Patents

Literature

88results about How to "Fully evenly dispersed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and application of MOF-derived porous carbon/graphene composite electrode material

ActiveCN108328706AFully evenly dispersedEvenly dispersedDispersed particle separationWater/sewage treatmentPorous carbonFreeze-drying

The invention discloses preparation and an application of an MOF-derived porous carbon / graphene composite electrode material. The preparation method comprises the steps as follows: (1) a clean container is taken, a graphene or graphene oxide dispersion liquid is added, then, MOFs crystal powder is added, the container is placed on a vortex mixer for continuous mixing after being sealed, the rotating speed is adjusted repeatedly from zero to the highest rotating speed, so that a sample is fully oscillated in the vertical direction, formation of a graphene sheet or graphene oxide sheet self-assembly three-dimensional structure and full and uniform dispersion of MOFs crystals in the three-dimensional frame structure are promoted, and finally, graphene / MOF porous aerogel is obtained through freeze drying; (2) the aerogel is subjected to high-temperature roasting in the N2 atmosphere and a carbonized product is obtained; (3) the carbonized product is subjected to acid treatment and the MOF-derived porous carbon / graphene composite electrode material is obtained. The MOF-derived porous carbon / graphene composite electrode material is applied in CDI or MCDI desalination and has good effects.

Owner:ZHEJIANG UNIV OF TECH

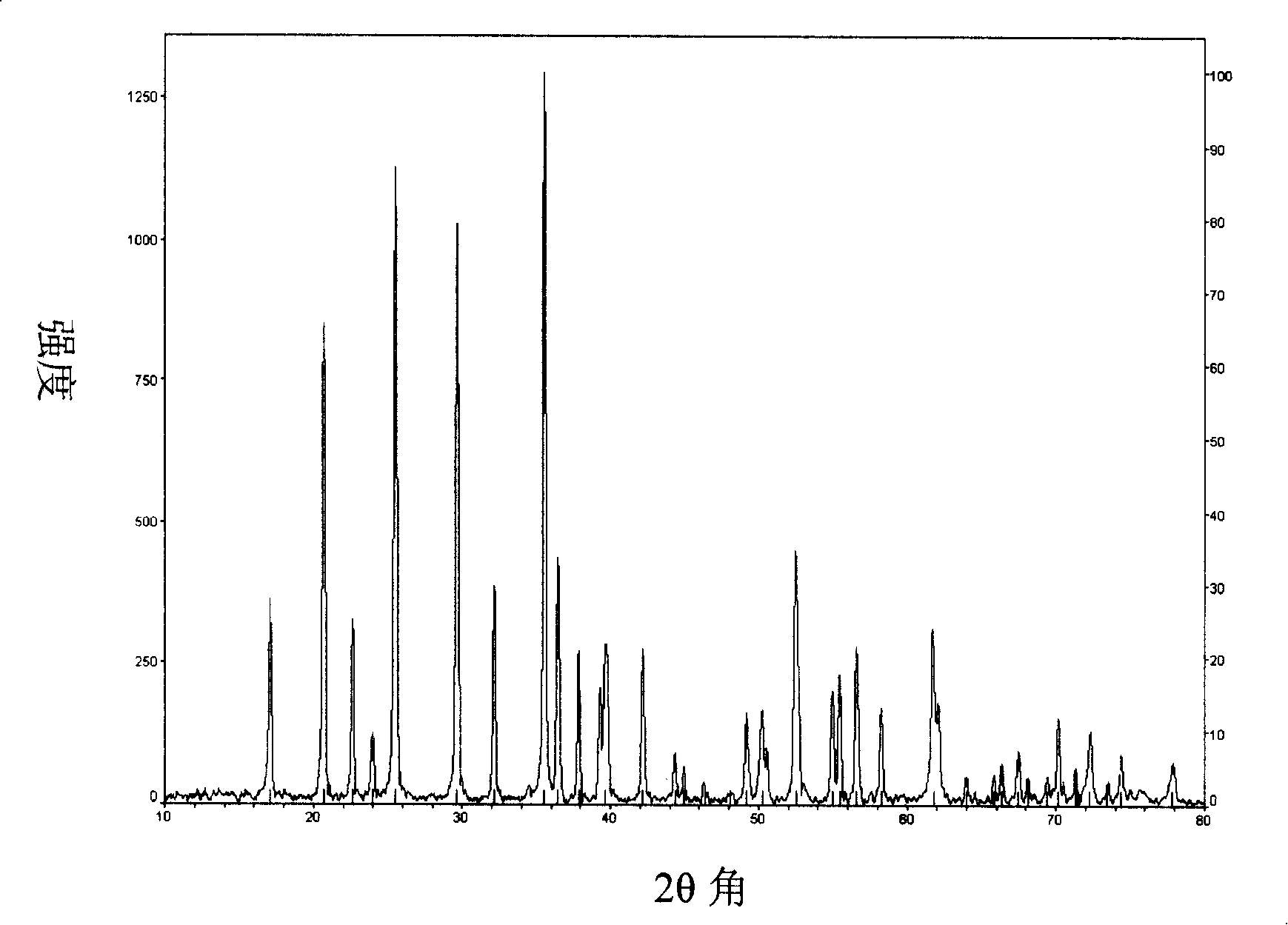

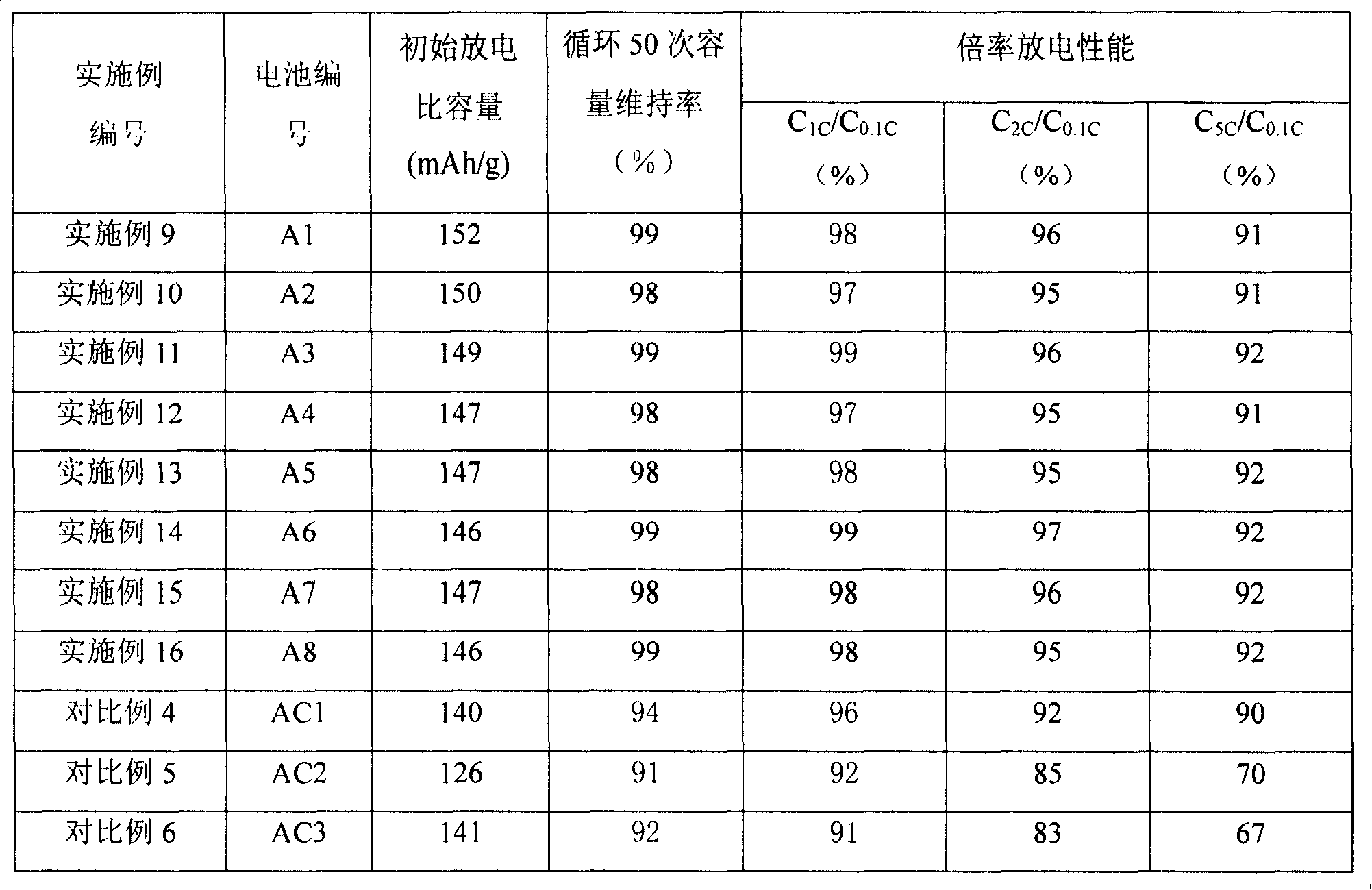

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

ActiveCN101209827AImprove conductivityImprove electrical conductivityCell electrodesPhosphorus compoundsLithium compoundAnode

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the sintering method comprises the step: the mixture that contains lithium compound, iron compound, phosphorus compound and partial carbon source additive is sintered at a first constant sintering temperature, then a mixture of the product acquired at the first sintering temperature and the residual carbon source additive is sintered at a second constant sintering temperature, and the second sintering temperature is at least 100 DEG C higher than the first sintering temperature. The batteries made of the lithium iron phosphate prepared by the method of the invention have markedly improved discharge performance at high current.

Owner:BYD CO LTD

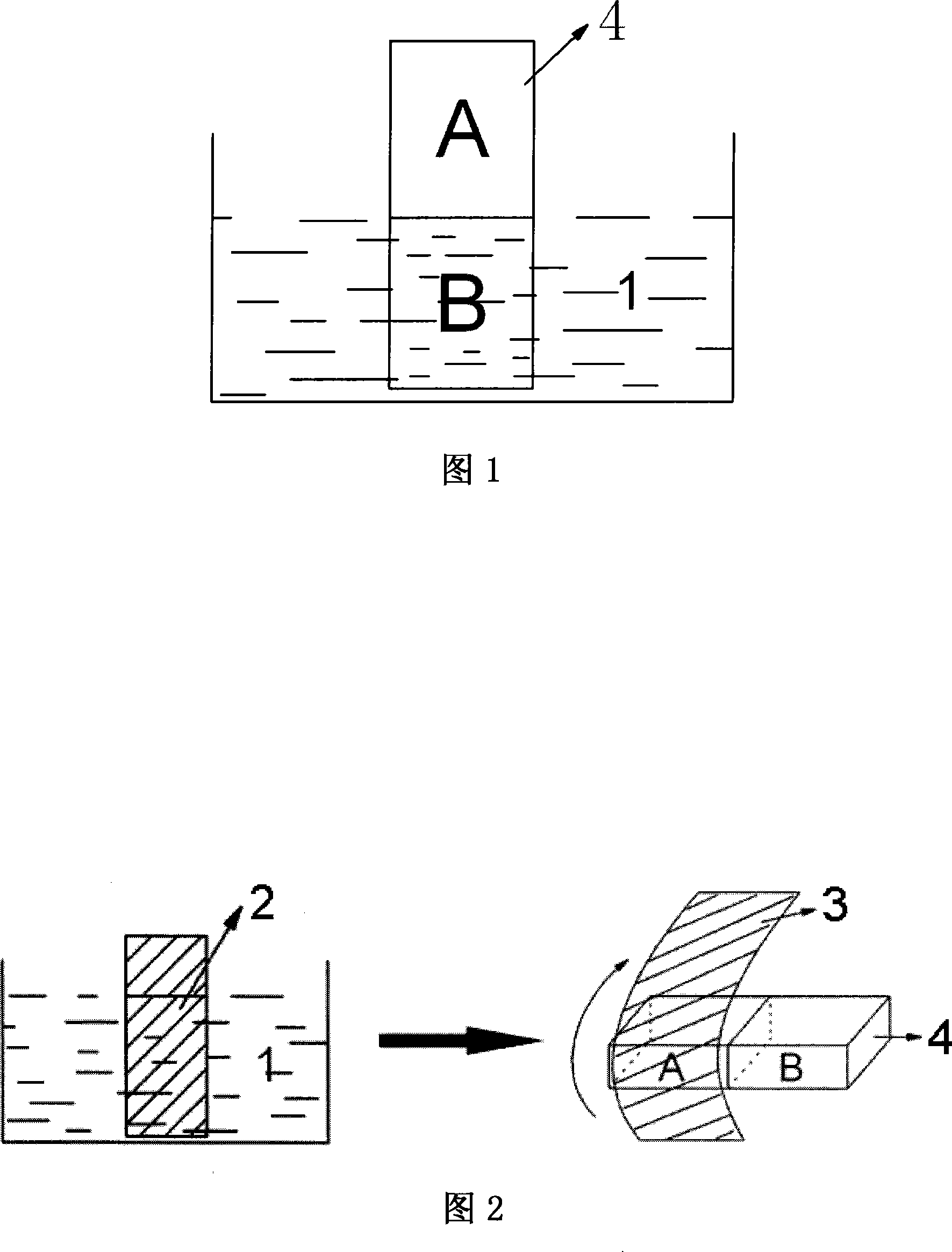

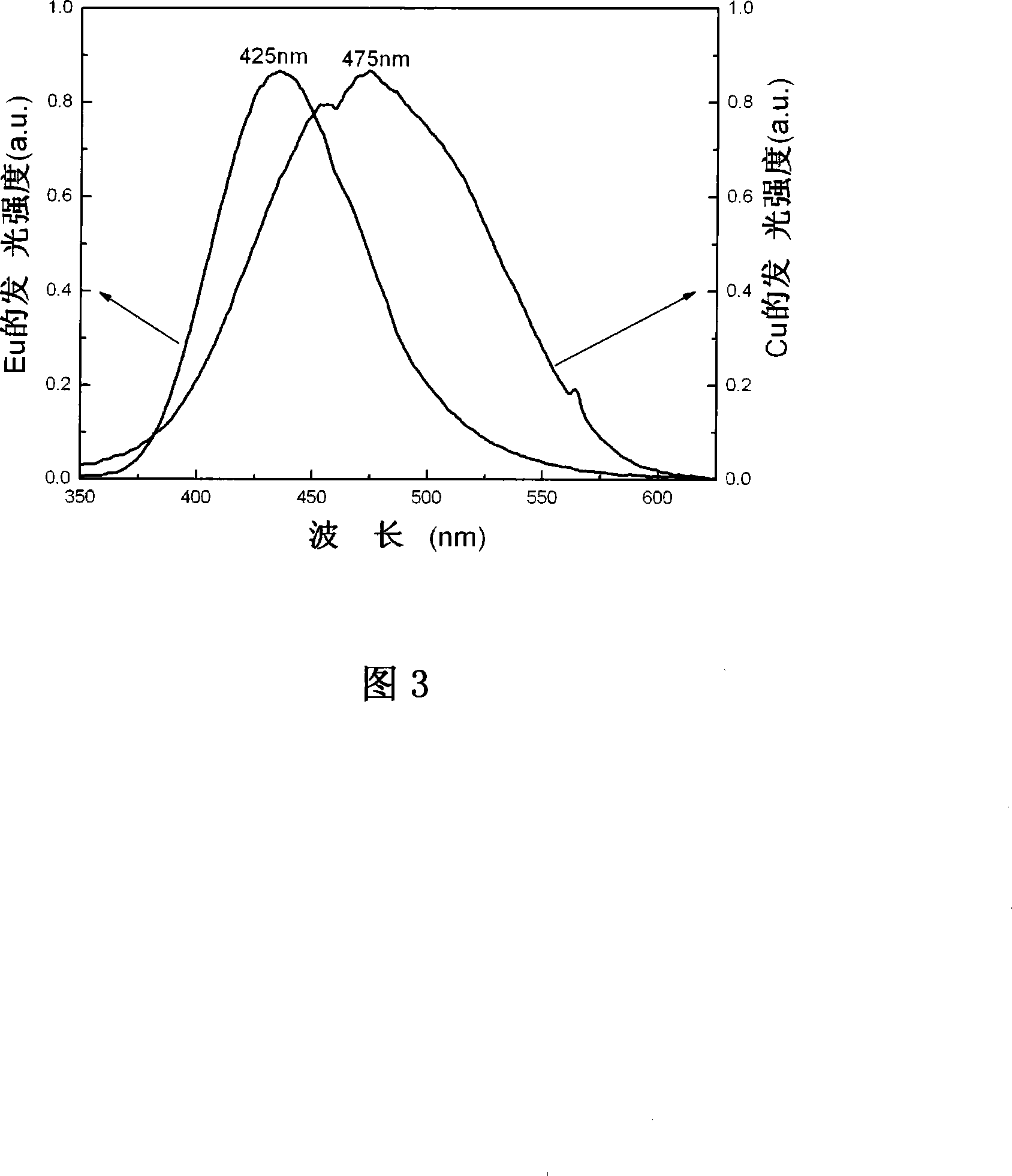

Method for manufacturing integrated color luminous vycor glass

A method for manufacturing integral chromatic luminous vycor glass, which is characterized in that the method comprises: (1) preparing cellular glass, (2) preparing rare earth with certain concentration or transition metal luminous solion, (3) introducing the rare earth or transition metal luminous solion in the cellular glass by employing the segmental doping method, (4) drying the cellular glass doped with the rare earth or transition metal luminous solion in the air at a temperature of 200-800DEG C and (5)placing the dried cellular glass doped with the luminous solion in a high temperature furnace and eliminating micropores to form dense, transparent and integral chromatic luminous vycor glass via solid-phase sintering of air at a temperature of 1100-1250DEG C or reducing atmosphere. The glass of the invention is colorless in appearance, dense and transparent, and can emit light with a plurality of colors when being shined by ultraviolet lamp. The method is simple in manufacturing process, needless in binding agent and low in cost, and has perfect optical property, chemical stability and mechanical strength, which are similar to that of quartz glass.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Nanometer calcium carbonate reinforced and toughened plastic master batch and preparation method thereof

