Patents

Literature

237results about How to "Does not affect product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed additive containing chitin oligose and its prepn and use

InactiveCN1608487AIncrease production capacityIncrease profitFood processingAnimal feeding stuffBiotechnologyImmunity

The present invention is feed additive containing chitin oligose and its preparation and use. Chitin oligose is prepared with chitosan and through dissolving in acid solution to obtain chitosan solution; heating chitosan solution at 30-60 deg.c, regulating pH value to 5-6, adding composite enzyme for enzymolysis of 2-5 hr to obtain enzymolyzed liquid; filtering to eliminate zymoprotein and other impurity to obtain clear enzymolyzed liquid; concentrating the enzymolyzed liquid to obtain concentrated liquid; spray drying to obtain solid chitin oligose. The obtained solid chitin oligose is mixed with Chinese medicinal materials and crushed to obtain the additive. The additive has bacteriostasis function, no toxic side effect, no residue of harmful matter and no drug resistance, and may be used in various feeds for farm animal and aquatic animal to raise feed utilization, raise product quality and strengthen immunity.

Owner:济南海得贝海洋生物工程有限公司

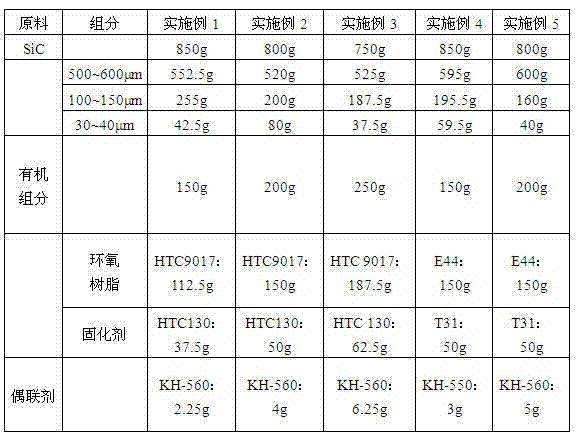

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Process for preparing and purifying quartz sand and quartz powder and products thereby

The invention discloses a process for preparing and purifying quartz sand and quartz powder and products thereby, which consists of quartz ore selection, squashing, water selection, sintering, water disintegrating, oxalic acid or citric acid immersing, dry grinding or wet grinding, magnetic selection, fractionation, floating selection, deionized water washing, special type drying and vacuum-packing.

Owner:刘少云

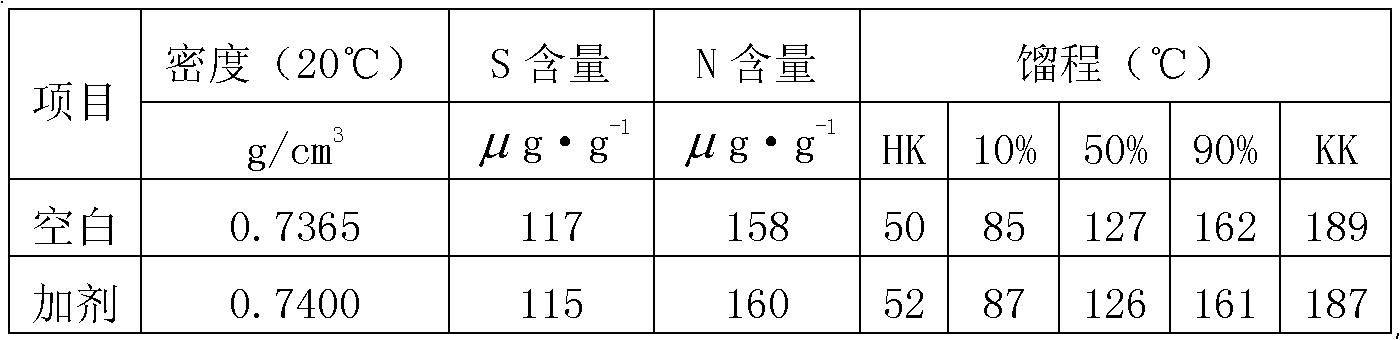

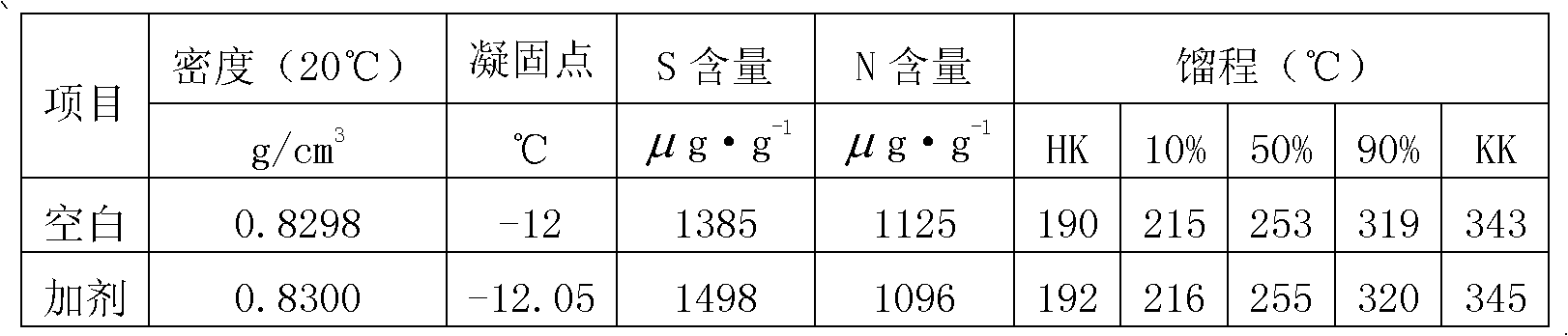

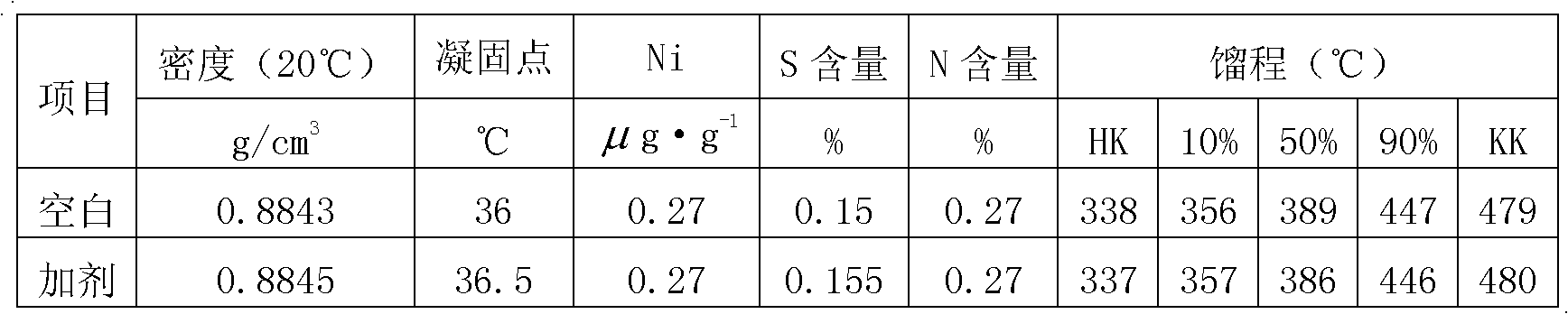

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

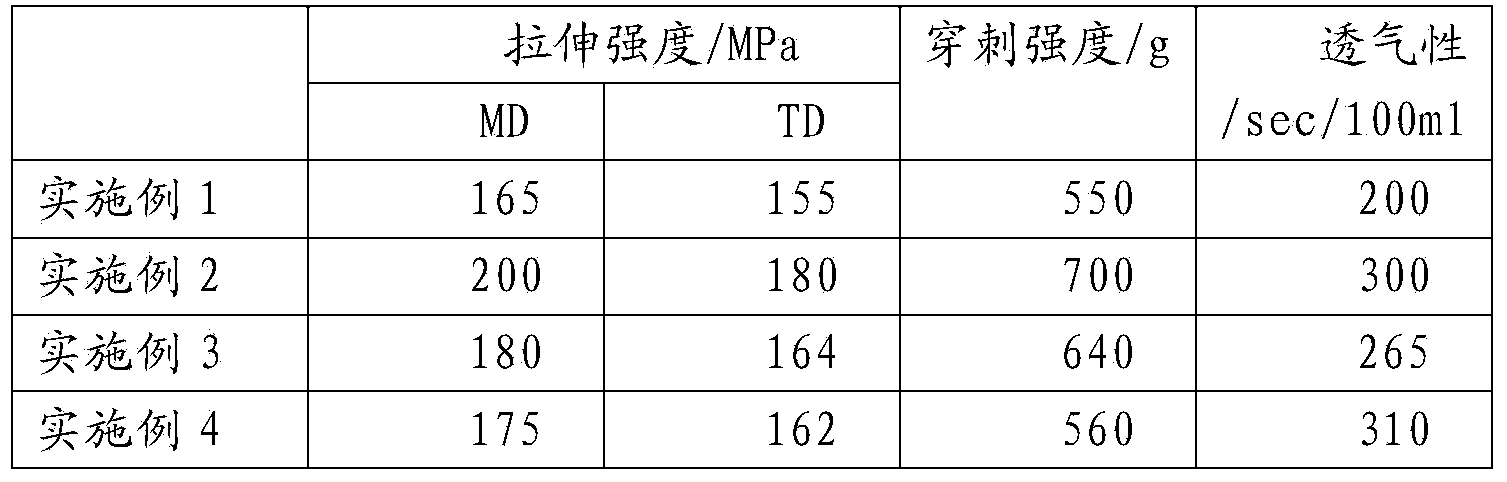

Ultrathin high-strength polyolefin microporous film and preparation method thereof

The invention discloses a preparation method of an ultrathin high-strength polyolefin microporous film. Polyolefin resin is used as a raw material, and the polyolefin microporous film is prepared by a thermally induced phase separation principle. The method comprises the following steps: a. polyolefin swelling dissolving; b. sheet casting; c. stretching a polyolefin cast film once; and d. stretching the polyolefin cast film secondarily. The invention also discloses the polyolefin microporous film prepared by the method. The method has the advantages of semi-continuous production convenience, simple process flow and simplicity in operation.

Owner:SHENZHEN SENIOR TECH MATERIAL

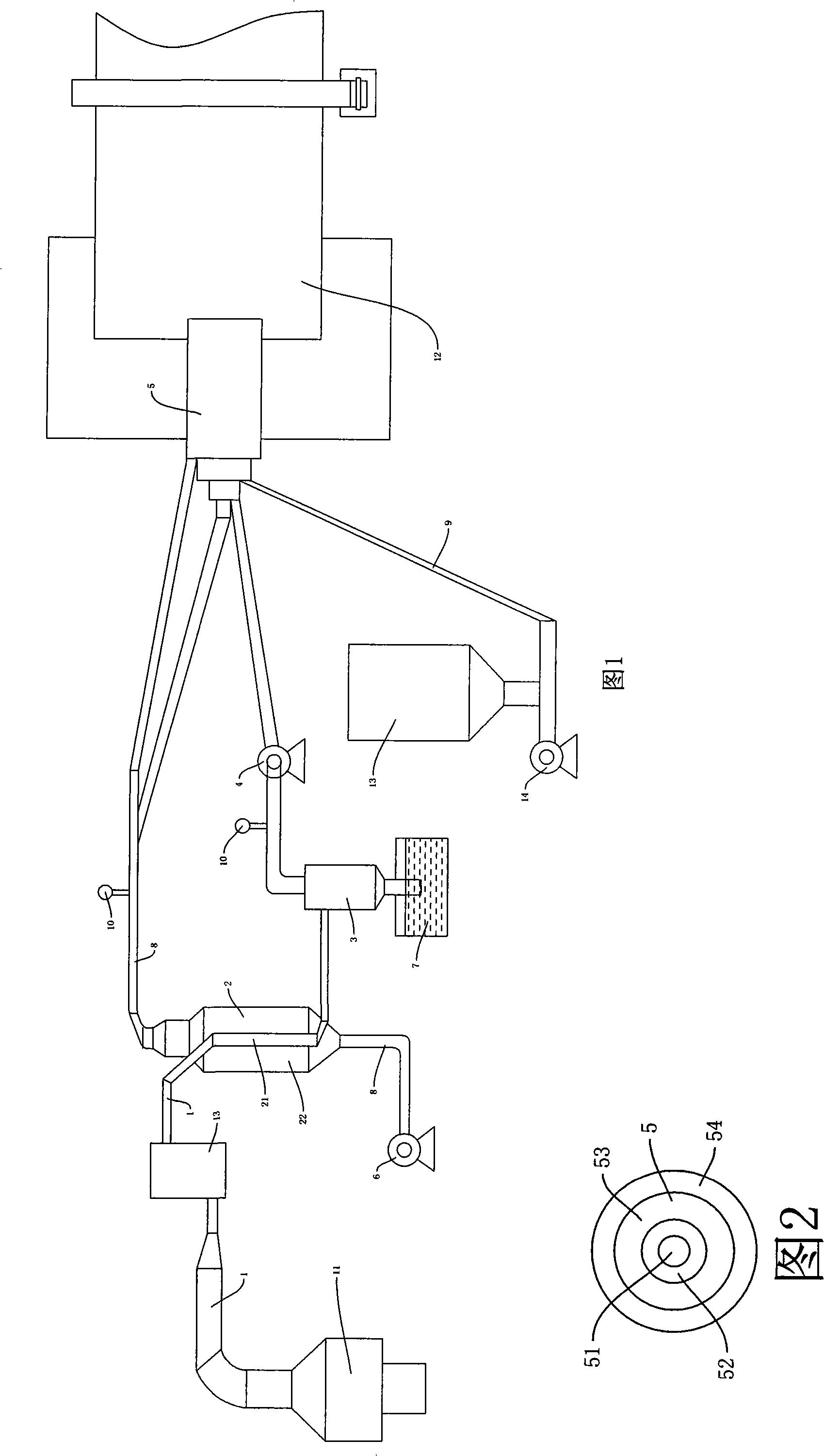

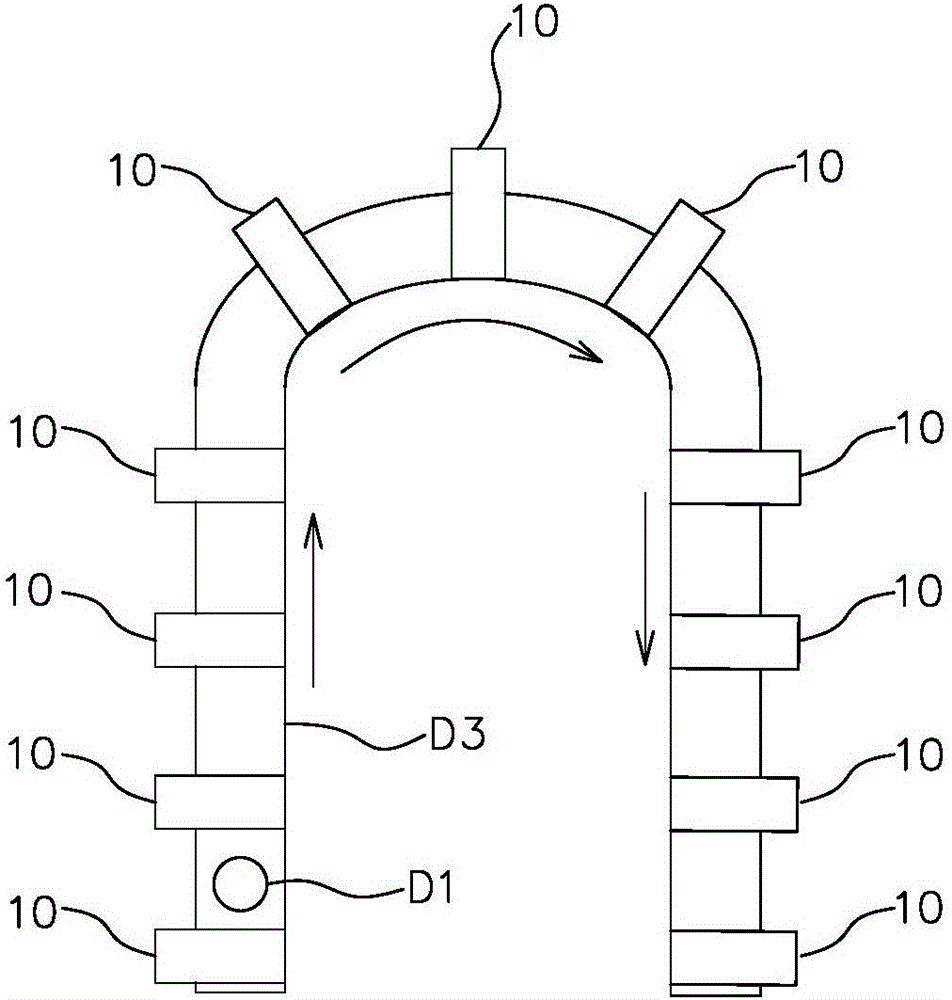

Calcium carbide stove exhaust combustion and utilization method and device

InactiveCN101403506ALess investmentDoes not affect product qualityStationary tubular conduit assembliesIncinerator apparatusThermal energyCombustor

