Inspection well mouth seat and inspection well with the same and construction, repair method thereof

A technology for inspecting wells and ring mouths, which is applied to drainage structures, buildings, underwater structures, etc., to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

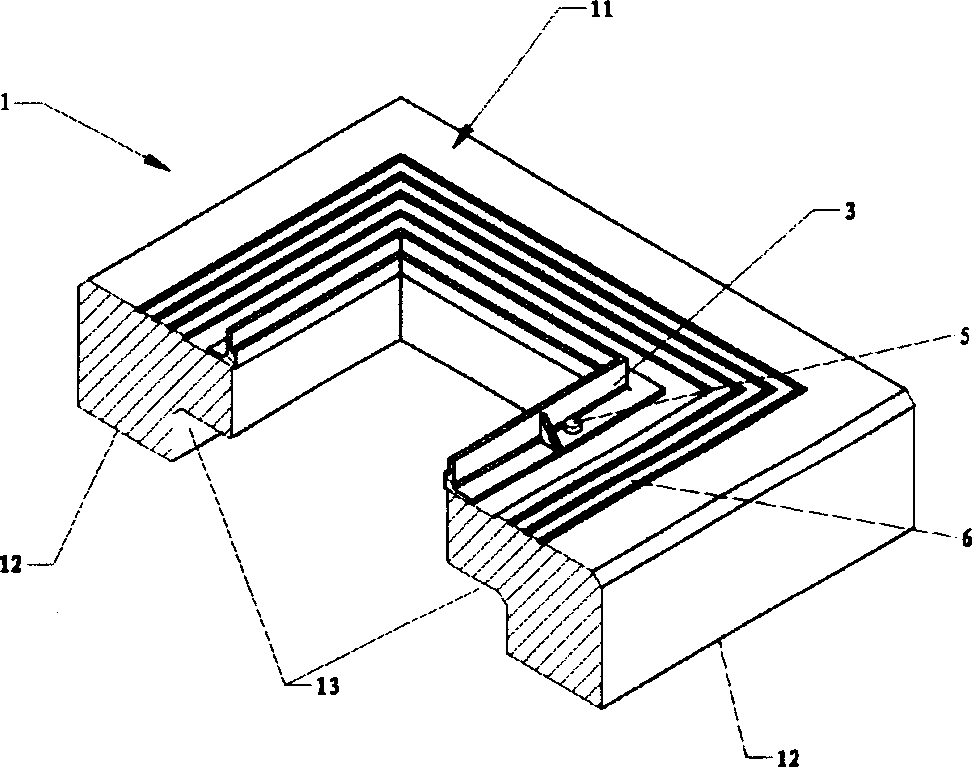

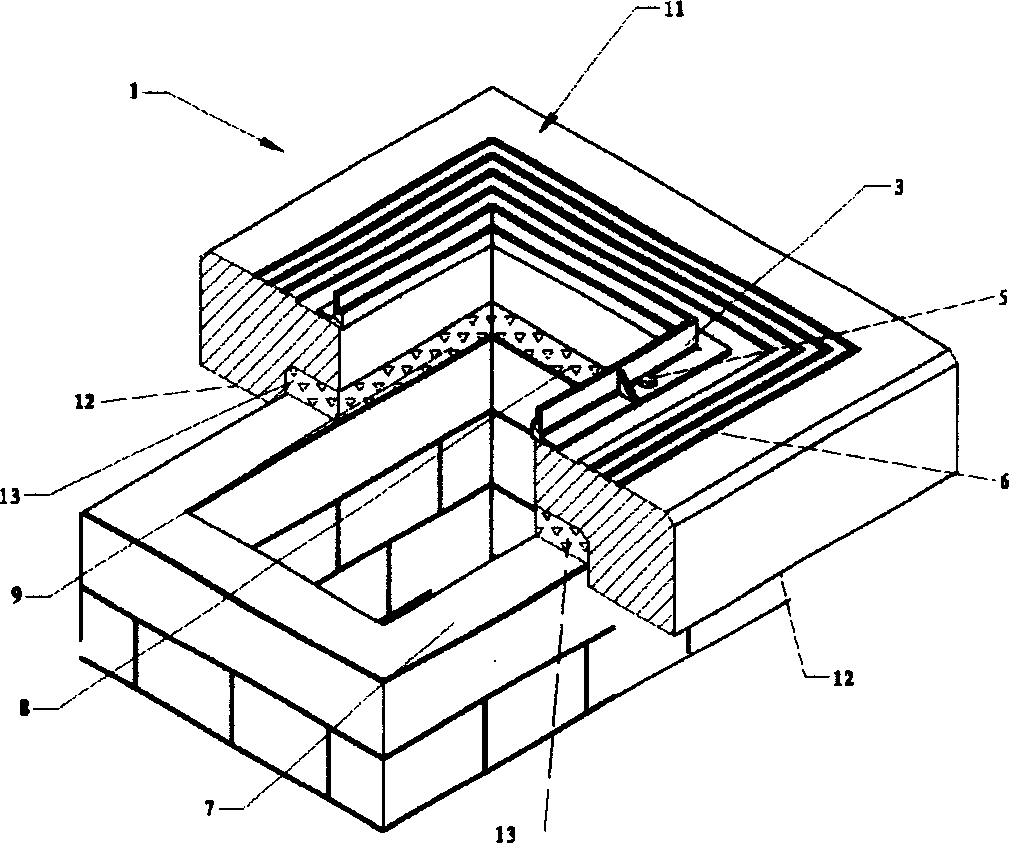

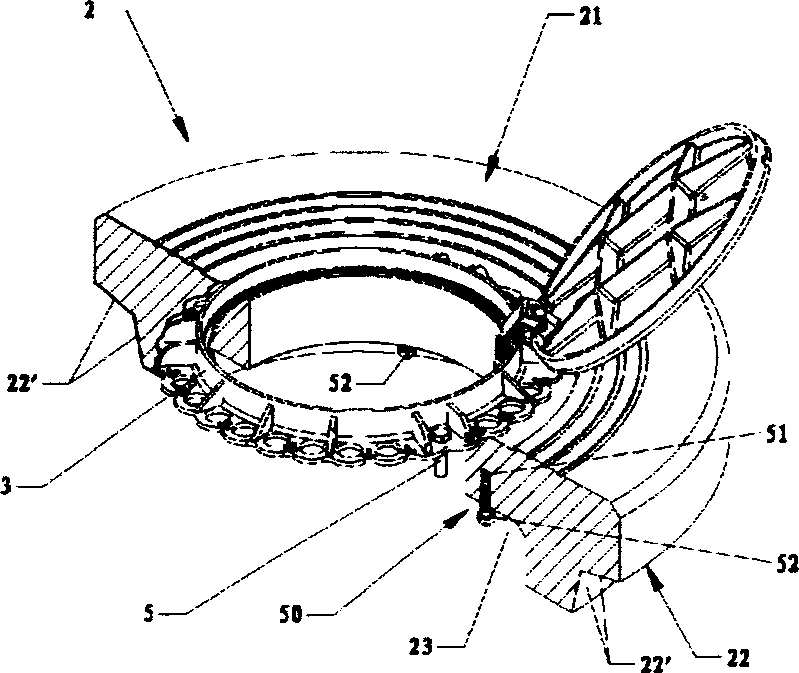

[0051] see figure 1 , the first embodiment of the present invention inspection well ring mouth seat is a square ring member 1 whose rigidity is greater than that of the surrounding soil layer; the upper placement surface 11 of the ring member 1 is used for the installation of the well ring 3 and the laying of pavement materials. The well collar 3 is fixedly installed on the upper placement surface 11 of the annular member 1 through the well collar fixing member 5 arranged inside the annular member 1, and the ring mouth of the well collar 3 is in contact with the annular member 1 opening is aligned. The outer part of the upper placement surface 11 of the annular member 1 is the pavement material laying area 6; the radial outer contour dimension of the annular member 1 is larger than the radial outer contour dimension of the shaft wall 7 of the inspection well. The outer part of the lower surface of the annular component 1 is the lower supporting surface 12 combined with the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com