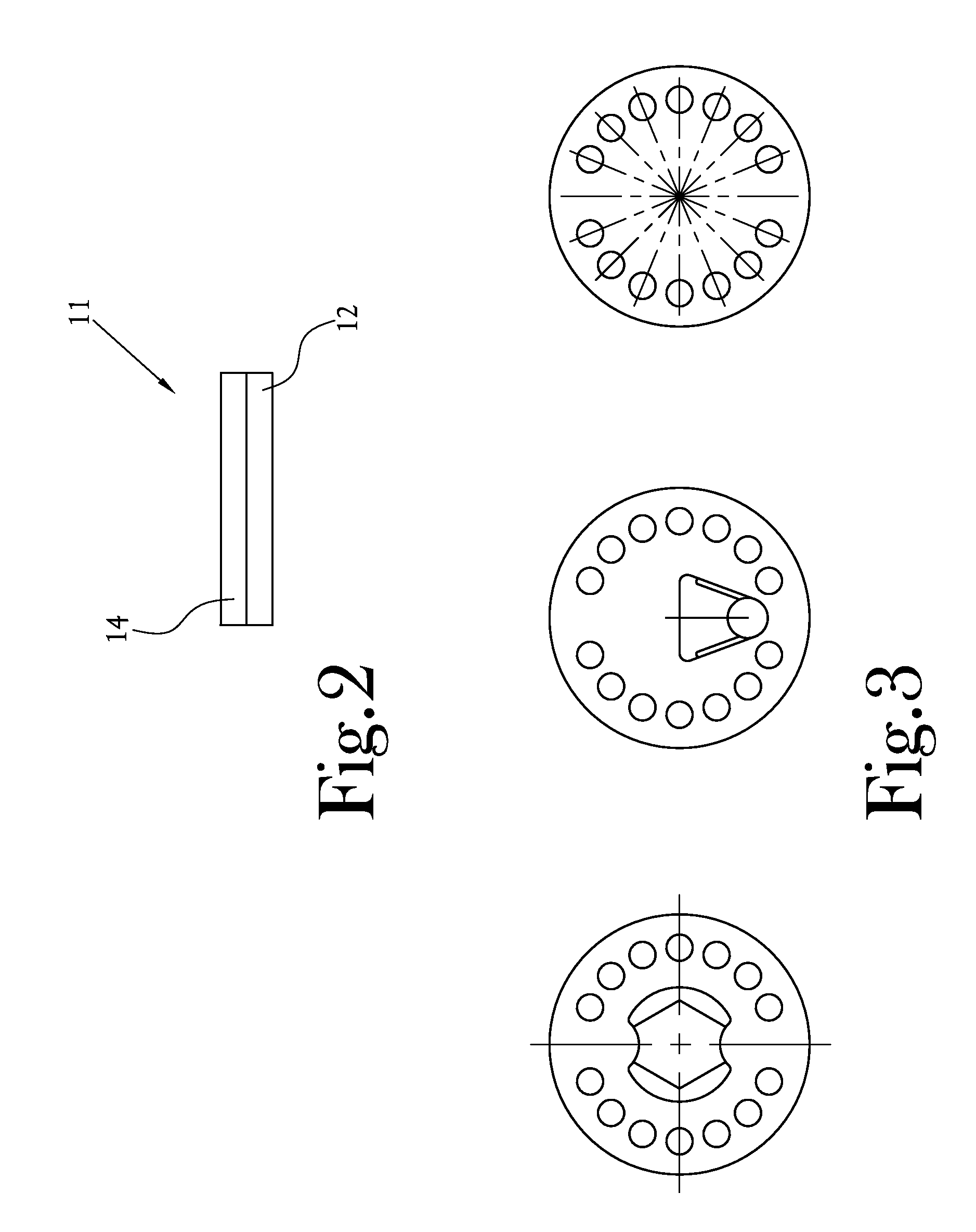

Deck screws suitable for use with composite lumber

InactiveUS7189045B2Reduce, if not eliminate, instances of volcanoing or mushroomingNutsBoltsButtressComposite lumber

A deck screw is intended for use with composite lumber, although it can be used with other wood products, such as pressure treated lumber. The deck screw has a head and a shaft that has two regions of different diameter. The upper region has threads that exceed the number of threads of the lower shaft, on a unit length basis. The threads of the upper shaft may be configured in an inverted buttress design. The lower region of the shaft terminates at a tapered distal end having a pointed tip that leads the screw through the wood material. Threads are provided on the lower region of the shaft. A crown extends around the perimeter of the head.

