Waste water treatment reusing complete plant for water spraying loom

A technology for wastewater treatment and complete sets of equipment, which can be used in textile industry wastewater treatment, flotation water/sewage treatment, adsorption water/sewage treatment, etc. Advanced problems, to achieve the effect of prolonging the response time, less investment, and obvious response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

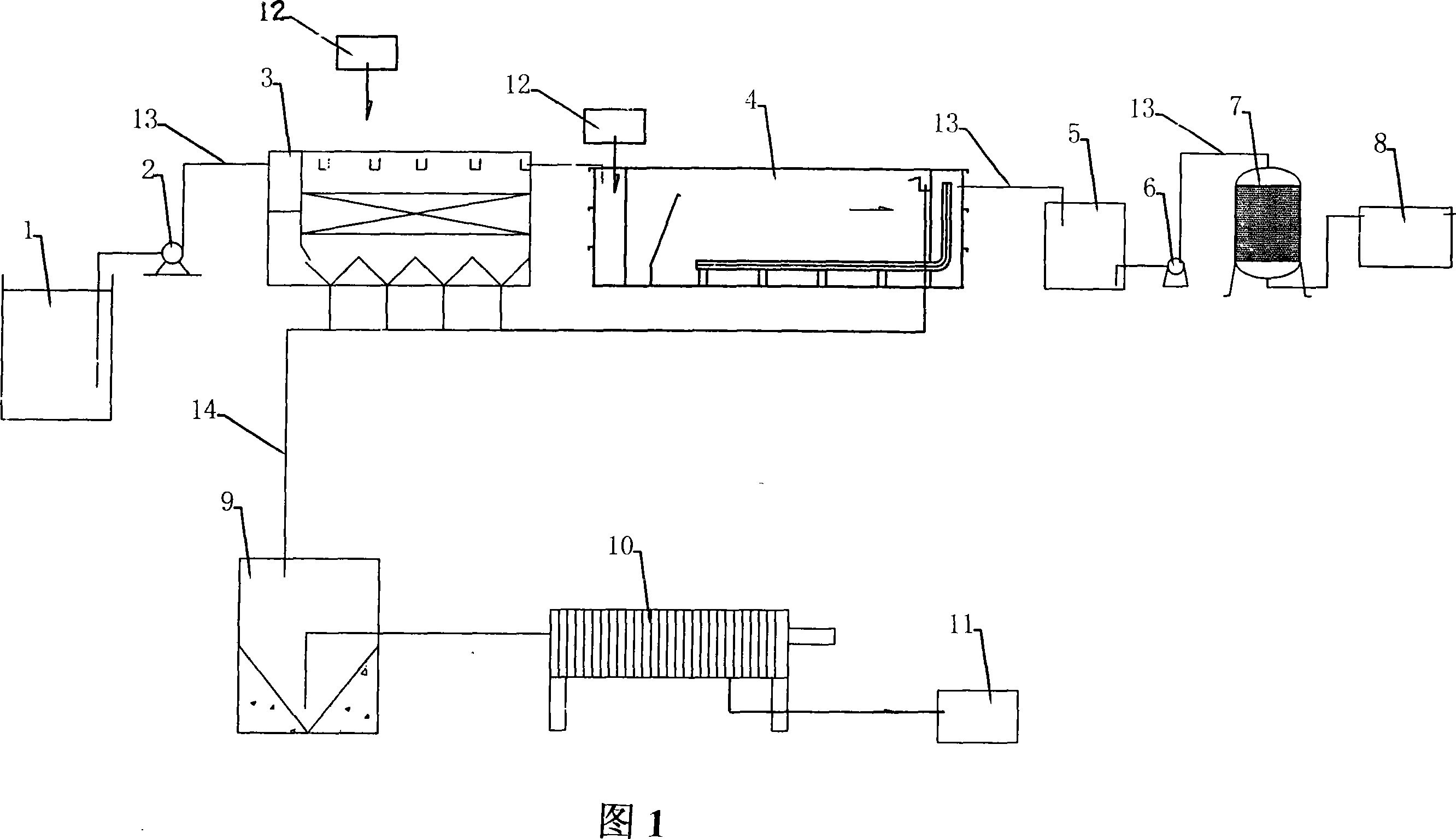

[0028] The present invention is mainly composed of an oil separation adjustment tank 1 connected in sequence through a water pipe 13, a bidirectional overflow separation processor 3 with a lift pump 2, a combined purification air flotation device 4, an intermediate pool 5, a multi-media filter 7, and a reuse pool 8. It is composed of a sludge thickening tank 9 and a plate and frame filter press 10 connected to the two-way overflow separation processor 3, the combined purification air flotation device 4, and the multimedia filter 7, respectively.

