Nanometer calcium carbonate reinforced and toughened plastic master batch and preparation method thereof

A nano-calcium carbonate and plastic masterbatch technology, applied in the field of plastics, can solve the problems of increasing the difficulty of preparation, particle agglomeration, and increasing production costs, and achieve the effects of improving toughness and surface finish, simple processing technology, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

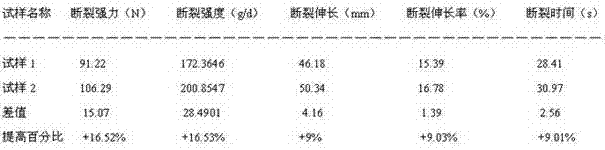

Examples

Embodiment 1

[0033] Embodiment 1: every part is 1kg

[0034] A nano-calcium carbonate reinforced and toughened plastic master batch is composed of the following raw materials in parts by weight:

[0035] Nano calcium carbonate 30 kg

[0036] Micron calcium carbonate 50 kg

[0037] Metallocene polyethylene 13 kg

[0038] Carrier resin 7 kg

[0039] Auxiliary 8 kg

[0040] Wherein, the carrier resin is a mixture of low-density polyethylene and polypropylene mixed in any proportion; the auxiliary agent is composed of amphiphilic coupling agent, oxidized polyethylene wax, calcium stearate in a mass ratio of 3:1 : 1 mixed preparation, namely: amphiphilic coupling agent 4.8kg, oxidized polyethylene wax 1.6kg, calcium stearate 1.6kg.

[0041] The preparation method of above-mentioned masterbatch comprises the steps:

[0042] 1) Weigh nano-calcium carbonate, micro-calcium carbonate, metallocene polyethylene, carrier resin and additives according to the ratio for use;

[0043] 2) Add 30% of th...

Embodiment 2

[0045] Embodiment 2: every serving is 1g

[0046] A nano-calcium carbonate reinforced and toughened plastic master batch is composed of the following raw materials in parts by weight:

[0047] Nano calcium carbonate 65 g

[0048] Micron calcium carbonate 35 g

[0049] Metallocene polyethylene 13 g

[0050] Carrier resin 10 g

[0051] Auxiliary 5 g

[0052] Wherein, the carrier resin is low-density polyethylene; the auxiliary agent is prepared by mixing amphiphilic coupling agent, oxidized polyethylene wax, and calcium stearate in a mass ratio of 3:1:1, namely: Amphiphilic coupling agent 3g, oxidized polyethylene wax 1g, calcium stearate 1g.

[0053] The preparation method of above-mentioned masterbatch comprises the steps:

[0054] 1) Weigh nano-calcium carbonate, micro-calcium carbonate, metallocene polyethylene, carrier resin and additives according to the ratio for use;

[0055] 2) Add 34% of the total weight of additives and nano-calcium carbonate into the high-spee...

Embodiment 3

[0057] Embodiment 3: Each serving is 1 catty

[0058] A nano-calcium carbonate reinforced and toughened plastic master batch is composed of the following raw materials in parts by weight:

[0059] Nano calcium carbonate 80 catties

[0060] Micron calcium carbonate 5 catties

[0061] Metallocene polyethylene 17 catties

[0062] Carrier resin 9 catties

[0063] Auxiliary 10 catties

[0064] Wherein, the carrier resin is polypropylene; the auxiliary agent is prepared by mixing amphiphilic coupling agent, oxidized polyethylene wax, and calcium stearate at a mass ratio of 3:1:1, namely: amphiphilic coupling agent 6 catties of joint agent, 2 kg of oxidized polyethylene wax, and 2 catties of calcium stearate.

[0065] The preparation method of above-mentioned masterbatch comprises the steps:

[0066] 1) Weigh nano-calcium carbonate, micro-calcium carbonate, metallocene polyethylene, carrier resin and additives according to the ratio for use;

[0067] 2) Add 32% of the total wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com