Owner:OMG INC

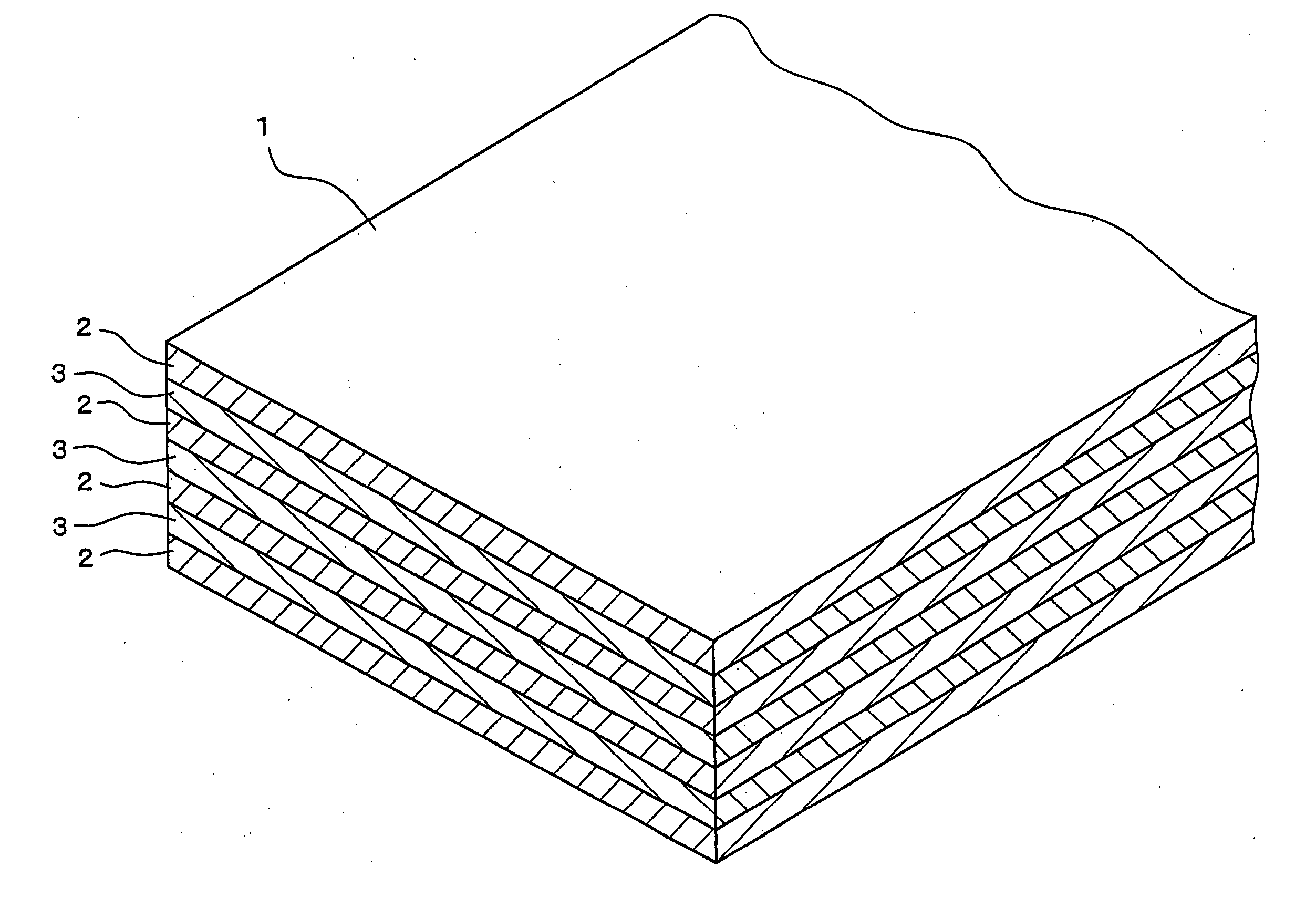

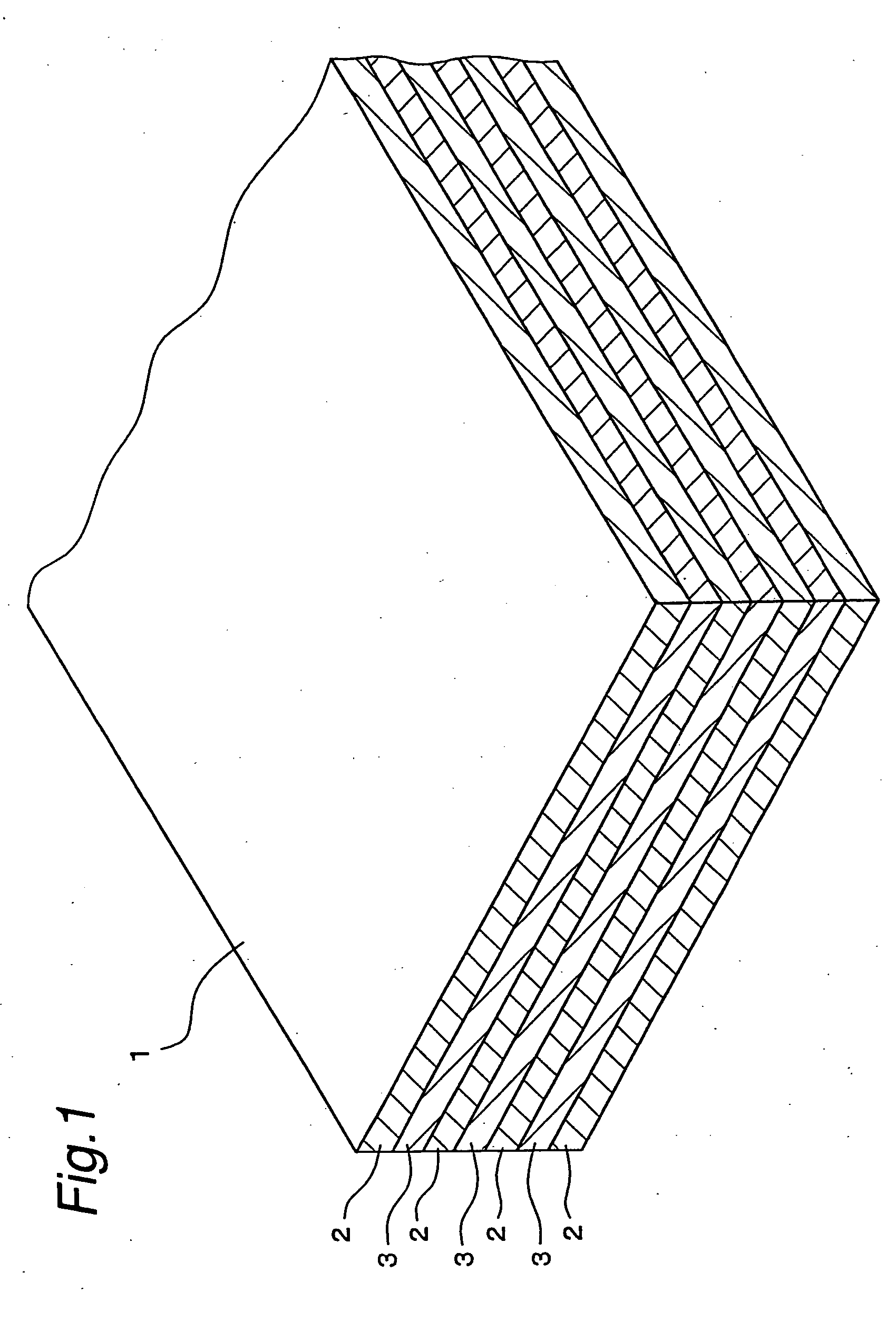

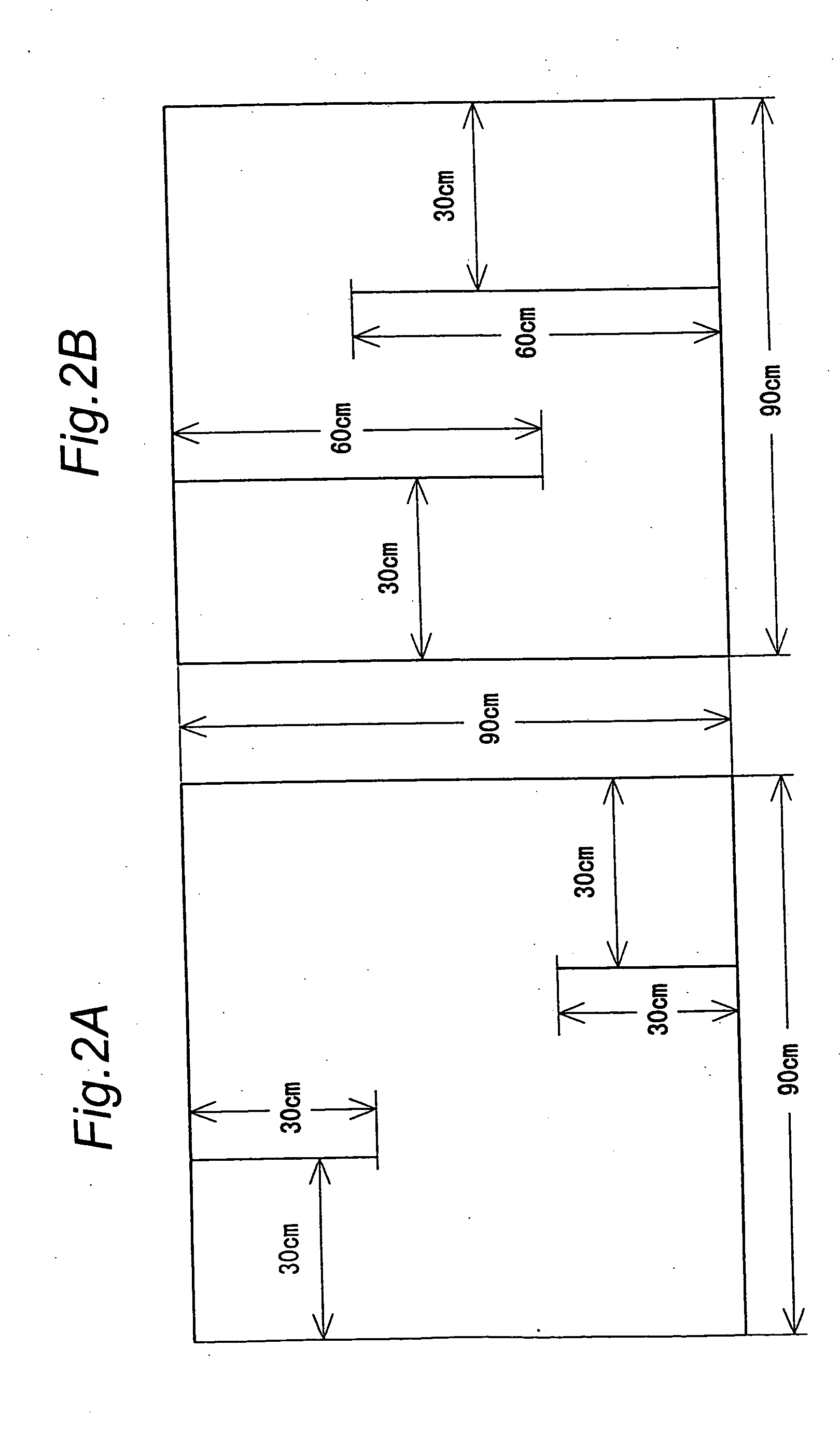

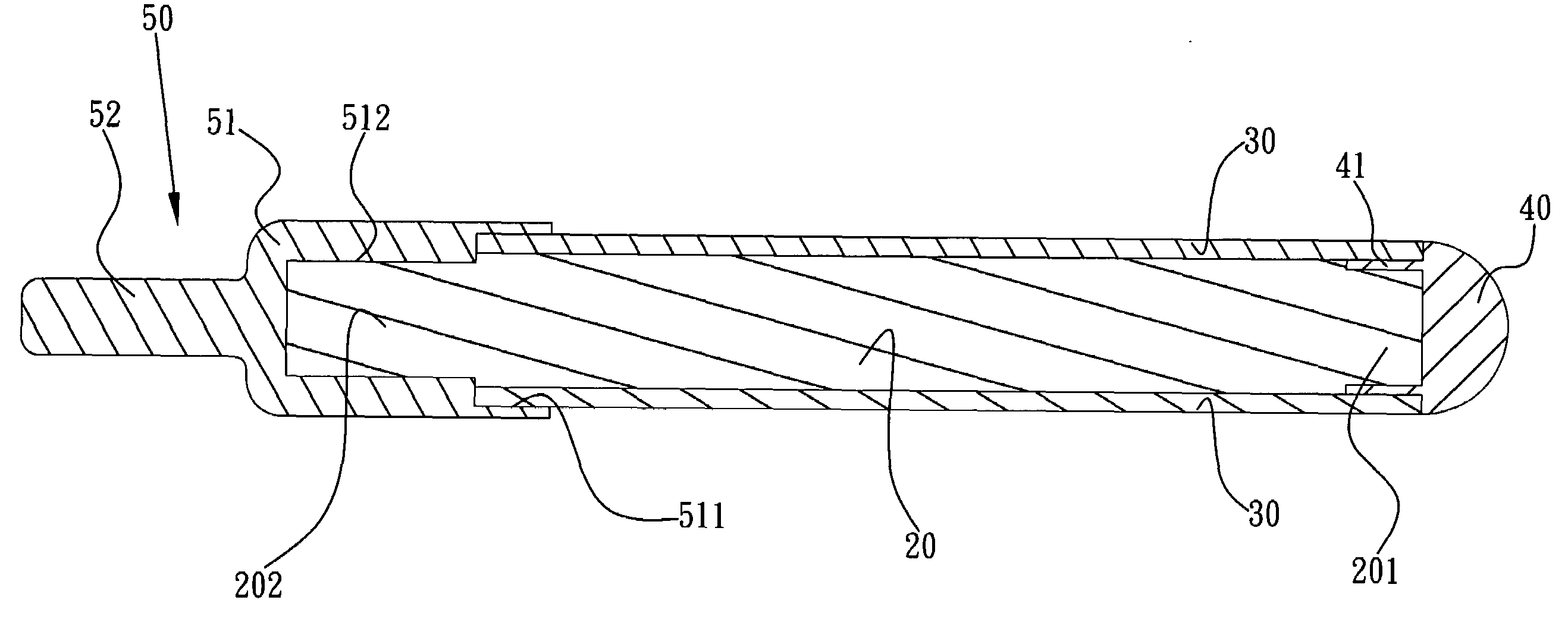

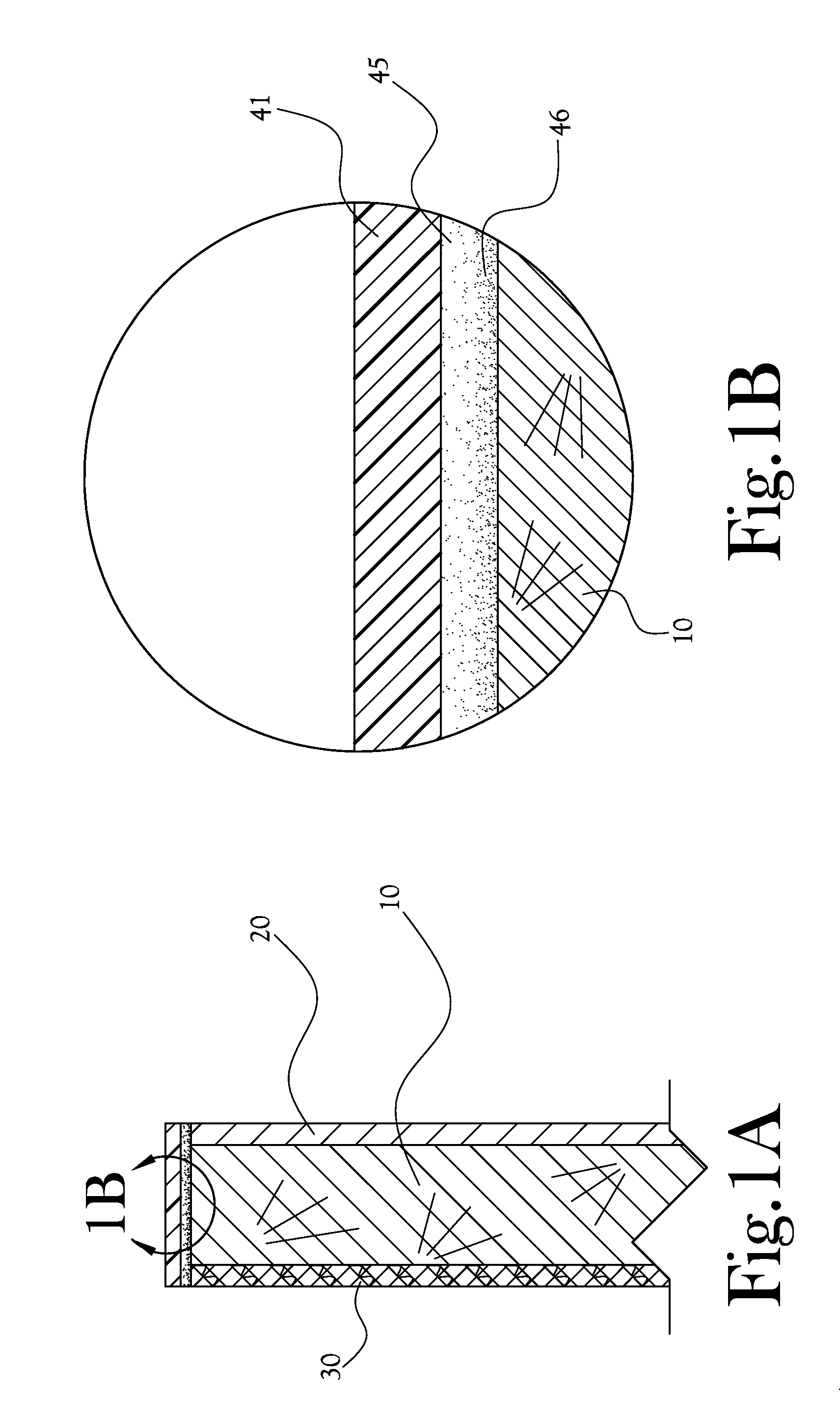

Laminated composite wooden material and method of manufacturing material

InactiveUS20050006003A1Light weightImprove bending strengthFoundation repairWood veneer joiningFlexural strengthComposite lumber

A seven-layered laminated composite lumber 1 is constructed by stacking veneers 2, whose oven-dry specific gravity is 0.6 or larger, alternately with veneers 3, whose oven-dry specific gravity is 0.4 or less, and by bonding them together. The invention can thus provide a laminated composite lumber that is light in weight, is substantially resistant to warping and distortion, and yet retains the desired bending strength and nail holding power, and a method of producing such a laminated composite lumber.

Owner:UNI WOOD CORP

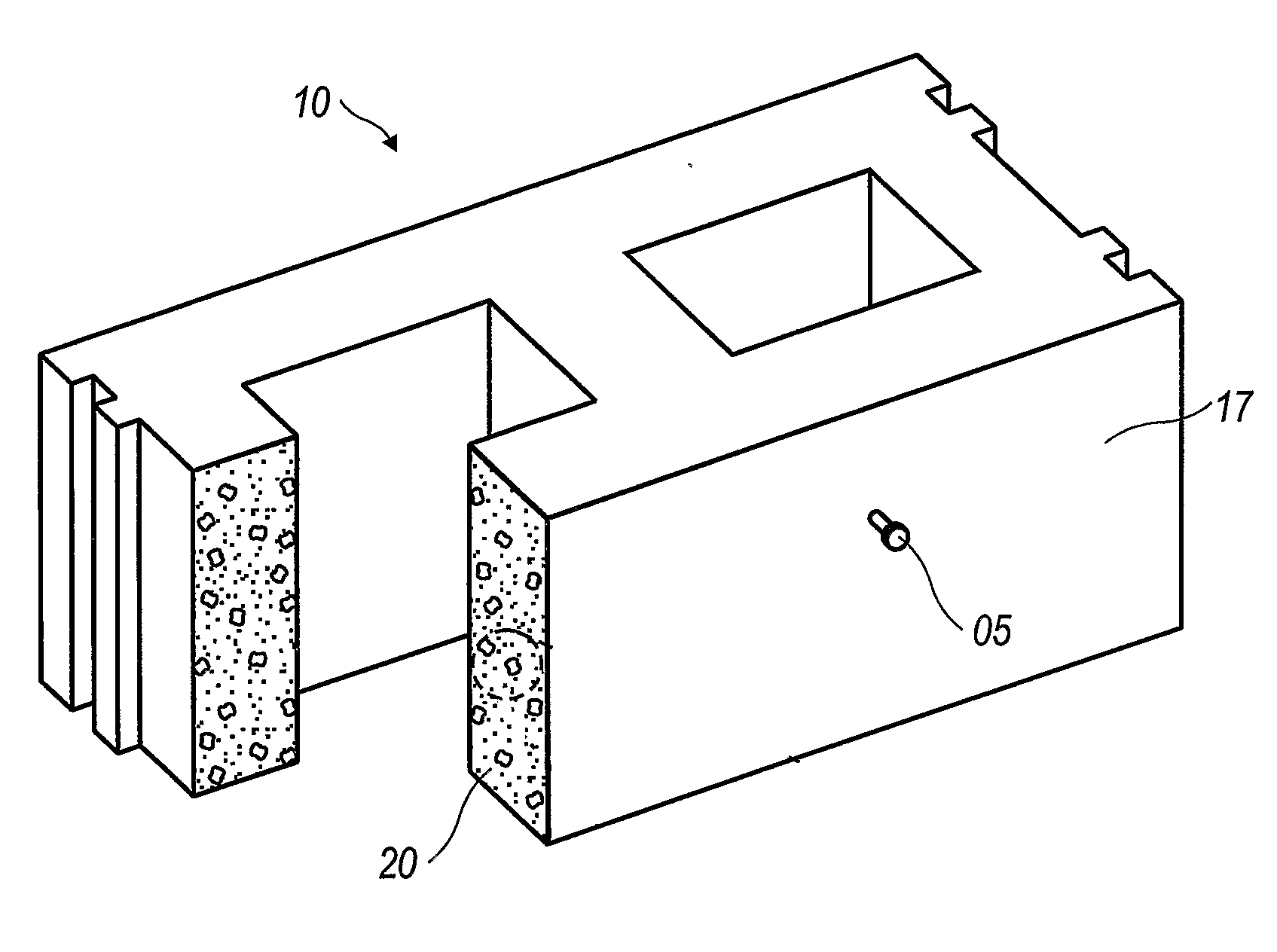

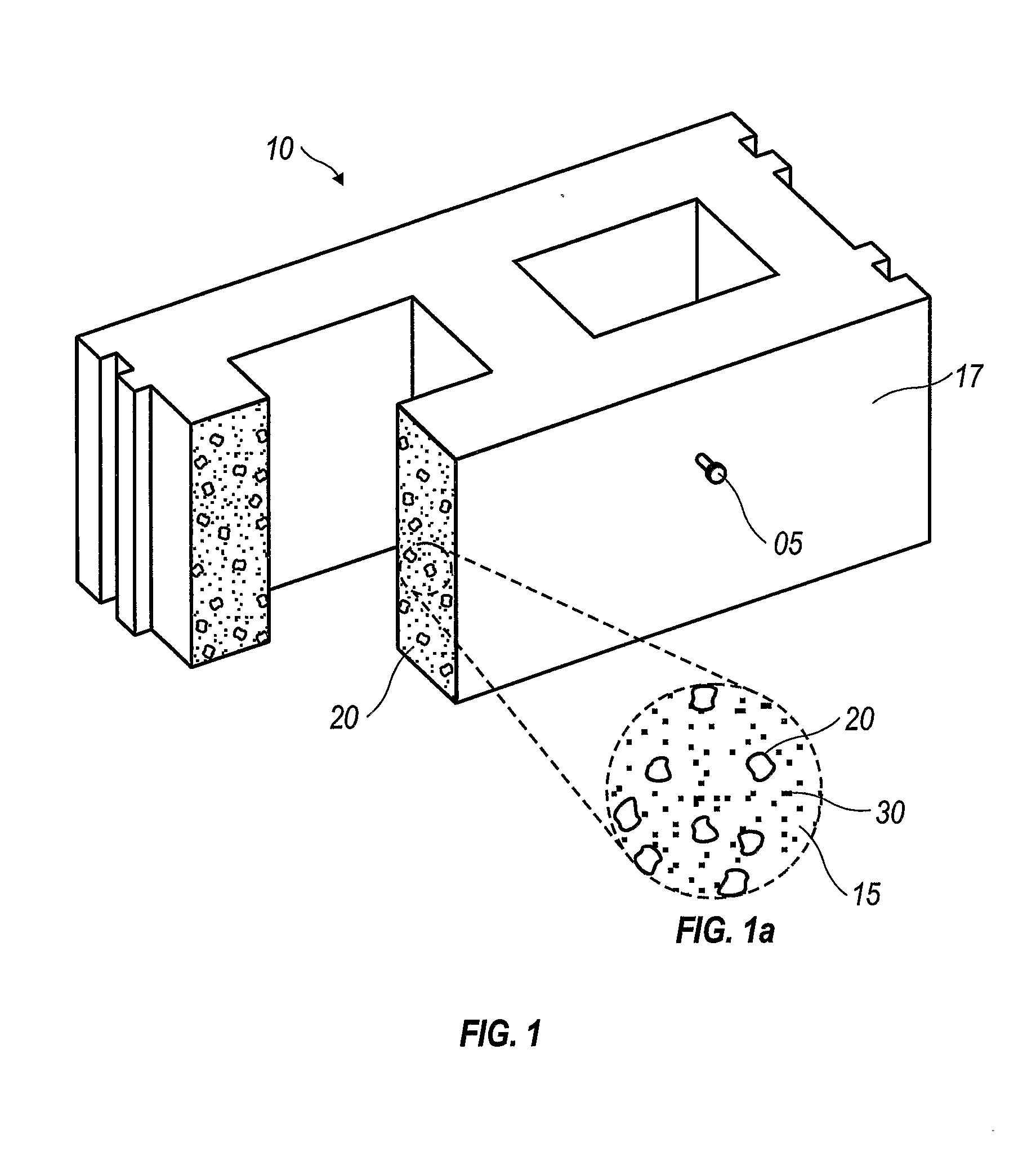

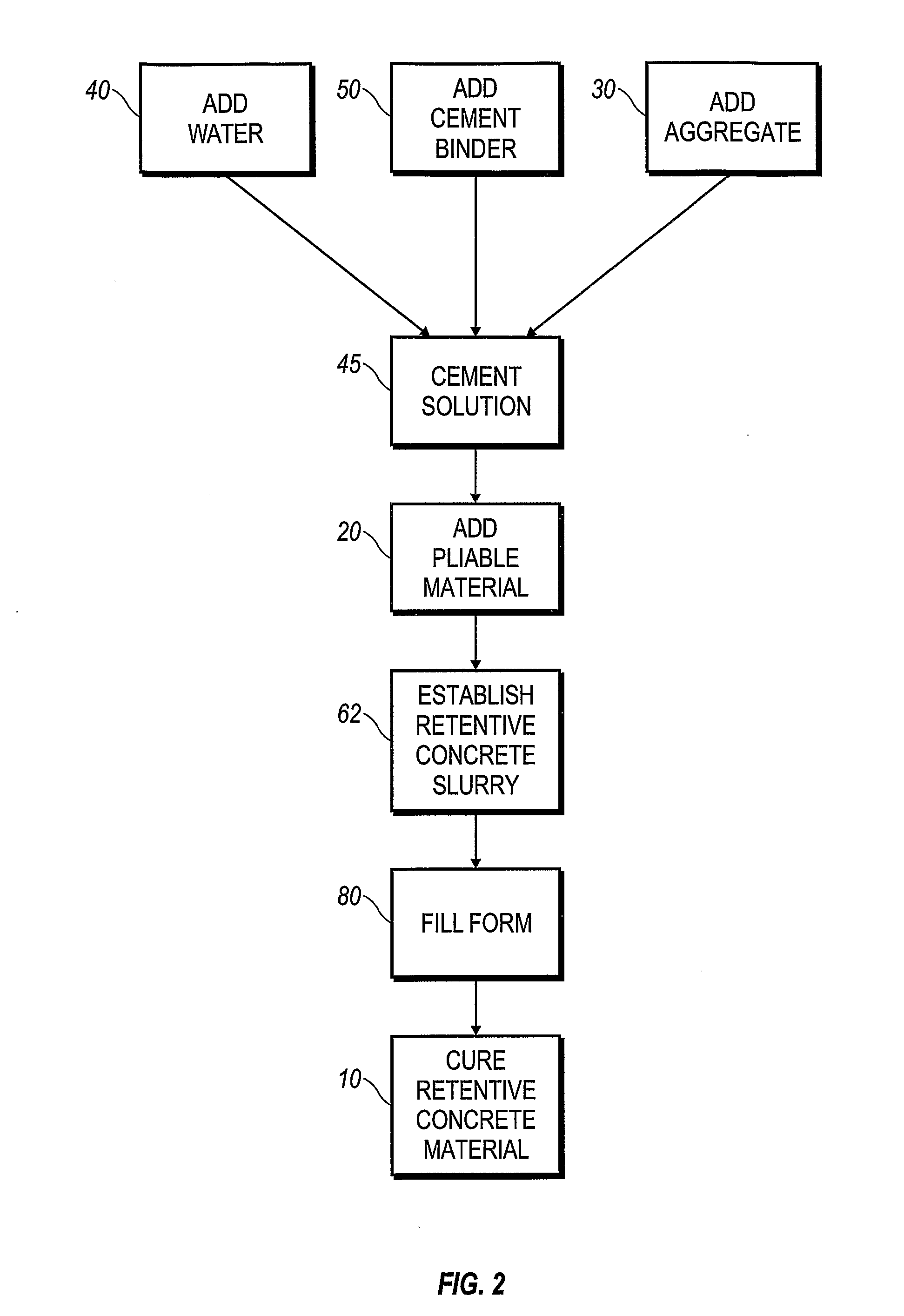

Retentive concrete material

A concrete material with fastener retentive qualities that can be varied to approximate the fastening holding characteristics of a selected variety of wood species or composite wood products comprising a mixture of cement binder, aggregate, and pliable material in the following volumetric ratio of approximately one-half (½) to one (1) part cement binder to approximately two (2) parts aggregate to approximately two (2) to five (5) parts pliable additive material. Cement binder can be Portland Cement, fly ash, slag and a combination thereof. Aggregate can be sand, gravel, stone, crushed rock, and a combination thereof. Pliable material can be plastic, cellulose, crumb rubber, and a combination thereof in pelletized, grannular or powdered form.

