Patents

Literature

37results about How to "Avoid phenomena such as cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic welding materials for high temperature kiln and a method

ActiveCN102086128ARemarkable effect of energy saving and consumption reductionExtended service lifeMicroparticleOxygen delivery

The invention discloses a method and corresponding ceramic welding materials for restoring damaged high temperature industrial kiln by ceramic welding technology, and the method comprises the following steps of: selecting materials the same as or similar torefractory materials at the kiln damaged position as base materials; selectively adding metal inflammable microparticles accounting for 10% to18% by weight of the base materials, such as aluminium, magnesium, silicon, zirconium and the like, and selecting chloride accounting for no more than 2% by weight of the base materials as additive; after mixing well under conveying of oxygen jetting the prepared welding material to a position of the kiln to be repaired; reacting the inflammable microparticles with the oxygen to produce a high temperature to allow the refractory materials rapid softening and fusion; combining together very tightly the refractory materials at the position to be prepared and the welding material; fully filling holes, junctions and slits with fused substance; and continuously filling on the heat repairing surface to achieve the purpose of kiln restoration.

Owner:山西高科耐火材料股份有限公司

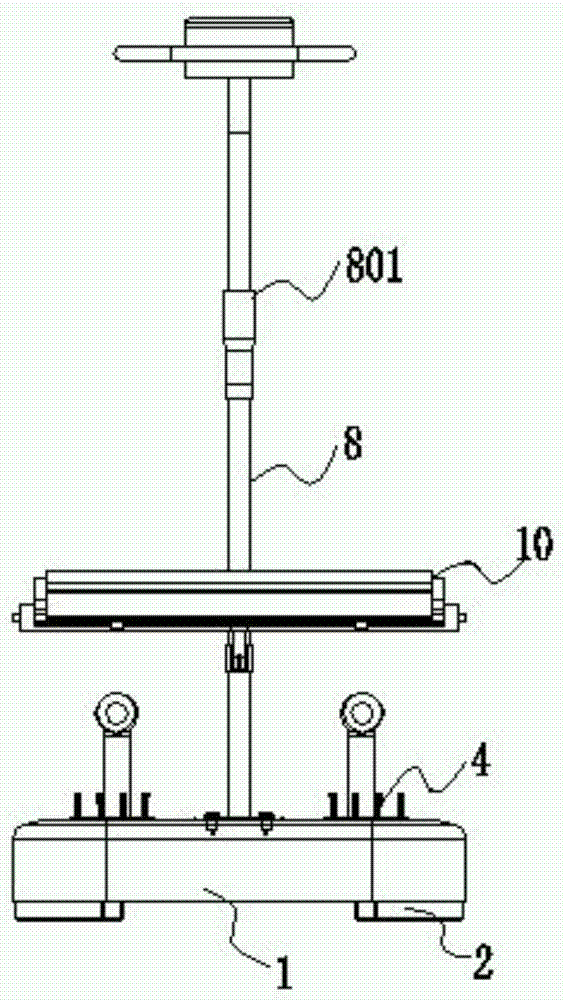

Interface mortar with ardealite-based hydraulicity composite cementing material as cementing material

The invention belongs to the technical field of building materials and particularly relates to interface mortar with an ardealite-based hydraulicity composite cementing material as a cementing material. The interface mortar is composed of ardealite, a slag powder, coal ash, metakaolin, a copper tailing slag powder, red mud, ordinary Portland cement, aluminate cement, quartz sand, a quartz powder,chesterite, calcium bentonite, a polycarboxylate-type water reducing agent, cellulose ether and latex powder. By adopting the interface mortar, the binding property of a base wall and a heat preservation layer in a wall heat preservation system can be effectively improved, the peeling risk of the heat preservation layer of a building wall can be reduced, and environment security problems caused bypiling of industrial ardealite can be also solved. When the interface mortar is produced, a great amount of industrial solid wastes such as non-calcined ardealite, coal ash, copper tailing slag powder and red mud are used, so that the interface mortar has the outstanding advantages of being low in energy consumption, low in cost, low in emission, and the like. The interface mortar is applied to heat preservation systems of various building walls, and the like.

Owner:TONGJI UNIV

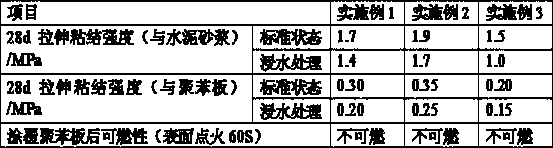

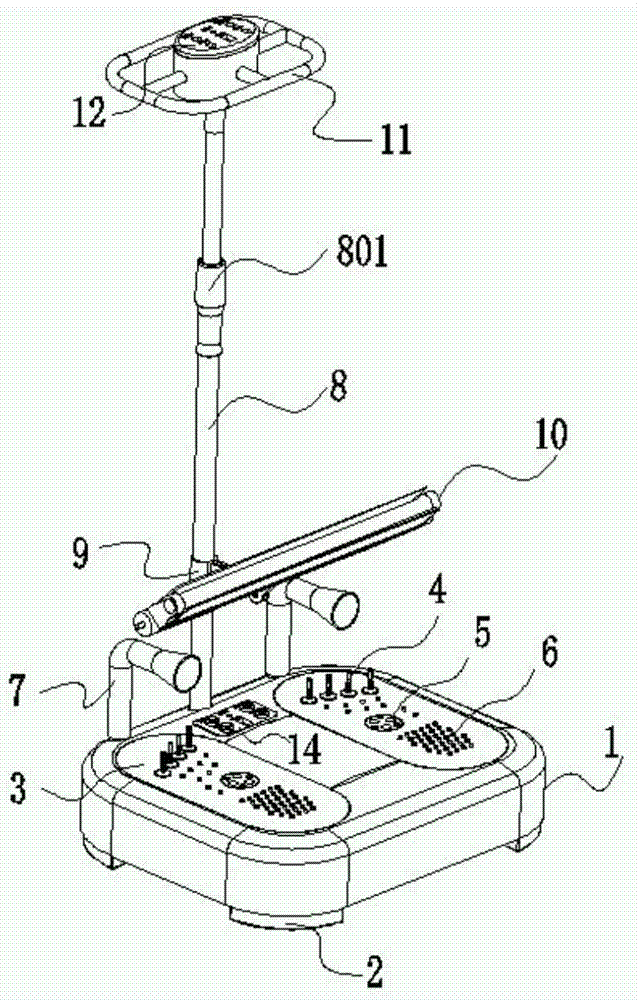

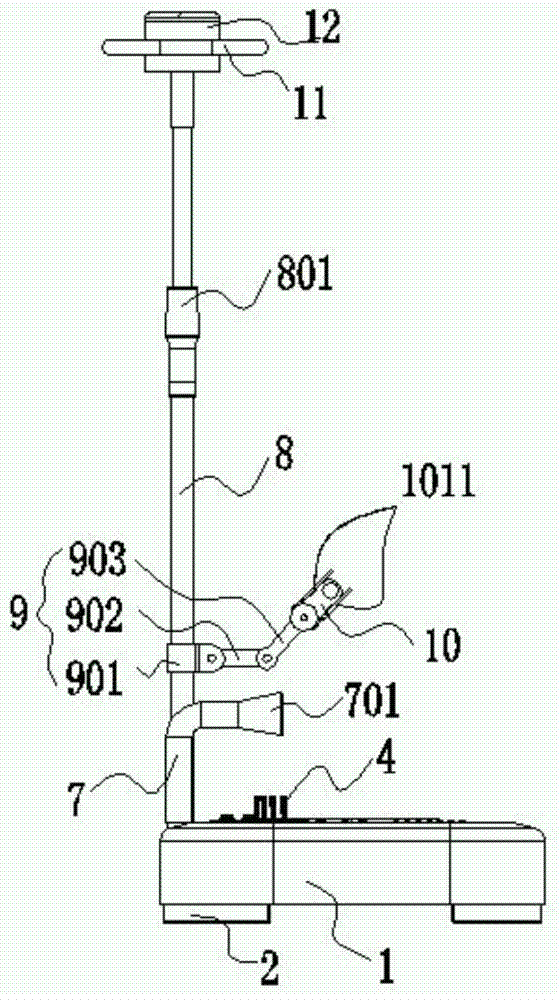

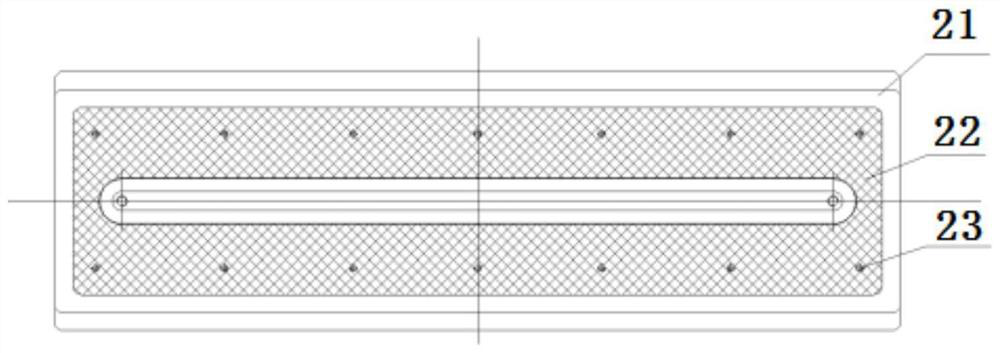

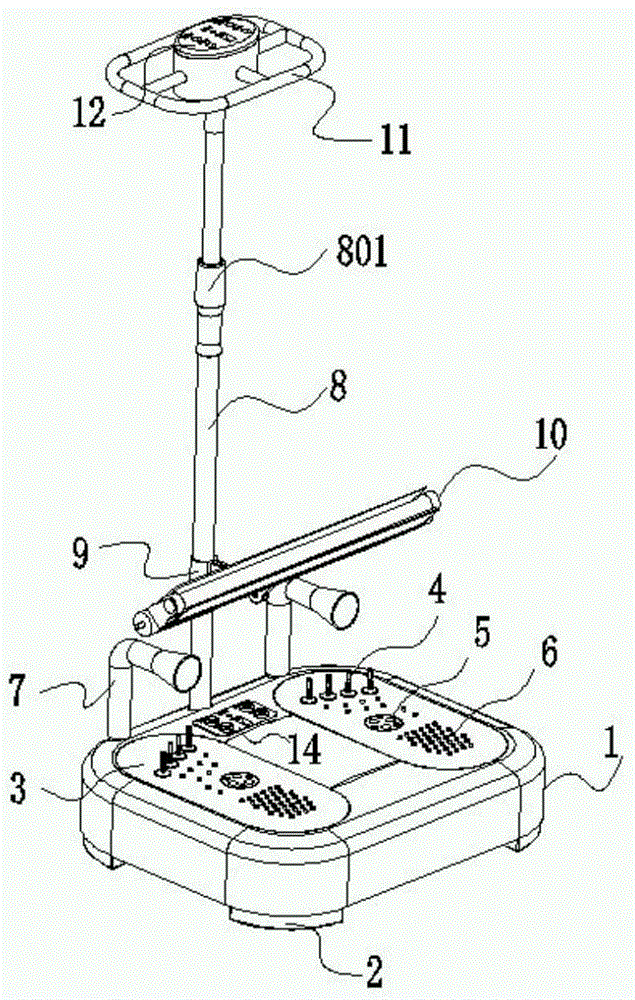

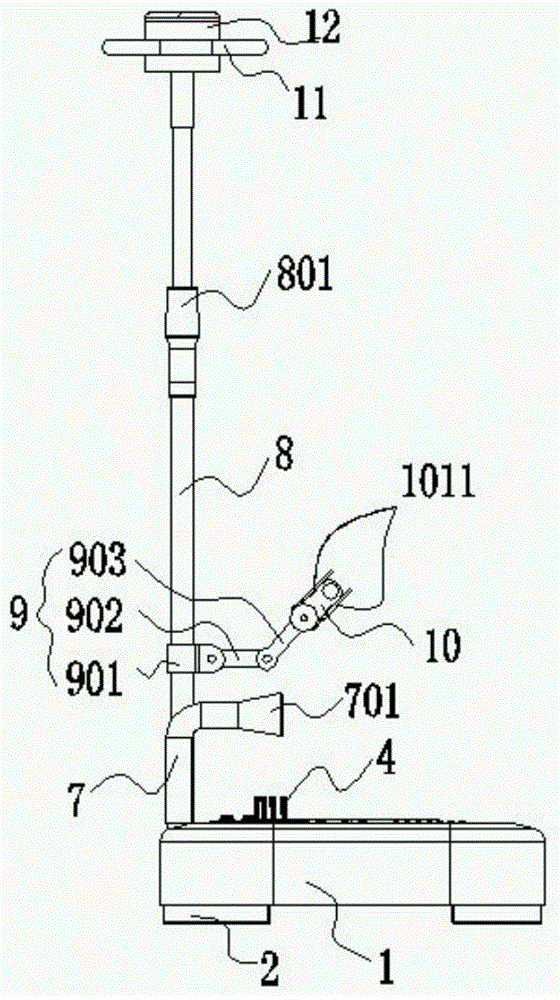

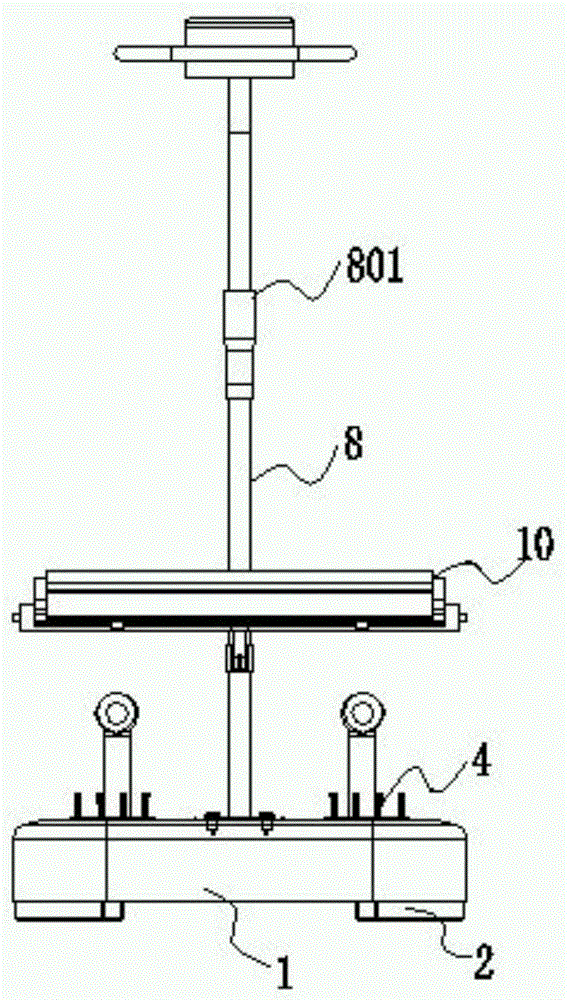

Multifunctional foot washing and massaging device

ActiveCN104758165AClean thoroughlyGood scrubbing functionDevices for pressing relfex pointsBathroom accessoriesMassageEngineering

The invention relates to a living assisted article, and discloses a multifunctional foot washing and massaging device. The multifunctional foot washing and massaging device comprises a base and support legs arranged below the base, wherein the base is of a hollow shape and the surface of the base is symmetrically provided with pedal holes, pedal plates are respectively and symmetrically embedded into the two inner sides of the pedal hole, and the pedal plate is provided with a sole massage device; a support column is arranged below the base, and a bottom plate is arranged at the bottom of the base; the sole massage device comprises a toe scrubbing device, an arch massaging device and acupoint points, wherein the toe scrubbing device is arranged on the pedal plate, the arch massaging device is embedded in the pedal plate, the acupoint points are movably arranged below the pedal plate, and acupoint holes are correspondingly formed in the pedal plate. According to the multifunctional foot washing and massaging device provided by the invention, the problems met can be solved in the process of cleaning, nursing and drying the feet when a user is showering, and the user does not need to stoop down, therefore the aged, children, pregnant women and fat people can be effectively protected, and the danger of sliding in a bathroom can be prevented.

Owner:JIAXING RIFENG METAL PROD CO LTD

Building sealing glue and preparation method thereof

InactiveCN106634754AGood film formingDense surfaceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPlasticizer

The invention provides building sealing glue. The building sealing glue is prepared from a component A, a component B and a component C, wherein the component A is prepared from the following components in parts by weight: 20 to 90 parts of epoxy resin, 3 to 40 parts of a plasticizer, 0.1 to 10 parts of a coupling agent, 0.1 to 10 parts of a thixotropic agent, 0.1 to 20 parts of hollow glass bead and 10 to 50 parts of filling; the component B is prepared from the following components in parts by weight: 20 to 90 parts of a curing agent, 0 to 8 parts of an accelerant, 0.1 to 10 parts of the thixotropic agent, 0 to 10 parts of the coupling agent, 0.1 to 20 parts of the hollow glass bead and 10 to 50 parts of the filling; the component C is prepared from the following components in parts by weight: 70 to 120 parts of quartz sand and 0.5 to 2 parts of carbon black. The building sealing glue provided by the invention has relatively suitable thermal expansion and cold contraction performance and has relatively good compatibility performance with a prefabricated part, so that phenomena that the building sealing glue is cracked and the like, caused by decoration, can be avoided.

