Method and device for removing salt for fractionate tower

A fractionation tower and salt washing technology, applied in hydrocarbon distillation, petroleum industry, etc., can solve problems such as poor fractionation effect of fractionation tower, reduction of feed amount, gas compression, absorption and stabilization system, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

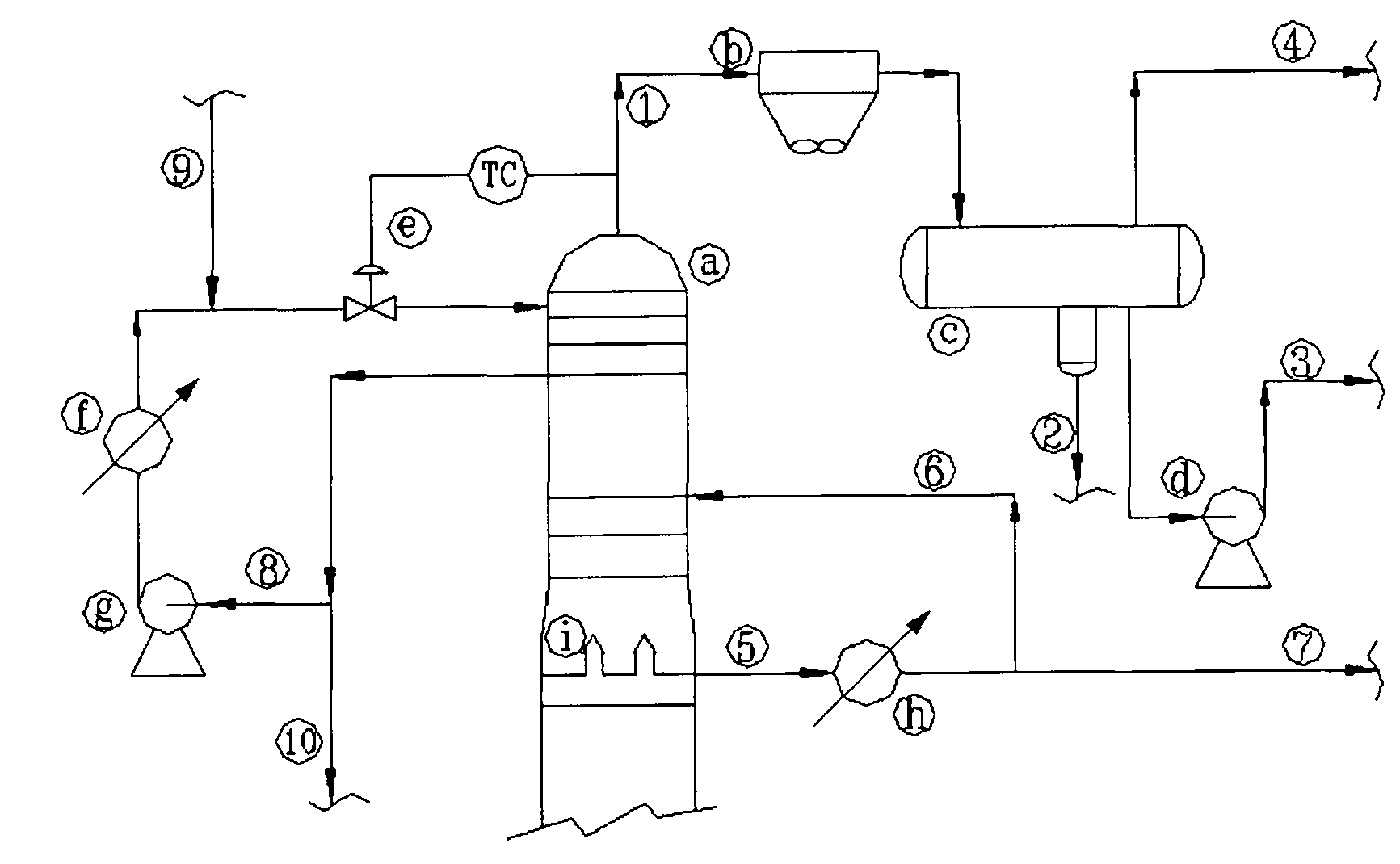

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment, further illustrate the present invention.