The invention discloses a nanometer calcium carbonate reinforced and toughened plastic master batch and a preparation method thereof. The master batch consists of nanometer calcium carbonate, micrometer calcium carbonate, metallocene polyethylene, carrier resins and aids, wherein the nanometer calcium carbonate and the micrometer calcium carbonate are blended and added, so that reinforcing and toughening functions of the master batch are enhanced; the metallocene polyethylene has high strength and toughness, so that reinforcing and toughening effects of the master batch can be simultaneously enhanced; and the master batch is prepared by two steps, so that the nanometer calcium carbonate passes through a co-rotating twin screw extruder for two times, the dispersibility of the nanometer calcium carbonate in the master batch is further enhanced, and the reinforcing and toughening functions is fully reflected. The master batch has the advantages that the nanometer calcium carbonate can be fully and uniformly dispersed in the carrier resins, so that the prepared master batch has the peculiar reinforcing and toughening functions of the nanometer calcium carbonate; and the master batch is simple in processing technology and low in cost, the stability, heat resistance and aging resistance of materials can be effectively enhanced, and particularly the plastic strength, the toughness and the surface smoothness are greatly improved.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

A process for washing and removing boron from polysilicon slag by metallurgical method

ActiveCN102259865AFully evenly dispersedImprovement of poor wettability conditionsSilicon compoundsMetallurgical slagMedium frequency

The invention relates to the technical field of metallurgical polycrystalline silicon purification, and in particular relates to a slag washing process for removing boron from metallurgical polycrystalline silicon. The technical schemes are as follows: a metallurgical slag-washing boron removing method is adopted, the same two composite slag agents are pre-melted into a slag agent molten pool, then industrial silicon is added for melting, boron (B) in molten silicon performs oxidation reaction with the slag agent so that boron (B) forms a multi-element slag phase, and boron (B) impurities in silicon are removed by slag-metal separation to obtain solar-grade high-purity polycrystalline silicon with a boron content being 0.15 ppmw. The process provided by the invention has the advantages that: the process is simple to operate, the cost is low, the used devices are formed by combination and transformation of traditional medium-frequency furnaces, the used slag agent can be used repeatedly after adding new SiO2 and CaO, and the process is conducive to large-scale industrial promotion.

Owner:宁夏高创特能源科技有限公司

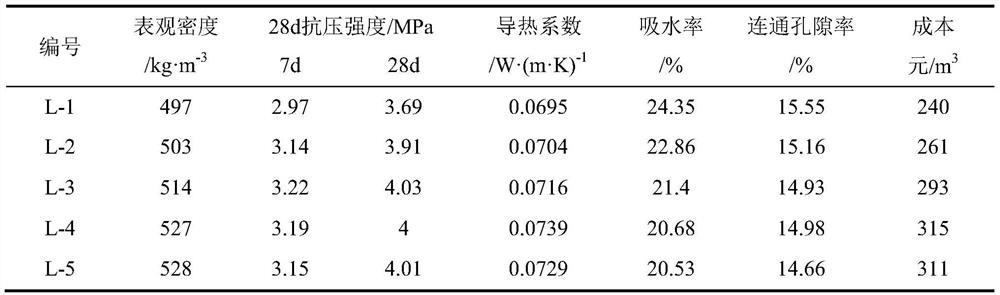

Non-autoclaved lightweight thermal insulation particle aerated concrete block and preparation method thereof

The invention discloses a non-autoclaved lightweight thermal insulation particle aerated concrete block and a preparation method thereof. The aerated concrete block comprises the following components:50 to 100 parts of cement, 0 to 37.5 parts of fly ash, 0 to 12.5 parts of superfine slag powder, 0 to 50 parts of light particles, 2 to 8 parts of a foaming agent, 0 to 5 parts of a coagulation accelerator, 0.025 to 0.175 part of a foam stabilizer, 0.2 to 1.4 parts of a water reducing agent, 0.1 to 0.7 part of a water repellent, 0 to 0.6 part of fibers and 30 to 60 parts of water. The aerated concrete block has the advantages of light weight, heat preservation and insulation, energy conservation, high strength, simple maintenance process and low cost, and solves the problems of non-ideal heatpreservation and insulation performance and complex maintenance process of the existing aerated concrete block.

Owner:CENT SOUTH UNIV +3

Inspection well mouth seat and inspection well with the same and construction, repair method thereof

InactiveCN1876972AGuarantee a smooth relationshipAvoid damageArtificial islandsSewerage structuresRoad surfaceEngineering

The invention relates to a check well ring base at the middle of road, which can reduce the non-uniform surface sink between the well structure and around soil, to cause the damage of around road. Wherein, said invention is an annular element whose rigidity is larger than around soil; its profile of radial wheel is larger than the profile of radial wheel of well wall; the outer side of lower surface is the lower support surface combined with around soil; the inner side of lower surface is molded into one groove; therefore, the well wall that embed into the groove can slide along the axis of well wall. The invention also provides a check well of said well ring base and relative construction.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Preparation method of graphene modified epoxy resin

The invention provides a preparation method of graphene modified epoxy resin. The preparation method comprises the following steps: first mixing a graphene aqueous solution, bisphenol A and epichlorohydrin to obtain a mixed solution; adding an initiator into the mixed solution obtained in the step, and performing the reaction to obtain the graphene modified epoxy resin. By utilizing an in-situ polymerization method, graphene is added at an initial synthetic phase, the surface of the graphene adsorbs epoxy resin molecules, sufficient and uniform dispersion can be realized in an epoxy resin matrix, the agglomeration phenomenon is avoided, and hole and solvent adsorption are reduced, so that the defects after the solidification are reduced, the reinforcing effect of the graphene is maximally realized, and the defects in the prior art that the graphene is easy to agglomerate and poor in compatibility when a graphene / epoxy resin composite material is prepared through a way of directly blending or solution blending graphene and epoxy resin can be effectively overcome.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

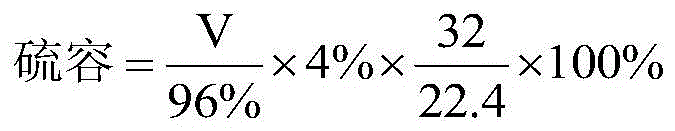

High-sulfur-capacity low-cost desulfurizing agent and preparation method thereof

InactiveCN105664706AHigh strengthImprove water resistanceGas treatmentHydrogen separation using solid contactAlkaline earth metalCoal

The invention discloses a high-sulfur-capacity low-cost desulfurizing agent and a preparation method thereof.The desulfurizing agent comprises the following materials according to parts by weight: 50-95 parts of iron oxide hydroxide, 1-48 parts of an inorganic binding agent and 1-50 parts of an aid, wherein the inorganic binding agent is calcium sulfate and its hydrate and / or alkaline-earth metal hydroxide, and the aid is pulverized coal ash and / or volcanic ash.The preparation method of the desulfurizing agent comprises the following steps: 1), mixing well the iron oxide hydroxide, the inorganic binding agent and the aid to obtain a mixture; 2), adding water to the mixture, and mixing well to obtain strip material to be extruded; 3), extruding the strip material to be extruded to obtain strip material; 4), naturally drying or baking the strip material to obtain the desulfurizing agent.The desulfurizing agent is low in cost and high in sulfur capacity, is high in strength and good in water resistance, is free of argillation and caking during usage and has good environmental and economic benefits.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

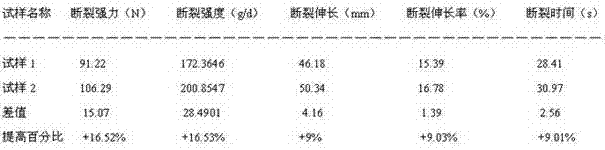

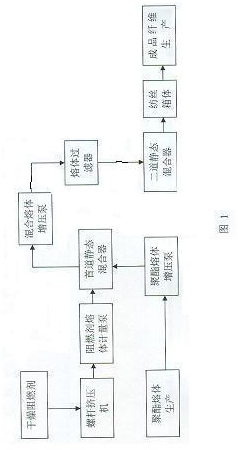

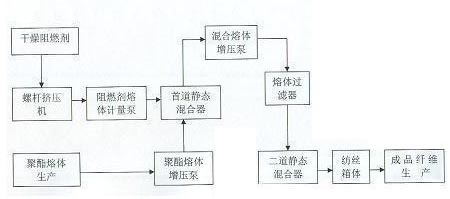

Production method of inflaming retarding hollow polyster fiber

ActiveCN102586907AQuality improvementGood physical propertiesFlame-proof filament manufactureFilament forming substance formingFiberPolymer science

The invention discloses a production method of an inflaming retarding hollow polyster fiber. The production method is characterized by comprising the following process steps of: mixing the polyester raw materials (namely terephthalic acid and ethylene glycol) uniformly in the mole ratio of 1.12:1, conducting esterification and condensation polymerization on the mixture to obtain polyethylene glycol terephthalate melt, and pumping the polyethylene glycol terephthalate melt in a primary-pass static mixer; after a phosphorus flame retardant is heated and dried, pumping by a metering pump an inflaming retarding melt heated and melted in a screw rod extruder into the primary-pass static mixer; mixing the polyethylene glycol terephthalate and the inflaming retarding melt by the primary-pass static mixer to form a mixed melt, processing the mixed melt by a mixed melt boosting pump, pumping the mixed melt by a melt filter and a secondary-pass static mixer in sequence so as to feed the mixed melt in a spinning jet to form small hollow filiform flows, shock-cooling the mixed melt to cure the mixed melt into fibers. The production method has the advantages that the process flow is reasonable, the quality of the fibers can be guaranteed easily, and the inflaming retarding efficiency of the fibers is high.