Owner:HUNAN KOSEN NEW MATERIAL

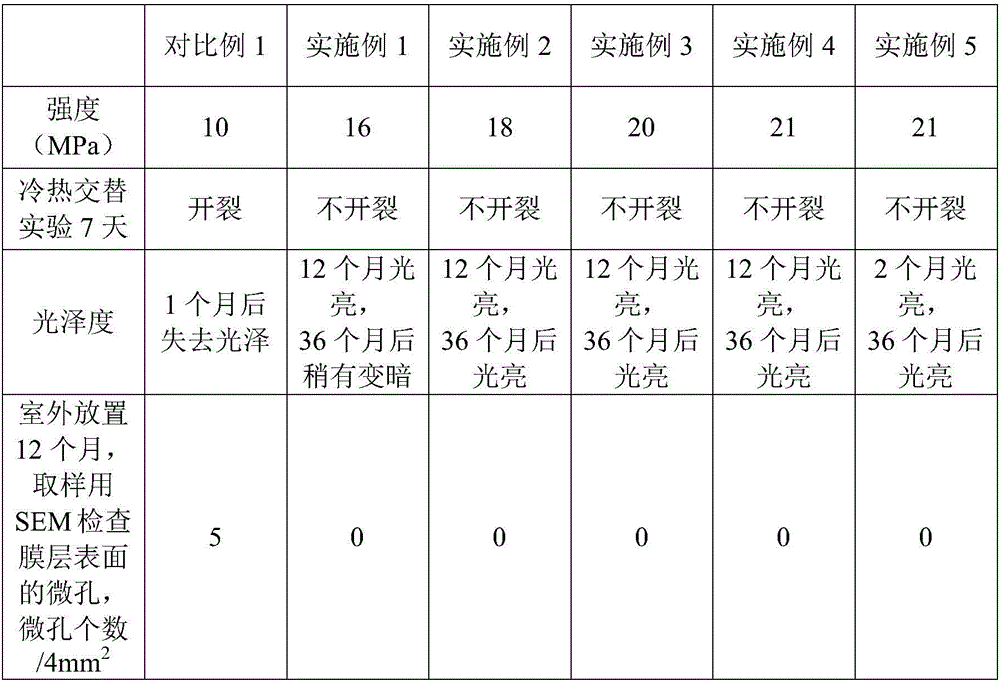

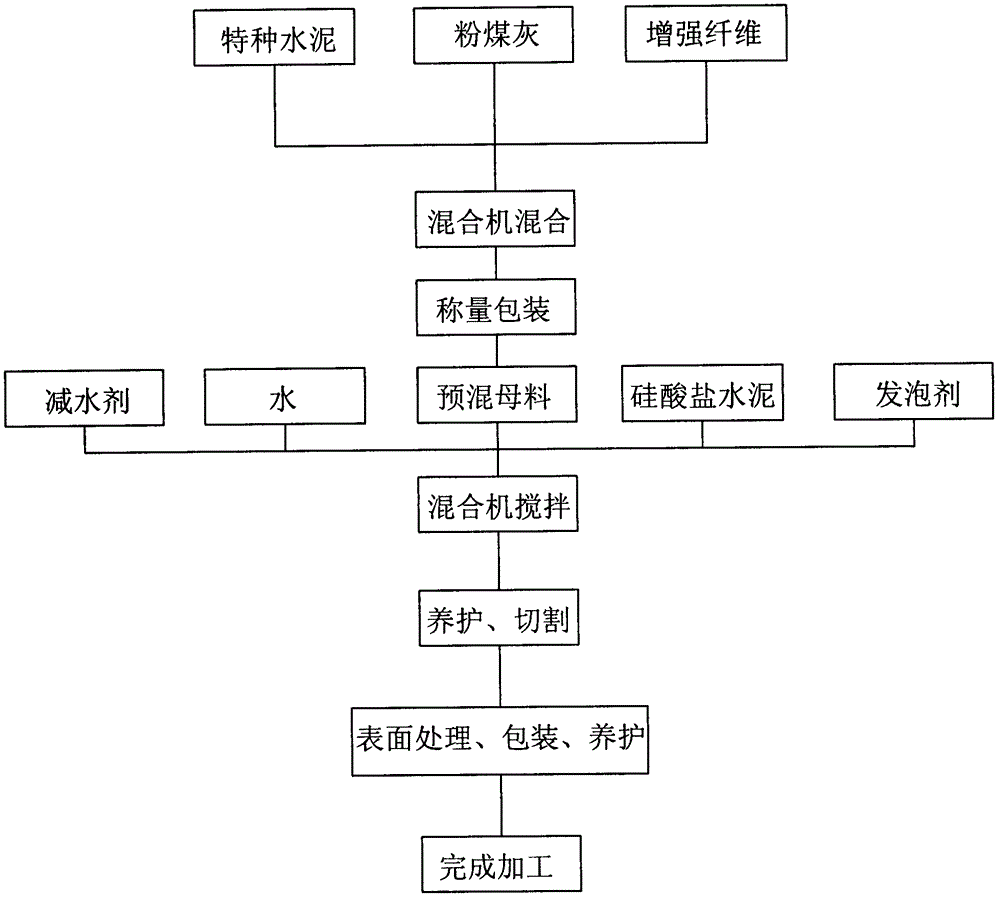

Method for cutting foaming cement board by means of wet process

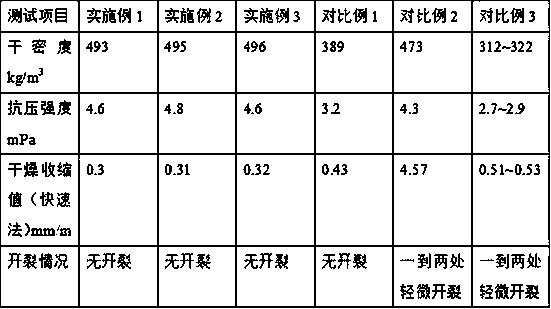

ActiveCN102744778APrevent leakageAvoid phenomena such as crackingCeramic shaping apparatusThermal insulationCement board

The invention discloses a method for cutting a foaming cement board by means of a wet process. The method comprises the following steps: (1) mixing and stirring cement, pulverized fuel ash, reinforced fibers and an additive with water according to the proportion and performing mould pouring, foaming and standing to prepare the foaming cement board; (2) maintaining the foaming cement board for 20-30 minutes, performing mould removal and cutting the foaming cement board into required foaming cement boards with various specifications through a cutting device; and (3) performing surface treatment, package and film coating maintenance of the cut foaming cement boards for 14 days. When the strength of the foaming cement boards is low, the wet process cutting is performed, the amount of dust produced in the cutting process is reduced, the cutting efficiency is improved, and the product quality is improved greatly. The problems that large amount of hydration heat is produced in the foaming process of the foaming cement boards, caused cracks do not easily disperse, cutting size deviation is large when the strength of the foaming cement boards is high, and the like are solved. Accordingly, phenomena including leakage, cracks and the like of a foaming cement board outer wall external thermal insulation system caused by self size deviation, the cracks and other problems of the foaming cement boards are avoided.

Owner:JIANGSU NIGAO SCI & TECH +1

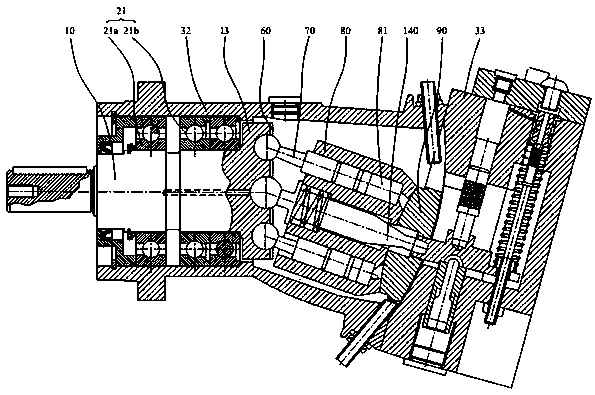

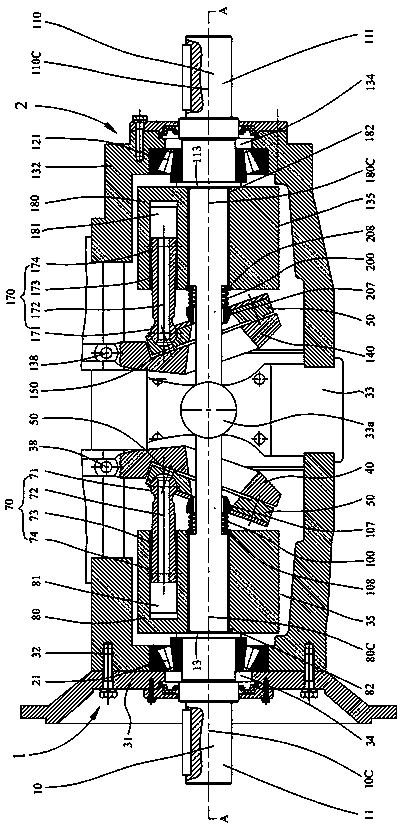

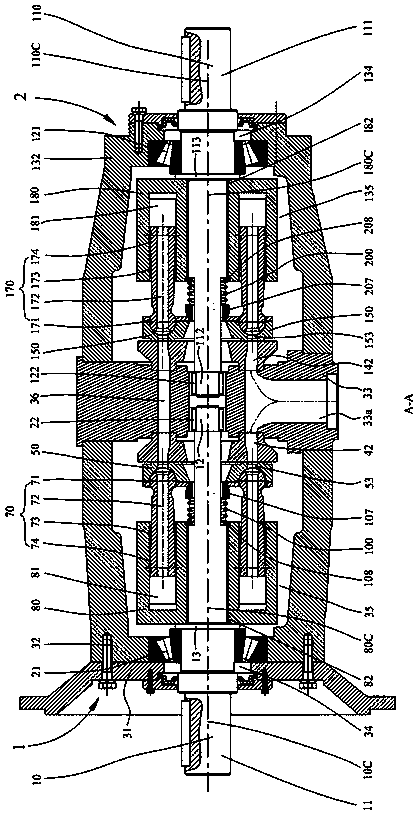

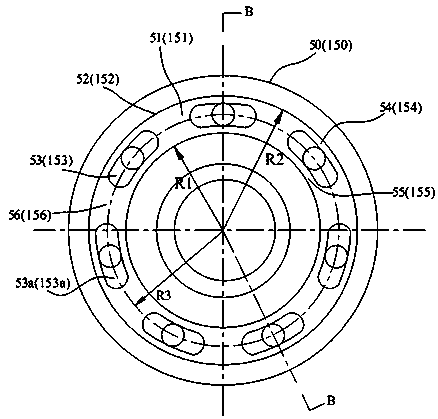

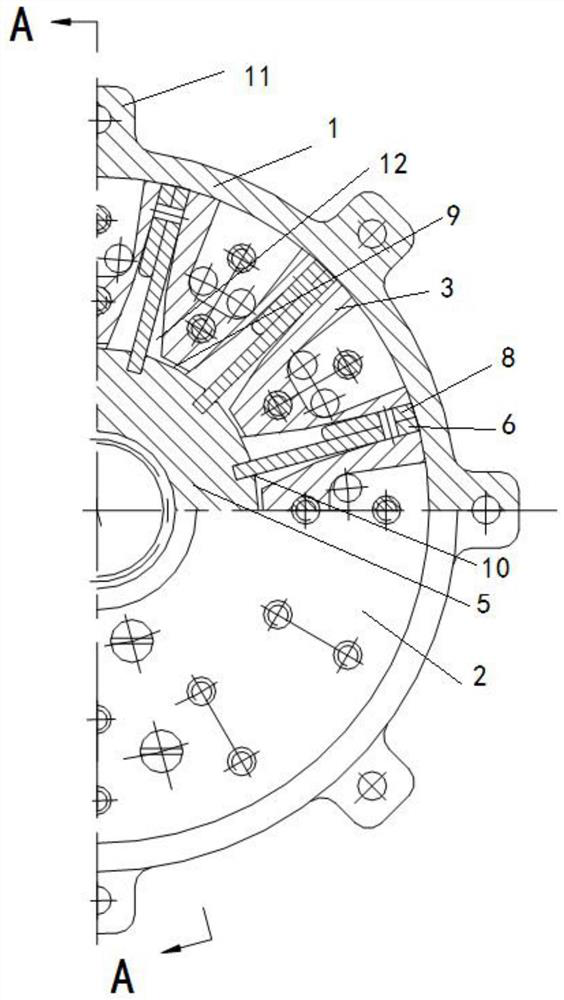

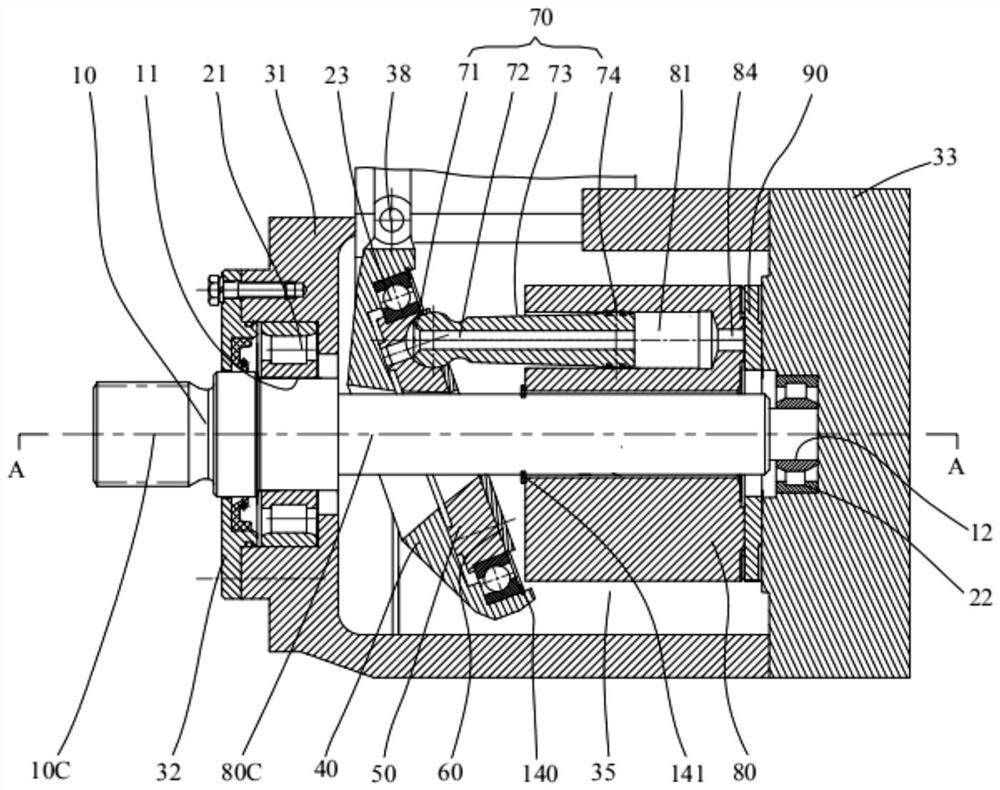

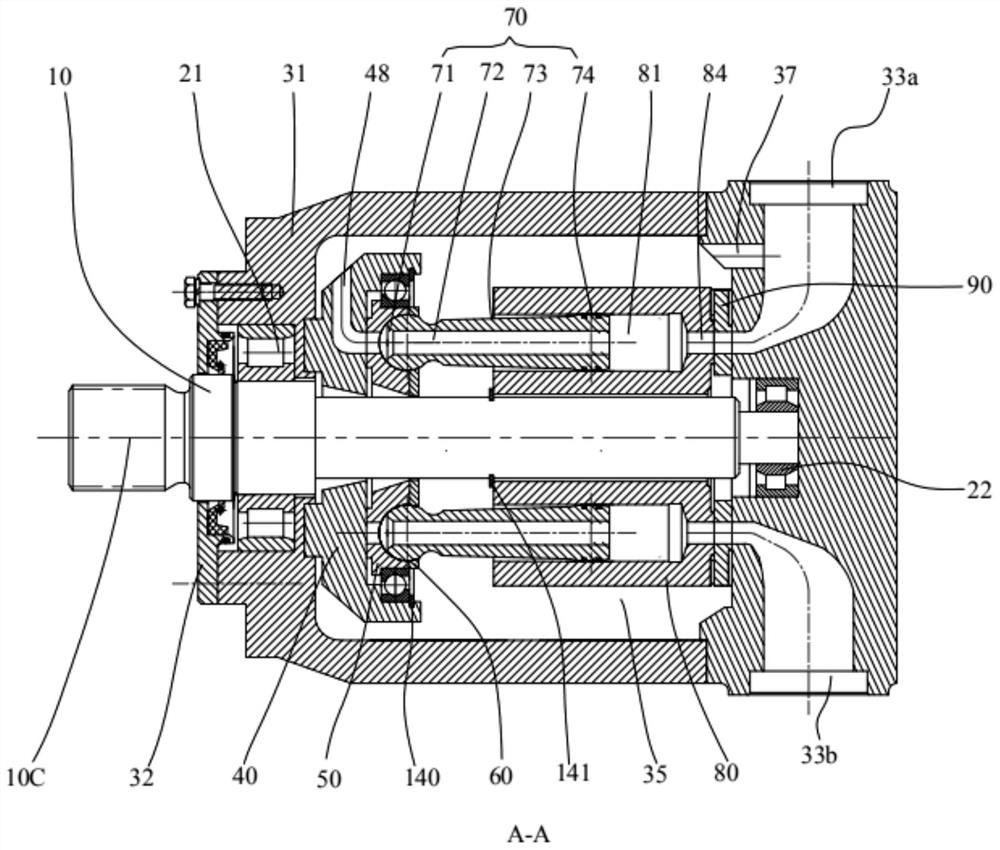

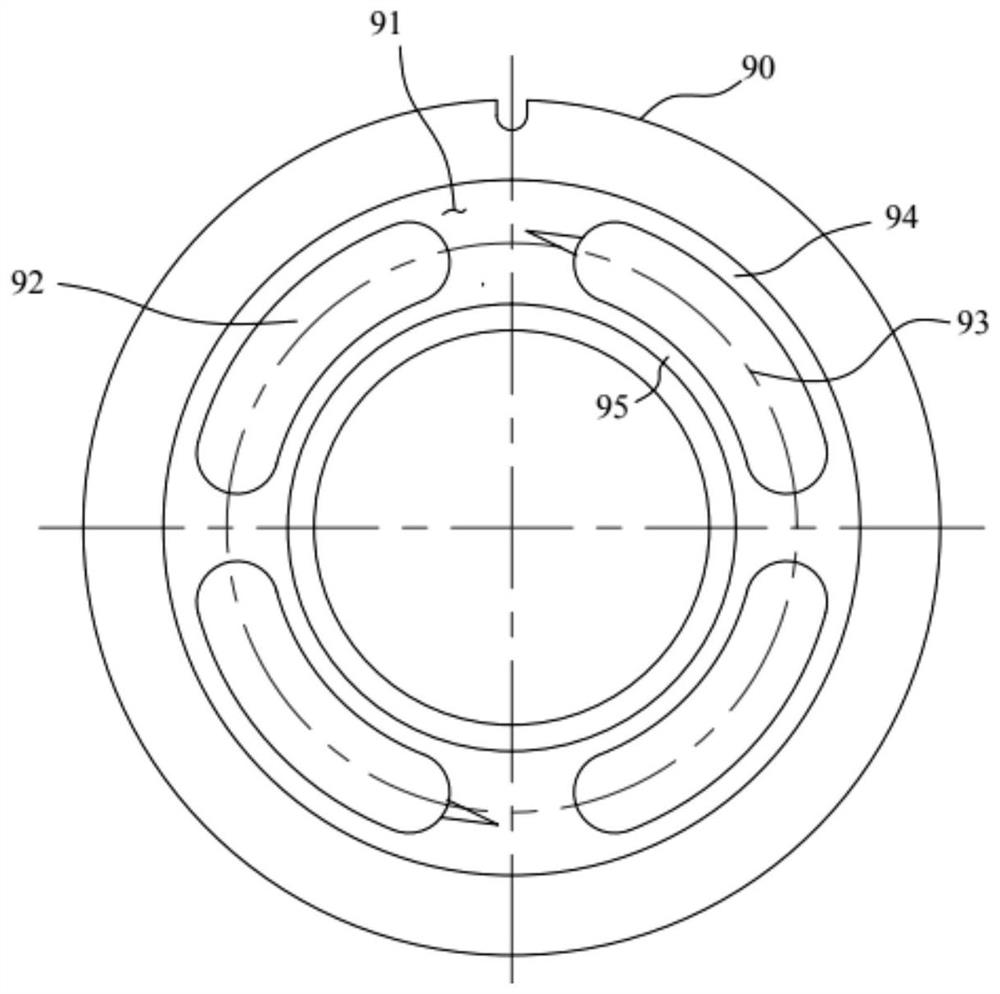

Flow distribution sliding disc pair and plunger pump or motor comprising structure