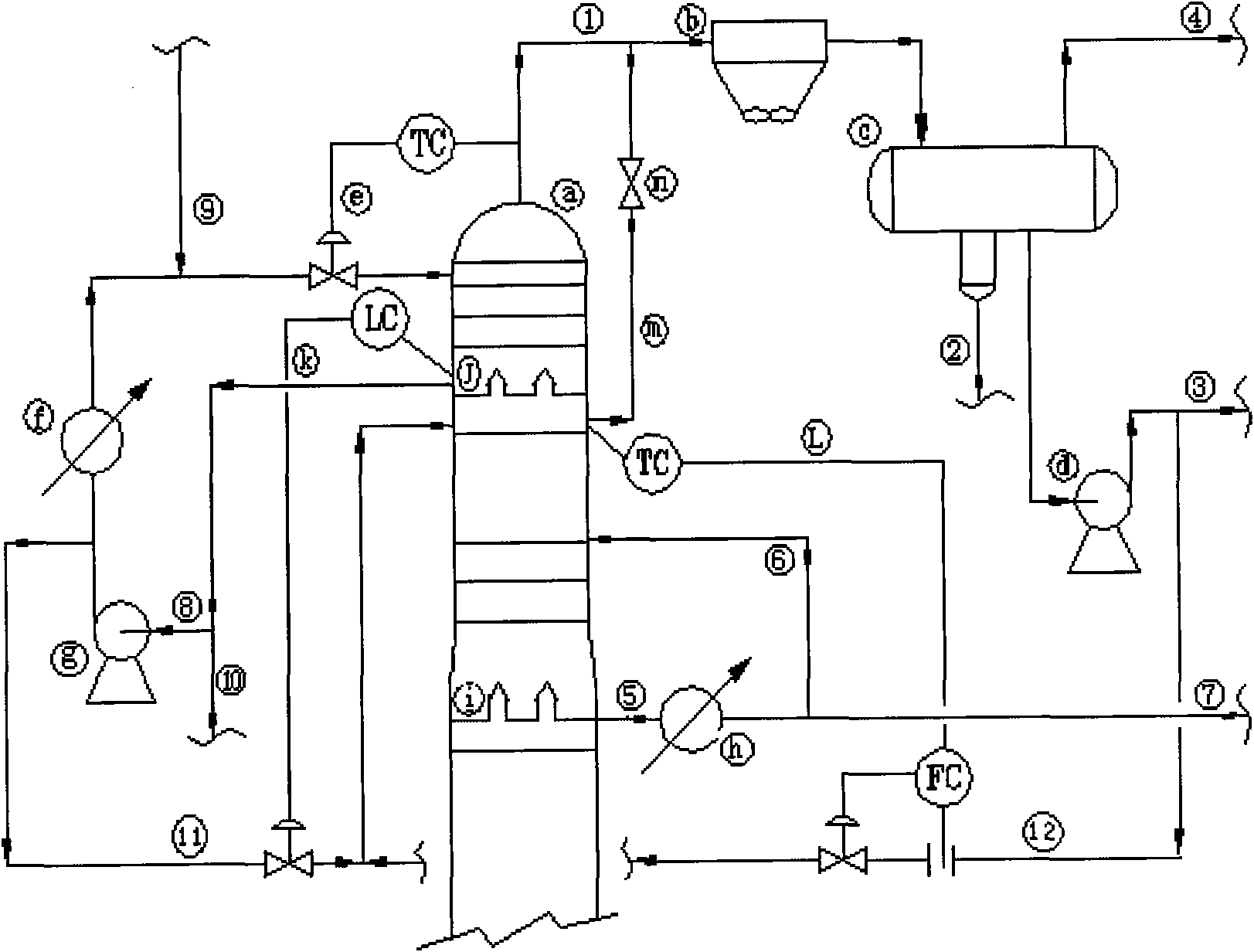

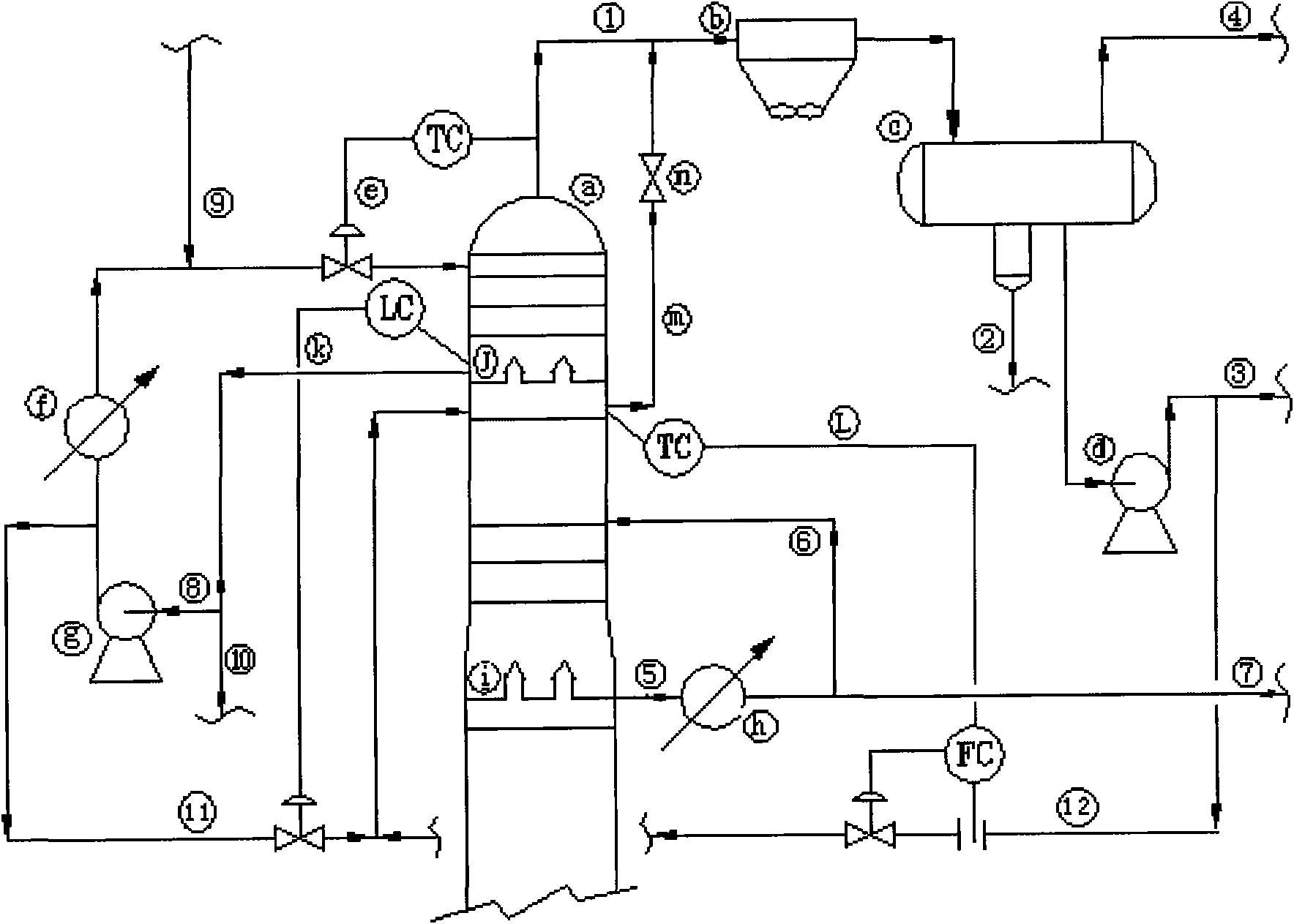

[0042] See attached figure 2

[0043] When the fractionation tower a is in normal operation, the oil and gas cross-line shut-off valve n is closed. After the oil gas 1 at the top of the fractionation tower is cooled to 40°C by the air cooler b at the top of the fractionation tower, it enters the gas-liquid separation tank c at the top of the fractionation tower, and the sulfur-containing sewage 2, naphtha 3 and coking rich gas 4 are separated, and the sulfur-containing sewage 2 is discharged; The coking rich gas 4 is sent to the follow-up device; the crude gasoline 3 is pumped out by the gasoline pump d and then sent to the follow-up device; the diesel oil 5 is taken out from the diesel oil collection tank i, and after being cooled by the diesel cooler h, it is divided into two streams. One is used as up-flow diesel oil 6 and returned to fractionation tower a; the other is used as diese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com