Patents

Literature

186 results about "Packaging Drum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

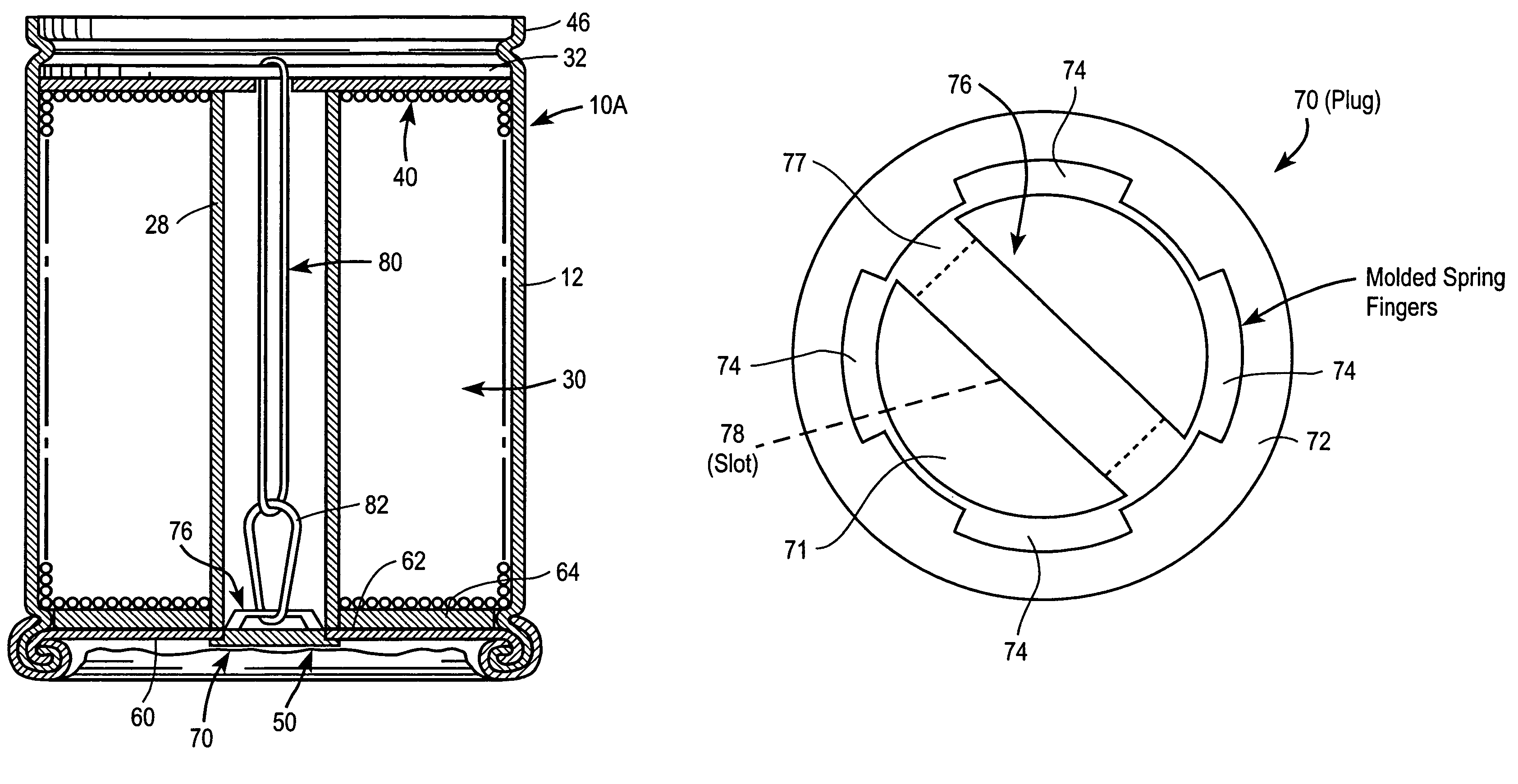

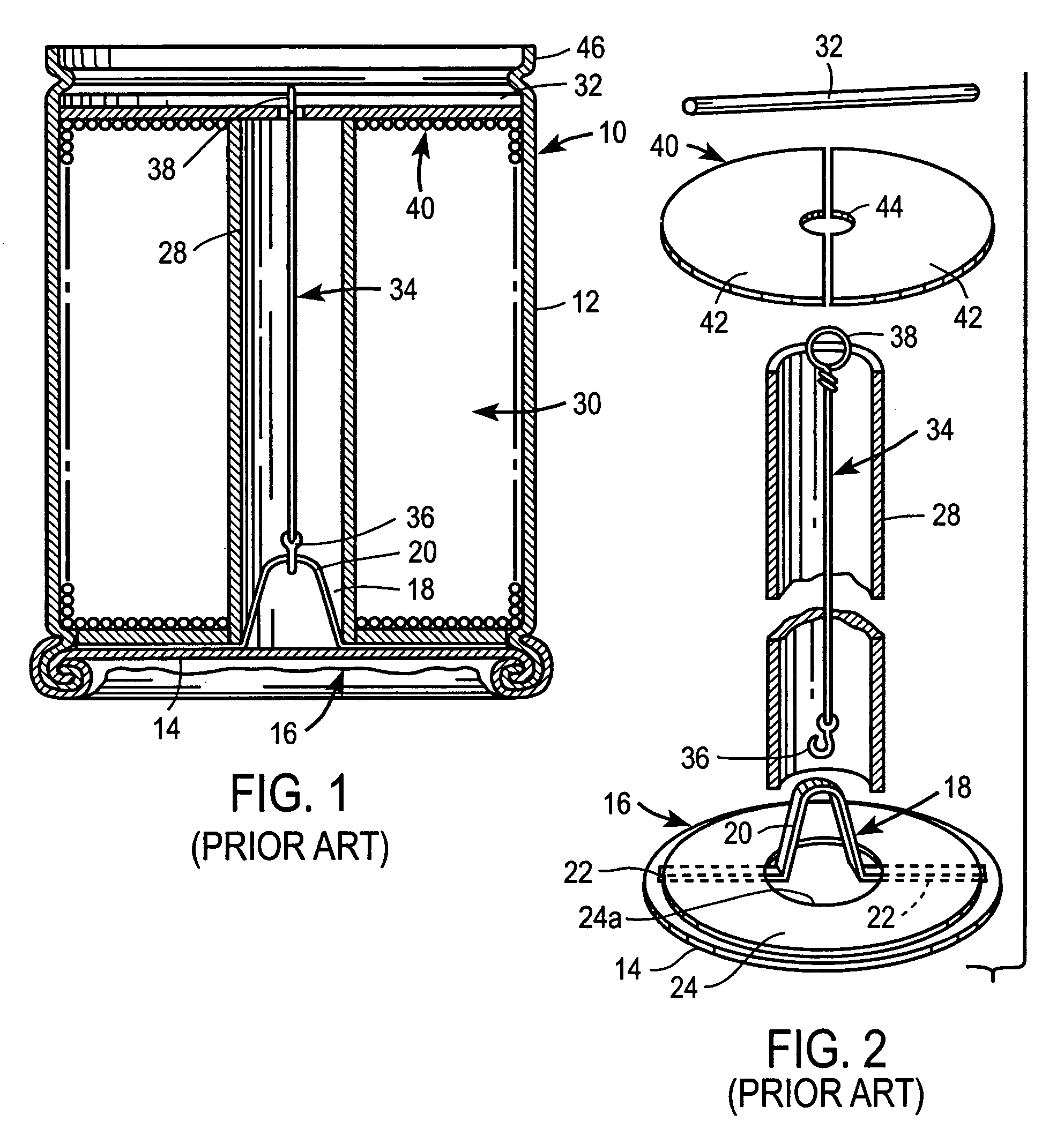

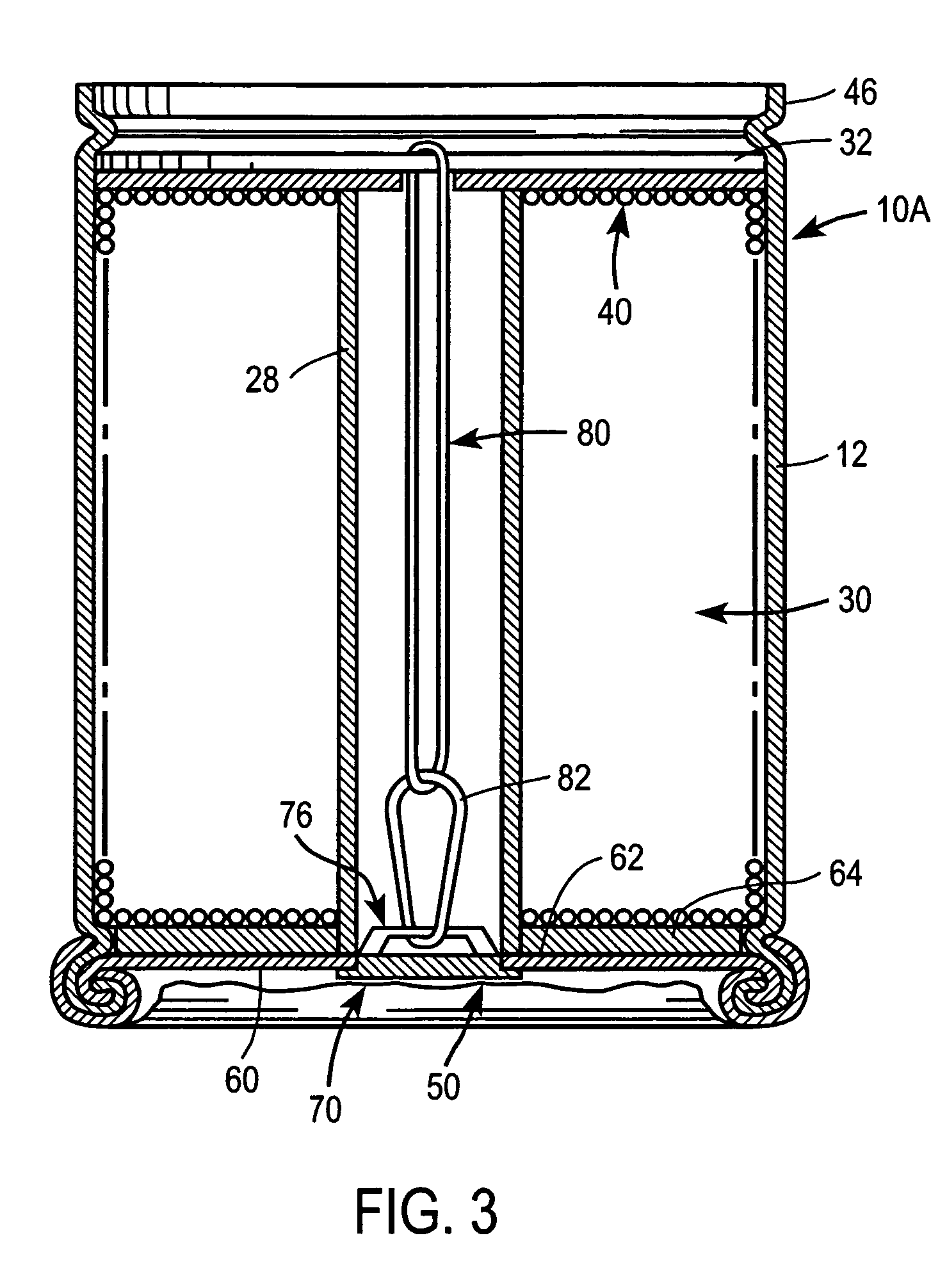

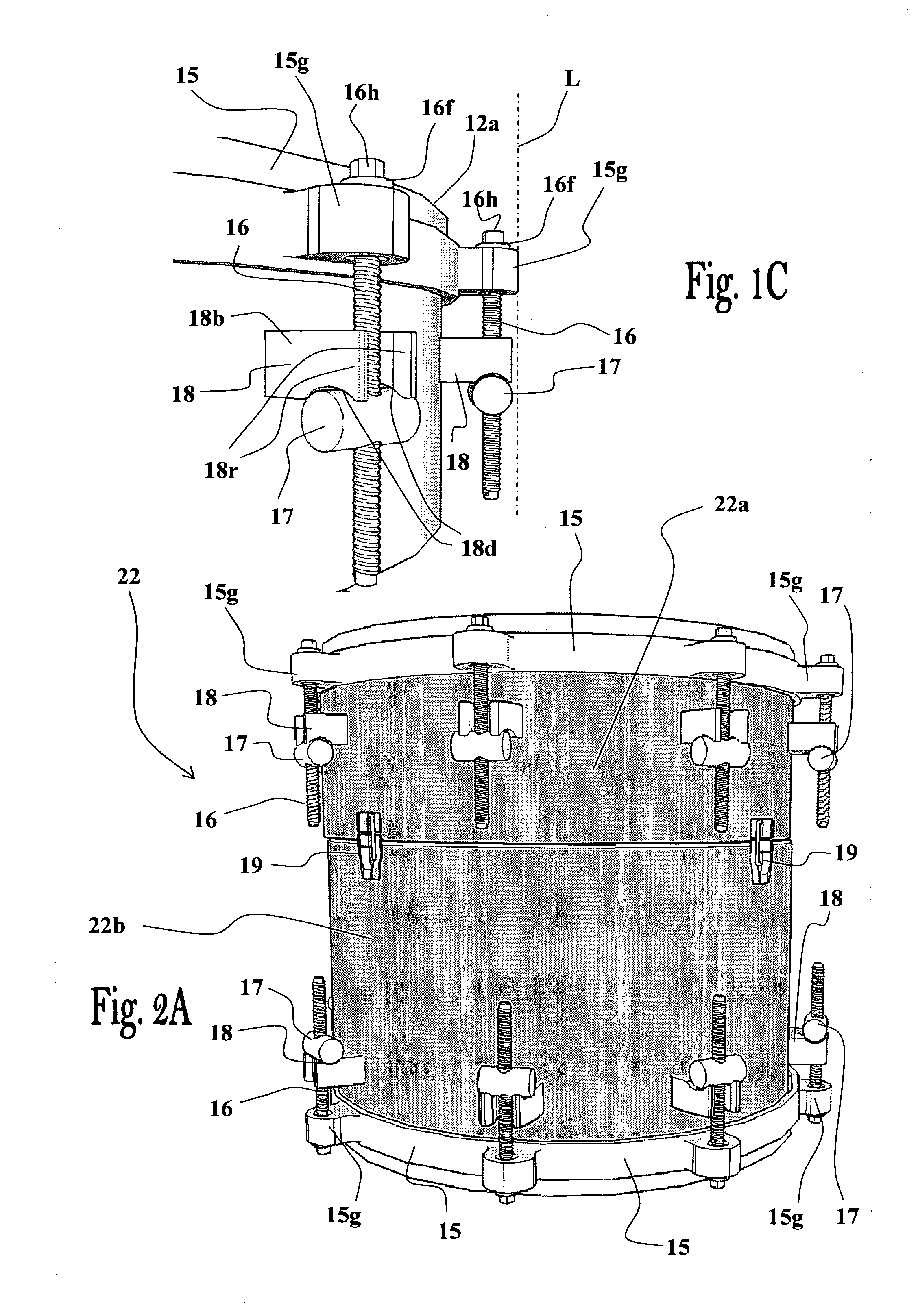

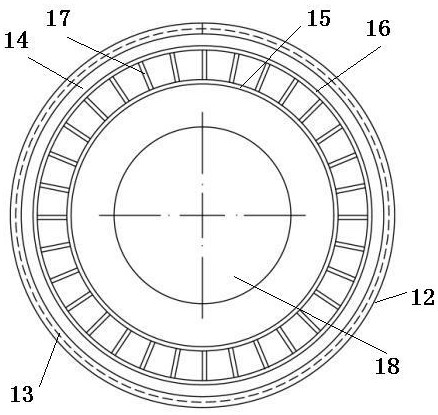

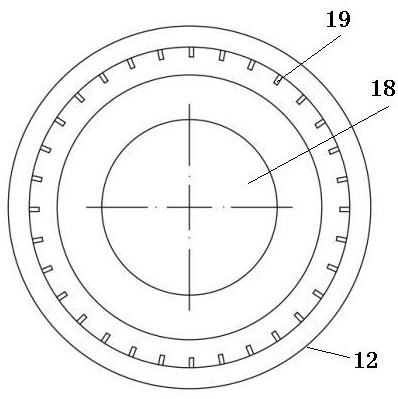

Wire-coil packaging drum with improved bottom assembly

A game machine (2, 200) which includes a playing field (6, 301) traversed by objects, such as balls (320). The playing field can have plural drop zones (381–383) which can be selected by the player using deflectors (108–110) that control where the balls are launched. Detectors (22, 392) indicate scoring positions assumed by the balls. A payline display (28, 335) displays scored events. A symbol selector is included to select symbols which are variably assigned to the scoring positions and displayed on displays (20, 397). The balls score symbols which can be displayed in the payline display and affect winning or bonus play. Game machine (200) includes traditional slot machine reels which works in conjunction therewith.

Owner:GREIF PACKAGING

Renovating and treating method for waste packaging barrel

InactiveCN107413828ASimple methodEasy to operateSolid waste disposalPlastic recyclingEngineeringWaste management

The invention discloses a renovating and treating method for a waste packaging barrel. The renovating and treating method is characterized by including an iron barrel renovating method, a waste plastic barrel smashing method and a paint packaging iron barrel smashing method. The method is simple, convenient, easy to operate, environment-friendly, safe and good in treating effect.