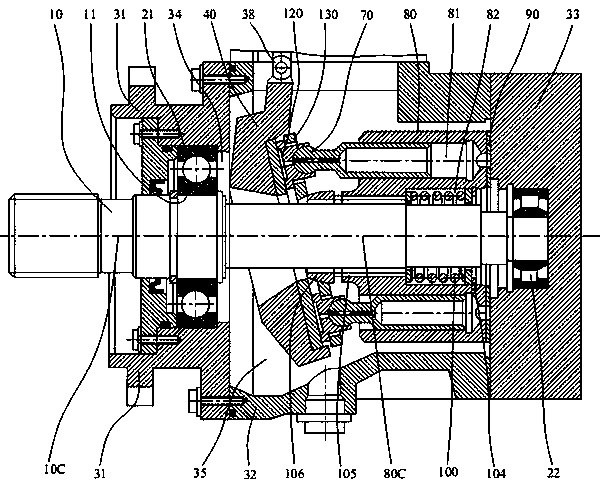

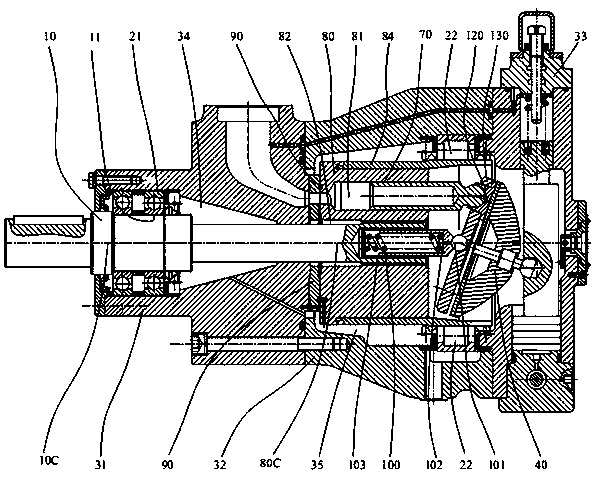

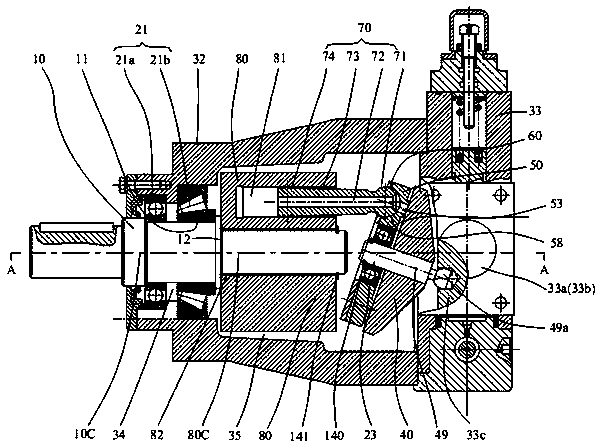

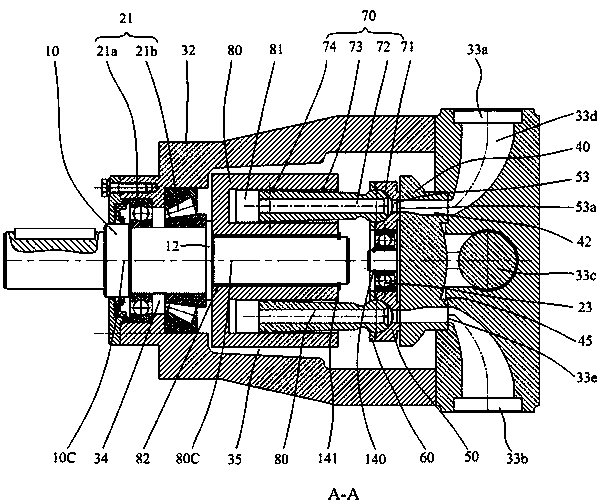

PendingCN110067715AEliminate or reduce overturning phenomenonQuick responsePositive displacement pump componentsPlungersWorking lifeCylinder block

The invention discloses a flow distribution sliding disc pair and a plunger pump or motor comprising the structure. The flow distribution sliding disc pair comprises swash discs and sliding discs supported on the swash discs, each sliding disc is of an integrated structure, the opposite end faces of the sliding discs and the swash discs are provided with static pressure bearing surfaces, the static pressure bearing surfaces are provided with a plurality of oil chambers, the end surfaces the other sides of the sliding discs are provided with a plurality of plunger ball sockets, and the slidingdiscs are provided with large-aperture oil passing holes for communicating the plunger ball sockets and the oil chambers; and the swash discs are provided with flow distribution oil grooves communicating with inlet and outlet ports, and the flow distribution oil grooves communicate with the inlet and outlet ports in the positions, close to the ends of one sides of the swash discs, on a shell of the plunger pump or motor. By means of the flow distribution sliding disc pair and the plunger pump or motor, flow distribution, variable inclination and the supporting function are integrated into theflow distribution sliding disc pair, the number of friction pairs is decreased, the influence of cylinder block overturning and oil pollution is reduced, the structure is greatly simplified, the workreliability and work pressure of the plunger pump or motor are improved, and the working life of the plunger pump or motor is prolonged.

Owner:钟彪

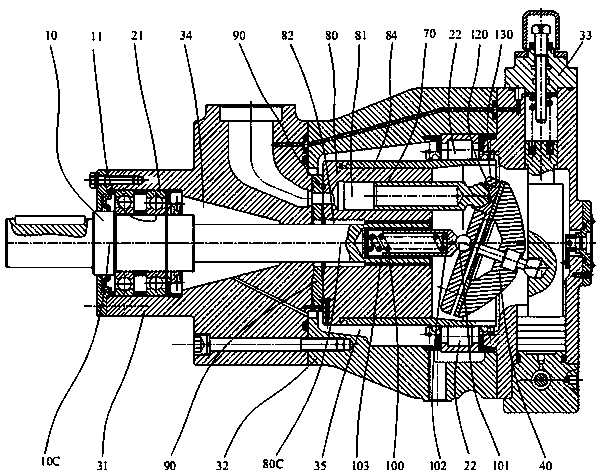

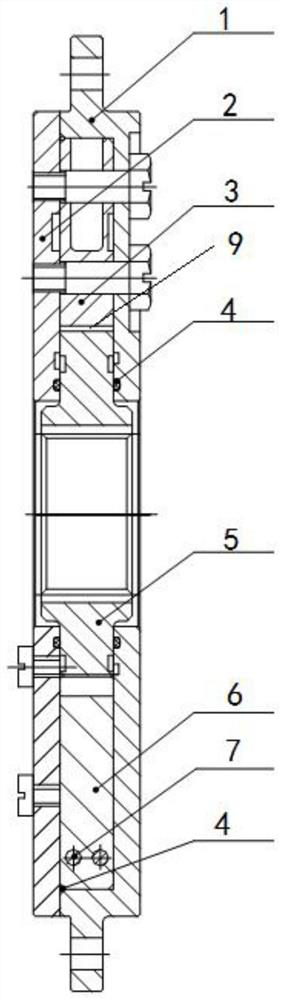

Sliding plate supported type non-through shaft plunger pump or motor

PendingCN110067725AReduce lateral forceSolution to short lifePositive displacement pump componentsPlungersWorking lifeEngineering

The invention discloses a sliding plate supported type non-through shaft plunger pump or motor. The sliding plate supported type non-through shaft plunger pump or motor comprises a spindle, a cylinderbody, a swash plate and a sliding plate, wherein the cylinder body and the spindle rotate synchronously; the sliding plate is supported on the swash plate; a cantilever at the end part of the spindle is used for supporting the cylinder body and is connected with the cylinder body through a key; the sliding plate is of an integrated structure; the end face, opposite to the swash plate, of the sliding plate is provided with a hydrostatic supporting surface; the hydrostatic supporting surface is provided with a plurality of oil chambers; the other end face of the sliding plate is provided witha plurality of plunger ball sockets; the sliding plate is provided with a large-hole-diameter oil passing hole which communicates with the plunger ball sockets and the oil chambers; the swash plate isprovided with a flow distributing oil tank which communicates with an oil inlet and an oil outlet; a third bearing is arranged between the sliding plate and the swash plate; and the sliding plate issupported on the third bearing in a manner of being restrained in the radial direction of the sliding plate. The sliding plate supported type non-through shaft plunger pump or motor disclosed by the invention improves the performances such as work reliability, volume efficiency and working life of a swash plate type axial plunger pump or motor.

Owner:钟彪

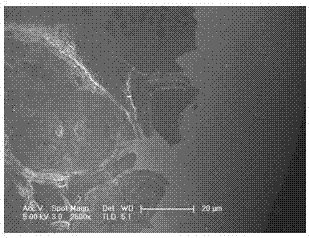

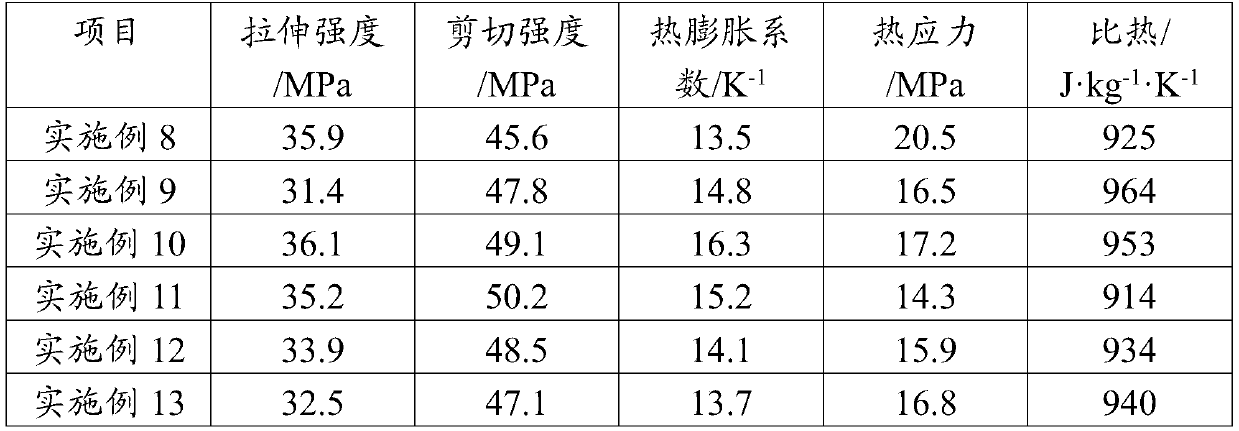

Method for electrodepositing iron-nickel alloy plating on surface of carbon-based material

The invention relates to a method for electrodepositing iron-nickel alloy plating on the surface of a carbon-based material and belongs to the technical field of surface treatment. The carbon-based material is subjected to heat treatment and ultrasonically cleaned, and thus a pretreated carbon-based material is obtained; an iron-nickel alloy electrodepositing solution is prepared; with the pretreated carbon-based material as a cathode, an iron-nickel alloy plate as an anode and the iron-nickel alloy electrodepositing solution serves as an electroplating solution, electrodepositing is conductedat 30-50 DEG C for 5-60 min through a direct-current power source; and the cathode is taken out, cleaned and dried, and thus the iron-nickel alloy plating is obtained. The iron-nickel alloy plating can be electroplated on the surface of the carbon-based material, the thermal expansion coefficient of the plating is close to that of the carbon-based material, micron-scale interface bonding is achieved between the plating and the carbon-based material, and tight interface bonding can be still kept after a heat cycle from the indoor temperature to the temperature of 800 DEG C.

Owner:KUNMING UNIV OF SCI & TECH

Hydraulic infinitely-variable speed transmission device

The invention discloses a hydraulic infinitely-variable speed transmission device which comprises a sliding disc type axial piston pump, a sliding disc type axial piston motor coaxially arranged together with the sliding disc type axial piston pump and an end seat clamped between the sliding disc type axial piston pump and the sliding disc type axial piston motor. The sliding disc type axial piston pump and the sliding disc type axial piston motor each comprises a flow distribution sliding disc pair assembly, the flow distribution sliding disc pair assembly comprises swash discs and sliding discs supported on the swash discs, each sliding disc is of an integrated structure, the swash discs are provided with flow distribution oil grooves and are supported on the common end seat, the end seat is provided with an oil way for communicating the pump and the motor and oil inlet and outlet ports, low-pressure oil forms high-pressure oil through the effect of the sliding disc type axial pistonpump to be input into the sliding disc type axial piston motor through the oil way of the end seat, the low-pressure oil is formed under the action of the motor, and transmission is formed. The hydraulic infinitely-variable speed transmission device improves the working reliability and prolongs the working life.

Owner:钟彪

Refrigerator stamping part machining treatment method

InactiveCN109623283AGuaranteed accuracyStress reliefEdge grinding machinesShaping toolsEngineeringRefrigerated temperature

The invention relates to the technical field of stamping part machining, in particular to a refrigerator stamping part machining treatment method. The refrigerator stamping part machining treatment method comprises the following steps that firstly, discharging is conducted, metal plate raw materials are checked, after qualification is reached, a metal plate is cut according to the size of a refrigerator stamping part, and a to-be-stamped material is obtained; secondly, first-time edge trimming is conducted; thirdly, forming is conducted; and fourthly, second-time edge trimming is conducted. Inthe preparing process, the two-time edge trimming treatment is sequentially conducted on the stamping part; during first-time edge trimming treatment, the situation that fixing and stamping of the product are influenced due to burrs and other defects on the cut edge is avoided, and the precision of the subsequent machining technology is guaranteed; and during second-time edge trimming, the appearance and the product precision of the stamping part can be guaranteed. Before stamping, air blowing and dust removal are conducted on a stamping cavity and the to-be-stamped plate, the technology precision is further guaranteed, heating softening treatment is conducted before stamping, stress in the material can be eliminated, the phenomena of cracking and the like after stamping part forming areavoided, and the forming quality is reliable.

