Preparing method of modified composite wood for furniture manufacturing

A wood and modification technology, applied in the direction of impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of complex hot pressing and setting process, performance deterioration, and difficulty in compounding modified agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

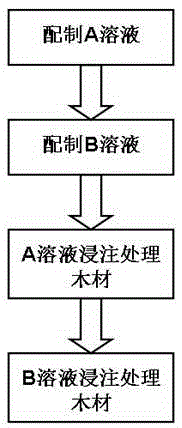

[0016] figure 1 It is a process step chart of the preparation method of modified composite wood used in furniture production according to the embodiment of the present invention; the preparation method includes the following steps: a) preparing A solution, b) preparing B solution, c) impregnating the A solution to treat wood, d ) B solution impregnation treated wood.

[0017] The modified composite wood preparation method that the present invention mentions is used for furniture and adopts aluminum sulfate, sodium silicate as the main, silane coupling agent, polyethylene glycol 400 is the composite modifier that is auxiliary, to the fast-growing Chinese fir After treatment, the aluminum ions immersed in the wood are combined with the silicate ions to generate aluminum sulfate precipitation in the wood microfibril gap and the cell cavity of the tracheid, so that the wood is filled with a large amount of inorganic substances, and the inorganic substance filling modification is ...

Embodiment

[0019] The specific preparation method is as follows:

[0020] a) To prepare solution A, first weigh the following raw materials by weight percentage: 91% aluminum sulfate, 0.5% silane coupling agent KH500, 8.5% polyethylene glycol 400; then dissolve them in a certain amount of water, adjust The pH value of the solution is 5.5, and it is prepared as a solution with a concentration of 20%.

[0021] b) To prepare solution B, first weigh a certain amount of sodium silicate raw material, then dissolve sodium silicate in a certain amount of water, adjust the pH value of the solution to 9, and prepare a solution with a concentration of 16%.

[0022] c) A solution impregnation treatment of wood, the specific treatment process is: first cut the fir material into boards that meet the specifications according to the specifications of furniture making materials, and immerse the boards in a water tank for cleaning, and put them into 103 ° C blasting after cleaning Dry in a drying oven fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com