Owner:南通天地和环保科技有限公司

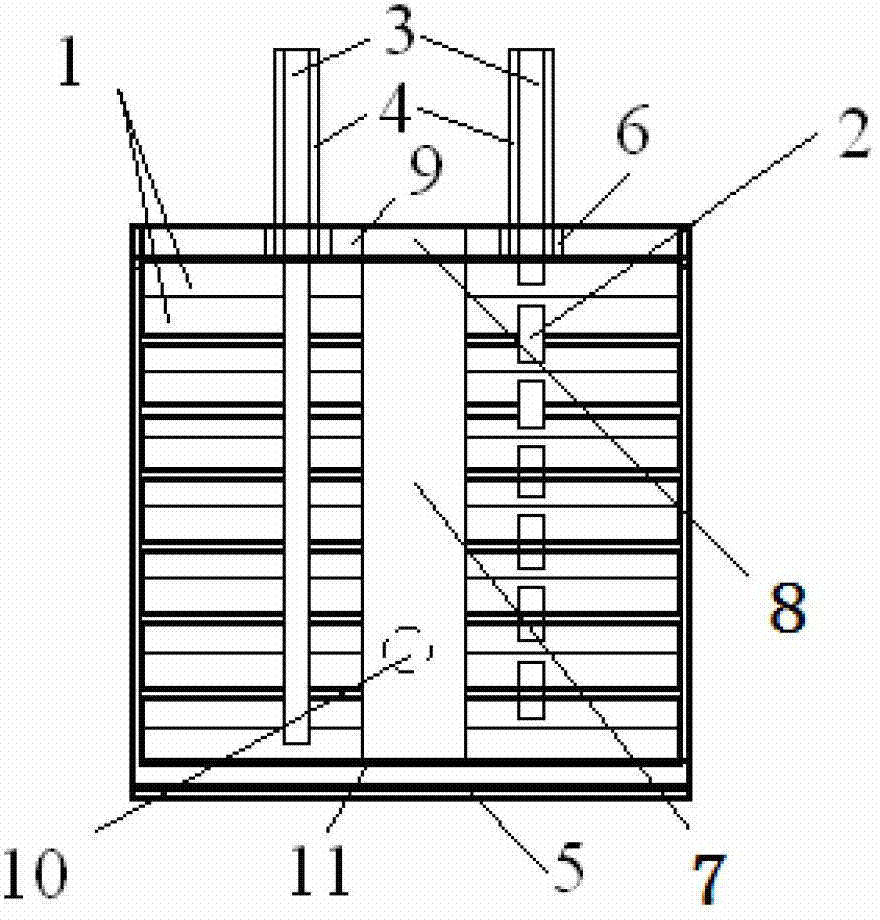

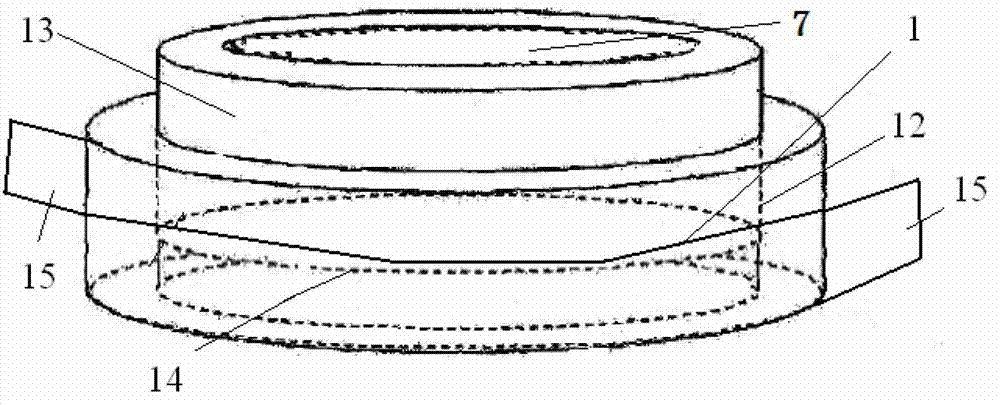

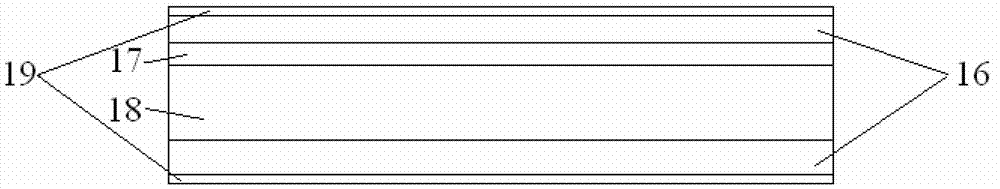

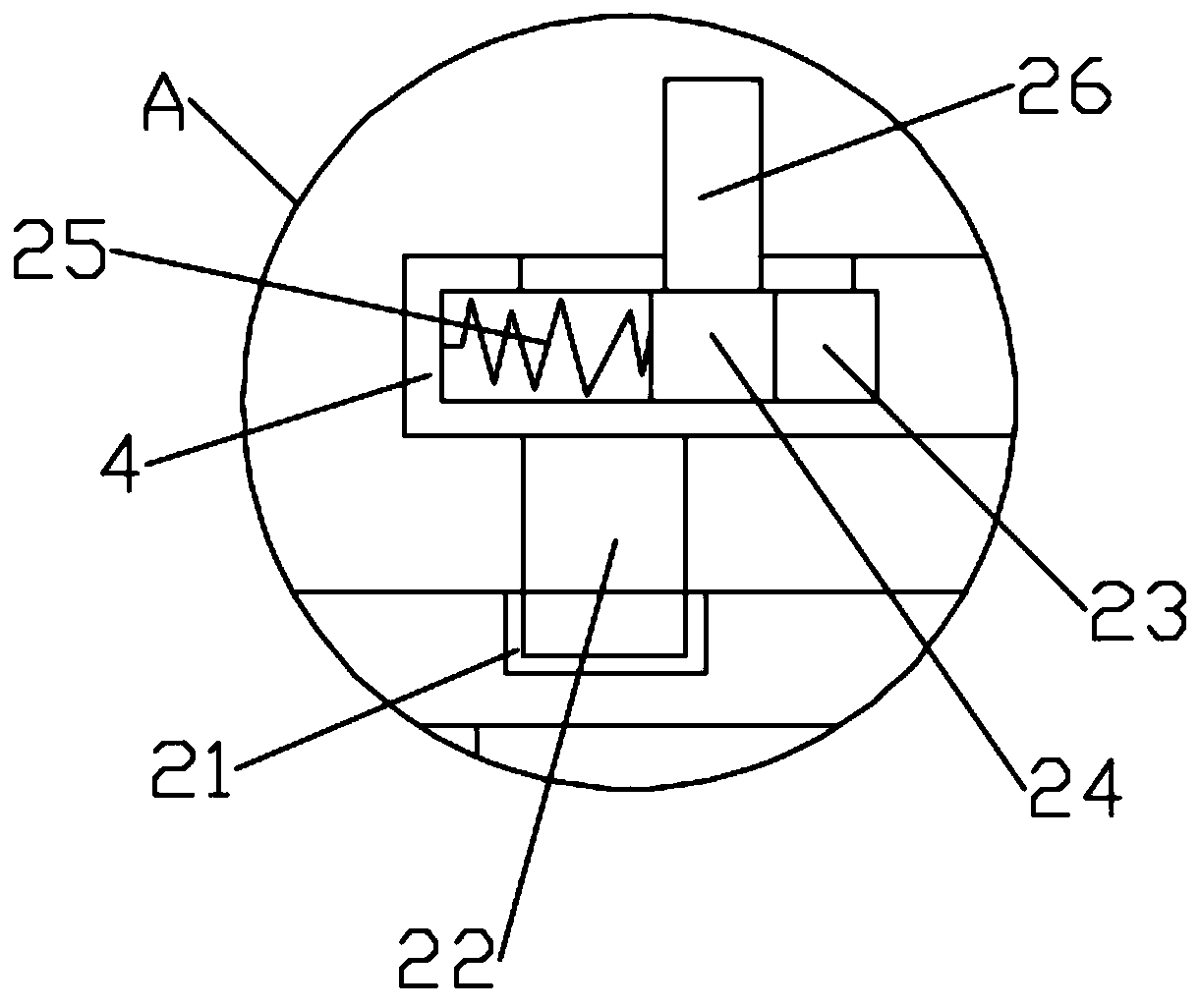

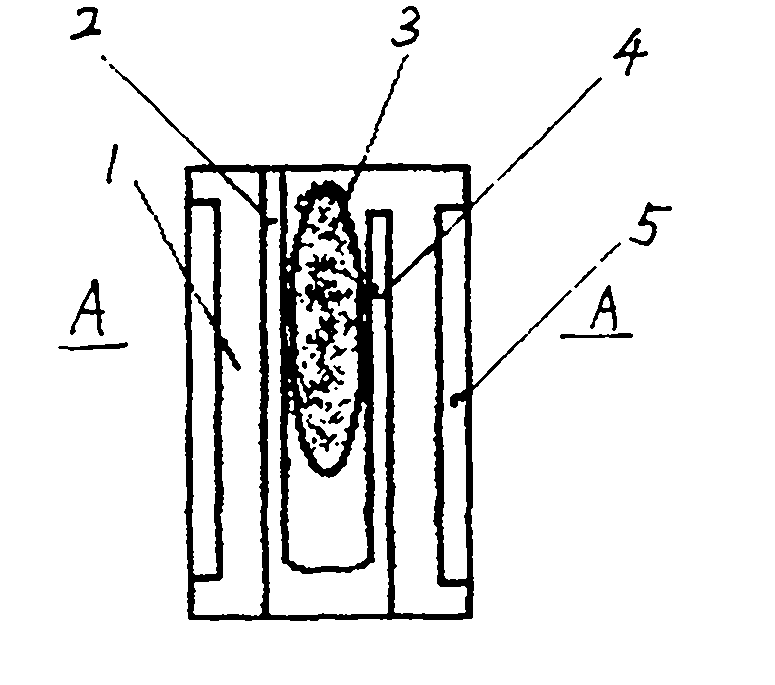

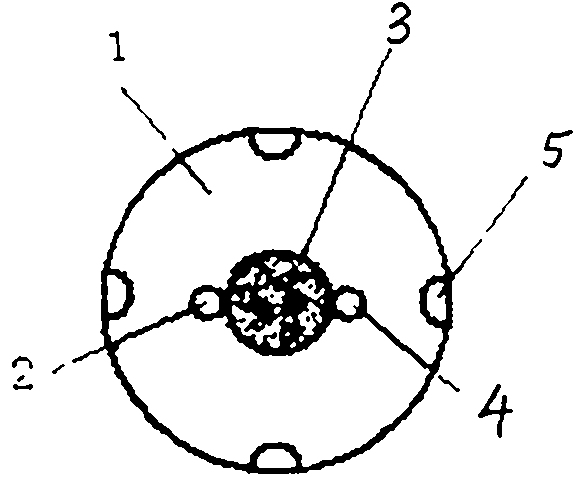

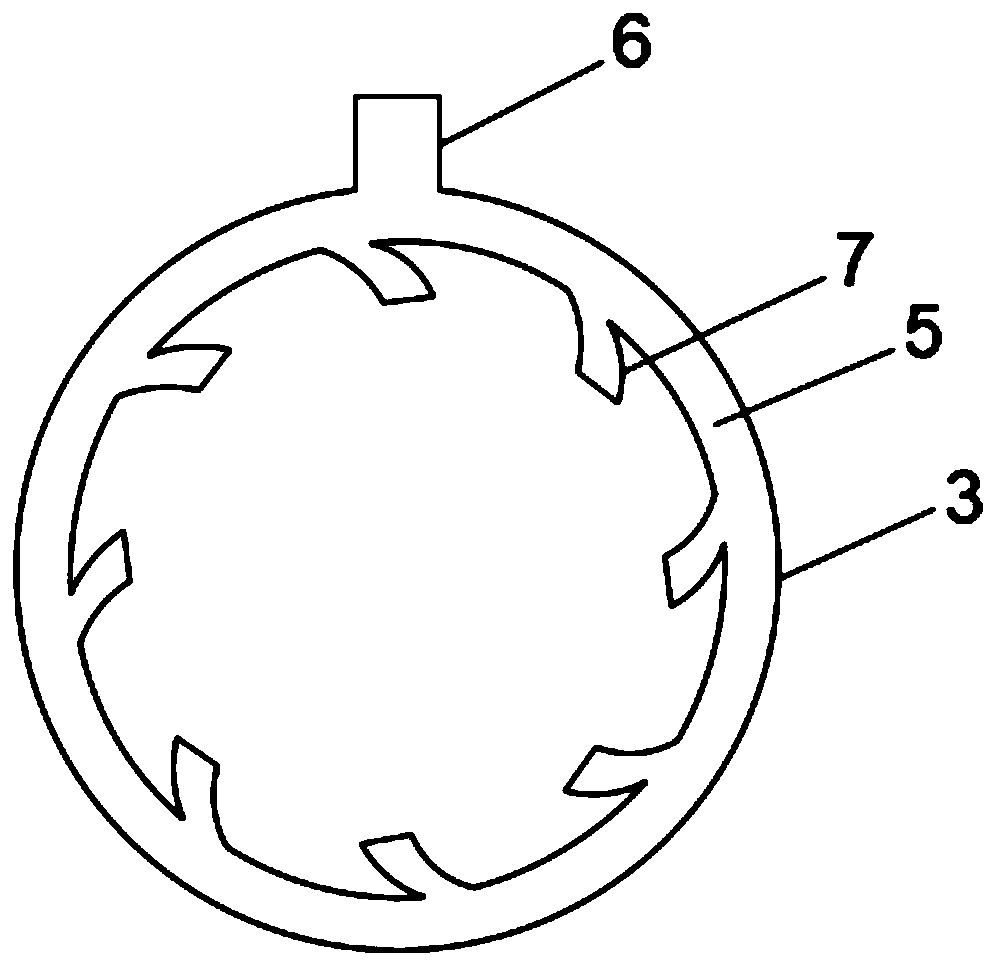

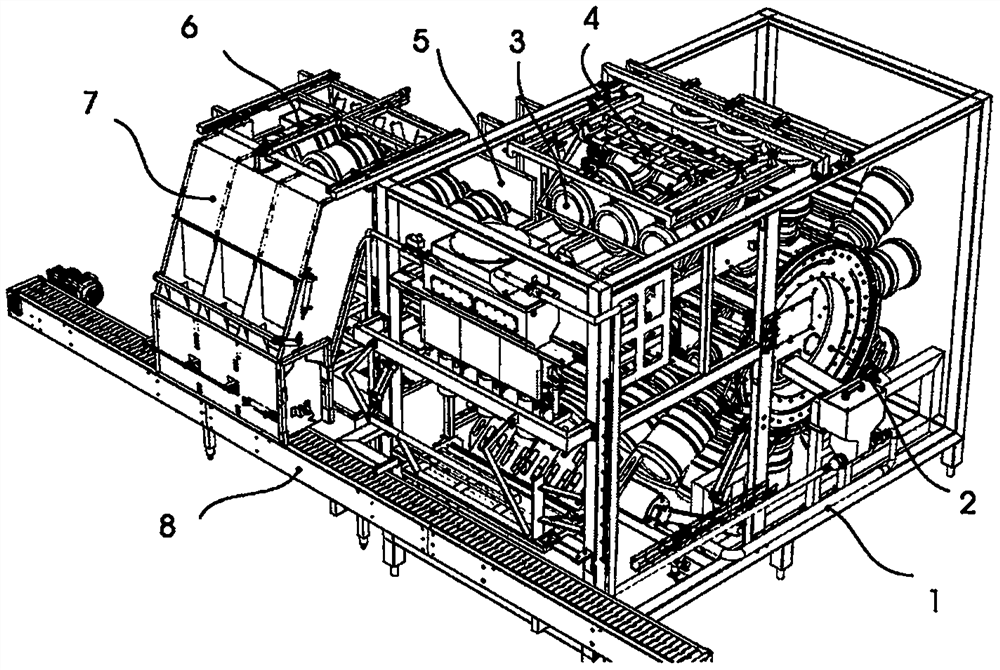

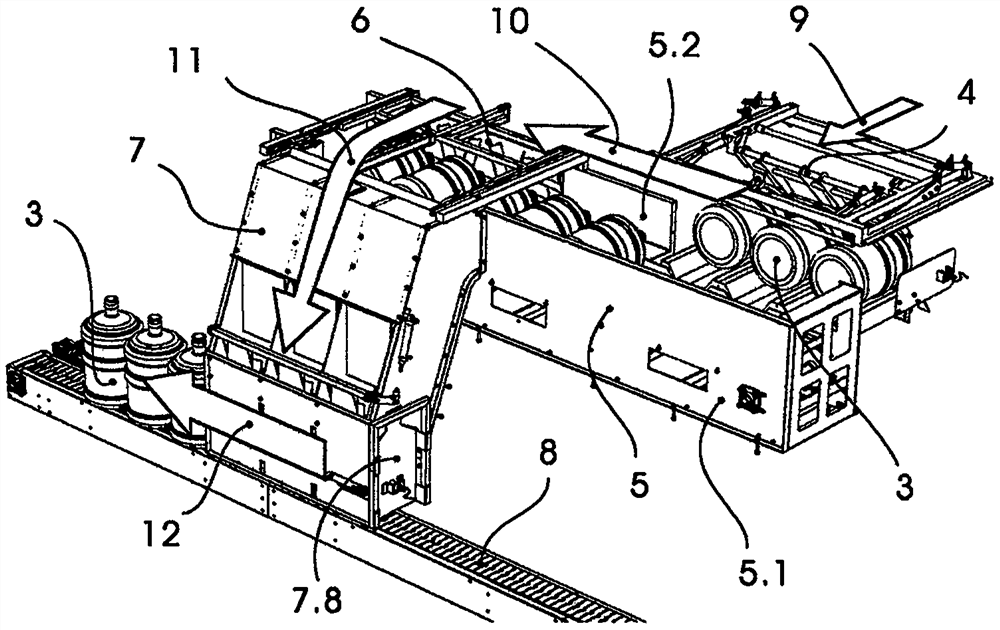

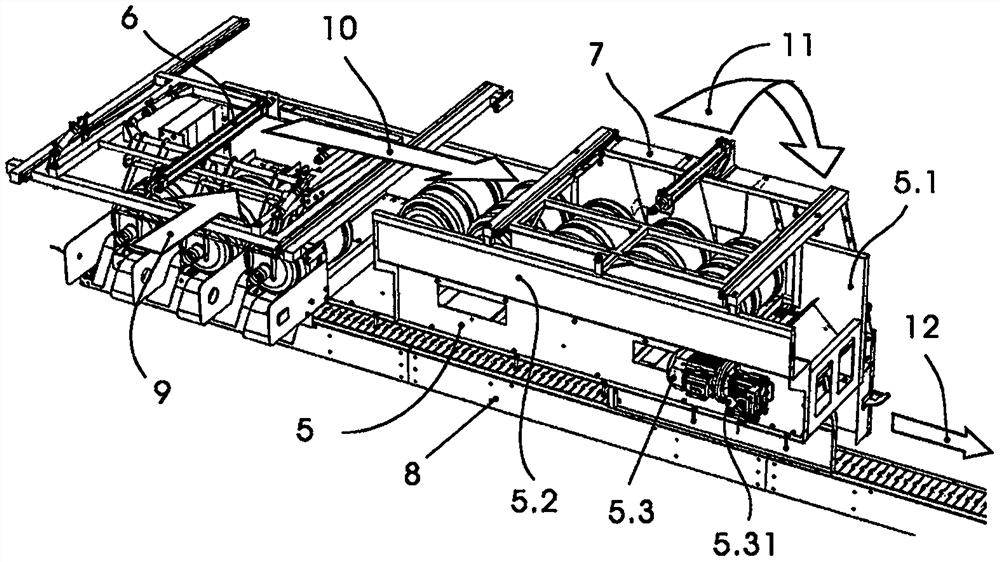

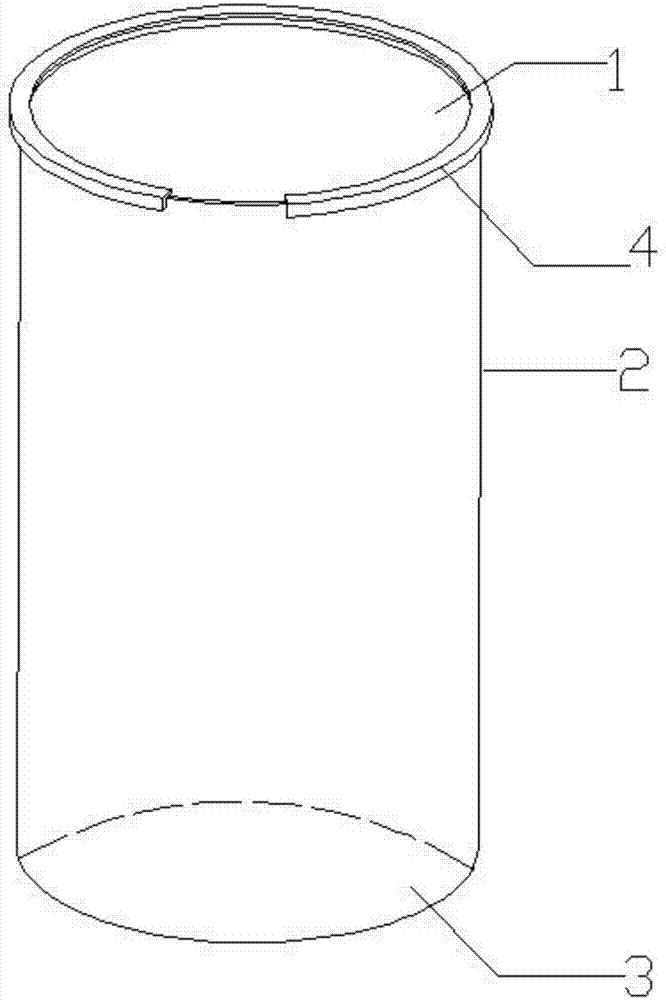

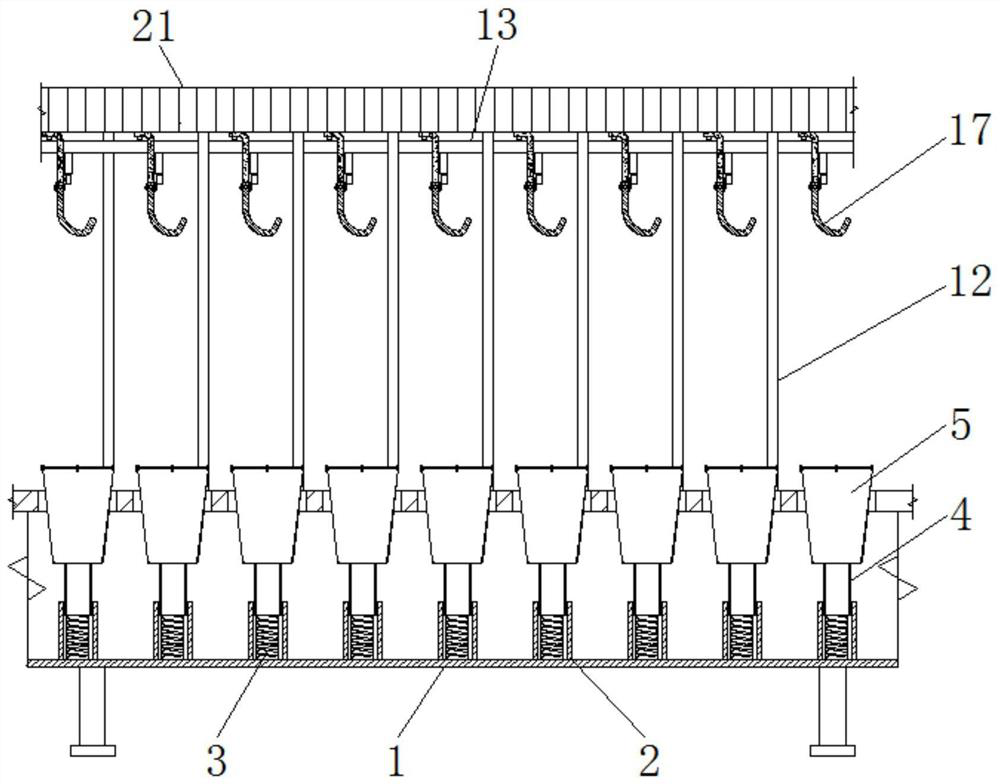

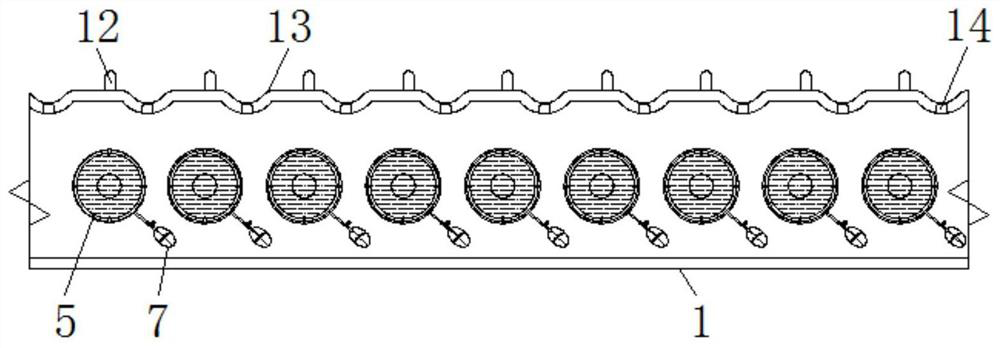

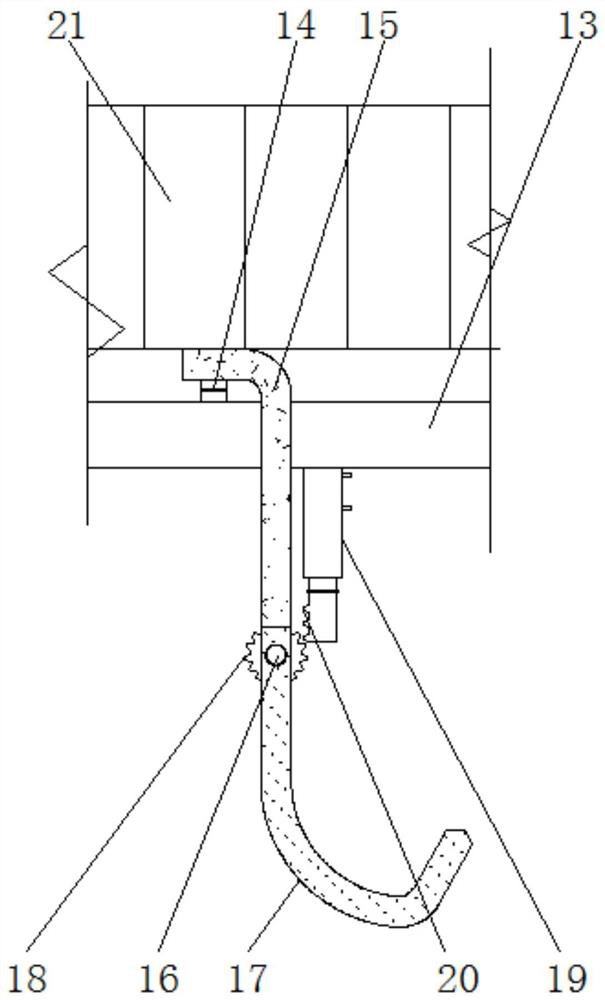

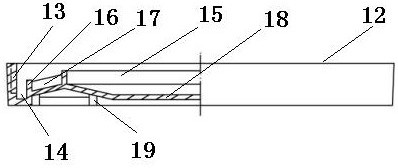

Superconducting magnet and manufacturing method thereof

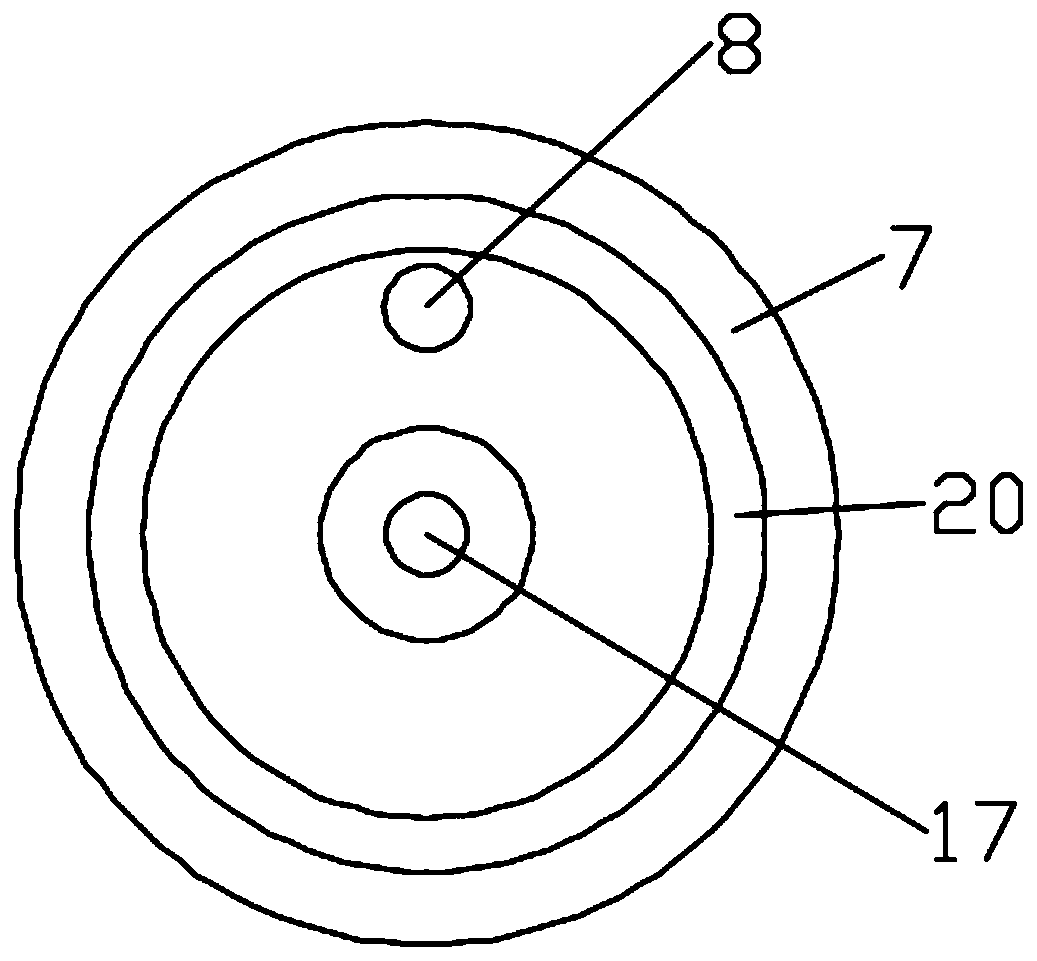

ActiveCN102810378AInductances/transformers/magnets manufactureSuperconducting magnets/coilsSuperconducting CoilsPackaging Drum

The invention discloses a superconducting magnet. The superconducting magnet comprises double-pancake coils (1), superconducting connectors (2), magnet current leads (3), magnetic field shielding tubes (4), a