Owner:滁州美业科技股份有限公司

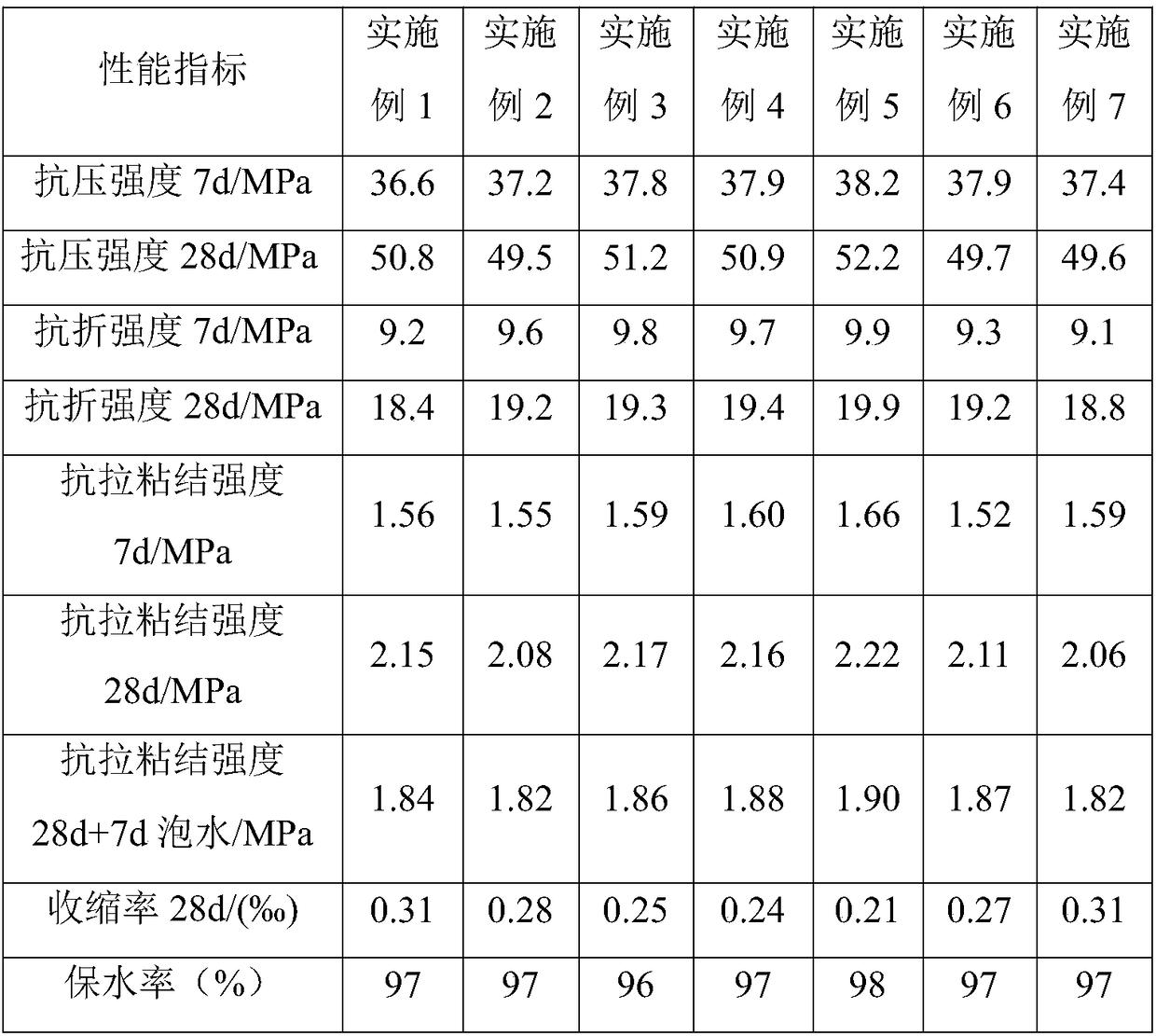

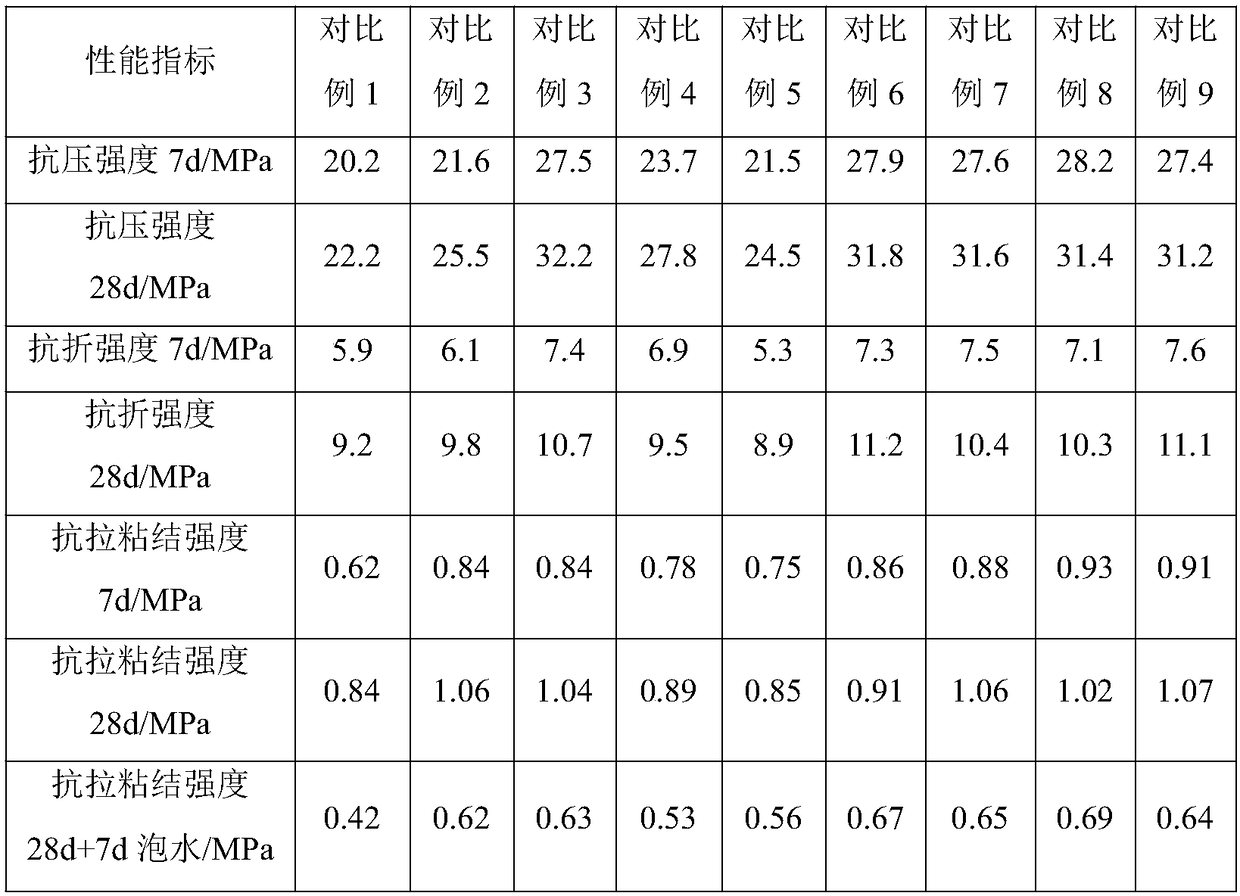

Special joint filling mortar for light partition wallboards

The invention discloses special joint filling mortar for light partition wallboards. The special joint filling mortar comprises, by weight, 300-400 parts of cement, 100-140 parts of fly ash, 400-450 parts of fine sand, 30-60 parts of calcined gypsum powder, 2-10 parts of macromolecule xanthan gum powder, 1-10 parts of redispersible latex powder, 1-3 parts of starch ether, 1-3 parts of cellulose ether, 1-3 parts of set retarders, 40-60 parts of expansive agents, 2-8 parts of graphene oxide modified carbon fibers and 1-5 parts of water repellents. A mass ratio of the macromolecule xanthan gum powder to the redispersible latex powder is 2-7:1; an expansion coefficient of the calcined gypsum powder is 120-130, and a mass ratio of graphene oxide to carbon fibers is 0.05-0.1:1. The special jointfilling mortar for the light partition wallboards has the advantages that various components of the special joint filling mortar are selected, the weights of the various components are matched with one another, respective excellent properties of the various components are comprehensively utilized, the strength of the components is drawn, and accordingly the special joint filling mortar is high inbonding strength, tensile and compressive property and water retention rate and low in shrinkage.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

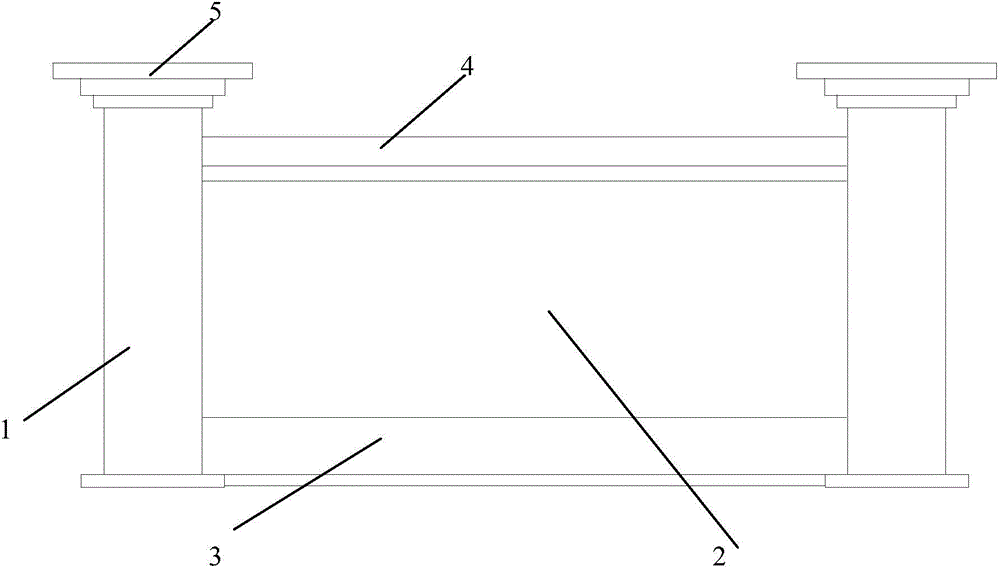

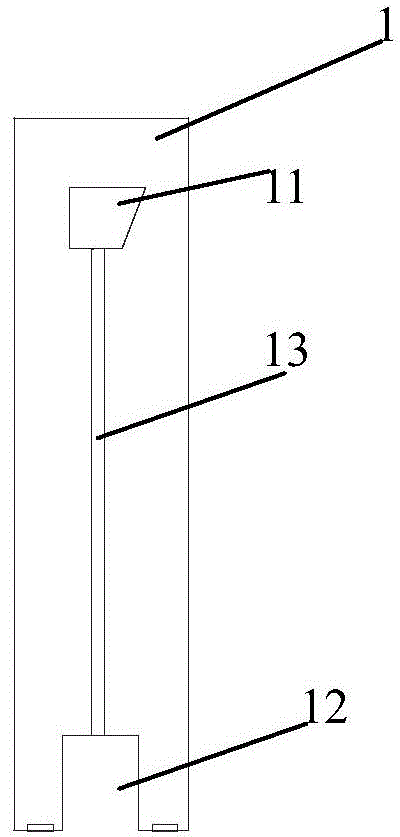

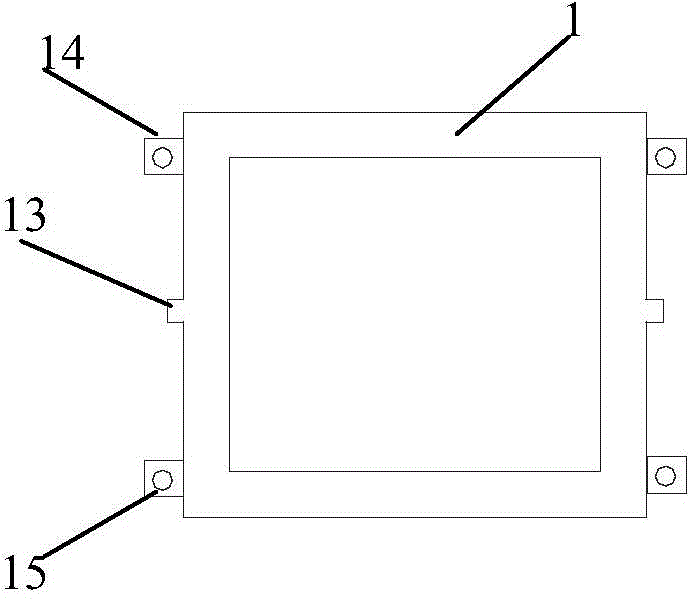

Anti-cracking wallboard of prefabricated wall

InactiveCN103603545AImprove deformation resistanceAvoid phenomena such as crackingFencingEngineeringUltimate tensile strength

The invention discloses an anti-cracking wallboard of a prefabricated wall. The anti-cracking wallboard comprises a wall body and embedding grooves formed on the left and right side edges as well as the upper and lower side edges of the wall body respectively, wherein a filling board is arranged in the center of the wall body; the embedding grooves on the left and right sides of the wallboard are formed symmetrically; the embedding grooves on the upper and lower sides are formed symmetrically; the embedding grooves on two adjacent sides are formed in a staggered way. According to the anti-cracking wallboard, the embedding grooves on two adjacent sides of the wallboard are formed in a staggered way, so that the deformation resistance of the wallboard is improved, the phenomena of cracking and the like of the wallboard caused by completely symmetrical arrangement are avoided effectively, and the product quality is improved; meanwhile, a foam board is arranged in the middle of the wallboard and is cast integrally with the wallboard, so that the weight is reduced while the predetermined thickness and strength of the wallboard are kept.