The invention provides a combustion utilizing method and a combustion utilizing device of the exhaust gas of a calcium carbide furnace; an exhaust gas discharging tube of the calcium carbide furnace, a heat exchanger, a dust remover, a booster fan and a pipeline used for a combustor are serially connected, and the nozzle of the combustor is inserted into a thermodynamic furnace. The exhaust gas of the calcium carbide furnace is treated with temperature reduction by the heat exchanger, dust removal by the dust remover and pressurization by the booster fan, sent into a combustion gas pipe of the combustor, and finally jetted into the thermodynamic furnace for combustion. The combustion utilizing device of the exhaust gas of the calcium carbide furnace is combined with the thermodynamic furnace and a furnace outlet dust removing system so as to be used in the production of lime or other products or in material parching, thus forming a product manufacturing system integrated with heat utilization, dust removal, purification and standardized discharge of the exhaust gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

Nanometer calcium carbonate reinforced and toughened plastic master batch and preparation method thereof

The invention discloses a nanometer calcium carbonate reinforced and toughened plastic master batch and a preparation method thereof. The master batch consists of nanometer calcium carbonate, micrometer calcium carbonate, metallocene polyethylene, carrier resins and aids, wherein the nanometer calcium carbonate and the micrometer calcium carbonate are blended and added, so that reinforcing and toughening functions of the master batch are enhanced; the metallocene polyethylene has high strength and toughness, so that reinforcing and toughening effects of the master batch can be simultaneously enhanced; and the master batch is prepared by two steps, so that the nanometer calcium carbonate passes through a co-rotating twin screw extruder for two times, the dispersibility of the nanometer calcium carbonate in the master batch is further enhanced, and the reinforcing and toughening functions is fully reflected. The master batch has the advantages that the nanometer calcium carbonate can be fully and uniformly dispersed in the carrier resins, so that the prepared master batch has the peculiar reinforcing and toughening functions of the nanometer calcium carbonate; and the master batch is simple in processing technology and low in cost, the stability, heat resistance and aging resistance of materials can be effectively enhanced, and particularly the plastic strength, the toughness and the surface smoothness are greatly improved.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

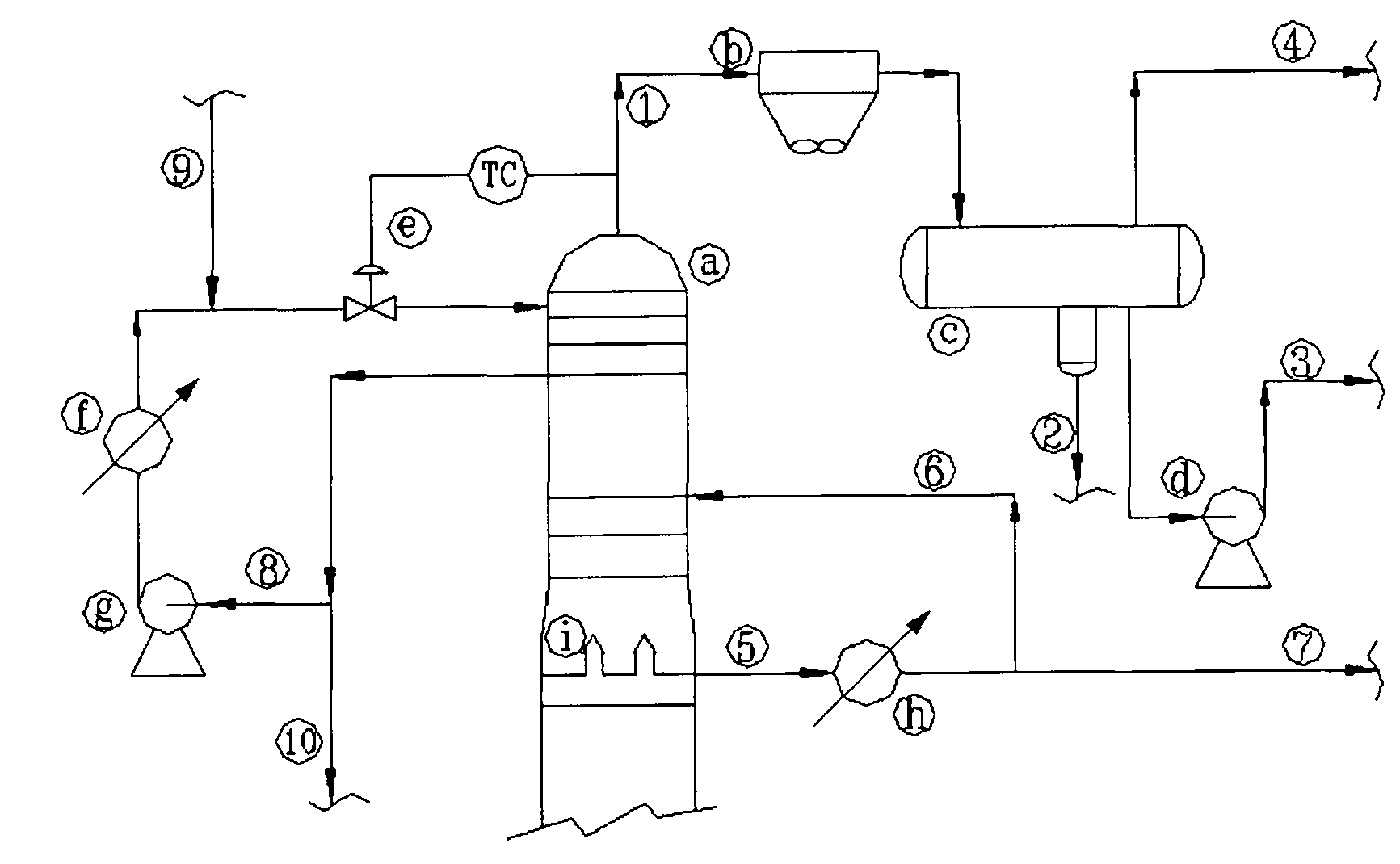

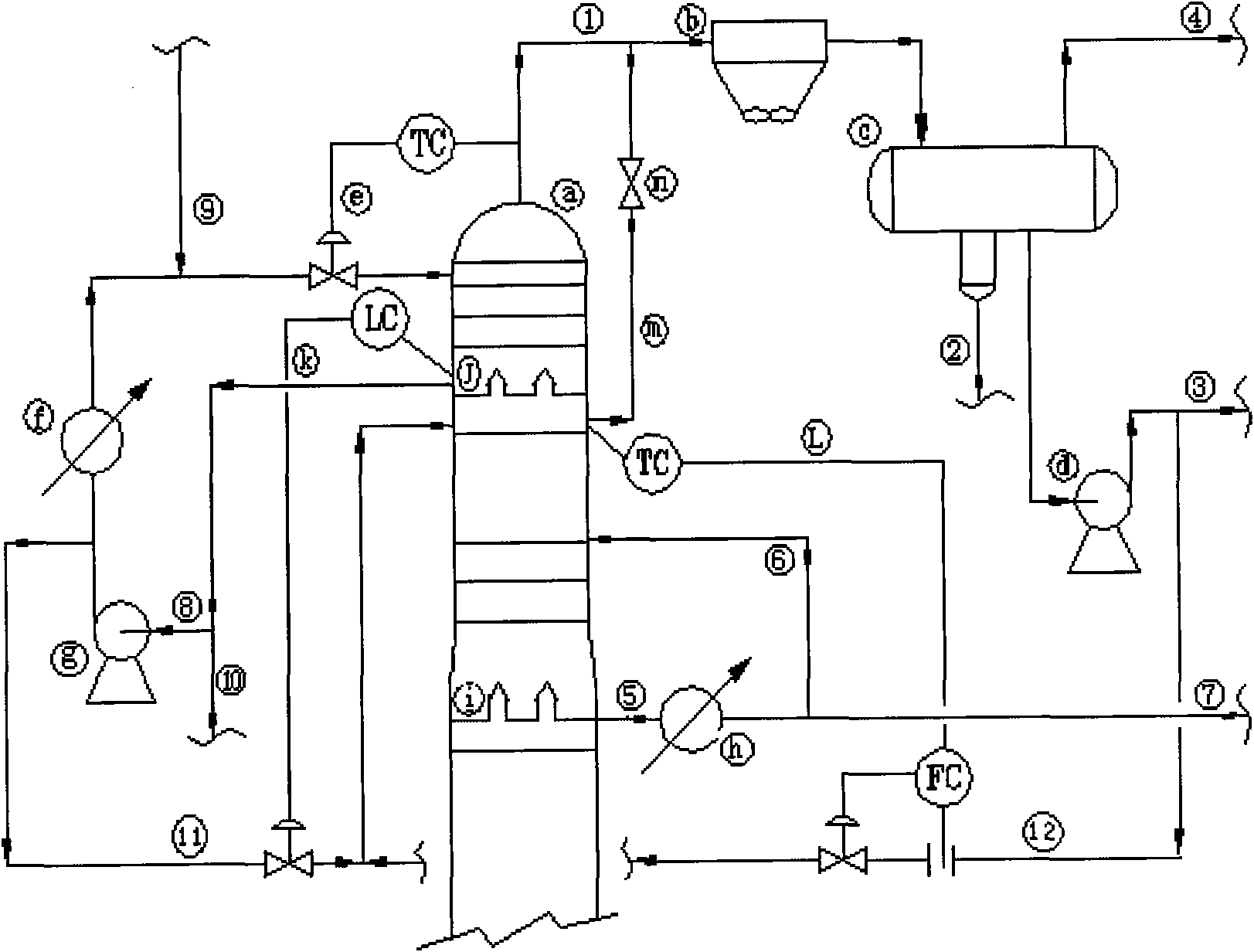

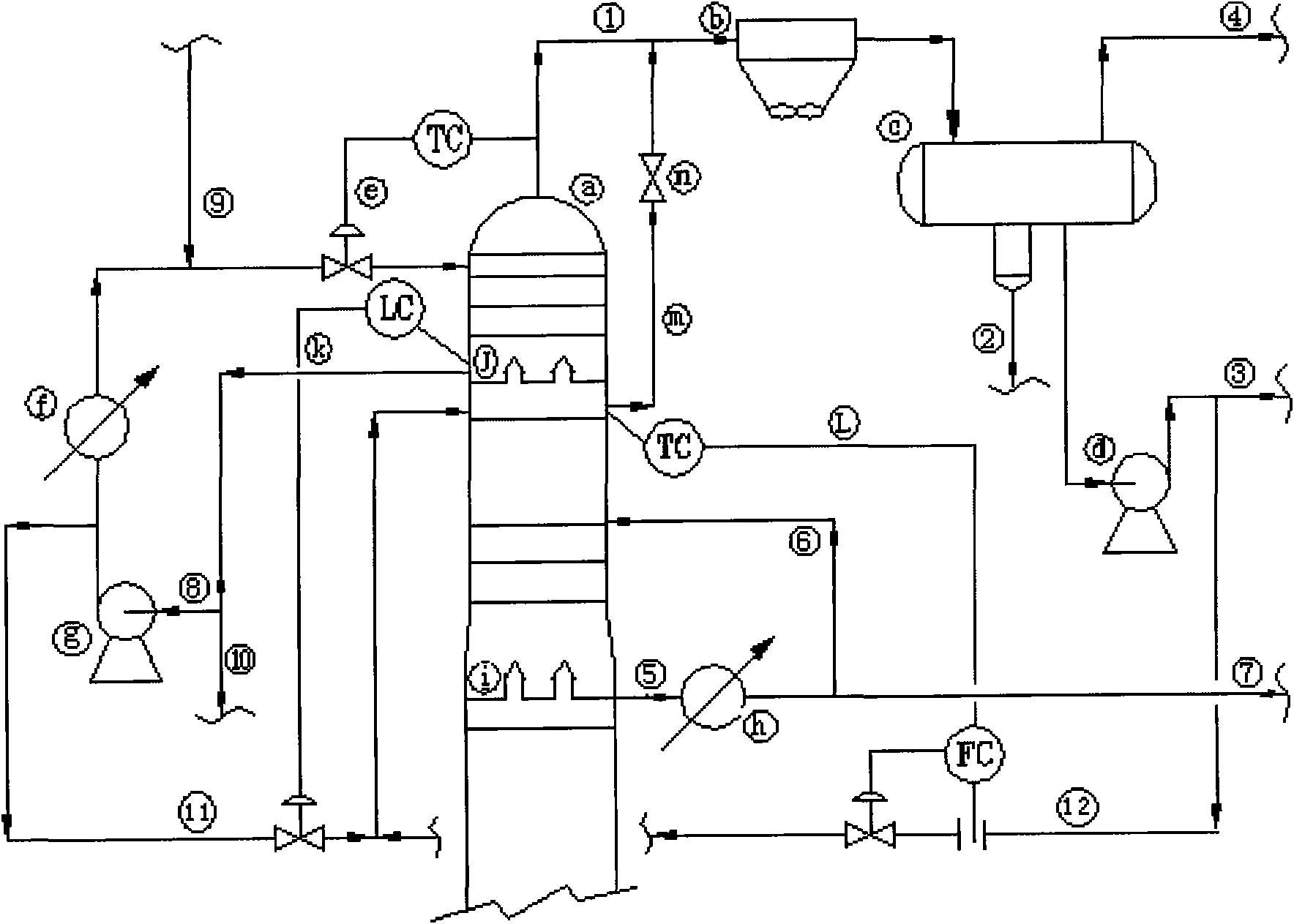

Method and device for removing salt for fractionate tower

ActiveCN102250635ADoes not affect the fractionation effectDoes not affect product qualityHydrocarbon distillationNaphthaWash water

The invention discloses a method and a device for removing salt for a fractionate tower. The device is characterized in that a gasoline sump tank is arranged at an overhead recycle oil extraction position of a fractionate tower and an oil gas over line is arranged between the upper space of a lower layer tower plate of the gasoline sump tank and the front portion of an air cooler located at the top of the fractionate tower. The method is characterized in that when a salt removing process is carried out in a fractionate tower, oil gas in the upper space of the lower layer tower plate of the gasoline sump tank reaches the air cooler located at the top of the fractionate tower directly through the oil gas over line; a part of overhead recycle oil is cooled and then reaches the top of the fractionate tower and a part of the overhead recycle oil reaches the lower layer tower plate of the gasoline sump tank; naphtha in a gas-liquid separation tank located at the top of the fractionate tower is partly fed to a follow-up device and partly enters into the lower layer tower plate of the gasoline sump tank from the gasoline sump tank of the fractionate tower; wash water is injected from a overhead recycle oil return opening; and water for removing salt is discharged from an overhead recycle oil extraction opening. Through the method and the device, the advantages of no influence on fractionation effects of a fractionate tower and quality of gasoline and diesel oil products in salt removal, no influence on follow-up processes of rich gas compression, absorption and stabilization, simple operation, and good safety and reliability are realized.

Owner:CHINA PETROCHEMICAL CORP +1

Treatment method for acyl-chlorination reaction tail gas

InactiveCN103908870ASafe and easy production operationDoes not affect product qualityHydrazine preparationDispersed particle separationP-chloroanilineAcyl group

The invention relates to a treatment method for acyl-chlorination reaction tail gas. The reaction tail gas successively enters a three-step series hydrogen chloride falling-film absorption tower and a two-step series ammonium hydroxide absorption tower; p-chloroaniline and recovered hydrochloric acid are taken as raw materials and subjected to diazotization reaction for generating a diazo salt; and an aqueous solution of ammonium sulfite is taken as a reducing agent, after the diazo salt is dropwise added at room temperature, the recovered hydrochloric acid is dropwise added for acidification hydrolysis and further for preparing p-chlorophenylhydrazine hydrochloride. By employing the method to treat the acyl-chlorination reaction tail gas, tedious technologies for discharging and drying solid materials and selecting low-temperature equipment for liquefying sulfur dioxide are avoided, and the production operation is safe and convenient; and the produced tail gas absorption solution can be used as a raw material for preparing organic chemical products, is environment-friendly and is capable of creating economic benefit.

Owner:TIANJIN QIDONG CHEM PLANT

Catalytic decomposition process of formic acid

ActiveCN108623457ASimple processLess investmentOrganic compound preparationCarboxylic acid esters preparationFormic acidEther

The invention discloses a catalytic decomposition process of formic acid. The catalytic decomposition process comprises: catalytically decomposing formic acid in a to-be-deacidified material into CO and H2O or CO2 and H2 through a catalyst, wherein the formic acid content in the to-be-deacidified material is less than or equal to 1 wt%. According to the present invention, a small amount of the formic acid contained in alcohols, ethers, esters and other organic products is decomposed, such that the advantages of simple process, less investment, low energy consumption, low cost and product quality improving are achieved, and the difficultly-treated secondary pollution cannot be generated to the original product and the environment.