Owner:JIANGSU DESAI CHEM FIBER

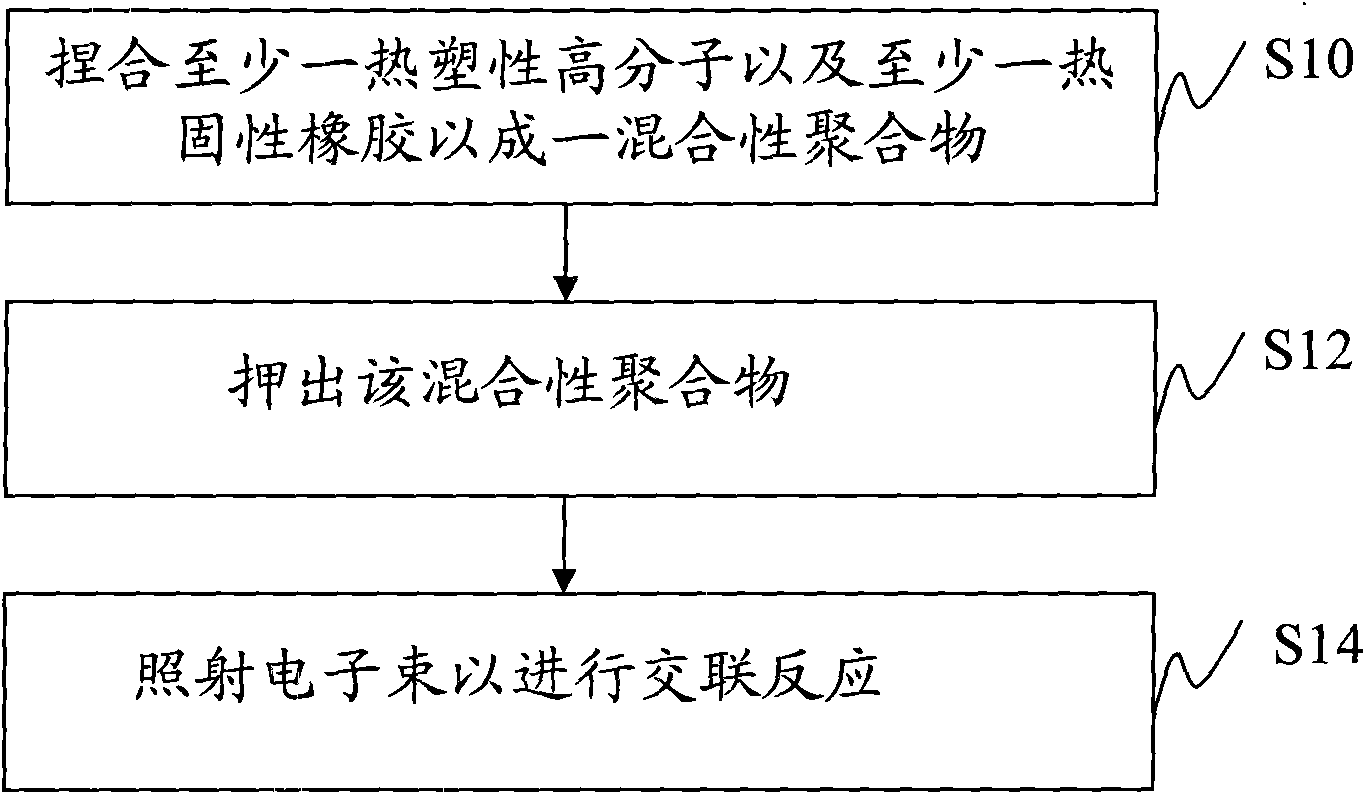

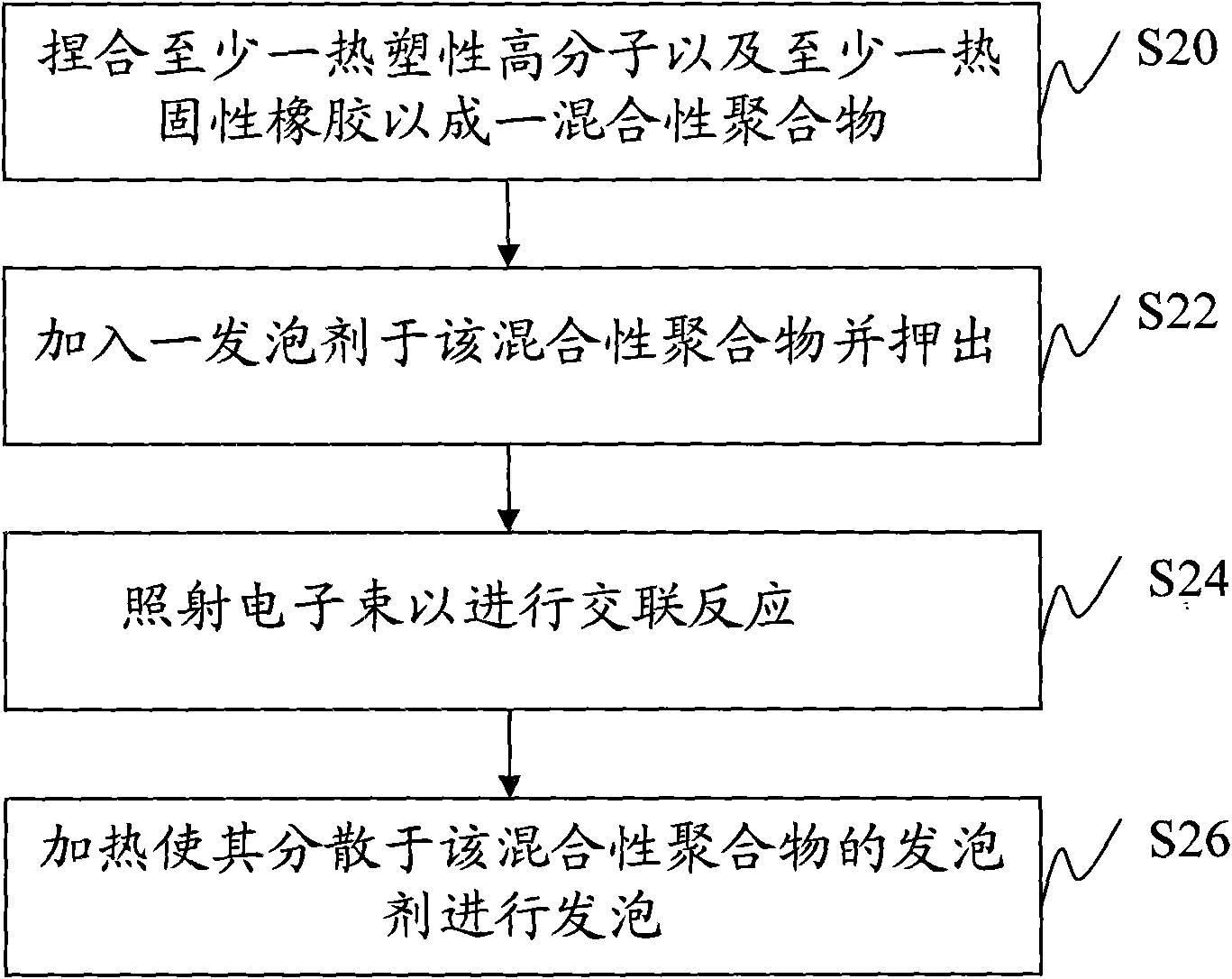

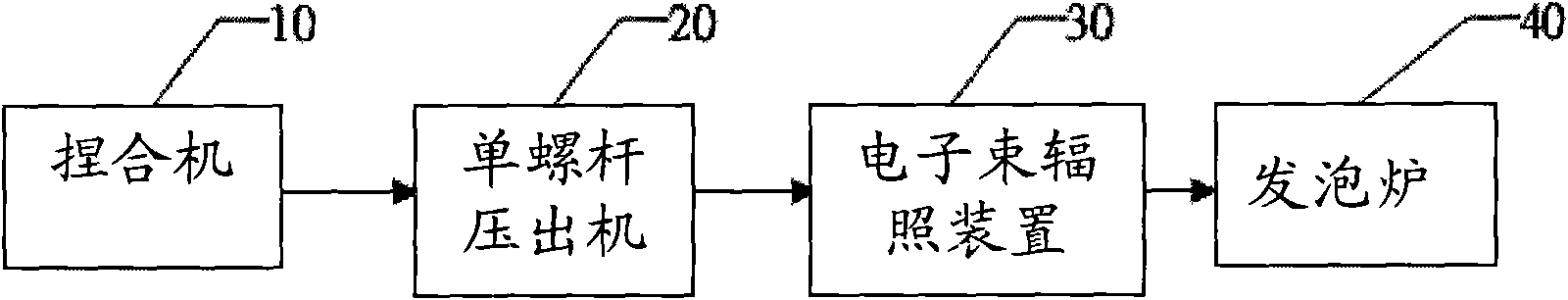

Preparation method of epispastic material employing electron beam radiation crosslinking and compositions thereof

InactiveCN101591449AFully evenly dispersedIncrease crosslink densityFoaming agentCrosslinked polymers

The invention relates to a preparation method of epispastic material employing electron beam radiation crosslinking and compositions thereof; when the epispastic material is applied, foaming agent is added at the moment of mixing one thermoplastic high molecular compound and at least one thermoset rubber, the foaming agent is ensured to be homodispersed fully in the crosslinked polymer and then the crosslinking is carried out by electron beam irradiation. After foaming, the foaming is even and good, the crosslinking density is increased and the crosslinking time is reduced.

Owner:LIANG HAW TECH

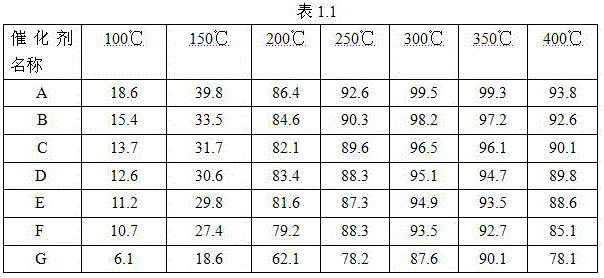

High-efficiency denitration catalyst and preparation process thereof

InactiveCN106311212AReduce secondary pollutionEvenly dispersedGas treatmentHeterogenous catalyst chemical elementsAfter treatmentSulfur

The invention discloses a high-efficiency denitration catalyst and a preparation process thereof. The catalyst is a cerium bismuth aluminum composite oxide, wherein based on the molar ratio of metal elements, the molar ratio of cerium to aluminum is 0.1-1.0, and the molar ratio of bismuth to aluminum is 0.1-1.0. The catalyst is prepared by utilizing a treatment process of integrating a homogeneous co-precipitation method and a hydrothermal method, after-treatment is performed by utilizing the technical means of azeotropic distillation, and solid solution can be formed when the cerium and bismuth oxides are positioned in a highly dispersed state in the metal compound oxide. The high-efficiency denitration catalyst prepared by the invention can achieve excellent denitration activity, reaction stability, water resistance and sulfur tolerance in a temperature range of 200-400 DEG C.

Owner:王欧庭

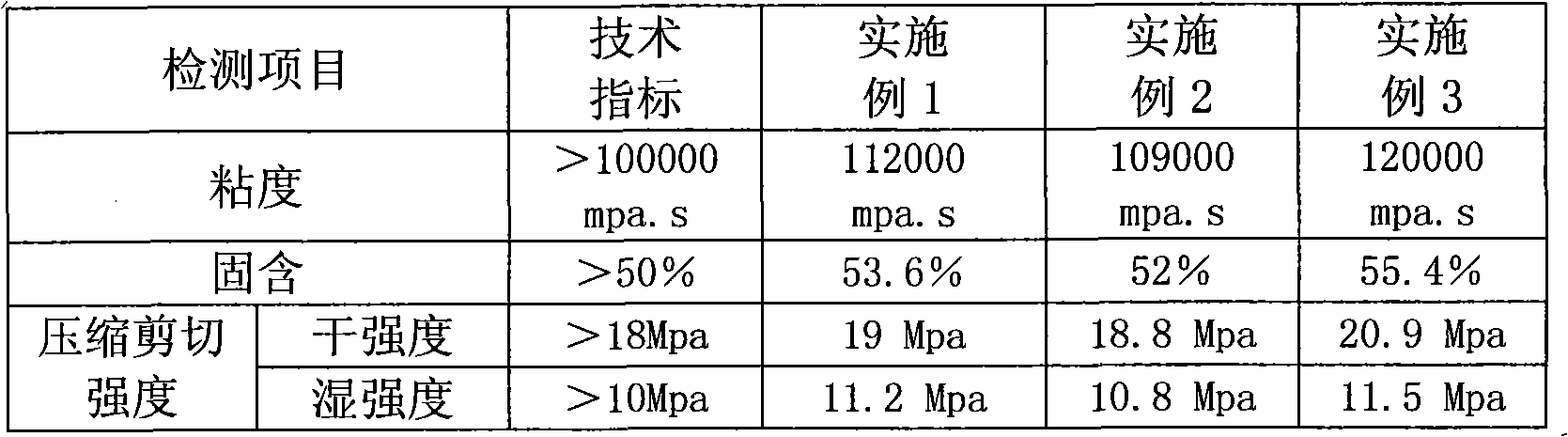

Preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive

ActiveCN101851475ASmall particle sizeImprove stabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedPolyvinyl alcohol

The invention relates to a preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive. The adhesive is widely applied in self-adhesion or cross-adhesion in the furniture, handicrafts, car interiors and other industries, and is prepared with the following raw materials of certain parts by weight: acetylated polyvinyl alcohol, vinyl acetate, plasticizer, nano-montmorillonite soil, emulsifier, initiator and the like. Instead of the method of preparing the existing product that the common polyvinyl alcohol is filled once into the reactor as the protective colloid, the preparation of the invention adopts the method of dropping the monomers and the initiator through two ports, the acetylated polyvinyl alcohol is filled in batches as the protective colloid, and the monomers, the initiator and the protective colloid are dropped simultaneously through a three-port dropping device, thereby improving the water resistance, stability, adhesive strength and sag resistance; and the reaction rate is controlled and the nano-montmorillonite soil, the environmental protection type plasticizer, the environmental protection type emulsifier and the like are added during preparation, thereby improving the adhesive property, environmental performance and sag resistance.

Owner:JIANGSU HEISONGLIN ADHESIVE FACTORY

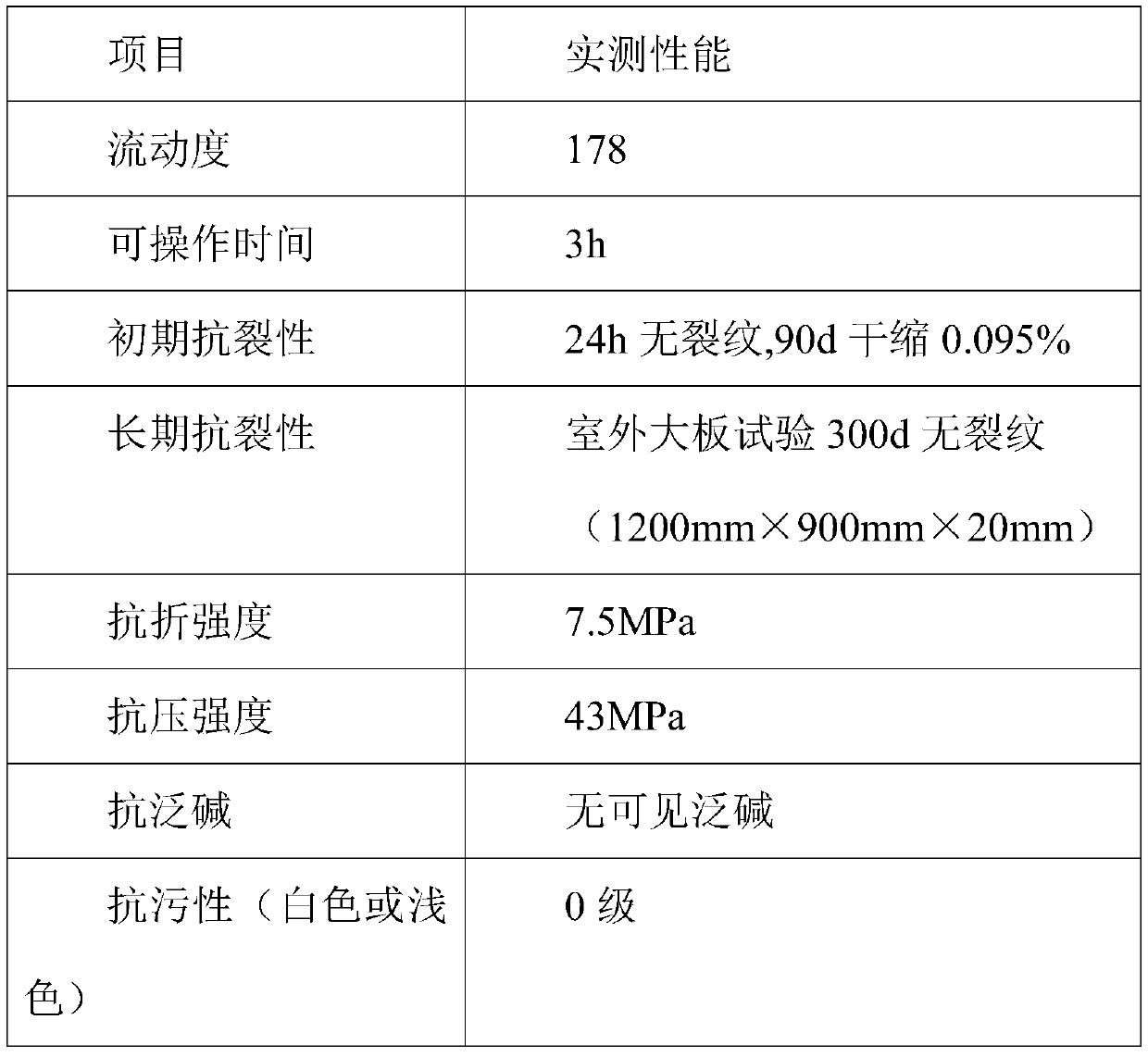

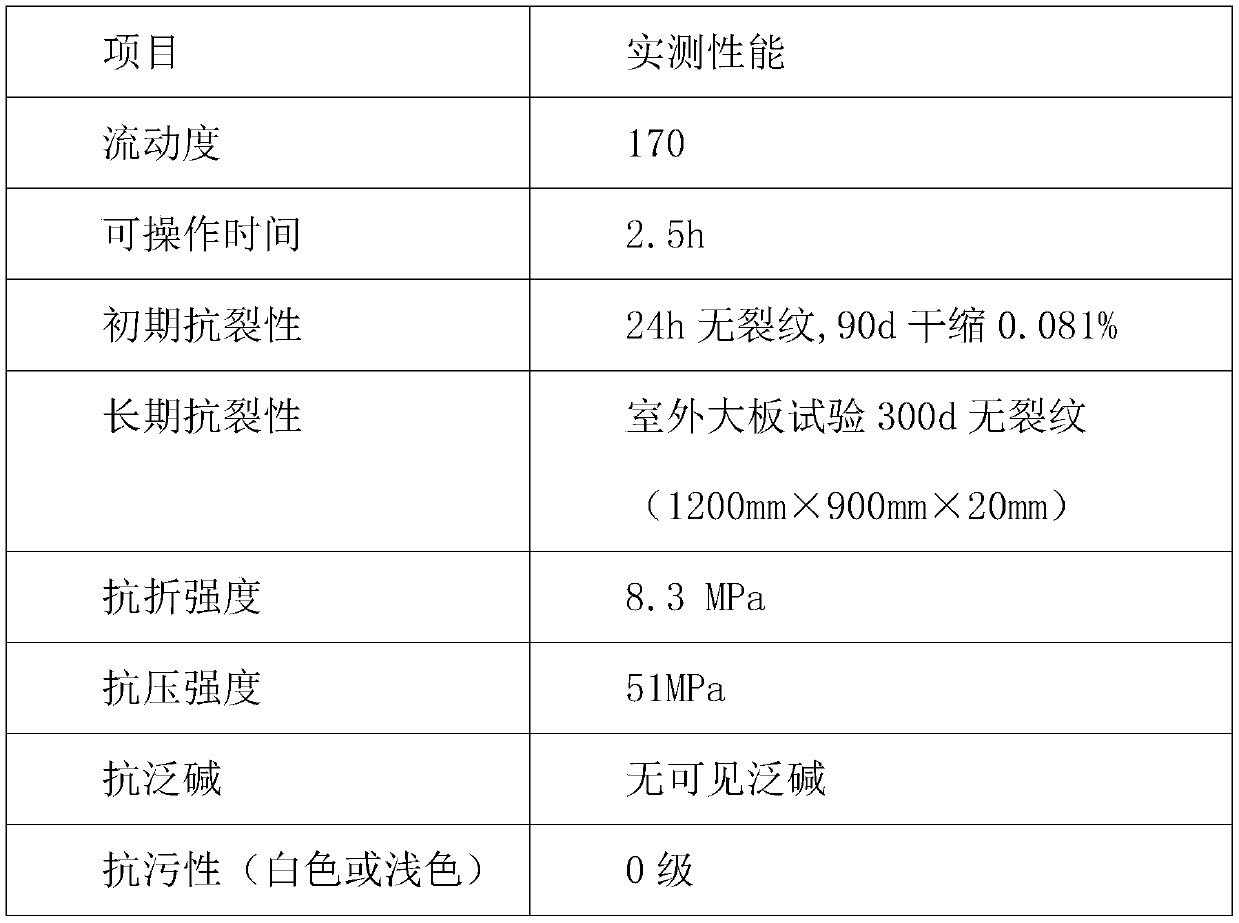

Self-cleaning high-crack-resistance self-leveling veneer mortar and preparation method

