Anti-aging high-transparency high-strength polypropylene plastic barrel and preparation method thereof

A polypropylene plastic and high-strength technology, applied in the field of plastic packaging barrels, can solve the problems of reduced mechanical strength and heat resistance, unsatisfactory transparent polypropylene products, and reduced polypropylene crystallinity, so as to improve mechanical strength and Heat deflection temperature, enhanced functionality and high transparency, effect of increasing heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

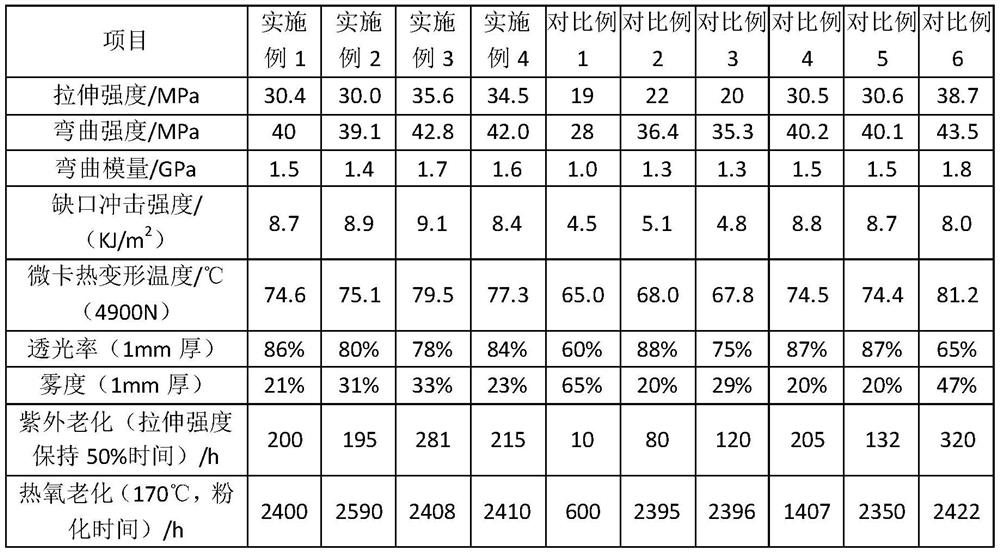

Examples

Embodiment 1

[0035] An anti-aging high-transparency high-strength polypropylene plastic bucket, its raw materials and parts by weight are:

[0036] 100 parts of polypropylene resin, 3 parts of maleic anhydride grafted polypropylene, 2 parts of paraffin oil, 5 parts of modified nano powder, 0.1 part of antioxidant 1010, 0.1 part of auxiliary antioxidant 619, 0.3 part of free radical scavenger GW3346 Parts, nucleating agent Millad NX80000.3 parts.

[0037] A method for preparing an anti-aging high-transparency high-strength polypropylene plastic barrel, comprising the following steps:

[0038] (1) Weigh 10 parts of nano-titanium dioxide, add it to anhydrous ethanol solution, stir it with an electric stirrer, and disperse it with ultrasonic waves to form a nano-powder dispersion; add 4 parts of sodium dodecylsulfonate to a volume ratio of water : In the mixture of ethanol=10:90, fully disperse, then add 6 parts of coupling agent KH570, put it into a magnetic stirrer for hydrolysis for 1 hour...

Embodiment 2

[0043] An anti-aging high-transparency high-strength polypropylene plastic bucket, its raw materials and parts by weight are:

[0044] 100 parts of polypropylene resin, 2 parts of maleic anhydride grafted polypropylene, 1 part of paraffin oil, 5 parts of modified nano powder, 0.3 parts of antioxidant 1010, 0.3 parts of auxiliary antioxidant 619, 0.6 parts of free radical scavenger GW3346 Parts, nucleating agent Millad NX80000.1 part.

[0045] The preparation method is the same as in Example 1, except that "10 parts of nanometer titanium dioxide powder" in step (1) is replaced with "10 parts of nanometer zinc oxide powder".

Embodiment 3

[0047] An anti-aging high-transparency high-strength polypropylene plastic bucket, its raw materials and parts by weight are:

[0048] 100 parts of polypropylene resin, 8 parts of maleic acid grafted polypropylene, 2 parts of paraffin oil, 10 parts of modified nano powder, 0.5 part of antioxidant 1010, 0.5 part of auxiliary antioxidant 619, free radical scavenger GW3346 0.5 parts, nucleating agent Millad NX80000.4 parts

[0049] The preparation method is the same as in Example 1, except that "10 parts of nano-titanium dioxide" in step (1) is replaced with "5 parts of nano-titanium dioxide and 5 parts of nano-zinc oxide powder".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com