Owner:成都汇嘉春天科技有限公司

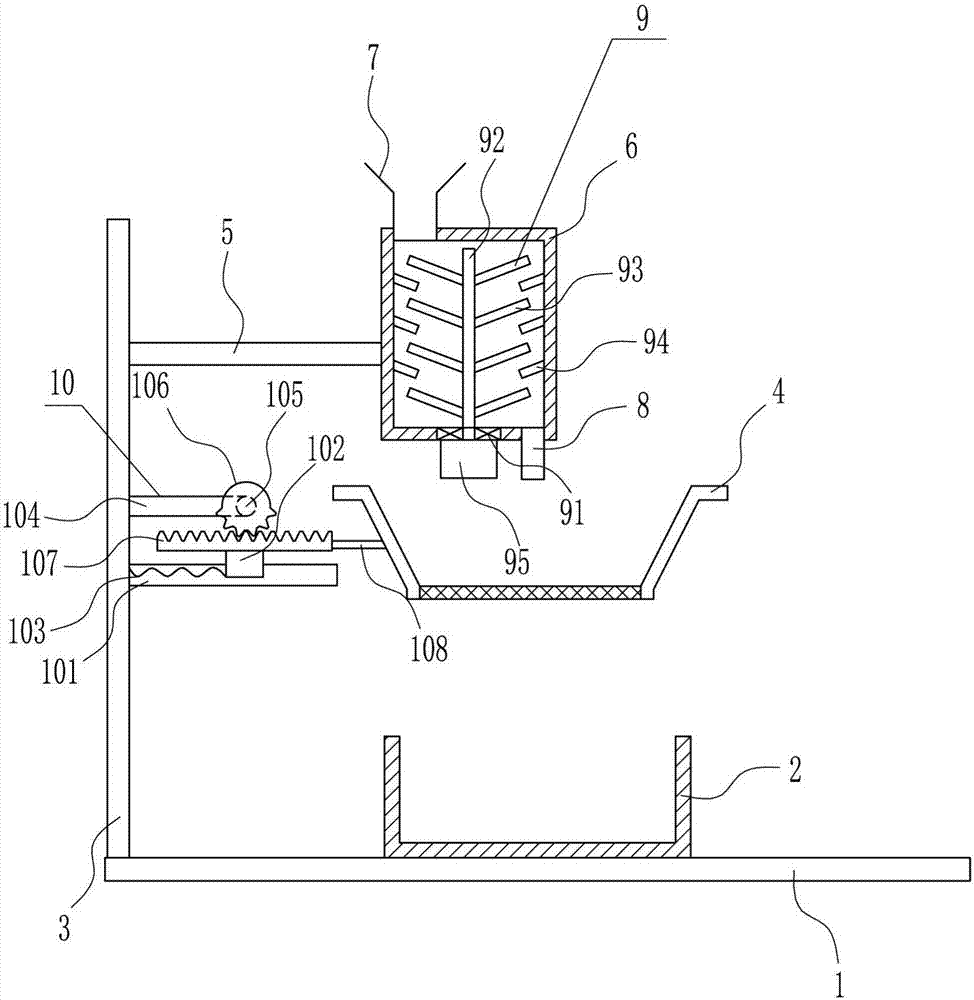

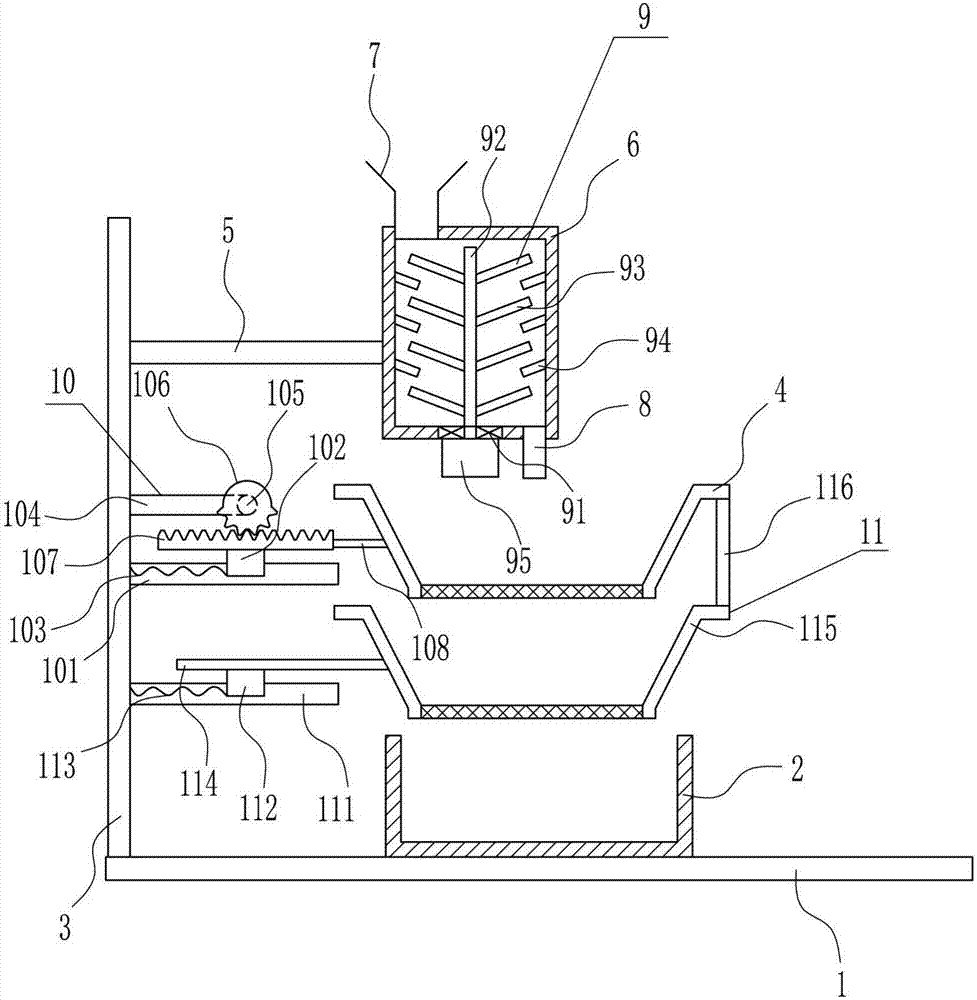

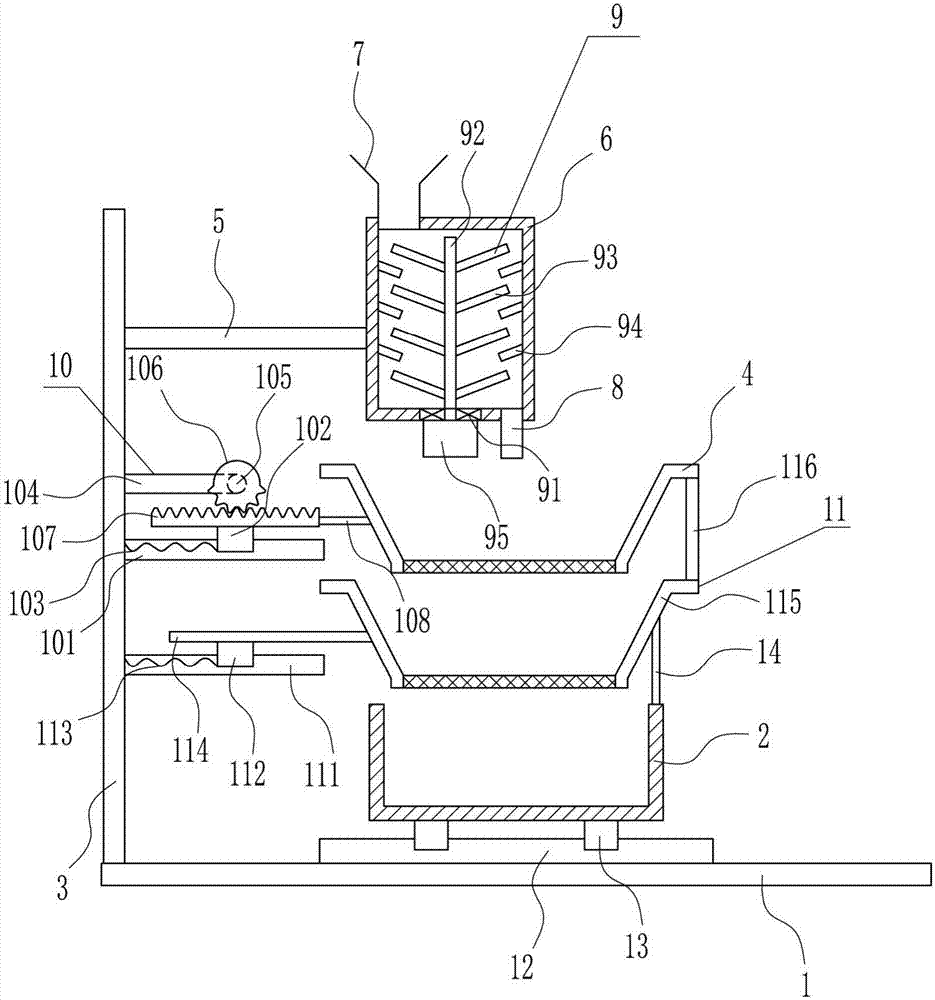

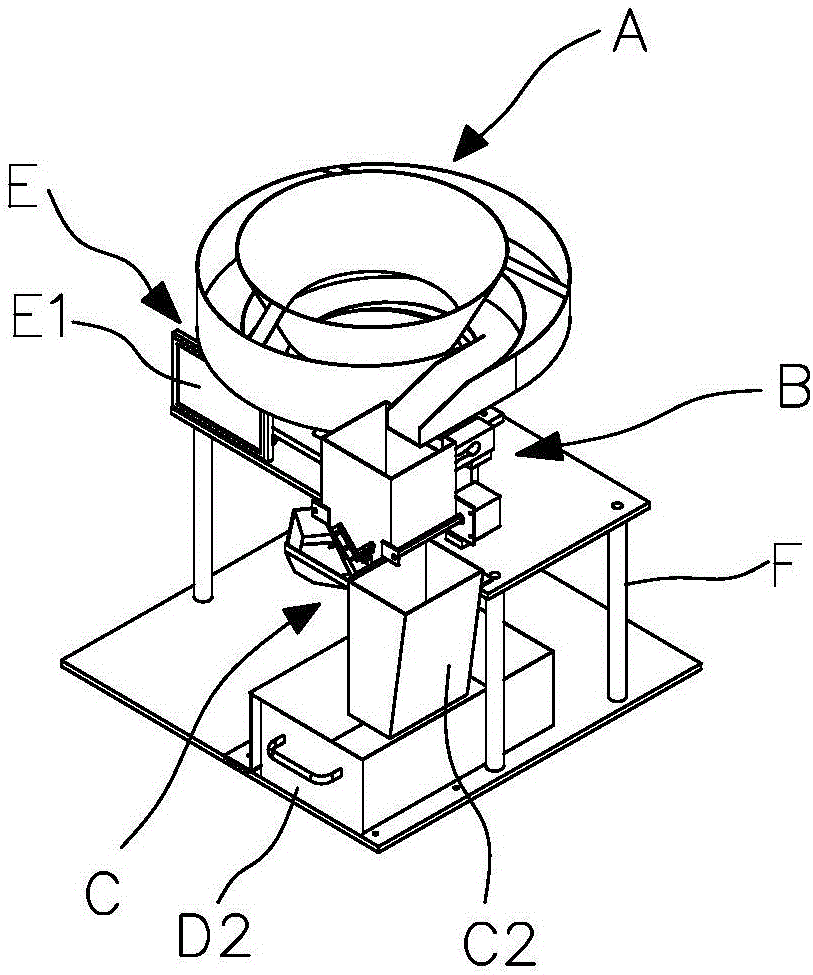

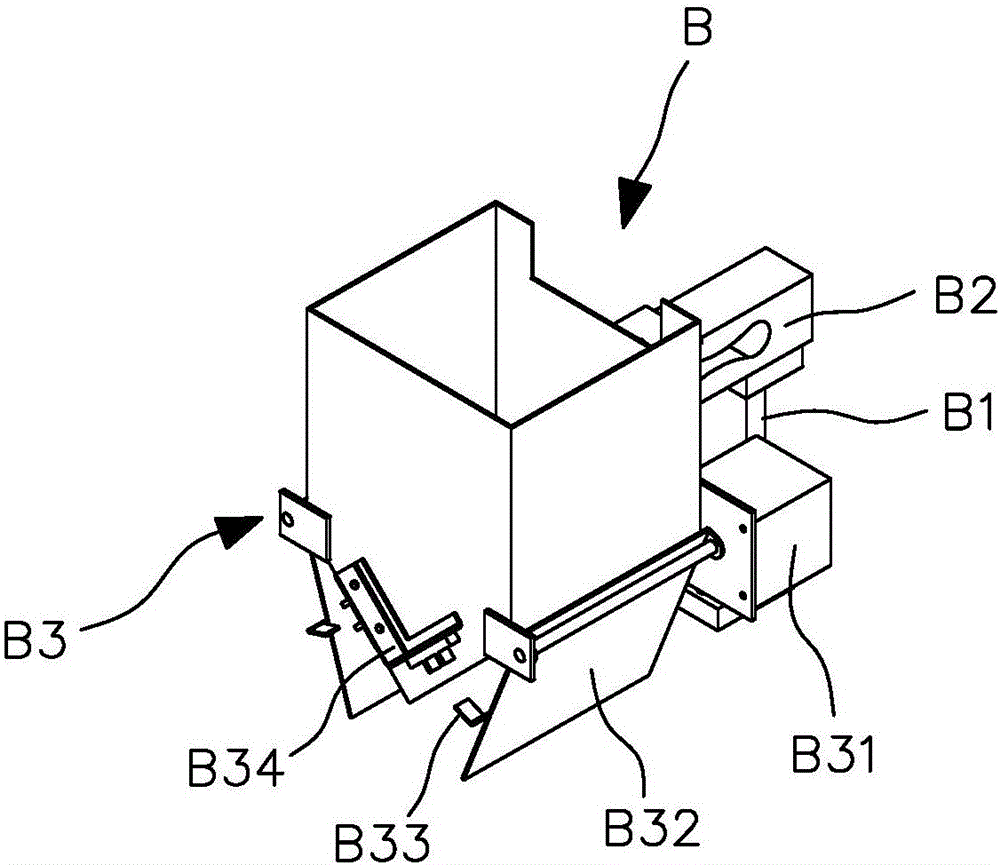

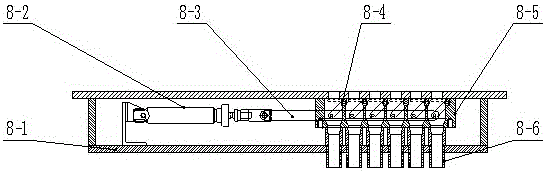

Device for screening graphite for boron carbide smelting raw material

InactiveCN107138233AImprove work efficiencyDoes not affect product qualitySievingScreeningGraphiteBoron carbide

The invention relates to screening devices, in particular to a device for screening graphite for a boron carbide smelting raw material. The device for screening the graphite for the boron carbide smelting raw material is provided for achieving the technical effects of being time-saving, labor-saving, high in working efficiency and capable of conducting repeated screening on impurities in graphite without affecting the product quality. In order to achieve the technical effects, the device for screening the graphite for the boron carbide smelting raw material is provided by the invention and comprises a bottom plate, a collection frame, a supporting plate, a first screening frame, a first cross rod, a stirring box and the like. The collection frame is mounted in the middle of the top of the bottom plate in a bolted connection mode. The supporting plate is mounted on the left side of the top of the bottom plate in a bolted connection mode. A left-right moving device is arranged in the middle of the right side of the supporting plate. The first screening frame is connected to a moving component of the left-right moving device. The device achieves the effects of being time-saving, labor-saving, high in working efficiency and capable of conducting repeated screening on impurities in graphite without affecting the product quality.

Owner:雷海涛

Workpiece spraying and processing device as well as processing method thereof

InactiveCN103962282AAvoid pollutionReduce labor costsLiquid surface applicatorsSpraying apparatusMechanical engineeringEngineering

The invention discloses a workpiece spraying and processing device as well as a processing method thereof. The device comprises a spraying device arranged at a spraying area, a drying chamber for drying workpieces and conveying devices arranged at the spraying area and the drying chamber, wherein the conveying devices comprise a first conveying device and a second conveying device which are respectively arranged at the spraying area and the drying chamber; a piece transferring device which is used for transferring workpieces is arranged between the spraying area and the drying chamber. According to the workpiece spraying and processing device provided by the invention, because the conveying devices at the spraying area and the drying chamber are arranged independently and separately, and the workpiece transferring device for transferring pieces is arranged between the spraying area and the drying chamber, each part of the conveying devices can be prevented from being polluted, and the transferring not only cannot increase labor cost, but also cannot lower the production efficiency, and additionally, the product quality is not affected, thereby saving energy, reducing consumption, improving the product quality, and improving the production efficiency and economical benefit of enterprises.