The invention discloses a self-cleaning high-crack-resistance self-leveling veneer mortar. The mortar is prepared from, by weight, 25-35% of white cement, 0.5-1.0% of a water reducing agent, 1-2% of an expanding agent, 0.2-0.5% of nano titanium dioxide, 2-6% of alkali activation pulverized fuel ash and 10-13% of water. The sum of the weight percentage of all the raw materials is 100%. The invention further discloses a preparation method of the self-cleaning high-crack-resistance self-leveling veneer mortar. The method comprises the following steps that after the titanium dioxide and the alkaliactivation pulverized fuel ash are mixed and stirred, the mixture, white Portland cement, metakaolin, redispersible emulsion powder and the expanding agent are added into a stirrer according to a proportion, white sand is added for stirring for one minute, and finally fibers are added for stirring for 3-5 minutes. The self-cleaning high-crack-resistance self-leveling veneer mortar has better crack resistance, fluidity and self-cleaning performance and can be widely applied to large-size outer wall face layers of assembly-type buildings, and the social and economic benefits are obvious.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

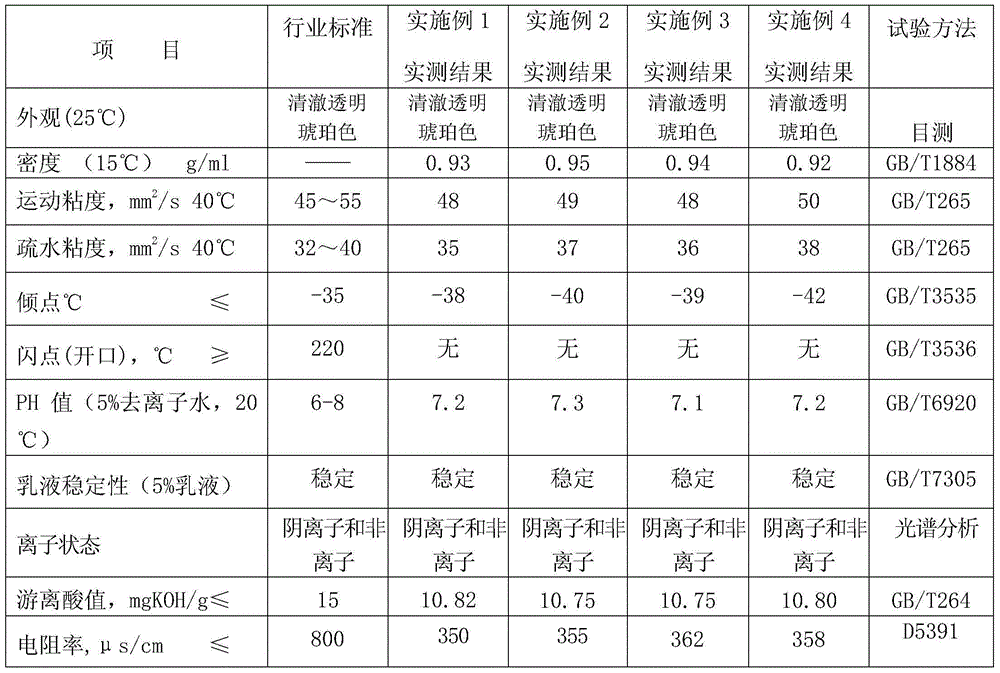

Extreme pressure type aluminium plate and aluminum tape hot rolling emulsion and preparation method thereof

ActiveCN104830516AImprove high temperature resistanceGuaranteed lubrication performanceLubricant compositionChemistryEmulsion

The invention discloses an extreme pressure type aluminium plate and aluminum tape hot rolling emulsion which consists of refined vegetable oil, hydrogenation naphthene base oil, environment-friendly synthetic ester, a biodegradable efficient compound nonionic emulsifier, a compound antioxidant, an anti-wear reagent at extreme pressure, a corrosion inhibitor, a defoaming agent, a preservative, a wetting agent and a bactericide, wherein the compound antioxidant consists of a phenolic antioxidant, a phenylamino antioxidant and an olefine acid antioxidant. The invention further provides a preparation method of the hot rolling emulsion. The hot rolling emulsion has good biological emulsion stability, excellent hot rolling lubricating property, excellent thermal separation property and excellent aluminium plate and aluminum tape corrosion resistance; an aluminium plate and an aluminum tape have no crack or nigrescence, and are easy to clean, so that the surface qualities of the aluminium plate and the aluminum tape are improved effectively; the hot rolling emulsion is low in consumption; the service life of a roll is prolonged effectively; the hot rolling emulsion is stable; the operation is convenient; the maintenance is easy; the service life and the efficiency of a rolling mill is prolonged and improved effectively; and the yields and excellent and good rates of the aluminium plate and the aluminum tape are increased effectively.

Owner:上海中孚油品集团有限公司

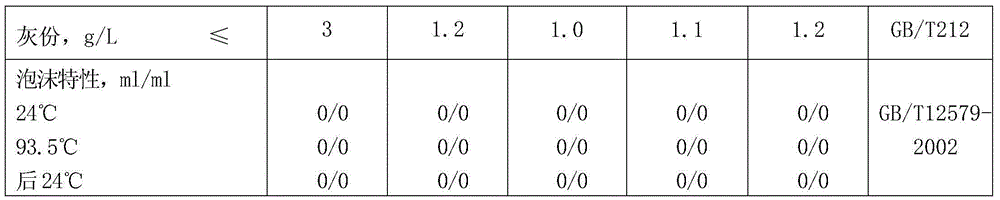

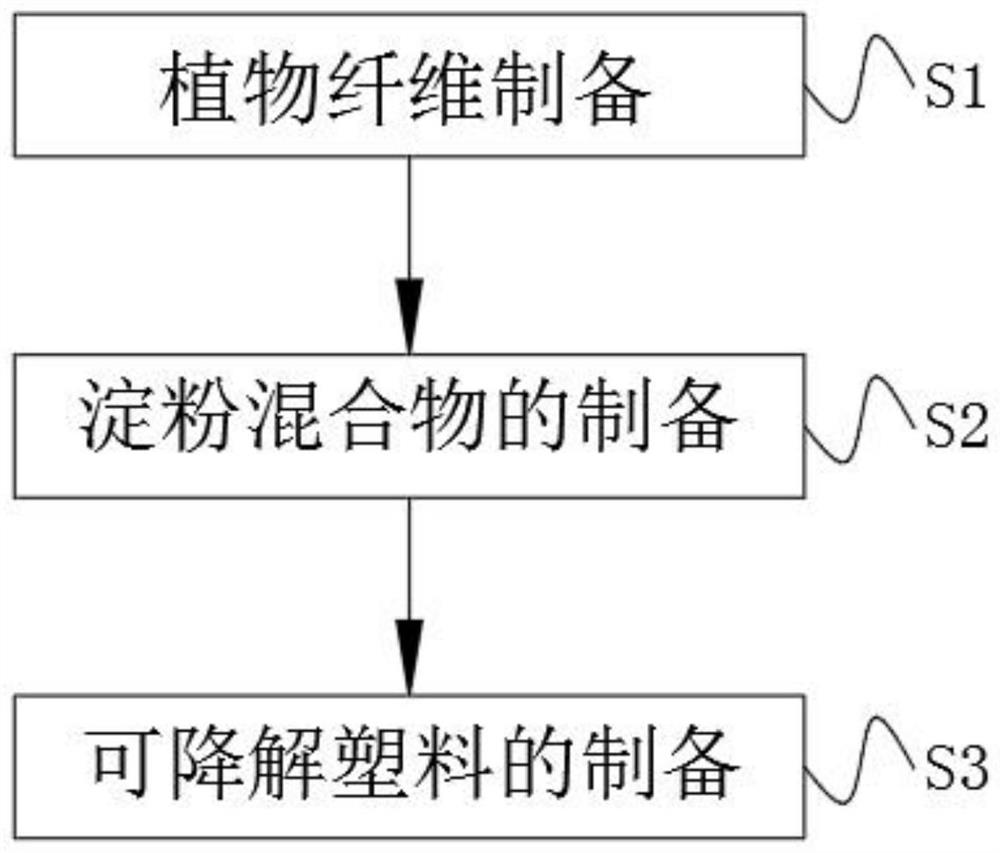

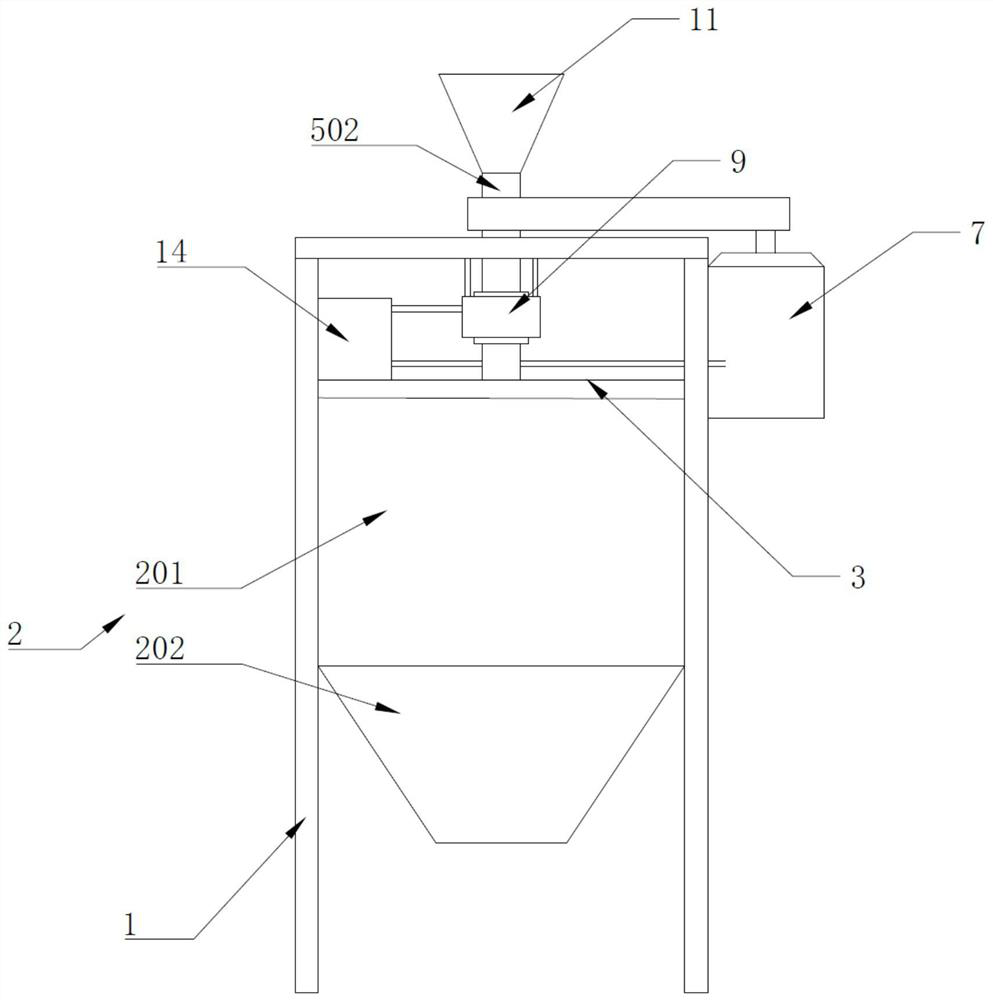

Degradable plastic based on plant fiber starch as well as preparation method and preparation system ofdegradable plastic

The invention discloses degradable plastic based on plant fiber starch as well as a preparation method and preparation system of the degradable plastic. The degradable plastic comprises the following raw materials of: rice straw, straw, cassava starch, absolute ethyl alcohol, deionized water, natural resin powder, bamboo fiber powder, seaweed gel powder, a degradation accelerant, a modified treatment material, a filling agent, a cross-linking agent, polylactic acid, biological enzyme, a dispersing agent, a plasticizer and an antioxidant. The invention belongs to the technical field of degradable plastics. According to the degradable plastic based on the plant fiber starch and the preparation method of the degradable plastic, the use safety of a plastic product can be improved by using the plant fibers as the raw materials, the raw materials have certain environmental friendliness and reproducibility, the plant fibers have excellent biodegradability; and polylactic acid is added, the polylactic acid is a polymer obtained by polymerizing lactic acid serving as a main raw material, the raw material is sufficient in source and can be regenerated, and the production process of the polylactic acid is pollution-free.

Owner:ZHEJIANG FORESTRY UNIVERSITY

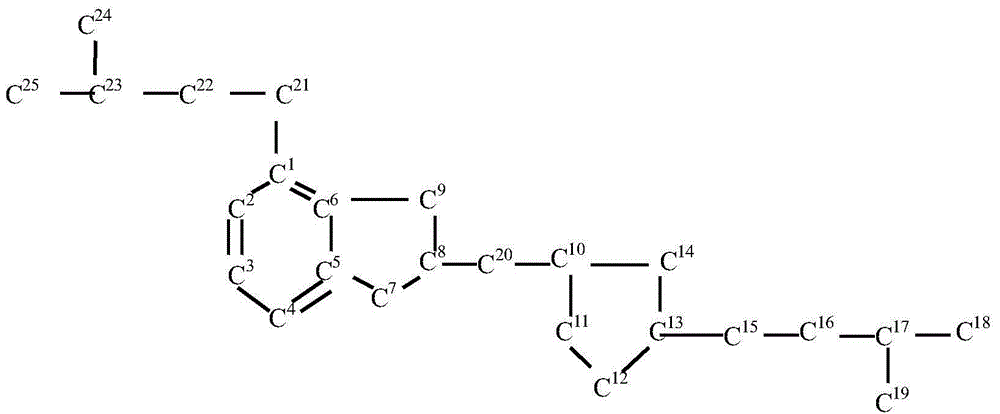

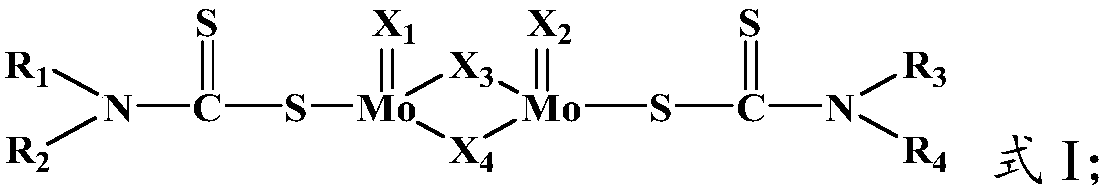

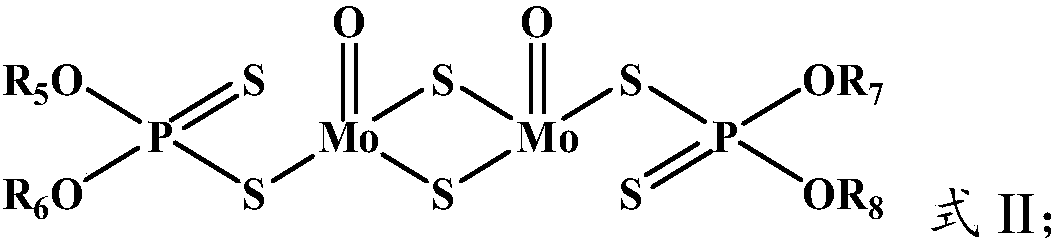

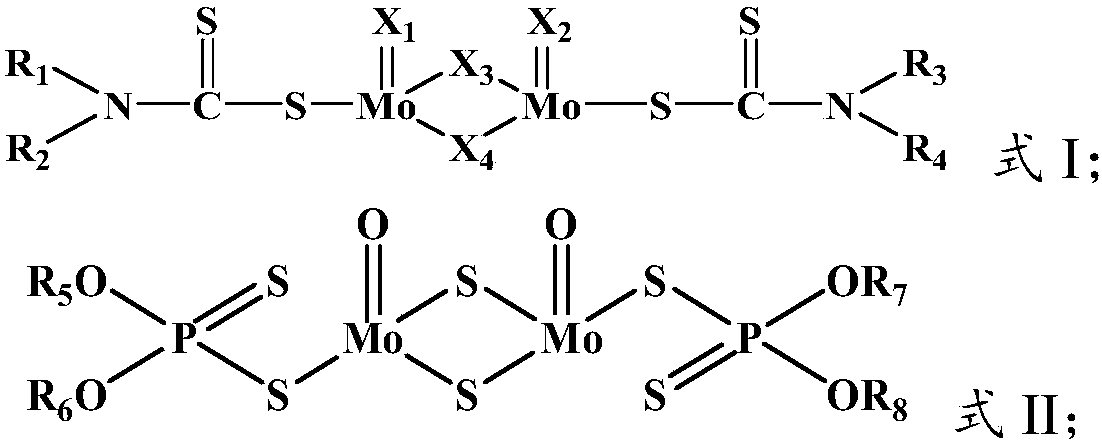

Liquid lubricating agent and drilling fluid

ActiveCN108624307AGood lubrication and anti-friction effectThe effect of lubrication and anti-friction is normalDrilling compositionFriction reductionEngineering