packaging drum (5), magnet current lead grooves (6) and an epoxy hole (10); a plurality of double-pancake coils (1) are tightly connected along axial directions of the coils, the double-pancake coils (1) are connected with superconducting belts (5) through the superconducting connectors to reduce heat, and the intensity of a magnetic field where the magnet current leads (3) are positioned is reduced through the magnetic field shielding tubes (4), so that electromagnetic force applied to the magnet current leads (3) is reduced. A circular cake-shaped magnet end plate (9) is sleeved at the upper ends of the double-pancake coils (1) which are tightly connected, and one end of each of two magnet current leads (3) at the upper end of the magnet end plate (9) is sleeved in each magnetic field shielding tube (4).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

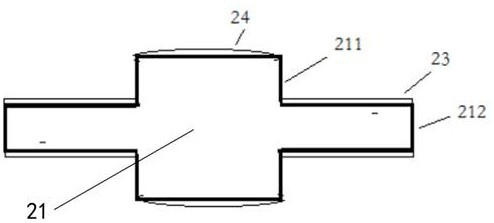

A kind of cleaning method of electrolyte packaging barrel for lithium ion battery

InactiveCN102274843AGuaranteed to blow dryAvoid wastingHollow article cleaningDistilled waterEngineering

The invention relates to a cleaning method for electrolyte packaging drums for lithium-ion batteries, which is characterized in that it comprises the following steps: 1) Residual liquid collection: add pressure to the packaging drum, use a special catheter quick 4P connector to clean the residual liquid in the packaging drum liquid collection; 2) Opening the cover: release the pressure inside the barrel through the quick 2P joint of the packing barrel, and open the top sealing flange; 3) Cleaning: put the packing barrel upside down on each rotary nozzle, open the valve of the nozzle, start the water pump, and use Spray washing with tap water and distilled water; 4) Water control: After cleaning, keep the water upside down for 1 to 3 hours; 5) Tightly cover; 6) Drying: Use a dew point of -30°C to 50°C and a purity of 99.5% to 99.99%, nitrogen at a temperature of 5°C to 50°C passes through the quick connector of the packaging barrel, and the gas source is turned off after blowing for 6 to 20 hours, and the pressure can be kept for use after passing the test.