Owner:SHENZHEN LIUSH MACHINERY EQUIP

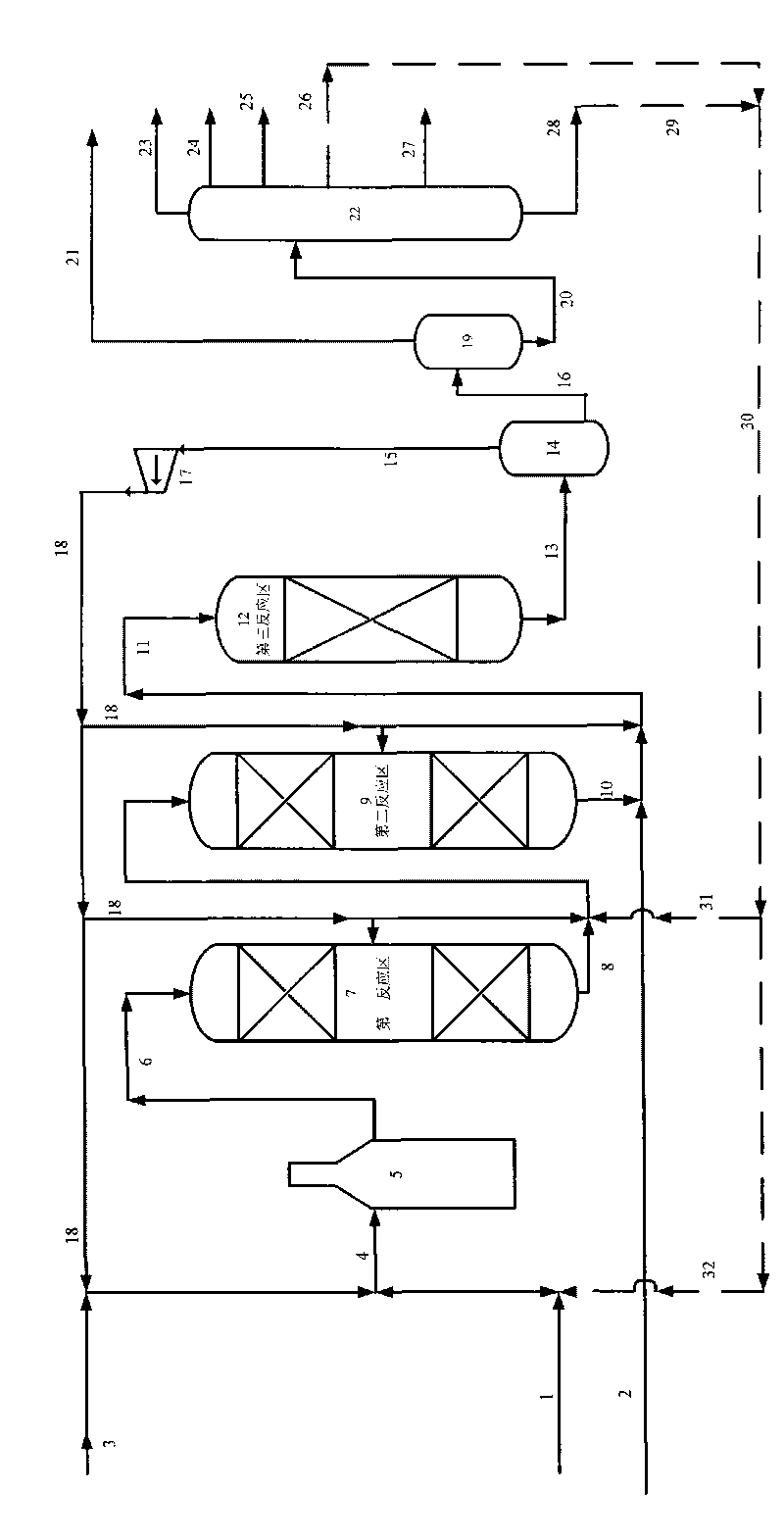

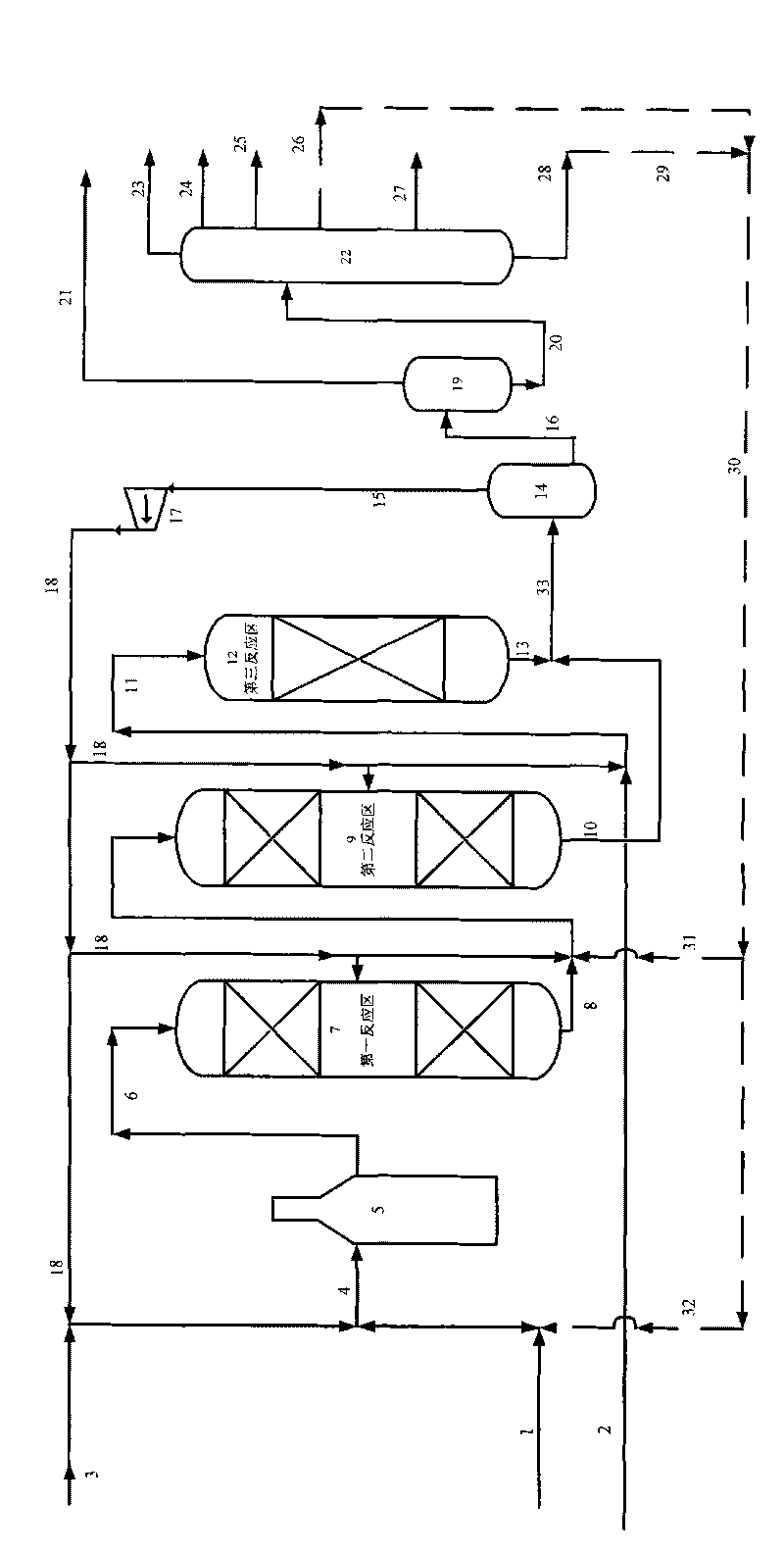

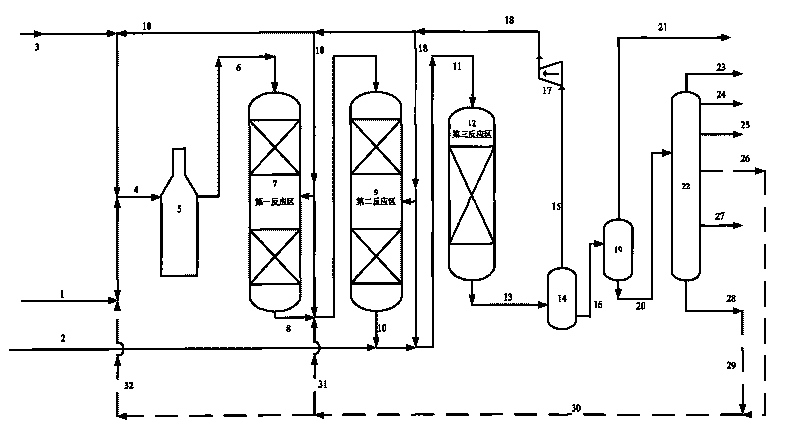

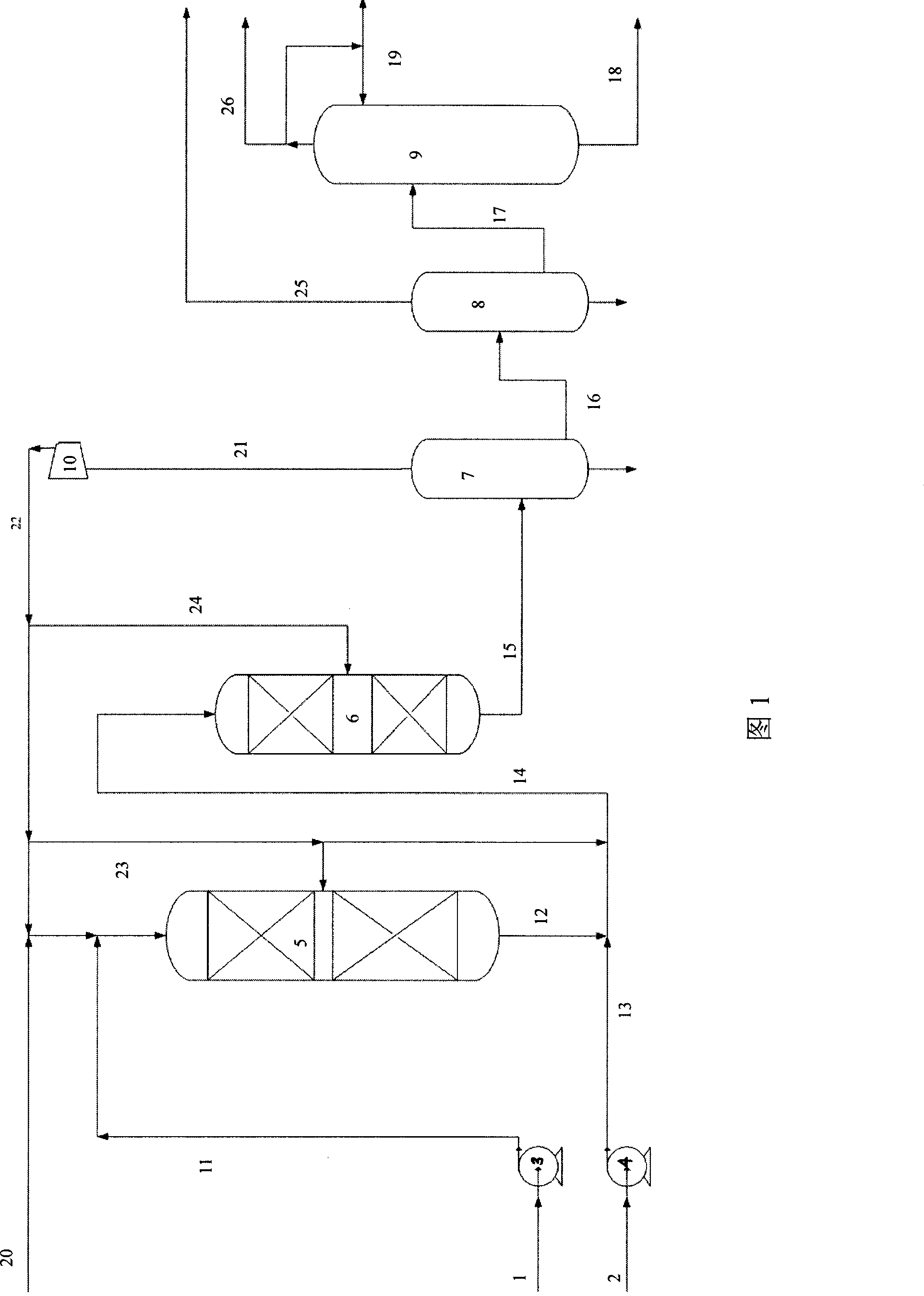

Hydrogenation method for producing high-quality low-sulfur diesel fraction

ActiveCN101747936AStrong displacementStrong Production Quality Low EmissionsTreatment with hydrotreatment processesSulfurHydrogenation reaction

The invention relates to a hydrogenation method for producing high-quality low-sulfur diesel fraction. The method sets hydrofining, hydrocracking and hydrofining reaction areas, wherein hydrocarbon material I with an end point less than 540 DEG C sequentially enters and reacts in the first hydrogenation reaction area and the second hydrogenation reaction area, hydrocarbon material II with an end point less than 400 DEG C enters and reacts in the third hydrogenation reaction area, and the reaction effluent of the reaction area is separated and fractioned, so that the diesel fraction is obtained. In order to solve the problems of the prior art, including diesel material shortage and the repeated construction of hydrogen circulation systems, fractioning systems and other auxiliary systems ina plurality of hydrogenation units, the invention provides the hydrogenation method for producing high-quality low-sulfur diesel fraction, which has the advantages of high integration and flexible production scheme.

Owner:CHINA PETROLEUM & CHEM CORP +1

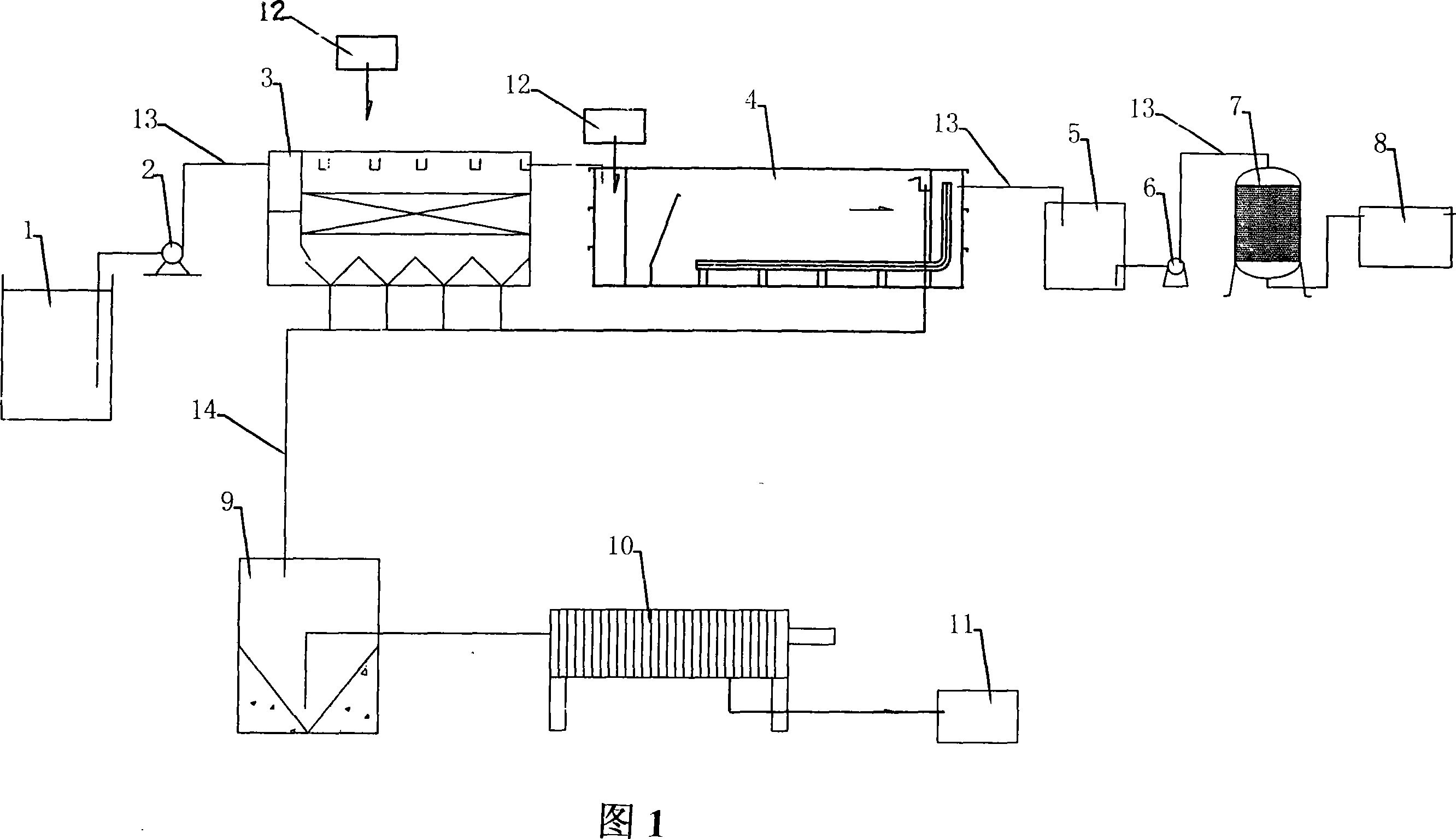

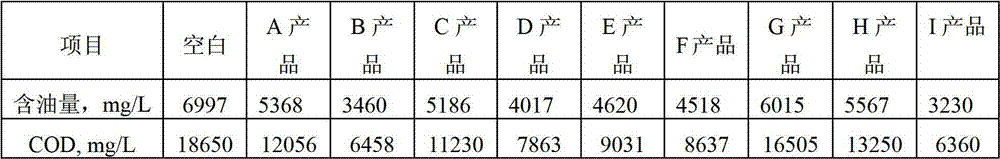

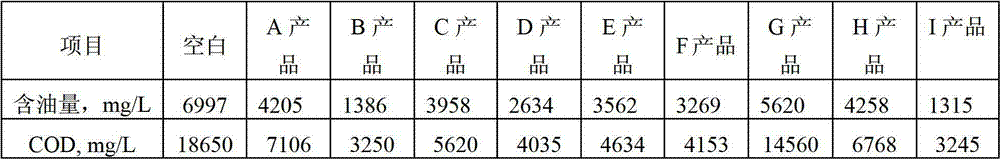

Waste water treatment reusing complete plant for water spraying loom

InactiveCN101033104AEfficient removalHas a mixed reactionMultistage water/sewage treatmentWaste water treatment from textile industrySludgeHoneycomb

This invention relates to whole set equipment for processing, recovering and utilizing waste water of spraying spinning machines composed of an oil-isolation adjusting basin, a two-way overfall separation processor, a compounding cleansed air-floater, a mide water-basin, a multi-medium filter and a recovery and utilization basin connected orderly, in which, the two-way overflow separating processor is composed of an internal overflowing tank, a honeycomb tilted tube, a multi-hole delivery pipe, a mud pipe, an overflowing basin of a mud bin and a multi-layer multi-section reaction basin divided into 8-16 sections, which combines a self-designed two-way overflow separator with a combined cleansed gas-floater, a multi-medium filter and a mud processor tightly to process and recover waste water of spraying spinning machines selectively.