The invention provides a liquid lubricating agent. Molybdenum dialkyldithiocarbamate and molybdenum dialkydithiophosphate are used as important ingredients of the liquid lubricating agent, and are oilsoluble organic molybdenum compounds; a secondary structure film can be formed on the friction surface at high pressure formed by contact of a drill tool and a well wall; damage cannot easily occur;good lubrication and friction reduction effects are achieved. In addition, carbon black in the liquid lubricating agent can form a thin slice layer; in the extrusion state, the carbon black thin sheetlayers are separated, so that better lubrication and friction reduction effects can be achieved; meanwhile, through surfactants, liquid lubricating agents form proper emulsification effects in a drilling fluid system, so that the liquid lubricating agent can be sufficiently and uniformly dispersed; the lubrication and friction reduction capability is improved. The invention also provides drillingfluid, which is prepared from the liquid lubricating agent. The lubrication and friction reduction effects are good at the high temperature.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

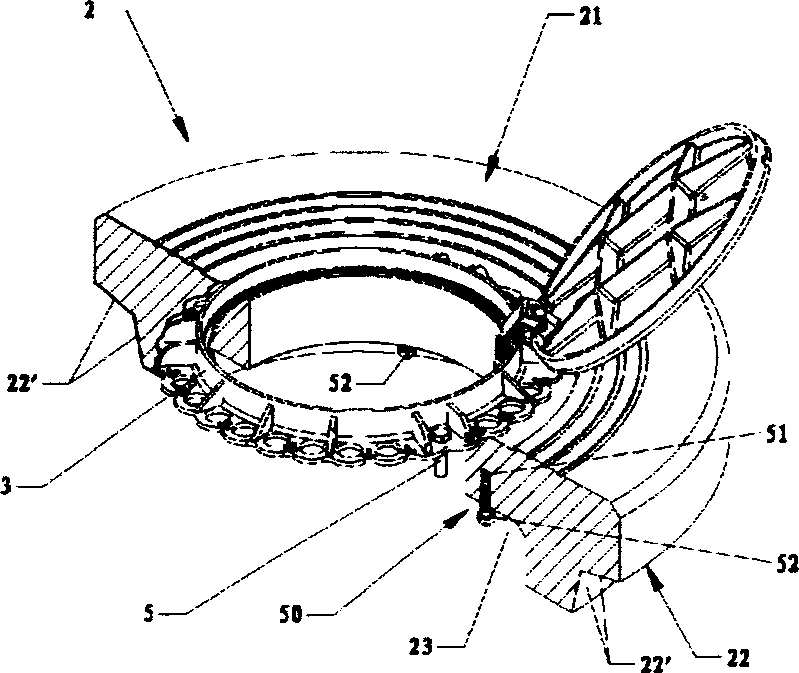

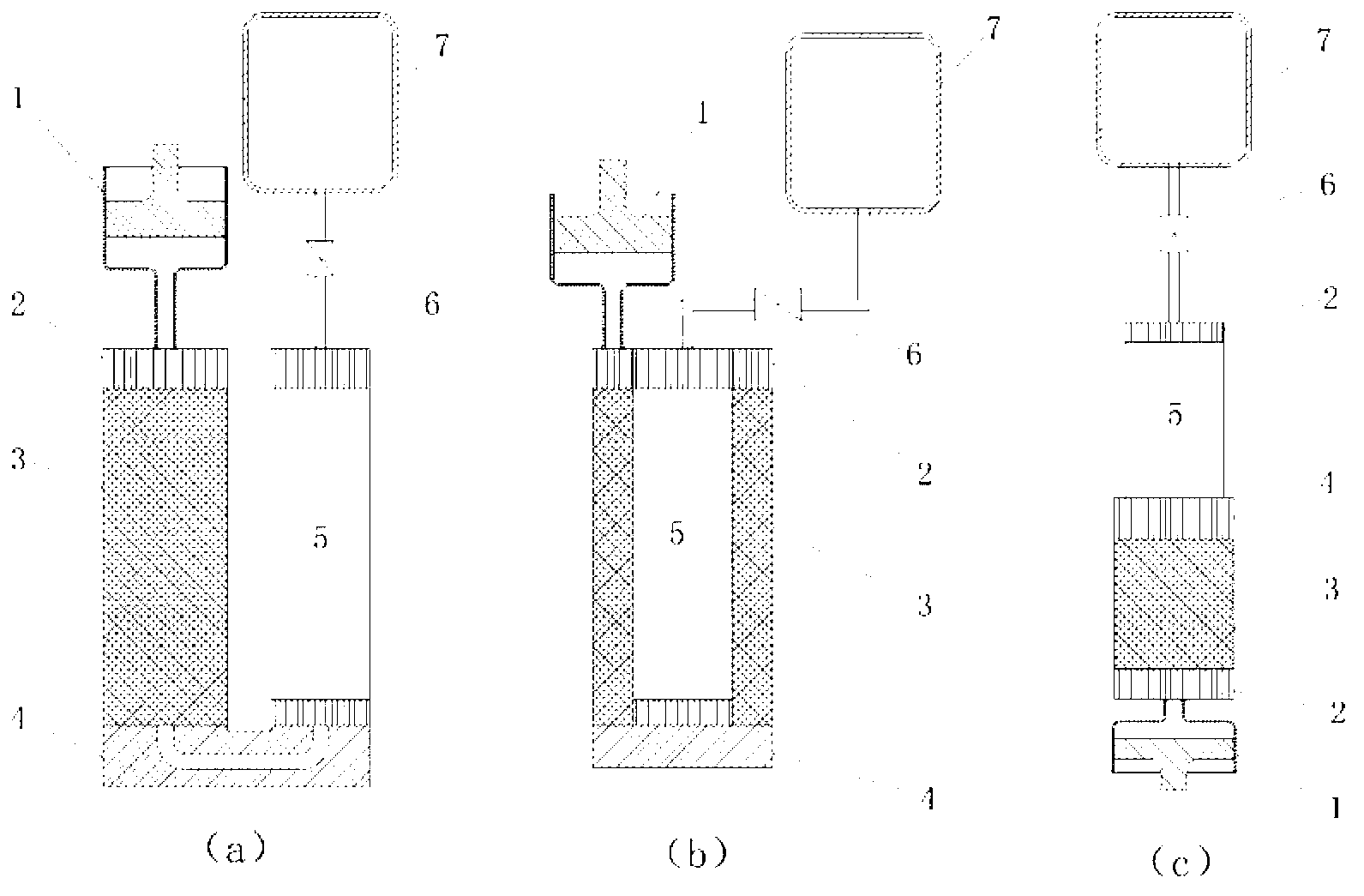

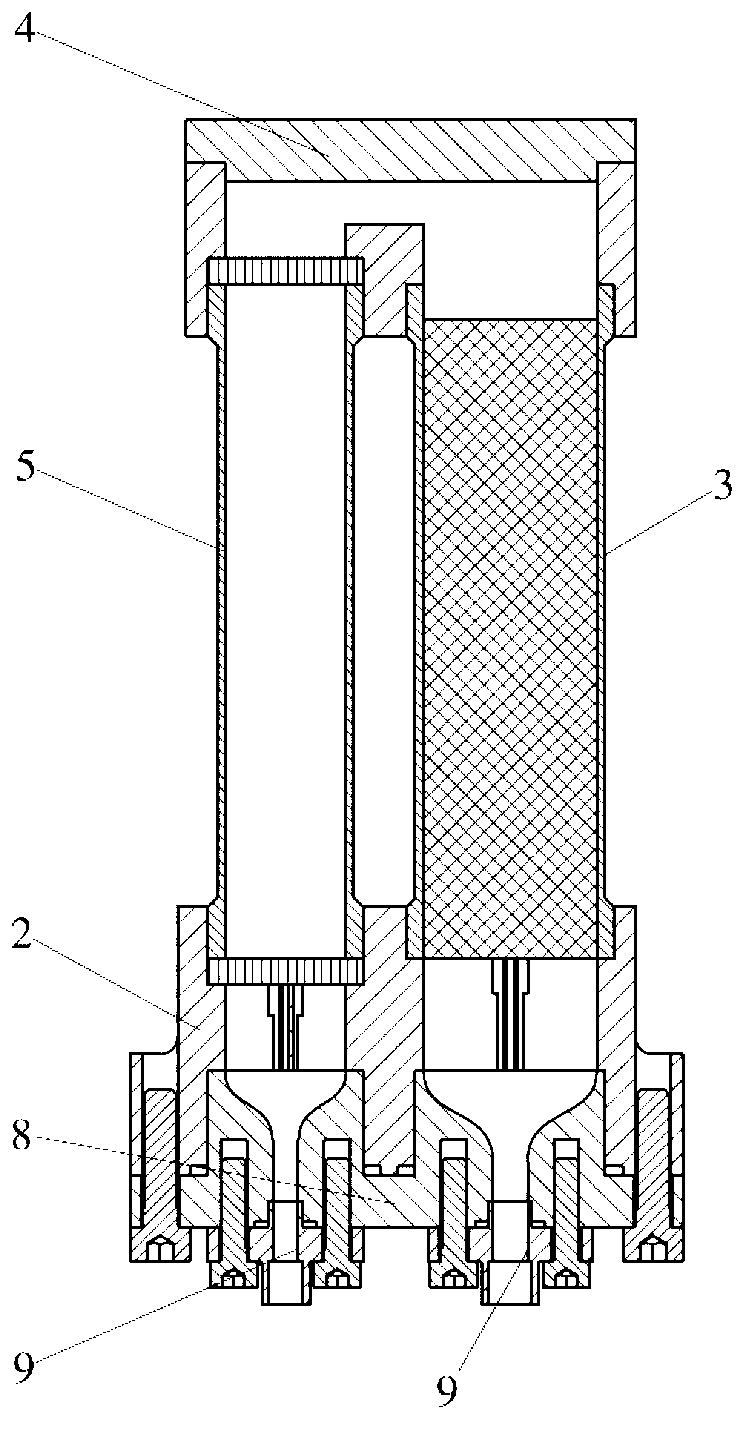

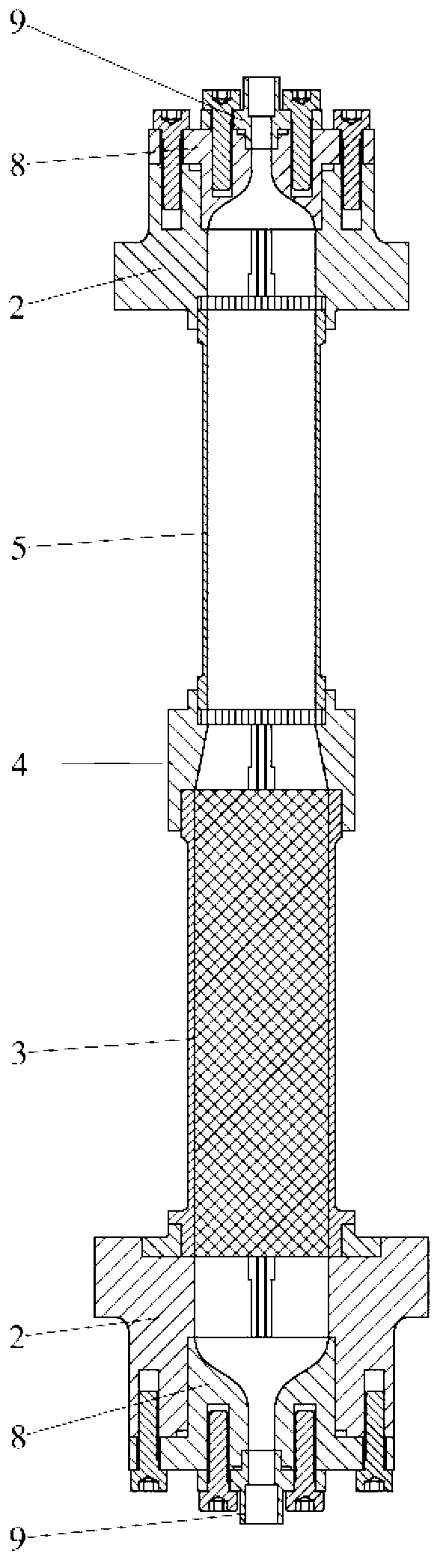

Flow guide structure inside hot end of U-type / linear pulse tube refrigerating machine and manufacturing method thereof

InactiveCN103175329AEliminate weak cornersIncrease the heat exchange areaCompression machinesGas cycle refrigeration machinesWire cuttingPulse tube refrigerator

The invention discloses a flow guide structure inside the hot end of a U-type / linear pulse tube refrigerating machine and a manufacturing method of the flow guide structure. The flow guide structure is composed of a hot end heat exchanger, a hot end plug and a flow guide core column. Cone-shaped fin structures are formed in the hot end heat exchanger in a cutting mode through the wire cutting technology and are evenly distributed around the center of the hot end heat exchanger in a ring-shaped mode. A T-shaped through hole is formed in advance in the central portion before a wire cutting process so as to eliminate a thin and weak sharp corner at the tail end of each fin. The flow guide core column which is also manufactured in a fin structure is inserted into the hot end heat exchanger, and a hole is formed in the central position of the flow guide core column in a penetrating mode. The hot end plug is inserted into the hot end heat exchanger, wherein a transition curved surface, which changes gradually in two directions inside the hot end plug is connected with slit body flow guide passageways and small hole channels, the curved surface is tangent to the surface of each of fluid passageways at two ends, and the hot end plug is tightly connected on the hot end heat exchanger through a sealing ring and screws. Through the design of the novel flow guide structure at the position of abrupt change of the cross section of a hot end gas flow passageway, loss of high-frequency oscillation gas flow at the position is enabled to be minimized, and the flow guide structure inside the hot end of the U-type / linear pulse tube refrigerating machine has important significance in improving refrigerating efficiency of the U-type / linear pulse tube refrigerating machine.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

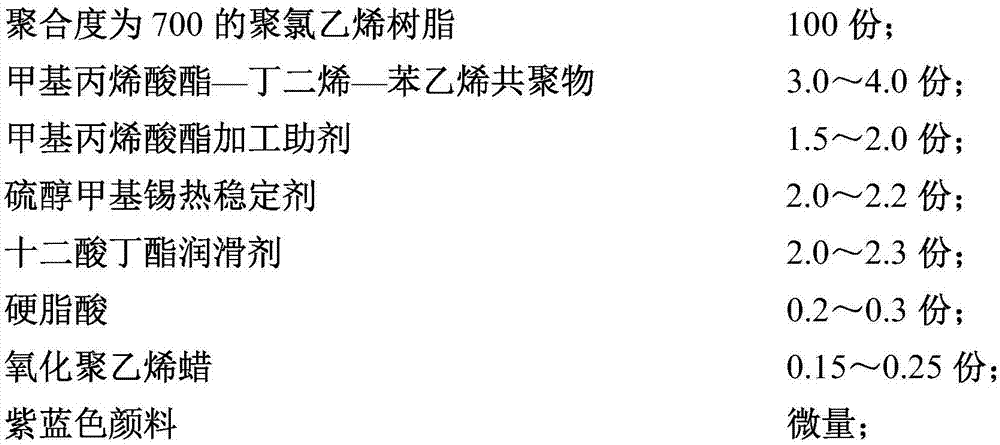

PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses

ActiveCN107141646AImprove thermal stabilityTransparency has little effectMethacrylateProcedure Agents