Owner:RODGERS MICHAEL S

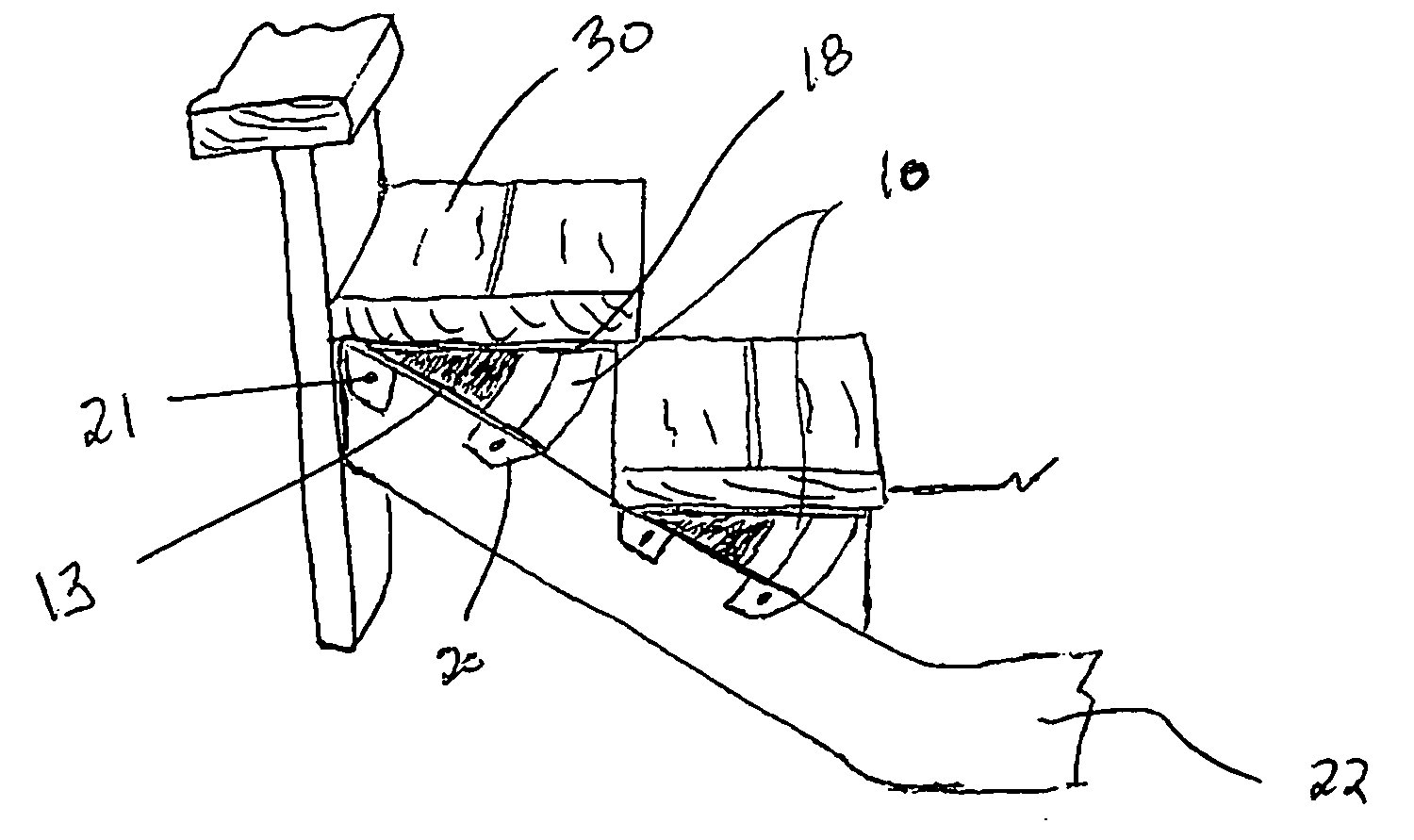

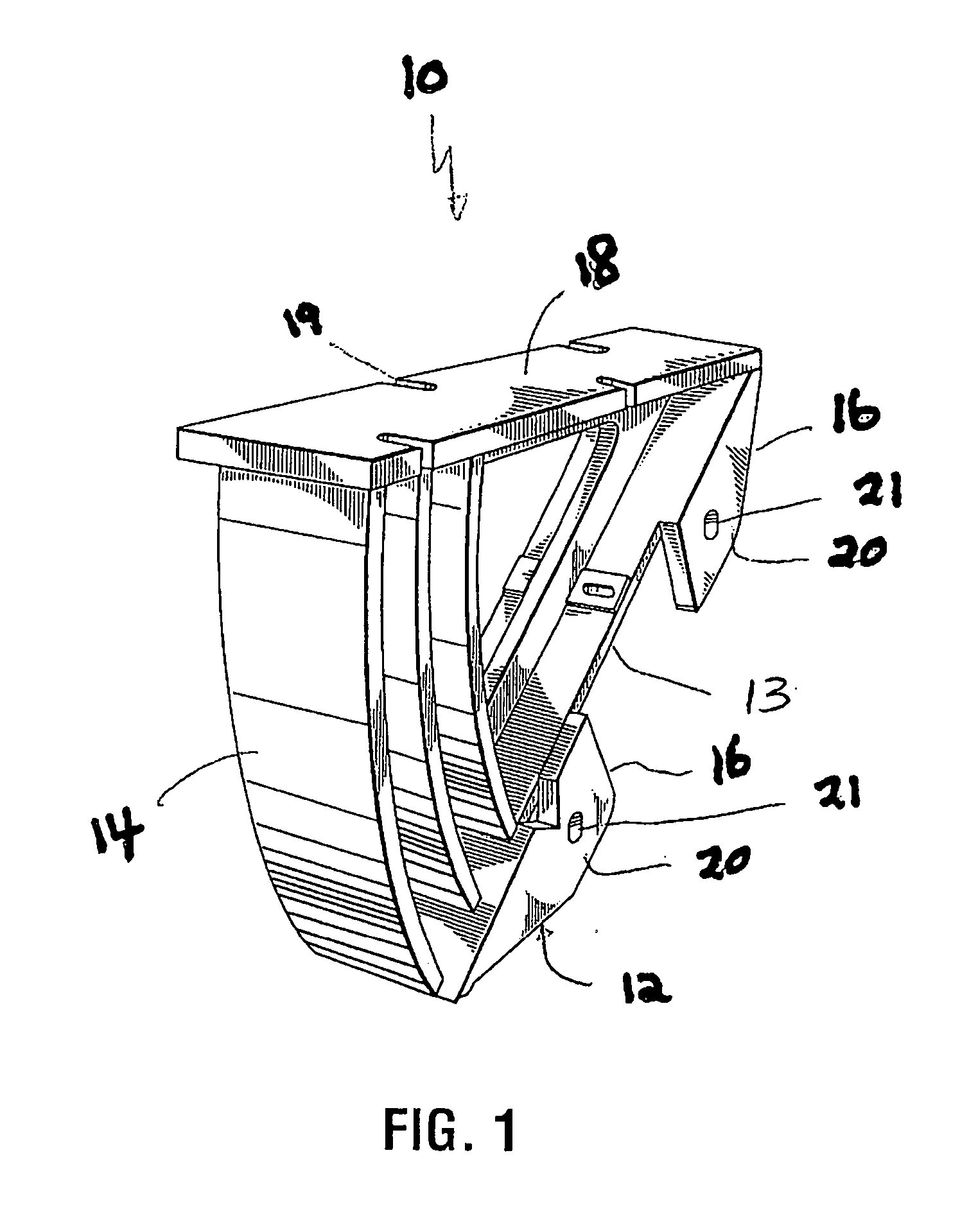

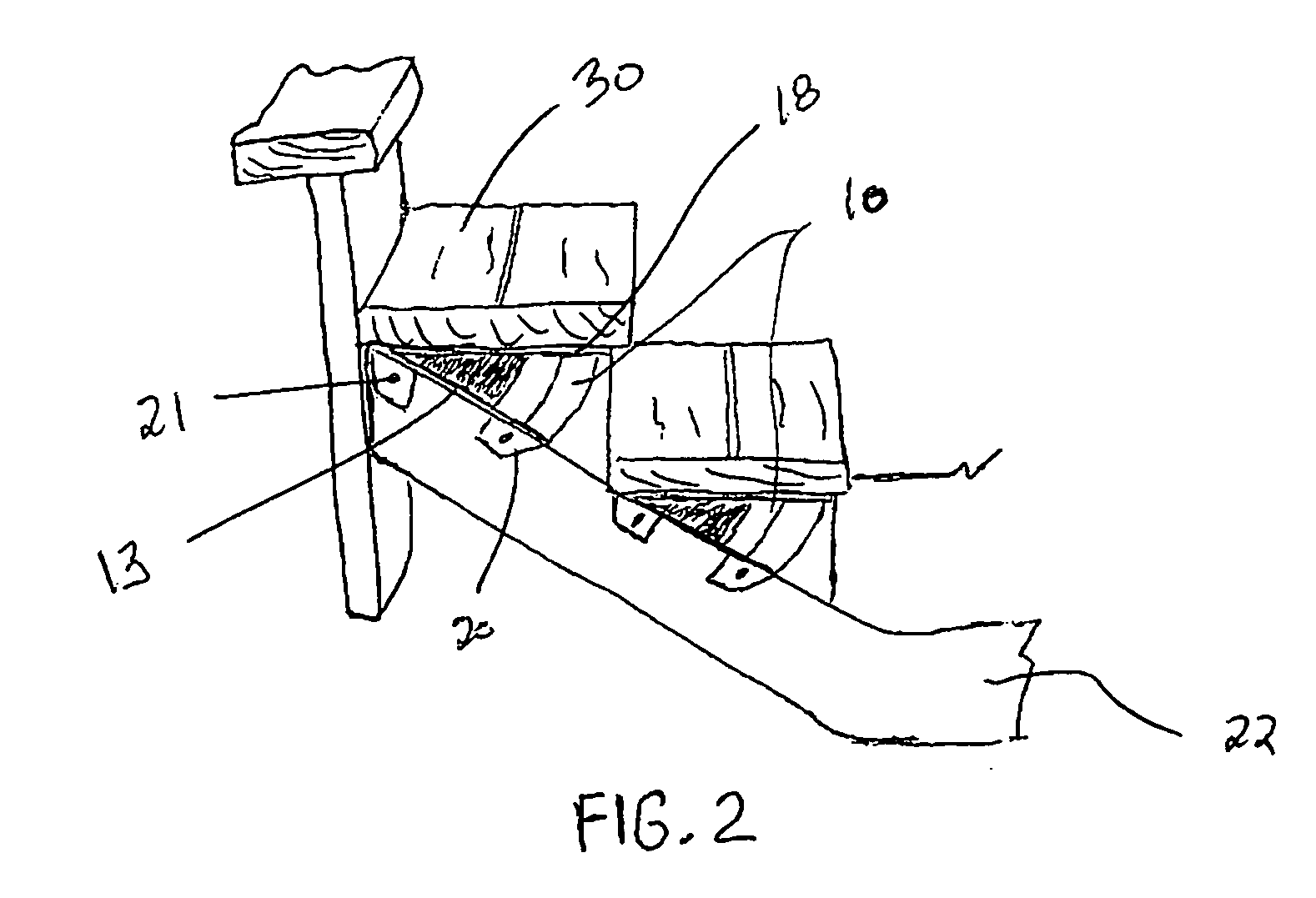

Stair bracket system and method

InactiveUS20050081461A1Easy to useQuick and efficientBuilding repairsBuilding material handlingComposite lumberMechanical engineering

A stair bracket system and method is provided for constructing the framework of a staircase or terrace seating, having a plurality of modular brackets which are assembled in combination with wooden or steel or composite lumber structural members to result in the risers. Each of the brackets of the present invention has a bottom edge, a front and lower section, a back end edge, a top section and bracing members, so that a staircase or terrace seating can be constructed by forming at least a pair of side frames.

Owner:SIDNEY GIBSON LTD

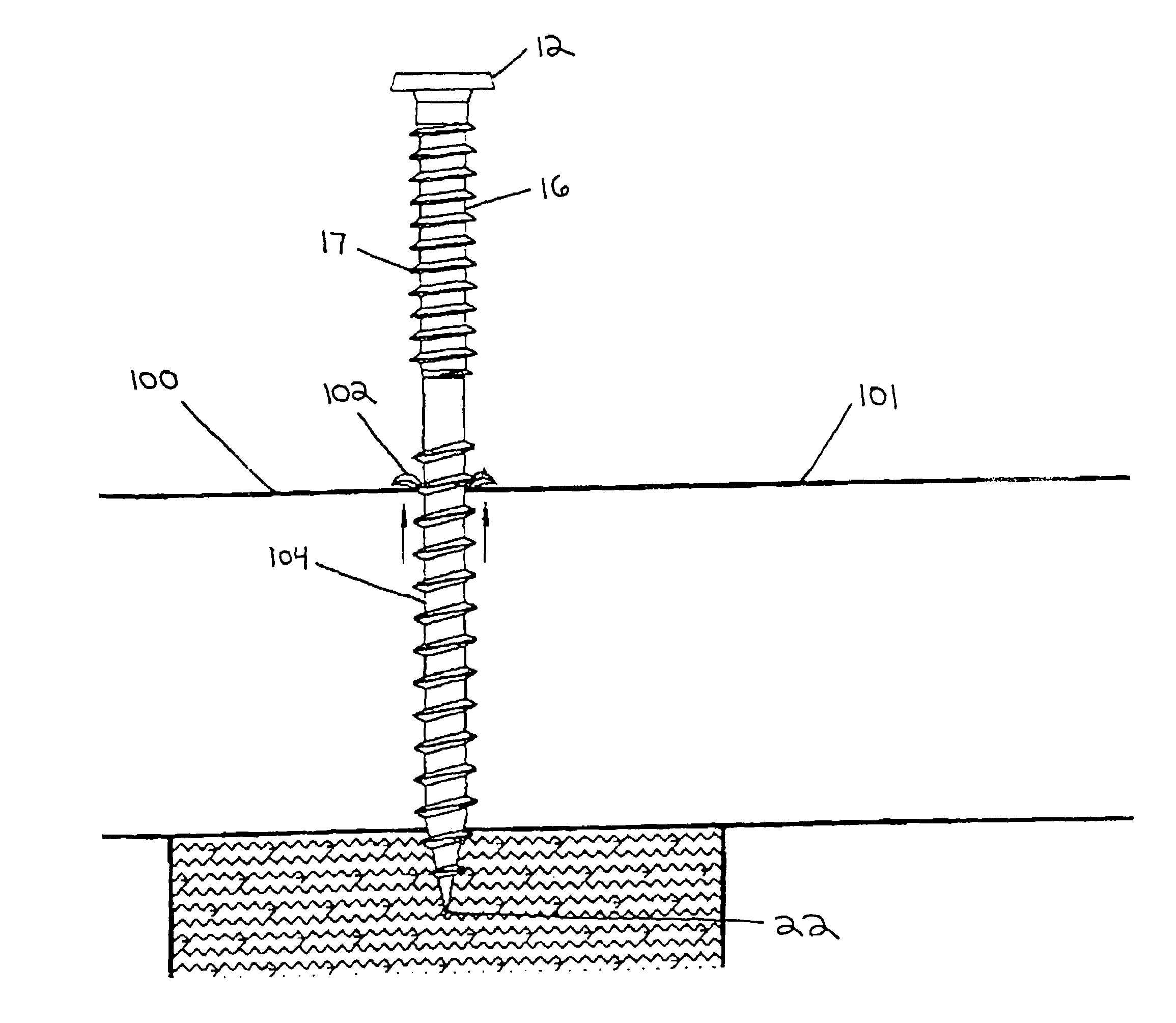

Ceramic composite timber precursor liquid and its preparation method

Ceramic composite timber precursor liquid and its preparation method, wherein the precursor liquid comprises inorganic composition, organic composition, functional enhancement component and process enhancement component, the inorganic composition is silicasol or soluble silicate, the organic composition is water-based polyurethane emulsion or water-based acrylic acid emulsion, the weight ratio of the organic composition with the inorganic composition is 0.25-0.7:1, the weight ratio of the methyl sodium metasilicate as the enhancement component with the inorganic composition is 4-7:100, the process enhancement component includes coupling agent KH-560 and sodium alkyl benzene sulphonate as penetrating agent, the weight ratio of the coupling agent and the organic composition is 1.2-2:100, the weight ratio of sodium alkyl benzene sulphonate and the inorganic composition is 1.6-2:100. And the preparation process comprises the steps of weighing according to the weight ratio, and mixing homogeneously.