Owner:TIANJIN JINNIU POWER SOURCES MATERIAL

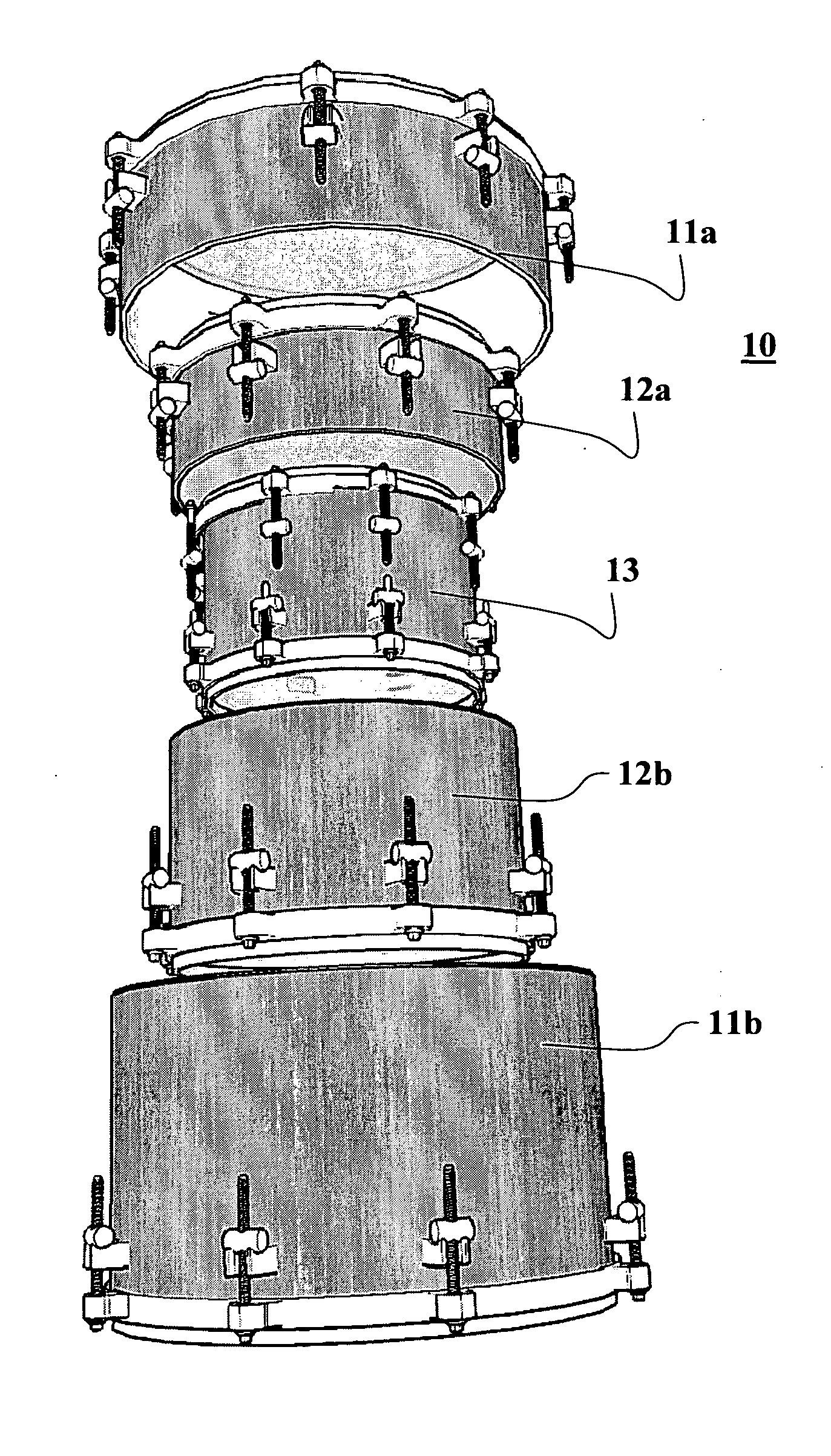

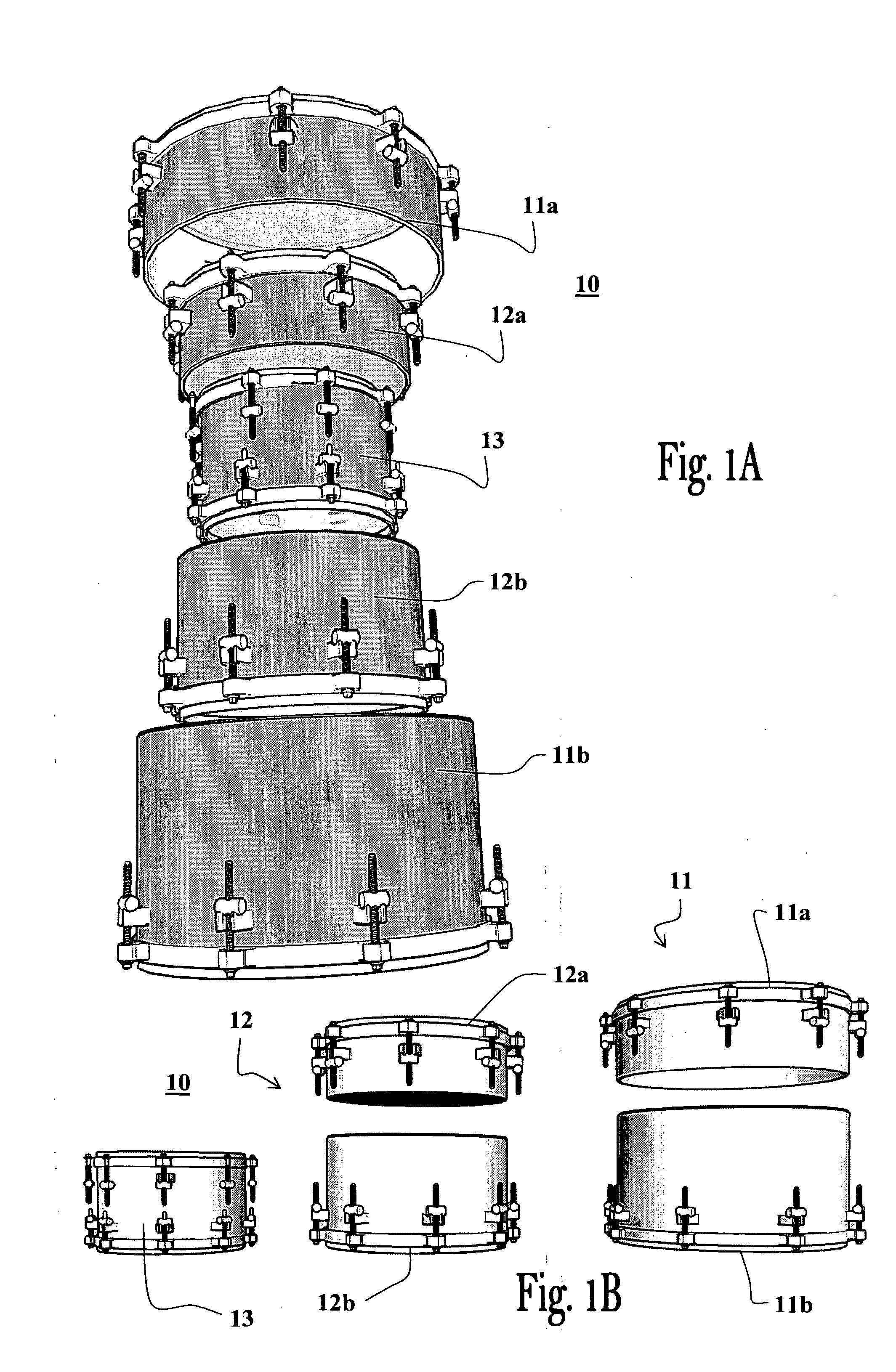

Nested drum set

InactiveUS20120000343A1Easy to packComfortably storedPercussion musical instrumentsEngineeringMechanical engineering

The invention provides nesting drum set designs suitable for packaging drums having standard height (depth) and standard drum head and fastening frames sizes in a self-contained fashion, wherein some of the drums have drum head diameter differences of circa 2″ one from the other, thereby providing a compact and relatively lightweight packed drum set that can be comfortably transported or stored while occupying substantially small storage / luggage space.

