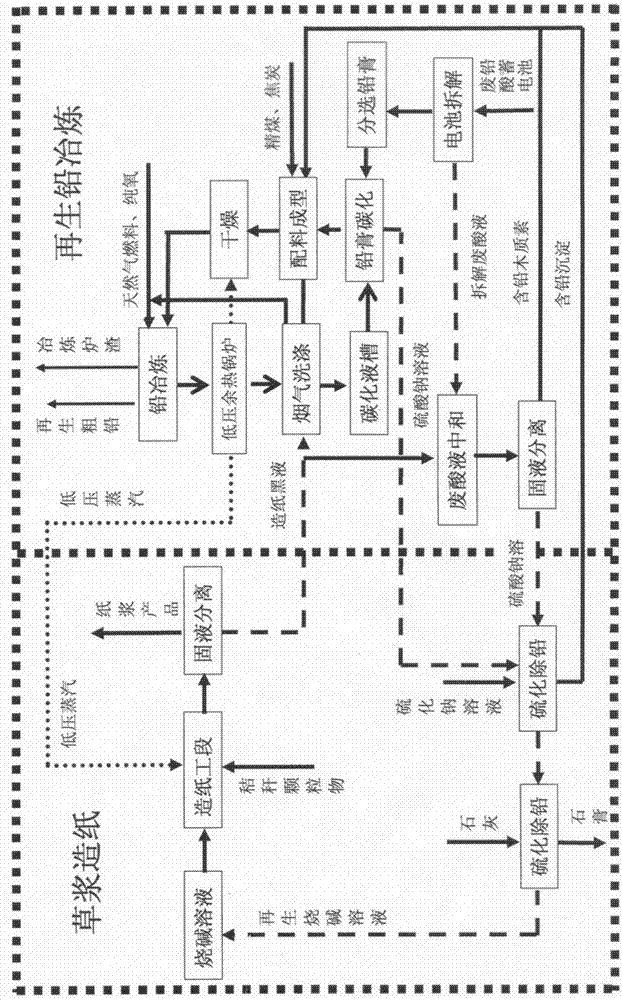

Energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology

A technology of recycled lead smelting, energy saving and environmental protection, applied in cross fields, can solve the problems of polluted pulp, inevitable lead in sedimentation tank effluent, lack of automatic sorting of dismantling materials, etc. The effect of reducing the cost of carbonization desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing 1, non-limiting embodiment is described as follows:

[0055] (1) Squeeze and shorten the straw to obtain straw particles less than 50mm, use industrial caustic soda as raw material to prepare a caustic soda solution with a mass concentration of 4% for the initial production; mix the prepared straw particles and caustic soda solution in a ratio of 1:4 ratio into the pulping and cooking reaction tank;

[0056] Use the low-pressure steam produced by the low-pressure waste heat boiler for lead smelting as the heat source to cook the straw particles with caustic soda solution at 120°C for 60 minutes;

[0057]centrifuging the slurry obtained after the completion of the cooking process, and centrifuging and drying the obtained solid with clear water accounting for 50% of the volume of the slurry to obtain pulp, which is sold after drying;

[0058] The centrifuged liquid is combined with the centrifugal washing liquid, which is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com