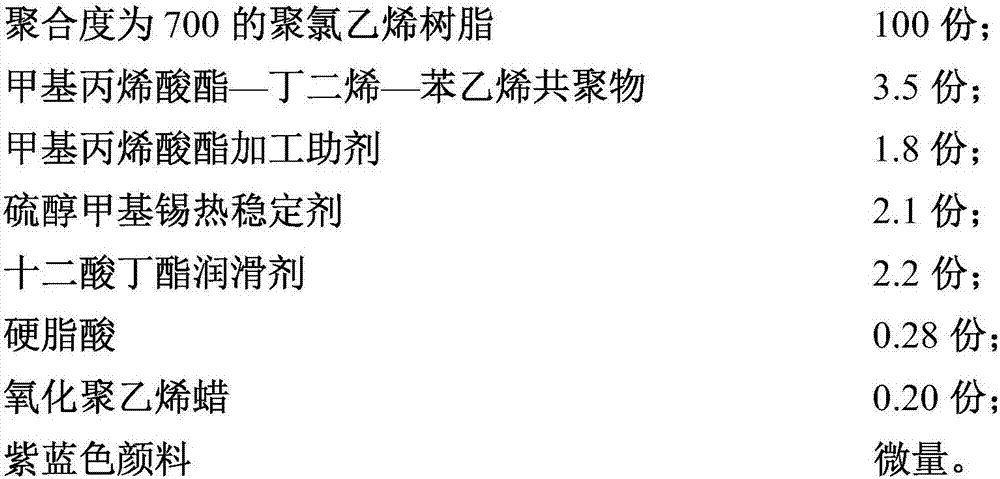

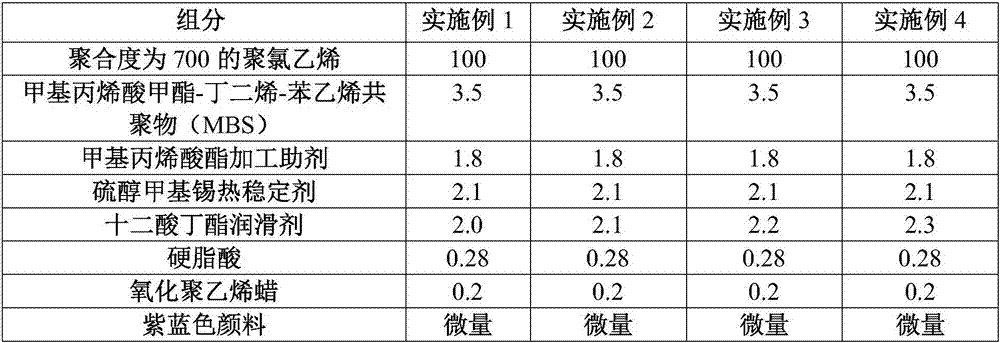

The invention discloses PVC (polyvinyl chloride) pellets special for ultrahigh-transparency hard medical injection molding apparatuses. The PVC pallets comprise, by weight, 100 parts of polyvinyl chloride resin with the degree of polymerization being 700, 3.0-4.0 parts of methacryIate-Butadiene-Styrene copolymer, 1.5-2.0 parts of methacrylate processing aid, 2.0-2.2 parts of methyltin mercaptide heat stabilizer, 2.0-2.3 parts of butyl dodecanoate lubricant, 0.2-0.3 part of stearic acid, 0.1-0.25 part of oxidized polyethlene wax and trace indigo pigment. The finished products are prepared by means of feeding the components into a high-speed heating mixer according to the proportion for high-speed mixing, performing kneading to the temperature of 123-125 DEG C prior to discharging, putting the discharged material into a low-speed cooling mixer to be cooled to room temperature to obtain mixed powder, feeding the mixed powder into a pelletizer for pelletizing, and cooling the pellets to the temperature lower than 40 DEG C prior to packaging. The medical injection molding apparatuses made of the PVC pellets have ultrahigh transparency and surface glossiness.

Owner:WUXI JIAHONG PLASTICS TECH

Three-dimensional tissue-like body of composite cells and preparation method and application thereof

InactiveCN108085294AFully evenly dispersedImprove retentionArtificial cell constructsCell culture supports/coatingBiocompatibility TestingUltraviolet lights

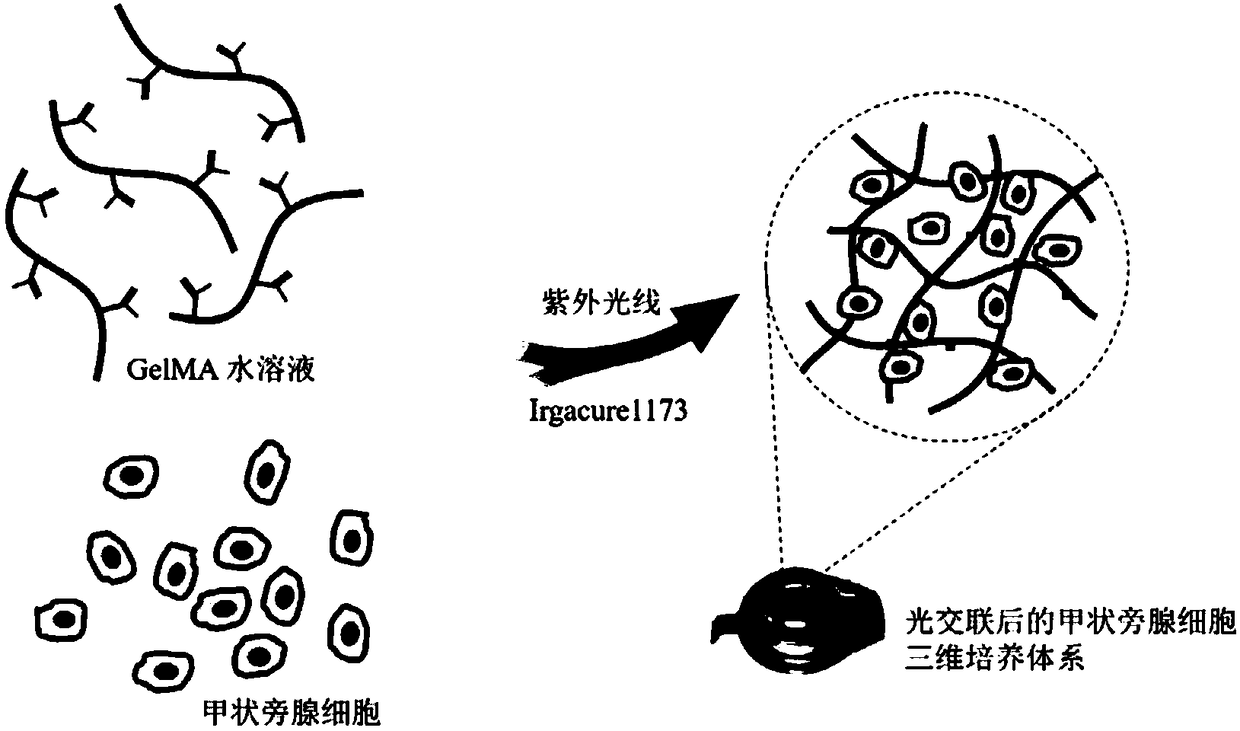

The invention discloses a three-dimensional tissue-like body of composite cells. By grafting small molecule compounds containing double bonds onto gelatin molecules with excellent biocompatibility tobuild gelatin DB-Gel modified by groups containing double bonds, a gelatin DB-Gel aqueous solution of a certain concentration is mixed with living cell (such as parathyroid gland cells) suspension, and through ultraviolet light curing, the three-dimensional tissue-like body of the composite cells is obtained. In the process of building the tissue-like body, DB-Gel is fully utilized as photo-polymerized hydrogel and has good bioactivity; by directly mixing the gelatin DB-Gel and the cells in a liquid state, the cells can be completely and uniformly dispersed in space, a three-dimensional growing environment closer to the internal environment is built for the cells, the efficiency of interaction between the cells and the external environment is improved in a three-dimensional cell culturingprocess, and compared with cells cultured in two dimensions, maintenance of cell forms and activity are both improved. A preparation method of the three-dimensional tissue-like body of the composite cells is simple, rapid and low in both equipment requirement and cost, and has great potential in internal and external research.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Downhole rotational flow shearing generator

ActiveCN102787823ALow viscosityReduce the power requiredFlushingSealing/packingPetroleumEnergy conversion efficiency

The invention discloses a downhole rotational flow shearing generator, comprising a coupling, an outer barrel and a guide holder and relating to the cementing technical field in the petroleum engineering. The downhole rotational flow shearing generator is characterized in that a shearing rotor is arranged in the outer barrel, the shearing rotor is provided with a blade grid, a locking screw is used for fixing a guide stator, the guide stator plays a flow guiding role, the guide stator is provided with a plurality of guide oblique holes, the flowing direction of the fluid is changed by the guide oblique holes, the fluid hits on the rotational flow rotor vertically, the energy conversion efficiency is increased, the rotational flow rotor generates the high-speed rotation, the spiral fluid continues to be under a shearing and stirring action and finally flows out through the guide seat arranged at the end part of the outer barrel in the shape of a large-intensity spiral flow. The downhole rotational flow shearing generator has the beneficial effects of reasonable structure and high intensity, after the downhole rotational flow shearing generator is arranged in the well cementing process, the peripheral shearing drive force of the well wall can be increased through the spiral flow of the downhole rotational flow shearing generator, the rock debris can be effectively carried, and the well wall can be washed more effectively, the interface cementing strength can be increased, the displacement effect of the cement paste to the drilling fluid can be increased by 5%-7%; the initial jelling time of the cement paste is shorted by 10%-15%, the cementing strength of the well cementing bi-interface is increased by 20%-30%, the compressive strength of the cement stone is increased by 15%-22%, and the cementing quality of the second interface is obviously better than the conventional cementing.

Owner:王震

Method for preparing Al4SiC4 ceramics

The weight ratio of each compound aluminium powder: graphite powder: polycarbonsilane is (2-4):(0.2-3.8):(1-5). The. prepn. steps are: (1) aluminium powder and graphite powder are fully mixed, polycabonsilane is dissolved in organic solution, then putting mixed aluminium and graphite powder into organic solution of polycarbonsilane, increasing temp. and stirring until that organic solution volatilizing completely; (2) dried powder is splited in temp. 800-1400 deg.C protected by argon, (3) splited powder material is fully grinded and mixed; (4) mixed material is put in model made of graphite to be fired in temp. 1600-2200 deg.C in heat pressing fire surface, argon gas is blew in for protection, firing pressure is 10-40 MPa, temp.-keeping 1-5 hours.

Owner:HARBIN INST OF TECH

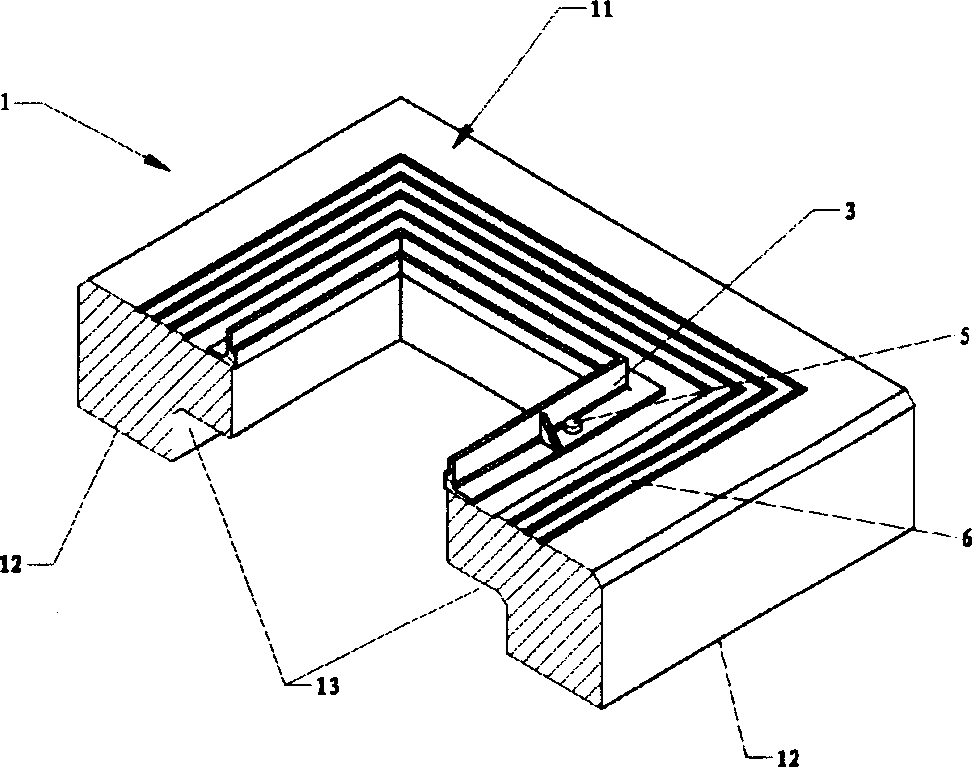

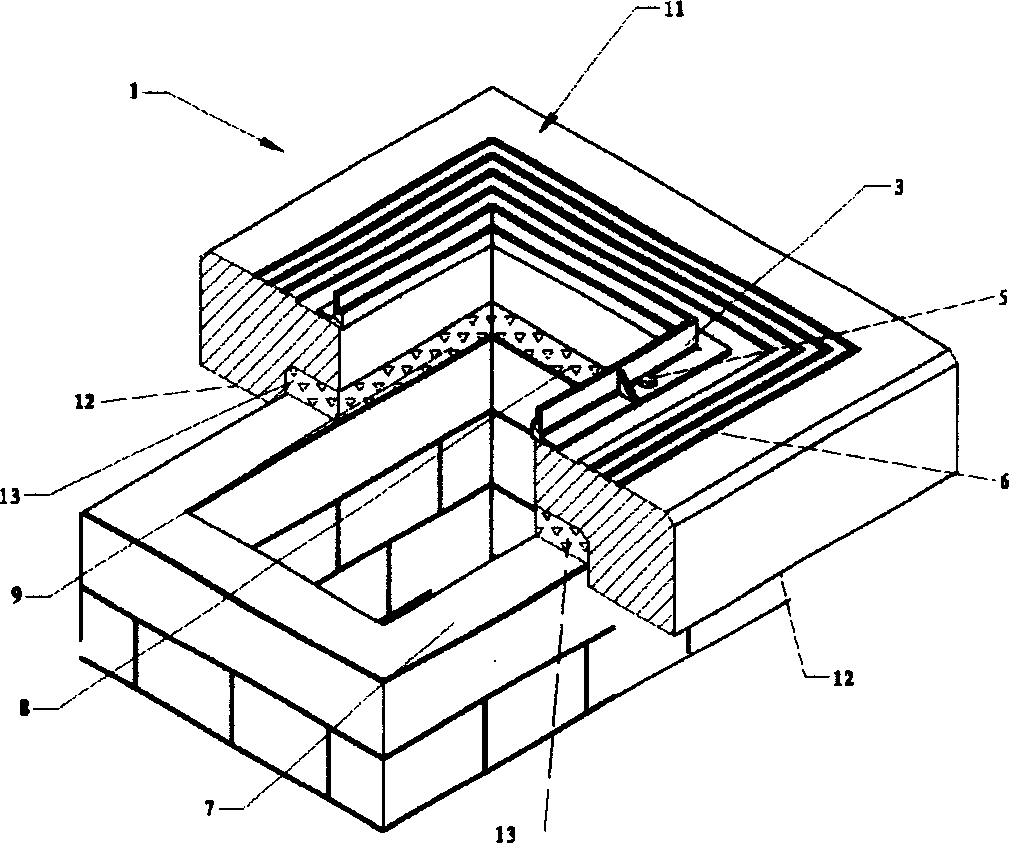

Flame-retardant fabric and method for manufacturing the same

InactiveCN1847515AFull flame retardancyImprove flame retardant performanceVehicle seatsHeat resistant fibresFiberPolymer science

A flame-retardant fabric 1 of the present invention comprises: a fiber fabric 4 ; and a back layer 5 formed on the back surface of the fiber fabric 4 and containing at least one of inorganic compound selected from the group consisting of calcium carbonate and magnesium hydroxide, thermally expansive graphite and a polymer substance. The adhering amount of solid of the back layer 5 is 50 to 150 g / m2. The adhering amount of the thermally expansive graphite is 15 to 60 g / m2. The adhering amount of the inorganic compound is 10 to 60 g / m2. The flame-retardant fabric causes no generation of noxious substances in case of fire and at incineration disposal, can impart sufficient initial flame retardancy, and has excellent flame-retardant performance in heat aging.