Owner:AMI DRUMS

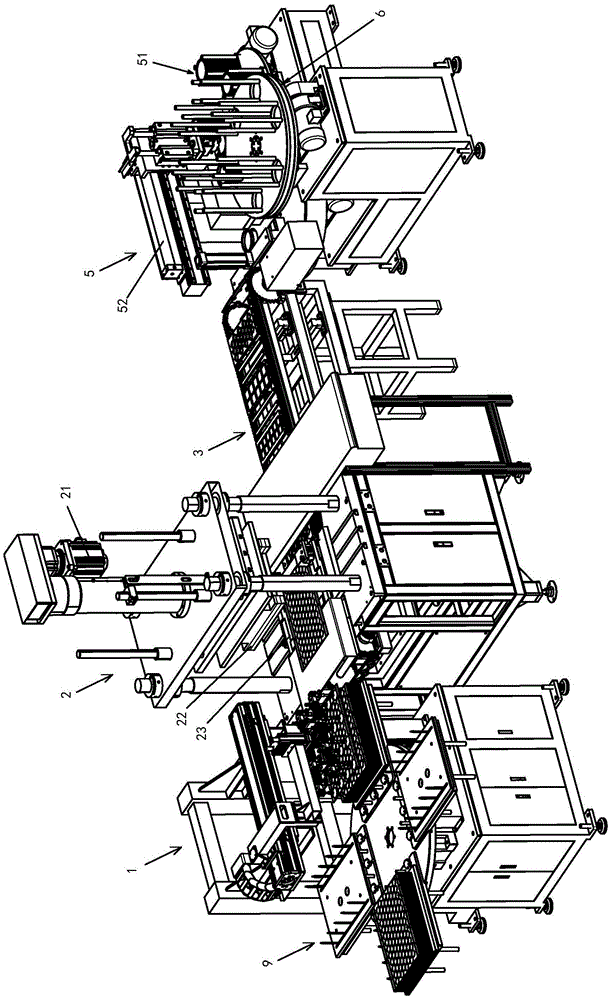

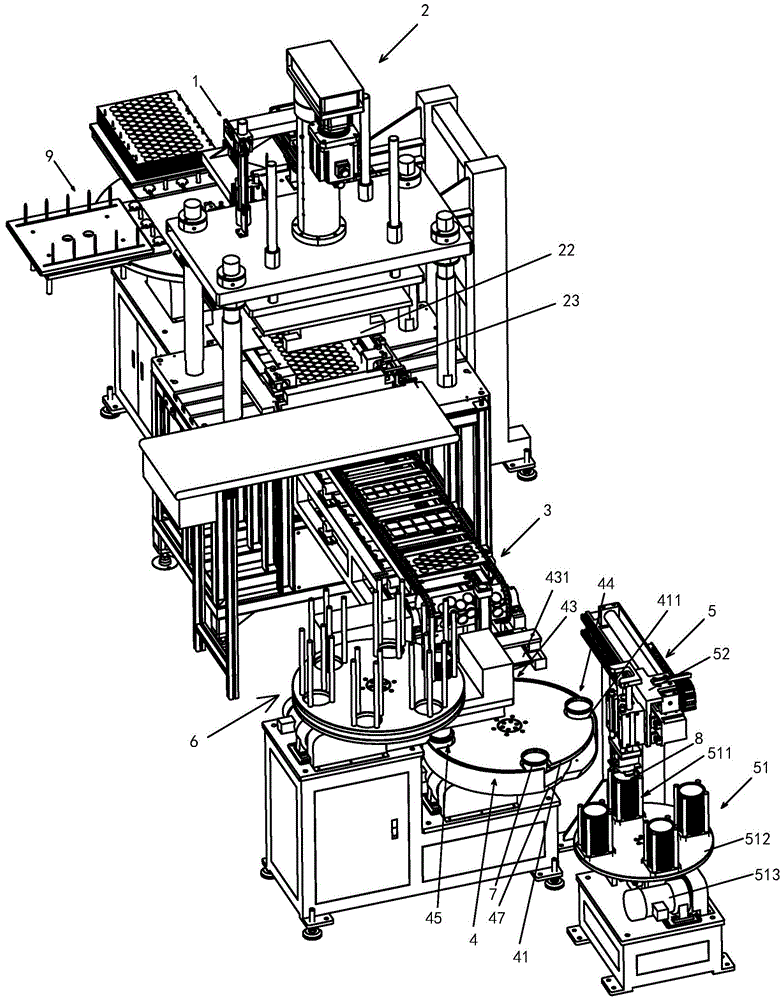

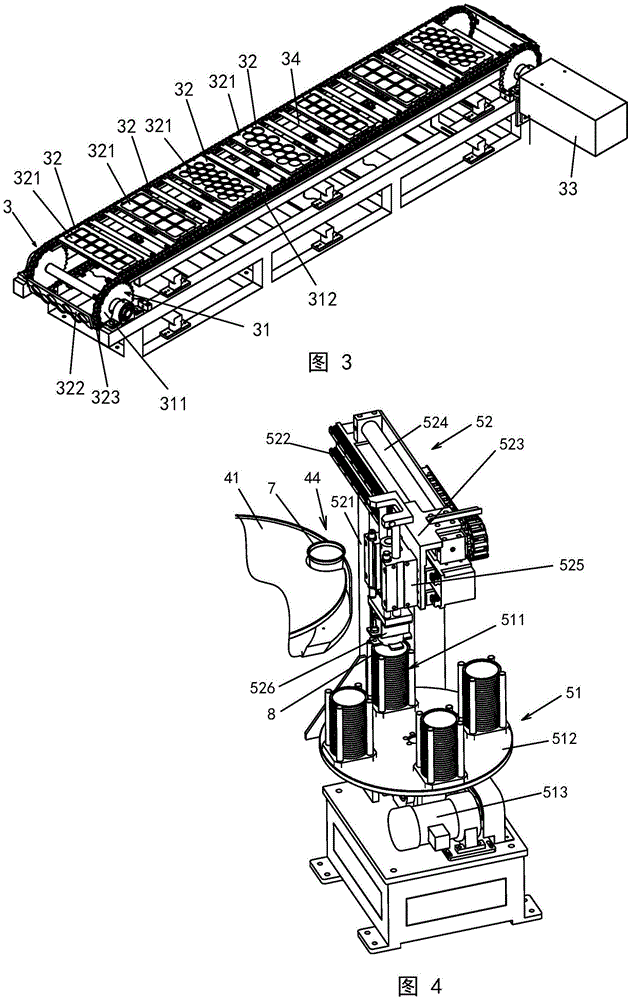

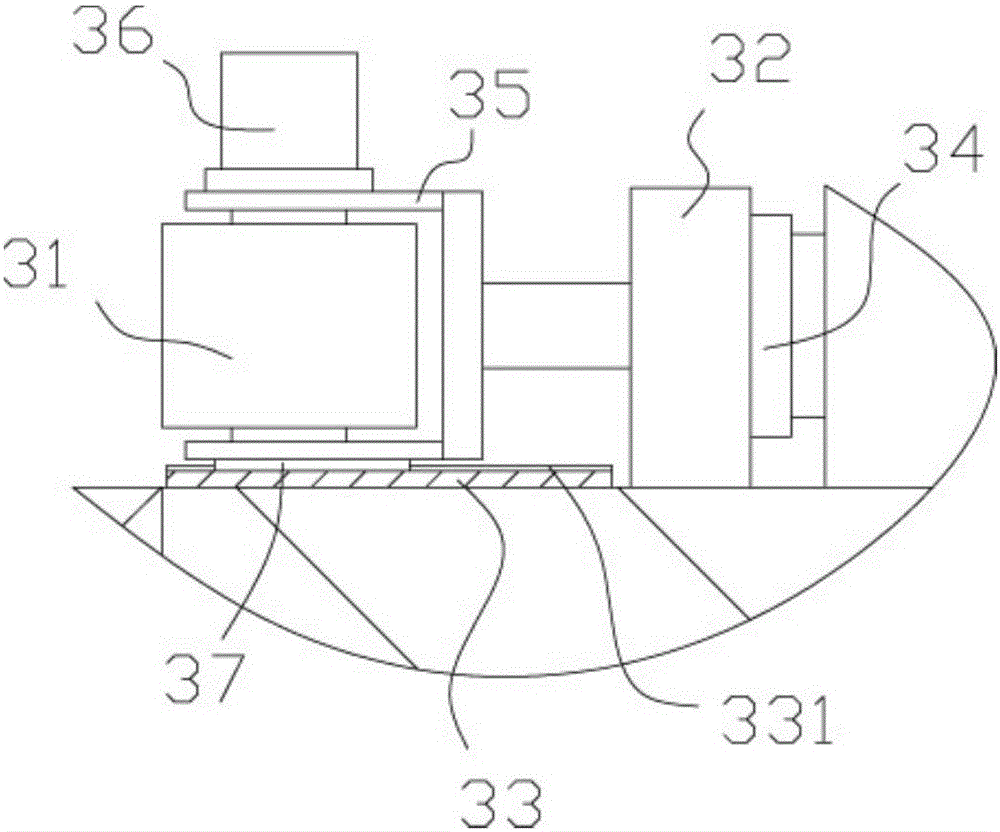

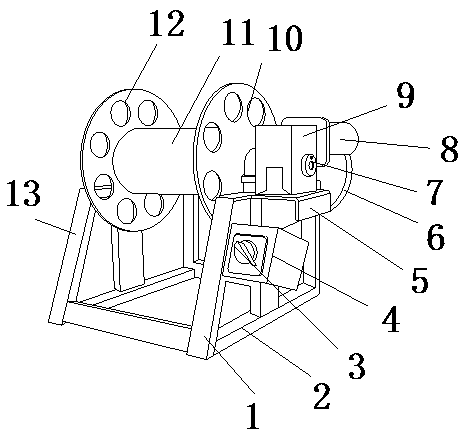

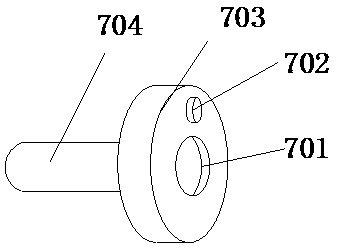

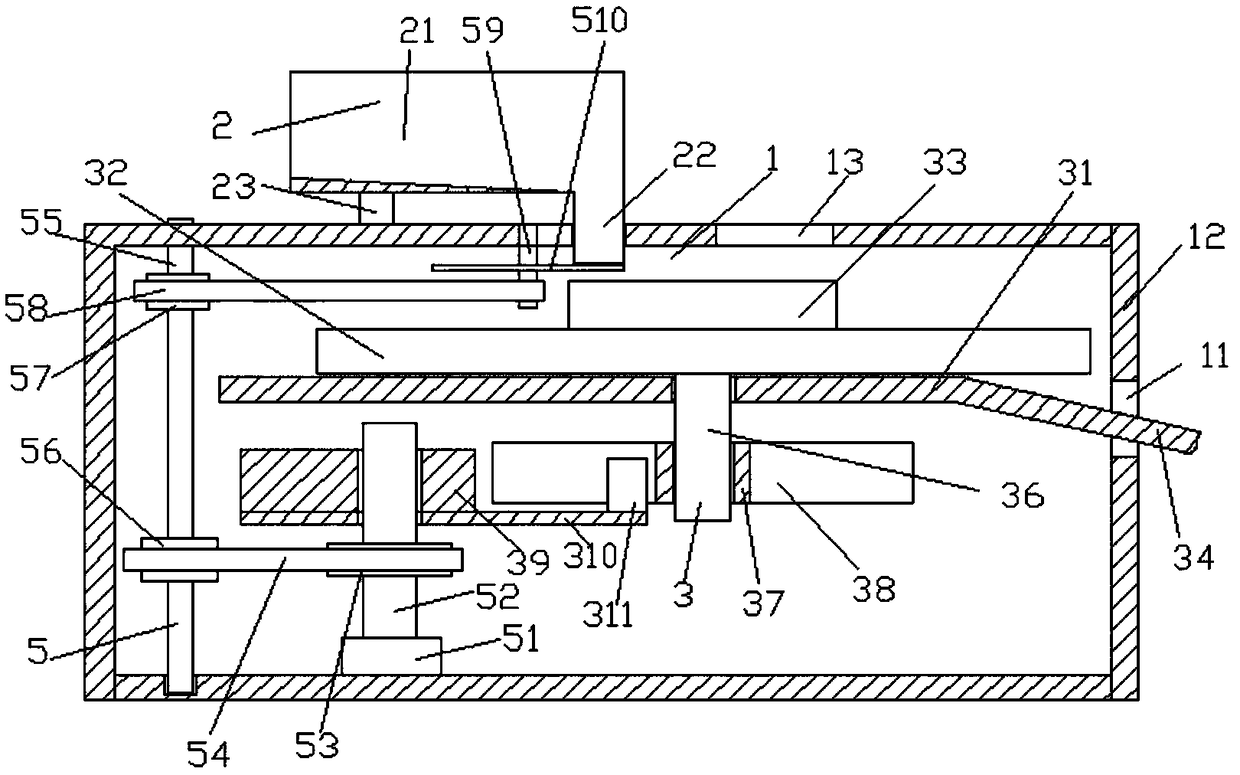

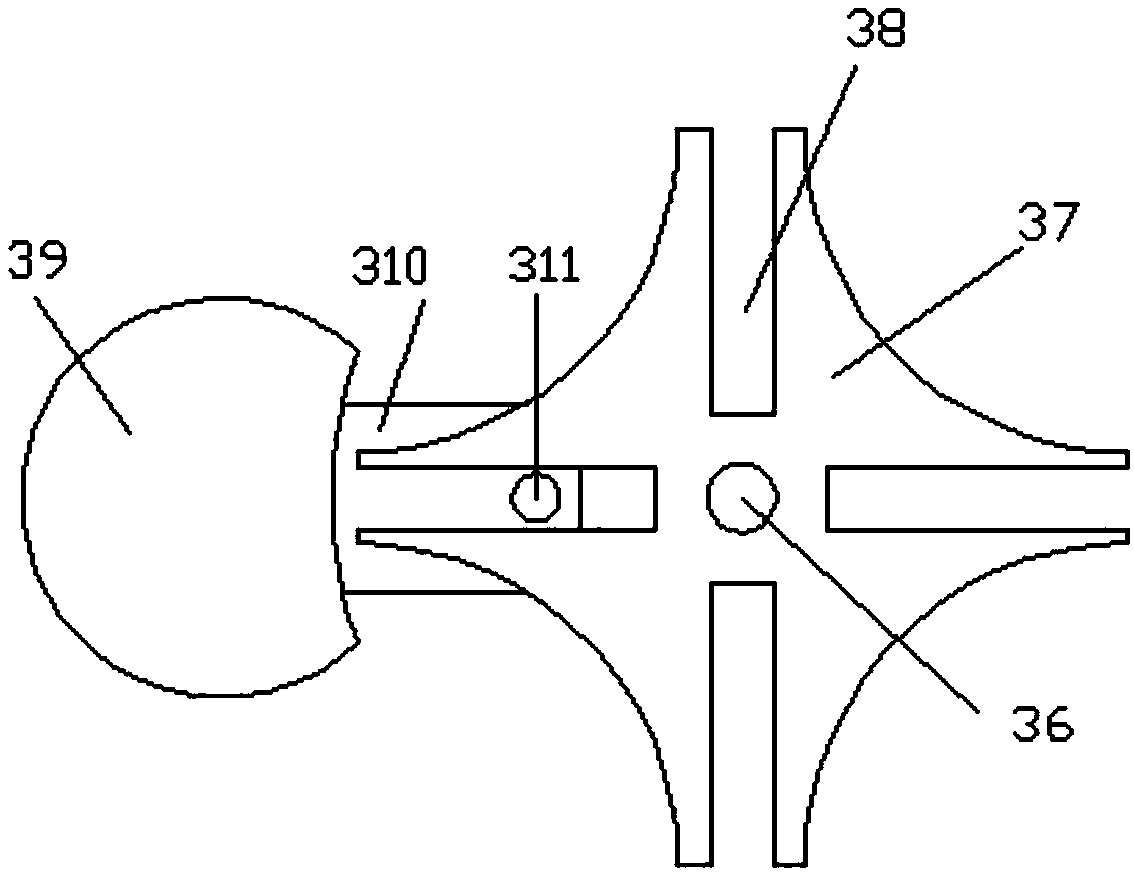

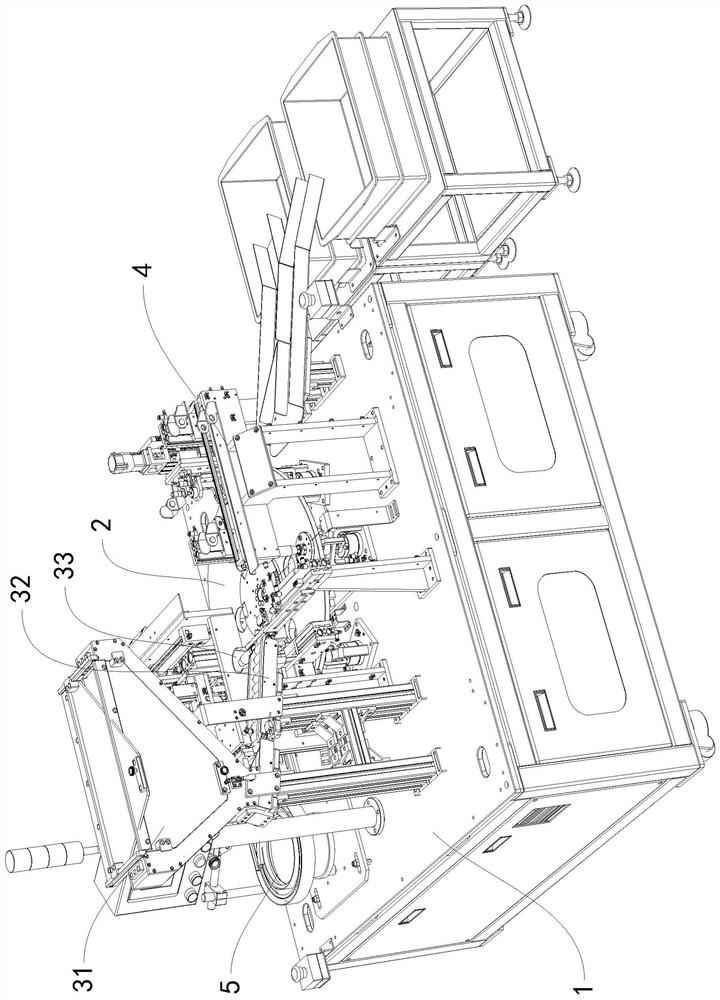

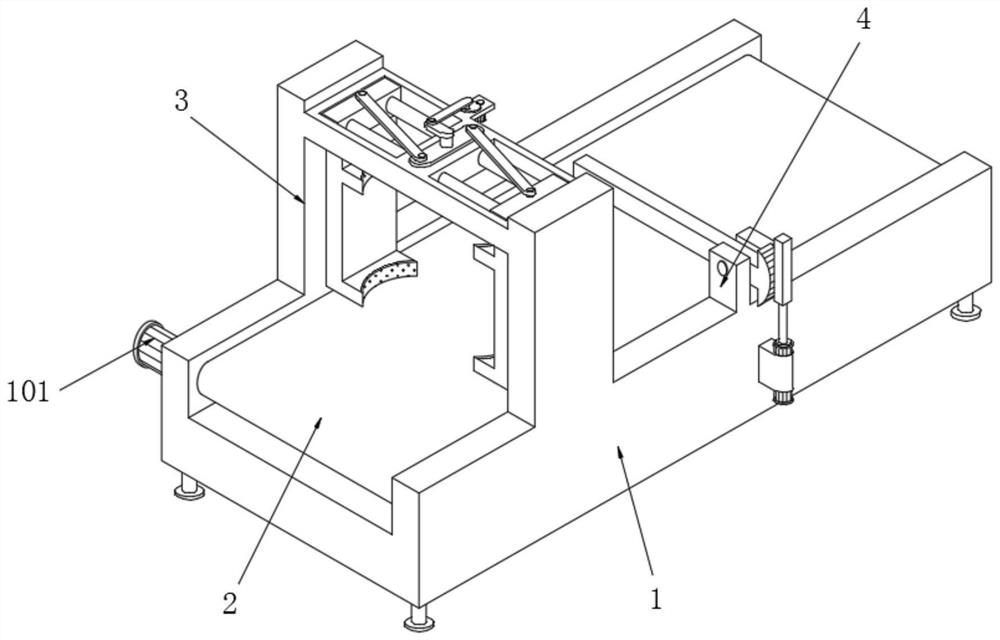

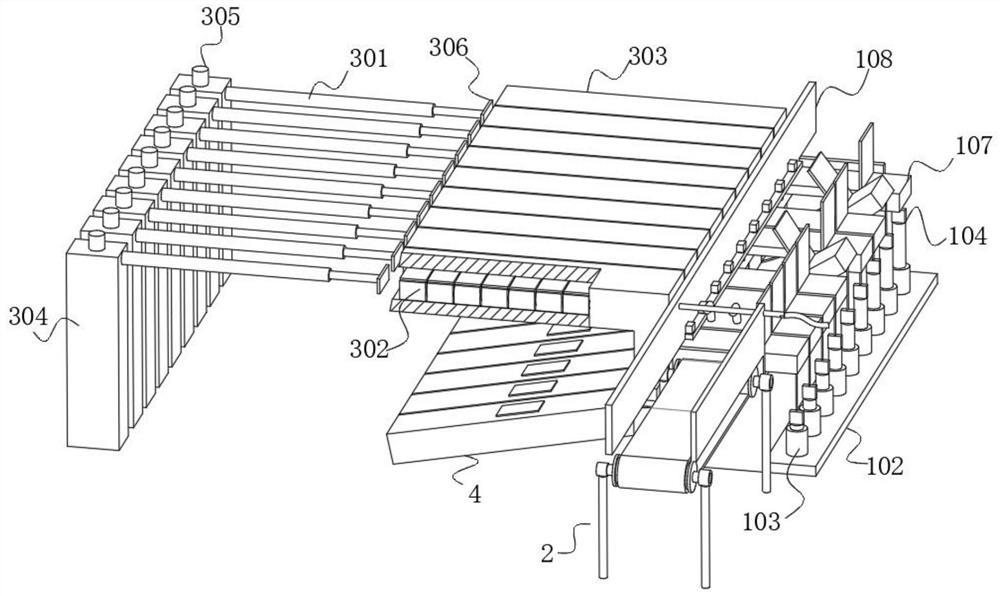

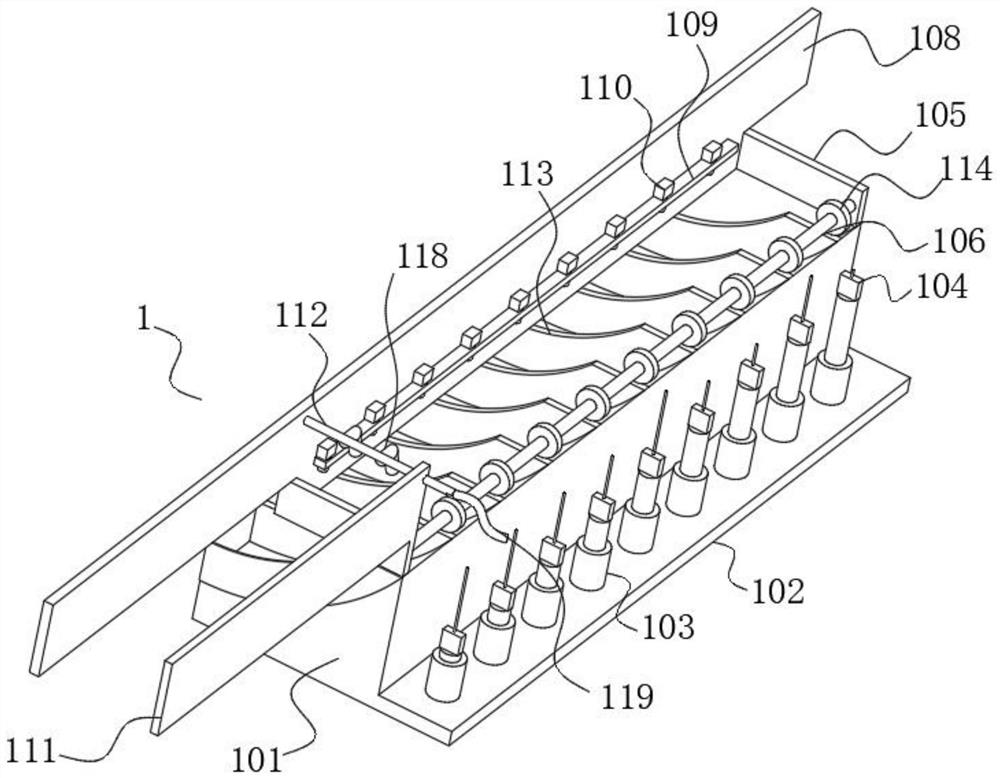

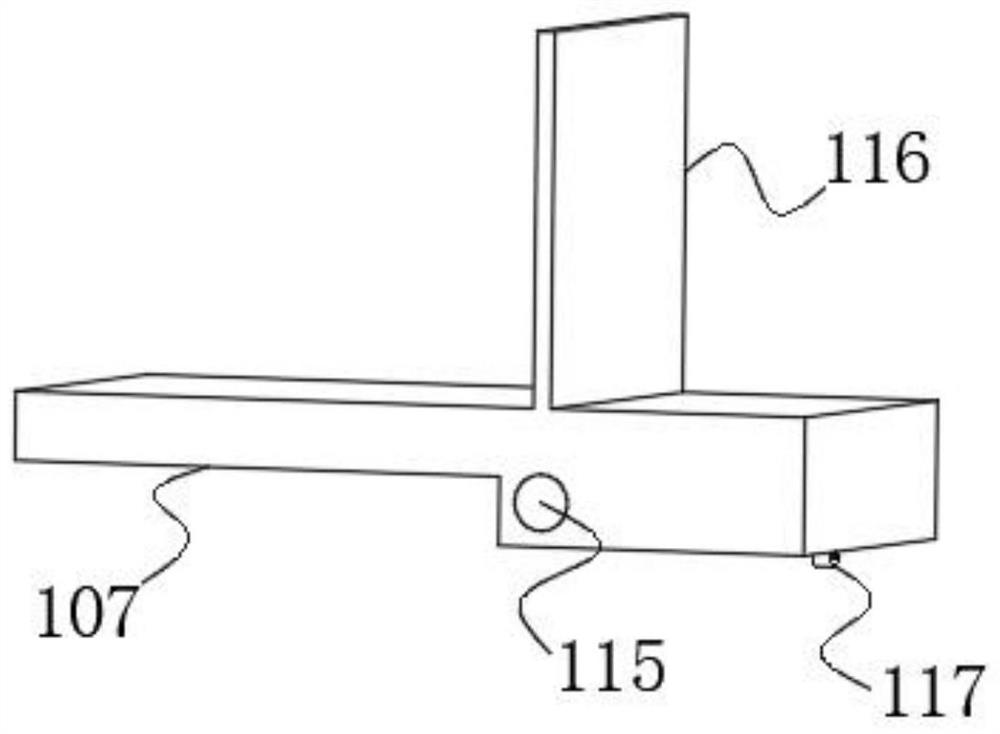

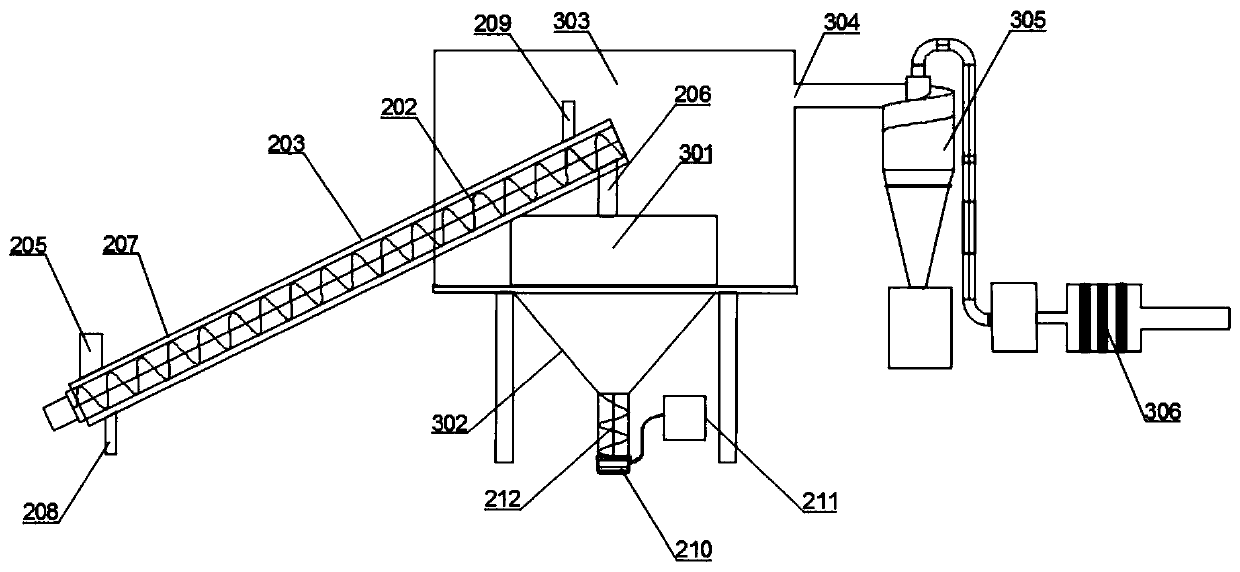

Automatic punching and packaging production line

The invention provides an automatic punching and packaging production line which is characterized by comprising a product feeding mechanism (1), a punching press (2), a quantitative product conveying chain (3) and a packaging drum turnplate mechanism (4) which are sequentially arranged, wherein the head end of the punching press (2) is lined below a lower punching die (23) of the punching press (2), a plurality of material plates (32) are connected between chains (312) of two transmission chain mechanisms (31), and a groove (321) corresponding to a product blanking through hole of the lower punching die (23) on the punching press (2) and being used for placing a product is formed in each of the material plates (32); the packaging drum turnplate mechanism (4) comprises a working turnplate (41), and packaging drum locating slots (411) or holes for placing packaging drums (7) are formed in the working turnplate (41) and correspond to a product storage station (43) and a capping station (44); and the product storage station (43) on the working turnplate (41) corresponds to the tail end of the quantitative product conveying chain (3) and is arranged below the tail end of the quantitative product conveying chain (3).

