Ultrathin high-strength polyolefin microporous film and preparation method thereof

A polyolefin microporous film, polyolefin technology, applied in the direction of coating, can solve the problems of easy thermal oxidation, mechanical degradation, lower yield, easy carbonization of polyolefin resin, etc., to ensure anti-oxidation effect, easy process flow The effect of simple operation and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing an ultra-thin high-strength polyolefin microporous membrane, which uses polyolefin resin as a raw material and adopts the principle of thermally induced phase separation to prepare a polyolefin porous membrane, comprising the following steps:

[0027] a. Polyolefin swelling and dissolving: dissolve the antioxidant in the diluent in the kneader, add polyolefin resin powder into the diluent and stir evenly. Swelling polyolefin; under the protection of nitrogen, add diluent to the swelling polyolefin, dissolve at 100-400°C to form a mixture;

[0028] b. Cast sheet: The mixture obtained in the previous step is sent into the extruder by the gear delivery pump, and the extruder is used to plasticize the mixture to form a polyolefin solution, and the obtained polyolefin solution is extruded from the die under the control of the metering pump , to obtain a polyolefin melt;

[0029] c. Primary stretching of polyolefin cast film: After the polyolefin melt ...

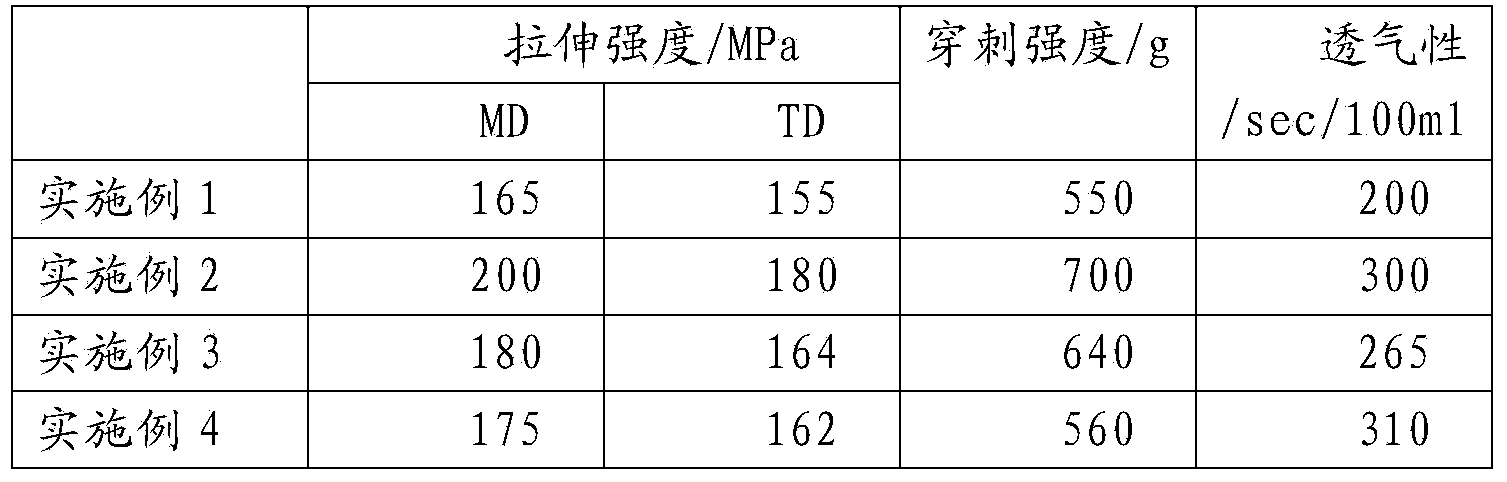

Embodiment 1

[0040] (1) Under the protection of nitrogen, first dissolve the antioxidant in the diluent, then add the polyolefin resin and the diluent to the kneader to swell and dissolve. The mass ratio of antioxidant to polyolefin resin is 1:8000, the mass ratio of polyolefin to diluent is 1:3, the swelling temperature is 100°C, and the dissolution temperature is 250°C.

[0041] The antioxidant in this embodiment is dioctadecyl pentaerythritol diphosphite, the polyolefin resin is an ultra-high molecular weight polyethylene resin with a weight average molecular weight of 2 million, and the diluent is paraffin oil.

[0042] (2) Add the mixture obtained by swelling and dissolving into the extruder through the gear pump, and obtain a uniform melt through mixing, dispersing and shearing. The sheet is cooled by the quenching roll, and then made into a polyethylene microporous membrane product through biaxial stretching, extraction and drying. The temperature of the extruder is 100-300° C., an...

Embodiment 2

[0044] (1) Under the protection of nitrogen, first dissolve the antioxidant in the diluent, then add the polyolefin resin and the diluent to the kneader to swell and dissolve. The mass ratio of antioxidant to polyolefin resin is 1:8000, the mass ratio of polyolefin to diluent is 1:3, the swelling temperature is 100°C, and the dissolution temperature is 250°C.

[0045] The antioxidant in this embodiment is dioctadecyl pentaerythritol diphosphite, the polyolefin resin is an ultra-high molecular weight polyethylene resin with a weight average molecular weight of 5 million, and the diluent is paraffin oil.

[0046] (2) Add the mixture obtained by swelling and dissolving into the extruder through the gear pump, and obtain a uniform melt through mixing, dispersing and shearing. The sheet is cooled by the quenching roll, and then made into a polyethylene microporous membrane product through biaxial stretching, extraction and drying. The temperature of the extruder is 100-300° C., an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com