Calcium carbide stove exhaust combustion and utilization method and device

A calcium carbide furnace tail gas and burner technology, applied in the direction of combustion method, combustion type, furnace, etc., can solve problems such as difficult to clean ash, high specific resistance of dust, high CO content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

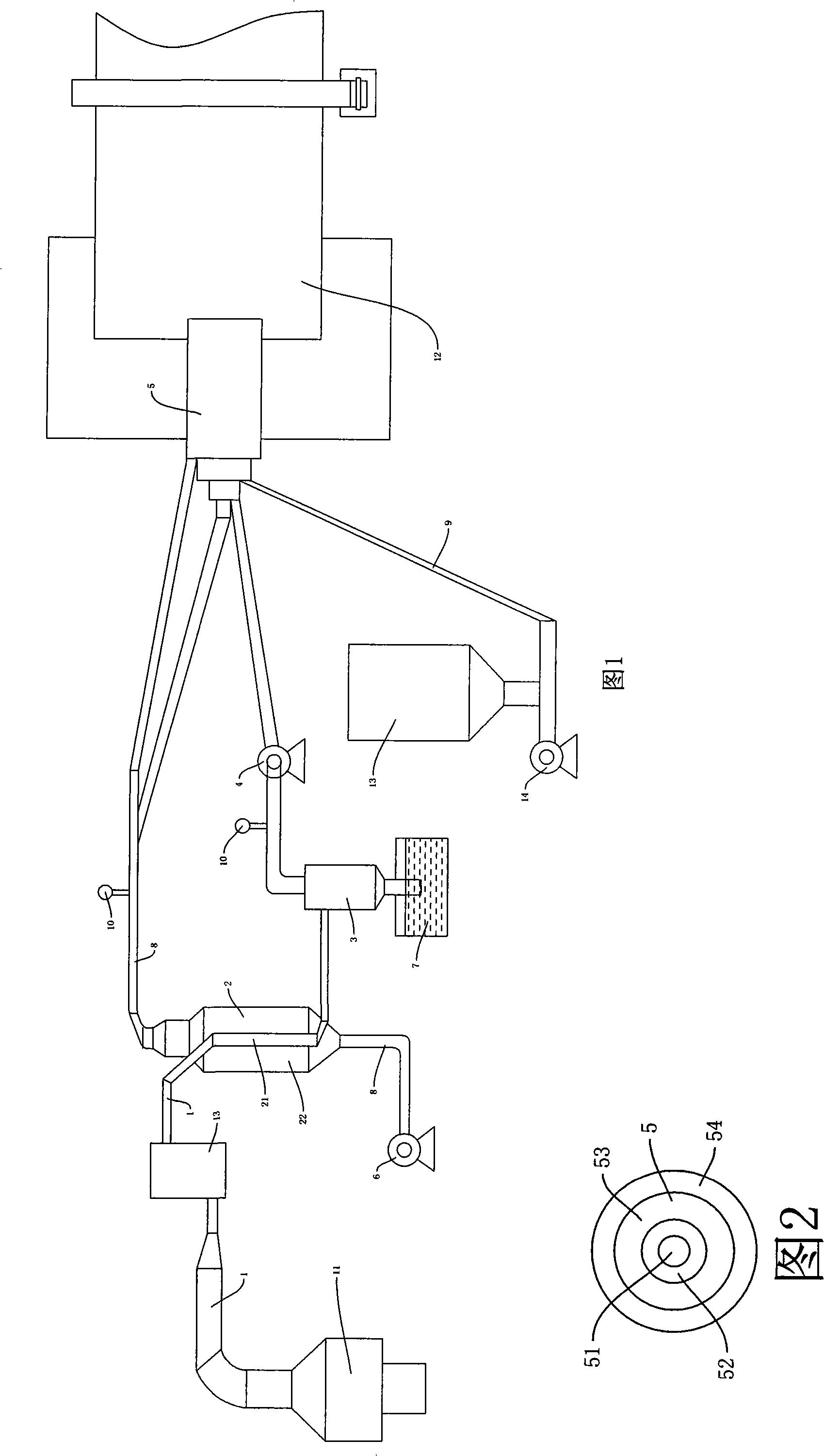

[0035] Figure 1 is a calcium carbide furnace gas combustion device consisting of a heat exchanger, a dust collector, a gas pressurizing fan, a cooling (and combustion-supporting) fan, a burner, a pulverized coal bin, a pulverized coal conveying fan, etc., and is connected with a rotary kiln and Combined with the kiln tail dust removal system attached to the rotary kiln, it is used for the production of lime or other products or for material drying, forming a complete system for utilization of calcium carbide furnace gas heat energy, dust removal and purification, standard discharge, and product production.

[0036] The gas source of the calcium carbide furnace, the gas storage steady flow buffer container, the heat exchanger, the dust collector, the pressurized fan, and the burner are connected in series with pipes. From the gas source 11 of the calcium carbide furnace, the conveying pipeline (the tail gas discharge pipe of the calcium carbide furnace) 1 is connected to the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com