Outer-wall insulating board made of reinforced-fiber composite vertical silk rock wool

A technology for external wall thermal insulation boards and standing silk rock wool, which is applied in the direction of thermal insulation, lamination devices, hydraulically coagulable material layered products, etc. Inconvenient construction and other problems, to achieve the effect of reducing the load-bearing burden, not easy to fall off and collapse, and convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

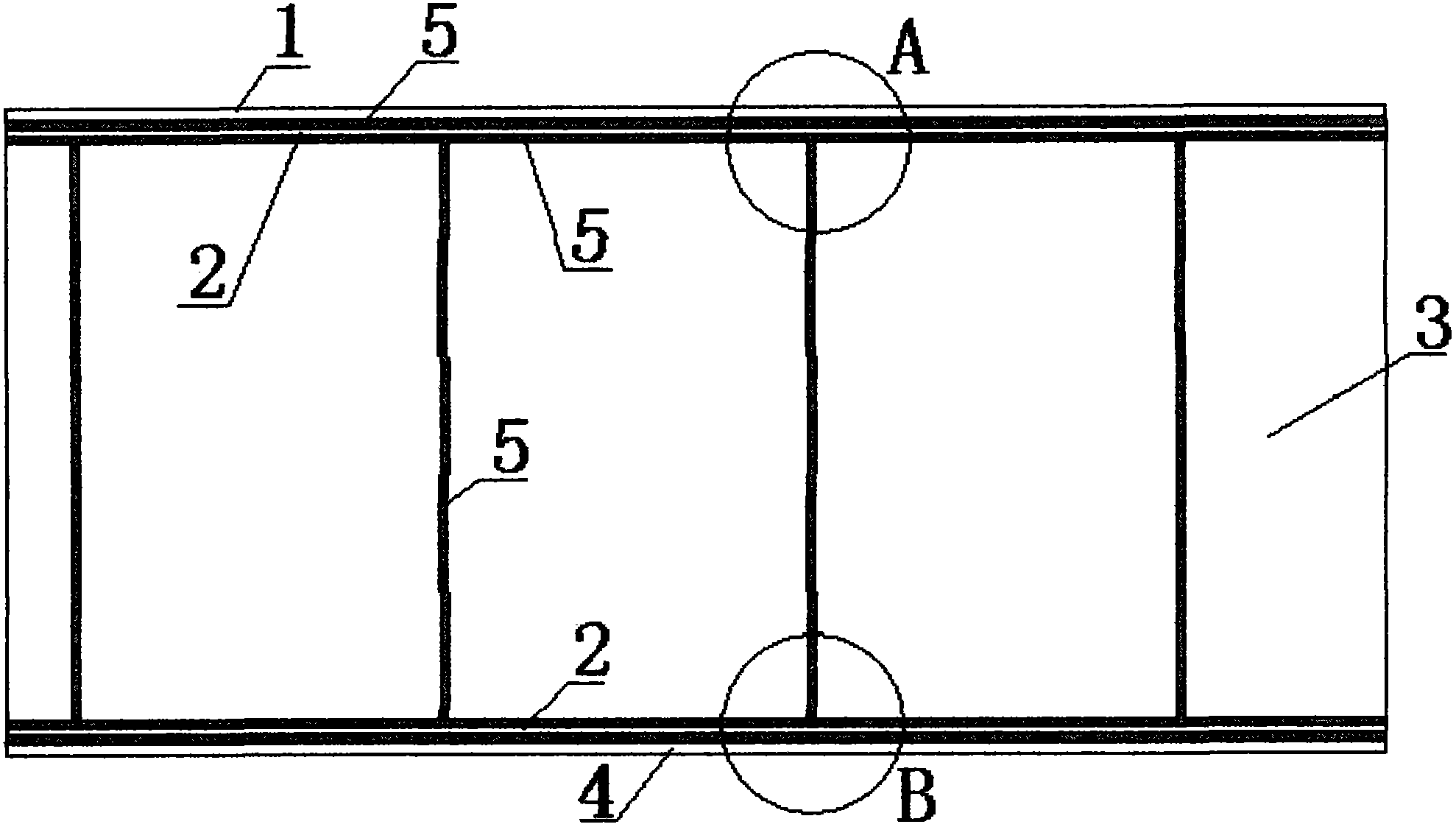

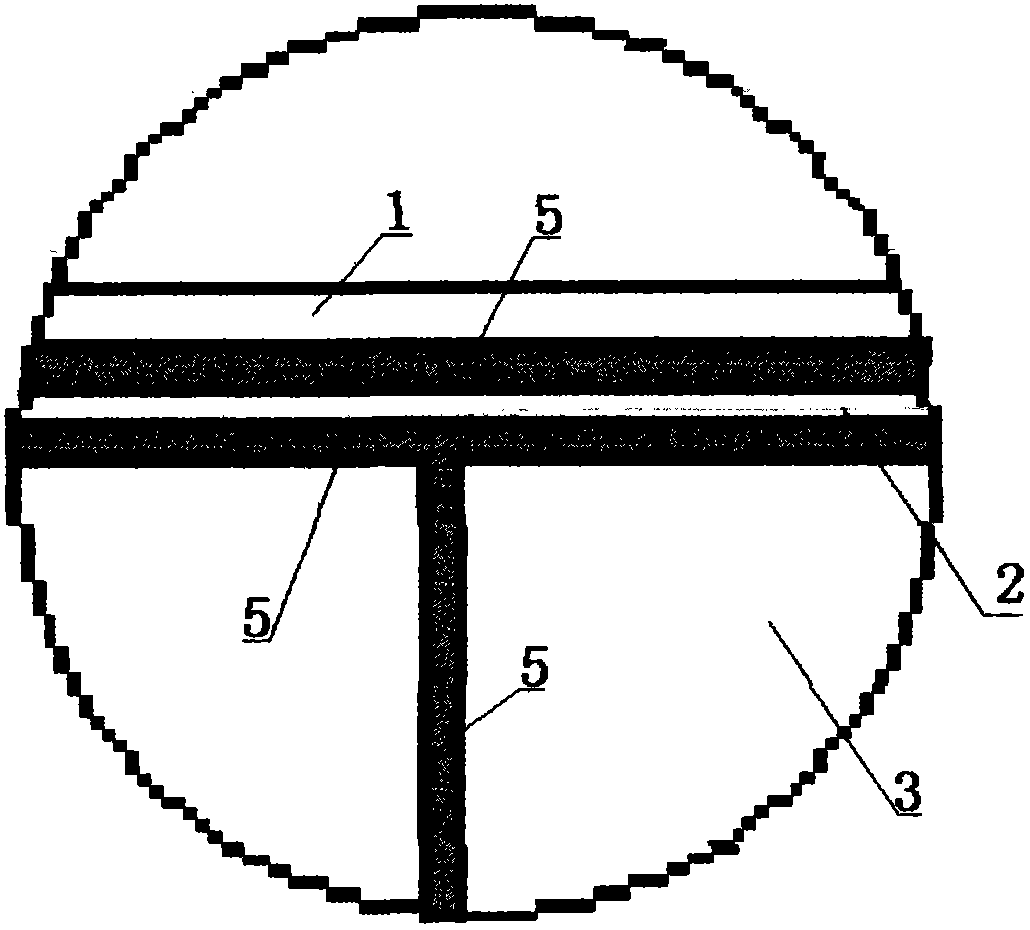

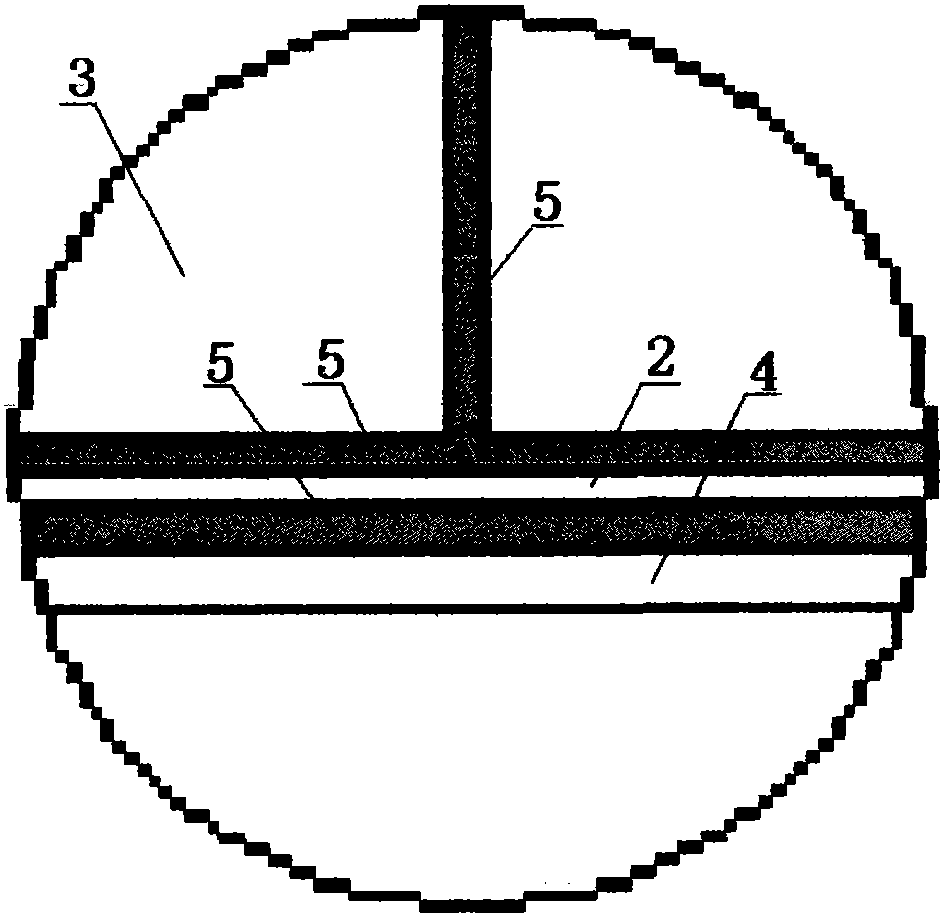

[0024] As shown in the figure, the layered structure from bottom to top of the reinforced fiber composite standing wire rock wool external wall insulation board of the present invention is advertising cloth layer 1 (or mesh cloth with concave-convex structure), glass fiber mesh cloth layer 2, side by side Cut into 8-15 cm thick strips, the vertical filament rock wool layer 3, the glass fiber mesh cloth layer 2 and the non-woven fabric layer 4; the adjacent advertising cloth layer, glass fiber net Cloth layer, rock wool strip, glass fiber cloth layer and non-woven fabric layer and between adjacent rock wool strips are all bonded by cement slurry prepared from magnesium oxide cement and brine (prepared from halogen sheet and water) . The bond is a prefabricated bond and is dried and demoulded. The rock wool strip is a lava-coated rock wool strip whose surface is covered with the cement slurry. The grout bonding joint 5 in the figure. The cement slurry can be replaced by therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com