Owner:天津东庆科技发展有限公司

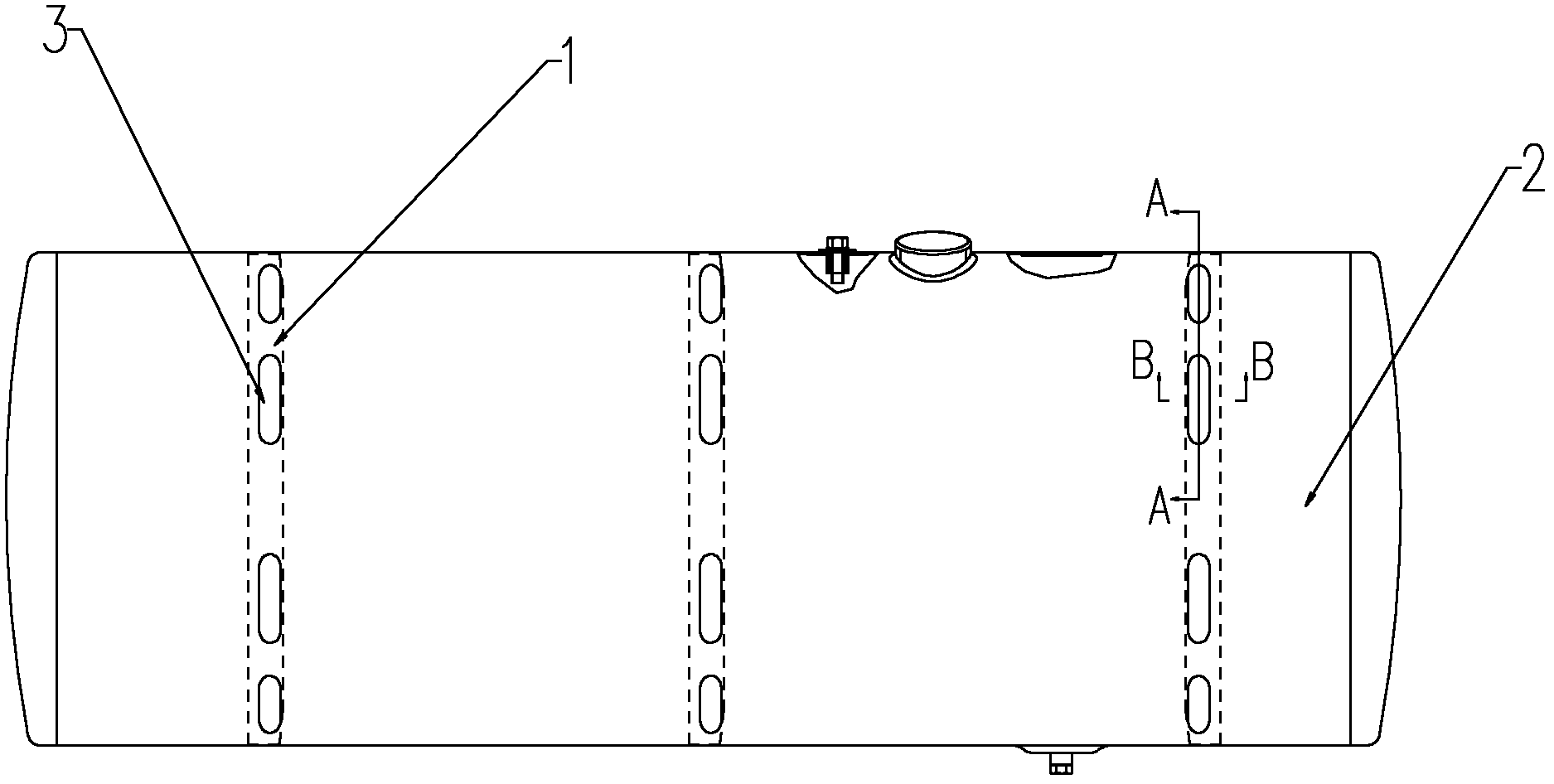

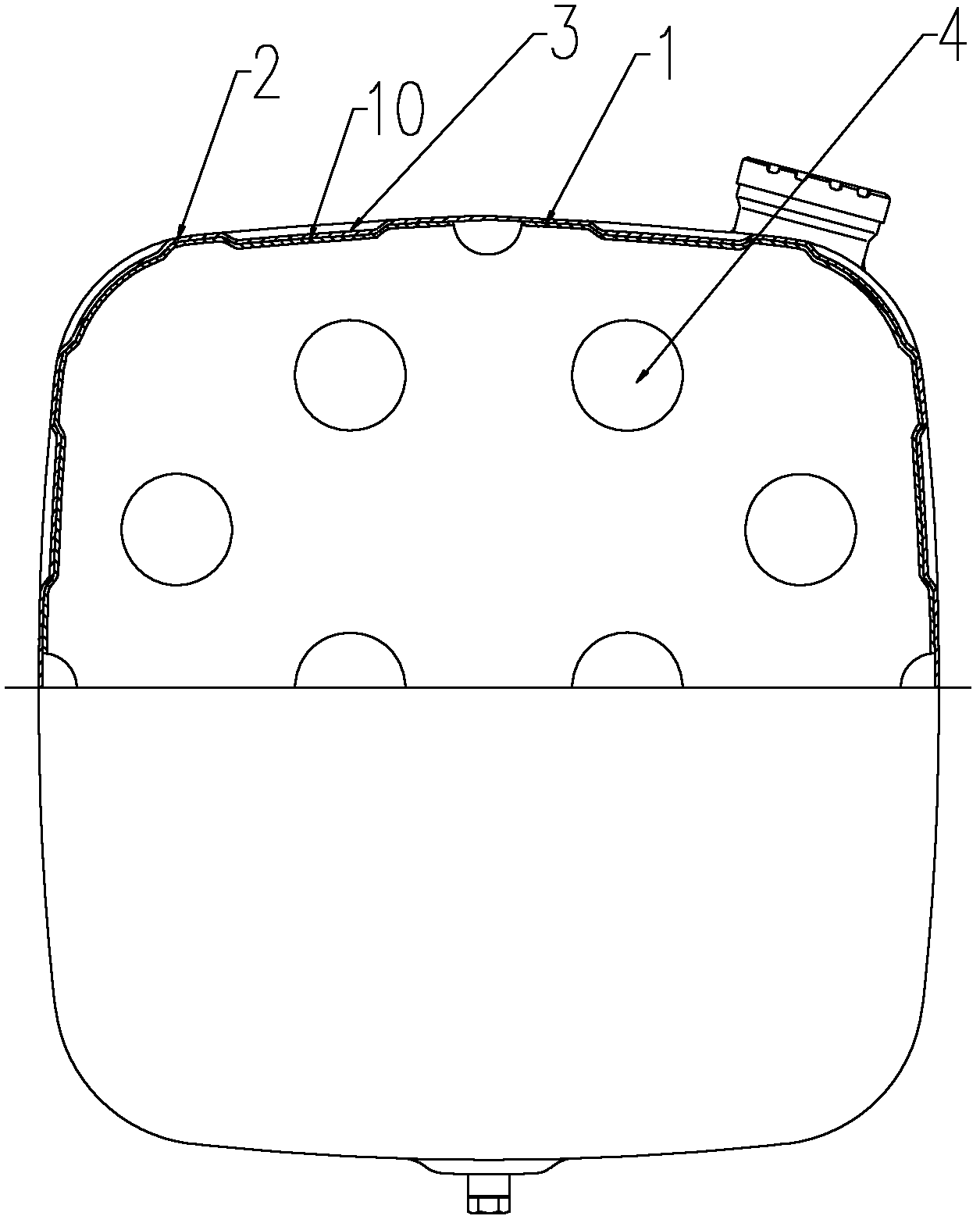

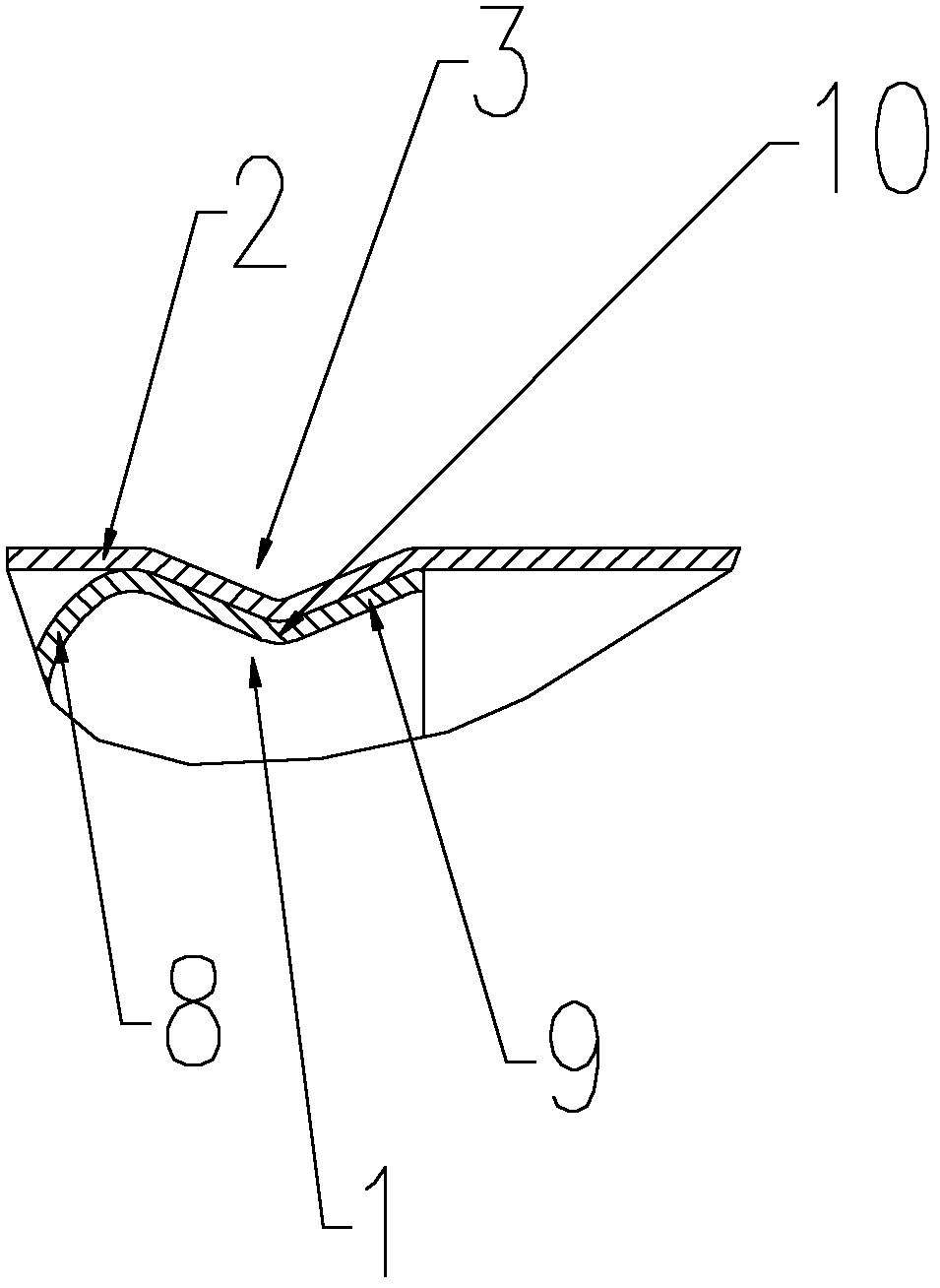

Fuel tank

ActiveCN103072469AAvoid deformationAvoid phenomena such as crackingFuel supplyFuel tankAutomotive engineering

The invention provides a fuel tank which comprises a barrel body (2) and an internal separator (1) positioned in the barrel body (2), wherein the internal separator (1) is provided with a main body part (8) and a connecting part (9), the periphery of the main body part (8) is bent to form the connecting part, and the barrel body (2) is fixedly connected with the connecting part (9) in a press-fitting manner. As the barrel body of the fuel tank provided by the invention is fixedly connected with the internal separator in the press-fitting manner, the internal separator can be firmly fixed on the barrel body, the phenomenon that the internal separator falls off in the use process of the fuel tank is avoided, the internal separator is guaranteed to powerfully support a fuel tank assembly, and the rigidity and strength of the fuel tank assembly are accordingly improved. The fuel tank assembly part with the structural characteristics, which undergoes a 12000 km real vehicle reliability test, indicates that the phenomena of deformation and cracking of the fuel tank, generated by the fuel tank assembly due to external force impact are effectively restrained, and the potential safety hazard is eliminated.

Owner:BEIQI FOTON MOTOR CO LTD

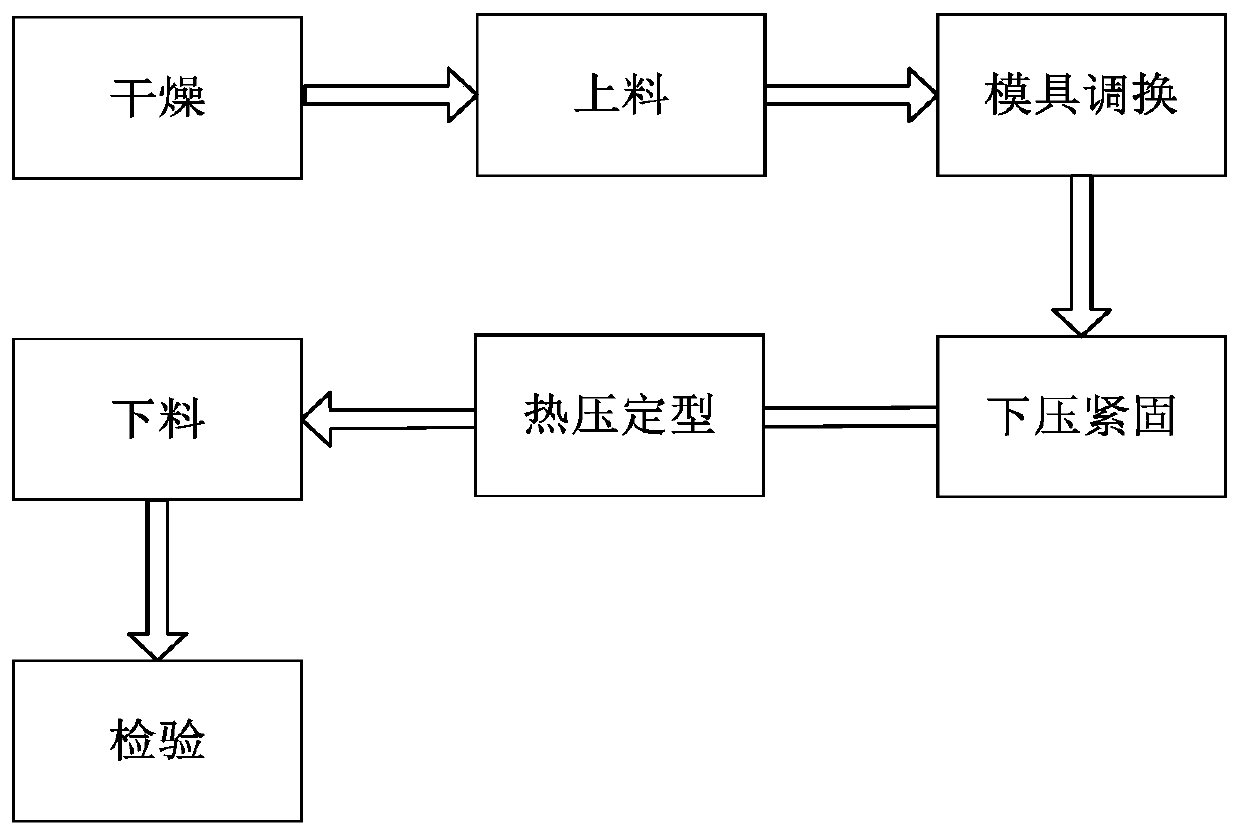

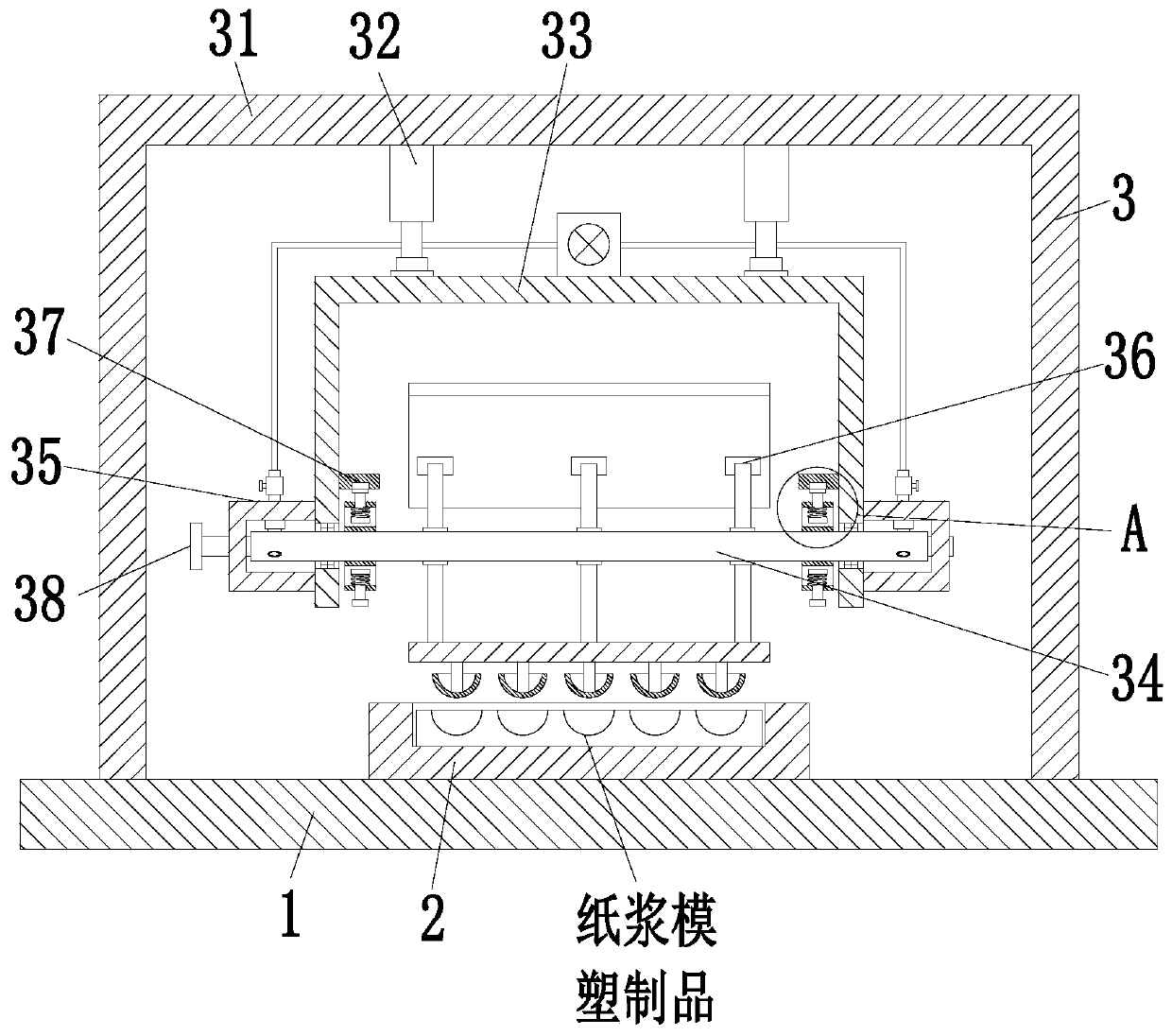

Shaping treatment method for molded packaging product after drying and setting

InactiveCN111055543AAvoid warpingAvoid phenomena such as crackingMechanical working/deformationProcess engineeringProcessing cost

The invention relates to a shaping treatment method for a molded packaging product after drying and setting. A machining device comprises a bottom plate, a lower template and a heat setting device; and the lower template is mounted in the middle of the upper end of the bottom plate, the heat setting device is arranged above the lower template, and the lower end of the heat setting device is mounted on the bottom plate. According to the method, the problems that when an existing device is used for shaping molded packaging products after drying and setting, the using effect is generally poor, and different devices need to be replaced when different molded packaging products are machined, so that the machining cost of the molded packaging products is high, and when the molded packaging products are heated and set, the setting effect is poor, positioning is inaccurate, the molded packaging products are prone to deformation, meanwhile, setting equipment cannot only heat a used mold, the heat utilization rate is low, and heat dissipation is fast are solved.

Owner:南京幸庄科技创新产业园管理有限公司

Thin plate covering part reinforcing rib forming die and method

PendingCN113878006AReduce relative flowReduce distortionShaping toolsMetal-working feeding devicesFrictional coefficientSurface roughness

The invention relates to a thin plate covering part reinforcing rib forming die and method. The thin plate covering part reinforcing rib forming die comprises a female die and a male die. The female die is located above the male die. According to the structure of the female die, polyurethane is embedded into the plane portion of a female die body, and a large forming fillet is adopted in the forming portion of the female die body. The male die is ejected from bottom to top. According to the thin plate covering part reinforcing rib forming die and method, the fillet of the female die of a reinforcing rib is enlarged, so that enough materials flow in during forming, the male die is reversely ejected to form the reinforcing rib after a part is pressed, and a polyurethane material is embedded into the contact surface part of the female die and the part to increase the surface roughness, increase the friction coefficient, increase the friction force and reduce the relative flow of the material, so that the required forming height is achieved, the phenomena of cracking and the like caused by insufficient materials participating in deformation in the forming process of small formed fillets are avoided, and deformation and warping of the part are reduced.

Owner:内蒙古第一机械集团股份有限公司

Extraction tank and preparation method thereof

The invention discloses an extraction tank. The extraction tank is prepared from the following components in parts by weight: 15-20 parts of novolac vinyl ester resin compositions, 5-10 parts of methylated benzoguanamine resin, 1-5 parts of polyurethane, 5-10 parts of nano-organic-silica, 5-10 of nano-silica, 80-100 parts of quartz sand, 5-10 parts of glass fiber and 1-2 parts of a curing agent. The extraction tank can meet the load requirements of carrying extraction liquid, a mixer and the like. The novolac vinyl ester resin compositions are high in acid and alkali corrosion resistance and impact resistance and high in thermal stress, and cracking of a tank body due to thermal stress in the curing process is avoided. The surface of the nano-organic-silica has a large number of hydroxyl groups and silicon-oxygen bonds, the addition of the hydroxyl groups and the silicon-oxygen bonds can greatly enhance the reaction and compactness between the resin composition and the inorganic quartzsand and glass fiber, and the overall firmness and heat stress of the extraction tank are improved. The glass fiber is dispersed in a skeleton of the entire extraction tank, and is insulated and heat-resistant, and the mechanical strength of the extraction tank is improved.

Owner:HANGZHOU SANAL ENVIRONMENTAL TECH

Aerated concrete and preparation method thereof

InactiveCN110683857AImprove water retentionPromote conversionCeramicwareSilicic acidMesoporous silica

The invention belongs to the technical field of concrete and in particular relates to aerated concrete and a preparation method thereof. According to the aerated concrete, cyanite and diatomite are adopted as basic materials, high temperature calcination is implemented, the cyanite is rapidly expanded, the expanded cyanite is filled with the diatomite, at the same time, zinc oxide is added, the zinc oxide is distributed to the surface of the cyanite at a high temperature state, carbon dioxide is adopted to implement cooling, a part of the carbon dioxide is adsorbed by the surfaces of solid particles, under the action of acetic acid, zinc acetate is formed by the zinc oxide, in addition, tetraethyl silicate is adopted as a raw material to form mesoporous silica, and due to an additive, themechanical properties of the concrete can be effectively improved. According to the aerated concrete, calcium carbide powder is adopted as an aeration agent, acetylene is released in the aeration process, through catalysis of the zinc acetate on the surface of the additive, ethyl acetate is formed and is polymerized to form a polymer, and through net-shaped combination of pores through the polymer, the combination degree of materials can be increased, and the mechanical properties of the materials can be improved.