Owner:BEIJING UNIV OF TECH

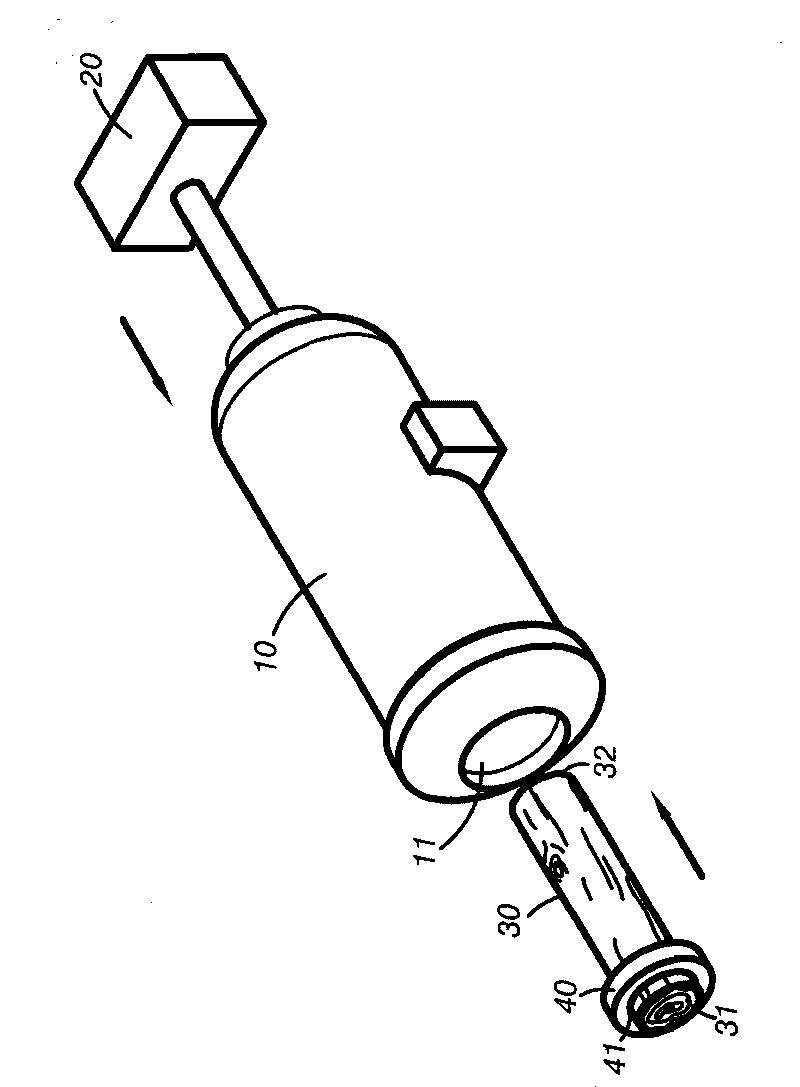

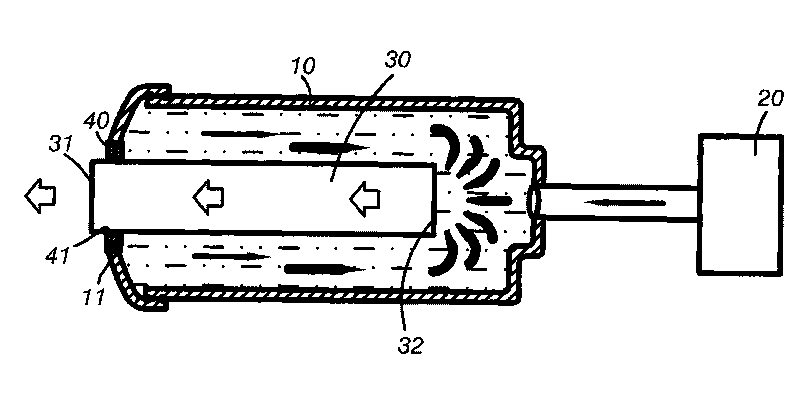

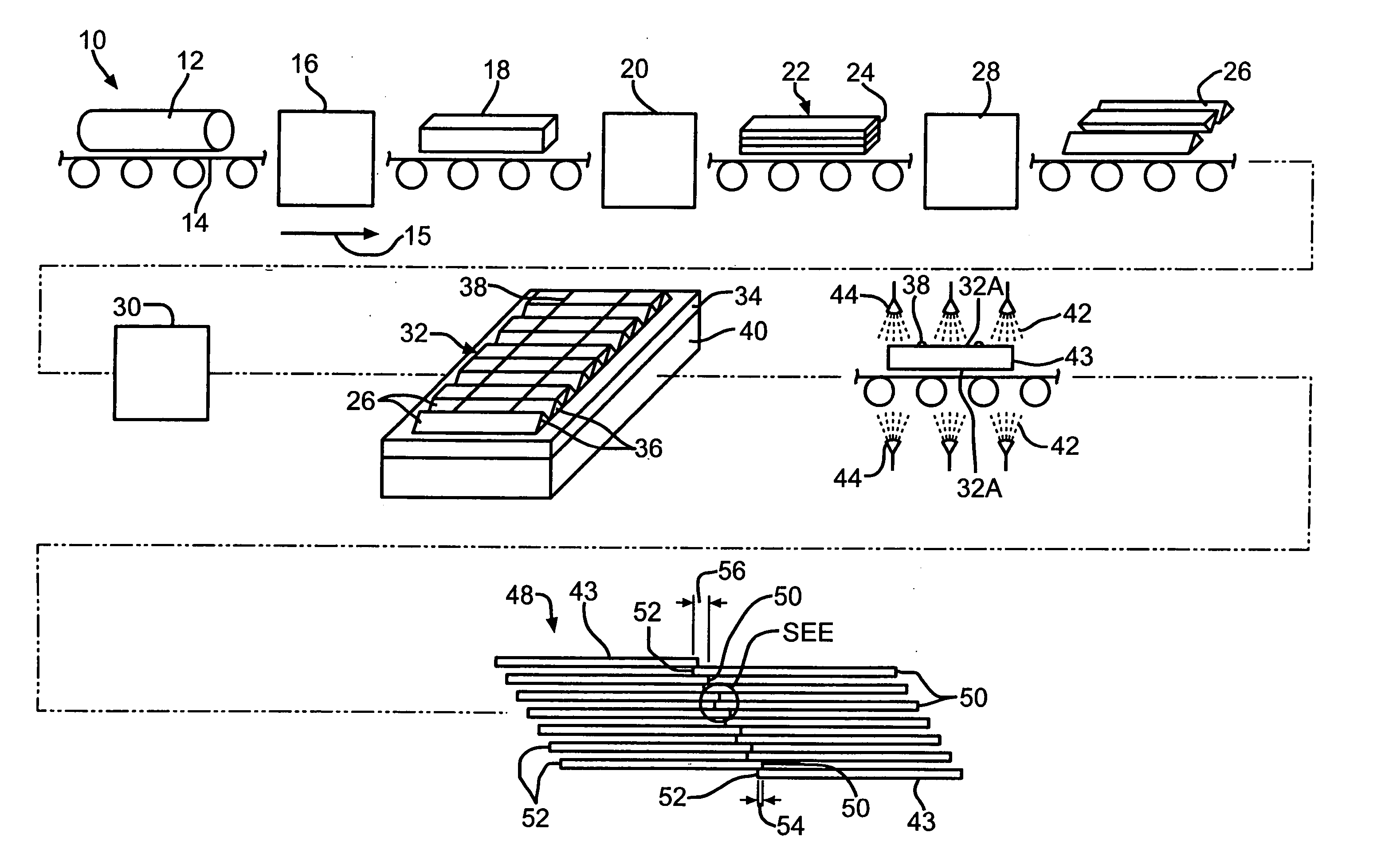

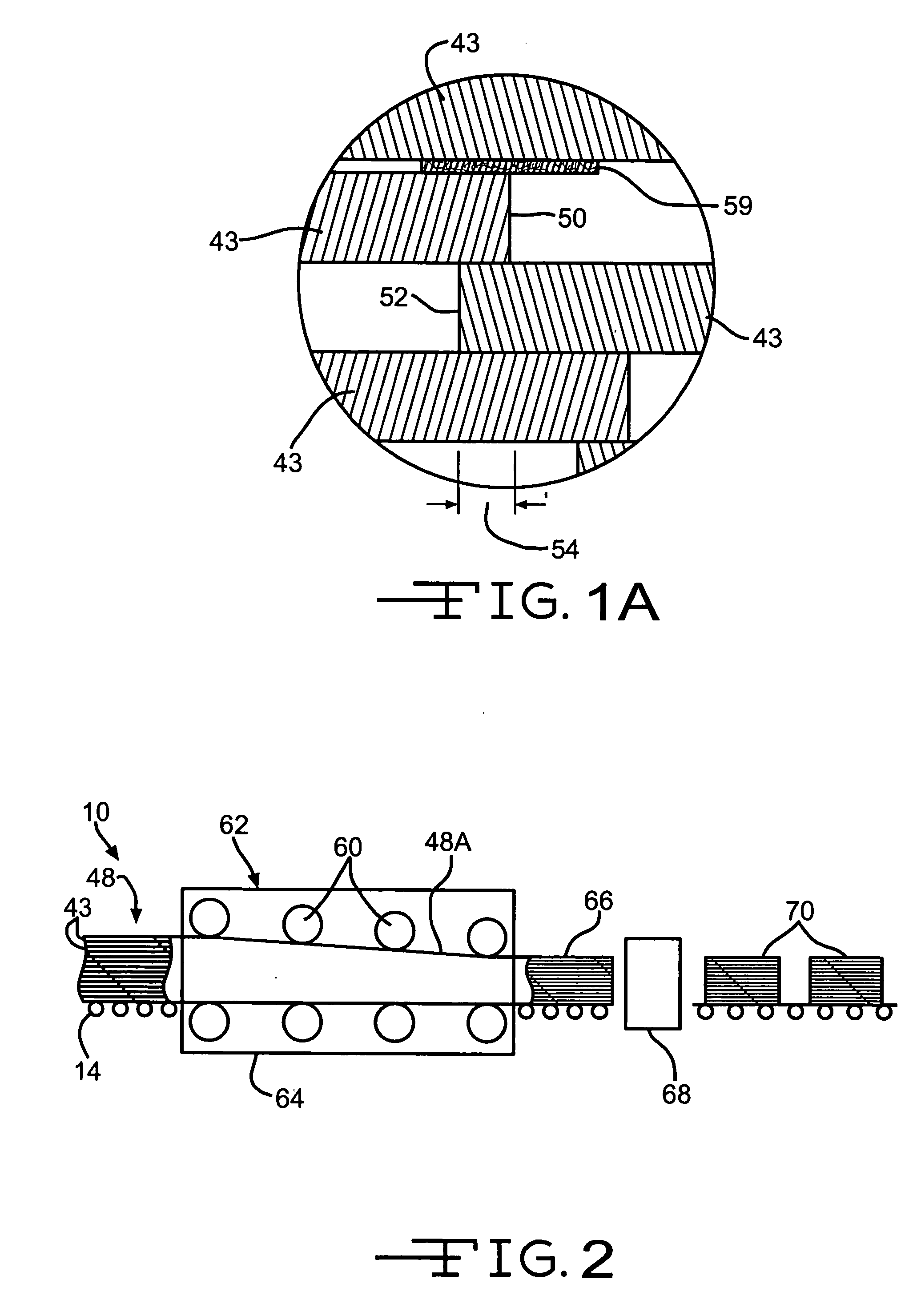

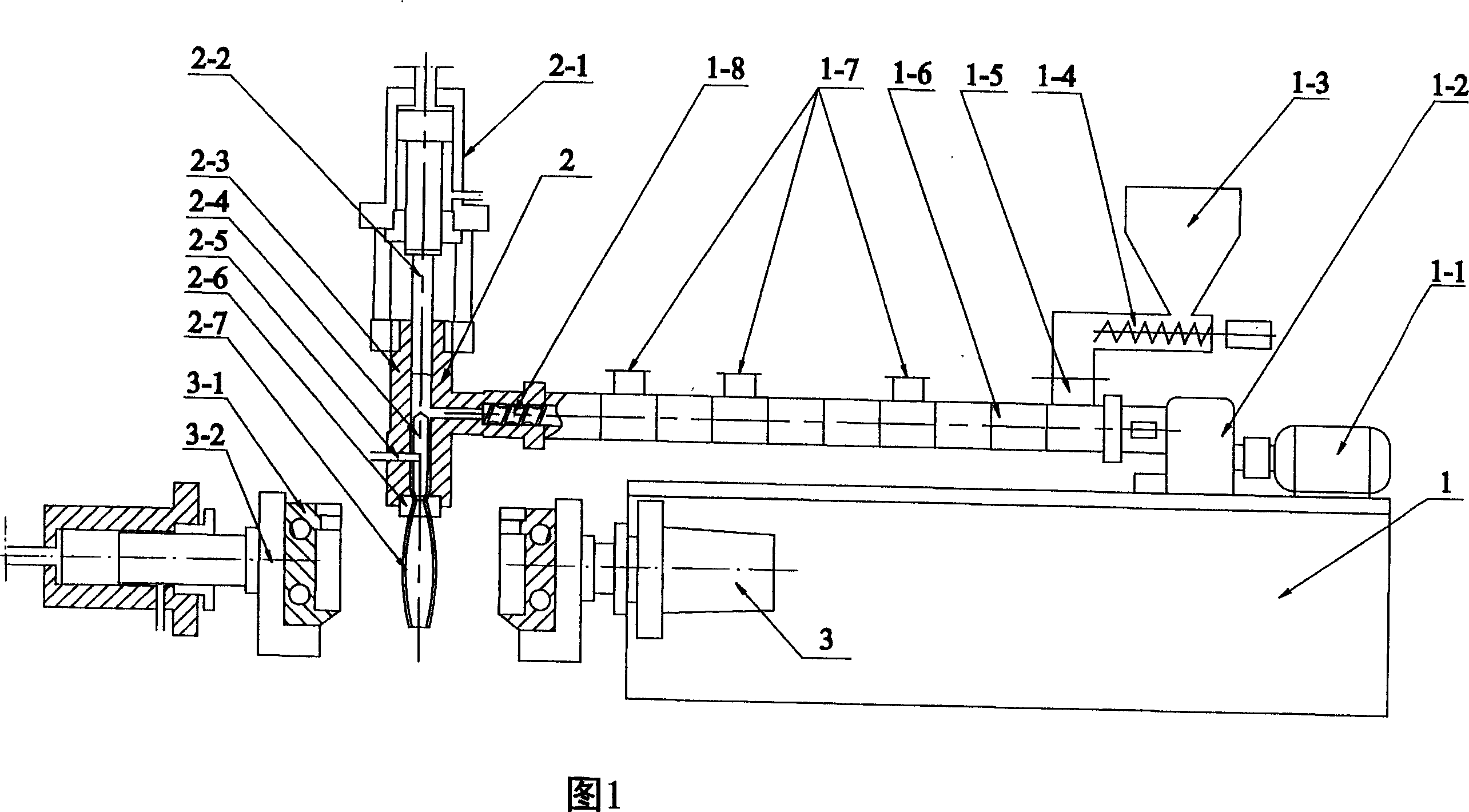

Composite wood treating equipment and method

InactiveCN101758536AHigh strengthExtended service lifePressure impregnationWood impregnation detailsEngineeringComposite lumber

The invention relates to composite wood treating equipment and a method. The equipment comprises a pressuring container and a solution pressuring device, wherein the inner part of the pressuring container can be lengthways contained with at least one of woods; one side of the pressuring container is provided with a plurality of openings, the amount of which is corresponding to that of the woods; the other side of the pressuring container is connected with the solution pressuring device; each opening of the pressuring container is provided with a plug; the outline of the plug is matched with the shape of each opening of the pressuring container for sealing each opening; and the inner edge of the each plug is provided with a through hole which is sealed with the outer edge of the wood, so that the front end of the wood is communicated with the air through the through hole of the plug. The treating method comprises the steps of: lengthways putting the wood into the pressuring container, so that the front end of the wood is communicated with the air; sealing between the wood and the pressuring container; and injecting the solution into the pressuring container in a pressuring way, so that the solution enters into the wood through moisture and nutrient-conveying pipelines of the wood. The invention can be realized by means of energy saving with lower pressure, and has the advantages of being fast, stable, labor-saving and time-saving.

Owner:范荣泰

Process for production of wood composites using mixed PMDI/solid novolac resin binder

InactiveCN1330668AImprove water resistanceLess tendency to stick to platenPolyureas/polyurethane adhesivesWood veneer joiningMethylene diisocyanateComposite lumber

This invention relates to a process for the production of composite wood products. This process comprises a) applying a binder composition to wood particles, and b) molding or compressing the wood particles treated with the binder to form a composite wood product. Suitable binder compositions comprise a polymethylene poly(phenyl isocyanate) and a solid novolac resin.

