Patents

Literature

42 results about "Mould removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Add one quarter of a tablespoon of baking soda to a spray bottle of water. Shake the bottle to dissolve the baking soda into the water. Spray the moldy area with the baking soda and water solution. Then use a sponge or scrubbing brush to make sure to remove all the mold from the surface.

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

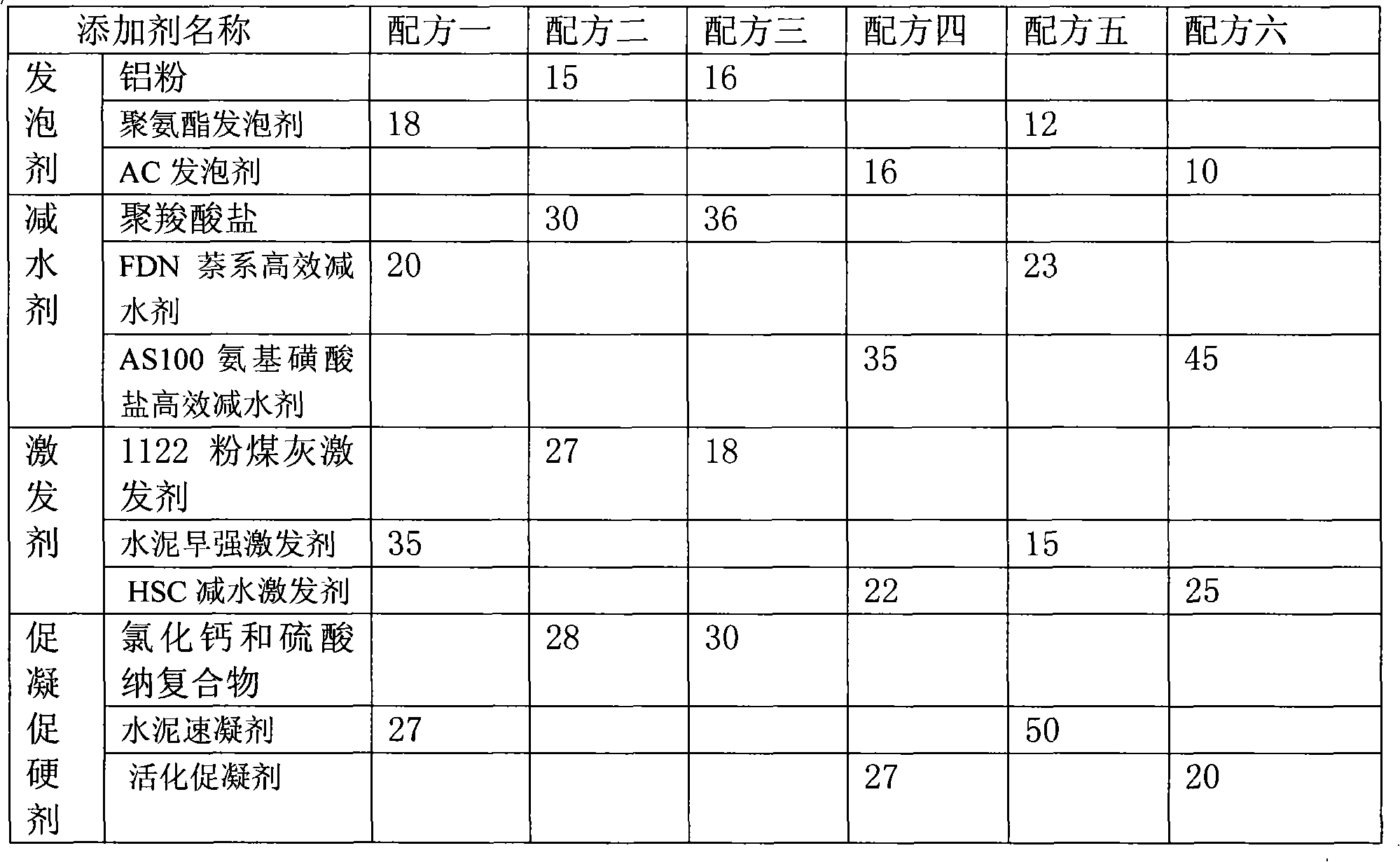

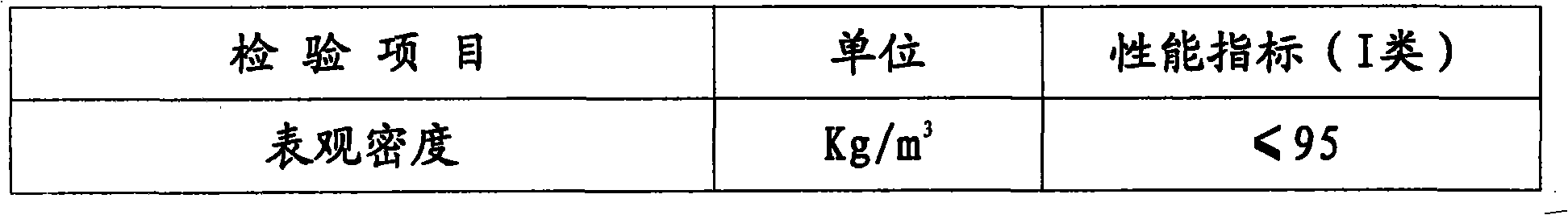

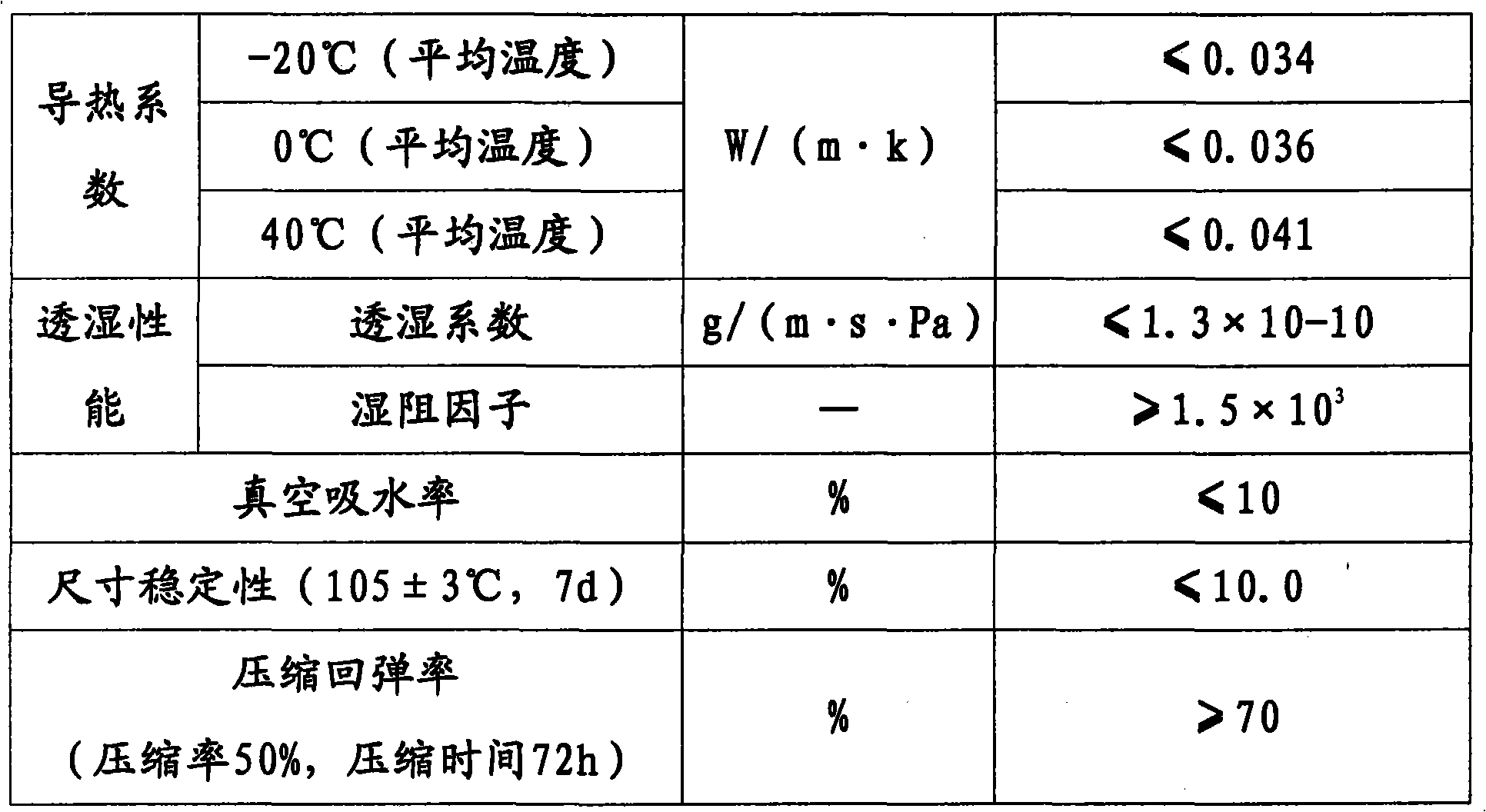

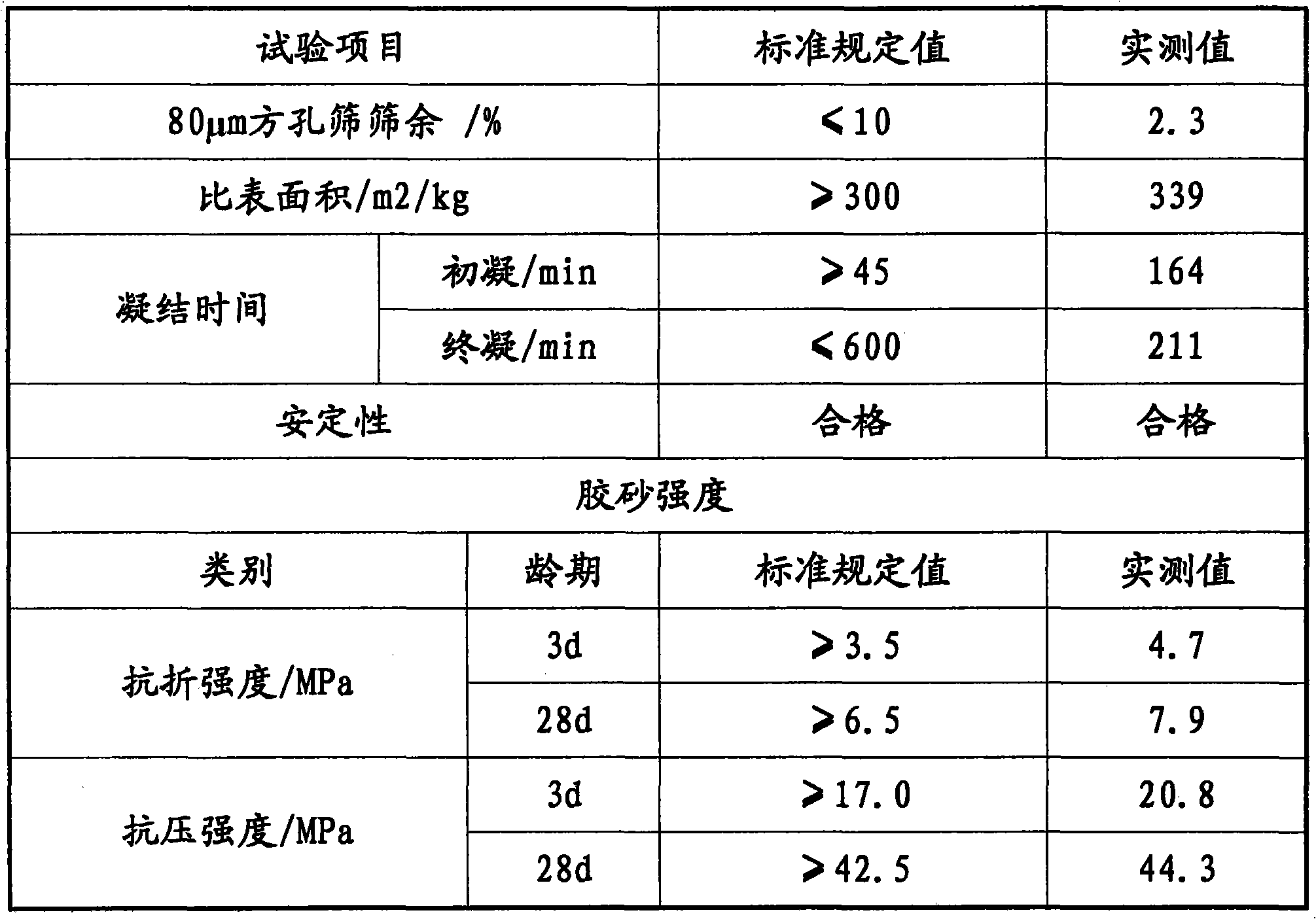

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Wood bunch recombining material and producing method thereof

InactiveCN101104286ALow technical requirementsReduce investmentDomestic articlesFlat articlesFiberVolumetric Mass Density

Disclosed is a wood bunch composite lumber, whose cross section is square, round or elliptical shaped, wherein the wood fiber is vertically arranged; the appearance of the cross section is a congregated section of numerous wood bunches, showing the combining color of the natural wood color and the color of the glue; the density is 0.7-1.1g / cm3; the static bending strength is 30-40MPa; the elasticity modulus is 5000 -11000MPa; the nail-holding ability is 1100-2000N. The production of the composite lumber includes the following procedures: material selection, wood-bunch preparation, desiccantion, gluing, measuring, assembling, mould packing, cold pressing, thermal initiated solidification, cooling and mould removal. The composite lumber can be applied directly to the architectural ornament industry, the sawed floor board and the furniture faceplate and so on. The invention has advantages that the raw materials adopted can make comprehensive use of the lumber resources; the material quality of the product is even; the structure and the nature of the lumber can basically be kept unchanged; the lumber is material-saving, stable and easy for secondary production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for maintaining high-performance concrete under severe environment

InactiveCN102029645AMeet the temperatureFulfil requirementsCeramic shaping apparatusMould removalUltimate tensile strength

The invention discloses a method for maintaining high-performance concrete under a severe environment, comprising the following steps of: after concrete pouring is completed, immediately covering a rubber and plastic plate or a geotextile or reserving a space on the top end of a template after the top surface of the concrete or the surface of concrete exposed to the air is closed, and watering in the space for maintenance; when the strength of the poured concrete achieves the requirements for mould removal and the central temperature of the concrete starts to be reduced, carrying out the mould removal; packing heat-preserving and moisture-preserving materials for the maintenance during the mould removal; and maintaining in the way of double packing with a heat-preserving and moisture-preserving material in the maintaining process.

Owner:LANZHOU JIAOTONG UNIV

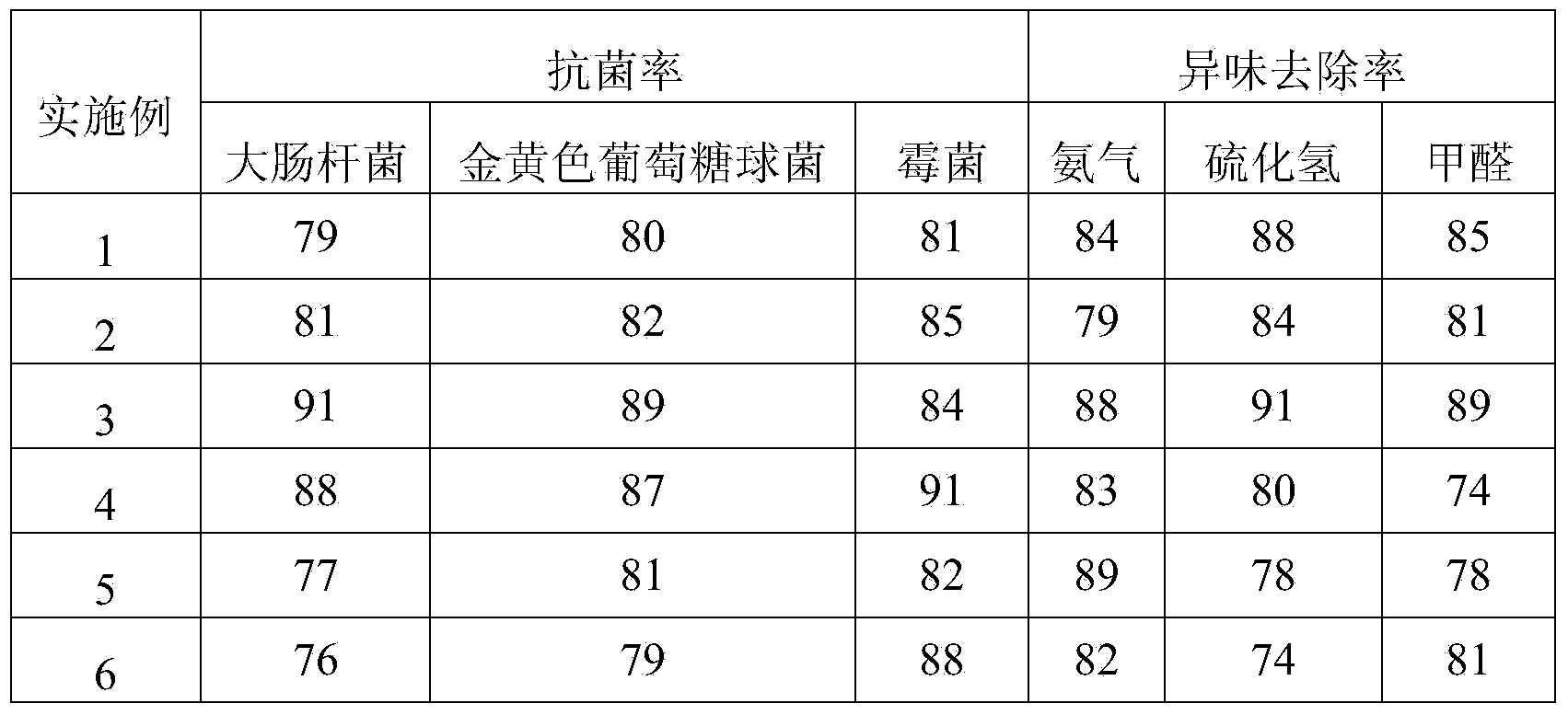

Purifying, adsorbing and sterilizing material and application thereof

ActiveCN103623780AHigh porosityLight in massAntibacterial agentsOther chemical processesPorosityHazardous substance

The invention discloses an adsorbing and sterilizing material, and particularly discloses an adsorbing material for air purification. The adsorbing and sterilizing material contains the following ingredients: zinc oxide, montmorillonite and activated carbon. According to the material for air purification, a composition formed by mixing the montmorillonite, the zinc oxide and the activated carbon has a large porosity, moreover, the three ingredients respectively have pertinence adsorption performance for toxic and harmful substances, and the respective selective adsorption characteristics of the three ingredients are utilized to mutually enhance the adsorption effect so that the toxic and harmful substances can be hidden nowhere. More importantly, after the montmorillonite, the zinc oxide and the activated carbon are mixed, the bulk density is decreased, the weight of adsorption material with the monomer size is relatively light, the weight of the air purifier is greatly reduced, and the air purifier is more conveniently used. The specific surface area of the activated carbon, the montmorillonite and the zinc oxide is large, the absorbability to harmful gas, bacteria and mould is good, and the sterilization, mould removal and detoxification effect is good.