Owner:王敏

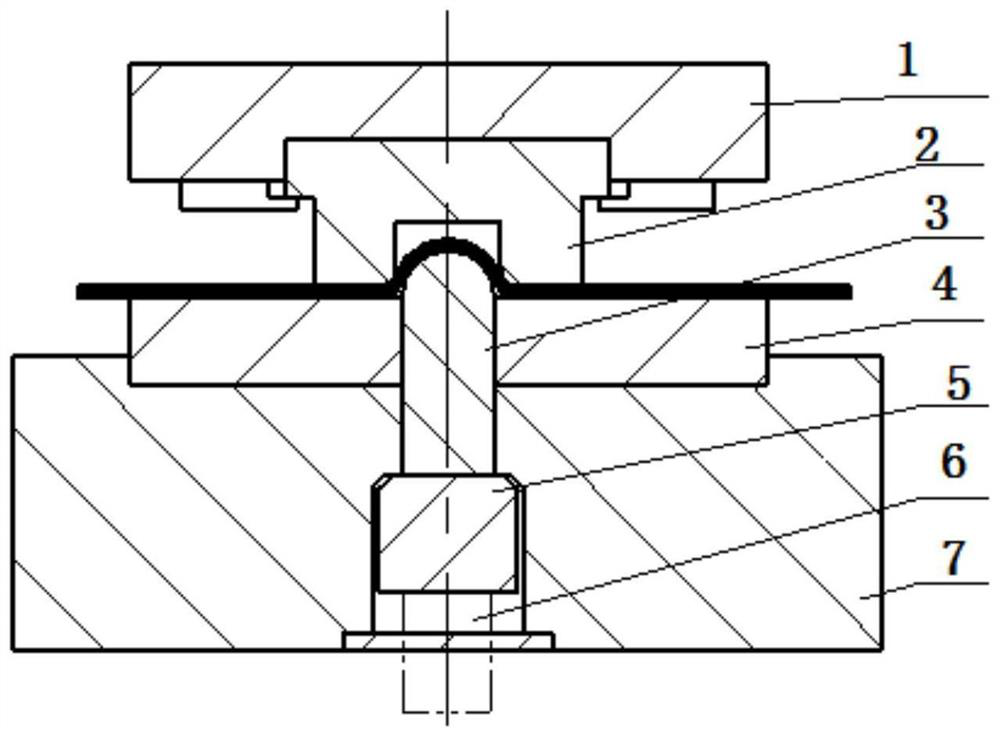

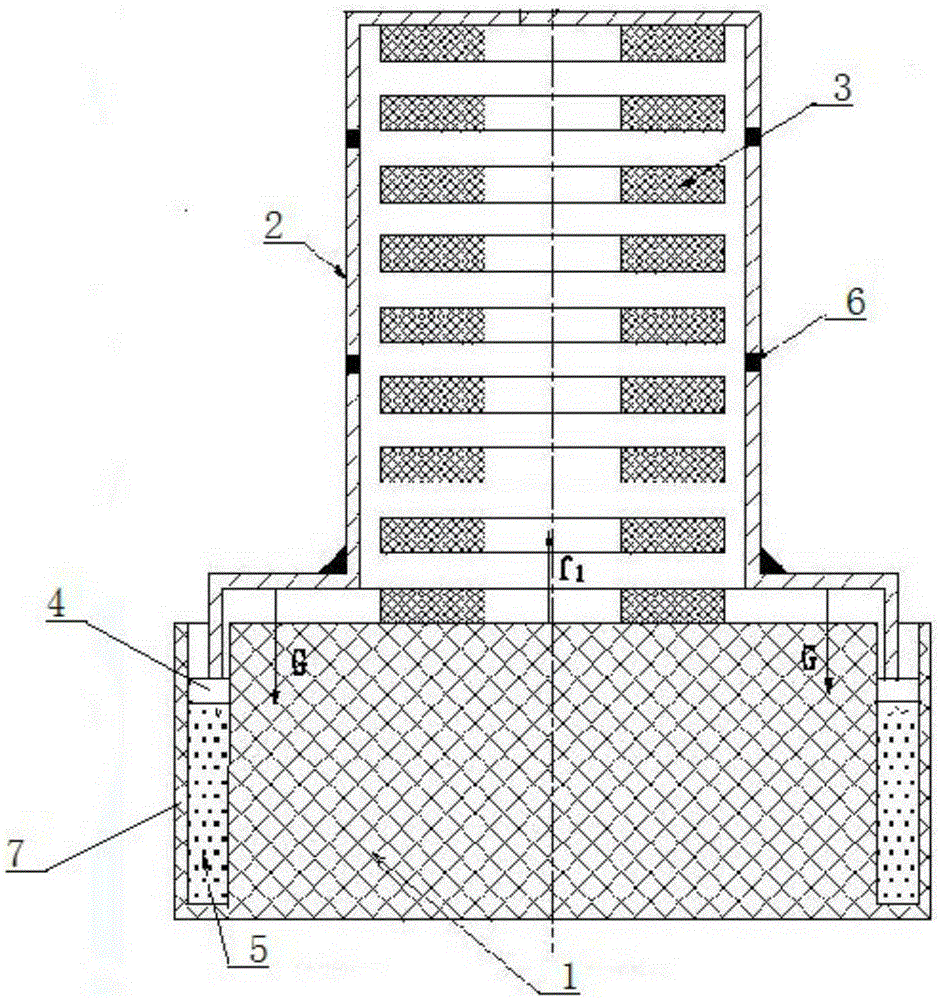

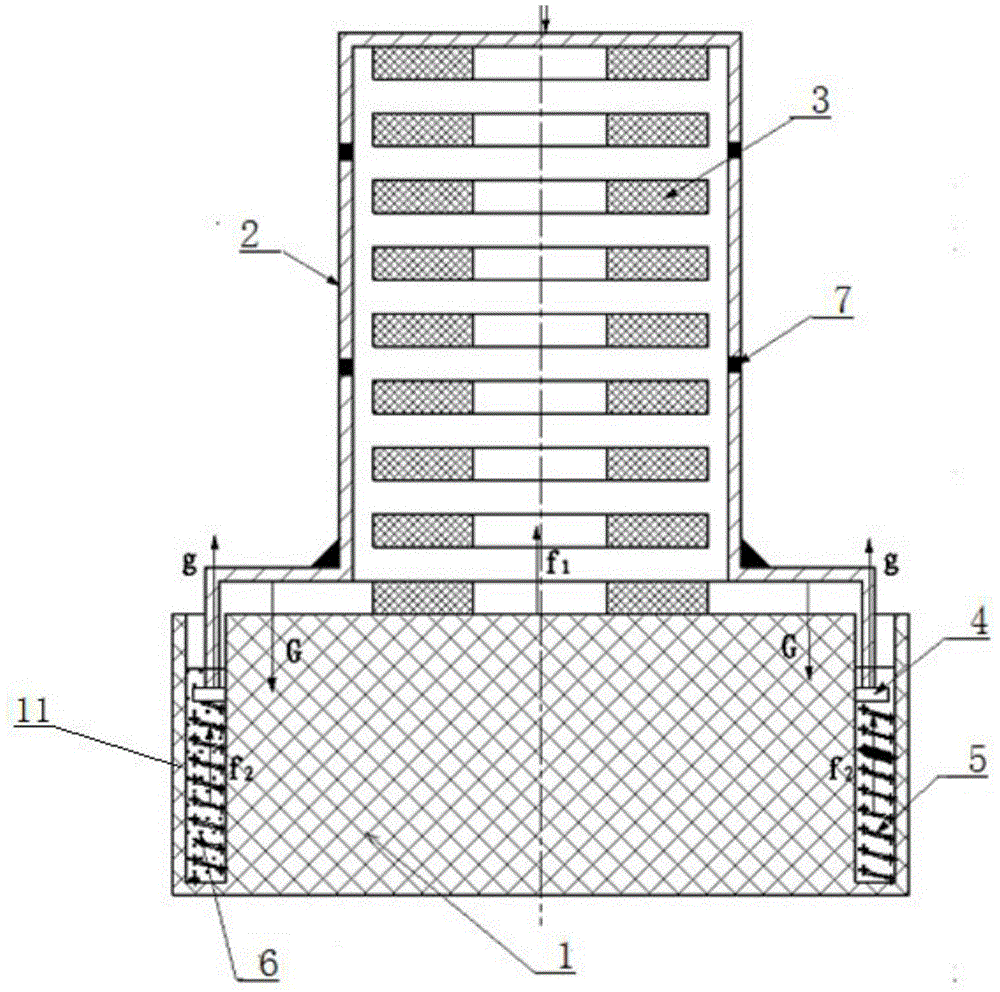

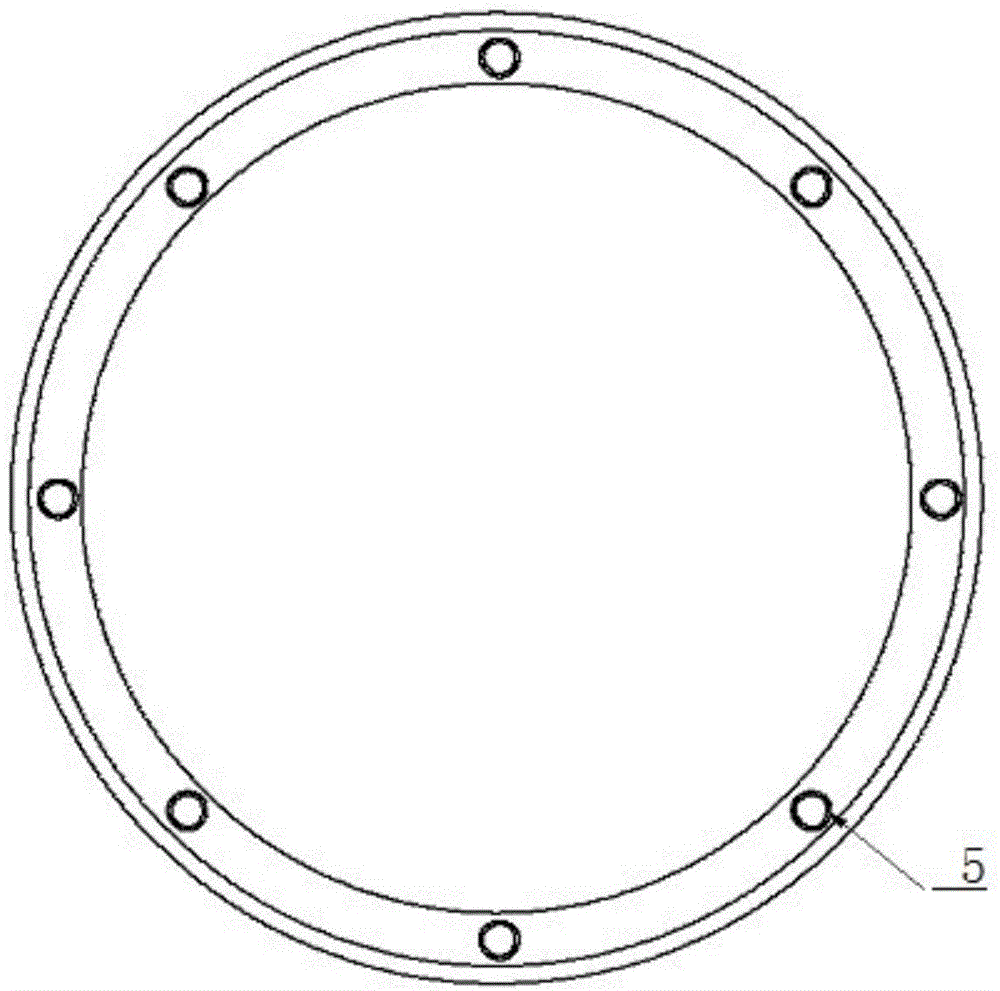

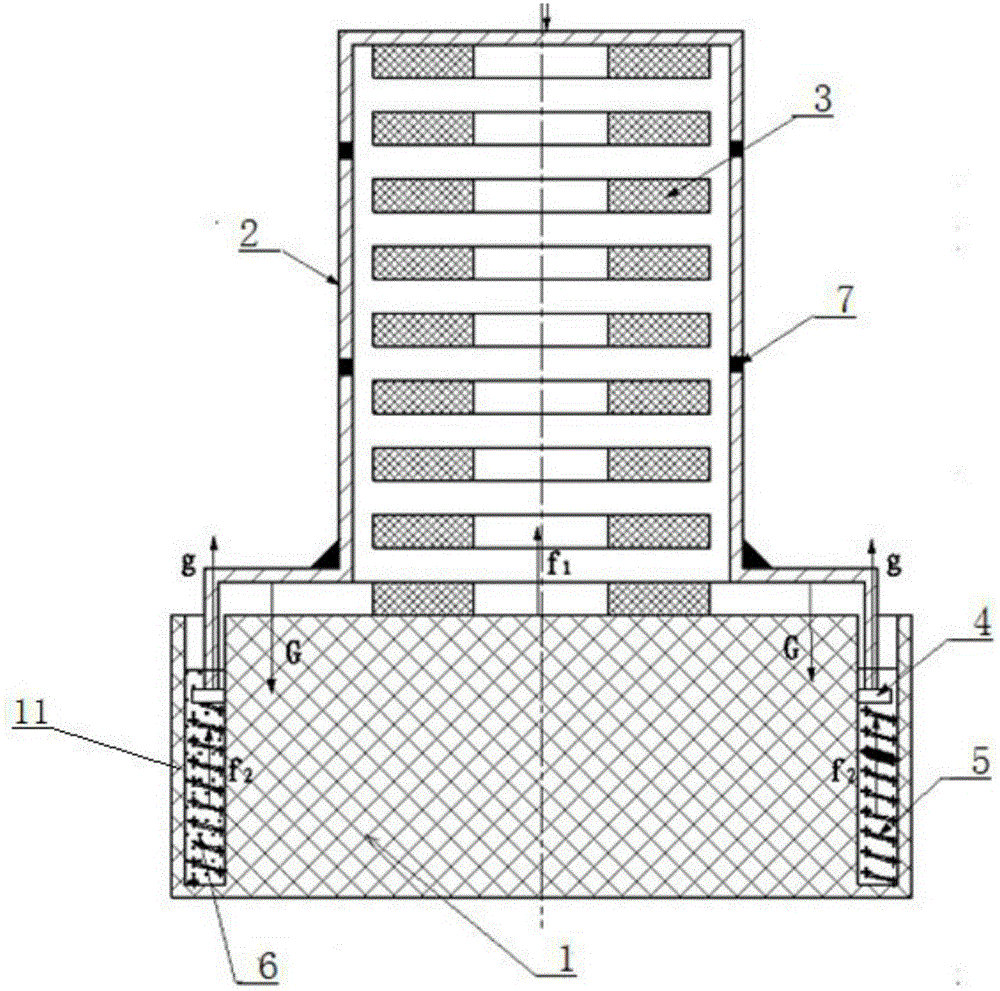

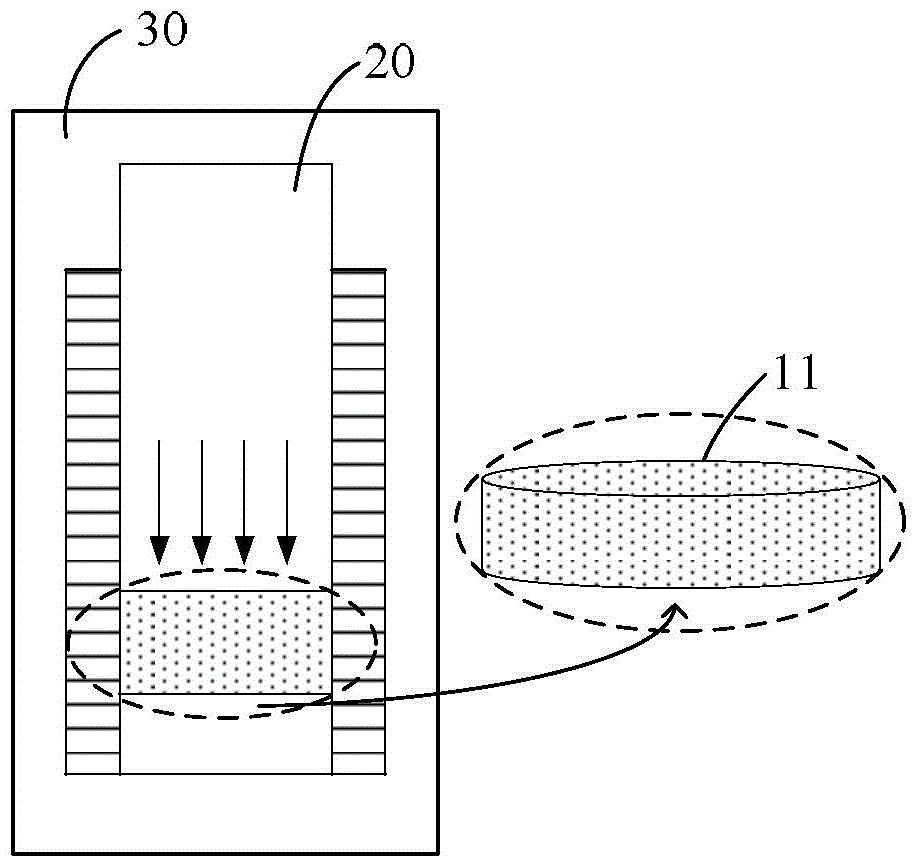

A bell type sintering box protection device

The invention discloses a bell-jar type sintering tank protecting device, and relates to bell-jar type sintering equipment. The device comprises a base (1), a sintering tank (2) and a graphite disc (3), wherein the graphite disc (3) is arranged in the sintering tank (2), the sintering tank (2) is provided with welding points (6), the edge of the base (1) is provided with a water tank (7), the bottom of the sintering tank (1) is provided with a cushion plate (4), the cross section of the cushion plate (4) is in an inverted U shape, the cushion plate (4) is arranged in the water tank (7), and sealing water (5) is arranged between the cushion plate (4) and the water tank (7) to realize the buffering function. The device has the advantages that by utilizing the compression and expansion of the sealing water (5), the phenomena of the cracking of the welding points (6), the lengthening of the jar body and the like due to the high-temperature expansion or low-temperature shrinkage of the sintering tank (2) are avoided, and the phenomena of the blocking of the resetting of a sintering transverse beam, the oxidization of products, the sintering of waste products and the like, caused by the gas leakage of the sintering tank (2) and the lengthening of the sintering tank body are avoided; the phenomenon of pressure not being applied to parts during sintering is avoided; meanwhile, multiple potential safety hazards are omitted.