Owner:HEXION SPECIALTY CHEM INC

Compound timber corrosionproof process liquid, its preparing method and method for modifying timber using the process liquid

InactiveCN101161431AIncreased average weight gainImprove anti-corrosion performanceWood impregnation detailsDispersityPreservative

The invention provides a composite preservative treatment liquid for modifying the wood, preparation method thereof and treatment method for modifying the wood using the said treatment liquid. The said treatment liquid comprises wood preservation liquid and organic montmorillonite with dispersion degree of 1.5-3.0%, wherein the organic montmorillonite is formed by reacting the aqueous suspension of sodium based montmorillonite (Na-MMT) with concentration of 3-8% and cetyl trimethyl ammonium bromide (CTMAB) at 60-90 degree. The wood is soaked by the said composite preservative treatment liquid, wood / montmorillonite composite material with good preservative anchor effect can be obtained, therefore the wood not only has good antiseptic property and increased physical mechanical property, hardness and dimensional stability.

Owner:BEIJING FORESTRY UNIVERSITY

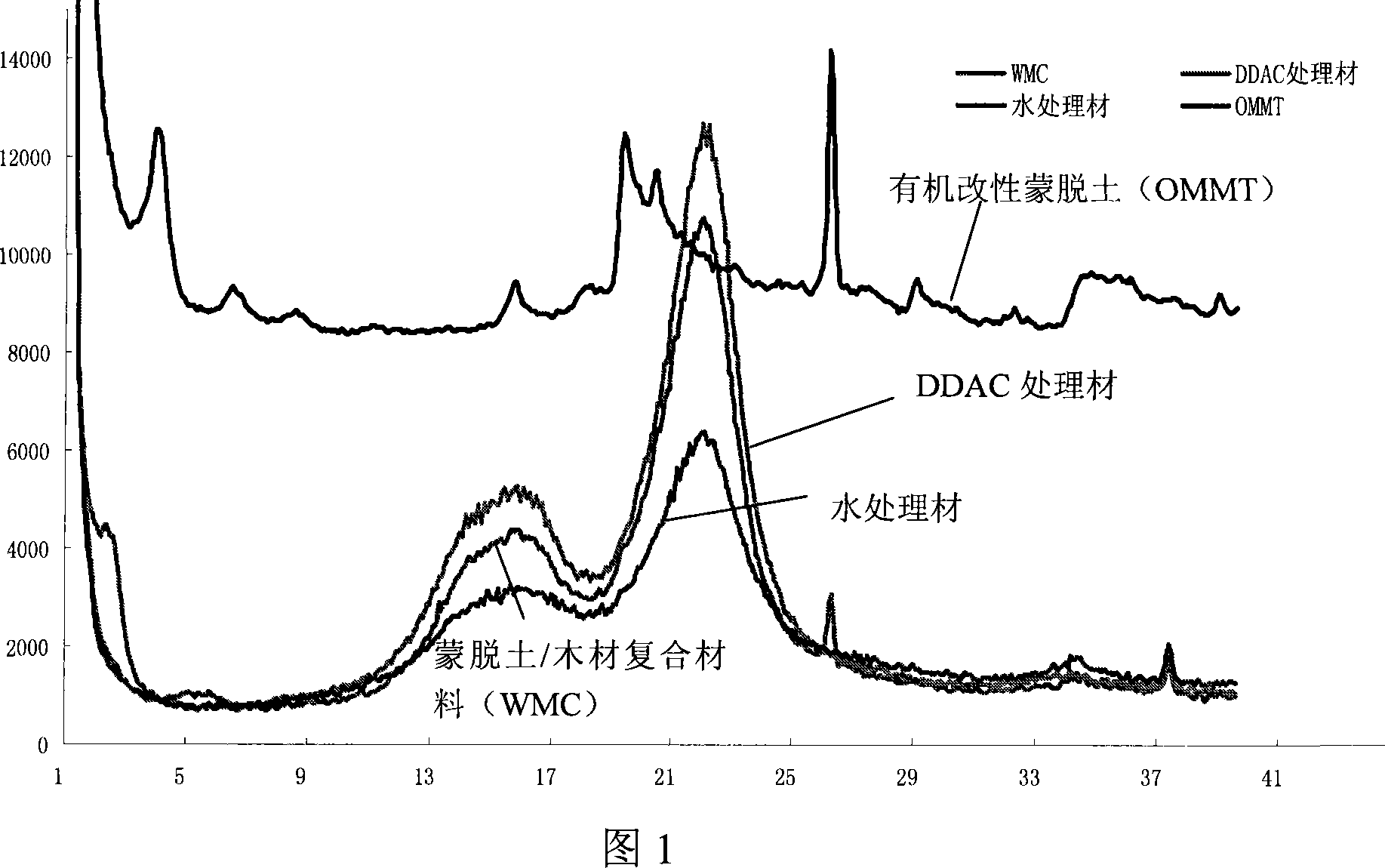

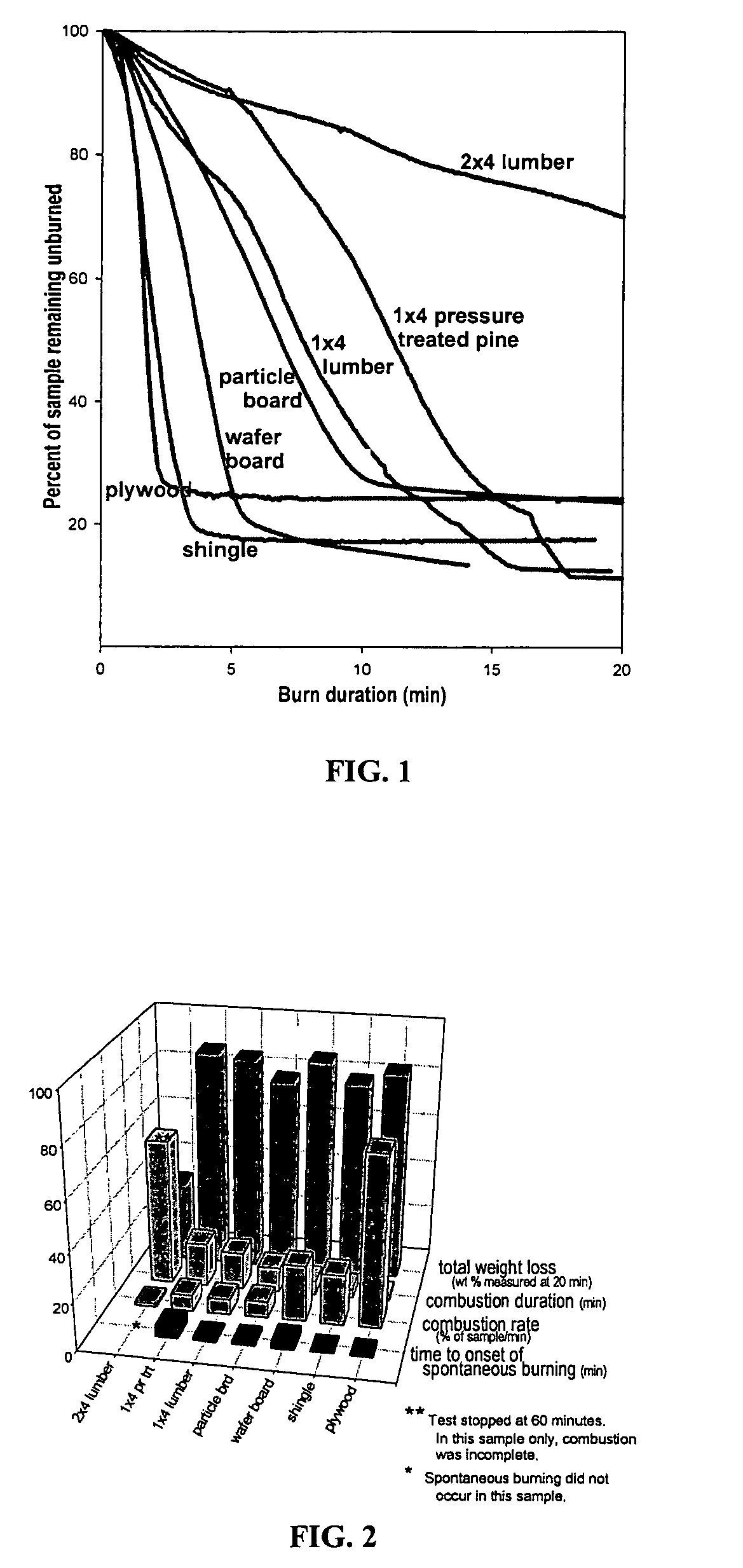

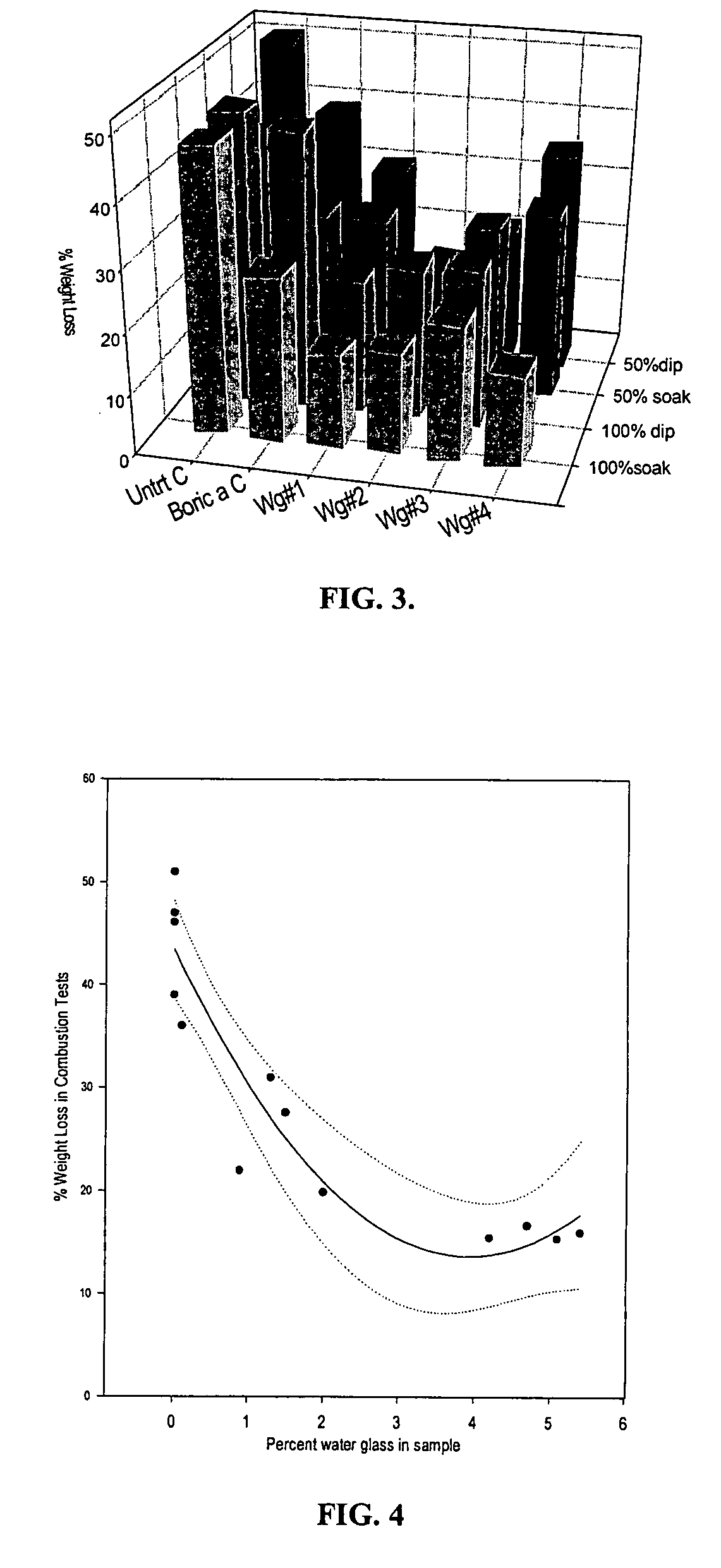

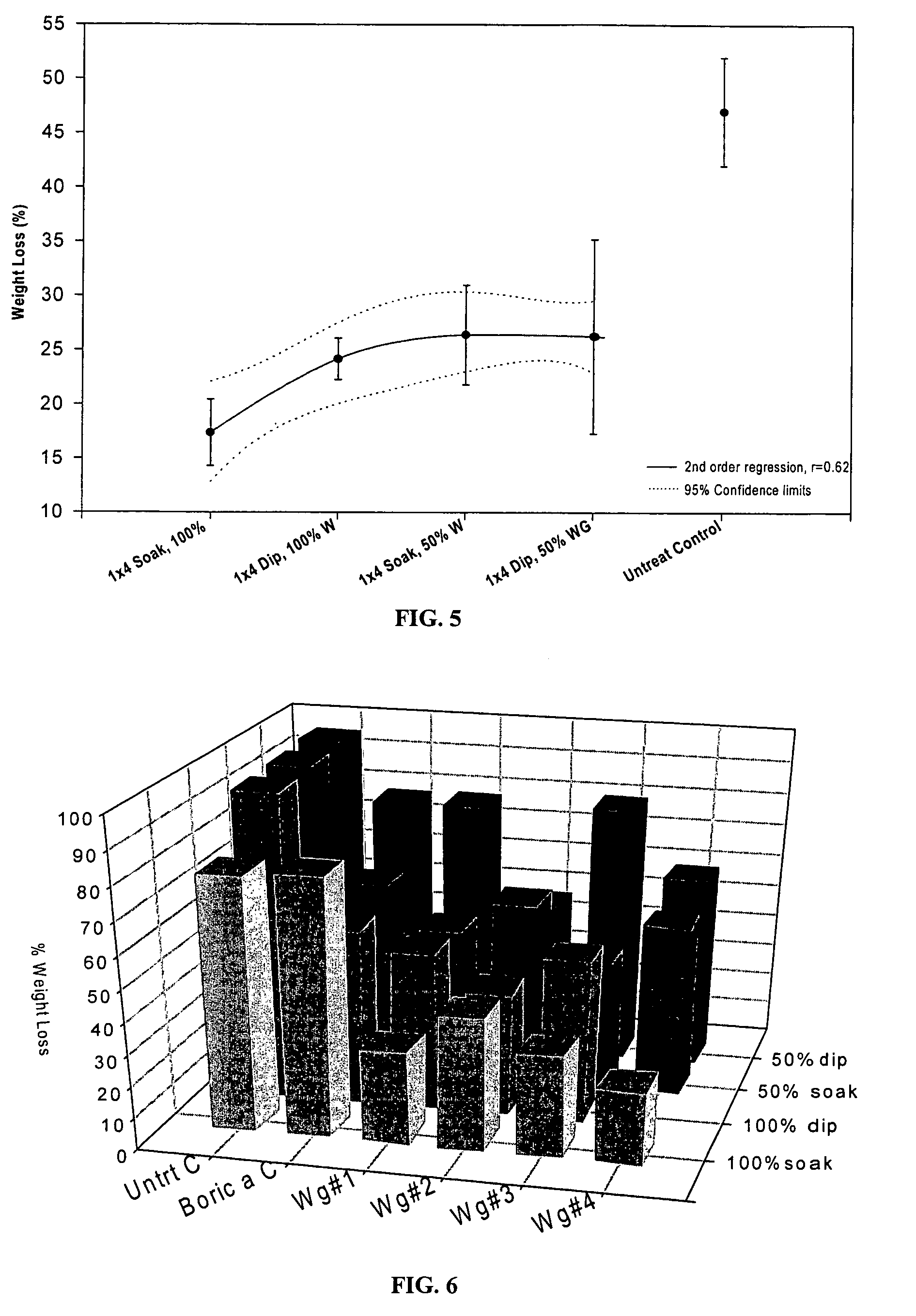

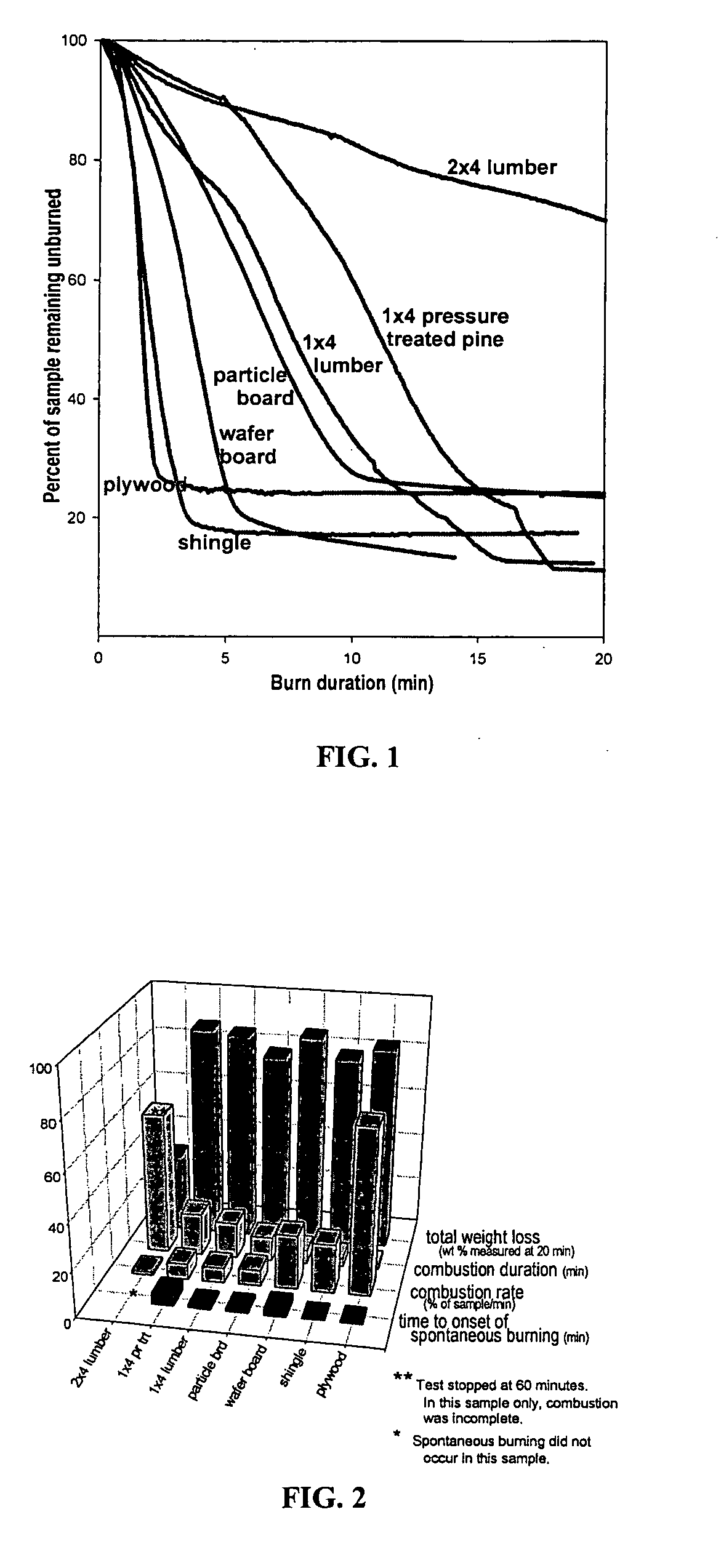