Owner:常熟荣瑞灭菌技术有限公司

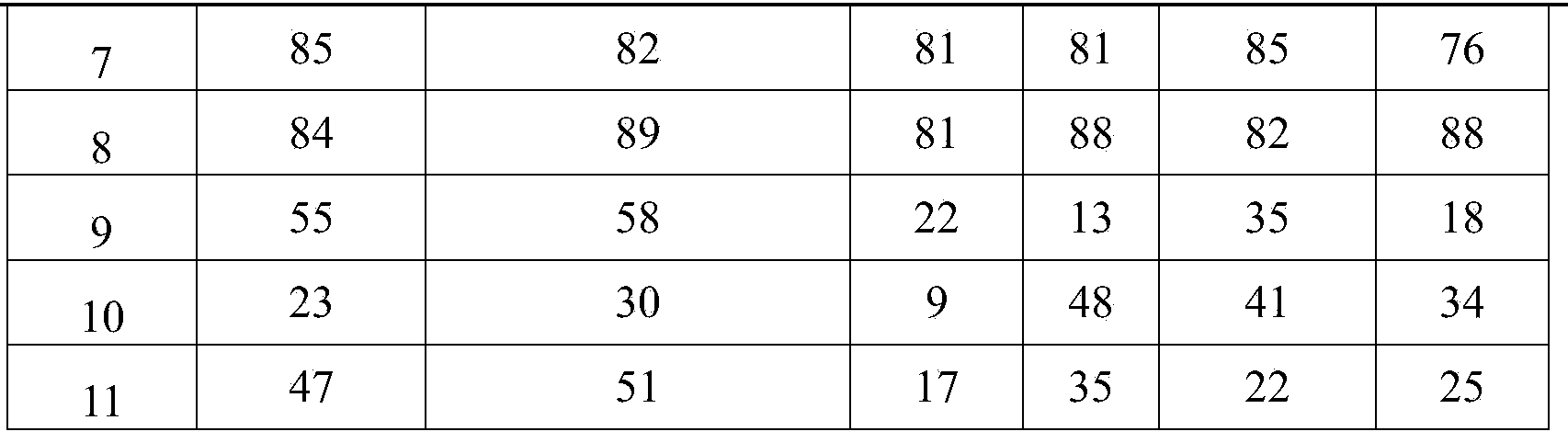

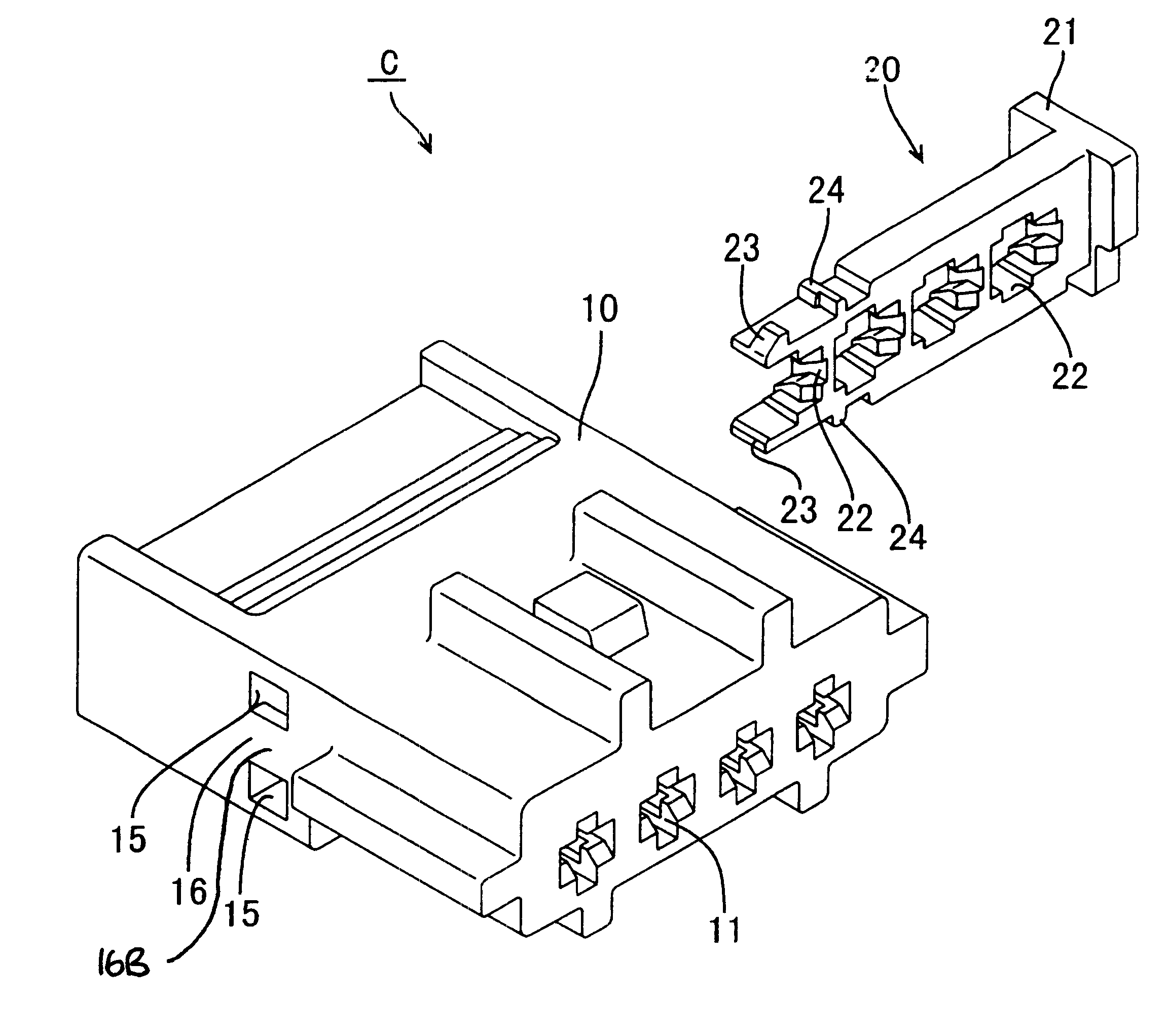

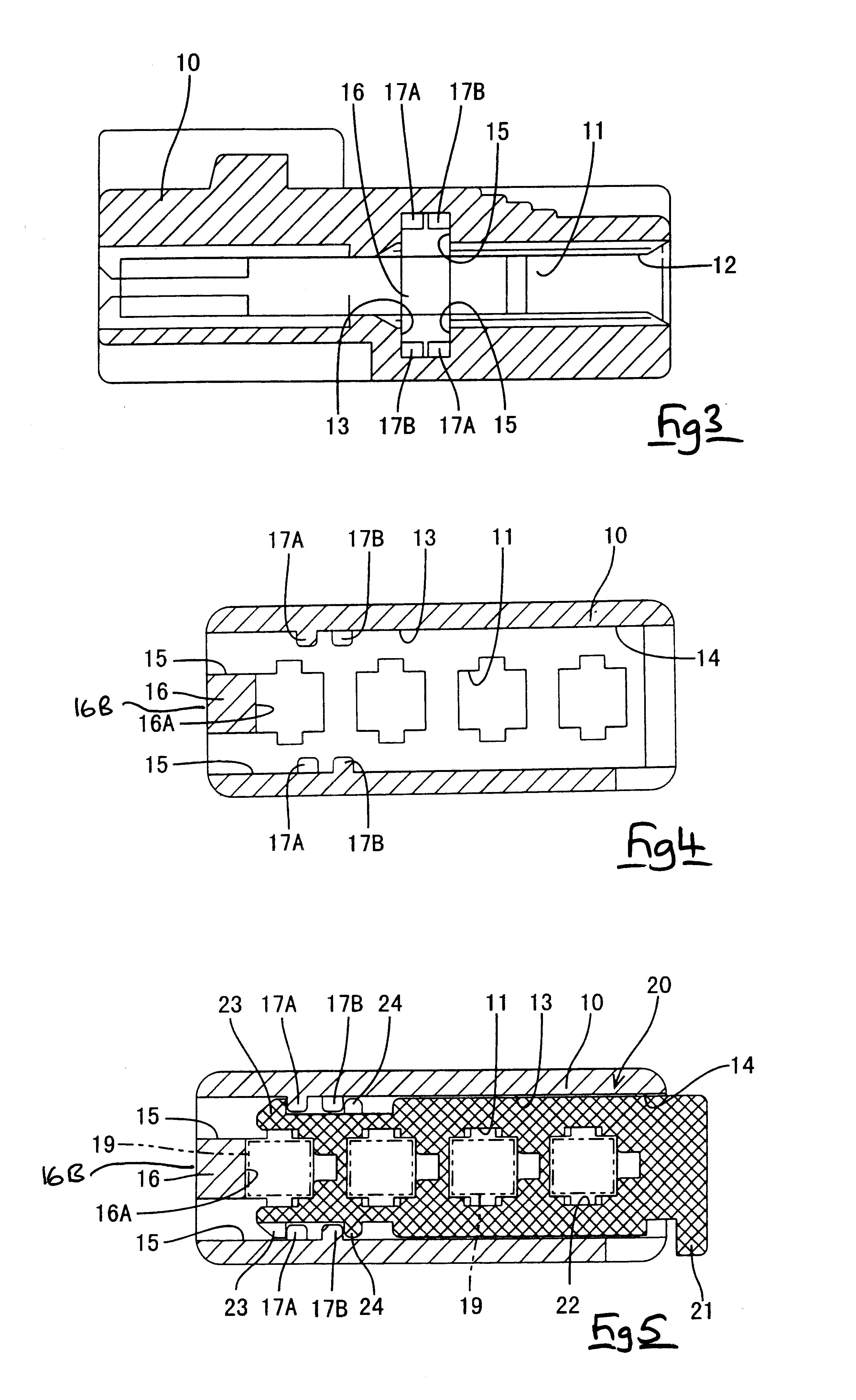

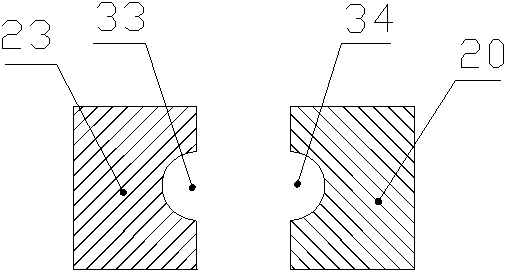

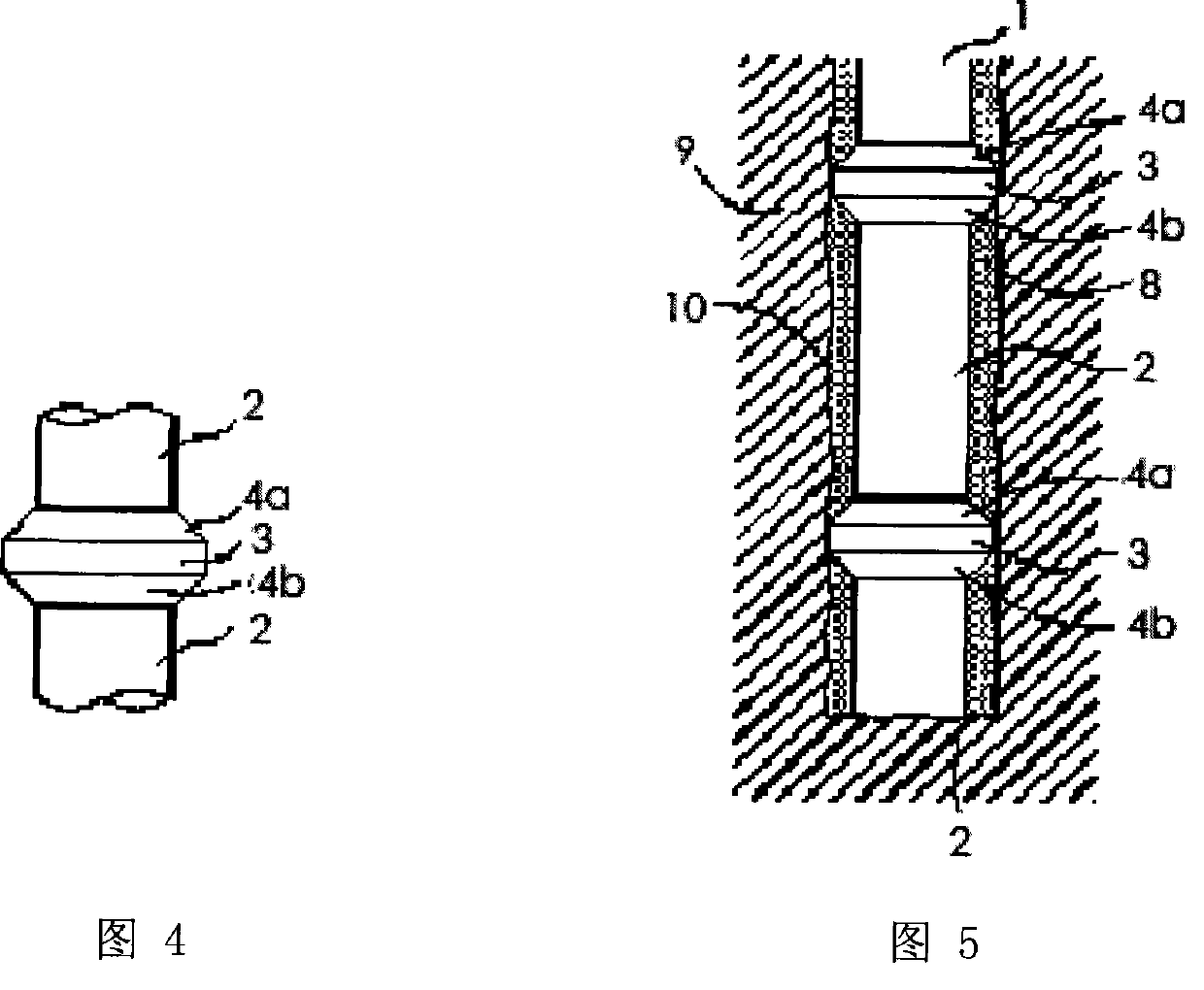

Connector and mould

InactiveUS6435919B1Contact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringMould removal

The invention provides a moulded plastic connector in which the mould is not weakened, and in which terminal fittings are not exposed. Portions of a side of a retainer attachment hole 13, which are opposite an insertion hole 14 for a retainer 20, are open to form mould removing holes 15, the remaining portion being covered by a wall 16. This wall 16 reduces the degree to which terminal fittings 19 are exposed from the interior of a housing 10. When a connector C is to be moulded, anterior ends of a first mould 30 (which is removed from the housing 10 via the insertion hole 14) and a second mould 40 (which is removed via the mould removing holes 15) fit together within the retainer attachment hole 13 in a doubled-over manner in a direction which intersects with the direction of mould removal. Consequently, the strength of the moulds 30 and 40 is not decreased.

Owner:SUMITOMO WIRING SYST LTD

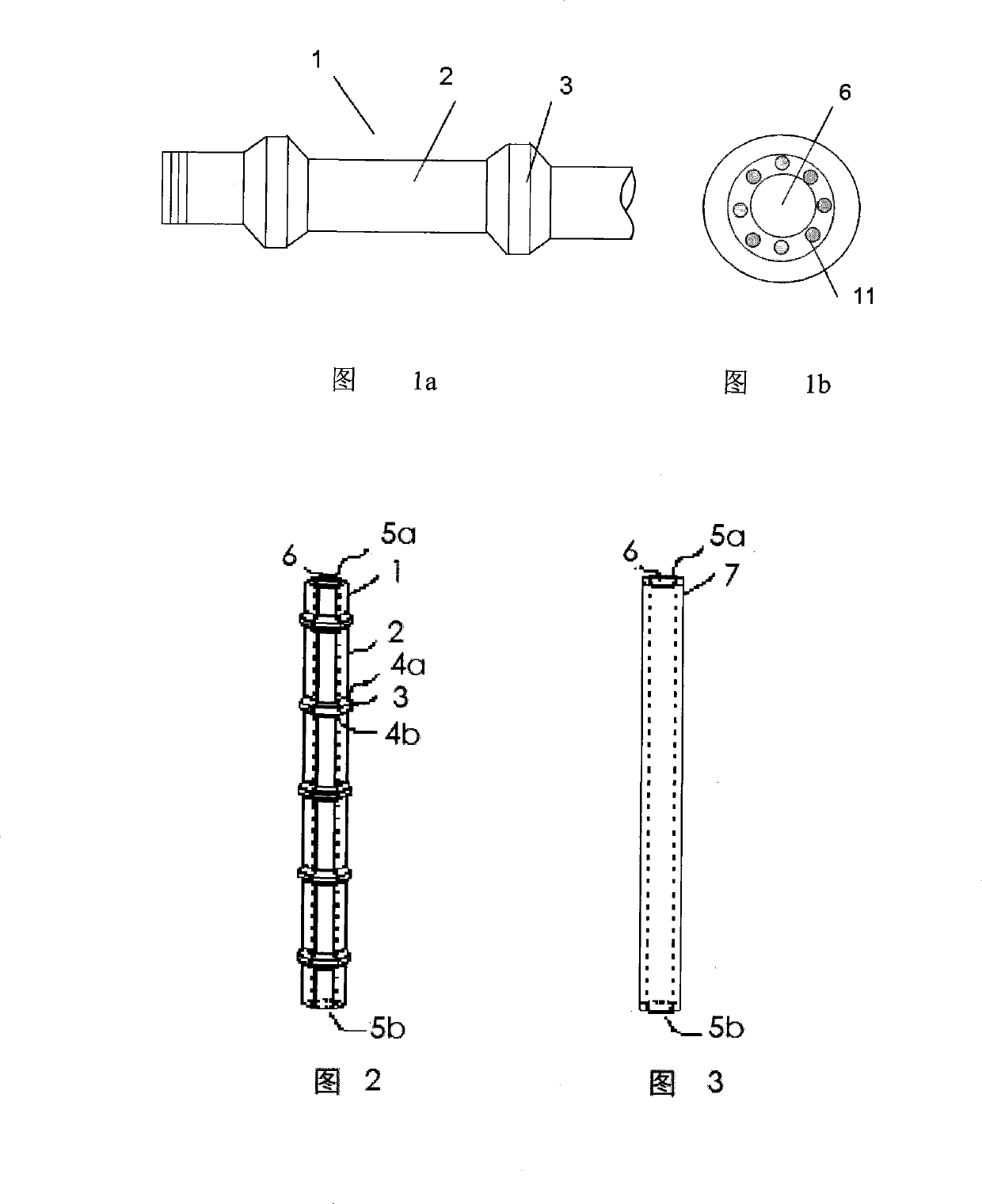

High-strength prestressed concrete pipe pile with section and its production method

The invention provides a high-strength pre-stress concrete pipe pile with knurls. A plurality of ring-shaped convex knurl parts are formed on the pipe pile body with spacing; the pipe pile body between all knurl parts forms a pile shaft part; all parts are integrally poured by concrete; the concrete pipe pile body with the knurls is embedded by PC steel bars and rebar; the concrete pipe pile is characterized in that the concrete of the high-strength pre-stress concrete pipe pile with the knurls is added by 5-25% of silica ashes (powder-shaped SiO2) with the average particle size of 0.1-0.5 Microns. According to the high-strength pre-stress concrete pipe pile with knurls, the silica ash is added in the raw material, thus preventing the cracking of knurl part and the like during the normal-pressure steam curing or the stage thereafter. Meanwhile, the knurl structure of the concrete pipe pile with the knurls can be changed, thus being beneficial for improving the strength. Furthermore, a conical part is used for connecting the difference between high position and low position between the pile shaft part and the knurl part, thus becoming easy for the mould removal operation of the pile fabrication process. Furthermore, as the knurl parts have an effect of increasing the strength, the high-strength pre-stress concrete pipe pile with knurls is beneficial to the transport and construction of the pipe piles.

