Stair bracket system and method

a technology for stair risers and brackets, which is applied in the field of assembly of stair risers, can solve the problems of deterioration of stair risers constructed out of wood, time-consuming construction of staircases, and inability to meet the needs of use, and achieves the effect of convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

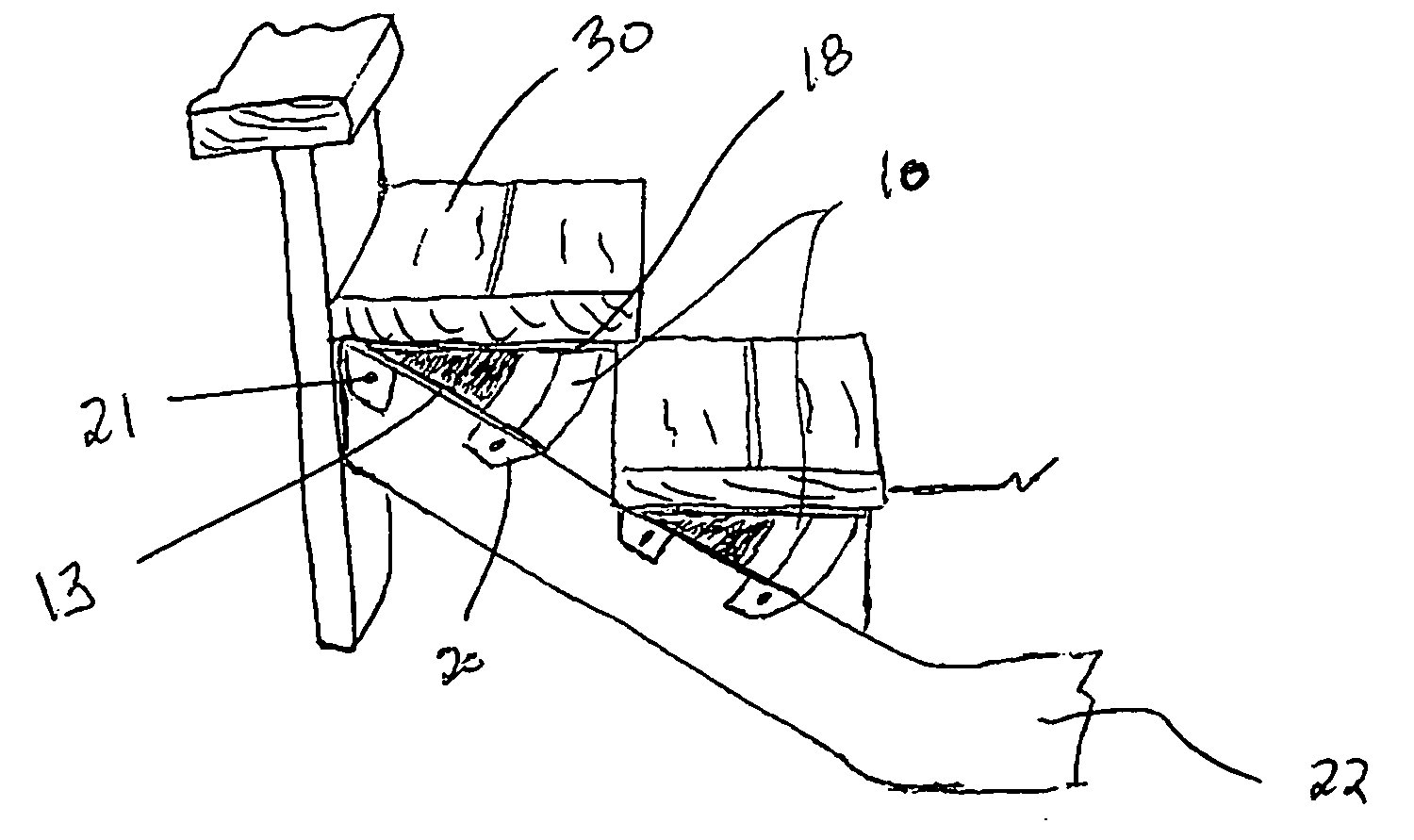

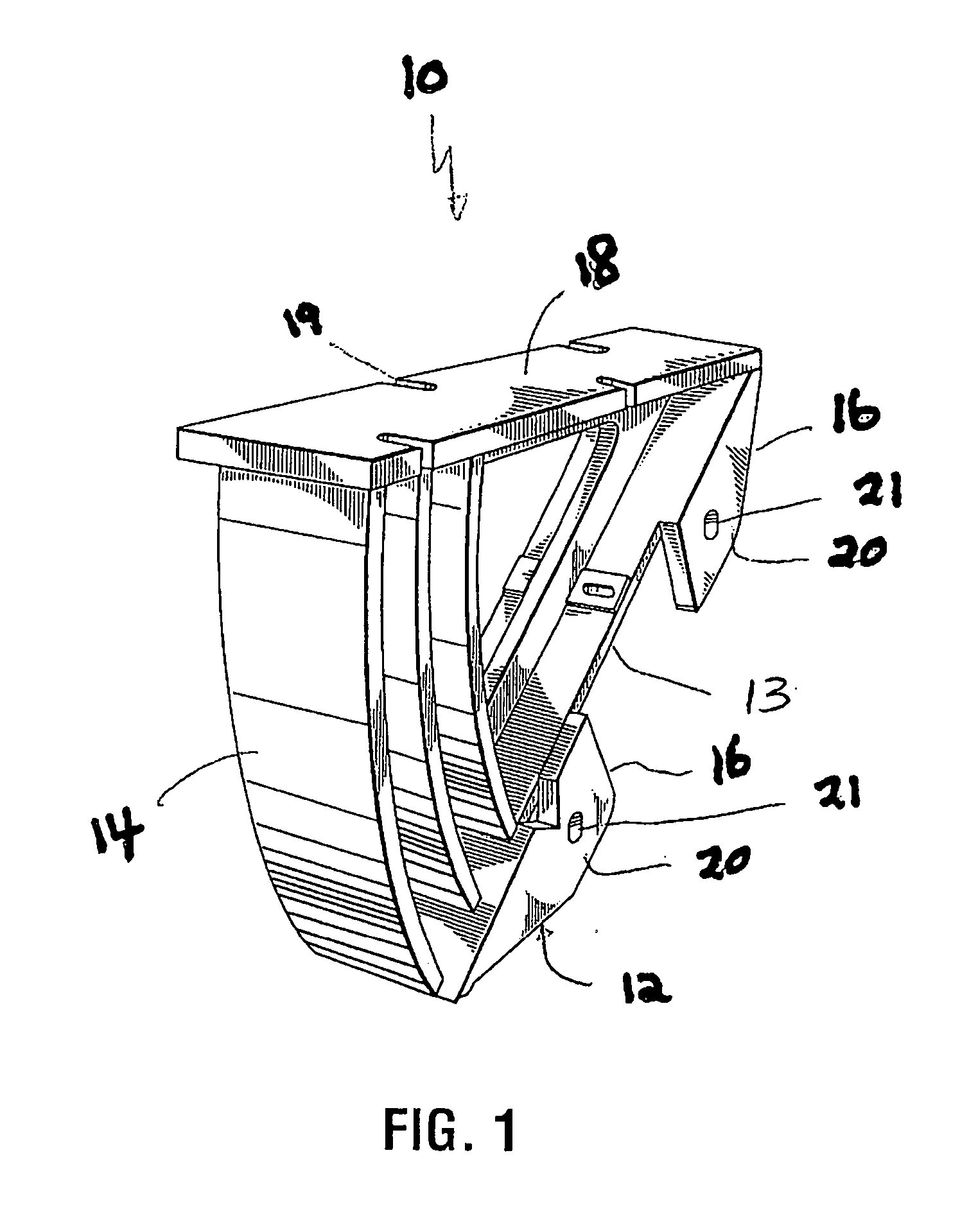

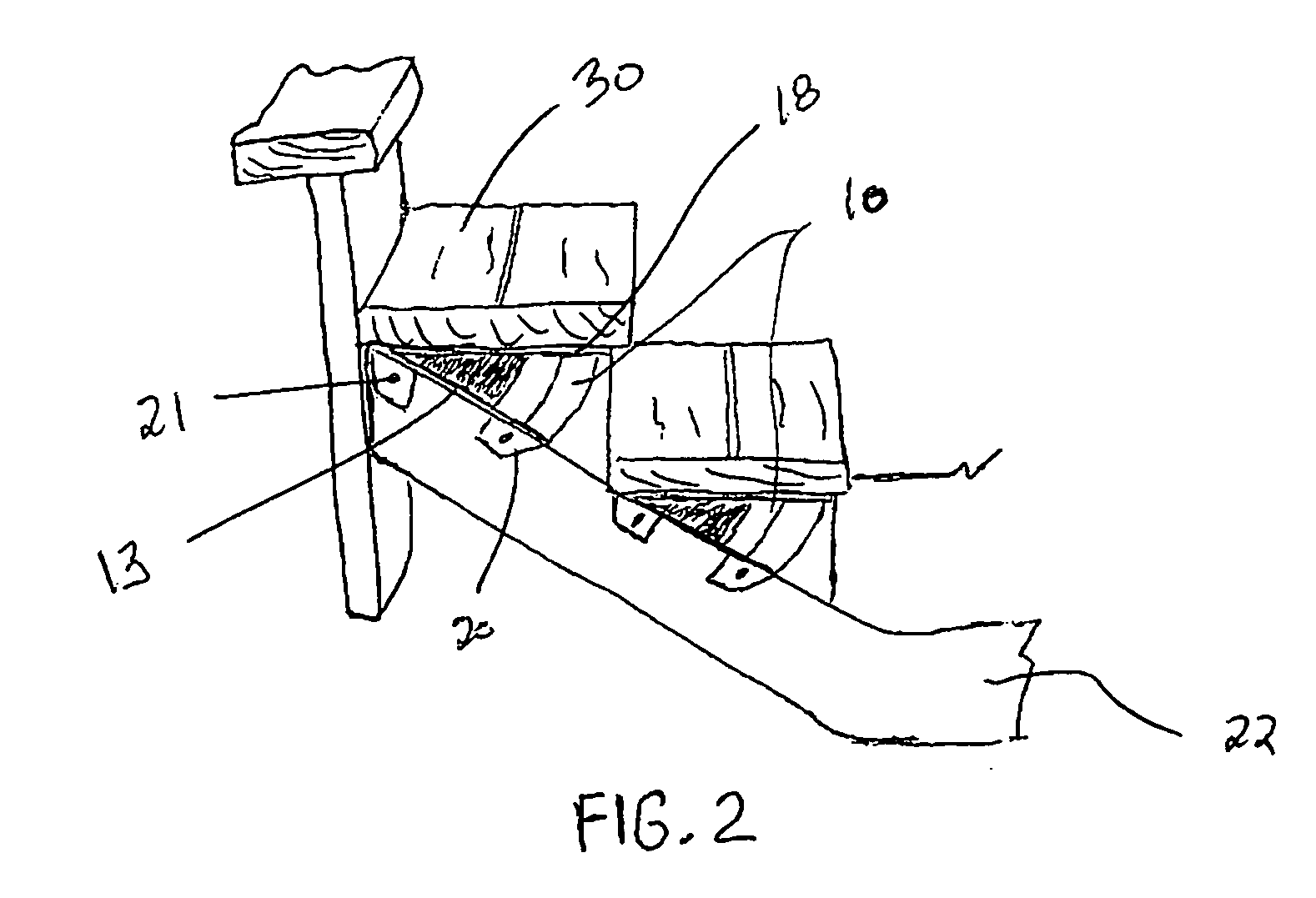

[0015] Referring first to FIG. 1, a bracket 10 of the present invention to be used in the construction of a riser is illustrated which is comprised of at least one bottom edge 12, a front section 14, a lower section 13, at least one back end edge 16, a top section 18 and at least one bracing member 20 wherein said lower section 13, front section 14 and top section 18 enclose an open space providing for great strength and rigidity. As further illustrated in FIG. 1, the top section 18 is comprised of apertures 19 for the secure positioning and attachment of treads therein. Bracing member 20 is also comprised of apertures 21 for secure positioning and attachment to a structural member 22 in the construction of risers which may be used for staircases or terrace seating, for instance. It is understood that the bracket 10 of the present invention may also be used for other similar purposes calling for the presence of at least one riser member.

[0016] Said bracing member 20 is adaptedly sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com