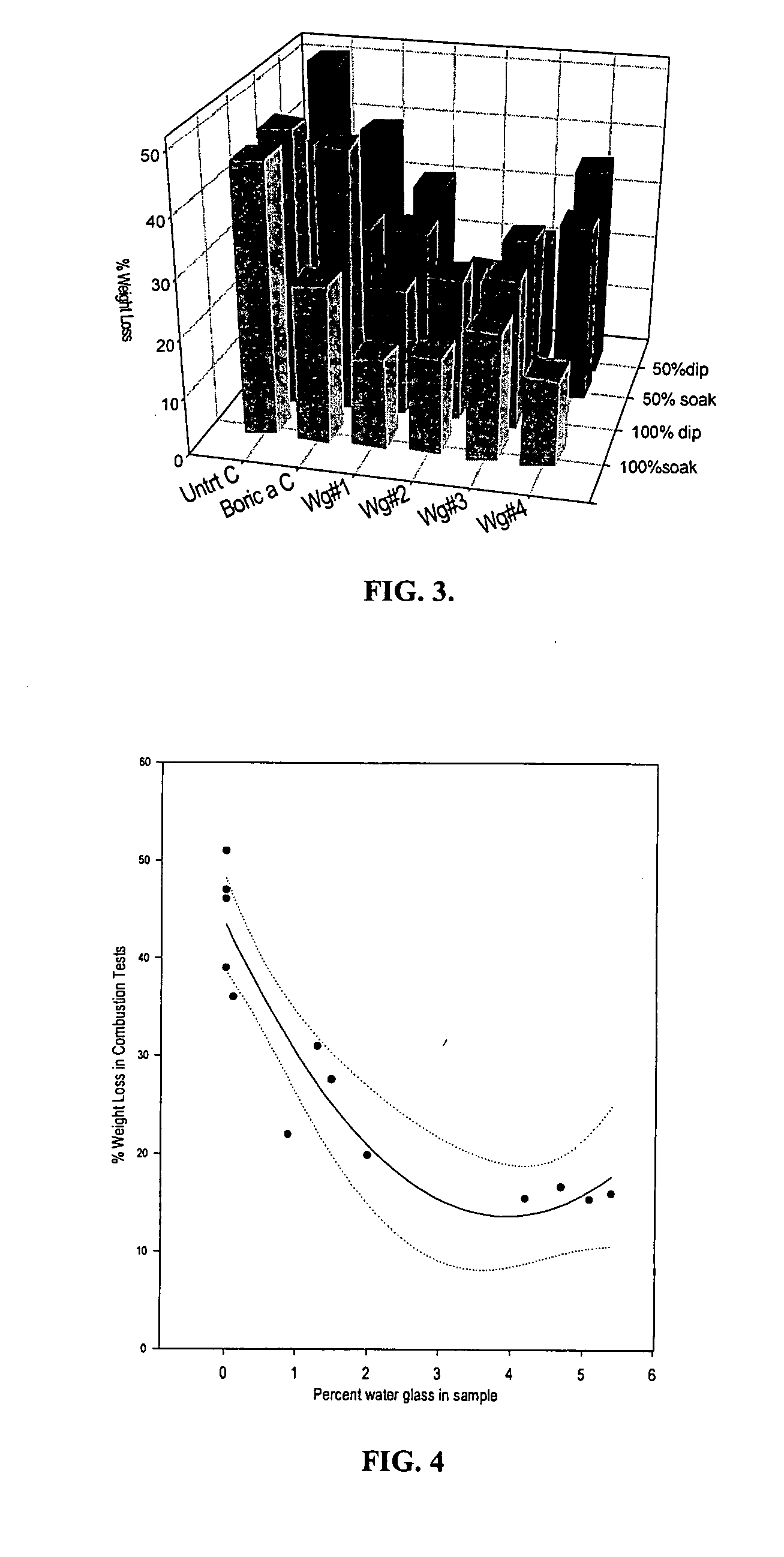

Process of using sodium silicate to create fire retardant products

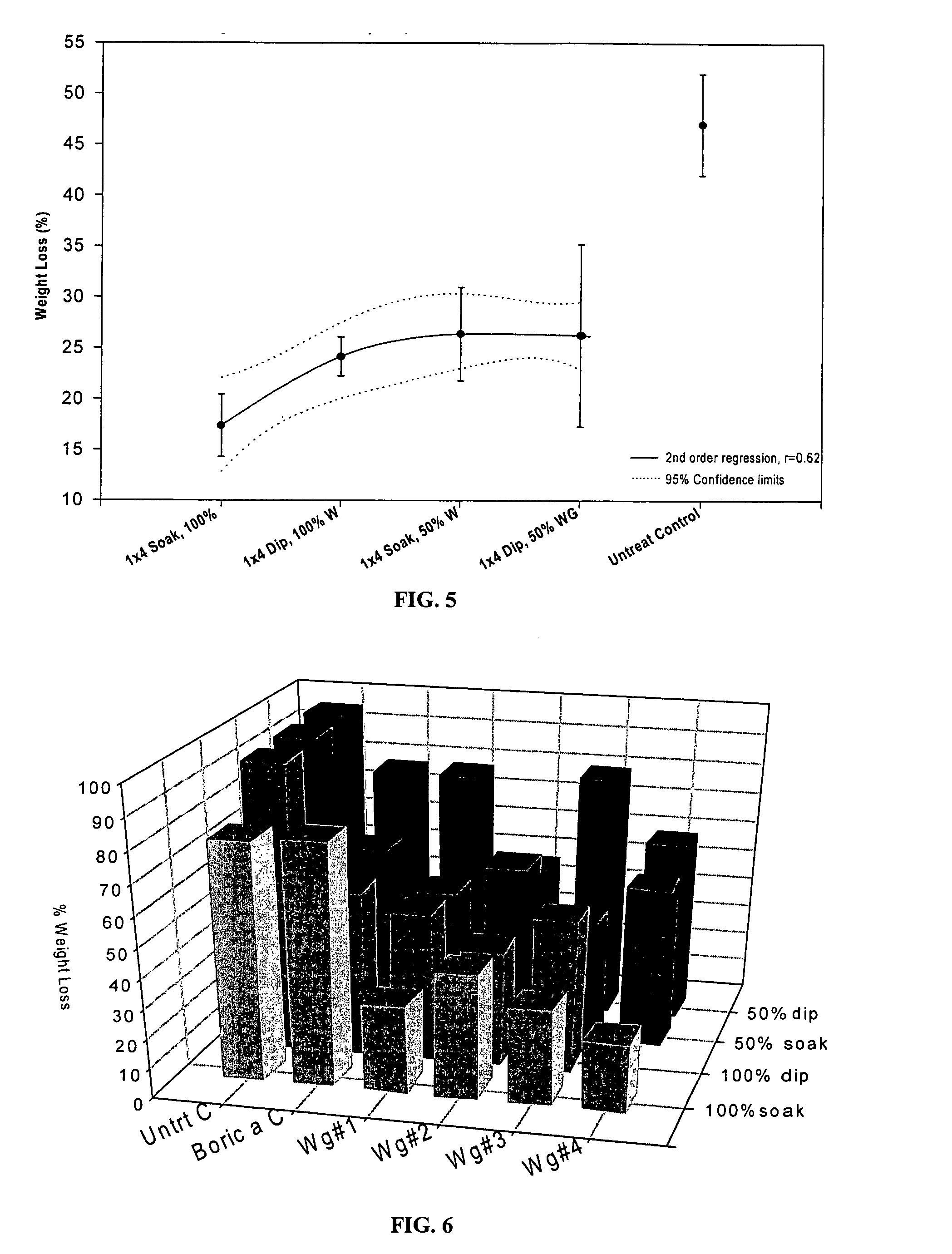

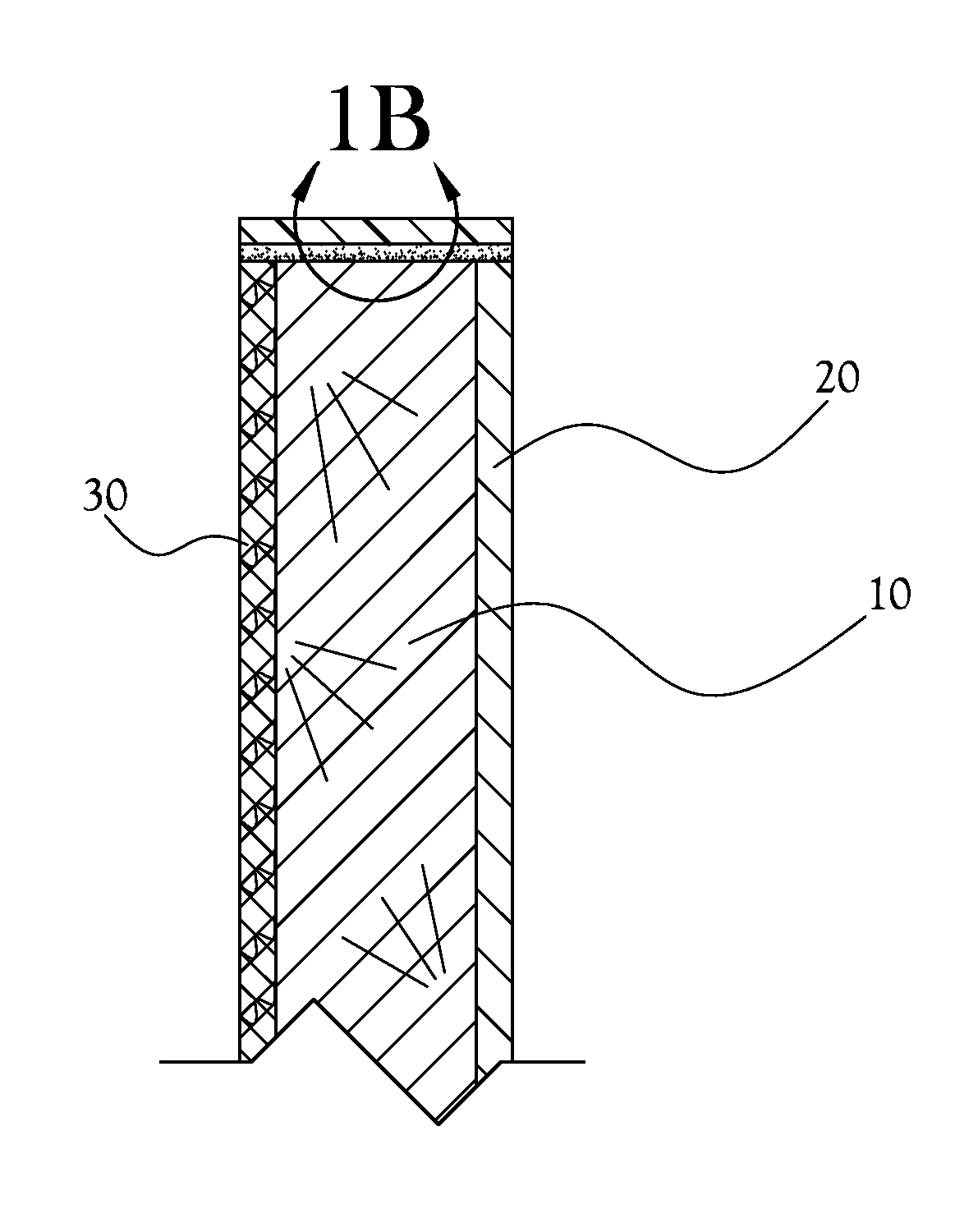

InactiveUS7297411B2Resistant to deteriorationSolid waste managementWood treatment detailsSolubilityWater insoluble

Wood products, specifically wood commonly used in construction including dimension lumber, pressure treated pine, composite wood materials such as plywood, particle board, and wafer board, and samples of paper and fabric were variously treated with concentrations of sodium silicate (Na2OSiO2) also known as water glass. Cellulosic materials including dimension lumber, plywood, particle board, wafer board, paper, and fabric were treated with sodium silicate (Na2O.SiO2) in concentrations ranging from 400-0.04 g Na2O.SiO2 / kg water. To overcome the disadvantages of sodium silicate, sodium silicate treated samples were further treated to convert the water soluble sodium silicate to a water insoluble form, thereby overcoming the disadvantages of water solubility. and rendering the material effective for internal and external uses. Although treated sodium silicate samples are composed of the same elements in similar proportions, as the untreated sodium silicate samples, the water solubility of the treated and untreated substances is very different.