Owner:龚先木

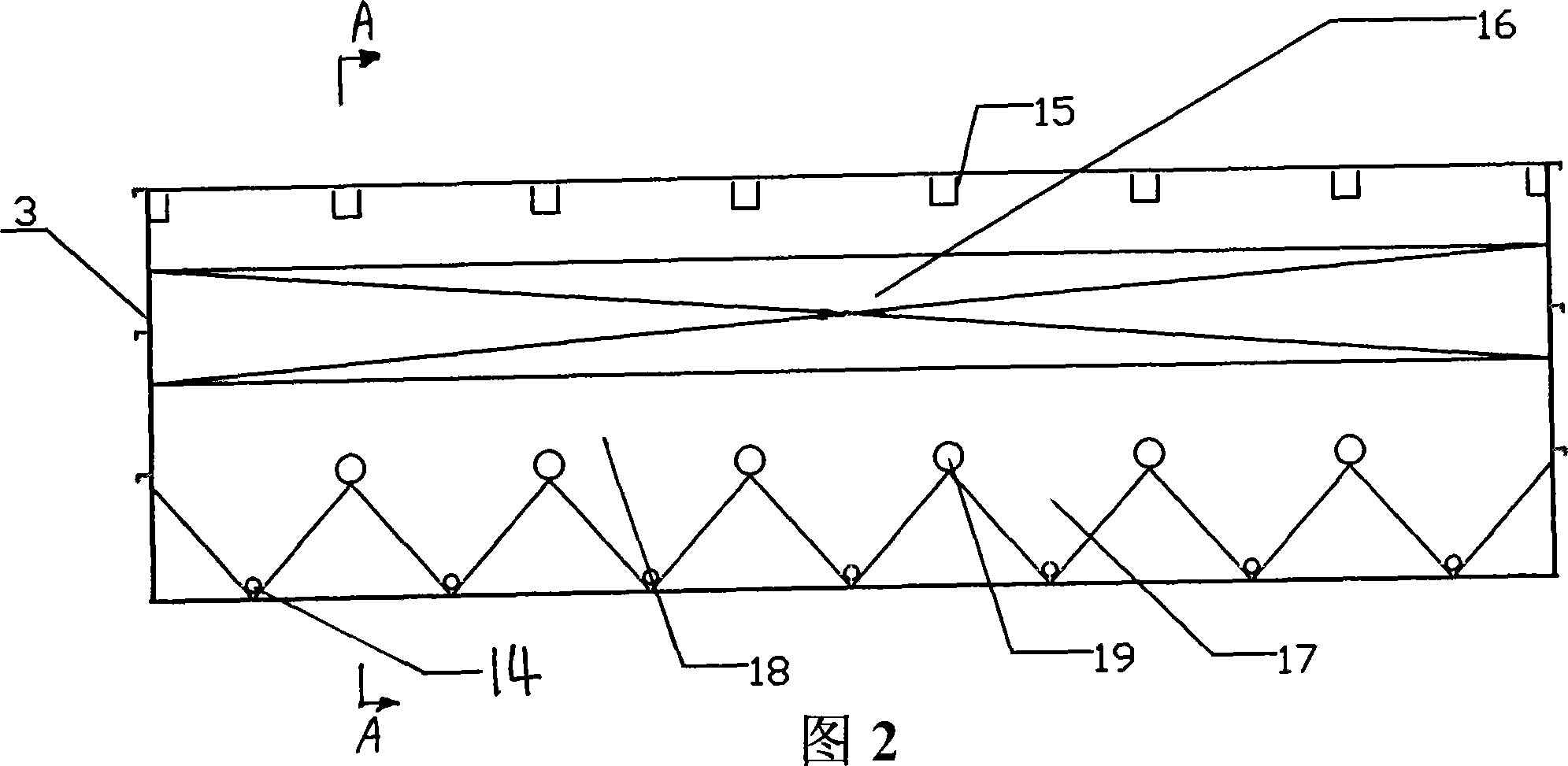

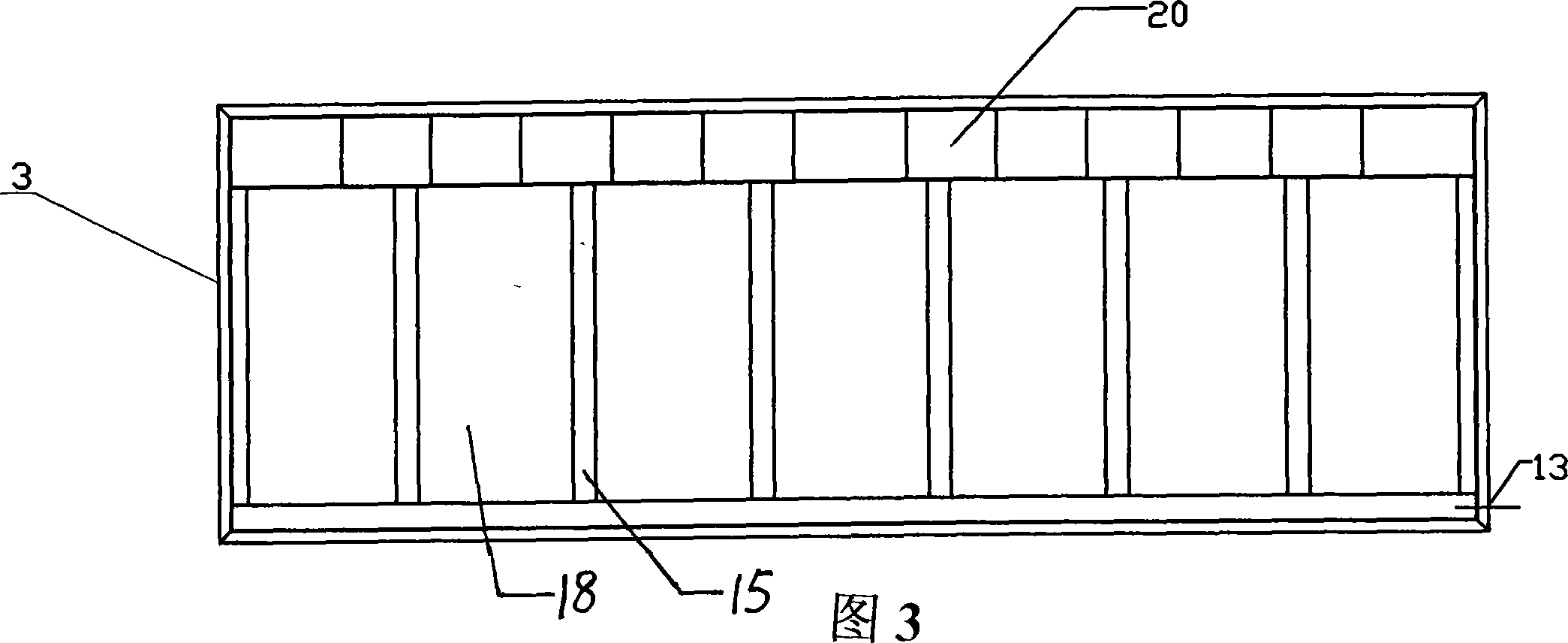

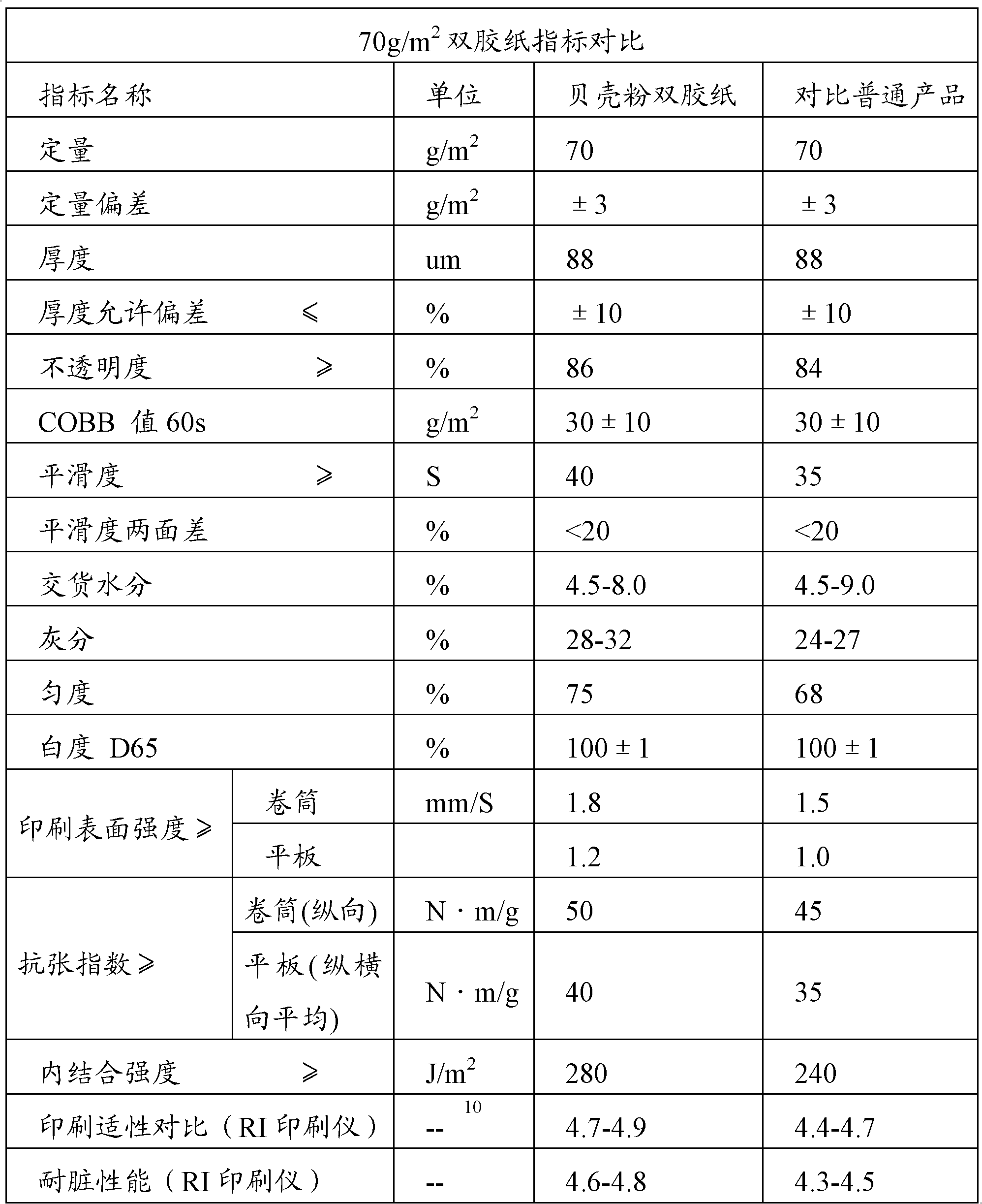

Side offset paper and preparation method thereof

ActiveCN102154927AReduce dosageHigh bonding strengthWater-repelling agents additionPaper coatingPapermakingUltimate tensile strength

The invention relates to the technical field of papermaking, in particular to a side offset paper produced by shell powder and a preparation method thereof. In the side offset paper, high-whiteness hard wood pulp and high-whiteness chemical-mechanical pulp serve as the main material, and meanwhile, shell powder is auxiliary filler for producing the side offset paper; oxidized Cual is added into surface amylopectin to improve the printing surface strength of the side offset paper and avoid the defects of printing hair slip and duslting because of high paper forming ash content; meanwhile, the paper forming printing adaptability and dirty resistance can be obviously improved; and the colorful printing quality of the product is substantially improved.

Owner:ASIA SYMBOL GUANGDONG PAPER

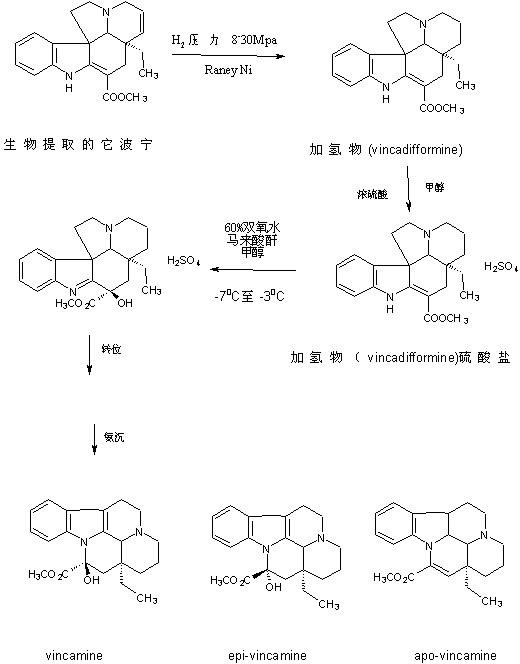

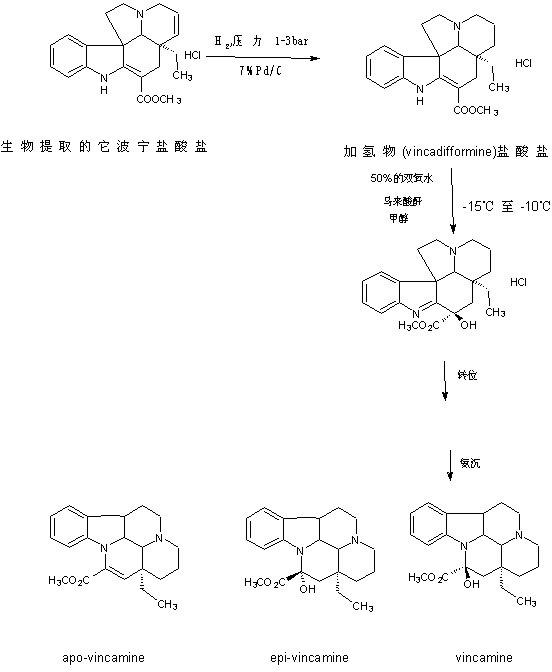

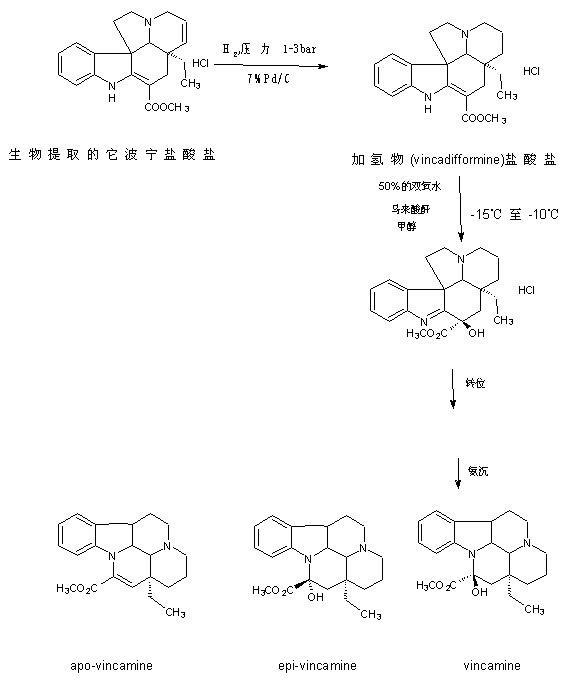

The preparation technology of semi-synthetic vincamine

The invention relates to a synthetic process for chemical medicines, in particular to a process for preparing vincamine by a semisynthetic method. At present, the process for preparing the vincamine is divided into a total synthetic method and the semisynthetic method, wherein the semisynthetic method has the problems of unstable and inflammable hydrogenation catalyst, large using amount, high hydrogenation pressure, insecurity in the preparation of monoperoxide maleic acid and the like. The process comprises the following steps of: preparing tabersonine vincadifformine hydrochloride, preparing the monoperoxide maleic acid, performing oxidizing reaction, performing reduction reaction and transposition reaction, precipitating ammonia and purifying products, wherein the low-cost and stable Pd / C hydrogenation catalyst is selected to reduce the pressure of the hydrogenation reaction; tabersonine sulfate is replaced by the tabersonine hydrochloride; the monoperoxide maleic acid is preparedby using low-concentration hydrogen peroxide; the reaction temperature is below 0 DEG C, and security coefficients are improved; the temperature of the oxidizing reaction is reduced, and the generation of isomers is reduced; purification and solvent recrystallization are performed by column chromatography; and the quality of the products reaches the pharmaceutical-grade standard.