Owner:贵州新安航空机械有限责任公司

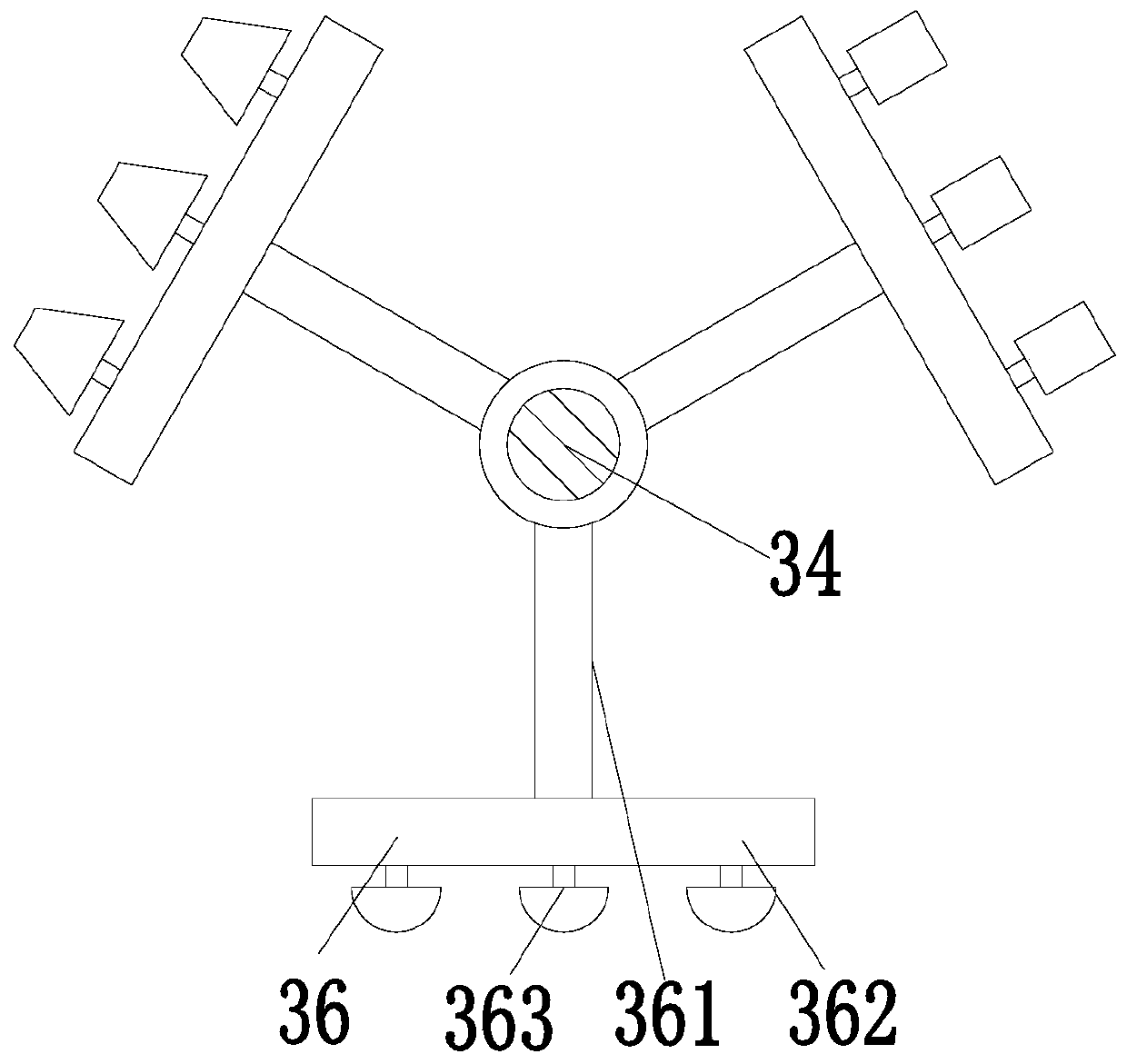

Shock absorber for rotational joint and shock absorption method thereof

PendingCN112855849ASmall rotation errorGuaranteed uniformityRotating vibration suppressionVibration dampersEngineeringShock absorber

The invention provides a shock absorber for a rotational joint and a shock absorption method of the shock absorber. The shock absorber comprises a driving hub and a driven connecting part, and the driving hub is connected with the driven connecting part through at least one strip-shaped plate spring capable of being bent in the circumferential direction of the driving hub. When the plurality of strip-shaped plate springs are arranged, the strip-shaped plate springs are arranged in the circumferential direction of the driving hub at equal intervals, for one thing, the characteristic that the strip-shaped plate springs can elastically deform in the circumferential direction is utilized, when the driven connecting part is impacted, the strip-shaped plate springs deform and absorb vibration and impact energy, for another thing, the characteristic that the rigidity of the strip-shaped plate springs is large is utilized, when the driving hub rotates forwards or reversely to drive the driven connecting part to rotate through the strip-shaped plate springs, the deformation of the strip-shaped plate springs is relatively small, and then the rotation error of the rotational joint can be fully reduced; and when the plurality of strip-shaped plate springs are arranged, the strip-shaped plate springs are arranged in the circumferential direction of the driving hub at equal intervals, and the shock absorption uniformity between the driving hub and the driven connecting part is further guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Magnesium oxide whisker/montmorillonite modified denture resin base material and preparation method thereof

InactiveCN108794961AIncrease layer spacingFully evenly dispersedDental prostheticsResin matrixIon exchange

The invention discloses a magnesium oxide whisker / montmorillonite modified denture resin base material and a preparation method thereof. After montmorillonite is pretreated, the crystal layer spacingis increased; then the montmorillonite is further modified by using modified magnesium oxide whisker; the modified magnesium oxide whisker and organic molecules enter a part between montmorillonite layers by using the ion exchange action, so that the interlamellar spacing of the montmorillonite is enlarged. The montmorillonite is enabled to be fully and uniformly dispersed in a resin matrix; the physical property of a composite material is enhanced and the condition of local stress imbalance is avoided; meanwhile, the phenomena of denture matrix cracking and the like due to stress imbalance are avoided, so that the service life of a denture matrix is prolonged.

Owner:蚌埠佳美仕义齿有限公司

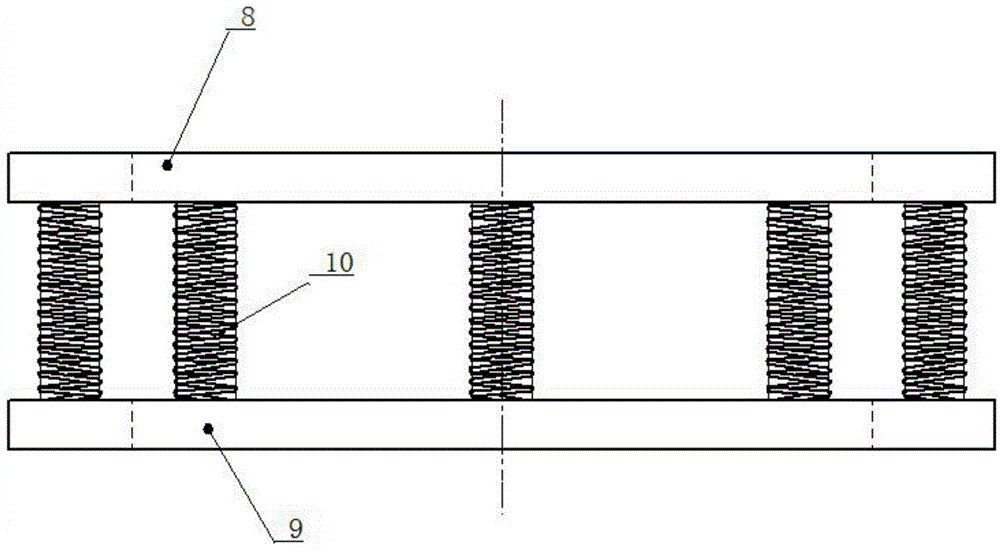

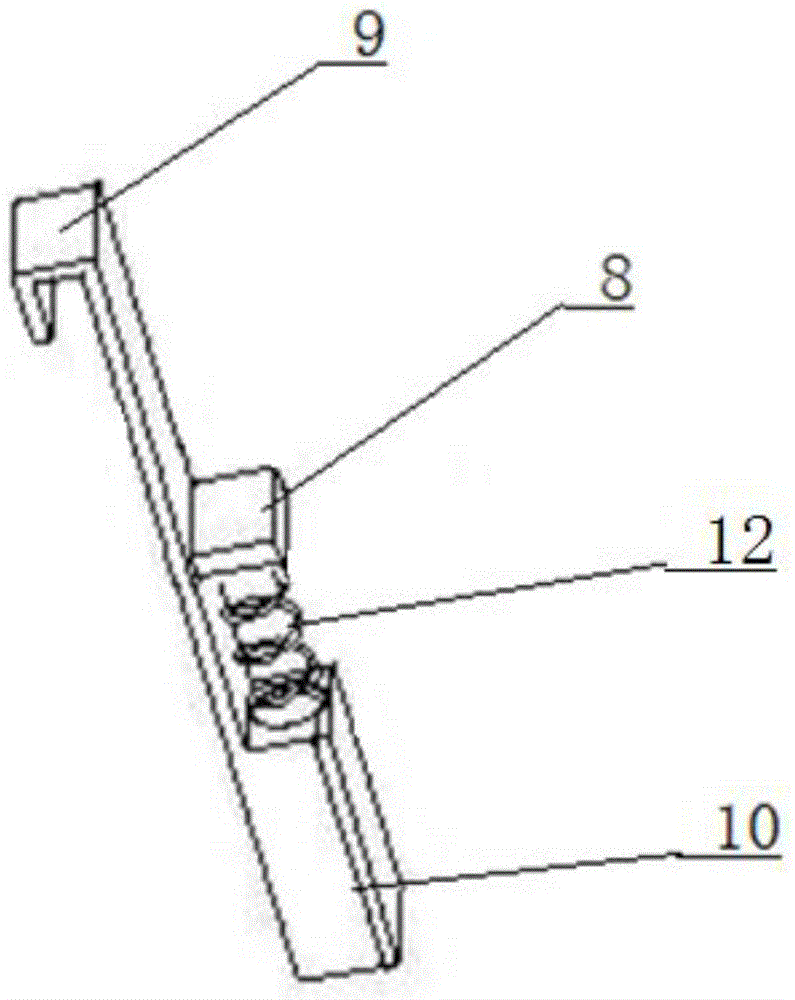

A fixed spring protection device for a bell-type sintering box

ActiveCN103557690BPrevent cracks etc.Avoid phenomena such as crackingBell type furnacesGraphiteBell jar

The invention discloses a fixing type spring protection device of a bell-jar type sintering tank, and belongs to bell-jar type sintering equipment. The device comprises a base (1), a sintering tank (2) and a graphite disc (3), wherein the graphite disc (3) is arranged in the sintering tank (2), and a water tank is arranged on the base (1). The sintering tank (2) is protected by the storage and releasing of energy through a fixing type spring (5) and sealing water (6), so the phenomena of the bursting of the sintering tank due to expansion, or the lengthening of the sintering tank, the cracking of welding points and the like due to the action of own gravity during shrinkage are avoided.

Owner:贵州新安航空机械有限责任公司

A multifunctional foot cleaning and massage device

ActiveCN104758165BClean thoroughlyGood scrubbing functionDevices for pressing relfex pointsBathroom accessoriesPhysical medicine and rehabilitationMedicine

The present invention relates to a life aid, and discloses a multi-functional foot cleaning and massage device, which includes a base and a foot arranged below it, the base is hollow and the surface is symmetrically provided with pedal holes; the two sides of the pedal hole are Foot pedals are symmetrically embedded respectively, and a foot massage device is arranged on the foot pedal; a support column is arranged under the base; a bottom plate is arranged at the bottom of the base; the foot massage device includes, arranged on the foot pedal The toe scrubbing device, the sole of the foot massage device nested in the pedal, and the acupuncture points movably arranged under the pedal; correspondingly, the pedal is provided with an acupuncture point hole. The present invention aims to provide a multifunctional foot cleaning and massage device to solve the problems encountered in the cleaning, nursing and drying process of feet during bathing. It does not need to bend down and effectively protects the elderly, children, pregnant women and obese people. Avoid slipping hazards in the bathroom.

Owner:JIAXING RIFENG METAL PROD CO LTD

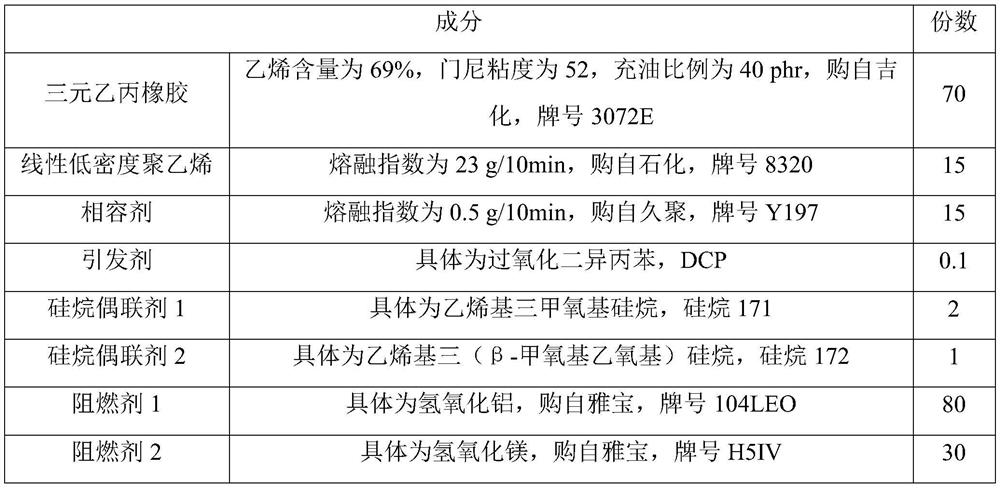

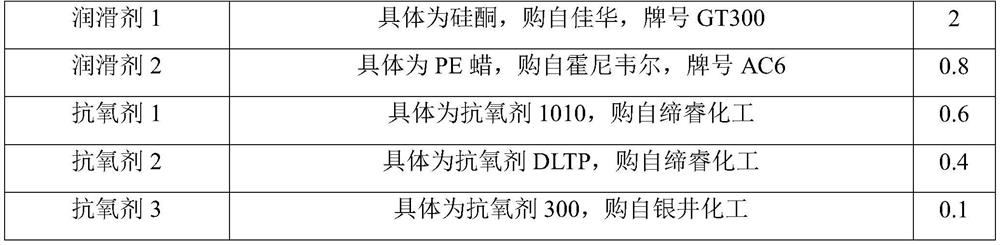

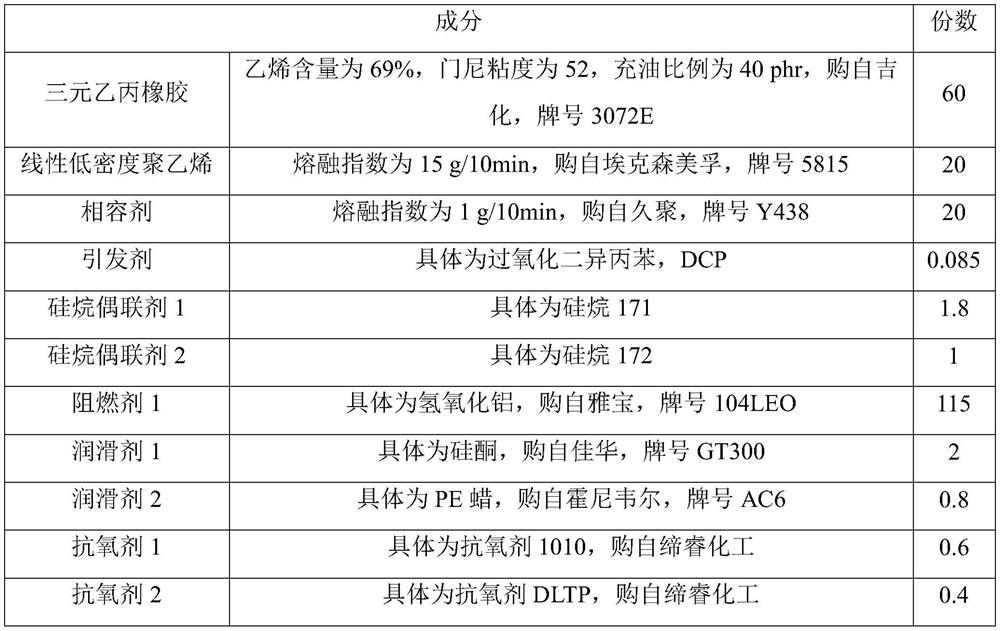

Anti-bending halogen-free flame-retardant sheath material for elevator flat cable as well as preparation method and application of bending-resistant halogen-free flame-retardant sheath material

ActiveCN113637265ANarrow the interface boundaryAvoid phenomena such as crackingRubber insulatorsLinear low-density polyethylenePolymer science

The invention discloses an anti-bending halogen-free flame-retardant sheath material for an elevator flat cable as well as a preparation method and application of the anti-bending halogen-free flame-retardant sheath material. The anti-bending halogen-free flame-retardant sheath material comprises the following raw materials: ethylene-propylene-diene monomer, a compatilizer, a flame retardant, a lubricant and an antioxidant, the ethylene content of the ethylene-propylene-diene monomer is 65-75%, the oil charge ratio is greater than or equal to 40 phr, and the Mooney viscosity is 40-75. The sheath material further comprises linear low density polyethylene, an initiator and a silane coupling agent. The sheath material is prepared by partially or completely grafting the linear low density polyethylene and the ethylene propylene diene monomer with the silane coupling agent under the action of the initiator before extrusion, and then conducting blending and extruding with other raw materials, or is prepared by subjecting all the materials in the raw materials to mixing, banburying and reaction and then conducting extruding. A sheath for the elevator flat cable prepared from the sheath material is simple in material formula, easy to process and low in cost, and particularly has excellent wear resistance, halogen-free flame retardance, high and low temperature resistance, excellent flexibility, excellent mechanical property and the like.