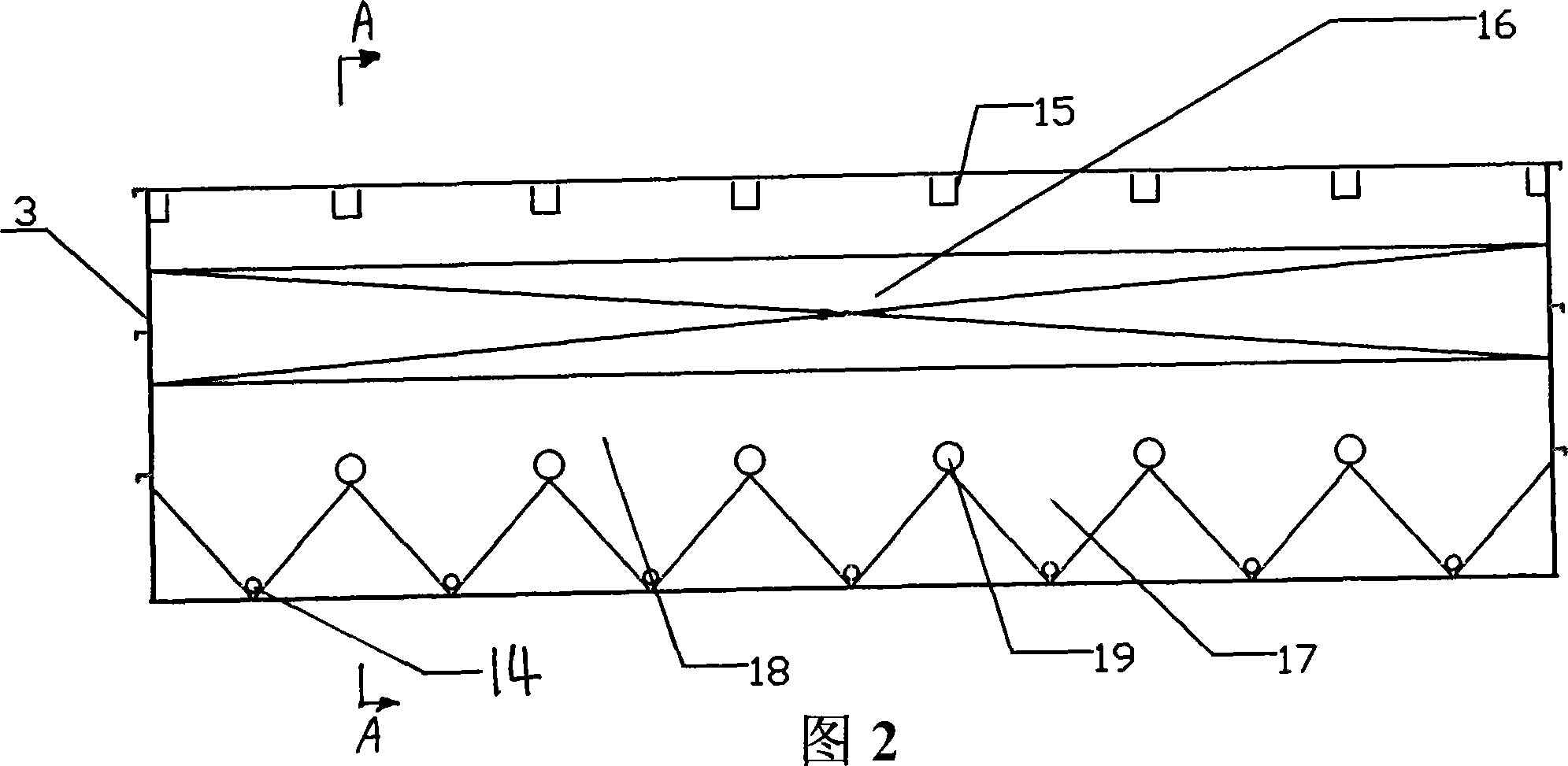

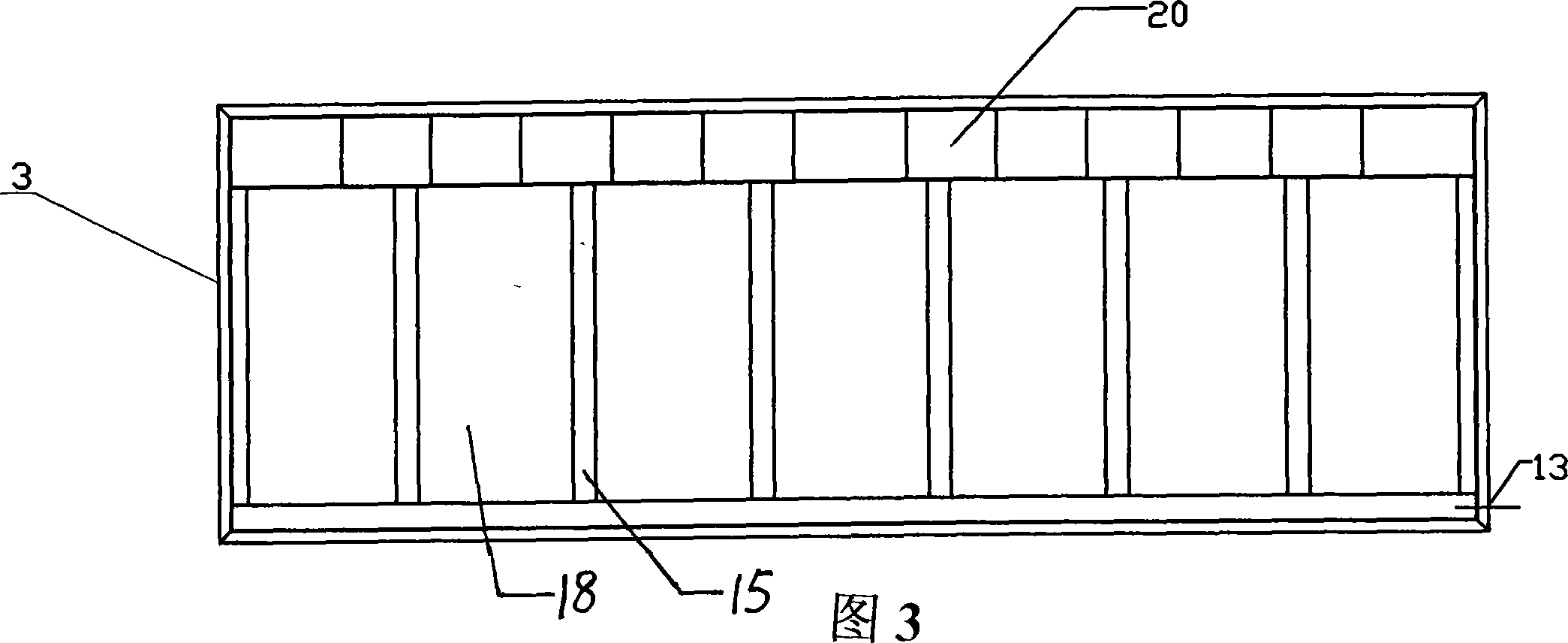

[0029] The two-way overflow separation processor 3 is composed of an overflow pool 18 and a multi-level multi-section reaction pool 20 divided into 8 to 16 sections. The upper part of the overflow pool 18 is provided with 5 to 10 overflow tanks 15 with water pipes 13 The middle part is provided with a honeycomb inclined pipe 16, and the bottom is provided with a sludge bucket 17 with a porous outlet pipe 19 and a sludge pipe 14, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com