Owner:ZHANGJIAKOU GERUI HIGH TECH

Preparation method and application of small-molecule panax notoginseng polysaccharide extract

InactiveCN106749731AResidue reductionHigh yieldOrganic active ingredientsImmunological disordersFreeze-dryingEthanol precipitation

The invention discloses a preparation method of small-molecule panax notoginseng polysaccharide extract. The preparation method includes: using panax notoginseng as the raw material, crushing the raw material, extracting with an ethanol solution, extracting panax notoginseng residues with water obtain crude panax notoginseng polysaccharide extract, performing ethanol precipitation, dissolving precipitate with water, and then adding trifluoroacetic acid or lysozyme to perform hydrolysis to obtain crude small-molecule polysaccharide liquid; using a cation-anion exchange column to remove the protein, pigment and the like of the crude small-molecule polysaccharide liquid, using activated carbon powder for decoloring, filtering with a titanium-bar filter to obtain a colorless low-viscosity small-molecule polysaccharide solution, concentrating, and performing freeze drying to obtain the small-molecule panax notoginseng polysaccharide extract. The preparation method has the advantages that the method is simple to operate, low in cost and high in industrialization degree; the small-molecule panax notoginseng polysaccharide extract can promote macrophage proliferation, further differentiation and maturation of macrophage can be achieved to obtain activated macrophage, and the phagocytic ability of the macrophage can be evidently enhanced; fast increasing of cell immunity during a cell culture immunity test can be achieved; the extract has application prospect in immunological disease treatment, and the preparation method is suitable for industrial production.

Owner:YUNNAN YUNKE PHARMA

Method for preparing steam-pressed brick through gold mine tailings

InactiveCN102976702ARealize resource utilizationImprove performanceSolid waste managementCyanideBrick

The invention discloses a method for preparing a steam-pressed brick through gold mine tailings, solving the problems that few technologies are provided for specially processing the gold mine tailings, the alkaline chlorination process and the pressure filtration and dry heaping process are unstable in effect, the bearing capacity of a tailings pond is limited, and the bearing capacity is needed to be maintained and managed for a long time. The method comprises the following steps in sequence: adding an oxidant in the gold mine tailings; uniformly mixing the oxidant and the gold mine tailings; feeding the mixture into a bin; crushing and grinding lime and gypsum and then adding to the bin; feeding cement and water to the bin in sequence; uniformly stirring cement and water and then mixing with the gold mine tailings, the oxidant, lime, gypsum and cement, so as to obtain the mixture; digesting the mixture in a digesting bin for 2 to 3 hours; milling through wheels; transferring the milled mixture into a brick machine; pressing the milled mixture to obtain the brick blank; standing for 3 to 6 hours at normal temperature; maintaining in a steam pressing kettle in a steam pressing way for 5 to 10 hours at 170 to 200 DEG C under 0.8 to 1.5MPa; and cooling to room temperature, so as to obtain the steam-pressed brick product. According to the method, cyanide in the gold mine tailings is damaged, the resource utilization of the gold mine tailings is realized, and the environmental protection benefit and the economic benefit are achieved.

Owner:HANGZHOU DIANZI UNIV

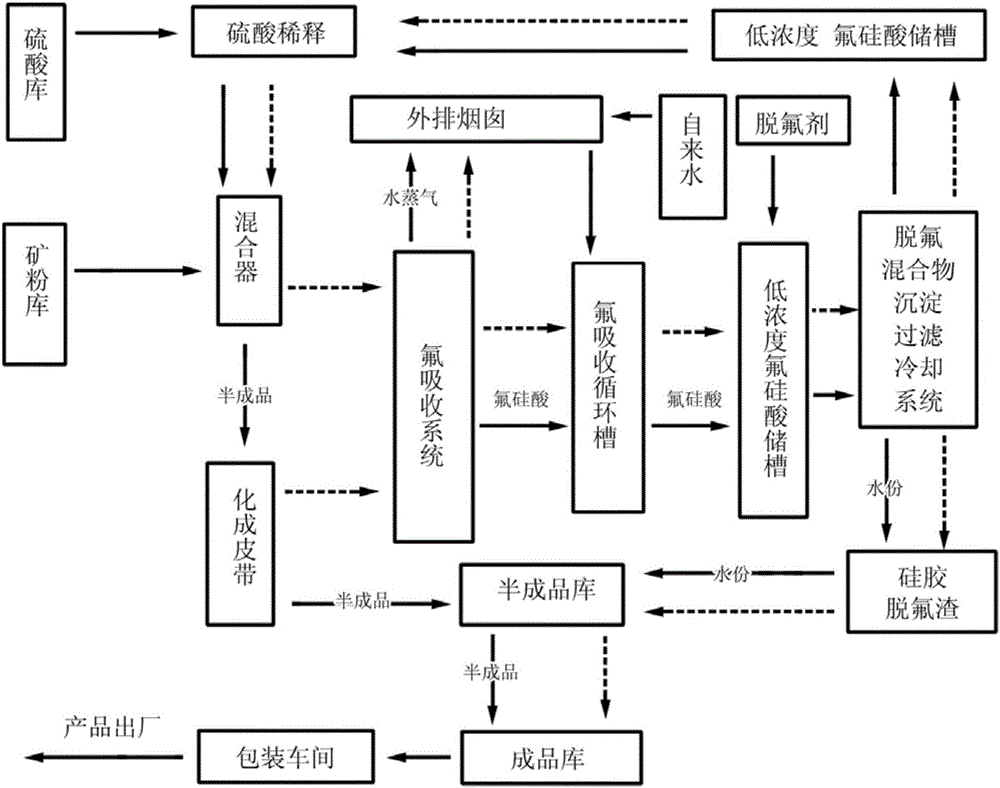

Fluosilicic acid comprehensive recycling technology

InactiveCN106587073ASatisfy the phenomenon of non-blocking wallEffective temperature controlFluosilicic acidPhosphoric acidHexafluorosilicic acid

The invention relates to a fluosilicic acid comprehensive recycling technology. The technology is characterized in that calcium superphosphate and a by-product, namely fluosilicic acid, generated by a fluorine absorption system in the wet-process phosphoric acid production technology are used as main materials. The technology includes the material reaction step, wherein clean water is added into a fluorine absorption circulating tank, after overflowing fluorine-containing gas is cyclically absorbed, circulating liquid enters a low-concentration fluosilicic acid storage tank and then enters a defluorination system after being cooled and precipitated, silica gel defluorination residues are removed after defluorination and filtering, filter residues serve as product filler, most of filter liquor serves as diluting sulfuric acid, very little part of the filter liquor overflows to the circulating tank through a high-place pond and absorbed and circulated again with newly added clean water, and sulfuric acid consumption is reduced; clean water circulating liquid injected into the fluorine absorption circulating tank for the first time is absorbed and then conveyed to the high-place low-concentration fluosilicic acid (1.5-1.8 baume degrees) storage tank to serve as diluted concentrated sulfuric acid, and remaining circulating liquid enters the fluorine absorption circulating tank to be absorbed. The technology has the advantage of effectively achieving the aims of energy conservation, emission reduction and efficient comprehensive recycling.

Owner:杨海

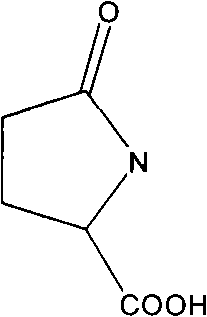

Preparation method for L-pyroglutamic acid

ActiveCN102558015AIncrease production costReduce manufacturing costOrganic chemistryL-Pyroglutamic AcidGlutamic acid

The invention relates to a preparation method for L-pyroglutamic acid. The preparation method comprises the following steps of: melting glutamic acid serving as a raw material at a high temperature, and purifying; and concentrating and crystalizing to obtain the L-pyroglutamic acid. The method for the L-pyroglutamic acid, disclosed by the invention, is easy to operate, and has low cost and high yield.

Owner:BENGBU BBCA MEDICINE SCI DEV

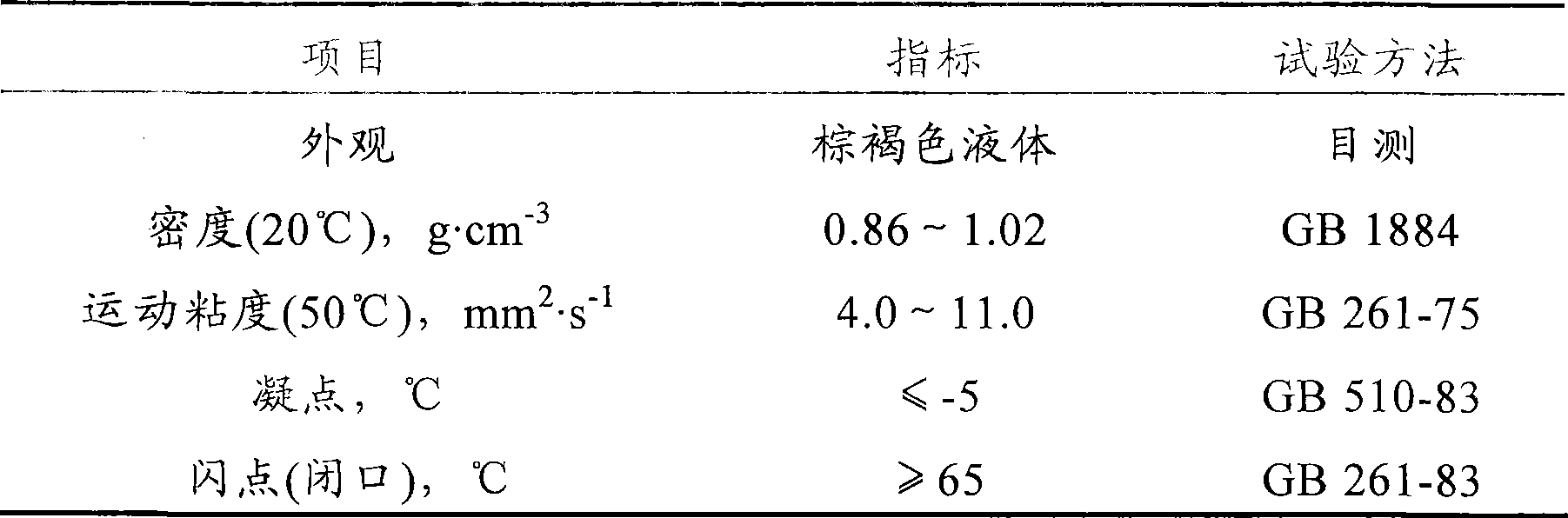

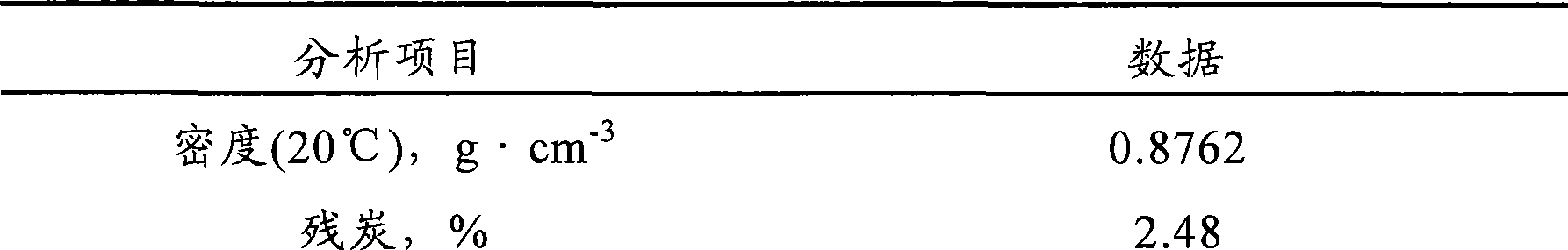

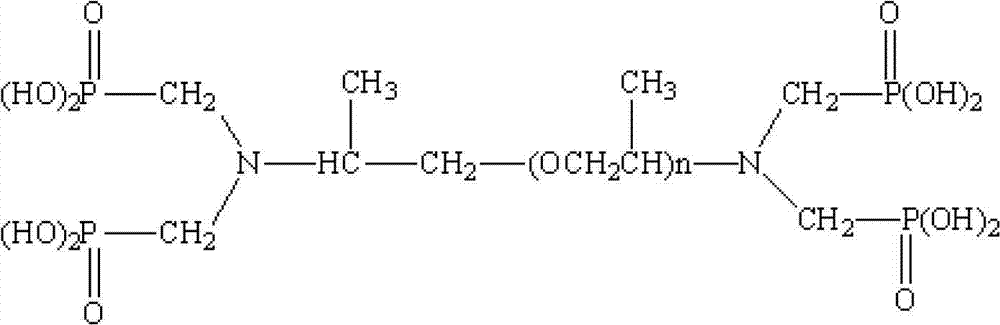

Residual oil modifier for coking delaying device and use thereof

InactiveCN102071047ADoes not affect generationReduce generationThermal non-catalytic crackingSolubilityDecomposition

The invention relates to a residual oil modifier for a coking delaying device and use thereof. Overcoming the drawbacks of the prior art, the invention provides the modifier, which has high practicality for raw material residual oil and can effectively improve the properties of residual oil, delay coking, effectively reduce coking amount and consequently improve the yield of middle-grade distillate. The modifier is prepared from 1 to 25 percent of antioxygen, 1 to 20 percent of oxidation and corrosion inhibitor, 1 to 25 percent of metal deactivator, 1 to 20 percent of dispersant and the balance of solvent, and by heating, uniformly stirring and cooling. The product has high oil solubility, and the product and raw material oil can quickly dissolve in each other; the filling is more convenient and does not influence the normal production of the device and the quality of the product; less dry gas and coke are produced, the yield of light oil is increased, and the coking and scale depositing of the system are prevented; and the thermal stability is high, so volatilization and decomposition at high temperature are prevented. The modifier is suitable for coking delaying devices which use paraffin-base, intermediate-base and naphthenic-base residual oil as raw materials.

Owner:天津市瑞德赛恩新材料开发有限公司

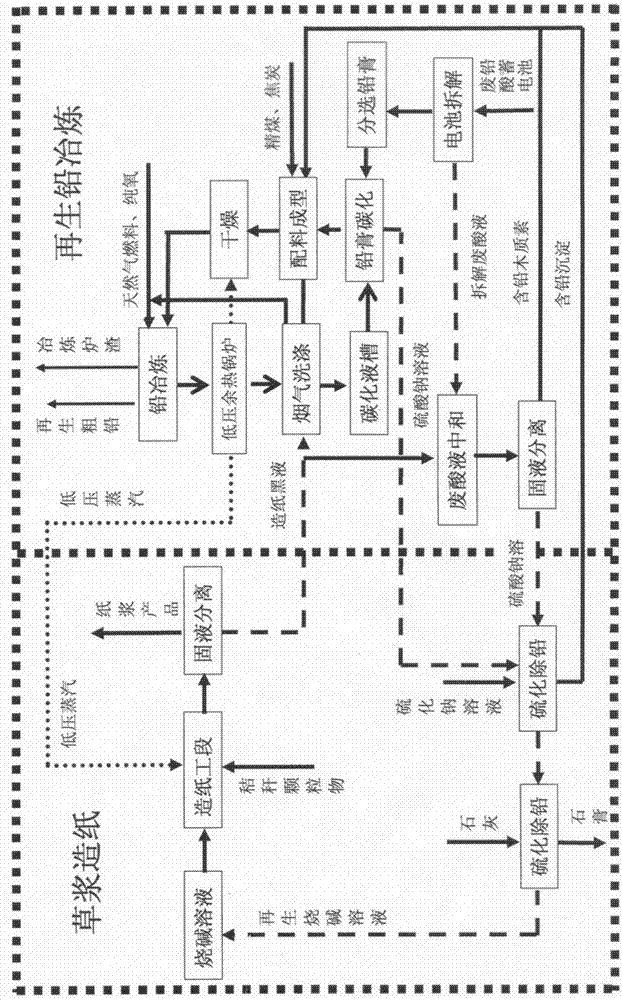

Energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology

ActiveCN104498716AEliminate smoke pollutionImprove gypsum qualityPulp liquor regenerationUsing liquid separation agentCogenerationLead smelting

The invention discloses an energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology. The energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology is characterized by comprising the following steps: recovering flue gas waste heat of a crude lead smelting furnace as a heat source for producing paper pulp; washing a lead smelting flue gas with a strong alkaline paper-making black liquor, and absorbing CO2 and a trace of SO2 in the flue gas, thus obtaining a sodium carbonate solution, carbonizing a lead plaster; neutralizing and disassembling a waste acid generated by a waste battery by using the paper-making black liquor; washing the flue gas with the black liquor, neutralizing the waste sulfur acid, and then merging the obtained sodium sulphate solution; and causticizing with lime, returning the obtained NaOH solution to a paper-making section. According to the technology disclosed by the invention, lead smelting and closed cycle of pulp production wastewater and the flue gas are achieved; the flue gas waste heat of the regenerated lead smelting furnace is utilized; the alkalinity of paper-making pulping and an acid waste liquid of the regenerated lead are mutually neutralized; and the technical problem of waste liquid treatment of the regenerated lead smelting industry and the paper-making production industry is solved by using waste to treat waste.