Owner:苏州通优新材料科技有限公司

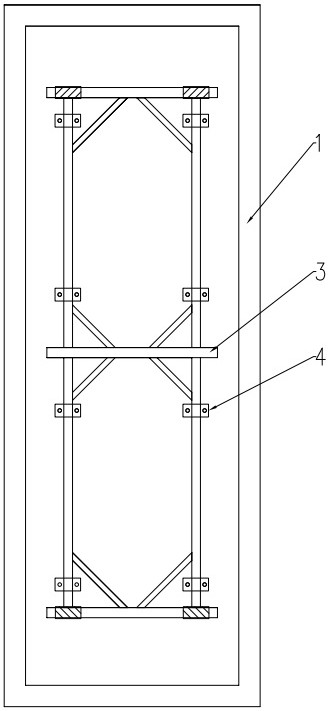

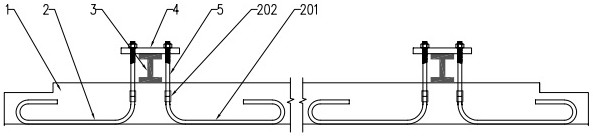

Hoisting structure of UHPC short rib precast slab

PendingCN112627053AAvoid difficult demouldingIncrease stiffnessBridge structural detailsBridge erection/assemblyStructural engineeringArchitectural engineering

The invention discloses a hoisting structure of a UHPC short rib precast slab, which comprises a UHPC short rib precast slab, a plurality of internal thread hoisting connecting devices are symmetrically embedded in the upper plane of the UHPC short rib precast slab with the central axis as the symmetry axis, and a rigid hanging bracket is arranged on the upper plane of the UHPC short rib precast slab and tightly attached to the UHPC short rib precast slab. The rigid hanging bracket is connected with the UHPC short rib precast slab into a whole after being connected with the internal thread hoisting connecting device through the connecting rod, and hoisting equipment hooks the rigid hanging bracket to hoist the UHPC short rib precast slab. According to the hoisting structure of the UHPC short rib precast slab, the cross arm, the screw rod and the internal thread hoisting connecting device pre-buried in the UHPC short rib precast slab are closely connected between the rigid hanging bracket and the UHPC short rib precast slab, and the rigid hanging bracket and the UHPC short rib precast slab are connected into a whole, so that the rigidity of the UHPC short rib precast slab is enhanced; and the phenomena of difficult demolding, cracking of the bottom of the prefabricated slab and the like caused by too large deformation of the UHPC short rib prefabricated slab in the hoisting process are avoided.

Owner:湖南中路华程桥梁科技股份有限公司 +1

A hook-type spring protection device for a bell-type sintering box

ActiveCN103557702BPrevent cracks etc.Avoid phenomena such as crackingBell type furnacesGraphiteEnergy storage

The invention discloses a hook-type spring protection device for a bell-type sintering box, which belongs to bell-type sintering box equipment, and includes a base (1), a sintering box (2) and a graphite disk in the sintering box (2) (3), mainly through the hook spring (5) and sealing water (6) to store and release energy to protect the sintering box (2), avoiding the expansion and cracking of the sintering box, or being affected by its own gravity when shrinking Effect, elongation of the sintering box and cracking of welding points.

Owner:贵州新安航空机械有限责任公司

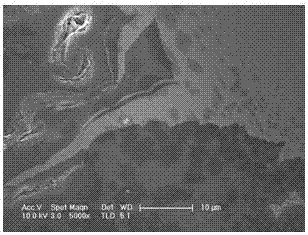

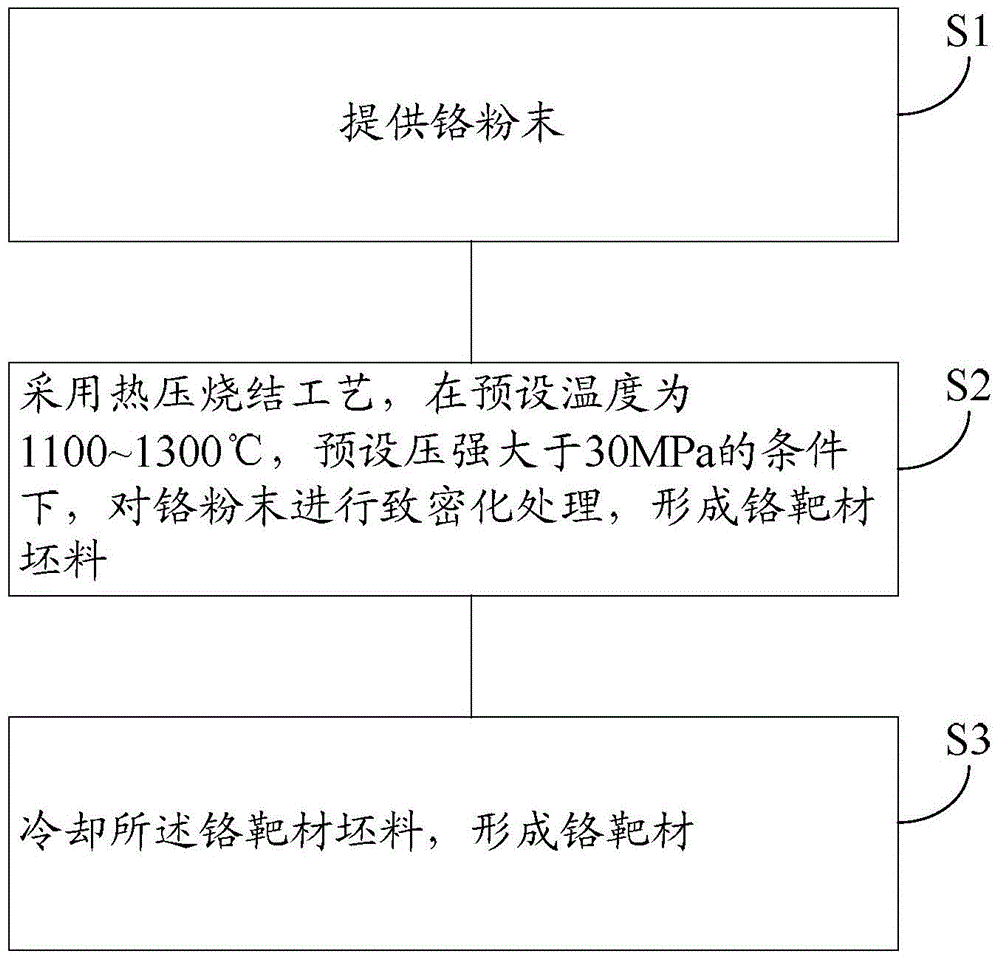

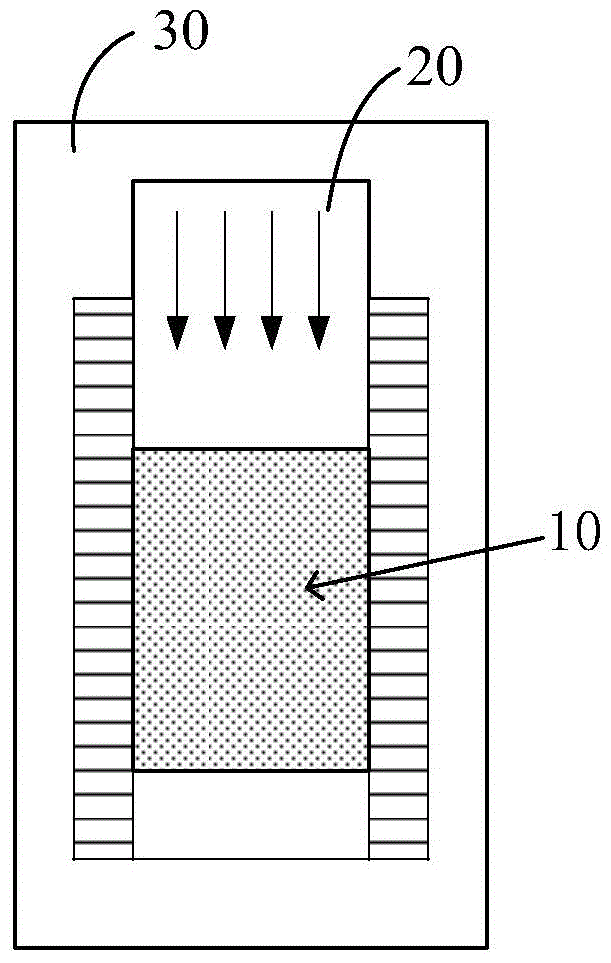

Chromium target manufacturing method

ActiveCN104439246BIncreased dislocation densityThe total volume of voids is reducedVacuum evaporation coatingSputtering coatingProcess equipmentProcess conditions

The invention discloses a chromium target production method. The method comprises the following steps: a hot-pressed sintering process is adopted to perform the compactness treatment for chromium powder to form a chromium target blank under the conditions of a preset temperature of 1100-1300 DEG C and a preset pressure higher than 30 MPa; and the chromium target blank is cooled to form a chromium target. The chromium target production method can form the chromium target with the compactness up to 99.5%, the average grain size smaller than 50 microns and the uniform structure. Compared with a hot isostatic pressure process, the process equipment requirements and the process conditions of the chromium target production process are reduced, and the process cost is saved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Sliding disc type axial plunger pump

PendingCN114562437AReduce axial forceOil film stabilizationPositive displacement pump componentsPositive-displacement liquid enginesBearing surfacePlunger pump

The sliding disc type axial plunger pump comprises a flow distribution sliding disc pair, a plunger pair and a flow distribution pair, the flow distribution sliding disc pair comprises a swash plate and a sliding disc supported on the swash plate, the sliding disc is of an integral structure, kidney-shaped holes communicated with center holes of plungers are formed in the sliding disc, and the plunger pairs are arranged in the kidney-shaped holes. A low-pressure oil distribution hole serving as an oil inlet channel is formed in the portion, opposite to the low-pressure plunger hole, of the swash plate supporting face, static pressure supporting is formed by the portion, opposite to the high-pressure plunger hole, of the swash plate supporting face and a kidney-shaped hole of the sliding plate, and the low-pressure oil distribution hole is communicated with a shell cavity through an oil inlet groove formed in the swash plate. Low-pressure oil enters a plunger hole of the cylinder body from a low-pressure flow distribution opening and an oil inlet groove or a groove-shaped low-pressure opening of the swash plate in a double-way mode, high-pressure oil is discharged from a high-pressure flow distribution opening of the flow distribution plate or a groove-shaped high-pressure opening of the swash plate in a single-way mode, and suction and discharge of hydraulic oil are achieved. The axial stress of the bearing can be further reduced, the stress working condition of the bearing is improved, the self-suction capacity is improved, the oil temperature is reduced, the working reliability of the plunger pump is improved, and the working life of the plunger pump is prolonged.

Owner:钟彪

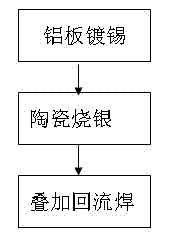

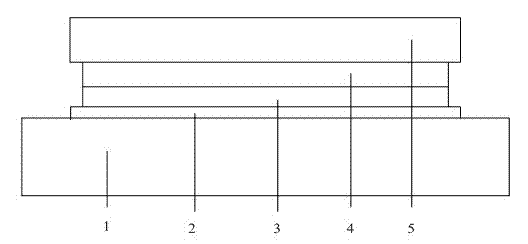

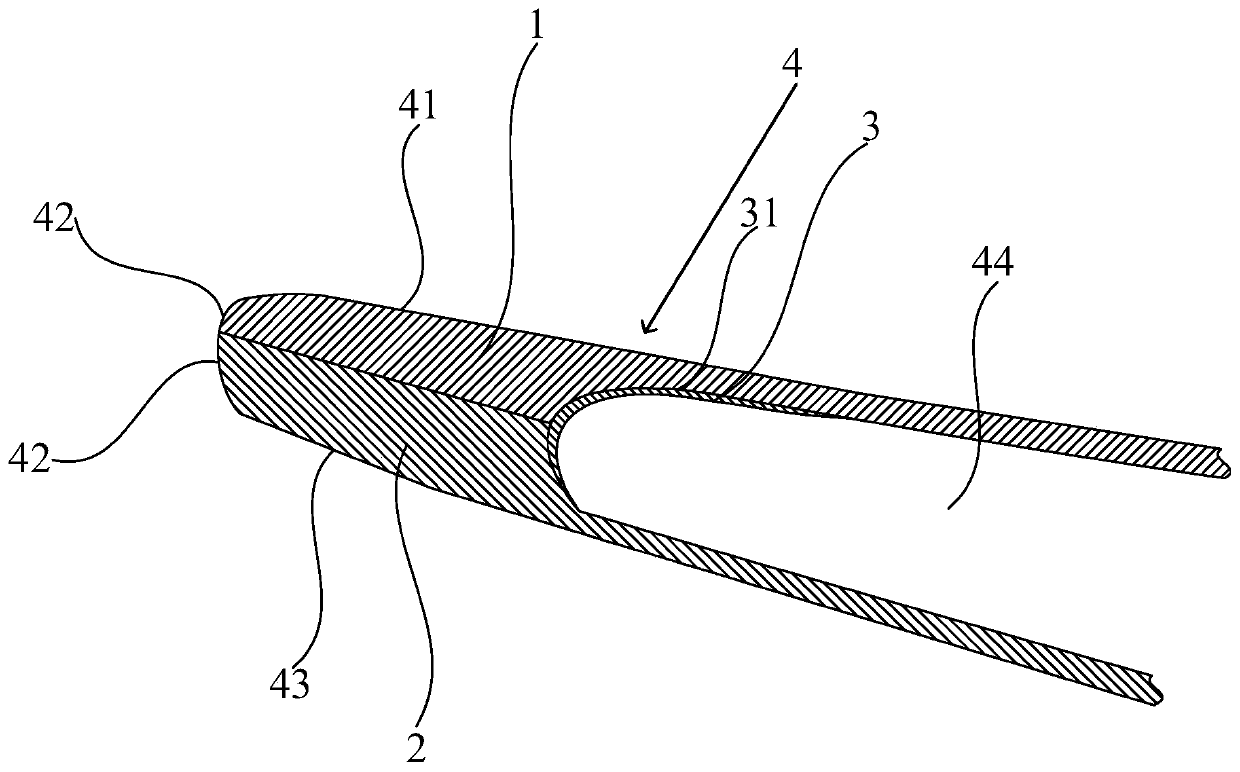

Superposition method for welding ceramic and aluminum

InactiveCN102303174BAvoid phenomena such as crackingSimple processSoldering apparatusCeramic sinteringTinning

Owner:SHANGHAI ZENGRONG DATA TECH CO LTD

Inorganic nonmetallic light fireproof thermal insulation board

InactiveCN102584121BChange the form of external insulationChange fire resistanceThermal insulationNational standard

The invention discloses an inorganic nonmetallic light fireproof thermal insulation board, which comprises raw material components in percentage by weight as follows: 45 to 55 percent of quartz sand, 12 to 16 percent of lime, 24 to 37 percent of cement, 5 percent of gypsum, 0.15 to 0.16 percent of aluminum powder and 0.1 to 0.3 percent of stabilized and enhanced type admixtures. According to the invention, an optimized basic formula is matched with the stabilized and enhanced type admixtures, so that products can be steadily produced and the strength of masonry blocks of the products reaches up to more than 1.8MPa, which is higher than the strength required by a class B03 product standard in the national standard. The inorganic nonmetallic light fireproof thermal insulation board has the advantages that the fireproof requirement is satisfied, the performance is steady, the construction cost is moderate, the outer thermal insulation manner of the prior building can be fundamentally changed from a sticky outer thermal insulation layer manner to a single material thermal insulation manner, and the occurrence of the phenomena of cracking is prevented; and the inorganic nonmetallic light fireproof thermal insulation board can have the same service life as the building.

Owner:天津滨海天筑永利建材有限公司

Blade tip trailing edge enhancing device and wind power generation blade with same

PendingCN109973293AImprove structural strengthAvoid phenomena such as crackingMachines/enginesWind energy generationEngineeringTrailing edge

The invention discloses a blade tip trailing edge enhancing device and a wind power generation blade with same. The device comprises a first trailing edge component, a second trailing edge component and an enhancing member, the first trailing edge component is bonded to the second trailing edge component, a blade tip end is formed between the first trailing edge component and the second tailing edge component, the outer surface of the blade tip end is provided with a tip end face, a windward face and a leeward face, the two ends of the tip end face are connected with the windward face and theleeward face respectively, the blade tip end is internally provided with a cavity, the enhancing member is located in the cavity, the outer side of the enhancing member is provided with a connecting face, the connecting face is connected with the first trailing edge component and the second tailing edge component, and the connecting face corresponds to the tip end face and the windward face. The wind powder generation blade comprises the blade tip trailing edge enhancing device, the cracking and the like of the blade tip end is effectively avoided, and therefore the stability of the blade tiptrailing edge enhancing device is greatly improved.

Owner:SHANGHAI AEOLON WIND ENERGY TECH DEVGRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com