Owner:上海陆丽科技有限公司

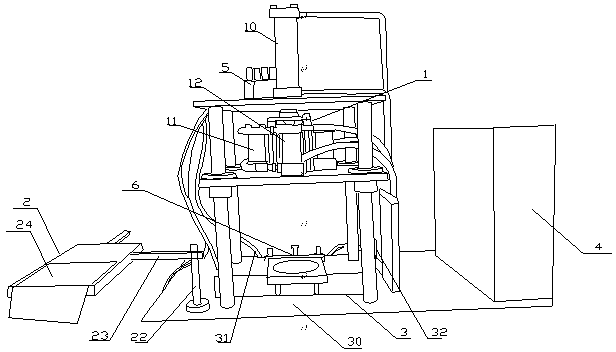

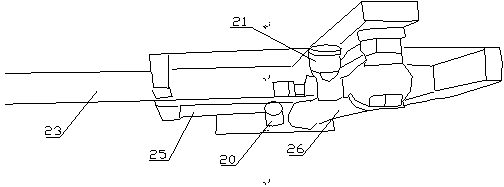

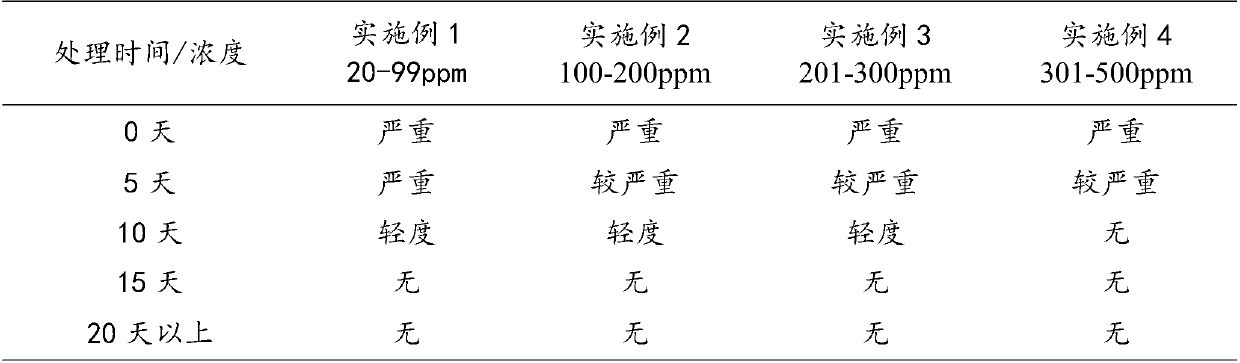

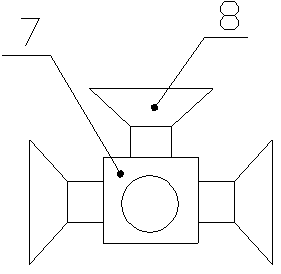

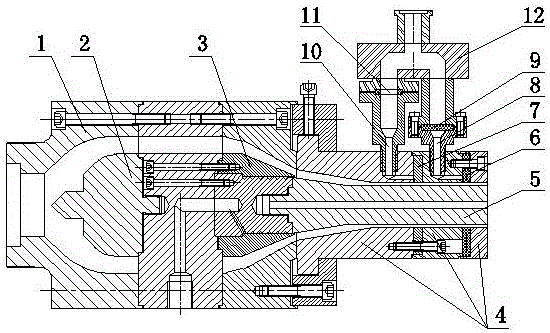

Fully-automatic ceramic hot pressure casting

InactiveCN103101111AEasy to operateIncrease productivityCeramic shaping plantsPressure castingControl valves

The invention discloses a full-automatic ceramic hot pressure casting comprising a mould hydraulic system, a mould, a ceramic blank conveying system, a raw material heating device, a mould cooling device, a control cabinet, a cylinder control valve and a material inlet heating device, wherein the mould hydraulic system is connected with the mould; the ceramic blank conveying system is arranged at one side surface of the mould hydraulic system; the raw material heating device is arranged below the mould hydraulic system; and the control cabinet is connected with the mould hydraulic system, the ceramic blank conveying system, the raw material heating device, the mould cooling device, the cylinder control valve and the material inlet heating device. No extra work is needed regardless of mould assembly, mould removal, product conveying after mould removal, shut down and mould replacement, and therefore the fully-automatic ceramic hot pressure casting is simple to operation, high in production efficiency and energy-saving.

Owner:福建省德化福杰陶瓷有限公司

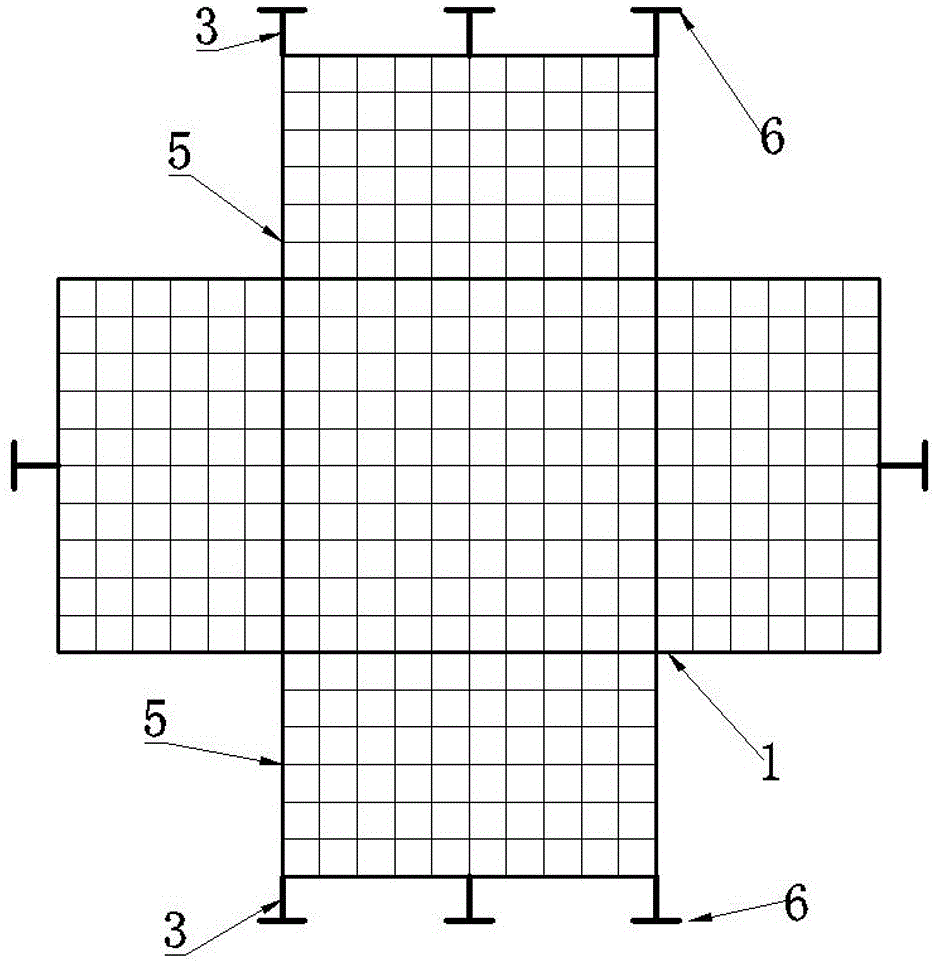

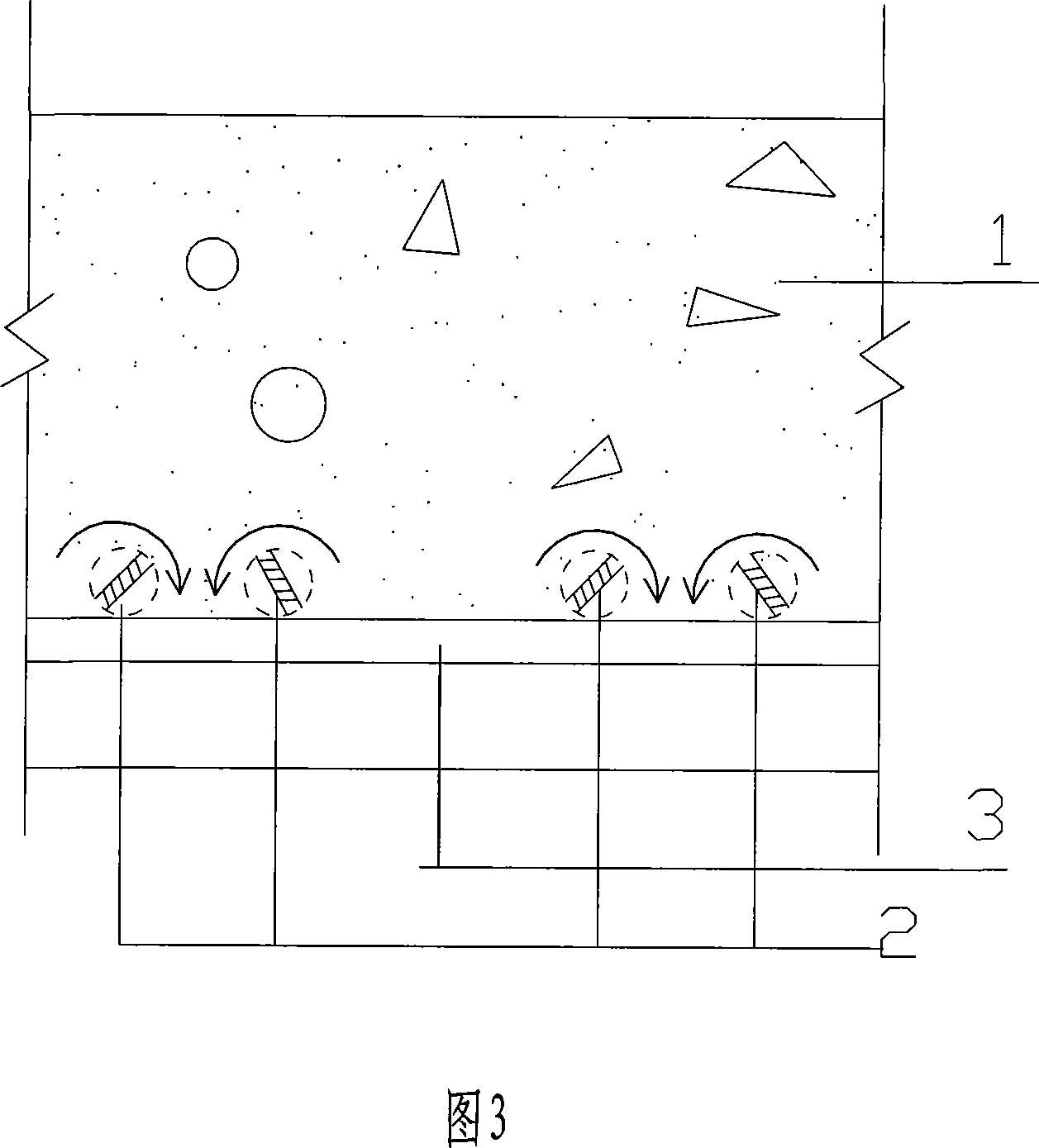

Hollow floor construction method using opening composite core mold

InactiveCN107435402ASimplify the construction processShorten the construction periodFloorsMould removalHollow core

The invention discloses a hollow floor construction method using an opening composite core mold. The composite core mold consists of a latticed framework, a face layer and at least three foot supporters, wherein the face layer and the framework jointly define a geometric body; the geometric body is hollow; an opening is formed in the bottom of the geometric body; and the foot supporters are positioned at the lower side of the opening and are exposed out of the face layer. The method has the critical steps that after the opening composite core mold is put in a gap position between ribs according to design requirements, concrete is cast for the first time to reach the opening position of the opening composite core mold, and vibration maintenance is performed; and then, the concrete is cast for the second time until the whole of the latticed ribs and cavity components is covered, and then, maintenance and mould removal are performed to form a cast-in-place concrete hollow floor. Compared with a conventional cavity construction process with the defects of complicated process and great construction difficulty, the hollow floor construction method provided by the invention has the advantages that the construction period can be effectively shortened; the construction difficulty is reduced; the labor cost is greatly reduced; and the transportation and storage of products are convenient.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

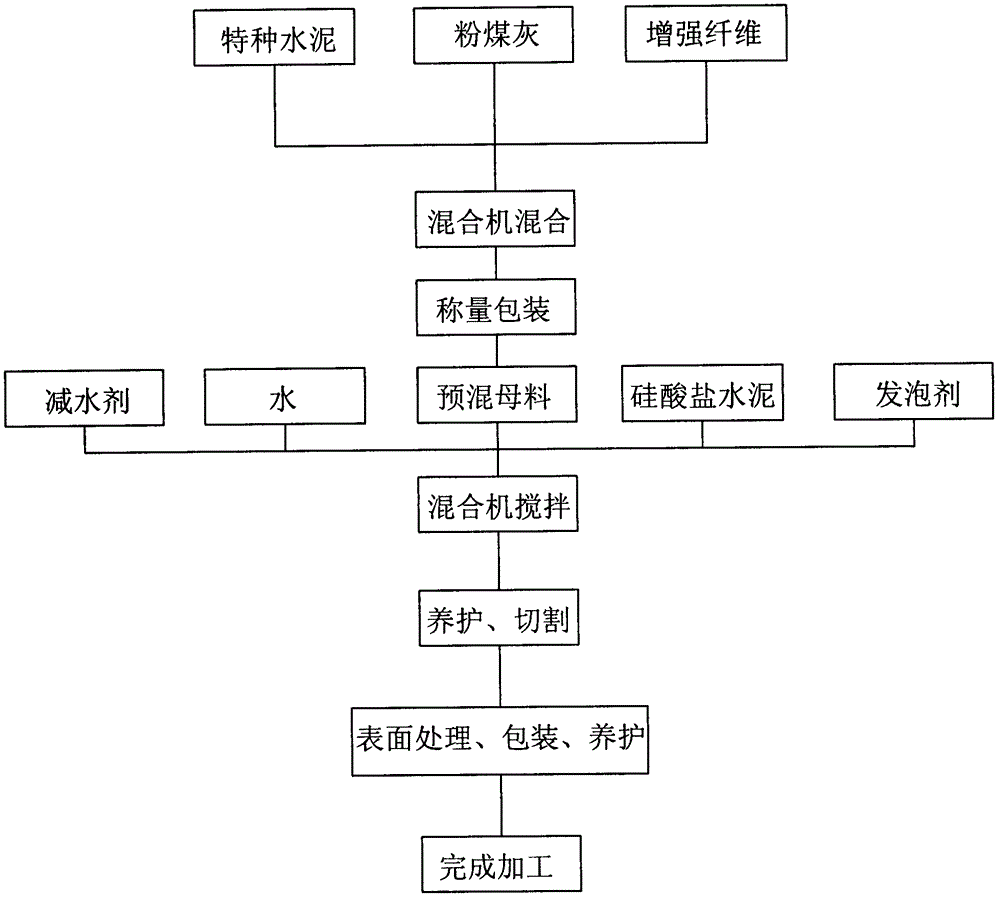

Method for cutting foaming cement board by means of wet process

ActiveCN102744778APrevent leakageAvoid phenomena such as crackingCeramic shaping apparatusThermal insulationCement board

The invention discloses a method for cutting a foaming cement board by means of a wet process. The method comprises the following steps: (1) mixing and stirring cement, pulverized fuel ash, reinforced fibers and an additive with water according to the proportion and performing mould pouring, foaming and standing to prepare the foaming cement board; (2) maintaining the foaming cement board for 20-30 minutes, performing mould removal and cutting the foaming cement board into required foaming cement boards with various specifications through a cutting device; and (3) performing surface treatment, package and film coating maintenance of the cut foaming cement boards for 14 days. When the strength of the foaming cement boards is low, the wet process cutting is performed, the amount of dust produced in the cutting process is reduced, the cutting efficiency is improved, and the product quality is improved greatly. The problems that large amount of hydration heat is produced in the foaming process of the foaming cement boards, caused cracks do not easily disperse, cutting size deviation is large when the strength of the foaming cement boards is high, and the like are solved. Accordingly, phenomena including leakage, cracks and the like of a foaming cement board outer wall external thermal insulation system caused by self size deviation, the cracks and other problems of the foaming cement boards are avoided.

Owner:JIANGSU NIGAO SCI & TECH +1

Thermal insulation antibacterial coating for external wall

InactiveCN102140292AEffectively removeLow thermal conductivityAntifouling/underwater paintsPaints with biocidesCrack resistancePolyvinyl alcohol

The invention discloses a thermal insulation antibacterial coating for an external wall, which is prepared by stirring the following raw materials by weight ratio: 45 to 60 parts of acrylic ester resin, 15 to 25 parts of polyvinyl alcohol, 44 parts of nanometer titanium dioxide, 25 parts of nanometer copper powder, 6 parts of leveling agent, 15 parts of nanometer silicon dioxide, 6 to 9 parts of silica acid aluminum powder, 12 to 15 parts of ethylene glycol, 10 parts of nanometer silicon dioxide, 8 parts of mildew-proof agent, 5 parts of calcium carbonate, 6 parts of cementing agent, 3 parts of antifoaming agent, 3 parts of modifier and 35 to 45 parts of water. The product has low heat conductivity and has the characteristics of good water-proof heat preservation, no-forming, no-cracking, good adhesive force, contamination resistance, cracking resistance and effectively mould removal.

Owner:WUJIANG LONGJING HONGBEI INTERIOR DECORATION

Pipe gallery group pipe transportation device

ActiveCN106594387AFinish the construction task wellBlocks to complete construction tasksPipe laying and repairLifting devicesPipeline transportMap design

The invention relates to a pipe gallery pipe horizontal sliding transportation device. An underground comprehensive pipe gallery top plate template is installed; a straight thread sleeve pre-buried position line is given out according to a monorail crane burying piece position map designed in advance; a straight thread sleeve is pre-buried on a bottom board according to the straight thread sleeve pre-buried position line; the lower end of the straight thread sleeve is sealed and blocked; the end portion of the outer end of the straight thread sleeve is glued to the upper surface of the top plate template; concrete is poured, and the top plate template is detached after the concrete reaches mould removal strength; a monorail crane rail is installed through a bolt; and the monorail crane rail is provided with a monorail crane. According to a pipe gallery pipe horizontal sliding transportation method, the thread sleeve is pre-buried to fabricate the detachable sliding rail for transporting pipes; the thread sleeve is pre-buried in a floor, then the bolt for the rail is installed on a top plate, and next the electric monorail crane is adopted for pipe transportation, so that a great amount of manpower is saved, personnel health is guaranteed, pipe transportation and installation efficiency is improved, and the construction coat is lowered.