Owner:HEFEI UNIV OF TECH

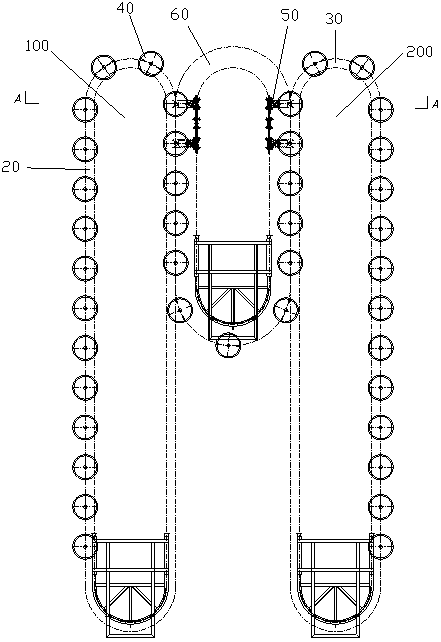

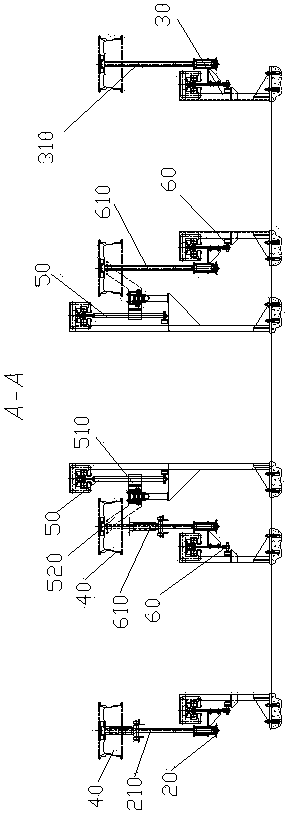

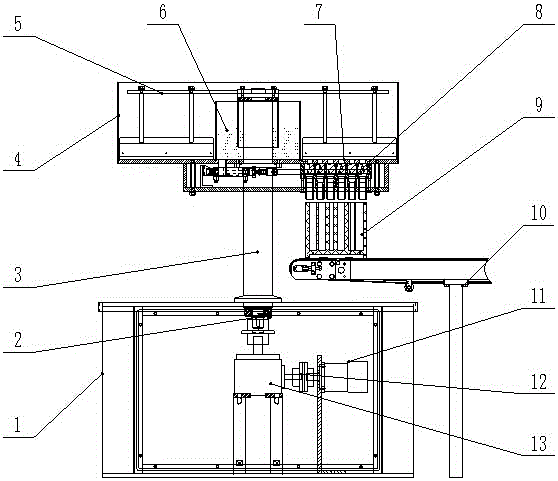

Automatic weighing and material preparing system and control method thereof

ActiveCN106644013AImprove configuration efficiencyReduce human inputControllers with particular characteristicsTotal factory controlMixed materialsLoad cell

The invention relates to an automatic weighing and material preparing system and a control method thereof. The automatic weighing and material preparing system comprises a plurality of automatic weighing and fixed-amount material placing devices and a material collecting device. The material collecting device comprises a material receiving container and a conveying device for conveying the material receiving container. The plurality of automatic weighing and fixed-amount material placing devices are used for weighing the different material components respectively; the material receiving container moves along the conveying device and collects the weighed material components that are automatically weighe. The automatic weighing and fixed-amount material placing device includes a material feeding part and a weighing part wherein the material feeding part is an electromagnetic vibration material feeding machine and the weighing part comprises a weighing sensor fixedly connected on a support rod and a bidirectional material hopper fixedly connected with the weighing sensor. The bidirectional material hopper is located under the material feeding part; and through a guiding groove, the bidirectional material hopper forms a bidirectional channel which guides materials into the material receiving container. The invention is suitable for the production and configuration of mixed materials, which greatly increases the configuration efficiency of the mixed materials and reduces the investment of human labor.

Owner:CAS HEFEI INST OF TECH INNOVATION

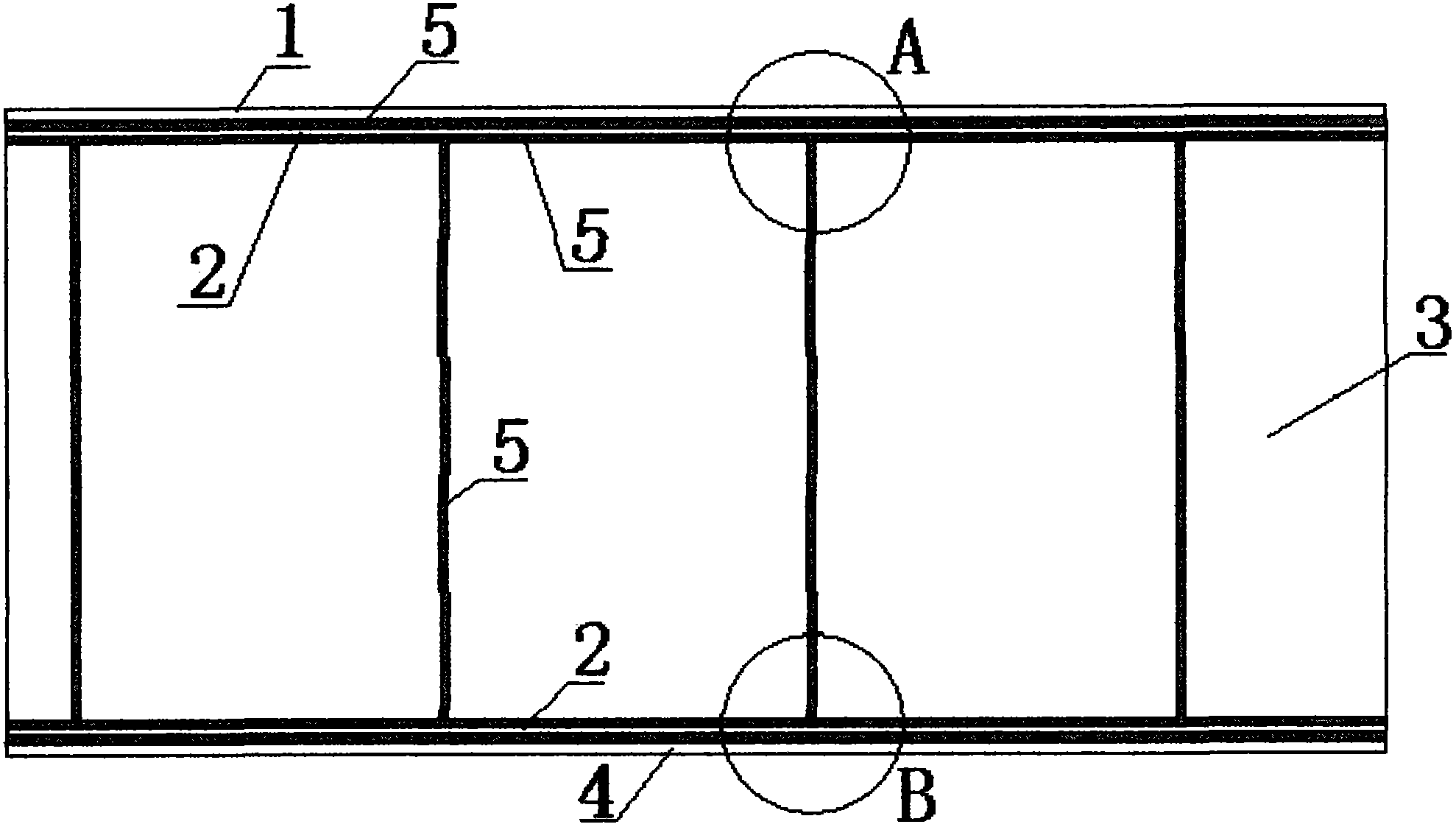

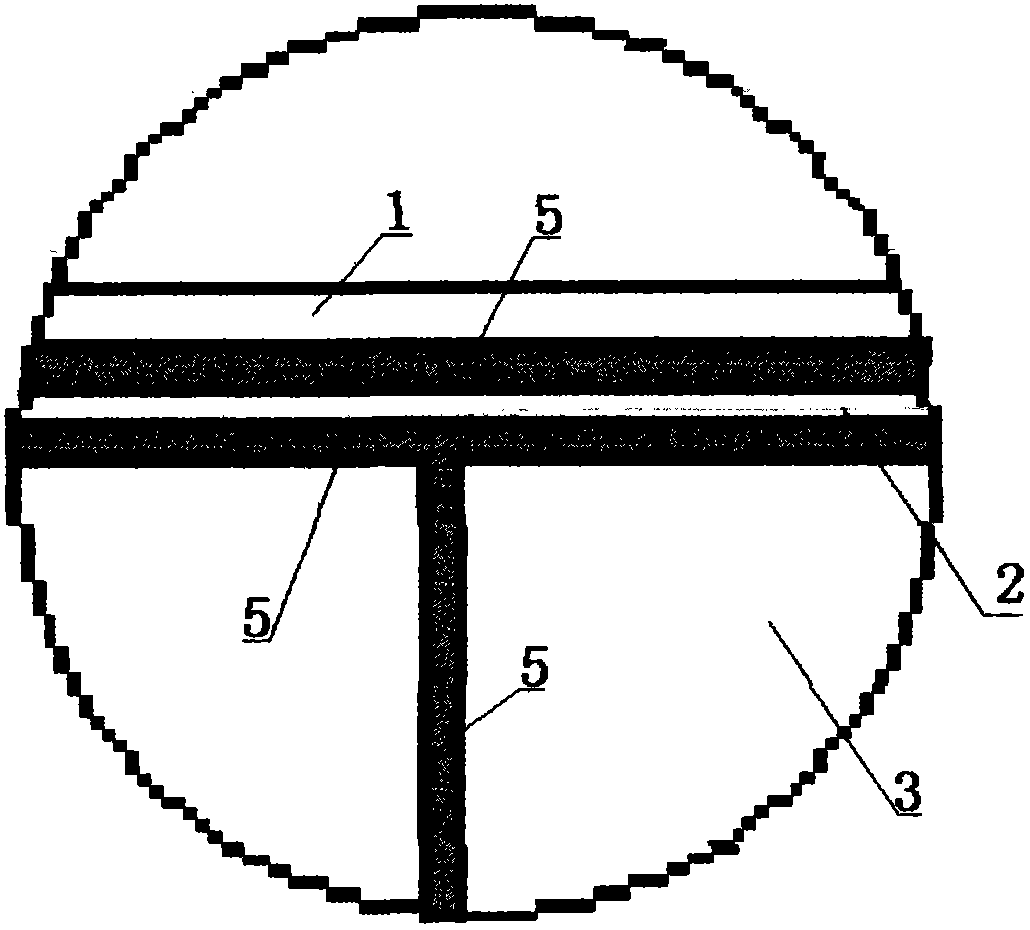

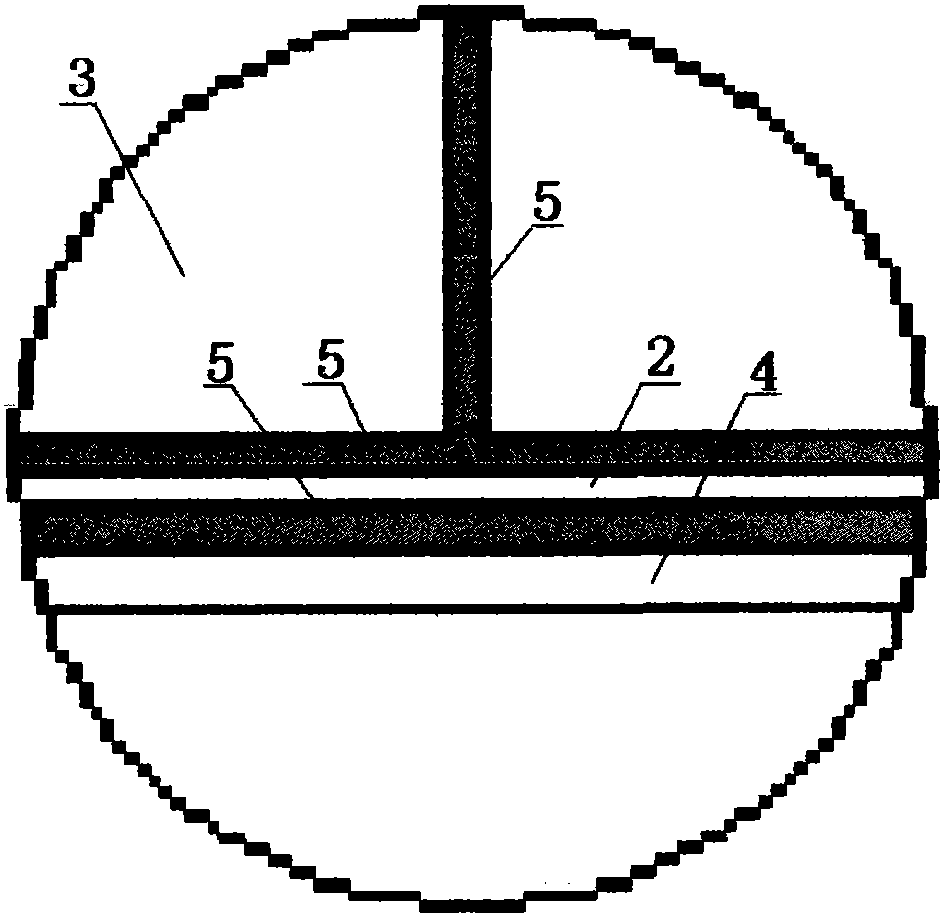

Outer-wall insulating board made of reinforced-fiber composite vertical silk rock wool

InactiveCN103572848ASimple structureReduce weightLaminationLamination apparatusGlass fiberFiberglass mesh

The invention relates to an outer-wall insulating board made of reinforced-fiber composite vertical silk rock wool, which is used for solving the problems of easy falling and collapse when the existing insulating board is used. The outer-wall insulating board comprises an advertising cloth layer, a glass fiber mesh cloth layer, a rock-wool strip layer, a glass fiber cloth layer and a non-woven cloth or advertising cloth layer which are arranged from bottom to top in sequence and are in a layered structure, wherein the rock-wool strip layer is cut into strips in a side-by-side manner, and cut openings are upward or downward; cement slurry or insulating mortar or adhesive mortar prepared by magnesia cement and brine is adopted for adhesion between every two adjacent parts of the advertising cloth layer, the glass fiber mesh cloth layer, the rock wool strips, the glass fiber cloth layer and the non-woven or advertising cloth layer and between every adjacent rock wool strips. Glass fiber mesh cloth is gridding cloth; the adhesion is prefabricated adhesion, and then the steps of drying and demolding are adopted. The rock wool strips are slurry-coated rock wool strips with the surfaces coated by the cement slurry, or the insulating mortar or the adhesive mortar. The outer-wall insulating board has the advantages of light weight, good texture, high integral structure strength, large compressive strength and difficult falling and collapse in use.