Owner:SUMINOE TEXTILE CO LTD +1

Surface treatment agent for wood floor material and mfg. method thereof

InactiveCN1359996AFully evenly dispersedNo risk of subsidenceWax coatingsOther chemical processesCarnuba waxPulp and paper industry

There is provided a surface treating agent for ligneous floorings that makes the surface of a treated floor resistant to slipping and thus is capable of preventing tumbling. The surface treating agent for ligneous floorings contains a drying oil, Japan wax, candelilla wax, and powdery carnauba wax.

Owner:SERARIKA NODA

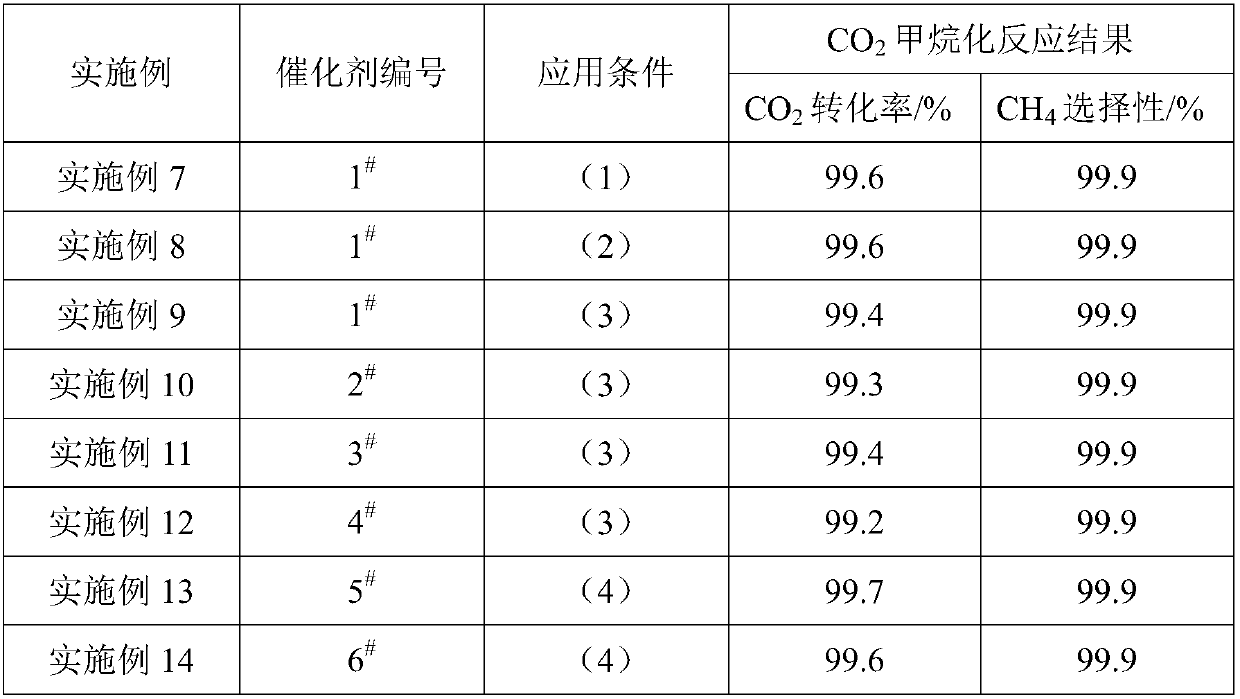

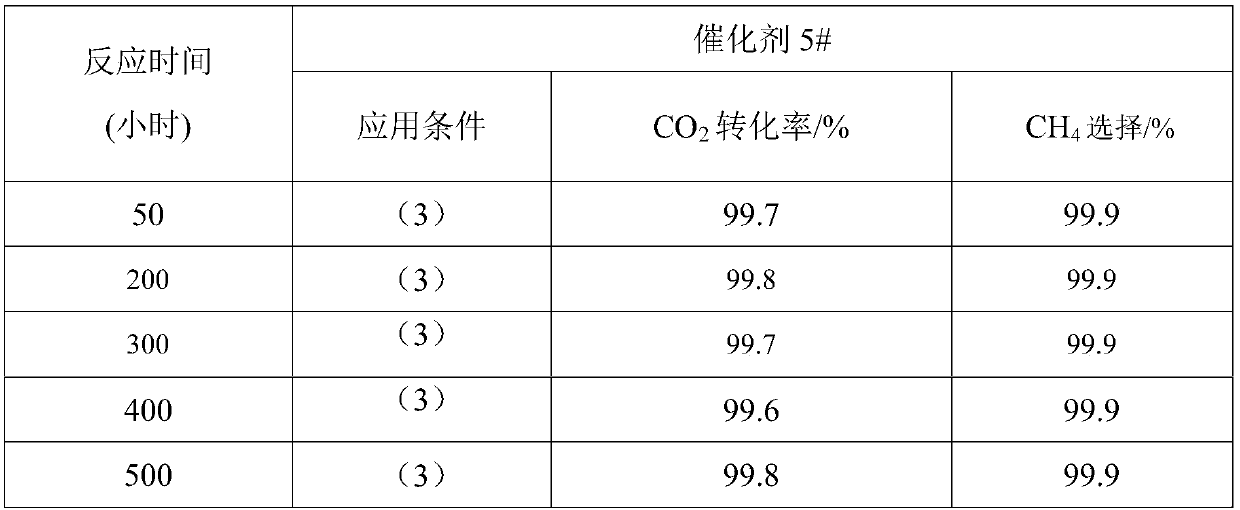

CO2 complete methanation catalyst as well as preparation and application thereof

PendingCN111229228AImprove performanceStrong interactionHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsPtru catalystMethanation

The invention provides a CO2 complete methanation catalyst, an active component of the catalyst is NiO; an auxiliary agent is La2O3 and / or CeO2; or the auxiliary agent is MgO and La2O3 and / or CeO2, orthe auxiliary agent is Fe2O3 and La2O3 and / or CeO2, a carrier is Al2O3, and the catalyst comprises the following components in percentage by mass: 10%-20% of the NiO, 1%-5% of the La2O3 and / or CeO2,1%-5% of the MgO, 1%-5% of the Fe2O3 and / or CeO2 and the balance of the Al2O3. The catalyst is prepared by adopting a coprecipitation method and is applied through drying, roasting and forming. According to the catalyst, under the reaction conditions that the pressure is 2.5-4.5 MPa, the temperature is 300-400 DEG C, the air speed is 15000-50000 ml.g <-1 >. H <-1 >, and H2 / CO2 is equal to 4-4.5, the CO2 conversion rate and CH4 selectivity can be close to 100%. The catalyst is simple to prepare, shows excellent performance at high space velocity, and is suitable for industrial production and application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

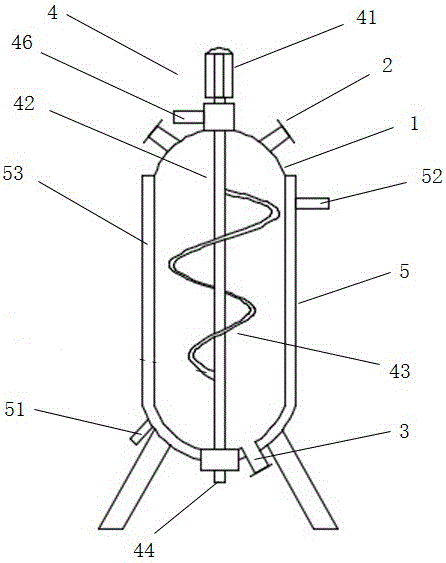

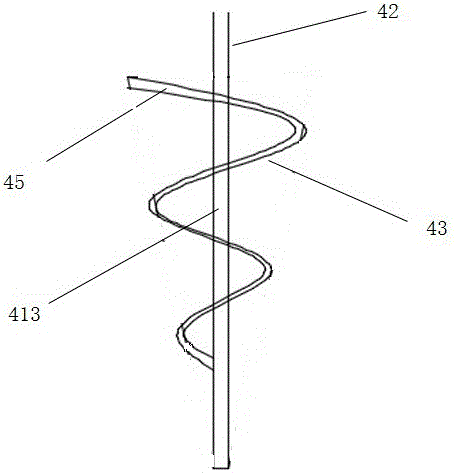

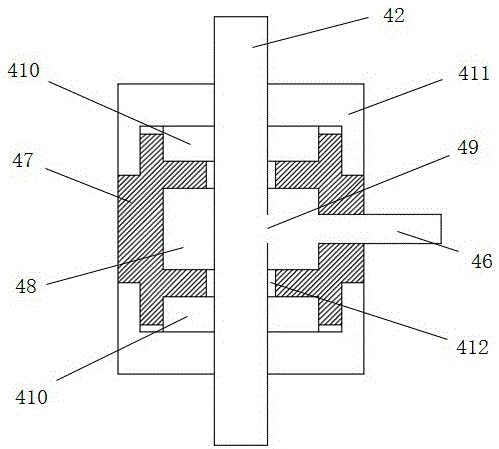

Efficient polymeric reactor

InactiveCN105771867AFully evenly dispersedInhibition of segregationChemical/physical/physico-chemical stationary reactorsEngineeringChemical engineering

The invention discloses an efficient polymeric reactor. The efficient polymeric reactor comprises a reactor body, a stirrer and a reactor jacket. The reactor jacket is arranged outside the reactor body. The stirrer comprises a servo motor, a stirring shaft and a stirring paddle. The servo motor is arranged at the top of the reactor body. The stirring shaft is connected with the servo motor and the stirring paddle. A through hole is formed in the stirring shaft axially. The stirring paddle is produced through bending of a flat pipe and is communicated with the through hole of the stirring shaft. A stirrer water inlet is arranged at the bottom of the reactor body and is connected with the through hole of the stirring shaft. A communication opening communicated with the through hole is formed in the side wall of the upper end of the stirring shaft. A stirrer water outlet is arranged at a position, located at the communication opening, of the upper end of the stirring shaft. The efficient polymeric reactor has the advantages that the stirrer is combined with a temperature adjustment device, so that the temperature of the reactor can be adjusted externally and internally, and temperature adjustment accuracy is improved greatly.

Owner:QINGFENG SHOE IND JIANGSU CO LTD

Composition for preparing three-dimensional greening cultivation container and preparation method

InactiveCN109704696AExcellent physical and chemical propertiesExcellent bonding strengthReceptacle cultivationSilica fumeGreening

The invention discloses a composition for preparing a three-dimensional greening cultivation container and a preparation method. The composition comprises an aluminate cementing material, fly ash, silica fume, mineral powder, an organic material, an additive, fibers and water. The method for preparing the cultivation container by adopting the composition comprises the steps of carrying out stirring, carrying out mold forming, carrying out curing and the like. The three-dimensional greening cultivation container prepared by the technical scheme provided by the invention has the advantages of greenness, environment protection, energy conservation and easy maintenance, and the problem that a conventional cultivation container is poor in durability, insufficient in ornamental value, too largein dead weight and insufficient in breaking and compressive strength is solved.

Owner:SHENZHEN CUILU TECH GREENING ENG CO LTD

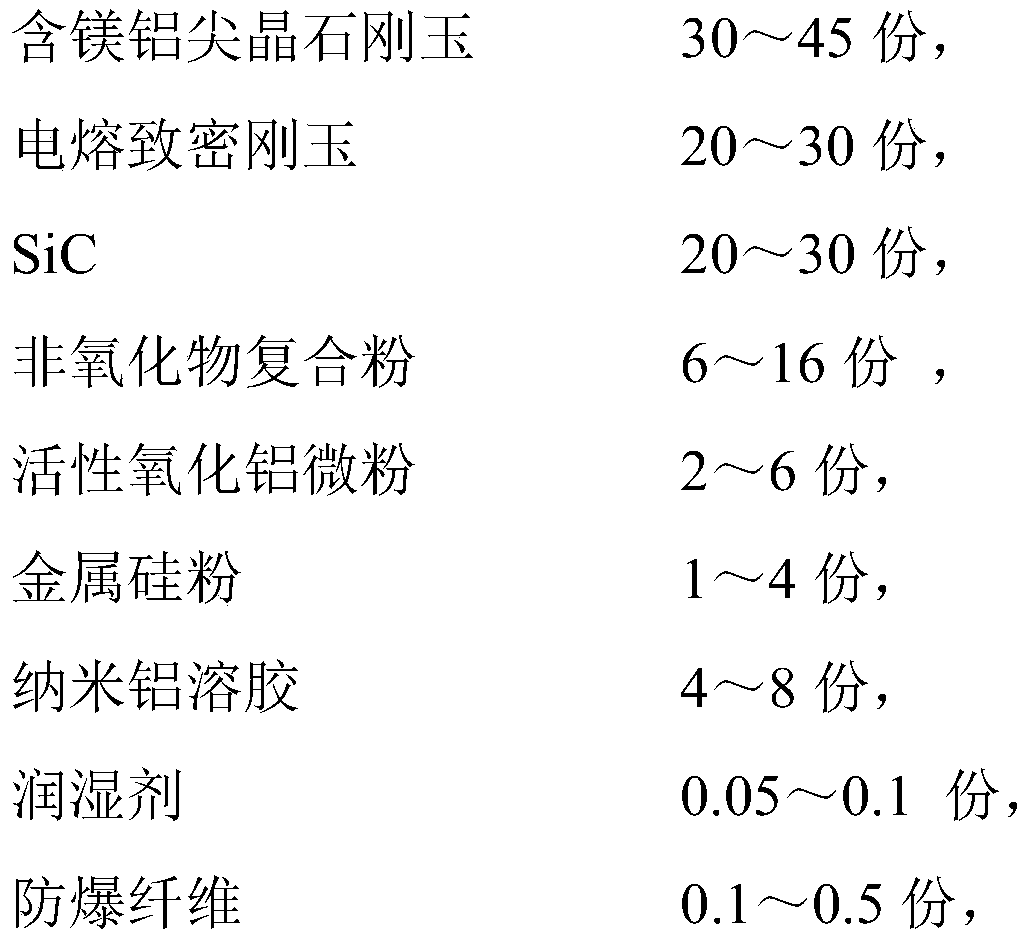

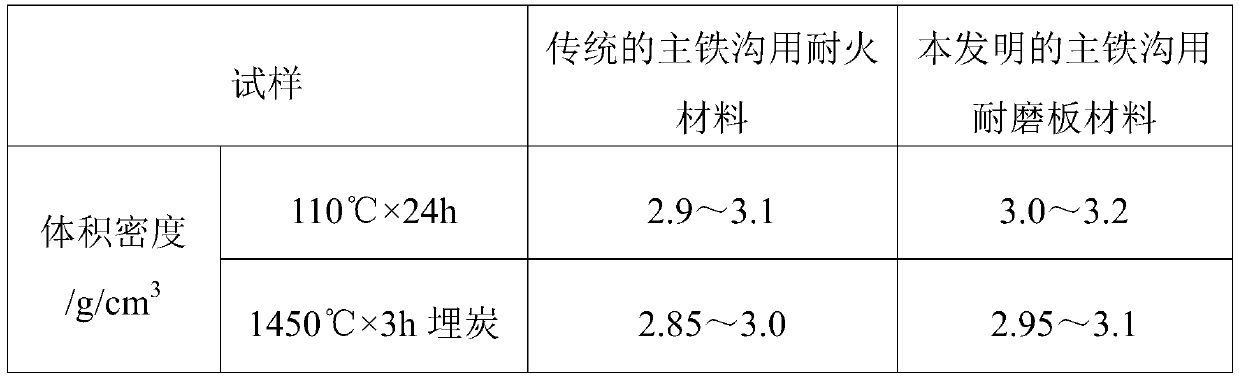

Nano-sol combined wear-resistant board used for main iron channel of blast furnace and production method and application thereof