Owner:二十二冶集团天津建设有限公司

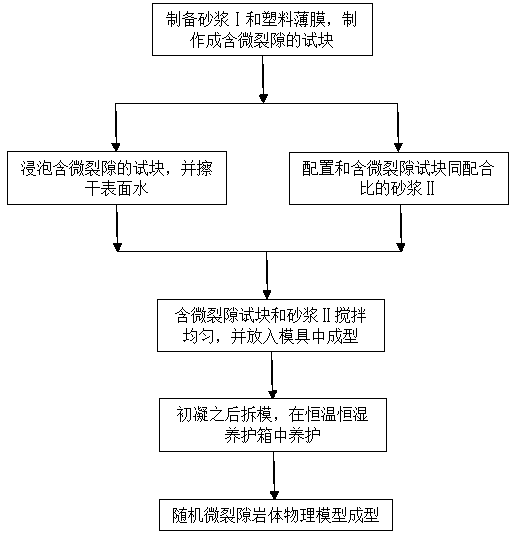

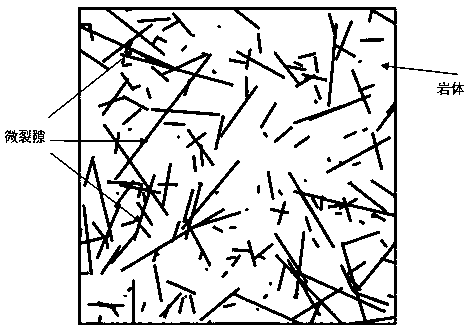

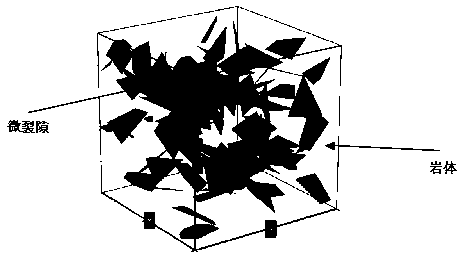

Manufacture method for random micro-fissure rock mass physical model

ActiveCN109883789AEasy to adjust quantityEasy to adjust geometryPreparing sample for investigationPhysical modelMould removal

The invention discloses a manufacture method for a random micro-fissure rock mass physical model, and belongs to the technical field of geotechnical engineering. The manufacture method comprises the following steps that: firstly, preparing first mortar and a plastic film, and manufacturing a test block containing a micro-fissure; then, dipping the test block containing the micro-fissure; preparingsecond mortar which has the same mix proportion with the test block containing the micro-fissure; thirdly, evenly stirring the test block containing the micro-fissure and the second mortar, and putting mixture in a mould for forming; and finally, after initial set is carried out, carrying out mould removal, curing in a constant-temperature constant-humidity curing box, and carrying out random micro-fissure rock mass physical model forming. By use of the manufacture method, through the first mortar and the plastic film, the test block containing the micro-fissure is firstly manufactured, then,the first mortar and the second mortar with the same proportion are mixed, and therefore, the problem of uneven fissure distribution is solved since the first mortar and the second mortar are almostthe same. The amount and the geometrical shape of the fissures in the random micro-fissure rock mass are the same with the practical rock mass which needs to be simulated so as to be convenient in regulating the amount and the geometrical shape of the fissures to more conform to the fissure distribution of the practical engineering rock mass.

Owner:CHINA UNIV OF MINING & TECH

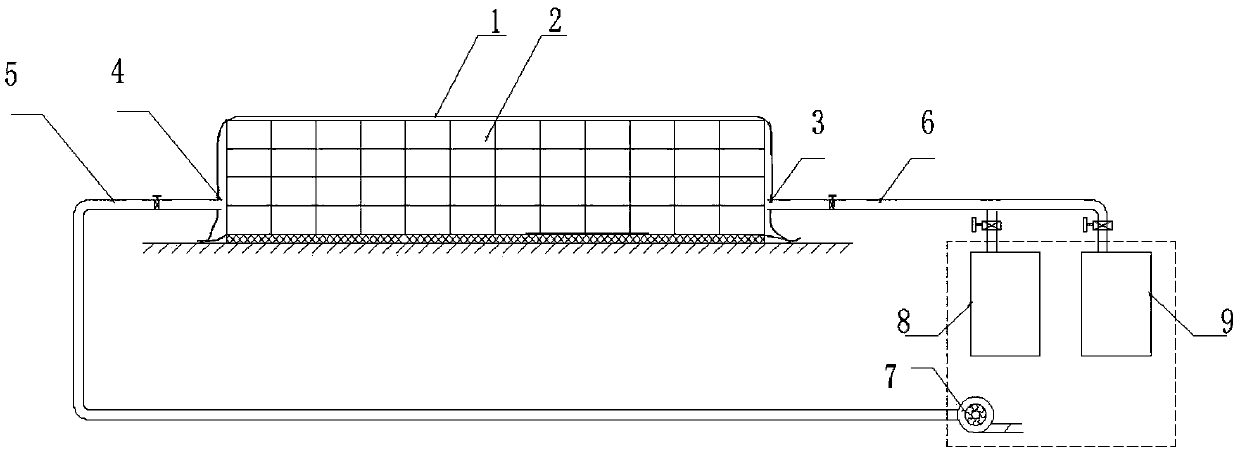

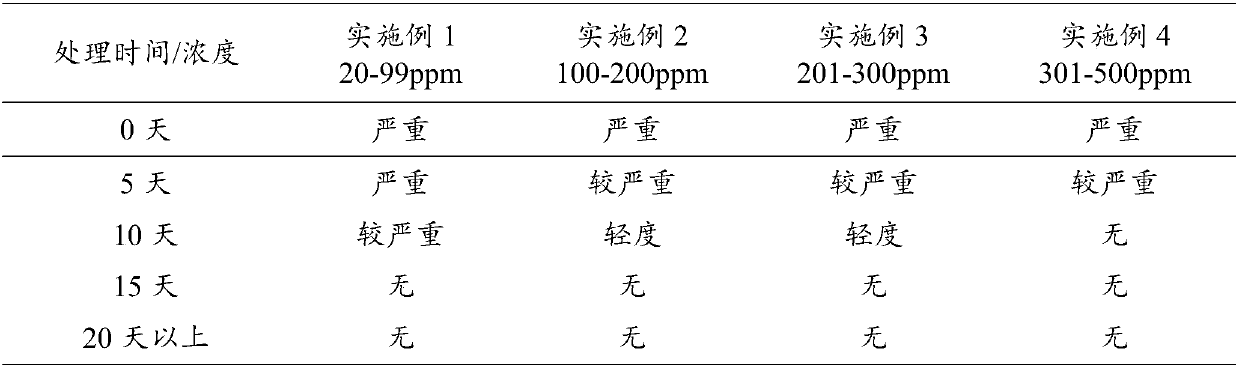

Mould removal processing method for alcoholizing expired mouldy tobacco leaves

The invention discloses a mould removal processing method for alcoholizing expired mouldy tobacco leaves; the method comprises the following steps: filling sealed tobacco stacks with nitrogen and keeping a low-oxygen environment, wherein by filling the nitrogen, oxygen concentration in the sealed tobacco stacks finally drops to 2% and below and is kept at the level; and filling the sealed tobaccostacks with ozone to process moulding, wherein ozone concentration is 20-500ppm, and frequency of filling the ozone is gradually reduced from the first stage to the third stage, wherein the first stage is implemented at 7-10 days, the second stage lasts from the 11 day to the 20 day, and the third stage is implemented after the second stage. With the application of the method, suchproblems that wind mould appears on the surfaces of tobacco leaves in a storage and care process of the tobacco leaves and the like can be effectively solved, and flavor and smoking taste of mouldy tobacco leaves can be guaranteed; the tobacco leaves, which become to be yellow from brown, are presented in ideal color; and therefore, a using rate of the mouldy tobacco leaves is increased, and tobacco loss and economic loss, which are caused by the mouldy tobacco leaves, are reduced.

Owner:WUHAN DONGCHANG STORAGE TECH

Concentrate supplementary feed for high yield period of cow and preparation method for concentrate supplementary feed

InactiveCN105995067AReasonable compositionIncrease milk productionFood processingAnimal feeding stuffMould removalWheat middlings

The invention relates to the technical field of feeds, and particularly discloses a concentrate supplementary feed for a high yield period of a cow and a preparation method for the concentrate supplementary feed. The supplementary feed is prepared from the following raw materials in percentage by weight: 38 to 42 percent of corn, 1 to 2 percent of molasses, 8 to 12 percent of soybean meal, 5 to 10 percent of cottonseed meal, 2 to 5 percent of bran, 3 to 8 percent of DDGS feed, 0.5 to 2 percent of wheat middling, 1 to 3 percent of corn gluten meal, 5 to 10 percent of corn germ meal, 10 to 15 percent of sprayed corn husk, 0.05 to 0.2 percent of a mould removal agent, 0.03 to 0.1 percent of enterococcus faecalis, 0.3 to 0.8 percent of table salt, 1.0 to 2.0 percent of baking soda, and 5.0 percent of cow premix. The raw materials of the supplementary feed are matched reasonably in the range of limited using amount, cooperate with one another, and provide nutrient elements required by the cow in the high yield period; the amino acid composition is reasonable, and the mild yield of the cow, the milk protein content and the butter-fat content are increased. The preparation method provided by the invention is easy to operate, and applicable to popularization and application.

Owner:河南全赫饲料有限公司

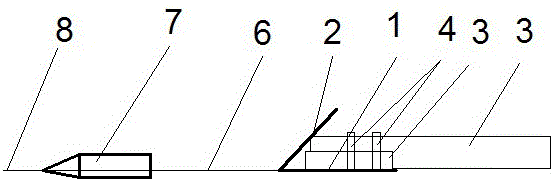

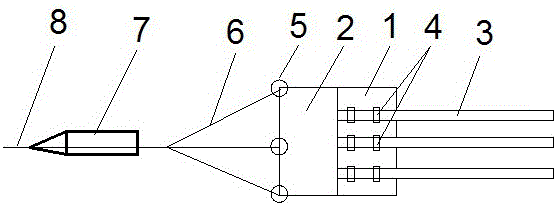

Low-loss nanometer touch film

ActiveCN106383606ASolve the flatnessSolve for uniformityInput/output processes for data processingSilver pasteAlcohol

The invention discloses a low-loss nanometer touch film, which comprises the following steps of 1: dipping a base material into alcoholic solution, cleaning with distilled water after ultrasonic cleaning is carried out, and carrying out airing; 2: coating the surface of the base material with transparent indium tin oxide liquid to obtain a transparent indium tin oxide film; 3: arranging a wire mould on the upper end of the transparent indium tin oxide film, and then, pouring mixed silver paste solution to obtain a conductive network of a nanometer structure; 4: adding micro-solidification to the conductive network in the step 3 to form a conductive filament network; 5: after mould removal is carried out, carrying out heating, pressurization and repairing reaction on the conductive filament network to form a fine conductive filament network; and 6: carrying out protective film solidification on a fine conductive filament, and carrying out heating solidification to obtain the product nanometer touch film. The preparation method is simple, the problems of low flatness and evenness, big defect, high roughness and the like of the material are solved, and the low-loss nanometer touch film is prospective and has the advantage of low cost which is unsurpassable for an existing industry technology.

Owner:牧东光电科技有限公司

Spraying device for casting demold cleaning

InactiveCN109261954AQuick sprayImprove spray uniformityHollow article cleaningCasting apparatusHydraulic cylinderSpray nozzle

The invention discloses a spraying device for casting demold cleaning. The spraying device comprises a support seat, a demolding agent storage box, a base A and a base B, the base A and the base B arepositioned on left and right sides of the demolding agent storage box, a hydraulic cylinder C is connected to the upper end of the support seat, a support plate is connected with the upper end of a piston rod C of the hydraulic cylinder C, a stand column is connected with the upper end of the support plate, a connection rod is connected with an upper portion of a right side of the stand column, acasting mold is connected with the lower end of the connection rod, a feeding pump is arranged in the middle in the demolding agent storage box, a liquid inlet tube is connected with an outlet end ofthe feeding pump, an air inlet tube C is connected with one side of a middle portion of the liquid inlet tube, a high-pressure air tank C is connected with the other end of the air inlet tube C, a liquid dispenser is connected with the upper end of the liquid inlet tube, and spraying nozzles are connected onto front, rear, left, right and upper end faces of the liquid dispenser. The spraying device has the advantages that the device is reasonable in structural design and simple and convenient to operate, uniformity in spraying and thoroughness in cleaning are realized, redundant demolding agent can be collected and recycled, production cost is saved, higher spraying and curing efficiency is realized, a cleaning period is shortened, and large-scale production is benefited.

Owner:禹州市毛吕铸造有限公司

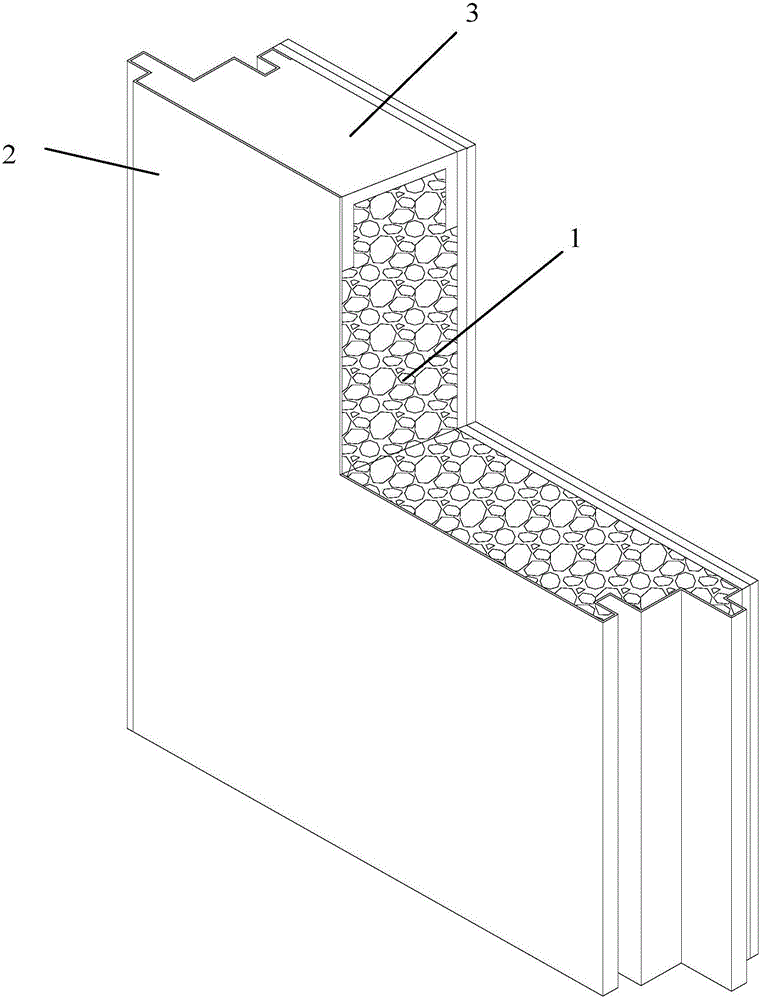

Assembled flame-retardant heat-insulation wall body unit for cold storage warehouse and production method thereof

The invention discloses an assembled flame-retardant heat-insulation wall body unit for a cold storage warehouse. The assembled flame-retardant heat-insulation wall body unit for the cold storage warehouse comprises a core layer, a surface layer and support frames, wherein the surface layer covers four side surfaces of the square core layer; the two support frames are respectively embedded into the surface layer from the upper and lower bottom surfaces of the core layer and are fixed with the surface layer; the core layer is formed by inorganic fiber filling materials and inorganic fiber spray coating bonding agents through matched synchronous spray coating filling; the surface layer is jointly defined by a wall face plate and a semi-enclosure metal frame; the metal frame comprises a metal face plate, a first connecting plate and a second connecting plate; the first connecting plate and the second connecting plate are respectively arranged at the two ends of the metal face plate; and the metal frame is used for the splicing joint of adjacent wall body units for the cold storage warehouse. The invention also discloses a production method of the wall body unit. The production method has the major steps of splicing a box-shaped structure; fixing a mold; performing spray coating filling; and forming shaping and mould removal. The invention relates to the field of building, and provides the assembled flame-retardant heat-insulation wall body unit for the cold storage warehouse and a mould pressing spray coating filling production method thereof. The assembled flame-retardant heat-insulation wall body unit for the cold storage warehouse has the advantages of high integral intensity, high heat insulation performance and obviously enhanced flame-retardant performance.

Owner:BEIJING NEW BUILDING MATERIALS PLC

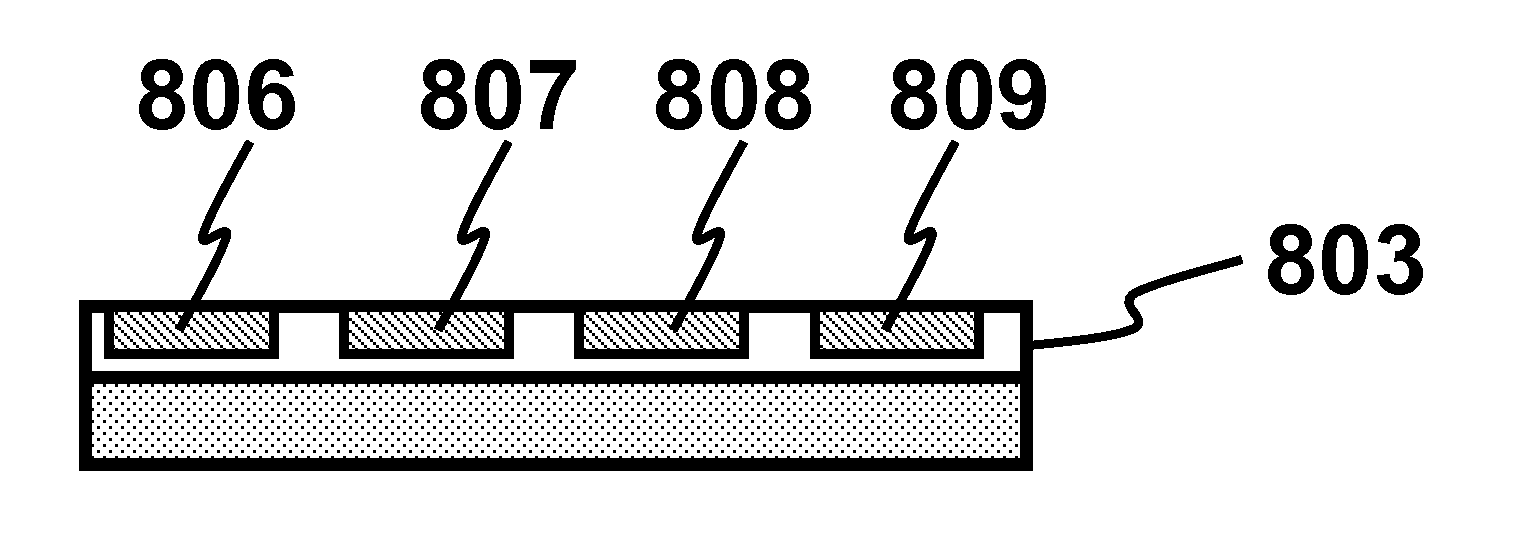

Method and System of Layered Thin-Film Device With Ceramic Substrates

InactiveUS20120017970A1Easily use processEasy to handlePV power plantsSemiconductor/solid-state device manufacturingHydrogenElectrical devices

A method for forming solar cells includes providing a crystalline silicon substrate which can be mono-, multi-, or poly-crystalline, the substrate being defined by a first thickness, the substrate including a first surface and a second surface, the first surface on an opposite side of the second surface. The method also includes forming a separation region within the first thickness, the separation region including hydrogen species, the separating region being substantially parallel to the first surface, the separation region defining a first portion and a second portion within the thickness. Additionally, the method includes providing a mould structure defining a support region on the first surface in which a layer of ceramic material is formed, followed by mould removal. Additionally, the method includes forming electrical devices on the first portion and packaging formed solar cells, including interconnections for solar tile applications.