Owner:吴洪成

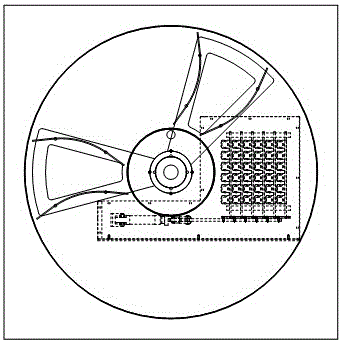

Propellant powder filling machine

Provided is a propellant powder filling machine. The propellant powder filling machine comprises a machine frame, a rotating mechanism, a filling mechanism and a conveying mechanism. The rotating mechanism comprises a rotary shaft, a stand column, a pushing plate, a hydraulic motor, a coupling and a speed reducer. The stand column is installed on the machine frame. The rotary shaft is installed on the stand column. The lower end of the rotary shaft is connected with the speed reducer. The speed reducer is connected with the hydraulic motor through the coupling. The pushing plate is installed at the upper end of the rotary shaft. The filling mechanism comprises a hopper, a metering plate, a gate opening mechanism, a collection hopper, a discharging hopper and an outer firework drum, wherein the hopper is installed at the upper end of the stand column; a water trough is arranged between the hopper and the stand column; the metering plate is installed in the hopper and located above the collection hopper; the gate opening mechanism and the collection hopper are installed below the hopper; the gate opening mechanism is connected with the hopper; the collection hopper is connected with the discharging hopper; and the outer firework drum is located above the conveying mechanism. When powder is charged through the propellant powder filling machine, the advantages that the labor intensity of workers is low, the production efficiency is high, raw material waste is not likely to be caused, the product quality is not influenced, and physical safety of the workers is guaranteed are achieved.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

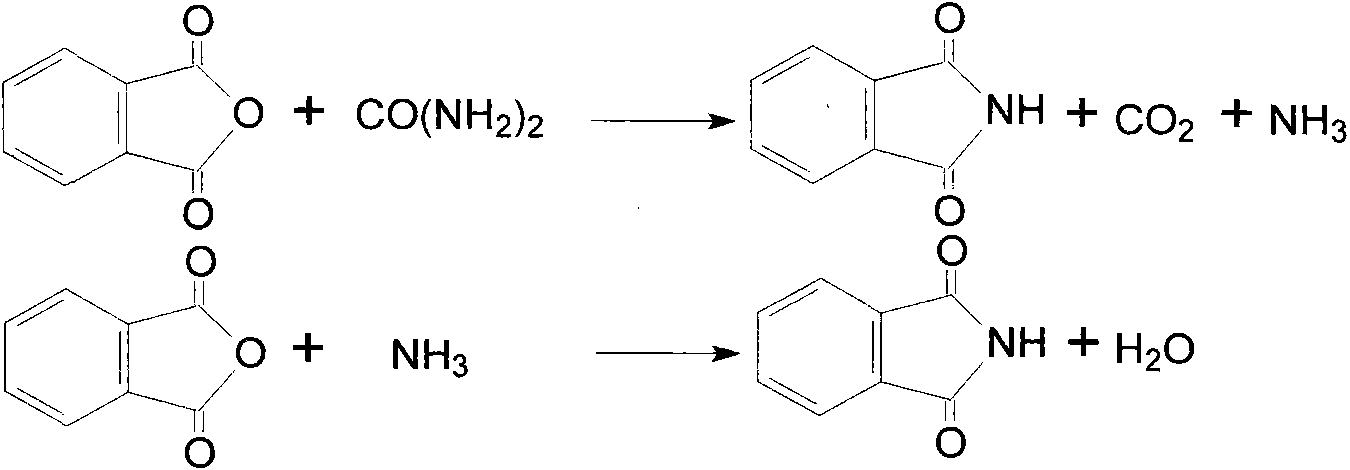

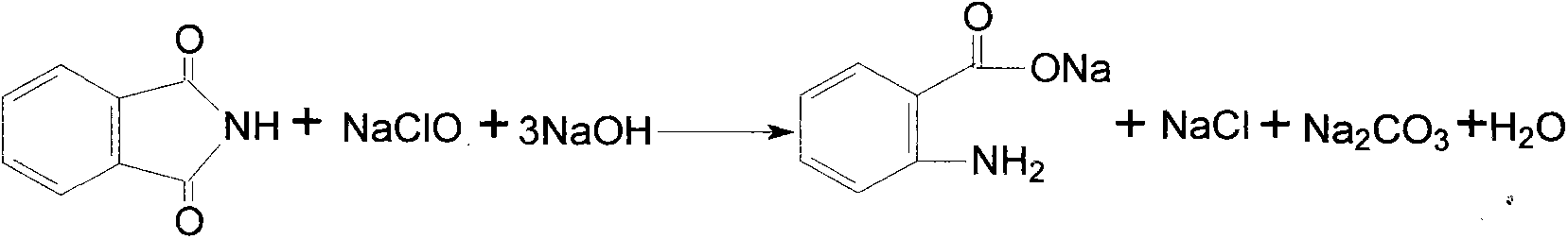

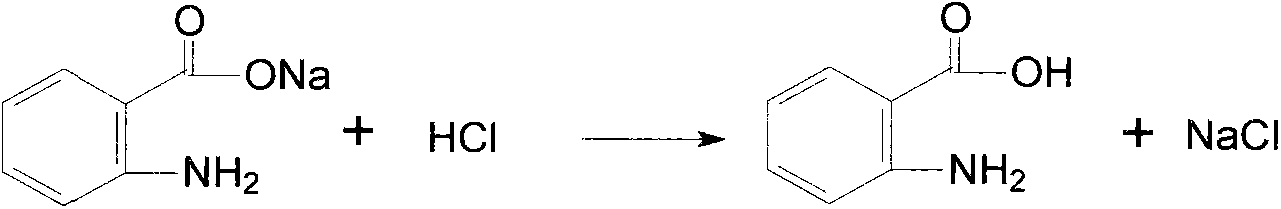

Method for treating and recycling waste water in anthranilic acid production technology

InactiveCN103408177ARealize resourcesDoes not affect product qualityOrganic chemistryMultistage water/sewage treatmentAfter treatmentDesorption

The invention discloses a method for treating and recycling waste water in an anthranilic acid production technology. Through the adoption of the method provided by the invention, waste water in the anthranilic acid production technology can be treated, and recycled organic substances can be directly subjected to cyclic utilization; the CODCr being about 24000 mg / L of waste water before treatment is reduced to 80 mg / L below after treatment to reach the national-level emission standard; coarse sodium chloride salt can be recycled; resin is subjected to desorption and regeneration by using 4-6% of dilute sodium hydroxide solution or dilute hydrochloric acid, and a desorption solution can be taken as raw materials to be input in the acidizing step or degrading step of the original production technology, so that the product quality is not affected, 99% of anthranilic acid and phthalimide in the waste water can be recycled, and distilled effluent can be utilized repeatedly; waste water can be treated while the waste recycling can be realized.

Owner:YANCHENG TEACHERS UNIV

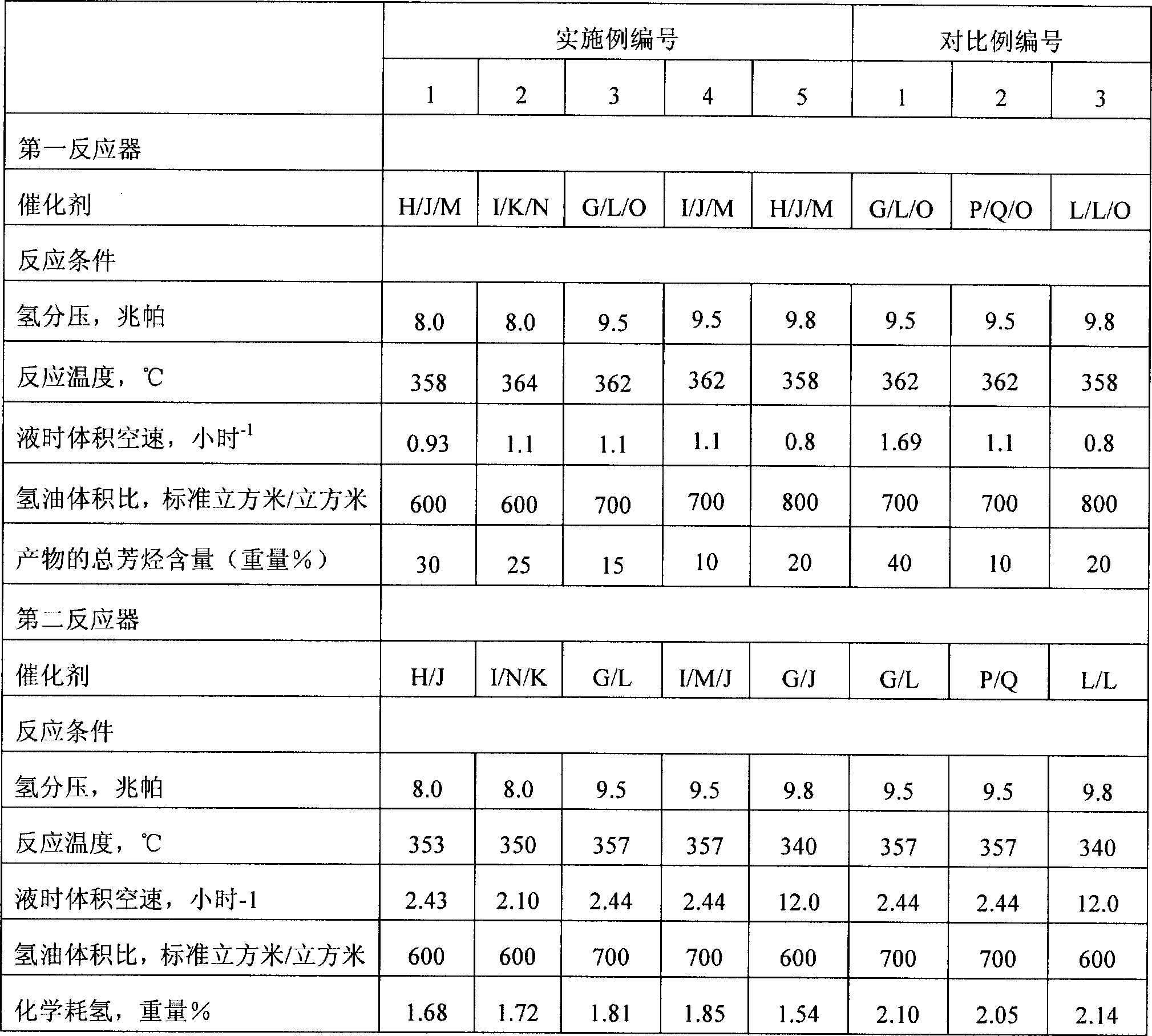

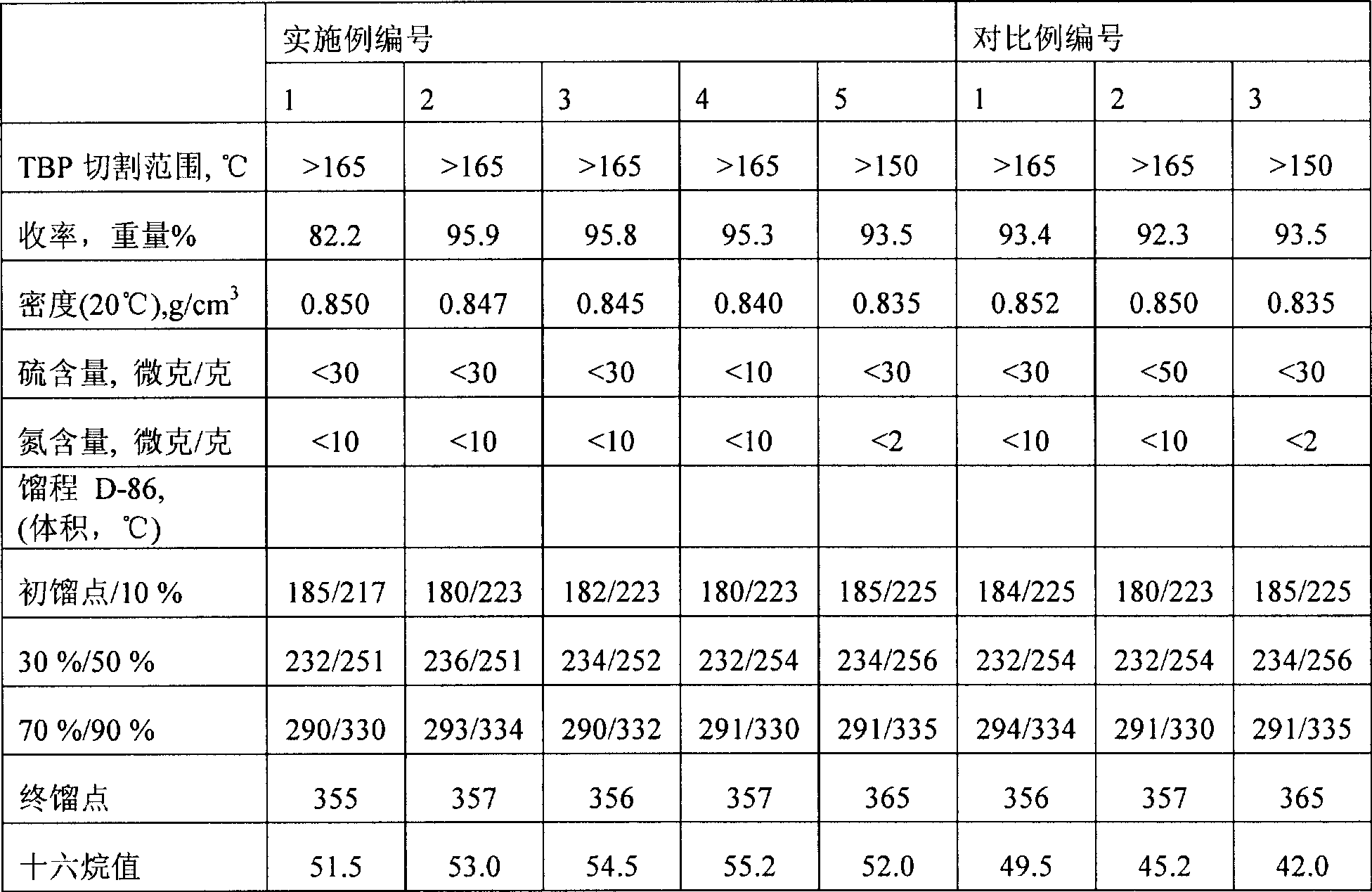

Hydro-upgrading method for diesel distillate

ActiveCN101463270AImprove product qualityHigh yieldRefining to eliminate hetero atomsHydrogenDiesel fuel

The invention discloses a hydro-upgrading method for diesel distillates, wherein, the method comprises the steps of: in the presence of a hydrorefining catalyst and a hydro-upgrading catalyst, facilitating the diesel distillates with the total aromatics content not less than 35 weight % to contact a hydrogen-rich gas in a first reactor, so that the products after the contact has the total aromatics content not less than 35 weight%; afterwards in the presence of the hydrorefining catalyst and in a second reactor, facilitating the obtained products to contact a mixture of the diesel distillates with the total aromatics content less than 35 weight%. The hydro-upgrading method for the diesel distillates provided by the invention improves the quality of the diesel products to a large extent while maintaining high diesel yield, namely, the diesel yield is 93-99 weight%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soluble L-calcium lactate preparation and preparing method

InactiveCN1422614ASolve the problem of foamingHigh yieldMetabolism disorderAnhydride/acid/halide active ingredientsDairy foodsNutrition

The present invention discloses a souble L-calcium lactate preparation and its preparation method. Said invention uses the ocean waste shell as raw material and adopts direct acidification process after cleaned without high-temp. calcination to get the invented product which can be extensively used in the fields of milk product, beverage, health-care food and pharmaceutical industry. Said preparation possesses high biological utilization rate, it is up to 64%, its solubility is 2400 times that of calcium carbonate and 67 times that of calcium citrate, so that it can promote growth of bone effectively.

Owner:HUAHONG BIOLOGICAL PROD SHANGHAI

Delay coking coke cooling water demulsifier composition and preparation method and application thereof

ActiveCN102765767AGood water solubilityRapid miscibilityFatty/oily/floating substances removal devicesLiquid separationDemulsifierInorganic ions

The invention relates to a delay coking coke cooling water demulsifier composition and a preparation method and application thereof. The demulsifier composition comprises the following components in percentage by mass: 1 to 25 percent of demulsifier, 1 to 20 percent of dispersing agent, 1 to 25 percent of penetrating agent, 1 to 20 percent of corrosion inhibitor and the balance of solvent. The invention also provides the preparation method for the demulsifier composition and the application of the demulsifier composition to a delay coking device. The demulsifier composition mainly contains the demulsifier, the dispersing agent, the penetrating agent, the corrosion inhibitor and the solvent. By the demulsifier composition, the coke cooling water can be demulsified quickly, and the oil content of water can be reduced obviously; a water body is clear after demulsification; the corrosion of the water body to equipment can be reduced; and meanwhile, the demulsifier composition does not contain any inorganic ion, so that the influence on the conventional water body system is avoided.

Owner:天津市瑞德赛恩新材料开发有限公司

Silicon mandrel heating starting method for polysilicon hydrogen reduction furnace

The invention discloses a method for heating and starting a silicon core rod of a polysilicon hydrogen reduction furnace, which includes the following steps: the doping treatment of the silicon core rod so as to reduce the resistivity to 0.05-0.1 Omega. cm, a conventional power supply is provided to heat the doped silicon core rod, and bake the undoped silicon core rod on the external circle with the rising of the temperature; when the undoped silicon core rod on the external circle is baked and the temperature raises to 600-650 DEG C and the resistivity drops to 0.05-0.1 Omega. cm, heat the undoped silicon core rod with the conventional power supply. The invention leads the silicon core rod to be heated and started initially by the conventional power supply at ordinary temperature, no start-up device or equipment is needed and the heating and starting procedure is very simple.

Owner:四川永祥新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com