Owner:T2EARTH HLDG LLC

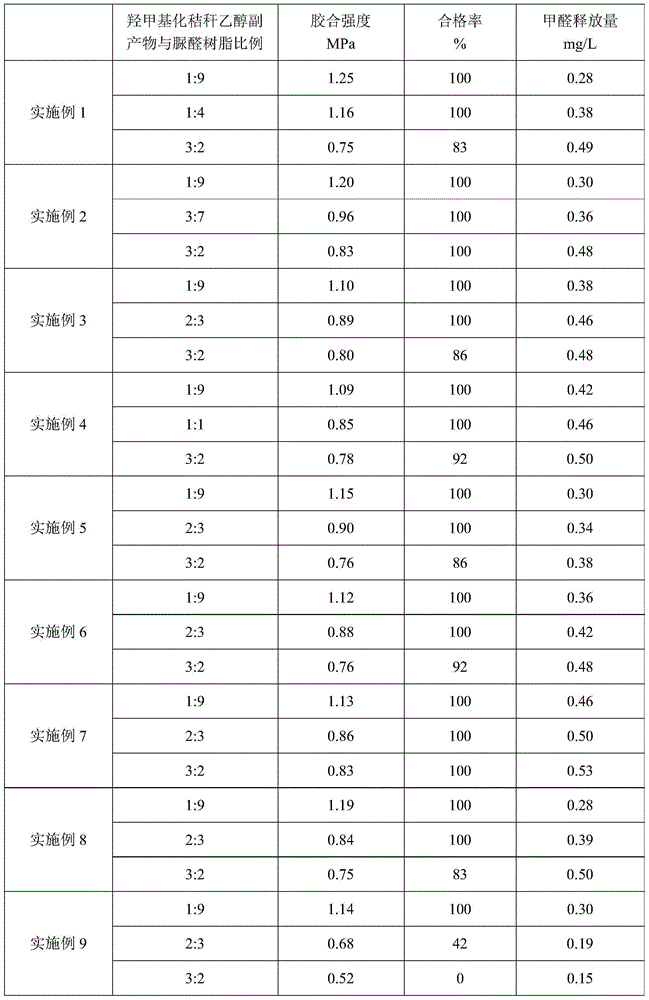

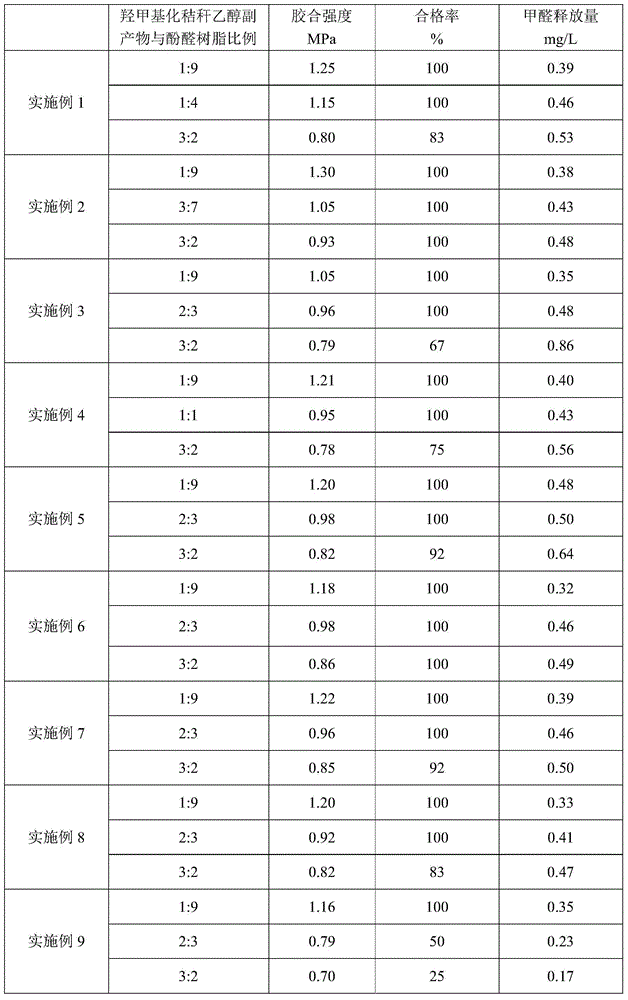

Method for preparing hydroxymethylated stalk ethanol byproduct and composite wood adhesive

InactiveCN104087217ALow ashLow in sugarAldehyde/ketone condensation polymer adhesivesScavengerAdhesive

The invention discloses a method for preparing a hydroxymethylated stalk ethanol byproduct and a composite wood adhesive. The method comprises the following steps: preparing the hydroxymethylated stalk ethanol byproduct: adding water, a stalk ethanol byproduct and a formaldehyde solution into a reactor in parts by mass, adjusting the pH value by using alkali liquor, heating and stirring; adjusting the pH value of the mixed system in the reactor by using alkali liquor, and heating for reacting; adjusting the pH value of the mixed system in the reactor by using alkali liquor, cooling, adding a formaldehyde scavenger, reacting, cooling to room temperature and discharging; preparing the stalk ethanol byproduct composite wood adhesive, namely mixing the prepared hydroxymethylated stalk ethanol byproduct and urea resin or phenolic resin uniformly at room temperature to obtain the composite wood adhesive. The method disclosed by the invention can be used for achieving the purpose of recycling wastes, and reducing the formaldehyde emission of prepared artificial boards.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

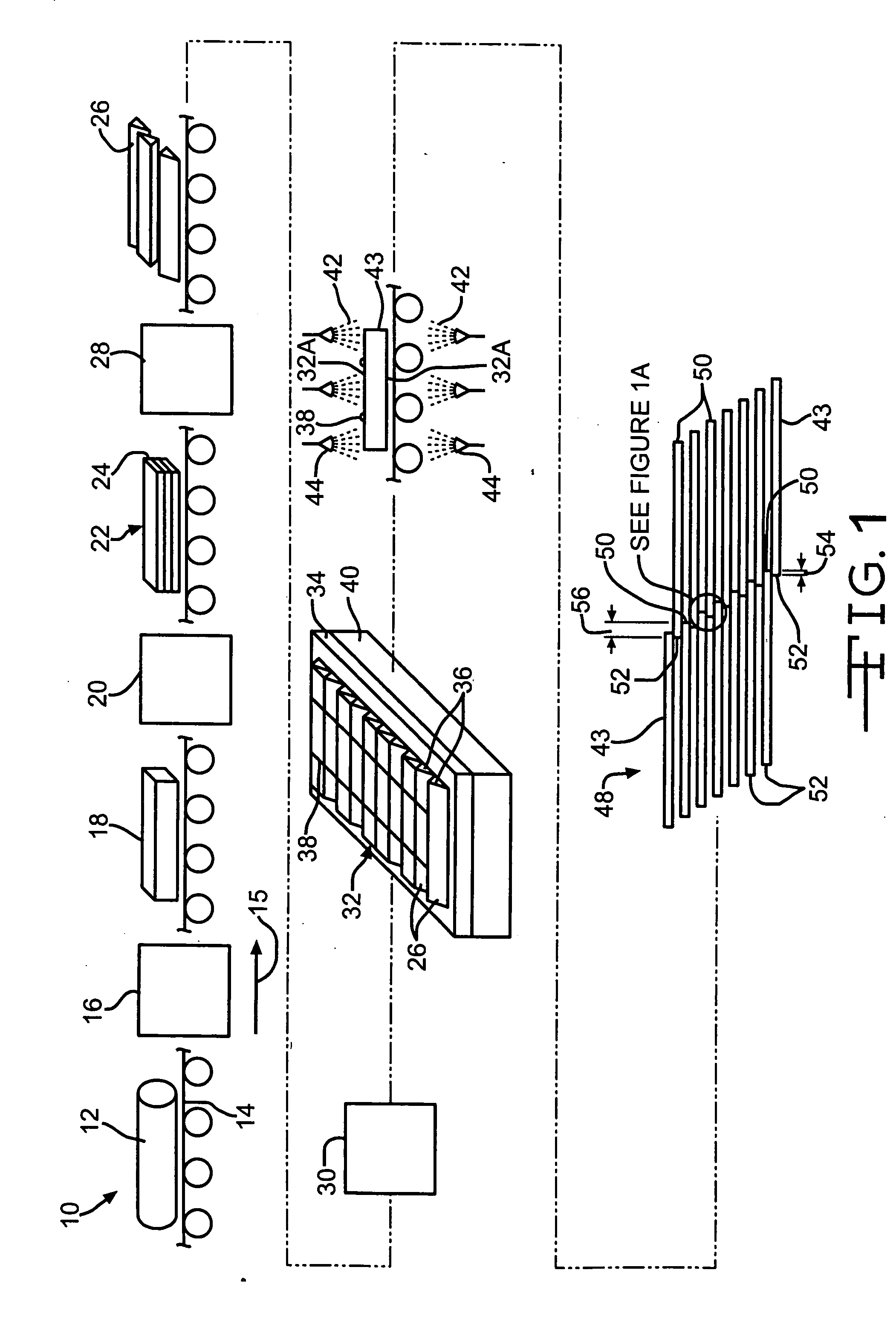

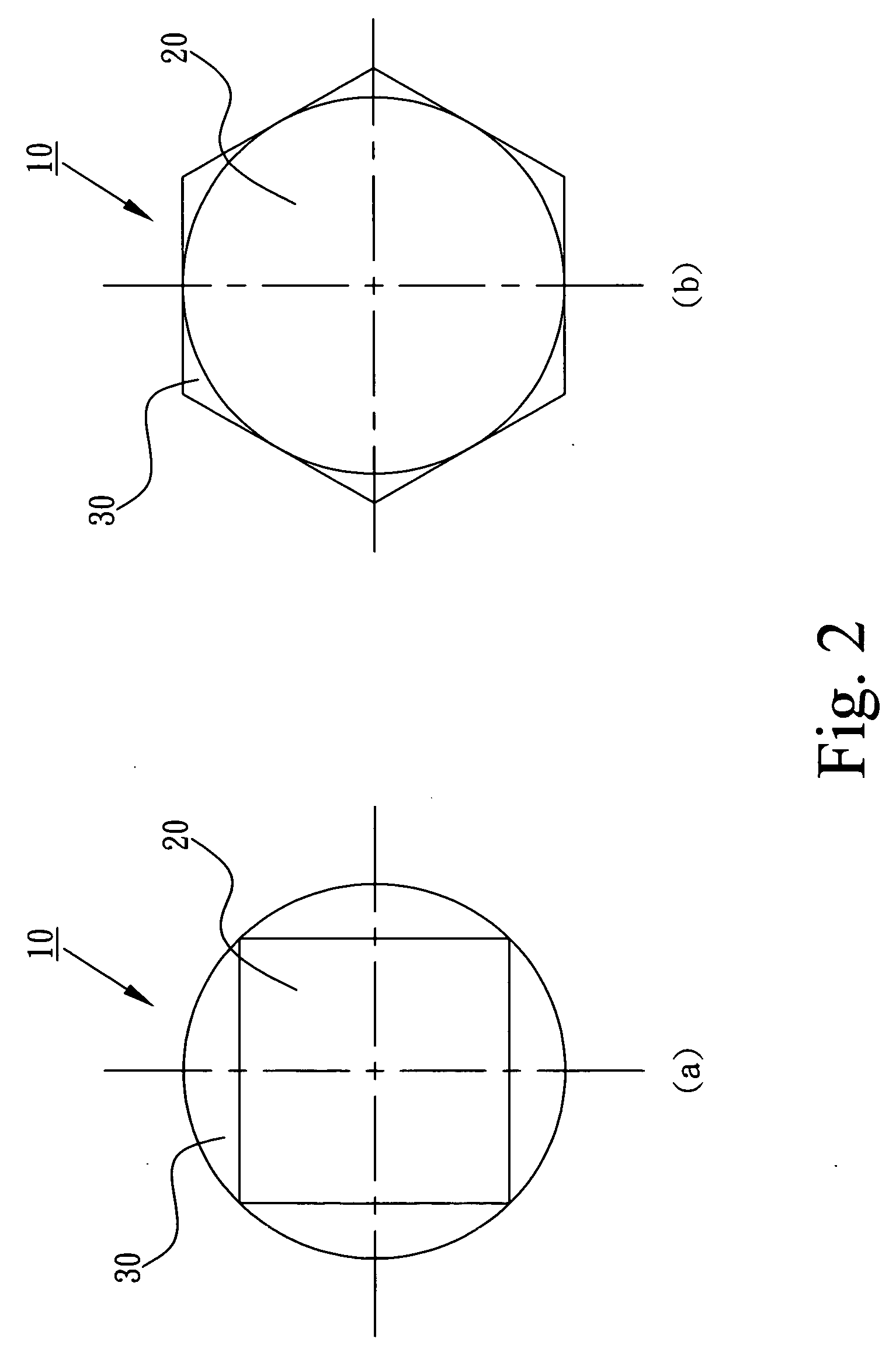

Equilateral strand composite lumber and method of making same

InactiveUS20050000185A1Simple methodLoad-supporting elementsNon-woven fabricsEngineeringComposite lumber

A method of forming a composite beam includes cutting an elongated piece of wood to produce strands having cross sections with a substantially symmetrical equilateral polygonal shape. Resin is then applied to the strands, and the strands are formed into a composite beam.

Owner:UNIVERSITY OF MAINE

Composite wood and bamboo stick

InactiveUS20080176025A1Reduce manufacturing costHigh strengthWood layered productsThin material handlingComposite lumberWear resistance

Owner:XU EDWARD

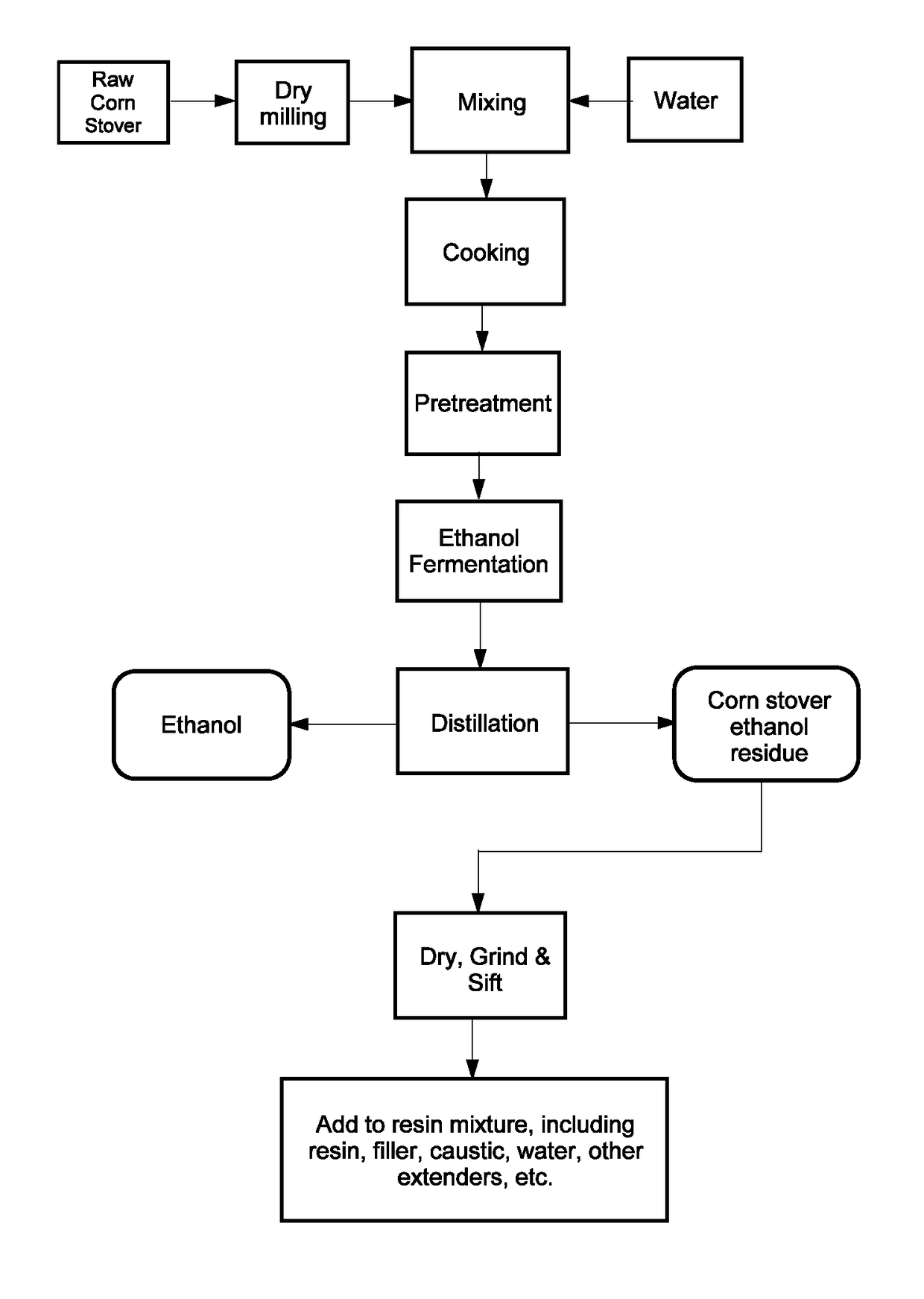

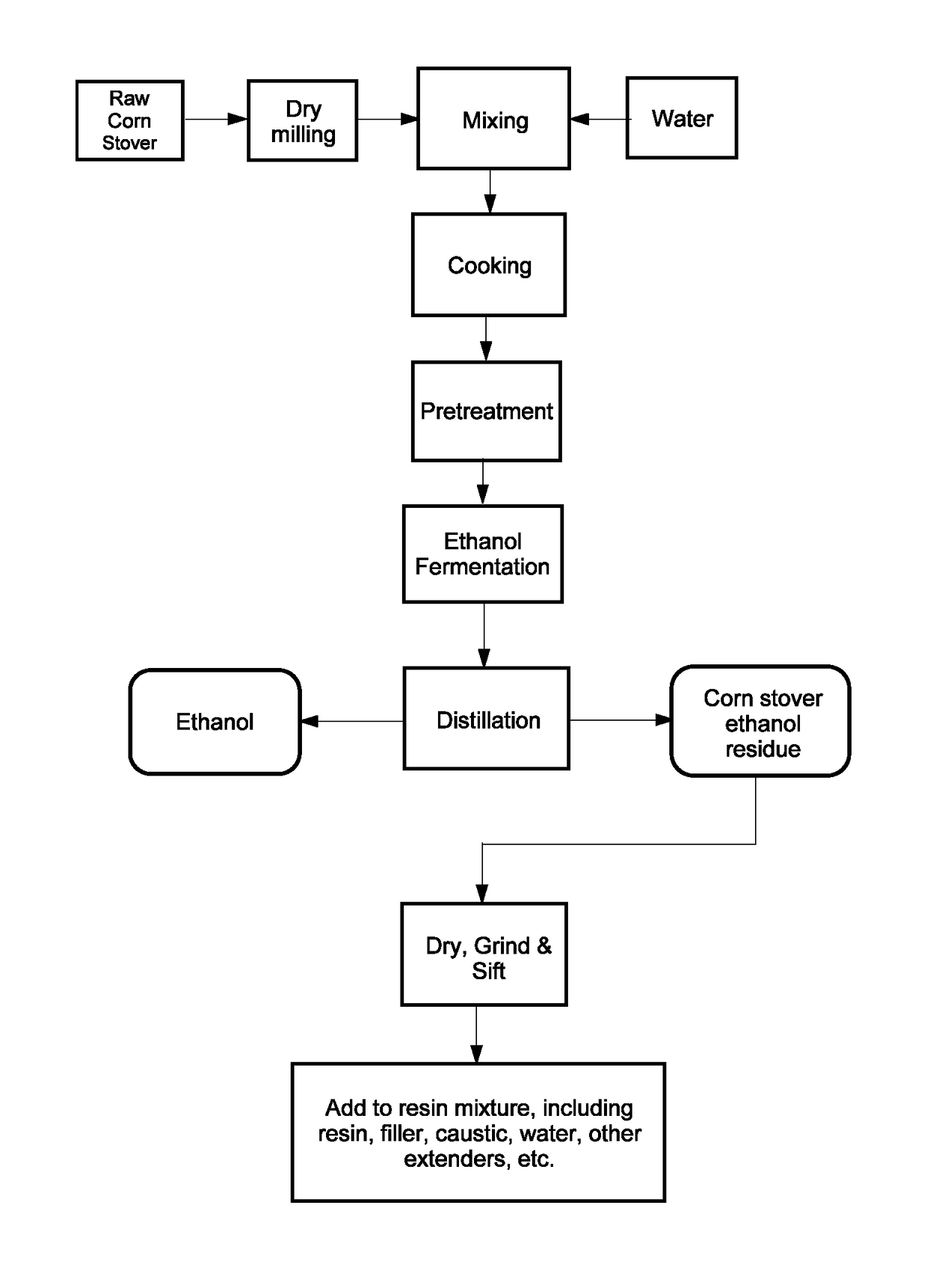

Composite wood adhesive filler

ActiveUS9683139B1Affect prepress characteristicAcceptable viscosityProtein adhesivesAldehyde/ketone condensation polymer adhesivesAdhesive cementWaste product

An improved composite wood adhesive filler, a method of producing such a filler, and an adhesive mixture including such filler are provided, with the filler having performance satisfactory to the manufacturing needs of composite and ply wood products. The adhesive mixture may comprise a filler and one or more extenders. The filler can replace extenders for weight, without introducing instability or viscosity problems. The filler may be drawn from the residue co-product of cellulosic ethanol production using corn stover as feed stock material, which would otherwise be a waste product.