Owner:SILICON CHINA HK

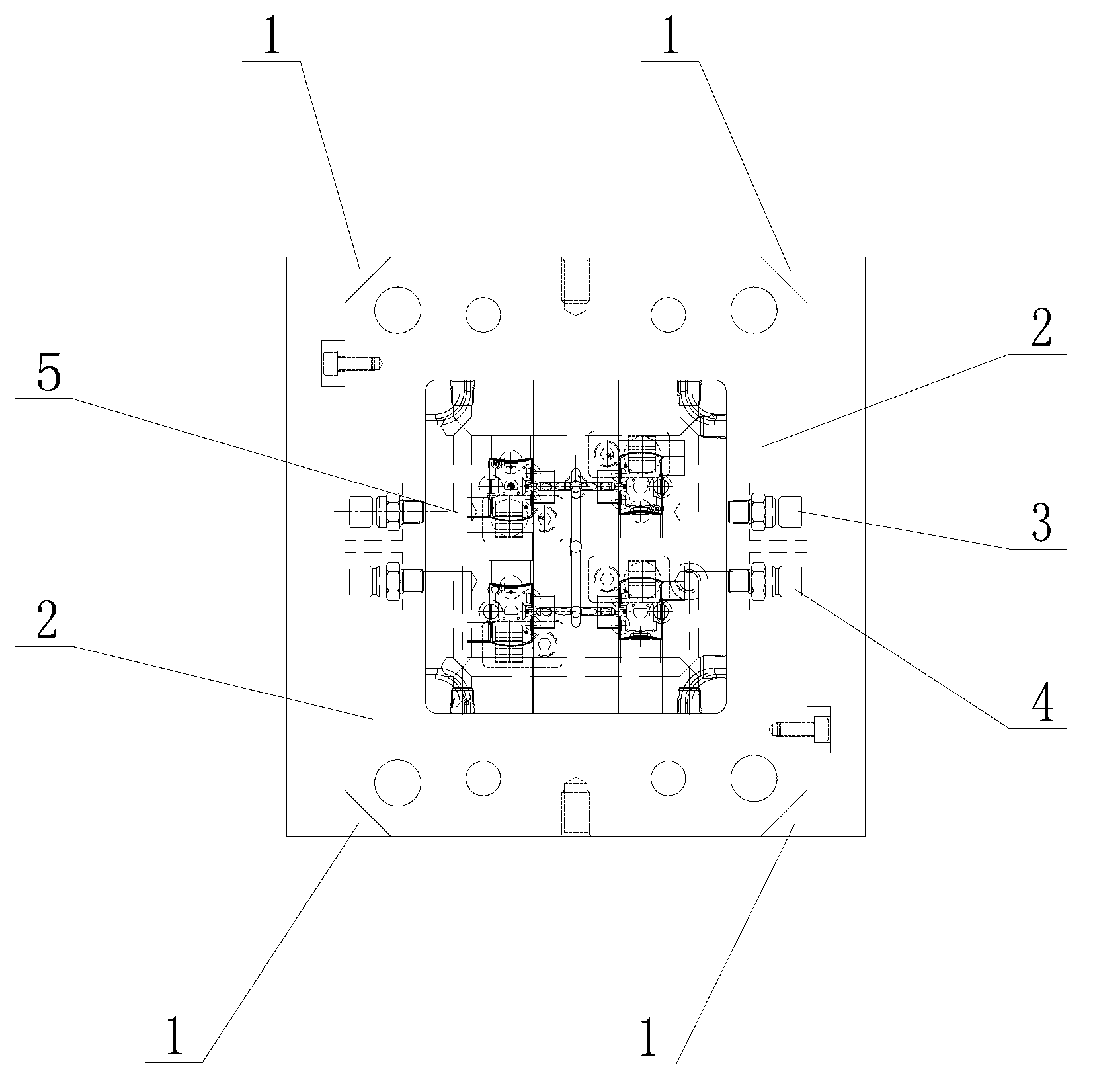

Upper cover mould

The invention discloses an upper cover mould, which comprises a mould body, and is characterized in that a plurality of mould removal devices are arranged on the same side surface of the mould body; a plurality of water cooling devices are arranged in the mould body; as an improvement, each water cooling device comprises a water inlet and a water outlet which are arranged on the mould body; a cooling pipeline is arranged between each water inlet and each water outlet; and the mould removal devices are pry pieces designed on the outer surface of the mould body. The pry pieces can be used for performing the mould removal operation conveniently, so that the working speed is increased; and meanwhile, the four water cooling devices are arranged on the mould body and uniformly distributed in the mould body respectively, so that the cooling effect of the whole mould body is guaranteed. The upper cover mould is high in working efficiency, convenient to use, wide in application range and convenient for popularization.

Owner:KUNSHAN HAOKUN MACHINERY

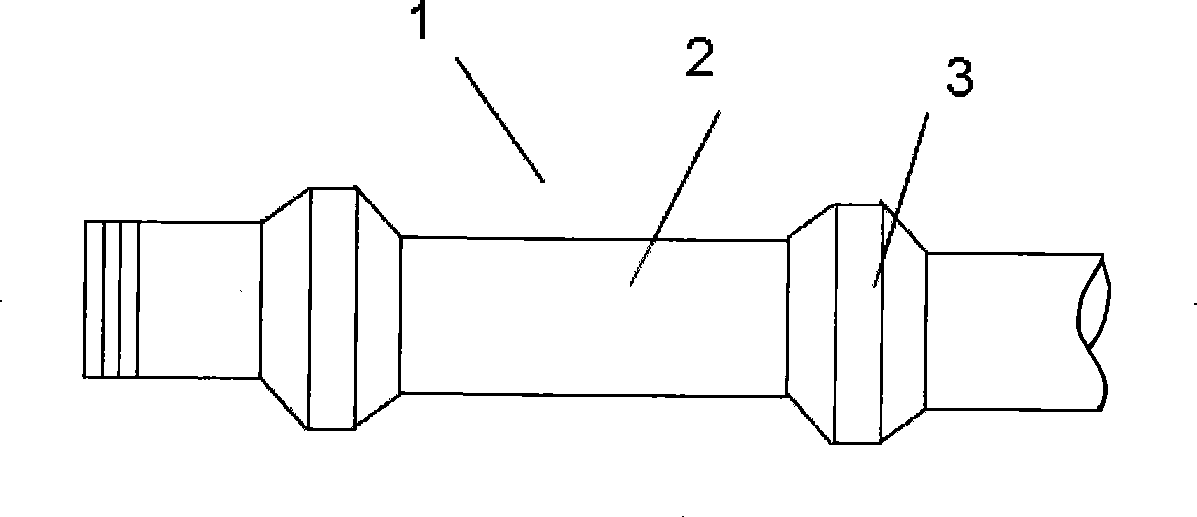

High-strength prestressed concrete pipe pile with section and its production method

The invention provides a high-strength pre-stress concrete pipe pile with knurls. A plurality of ring-shaped convex knurl parts are formed on the pipe pile body with spacing; the pipe pile body between all knurl parts forms a pile shaft part; all parts are integrally poured by concrete; the concrete pipe pile body with the knurls is embedded by PC steel bars and rebar; the concrete pipe pile is characterized in that the concrete of the high-strength pre-stress concrete pipe pile with the knurls is added by 5-25% of silica ashes (powder-shaped SiO2) with the average particle size of 0.1-0.5 Microns. According to the high-strength pre-stress concrete pipe pile with knurls, the silica ash is added in the raw material, thus preventing the cracking of knurl part and the like during the normal-pressure steam curing or the stage thereafter. Meanwhile, the knurl structure of the concrete pipe pile with the knurls can be changed, thus being beneficial for improving the strength. Furthermore, aconical part is used for connecting the difference between high position and low position between the pile shaft part and the knurl part, thus becoming easy for the mould removal operation of the pile fabrication process. Furthermore, as the knurl parts have an effect of increasing the strength, the high-strength pre-stress concrete pipe pile with knurls is beneficial to the transport and construction of the pipe piles.

