Fluosilicic acid comprehensive recycling technology

A technology of fluosilicic acid and process, which is applied in the field of comprehensive recovery and utilization of fluosilicic acid to achieve the effects of avoiding environmental pollution, improving absorption efficiency, and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

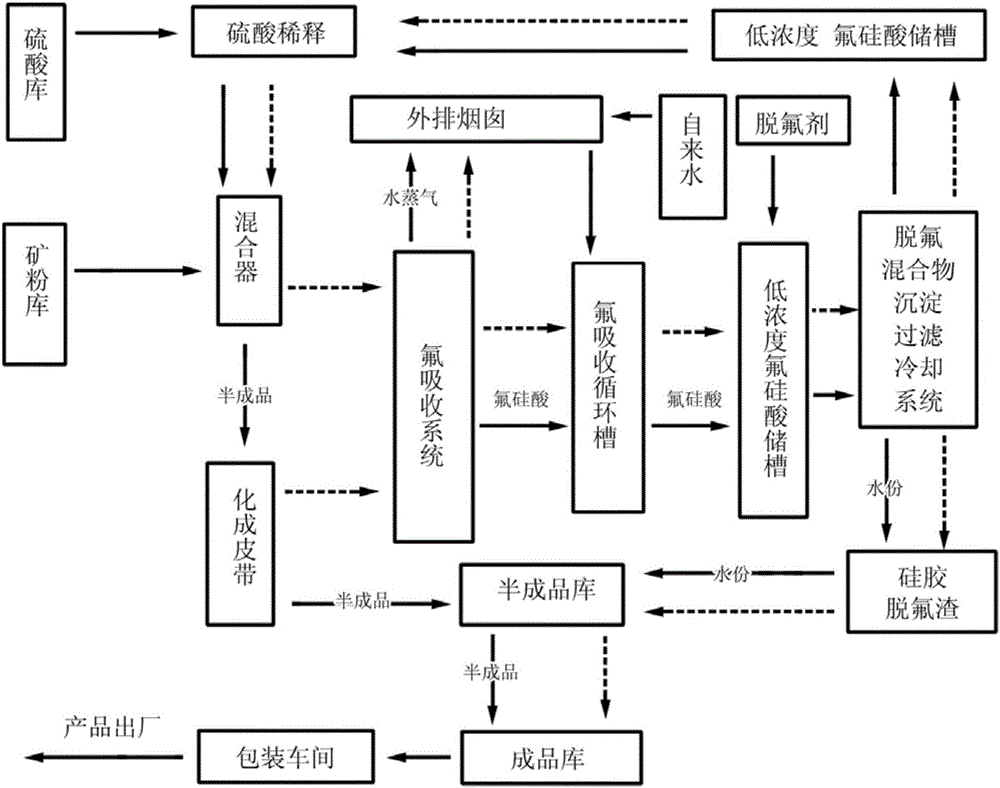

[0014] The present invention will be described in detail below with reference to the accompanying drawings. The process flow is: material reaction process: add clean water into the fluorine absorption circulation tank, and after the fluorine gas is absorbed and overflowed, the circulation liquid enters the low-concentration fluorosilicic acid storage tank and enters the defluorination system after cooling and precipitation, and removes the silica gel after defluorination and filtration Defluorination residue and filter residue are used as product fillers, most of the filtrate is used for diluting sulfuric acid, and a very small part overflows through the high-level pool to the circulation tank and newly replenished clean water for re-absorption cycle. This process performs a cycle, which effectively reduces At the same time as the temperature and concentration of the absorption liquid, it can effectively remove most of the fluorine element in the absorption liquid, fully improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com