Owner:PLY BOND CHEM & MILL SUPPLIES

Modified China fir composite wood

InactiveCN108098950AGood dimensional stabilityReduced impact toughnessPressure impregnationWood impregnation detailsPerformance indexComposite lumber

The invention provides modified China fir composite wood. The composite material has better dimensional stability. Impact toughness of modified China fir is reduced slightly, while other main mechanical performance indexes such as bending strength, bending elasticity modulus, parallel-to-grain compressive strength, hardness and the like are all increased. Fast growing China fir wood is treated with an aluminium sulfate solution and a water glass solution in sequence in experiments in order to improve properties of the fast growing China fir wood. Aluminium ions immersed into the wood are boundwith silicate ions, aluminium sulfate precipitates are generated in wood microfiber gaps and cells of tracheids (or fiber), so that the wood is filled with a large amount of inorganic matter, and theChina fir inorganic composite wood is obtained. Dimensional stability of the inorganic composite wood is improved substantially, anti-shrinkage coefficient can reach 34.21, and stability coefficientreaches 80% or higher.

Owner:哈尔滨正灏建筑设备安装工程有限公司

Preparing method for environment-friendly resin reinforced flame-retardant modified wood

InactiveCN107599086AGood dimensional stabilityHigh densityWood treatment detailsPressure impregnationPtru catalystComposite lumber

The invention relates to a wood preparing method based on environment-friendly resin reinforcement and flame-retardance modifying. The method comprises the following steps: furfuryl alcohol, maleic anhydride (catalysts), ethanol and ammonium dihydrogen phosphate (flame retardants) ) are used as raw materials, the raw materials are used to prepare an organic-inorganic composite wood modified solution according to a certain ratio; the modified solution is used for carrying out dipping treatment on artificial forest wood, and furfuryl alcohol resin and ammonium dihydrogen phosphate are fixed inside the wood through the solidifying and drying treatment, and the modified wood is finally obtained. According to the method, the dimensional stability, the density, the bending-resistant elasticity modulus and the anti-wrinkle compressive strength of the wood can be improved, the flame retardant is not prone to run off, the loss resistance is high, and the method is green and environment-friendly; and meanwhile, the wood is endowed with good flame-retardancy and dimensional stability, and the method has the advantages of remarkably improving the quality and the additional value of the artificial forest wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Hybrid screw for composite lumber and wood

InactiveUS20070071576A1Easy clampingOvercome disadvantagesNutsBoltsComposite lumberMechanical engineering

A screw for use in a composite lumber member or a wood member has at least one disruptive surface that cuts composite material away from the composite lumber member as the screw is driven into the member to prevent a mound and / or strings from being formed that are attached to the composite lumber member when the screw is set therein. The screw may be used with conventional wood members wherein the screw of the present invention provides increased clamping when driven into a wood member to fasten the wood member to a support member or the like.

Owner:ROMANO MARK +1

Composite wood made of rice straw polymer and its producing process

InactiveCN101015929AReduce pollutionSave forest resourcesFibrous raw materialsDomestic articlesFiberPolymer science

A straw polymer composite wood is characterized in following materials (mass) that straw fiber is 45-85%, thermal plastic polymer is 15-40%, inorganic stuff is 5-15%, elastic element is 2-8%, graft polymer is 2-5%, strengthen filament is 6-10%, and agent is 2-4%. The invention can utilize waste straw to prepare composite wood to save resource and reduce pollution with wide application.

Owner:徐凌秀

Process of using sodium silicate to create fire retardant products

InactiveUS20050042377A1Resistant to deteriorationIncrease costSolid waste managementWood treatment detailsSolubilityWater insoluble

Wood products, specifically wood commonly used in construction including dimension lumber, pressure treated pine, composite wood materials such as plywood, particle board, and wafer board, and samples of paper and fabric were variously treated with concentrations of sodium silicate (Na2O.SiO2) also known as water glass. Cellulosic materials including dimension lumber, plywood, particle board, wafer board, paper, and fabric were treated with sodium silicate (Na2O.SiO2) in concentrations ranging from 400-0.04 g Na2O.SiO2 / kg water. To overcome the disadvantages of sodium silicate, sodium silicate treated samples were further treated to convert the water soluble sodium silicate to a water insoluble form, thereby overcoming the disadvantages of water solubility. and rendering the material effective for internal and external uses. Although treated sodium silicate samples are composed of the same elements in similar proportions, as the untreated sodium silicate samples, the water solubility of the treated and untreated substances is very different..

Owner:T2EARTH HLDG LLC

Preparation method of composite wood adhesive

InactiveCN106433557AImprove adhesionImprove liquidityNon-macromolecular adhesive additivesProtein adhesivesAdhesiveComposite lumber

The invention relates to a preparation method of a composite wood adhesive, belonging to the technical field of adhesive preparation. The preparation method comprises the following steps: modifying soybean protein isolate with urea, and reacting with mussel mucoprotein under alkaline conditions to obtain the modified soybean protein isolate; carrying out enzymolysis on Boston ivy suckers to obtain viscous polysaccharases; and finally, mixing to obtain the adhesive. Under alkaline conditions, the urea is utilized to induce the denaturation of the soybean protein, and the dopamine structure of the introduced mussel protein and soybean protein molecule form a stable structure, so that the modified soybean protein has the advantages in both the soybean protein and the mussel protein, and thus, has high water resistance and flowability. The Boston ivy viscous polysaccharases increase the strength of the adhesive. The method solves the common problems of poor binding strength, poor water resistance and poor flowability in the soybean-base adhesive. The peel strength of the prepared adhesive reaches 1.8-2.0 kN / m, and the binding strength between boards reaches 85-88 MPa.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

Primerless Edge Banding

InactiveUS20150064414A1Without usingLiquid surface applicatorsFilm/foil adhesivesEngineeringComposite lumber

The present invention pertains to bonding an edge banding to the edge of wood or wood composite furniture by using a co-extruded dual compound polypropylene edge band that contains a main body of polypropylene and a primerless EVA backing layer. The edge of the wood or wood composite material is bonded to a polypropylene edge band by an EVA-based glue applied by an edge banding machine at the point of furniture manufacture. Bonding between the edge band and composite wood material is achieved without the use of a primer.

Owner:EMPTING JR HARRY V

Preparing method of modified composite wood for furniture manufacturing

InactiveCN105382895APressure impregnationWood impregnation detailsPulp and paper industryComposite lumber

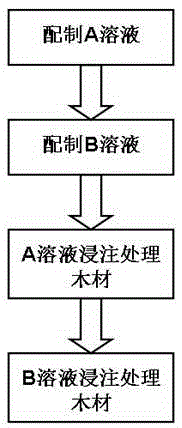

The invention provides a preparing method of modified composite wood for furniture manufacturing. The preparing method comprises the first step of preparing a solution A, the second step of preparing a solution B, the third step of immersing processing of the wood through the solution A and the fourth step of immersing processing of the wood through the solution B. According to the preparing method of the modified composite wood for furniture manufacturing, the composite technology and a self-manufactured inorganic modifying agent are adopted in the preparing method, the size stability of the composite wood is greatly improved, the mechanical performance of the composite wood is obviously improved, and the application range of the composite wood is enlarged accordingly.

Owner:SUZHOU DONGBANG FURNITURE

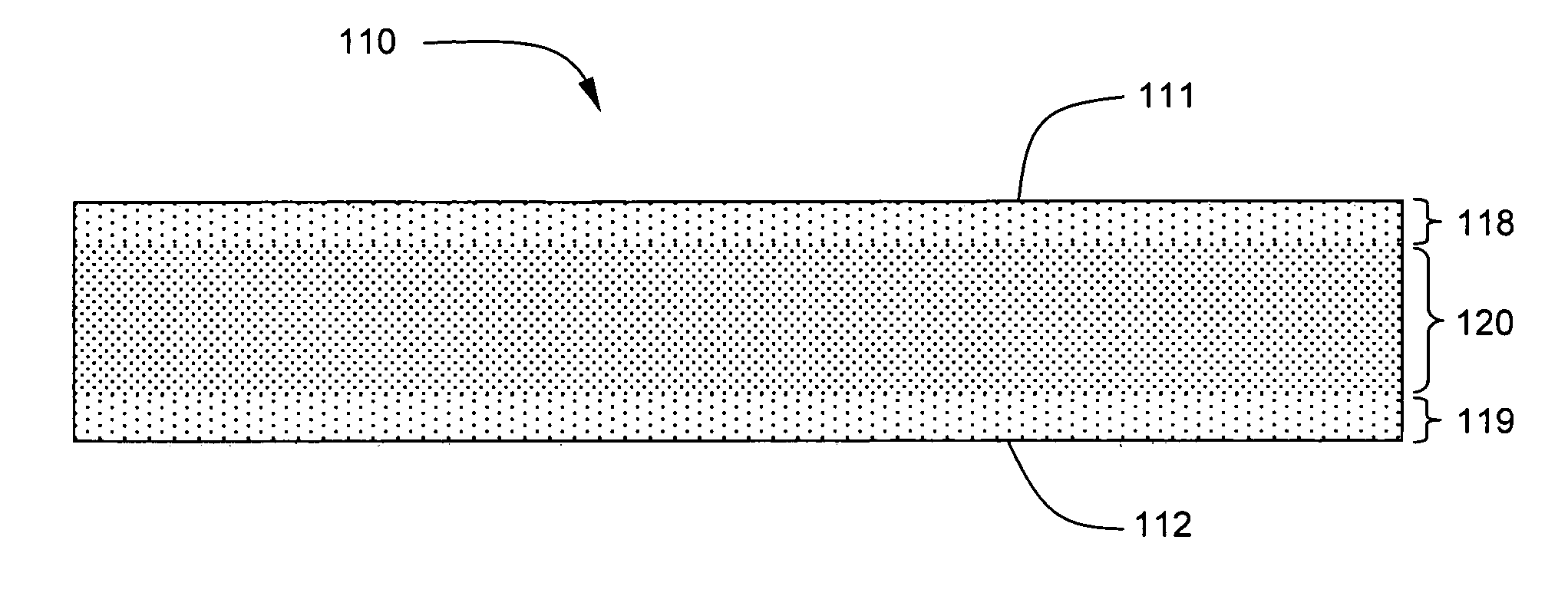

Foamed polymer fiber composite lumber

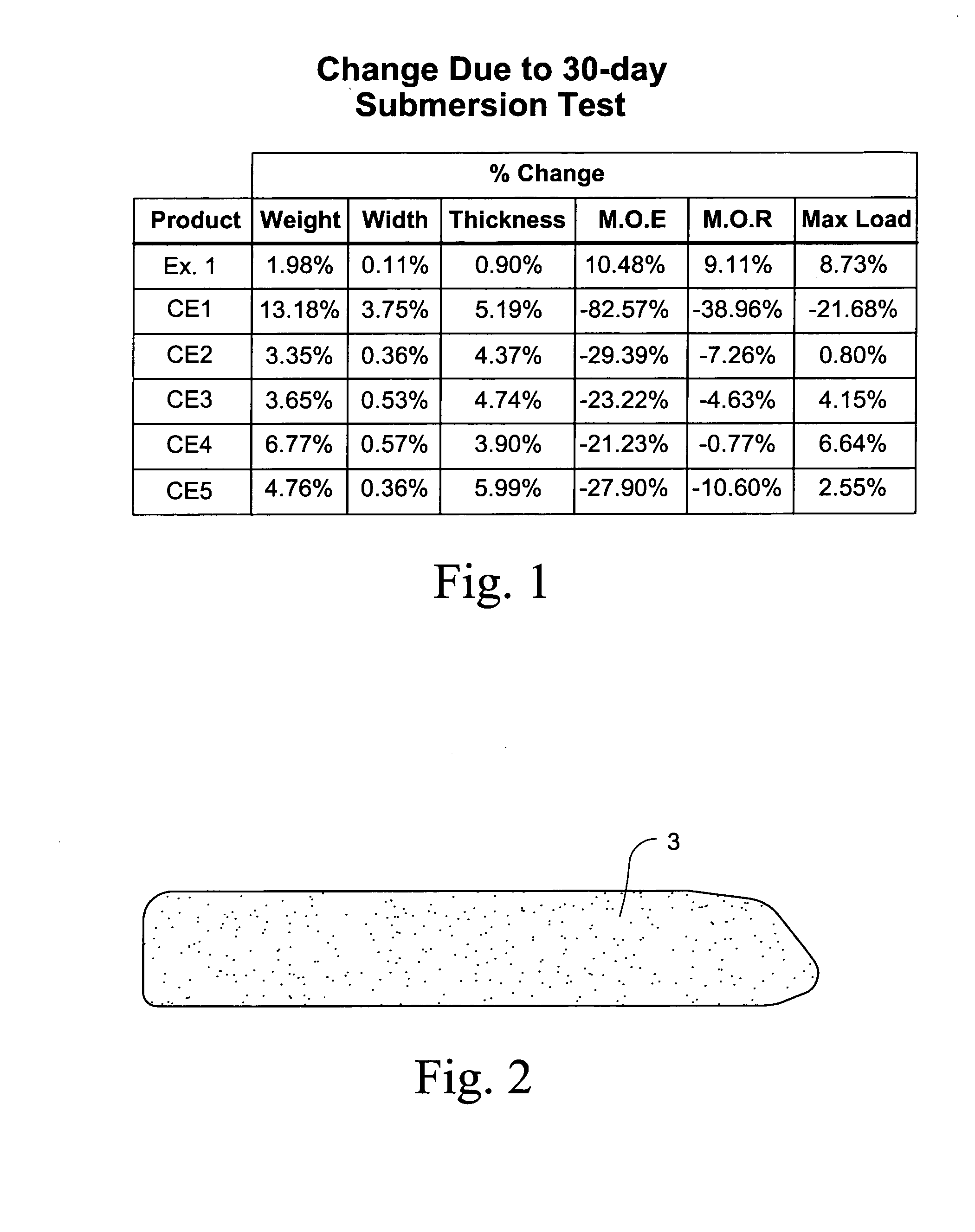

InactiveUS20080096004A1Easy to cut/sawReduced change in stiffnessLayered productsThin material handlingWeight gainingFiber

Certain example embodiments of this invention relate to a composite lumber product include from about (i) 38-46% wood fiber, (ii) 0.2-5.0% foaming agent, and (iii) 46-60% polymer such as homopolymer polypropylene. Optionally, the lumber product may also include one or more of from about: (iv) 0.5 to 5% lubricant, (v) 0.5 to 6% pigment, and / or (vi) 0.4 to 5.0% coupling agent. Surprisingly, it has been found that such a composite lumber product is surprisingly less subject to moisture absorption thereby leading to a more stain resistant product and a product less likely to absorb moisture (less weight gain) during wet environmental conditions. Moreover, such a composite lumber product is easier to cut / saw, and easier to screw into, thereby leading to a more user-friendly product.

Owner:GUARDIAN GLASS LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com