Owner:上海陆丽科技有限公司

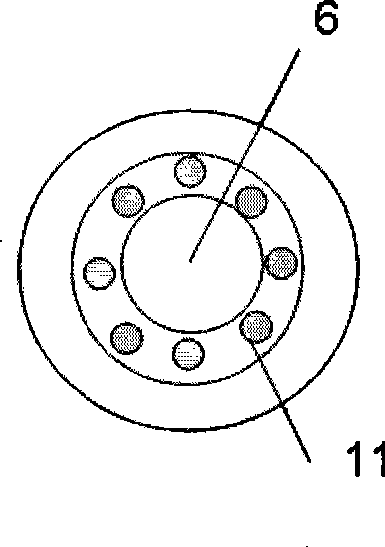

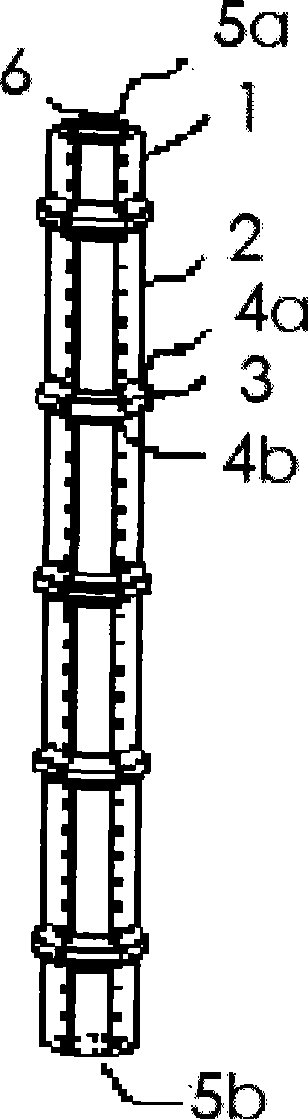

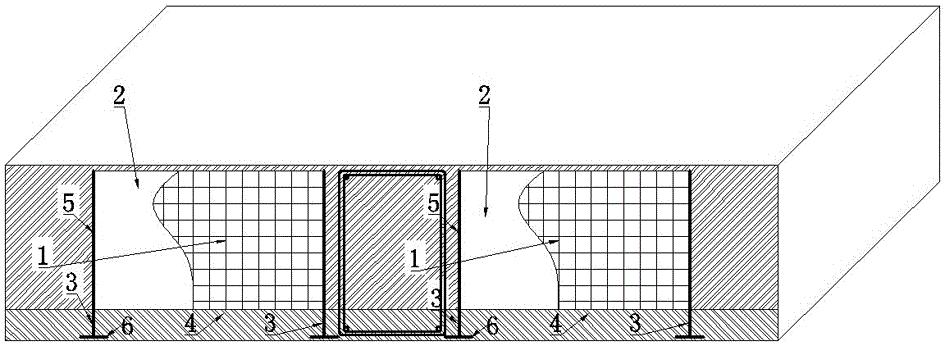

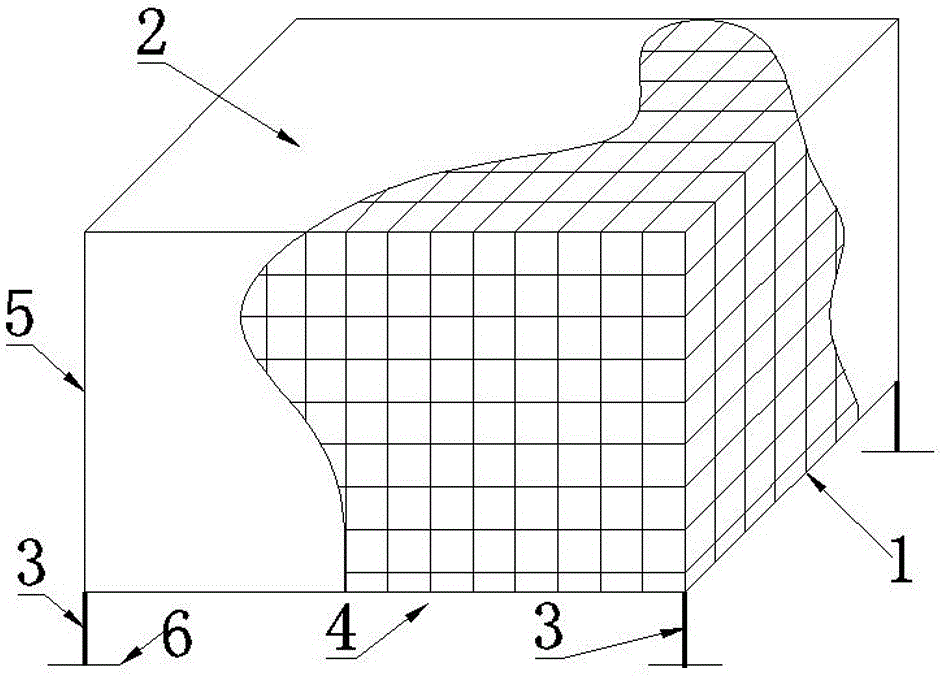

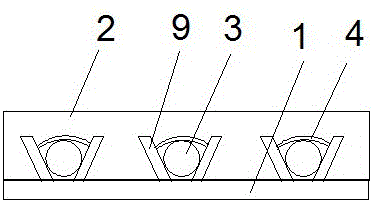

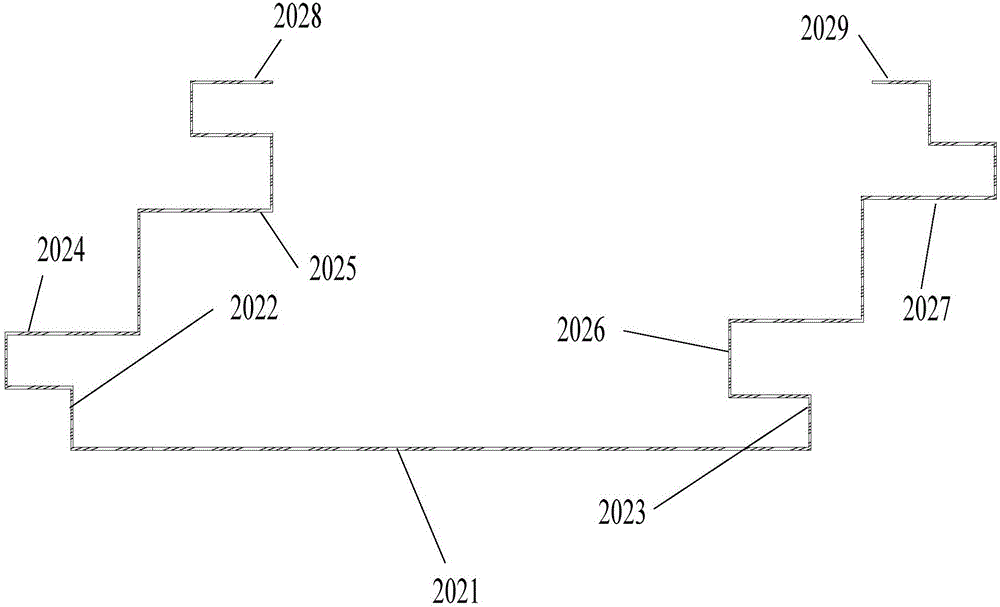

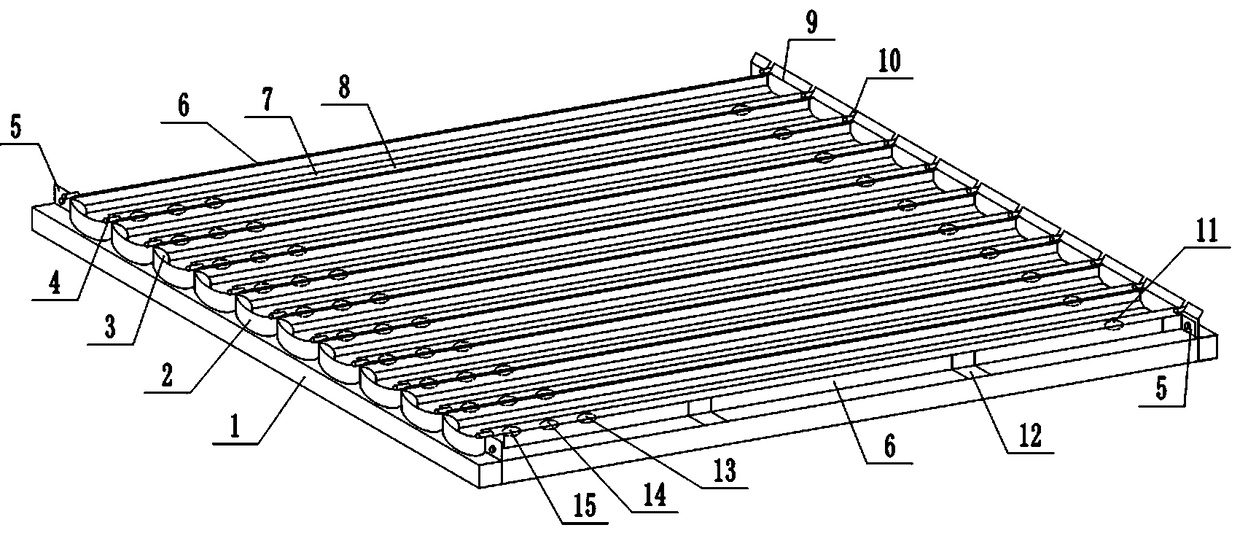

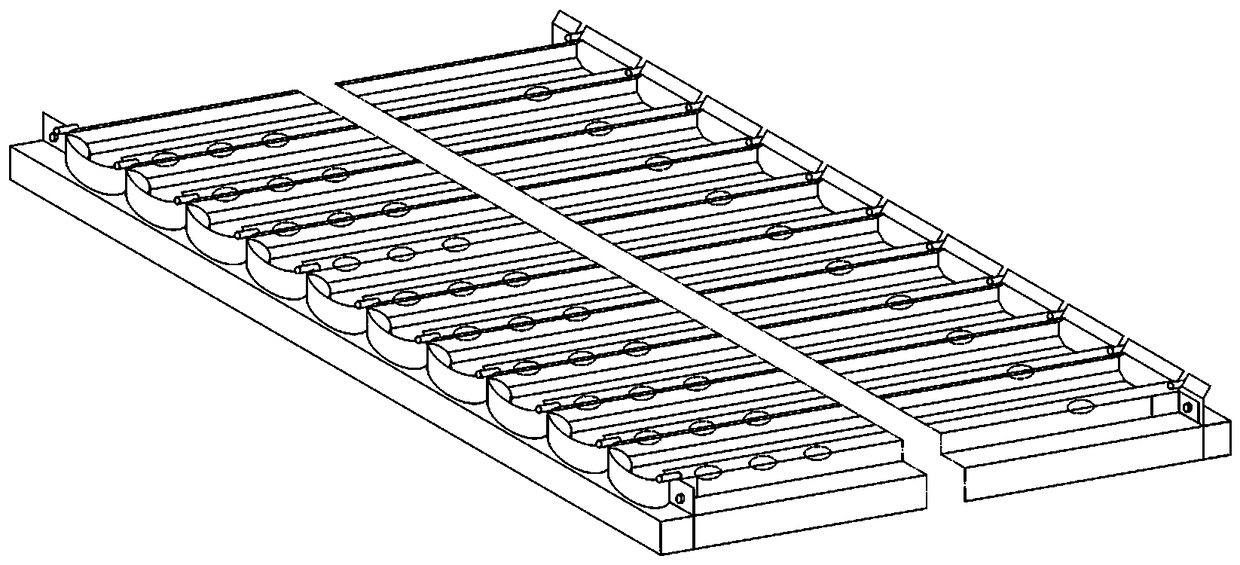

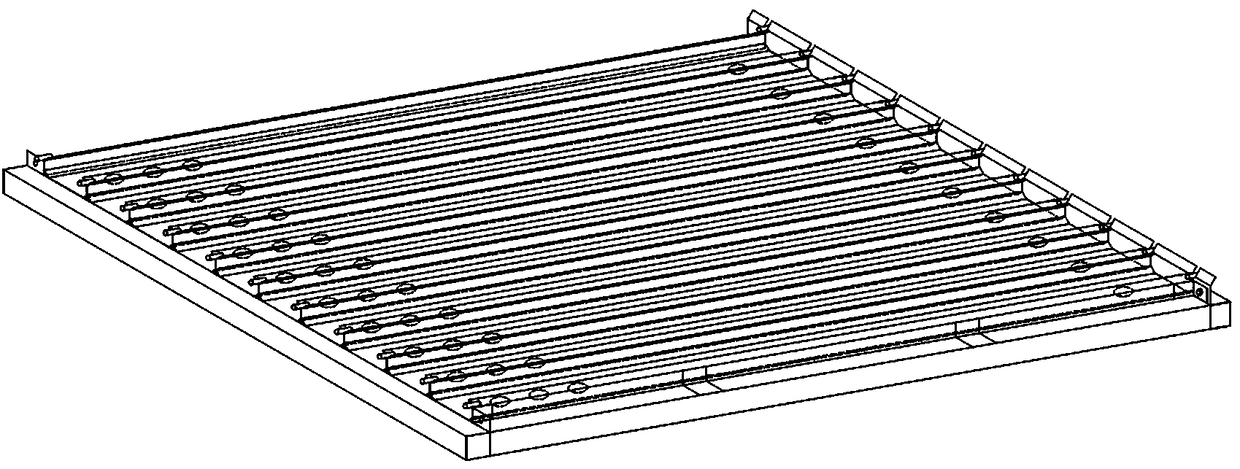

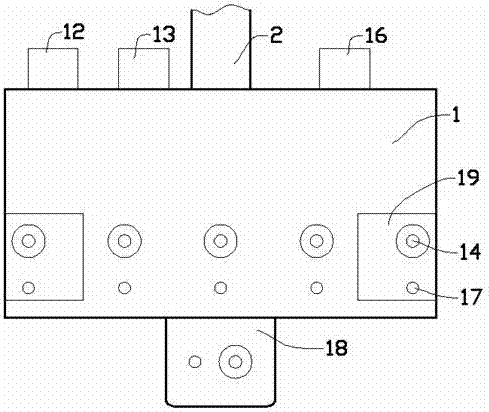

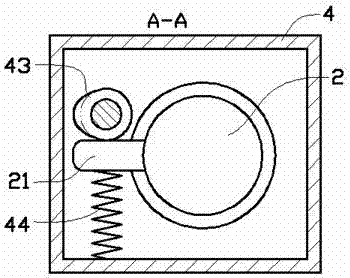

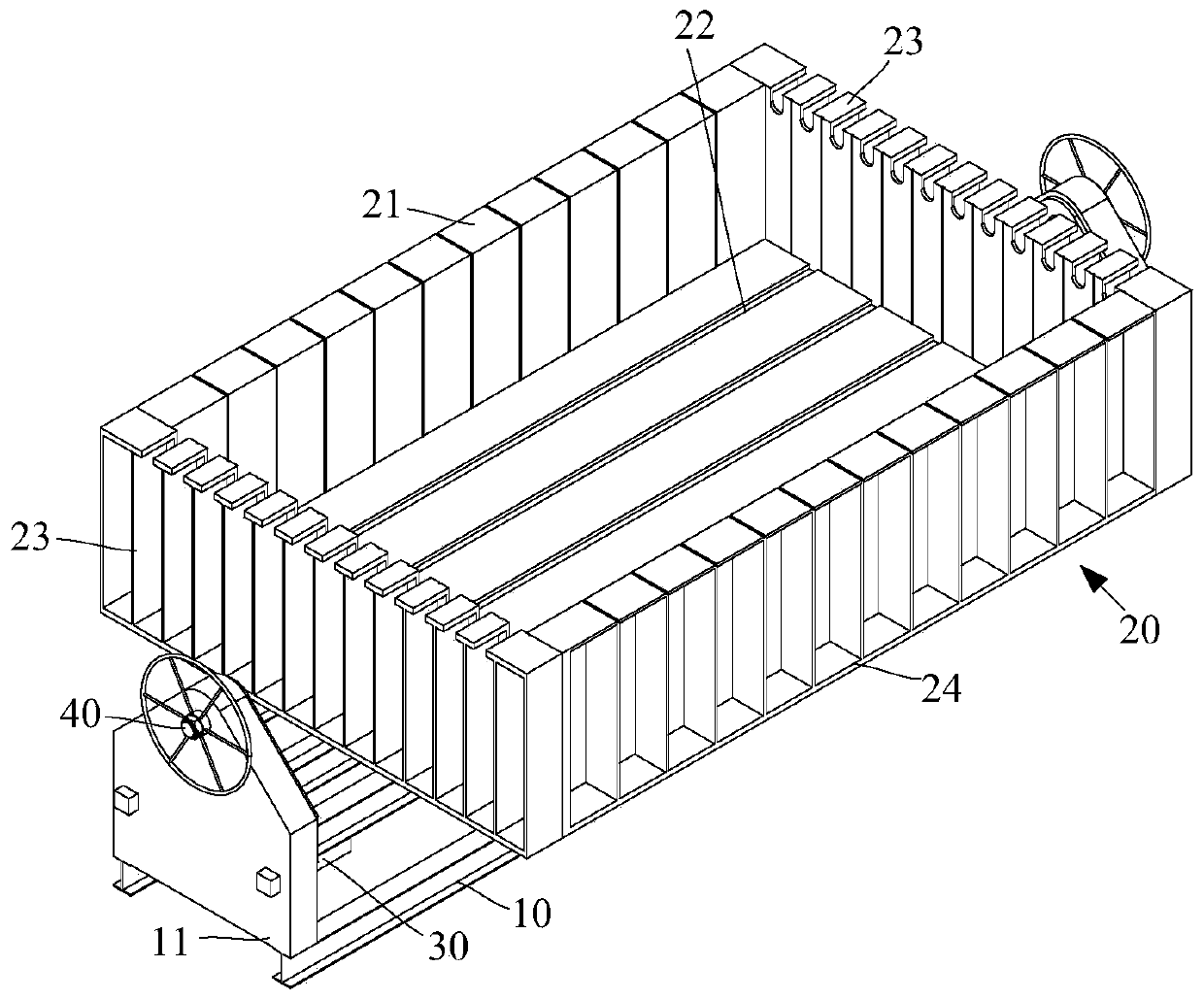

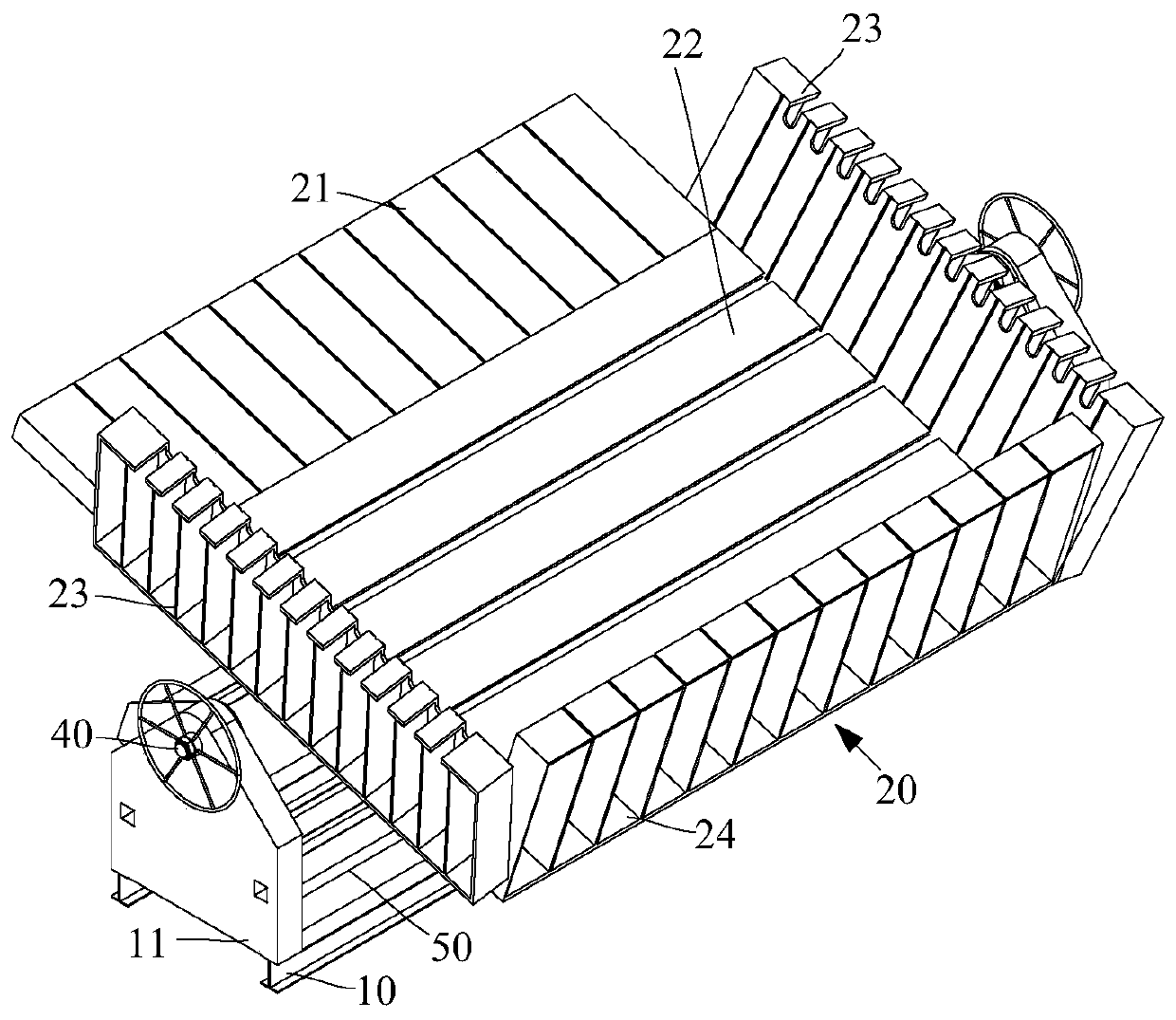

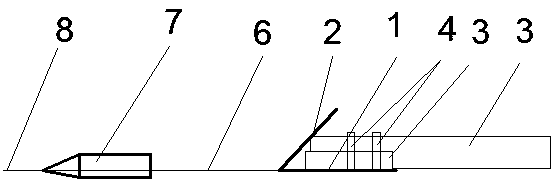

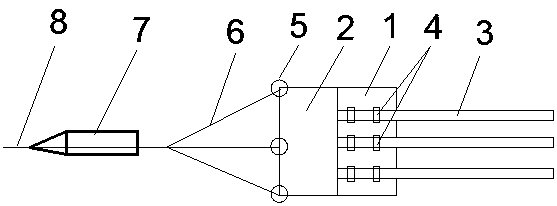

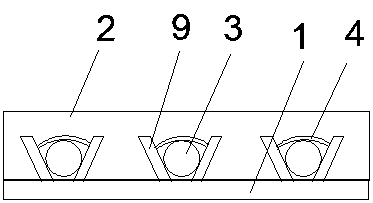

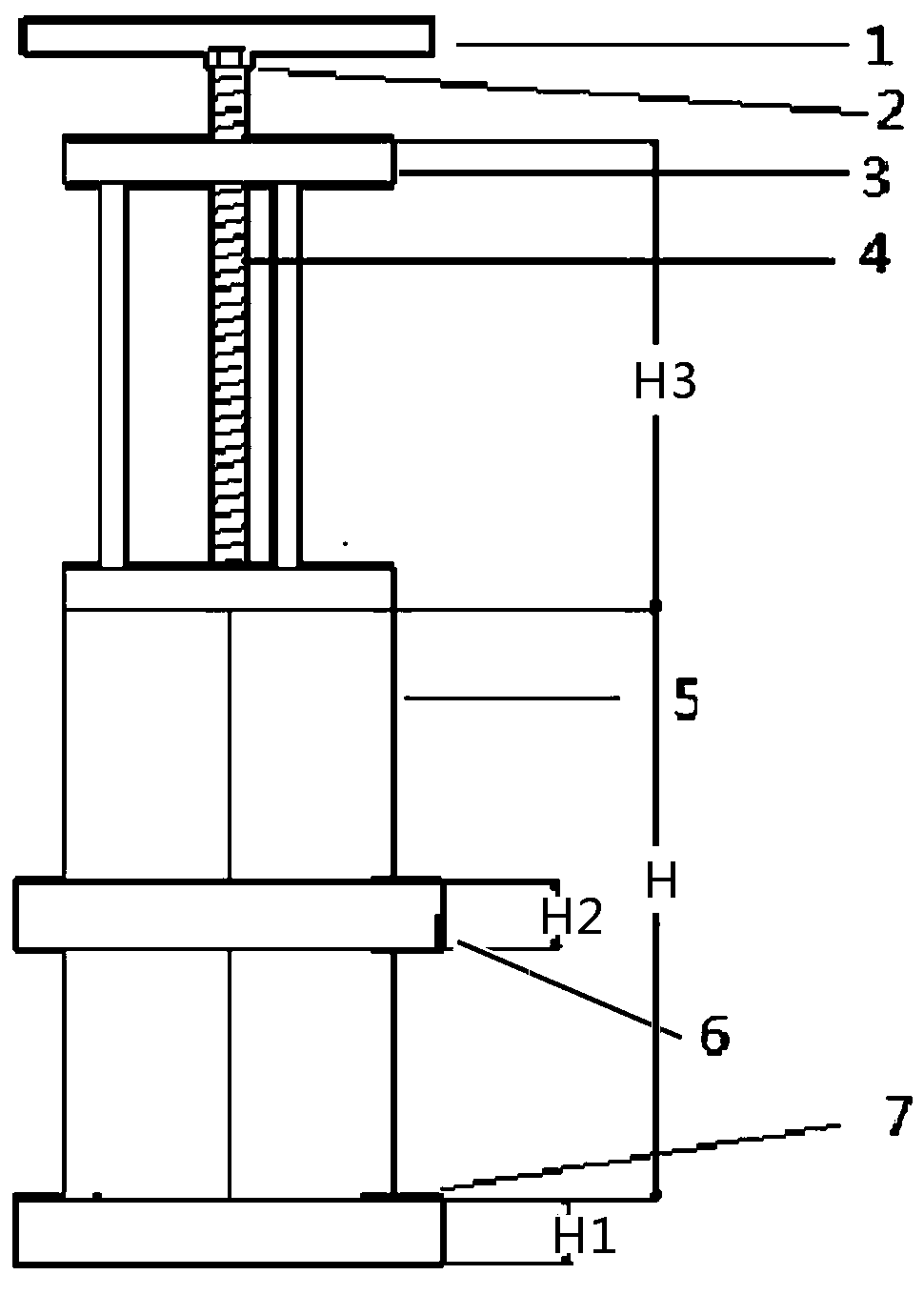

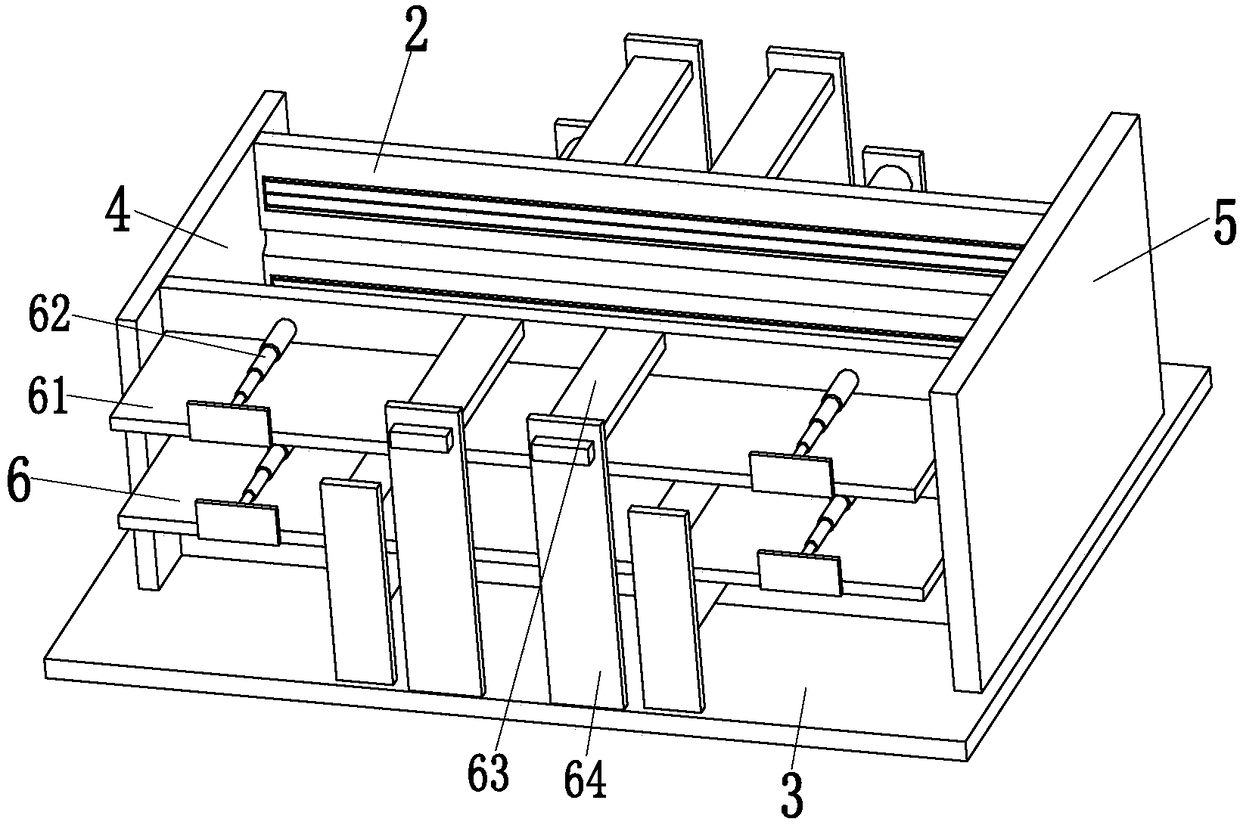

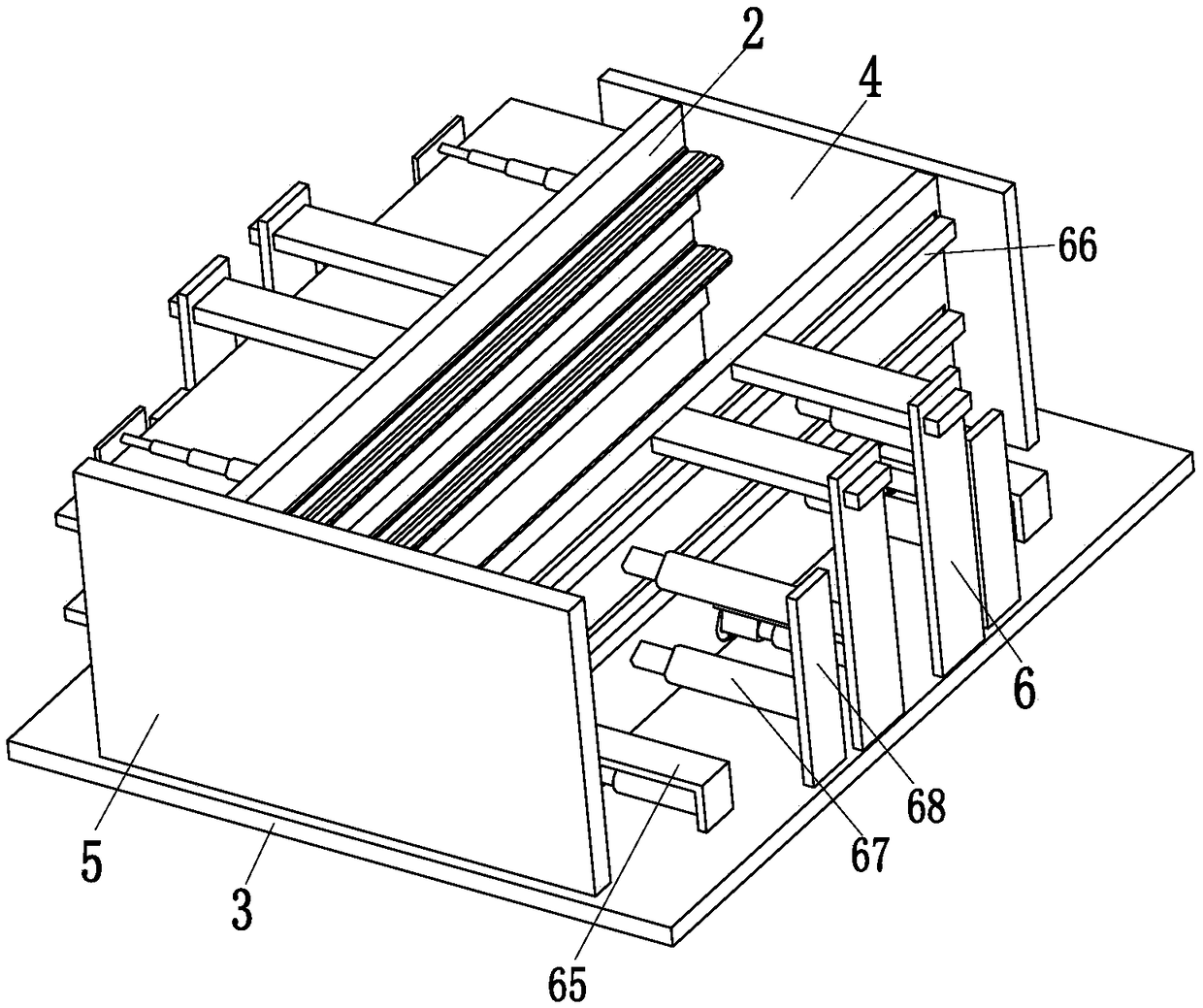

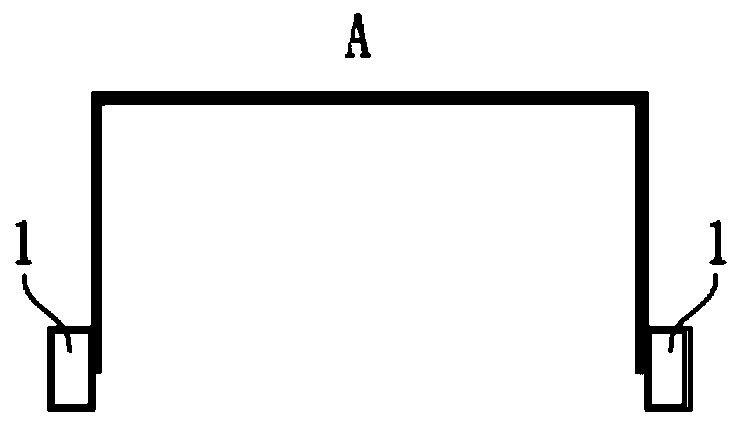

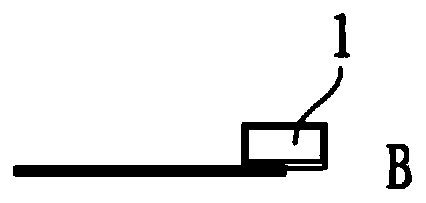

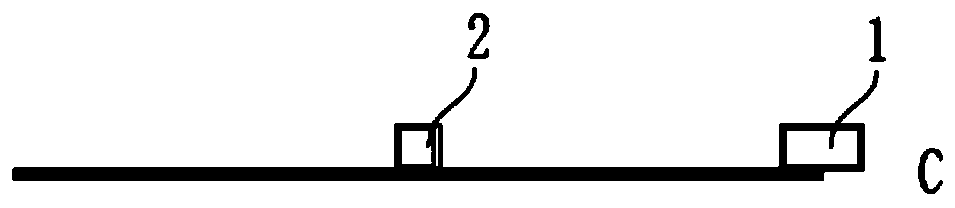

Mould structure for precast concrete column

The invention relates to the technical field of concrete mould, in particular to a mould structure for a precast concrete column. The mould structure for the precast concrete column is characterized in that the mould structure for the precast concrete column includes a support frame (1), top mold templates (2), side templates (6), base templates (7), middle templates (8) and base mold templates (9); and the base templates (7) are arranged on the support frame (1) side by side, the middle templates (8) is installed between each two base templates (7), the side templates (6) are installed on thebase templates (7) which are located on the edges of two sides of the support frame (1), the top mold templates (2) and the base mold templates (9) are installed at two ends of the support frame (1).The mould structure for the precast concrete column has the characteristics of rapid assembly, convenient and quick mould removal, convenient demoulding, and firm structure of the precast concrete column.

Owner:潘春光

Casting demolding cleaning and spraying device

The invention provides a casting demolding cleaning and spraying device. The casting demolding cleaning and spraying device comprises an installing block. A liquid buffering cavity is designed in the installing block. A clean water connector and a demoulding liquid connector which communicate with the liquid buffering cavity are designed at the upper portion of the installing block. Liquid spraying pipes horizontally stretching out are assembled on the front face and the back face of the installing block and communicate with the liquid buffering cavity. A gas buffering cavity is designed in the lower portion of the liquid buffering cavity. An airflow connector communicating with the gas buffering cavity is further designed in the upper portion of the installing block. An air spraying pipe horizontally stretching out is further assembled on the front face and the back face of the installing block. The liquid spraying pipes and the air spraying pipe are right opposite to the inner wall of a forming cavity in a casting die. When the device works, the casting die can be rapidly cooled, a uniform film can be formed in the forming cavity through the demoling liquid, and the casting defective rate is greatly reduced. Meanwhile, the usage amount of the demolding liquid is reduced, and the production cost is reduced.

Owner:安徽凯斯汀科技有限公司

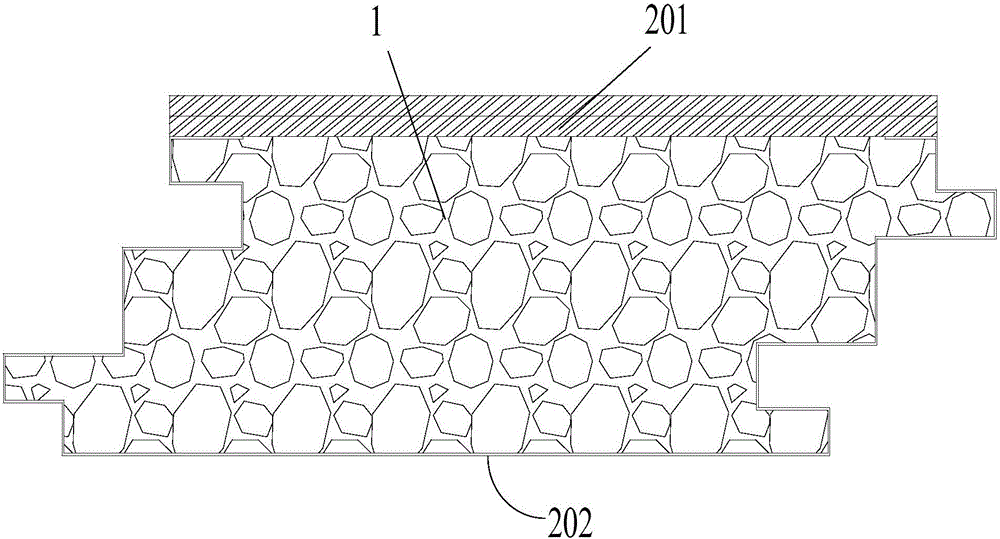

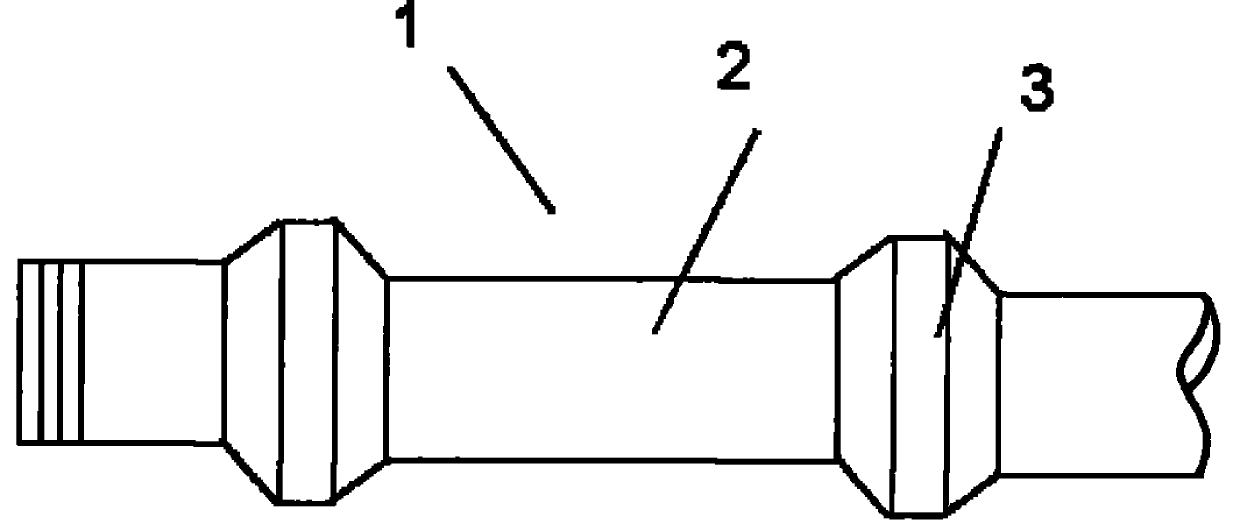

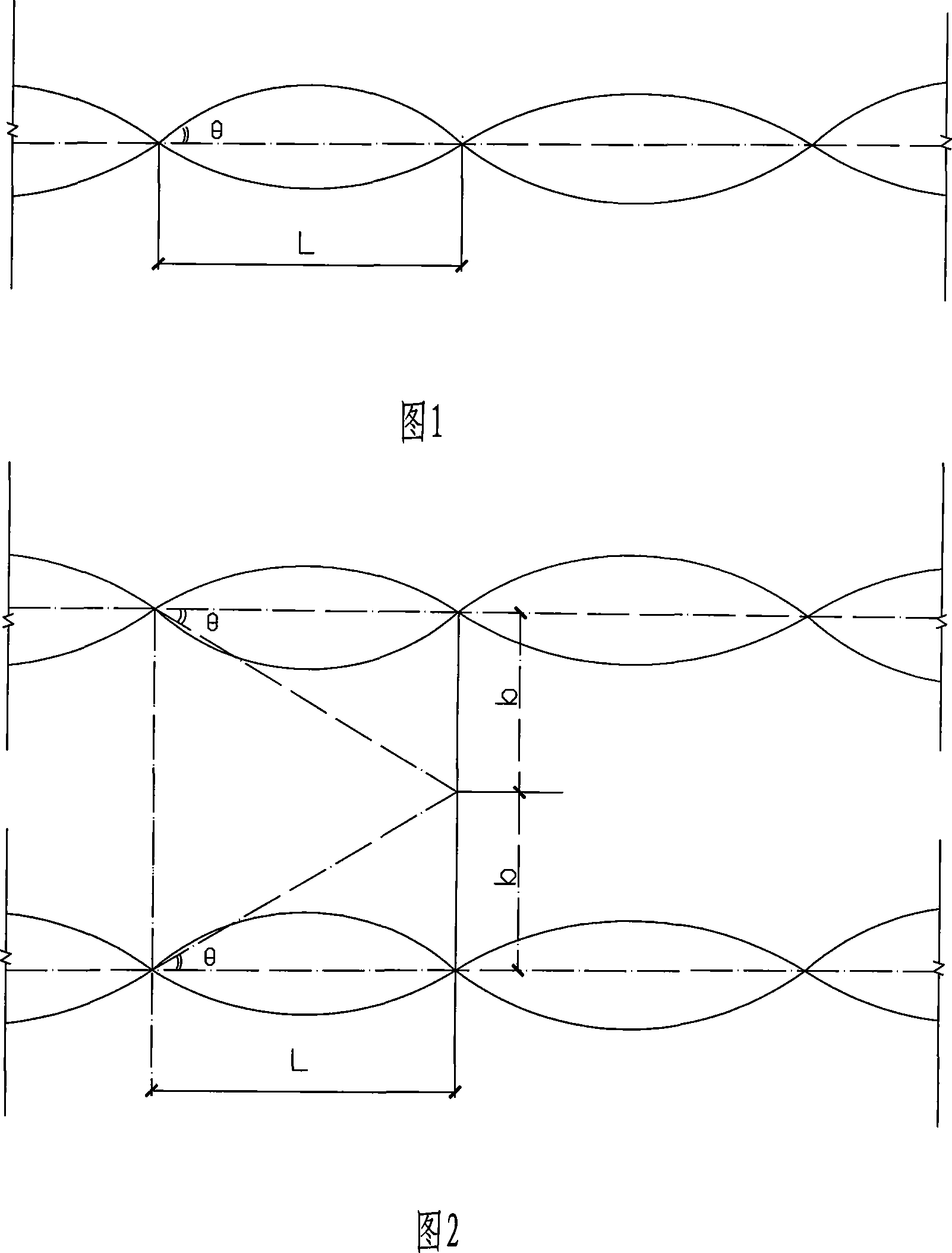

Limited self-restricting reinforced concrete slab member in bending and manufacturing method thereof