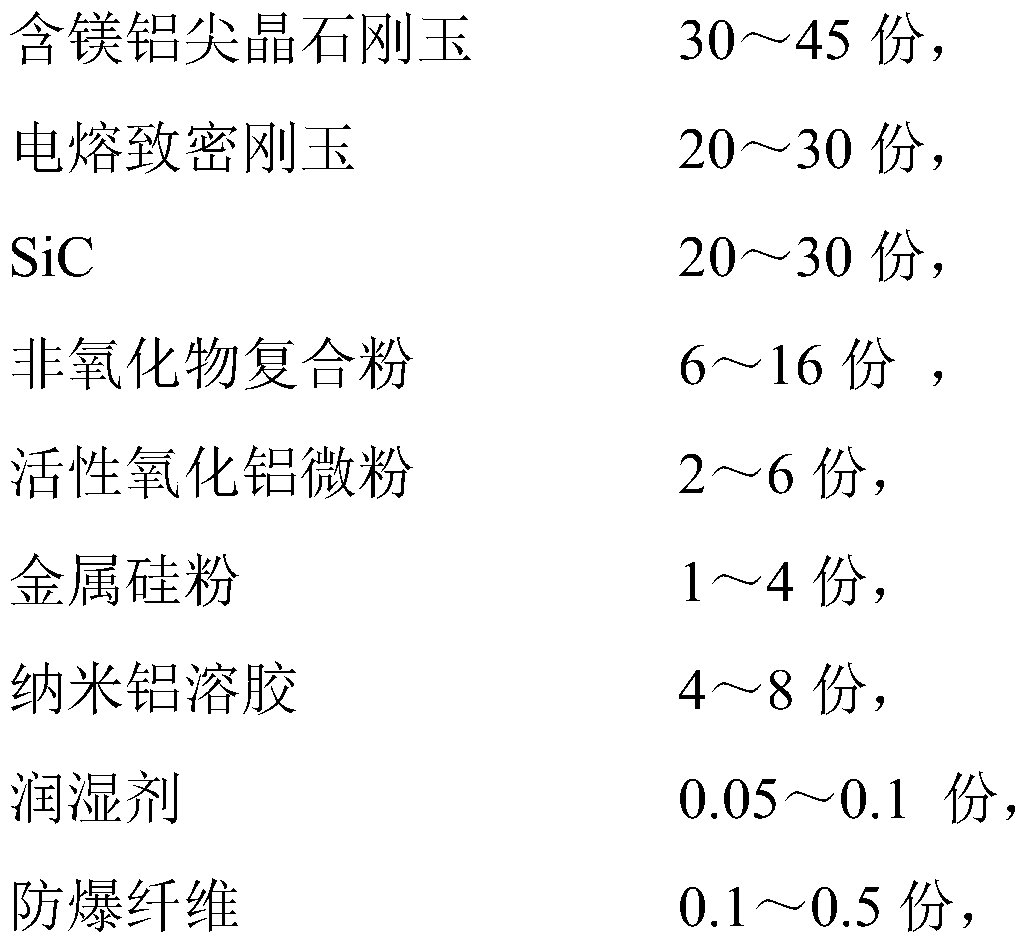

ActiveCN109851333AImprove erosion and wear resistanceImprove thermal shock resistanceFiberWear resistant

The invention discloses a nano-sol combined wear-resistant board used for a main iron channel of a blast furnace. Raw materials of the wear-resistant board comprise, in parts by weight, 30-45 parts ofmagnesium-containing aluminium-containing spinel alumina, 20-30 parts of electro-fused dense alumina, 20-30 parts of SiC, 6-16 parts of nonoxide compound powder, 2-6 parts of activated aluminium oxide micro powder, 1-4 parts of silicon metal powder, 4-8 parts of nano-aluminum sol, 0.05-0.1 part of wetting agent and 0.1-0.5 part of explosion-proof fibers, wherein the nonoxide compound powder is composed of, in parts by weight, 1-3 parts of carbon black, 2-4 parts of silicon nitride, 1-5 parts of titanium carbonitride and 2-4 parts of aluminium titanate. The invention further discloses a production method and application of the wear-resistant board. By means of the nano-sol combined wear-resistant board used for the main iron channel of the blast furnace and the production method and the application thereof, the erosion resistance, the wear resistance and the corrosion resistance of a lining material of the main iron channel can be improved, a work environment of workers can be improved, remedial work time of the main iron channel can be shortened, and the service life of the main iron channel can be prolonged.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Production method of golden condom

InactiveCN101836914AViscosity does not increaseDipping production is beneficialMale contraceptivesOrganic chemistryComposite material

The invention relates to a production method of a golden condom, comprising the following steps: A) golden paste is prepared; B) golden latex is prepared, and pre-vulcanization centrifuged latex, anti-settling agent and the golden paste are mixed and stirred according to proportion, so as to lead the mixture to be fully and uniformly dispersed and obtain the golden latex; C) the golden latex obtained in the step B) is utilized and is manufactured into the golden condom adopting the process for producing the condom normally. By adopting the production method of the golden condom, the golden paste can be fully and uniformly dispersed in the golden latex, and the viscosity of the latex system is not increased, and the production method is suitable for dipping producing the condoms in a continuous production line, thereby being beneficial to producing good golden condom products in a large scale.

Owner:QINGDAO DOUBLE BUTTERFLY GROUP

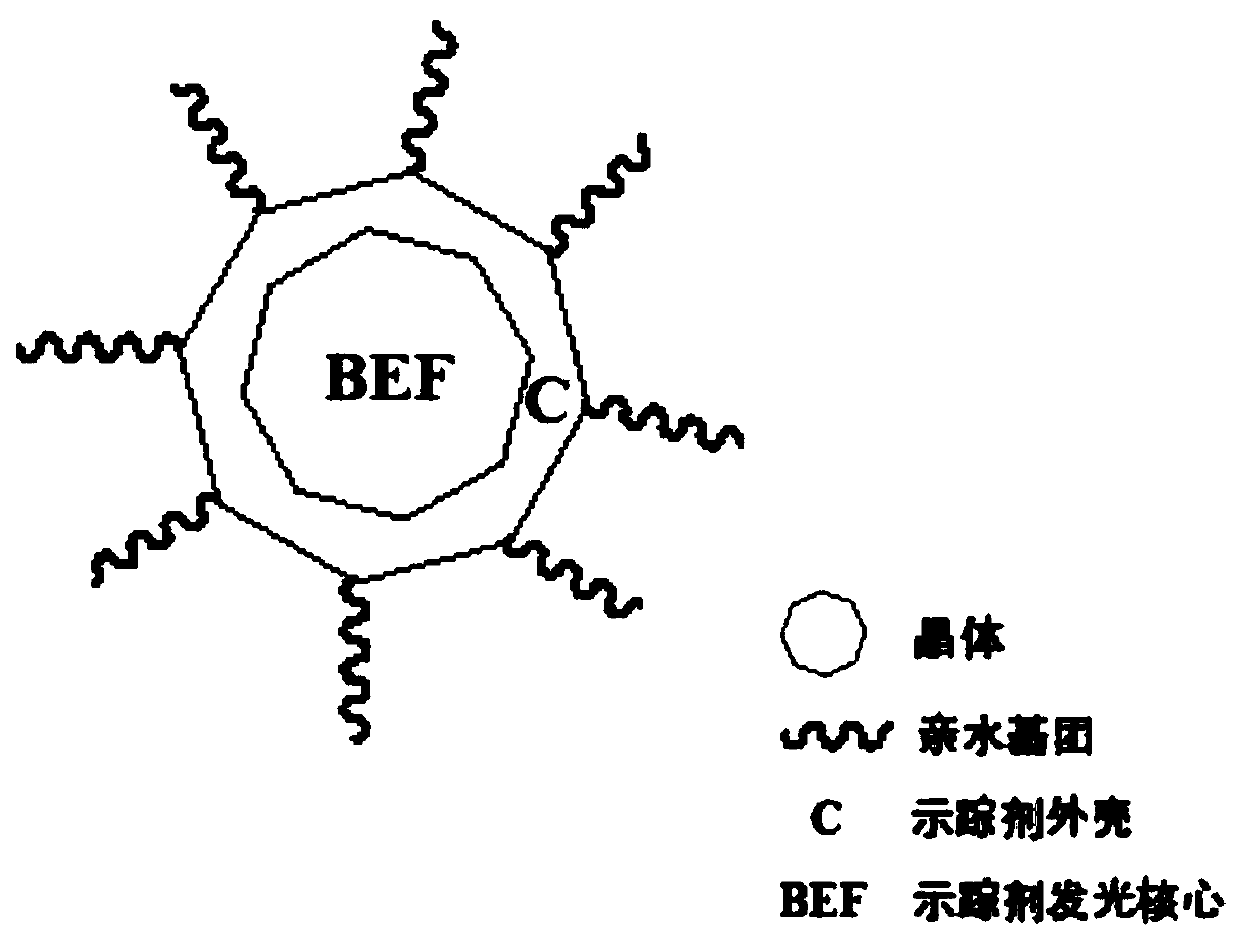

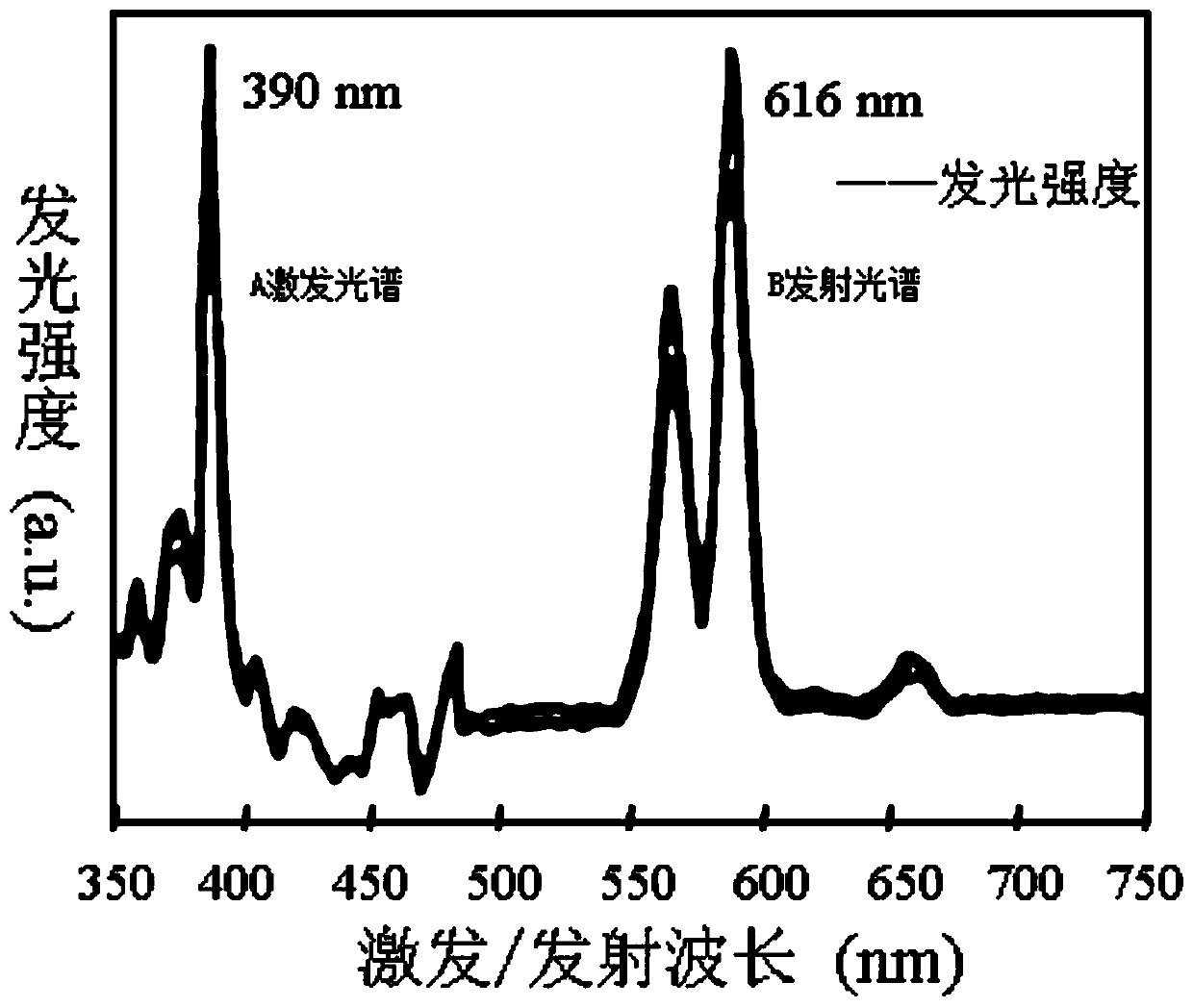

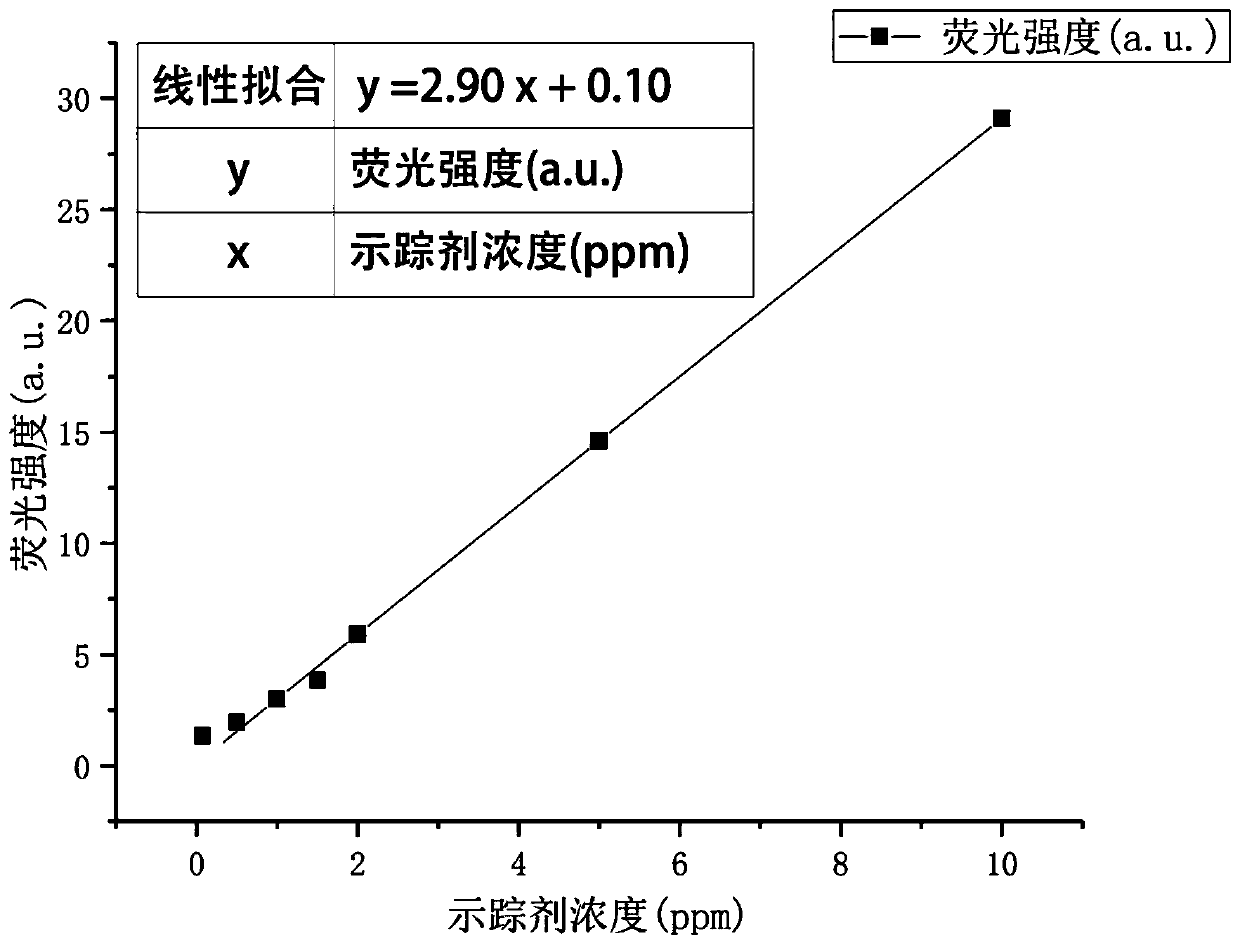

Synthetic method and application of BEFC tracer

ActiveCN109735336AReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementSolubility

The invention relates to a synthetic method and application of a BEFC tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A NaBiF4:Eu3+@C4H4Na2O6 fluorescent nano material with core-shell structure is synthesized herein and may act as an oilfield tracer, named as BEFC tracer. The tracer herein has the advantages of good water solubility, low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility with polymers, and zero impact on polymer flooding. The application of the BEFC tracer as one fluorescent nano material in the field of oilfield detection is innovatively achieved herein; afeasible operating scheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com