Downhole rotational flow shearing generator

A generator and fluid technology, applied in the direction of flushing boreholes, boreholes/well components, earthwork drilling and production, etc., can solve problems such as increased operational risk, excessive rotational torque, and low swirl degree, and achieve enhanced turbulent flow The effect of pulp replacement, improvement of displacement effect, and improvement of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

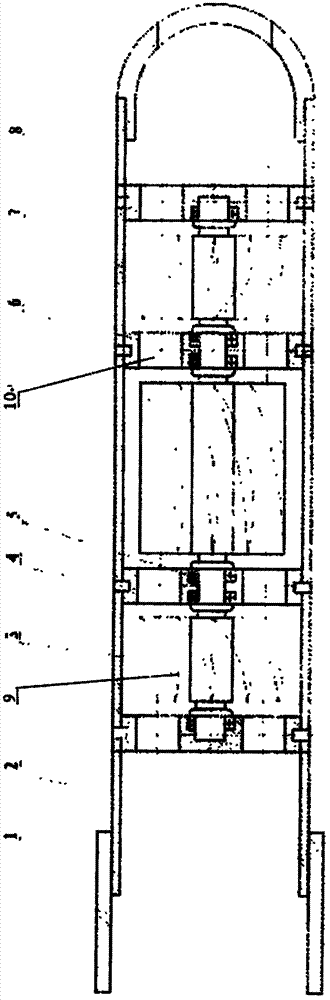

[0010] Embodiments of the present invention are further described in conjunction with the accompanying drawings:

[0011] As shown in the accompanying drawings, the structure and function of the device from top to bottom are as follows: the coupling (1) has a standard casing buckle for connecting with the casing, and the upper part of the outer cylinder (2) and the casing are directly passed through the screw thread. The lower part of the connection is connected with the guide seat (8), and the middle is used to accommodate the guide stator (6) and multiple sets of rotors: shear rotor (3), swirl rotor (7), and to prevent fluid leakage and bear circumferential pressure, etc. With the cementing fluid as the power source, when the fluid flows into the present invention, the shearing rotor (3) rotates at a high speed to generate shearing and stirring effect on the fluid, and at the same time, the fluid flows along the flow channel of the cascade (9) to form a spiral flow, The lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com