The invention discloses a bent component for limited self-restraining steel bar concrete plate, which includes the concrete (1) and a plurality of stressed cold rolled and twisted steel bars (2) arranged in the concrete and with spiral cross sections, and a plurality of distribution steel bars (3) which are connected and spread vertically to the stressed cold rolled and twisted steel bars (2); the stressed cold rolled and twisted steel bars (2) are deployed in pairs; the spiral rotation angles of the two stressed cold rolled and twisted steel bars (2) in every pair are the same, but the spiral rotation directions are to the opposite. The making method includes making of the stressed cold rolled and twisted steel bars (2) and the distribution steel bars (3), making of installation templates, installing and binding of the stressed cold rolled and twisted steel bars (2) and the distribution steel bars (3), casting of the concrete, maintenance and mould removal of the cast steel bar concrete structure. The component can form the self-restraining concrete, to improve the structure rigidity and control the crack width, and so that the making technology becomes convenient.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation method of mould removal and mould-proof spray for high polymer topcoat walls

ActiveCN109287656AGood compatibilityLong-term antibacterial effectBiocideAntifouling/underwater paintsPolymer scienceMontmorillonite

Belonging to the technical field of preparation of mould inhibitors for building walls, the invention discloses a preparation method of a mould removal and mould-proof spray for high polymer topcoat walls. The method includes raw material preparation, pre-mixing, blending and other steps. Specifically, calcined shell powder is adopted as the mould removal component, a modified montmorillonite mould-proof agent is used as the long-acting mould-proof agent, and specific formula design is carried out for high polymer topcoat walls to adapt high polymer paint treated wall surfaces. The preparationprocess adopts components harmless to the human body, the prepared product has sterilizing and antibacterial efficacy, and also can reach a long-acting bacteriostatic effect after rapid sterilization. The mould removal and mould-proof spray obtained by the method provided by the invention has good compatibility with high polymer topcoat walls, also can restore the brightness of walls after beingadded with corresponding pigments, and can be attached to the surfaces of wall firmly after use without stripping and shedding.

Owner:ZHEJIANG OCEAN UNIV

Co-extrusion mould capable of replacing identification strip online

ActiveCN106239863AReach replacementTo achieve the purpose of replacing the identification stripEngineeringMould removal

The invention relates to a co-extrusion mould capable of replacing an identification strip online, and belongs to the technical field of plastic processing. The co-extrusion mould capable of replacing the identification strip online comprises a pipe machine head body, a flow distribution shuttle, an internal mould, a mouth mould assembly, a core mould, an identification strip machine head body and the like; the right end of the pipe machine head body is fixedly connected with the mouth mould assembly; the flow distribution shuttle and the internal mould are mounted in the cavity of the mouth mould assembly in sequence from left to right; the right end of the internal mould is fixedly connected with the core mould; an identification strip rib plate (a) and an identification strip rib plate (b) of different types are embedded into the mouth mould assembly; a connecting nozzle (a) with a check valve (a) and a connecting nozzle (b) with a check valve (b) are mounted at the upper part of the mouth mould assembly; the identification machine head body is mounted at the upper parts of the connecting nozzle (a) and the connecting nozzle (b). According to the co-extrusion mould capable of replacing the identification strip online, the types of pipe identification strips can be replaced online by only opening and closing the check valves; moreover, the structure is simple; the operation is convenient; compared with original artificial mould removal, the rejection rate is reduced by 80 percent; the labour intensity is low; the production efficiency is high. The existing problems of waste of time and artificial energy consumption caused by stopping a machine and removing the mould when the identification strip is replaced are effectively solved.

