Magnesium oxide whisker/montmorillonite modified denture resin base material and preparation method thereof

A technology of magnesium oxide whiskers and montmorillonite, which is used in dental prosthesis, medical science, dentistry, etc., can solve the problem that the mechanical properties and light transmittance of the base material cannot be balanced, avoid fly ash, and expand the interlayer spacing. , the effect of promoting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

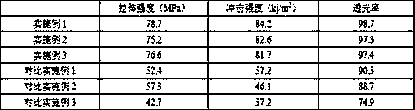

Examples

Embodiment 1

[0017] A denture resin base material modified by magnesium oxide whiskers / montmorillonite is made from the following raw materials in parts by weight:

[0018] Montmorillonite 10, sodium lauryl sulfate 2, modified magnesium oxide whiskers 5, methyl methacrylate 40, ammonium persulfate solution 5, tray powder 100, tray water 40;

[0019] The concentration of the ammonium persulfate solution is 20%, and both the tray powder and the tray water are thermosetting type.

[0020] Further, its preparation method comprises the following steps:

[0021] (1) Place the montmorillonite at -25°C to freeze-dry for 1 hour, take it out, and ball mill it for 10 minutes to peel off the montmorillonite initially, then add the montmorillonite to distilled water 10 times its volume, raise the temperature to 50°C, and rotate at 800rpm After stirring for 20 minutes under the same conditions, raise the temperature until the solution boils, reduce the speed to 500rpm, continue to stir for 10 minutes, ...

Embodiment 2

[0027] A denture resin base material modified by magnesium oxide whiskers / montmorillonite is made from the following raw materials in parts by weight:

[0028] Montmorillonite 15, sodium lauryl sulfate 3, modified magnesium oxide whiskers 10, methyl methacrylate 45, ammonium persulfate solution 8, tray powder 110, tray water 50;

[0029] The concentration of the ammonium persulfate solution is 30%, and both the tray powder and the tray water are thermosetting type.

[0030] Further, its preparation method comprises the following steps:

[0031] (1) Place the montmorillonite at -28°C to freeze-dry for 2 hours, take it out, and ball mill it for 20 minutes to peel off the montmorillonite initially, then add the montmorillonite to distilled water 15 times its volume, raise the temperature to 55°C, and rotate at 900rpm After stirring for 25 minutes under the same conditions, raise the temperature until the solution boils, reduce the rotation speed to 600rpm, continue to stir for 1...

Embodiment 3

[0037] A denture resin base material modified by magnesium oxide whiskers / montmorillonite is made from the following raw materials in parts by weight:

[0038] Montmorillonite 20, sodium lauryl sulfate 5, modified magnesium oxide whiskers 15, methyl methacrylate 0, ammonium persulfate solution 12, tray powder 120, tray water 60;

[0039] The concentration of the ammonium persulfate solution is 50%, and both the tray powder and the tray water are thermosetting type.

[0040] Further, its preparation method comprises the following steps:

[0041] (1) Place the montmorillonite at -30°C for 3 hours, take it out and ball mill it for 30 minutes to peel off the montmorillonite initially, then add the montmorillonite to distilled water 20 times its volume, raise the temperature to 60°C, and rotate at 1000rpm After stirring for 30 minutes under the same conditions, raise the temperature until the solution boils, reduce the rotation speed to 700rpm, continue to stir for 20 minutes, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com