Owner:HUBEI KAILE SCI & TECH

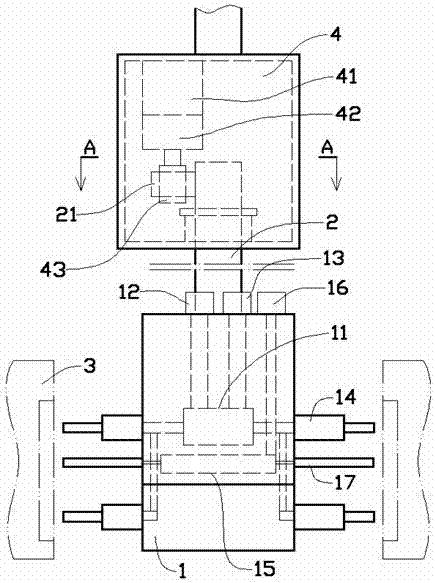

Prefabricated part mould convenient to remove and hoist and construction method thereof

PendingCN110948653AEasy to liftAvoid damageDischarging arrangementMouldsMould removalMechanical engineering

The invention relates to a prefabricated part mould convenient to remove and hoist and a construction method thereof. The mould comprises a base, a mould box and a plurality of balance pins, wherein the two opposite ends of the mould box are hinged to the base through adjusting pieces, a pouring space is formed in the mould box, the mould box comprises an openable side mould located on the side, the balance pins are detachably inserted to the base, and the mould box is poured, the balance pins are inserted into the two opposite ends of the base and supported on the bottom of the mould box to limit the mould box. Before mould removal and hoisting, the plurality of balance pins are removed, the adjusting pieces are adjusted to turn the mould box around the adjusting pieces till the side mould is upward, and the prefabricated part is prevented from being damaged due to collision in the process. The mould box is directly rotated by the adjusting pieces, and the problems that in the prior art, the mould is overturned by erecting oil pressure equipment, the mould needs to be moved to the oil pressure equipment every time, and operation procedures are multiple are solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Pipe gallery group pipe transportation device

ActiveCN106594387BFinish the construction task wellBlocks to complete construction tasksPipe laying and repairLifting devicesPipeline transportMap design

The invention relates to a pipe gallery pipe horizontal sliding transportation device. An underground comprehensive pipe gallery top plate template is installed; a straight thread sleeve pre-buried position line is given out according to a monorail crane burying piece position map designed in advance; a straight thread sleeve is pre-buried on a bottom board according to the straight thread sleeve pre-buried position line; the lower end of the straight thread sleeve is sealed and blocked; the end portion of the outer end of the straight thread sleeve is glued to the upper surface of the top plate template; concrete is poured, and the top plate template is detached after the concrete reaches mould removal strength; a monorail crane rail is installed through a bolt; and the monorail crane rail is provided with a monorail crane. According to a pipe gallery pipe horizontal sliding transportation method, the thread sleeve is pre-buried to fabricate the detachable sliding rail for transporting pipes; the thread sleeve is pre-buried in a floor, then the bolt for the rail is installed on a top plate, and next the electric monorail crane is adopted for pipe transportation, so that a great amount of manpower is saved, personnel health is guaranteed, pipe transportation and installation efficiency is improved, and the construction coat is lowered.

Owner:二十二冶集团天津建设有限公司

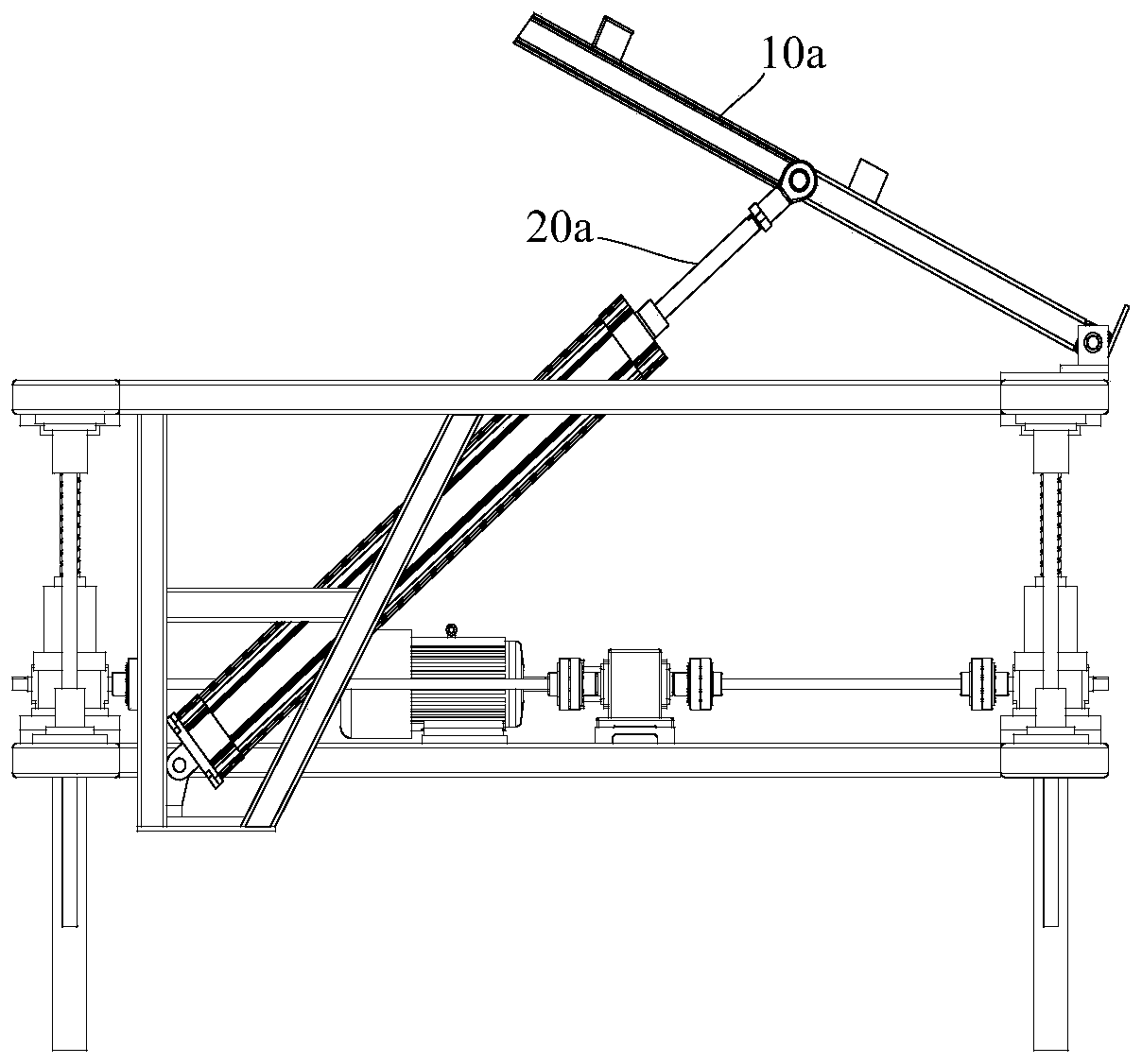

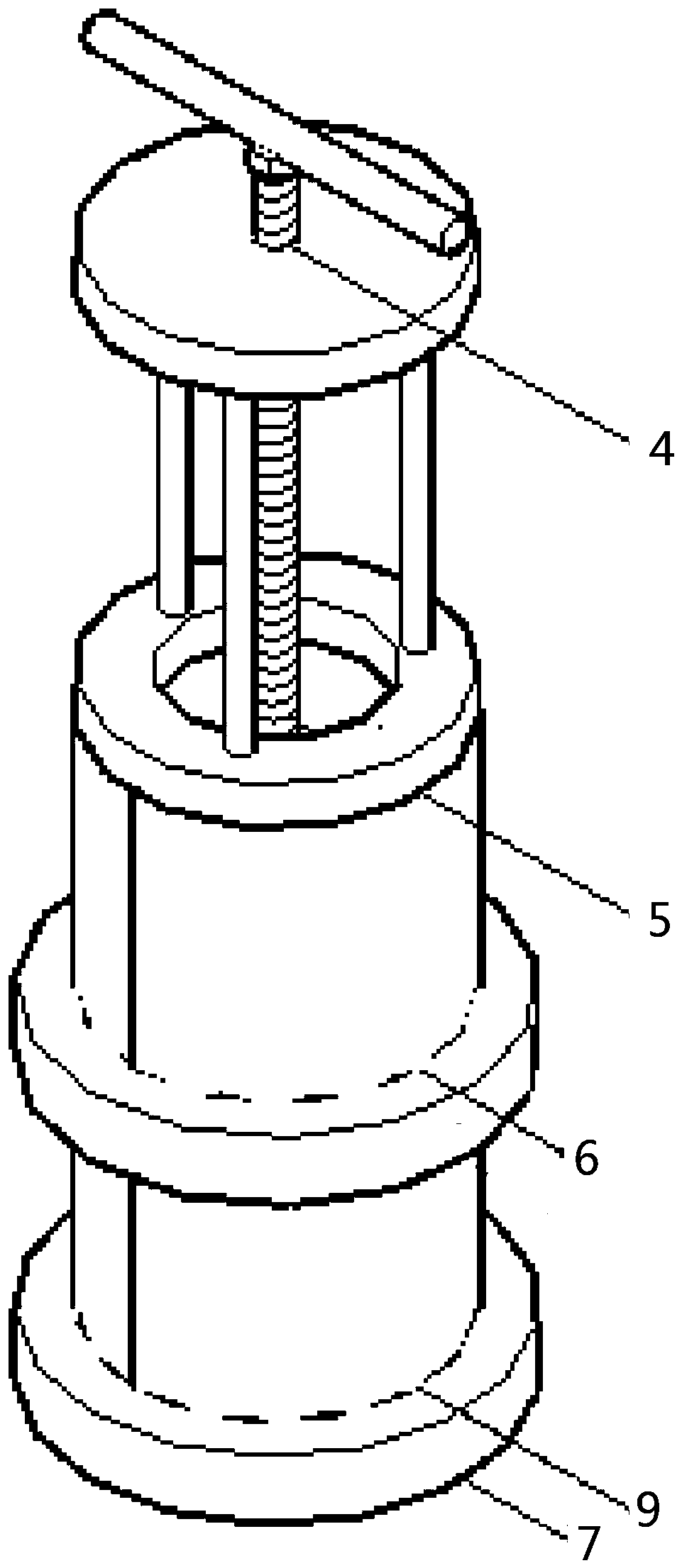

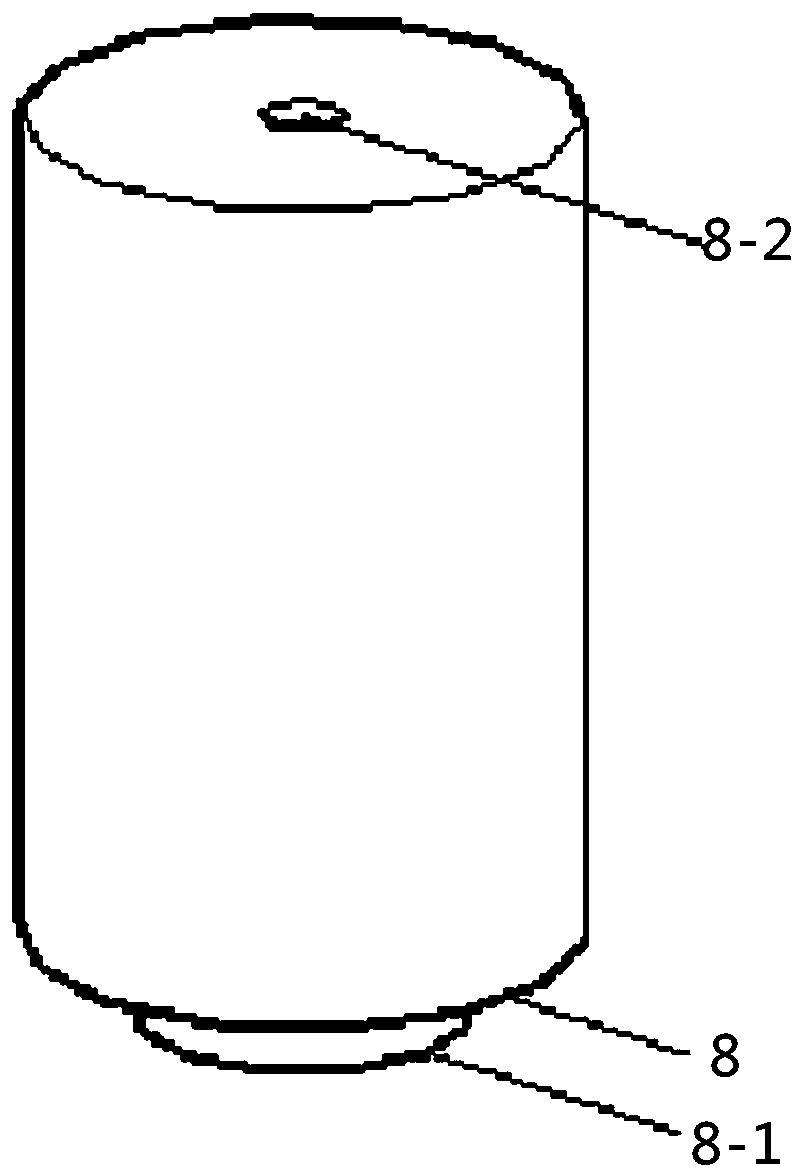

Mould segment ring (well wall) prefabrication device and mould segment ring (well wall) prefabrication method

The invention discloses a mould segment ring (well wall) prefabrication device and a mould segment ring (well wall) prefabrication method, and belongs to the technical field of simulation experimentsof segment rings and well casings. The mould segment ring (well wall) prefabrication device is divided into a pouring device and a mould removal device; and the mould segment ring (well wall) prefabrication device has the removability integrally, and is convenient to operate. The device adopts a low-speed rotating coring method, so that the integrity and the strength of a test sample are protectedto the greatest extent. A mould segment ring (well wall) adopts the prefabrication method, prepared materials are poured into the device for pouring, after natural curing reaches the design strength,mould removal is carried out, and finally the formed segment ring (well wall) is obtained. The device is placed into a similar material of surrounding rock (a soil body), and a novel approach is provided for researching deformation, a broken mechanical mechanism and a structural mechanical characteristic of the segment ring (well wall), and an interactive relationship between the segment ring (well wall) and the surrounding rock (the soil body) in a small similar simulation experiment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Jolting-compacting isolation forming mould for building composite plate

ActiveCN109049458ADamage will notRealize the function of vibration isolation moldingArchitectural engineeringMould removal

The invention relates to a jolting-compacting isolation forming mould for a building composite plate. The jolting-compacting isolation forming mould for the building composite plate comprises transverse partition plates, a forming base frame, a left vertical frame, a longitudinal vertical plate and jolting separation devices. The longitudinal vertical plate is installed at the top of the right endof the forming base frame, and the transverse partition plates are distributed on the front and rear sides of the left end of the longitudinal vertical plate correspondingly. The transverse partitionplates are matched with the longitudinal vertical plate in a sliding friction mode, and the left vertical plate is matched with the left ends of the transverse partition plates in a friction mode. The left vertical plate is mounted at the top of the left end of the forming base frame, and the jolting separation devices are mounted on the transverse partition plates. The jolting separation devicescomprise isolation plates, isolation multistage push rods, sliding connecting columns, sliding supporting columns, jolting mechanisms, separation mechanisms, position push rods and position connecting plates. The jolting-compacting isolation forming mould for the building composite plate can solve the existing problems that a partition plate mould needs to be assembled manually, the mould is difficult to assemble and disassemble, a partition plate mixture needs to be jolted and compacted manually, and after the partition plate is hardened, damage can be caused to the partition plate due to mould removal in the production of an existing polyphenyl granule partition plate.

Owner:中铁建设集团中南建设有限公司

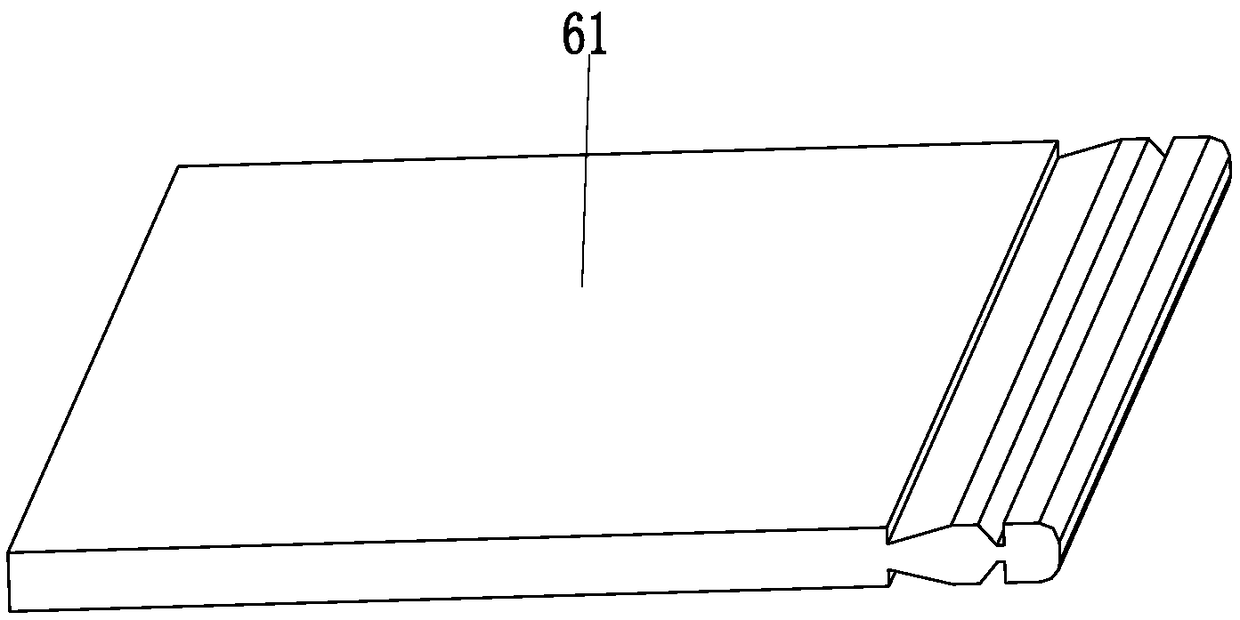

FRP template for building and manufacturing method thereof

The invention belongs to the technical field of buildings, and particularly relates to an RRP template for a building and a manufacturing method thereof. The FRP template for the building is formed bysplicing a plurality of FRP flat plates or splicing FRP flat plates and part of auxiliary materials; each FRP flat plate is formed by taking 4800TEX twistless roving with mass content being 35-45% and an alkali-free glass fiber felt with specification being 300-900g / m<2> as reinforcing materials and taking unsaturated polyester resin with viscosity being 350-750 mPa.s as a base body through a pultrusion process, wherein a forming process is mainly a pultrusion forming process and also can be other FRP forming processes such as mould-pressing forming, vacuum guide forming, hand lay-up formingand the like; and any end of each FRP flat plate is fixedly equipped with a connecting tube for connecting the adjacent FRP flat plate. The FRP template has comprehensive advantages of light mass, high strength, convenient splicing, convenient mould removal, high use and transfer time number and low cost.

Owner:南京斯贝尔复合材料有限责任公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com