Owner:SUZHOU TONGJIN PRECISION IND

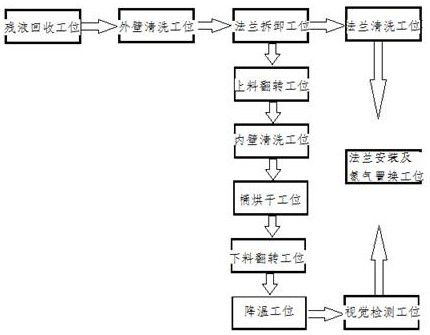

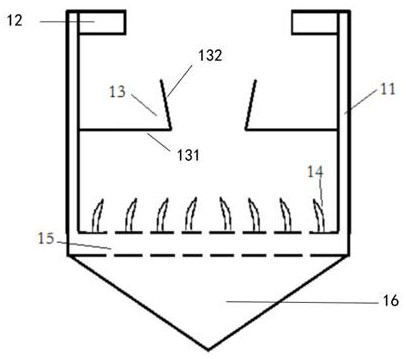

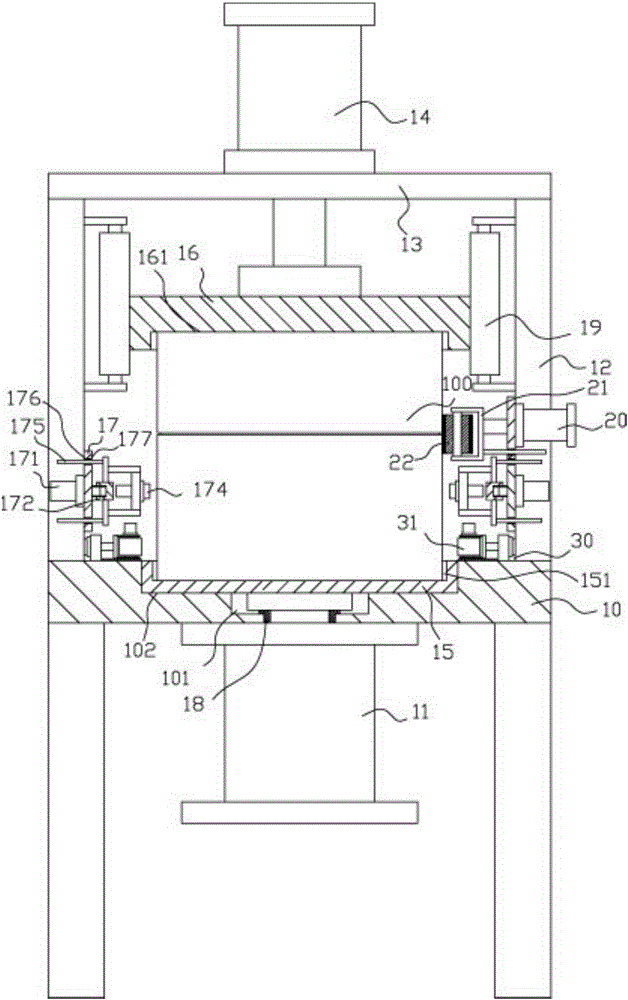

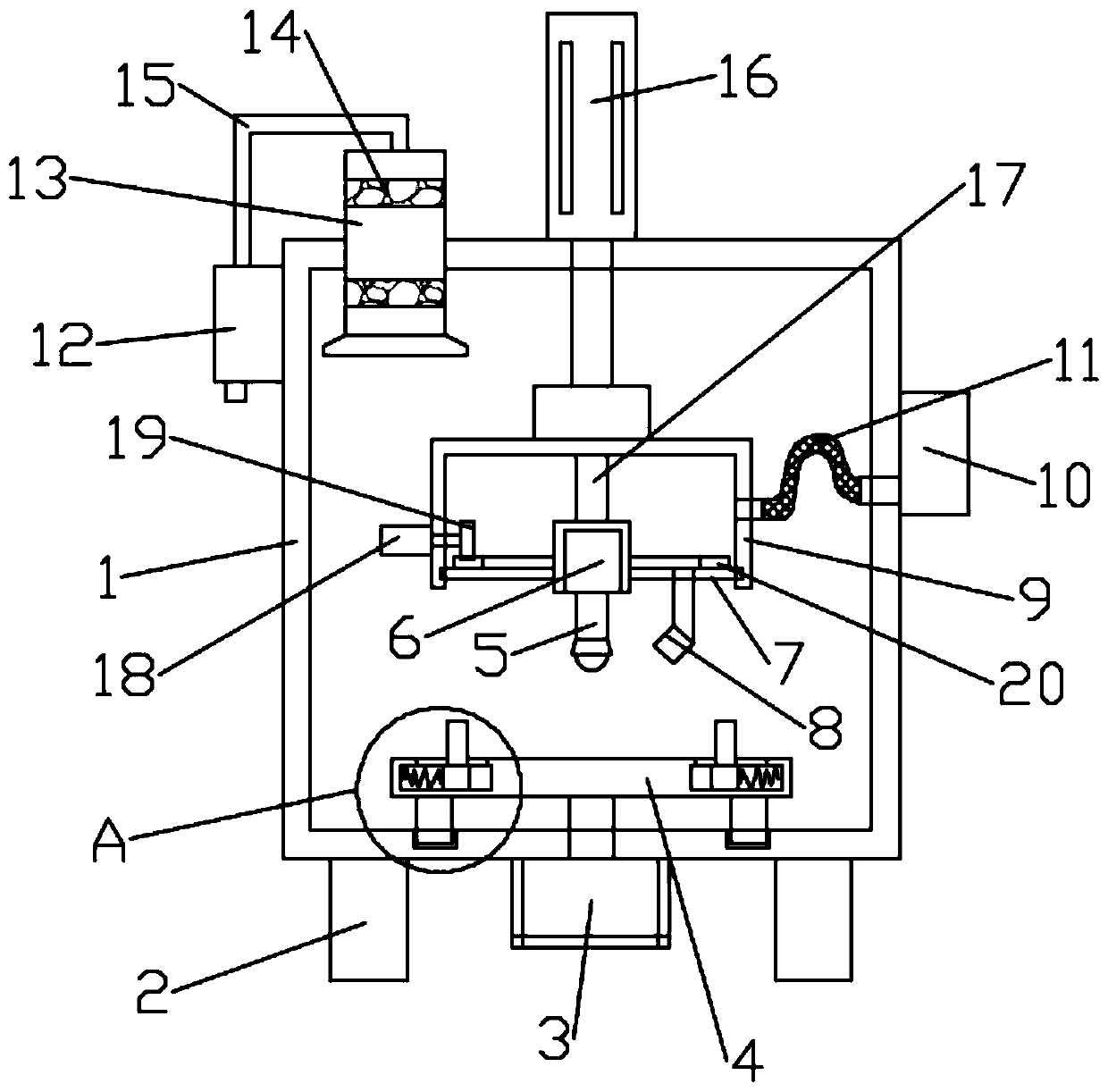

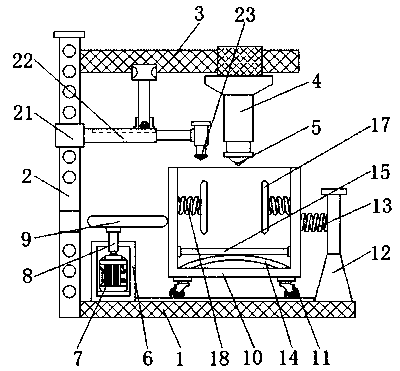

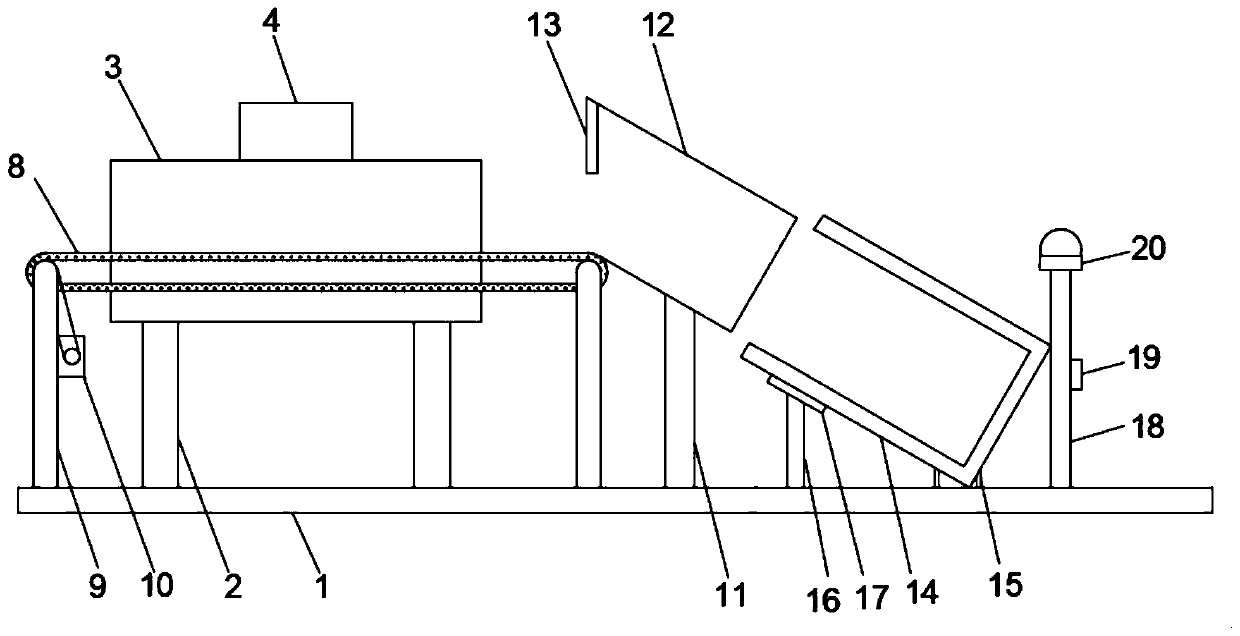

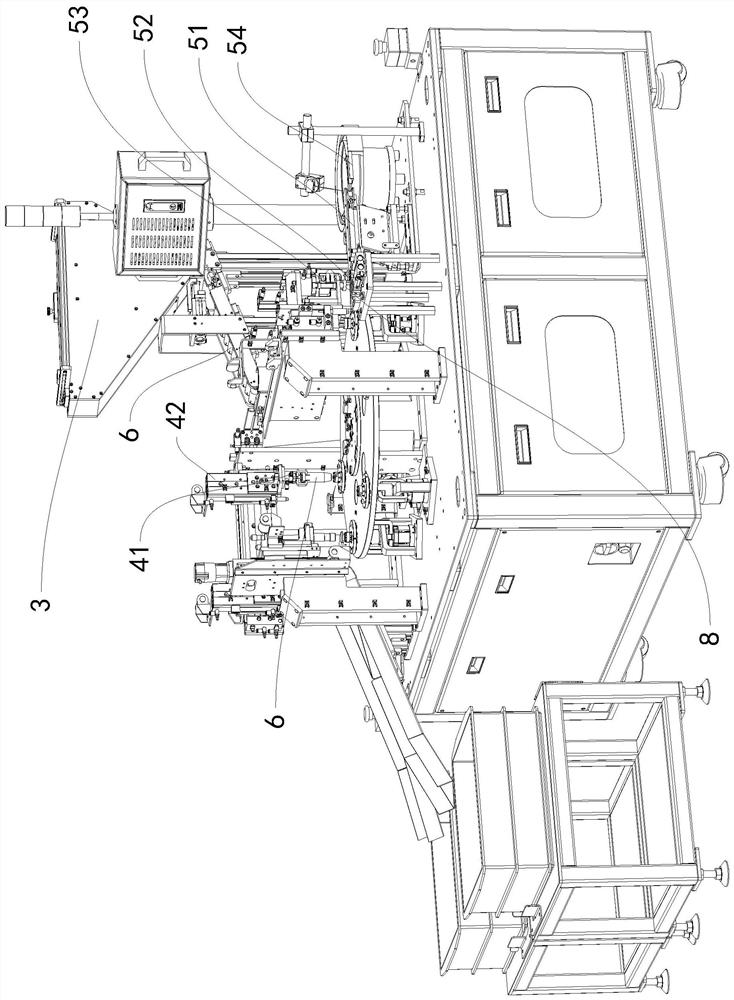

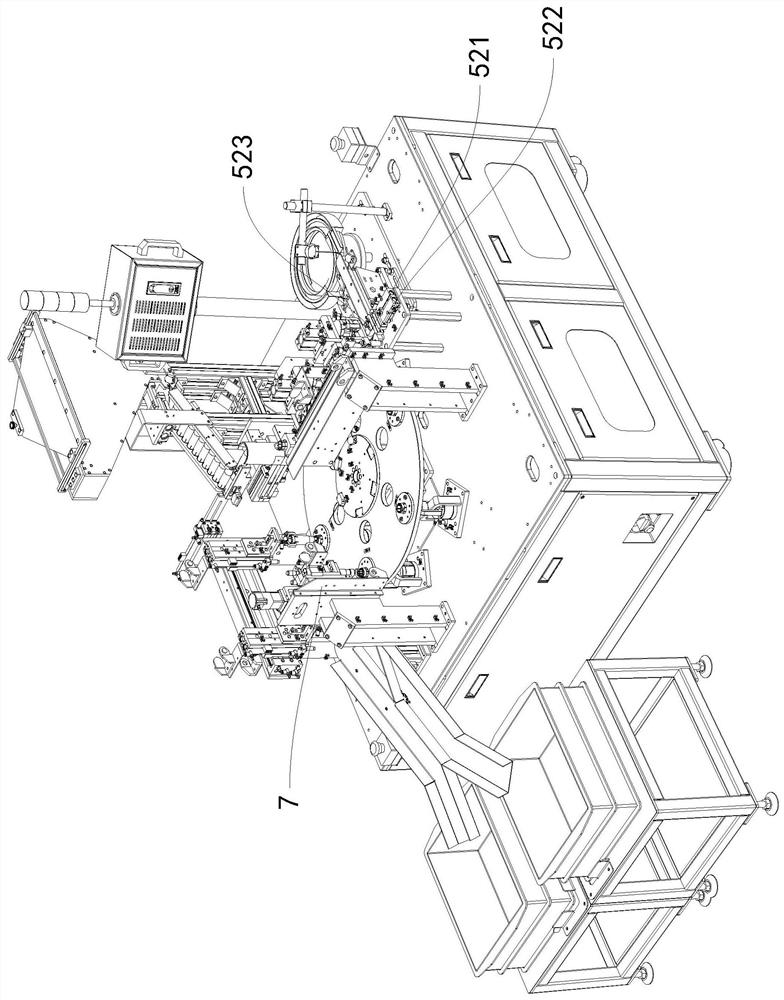

Full-automatic cleaning and detecting production line for lithium battery electrolyte packaging barrel

ActiveCN112371675AHollow article cleaningOptically investigating flaws/contaminationProduction lineVisual inspection

The invention discloses a full-automatic cleaning and detecting production line for a lithium battery electrolyte packaging barrel. The full-automatic cleaning and detecting production line for the lithium battery electrolyte packaging barrel sequentially comprises a residual liquid recovery station, an outer wall cleaning station, a flange dismounting station, a flange cleaning station, a feedingoverturning station, an inner wall cleaning station, a barrel drying station, a discharging overturning station, a cooling station, a visual inspection station and a flange mounting and nitrogen replacement station, wherein the residual liquid recovery station is used for discharging residual liquid out of the packaging barrel when the residual liquid does not exceed a threshold value; the outerwall cleaning station is used for cleaning the outer wall of the packaging barrel; the flange dismounting station is used for dismounting a flange; the feeding overturning station is used for overturning the packaging barrel by 180 degrees; the inner wall cleaning station is used for cleaning the inner wall of the packaging barrel; the discharging overturning station is used for overturning the packaging barrel by 180 degrees; and the visual inspection station is used for obtaining an inner wall image and determining the cleanliness of the inner wall based on the inner wall image.

Owner:宁波格劳博智能工业有限公司

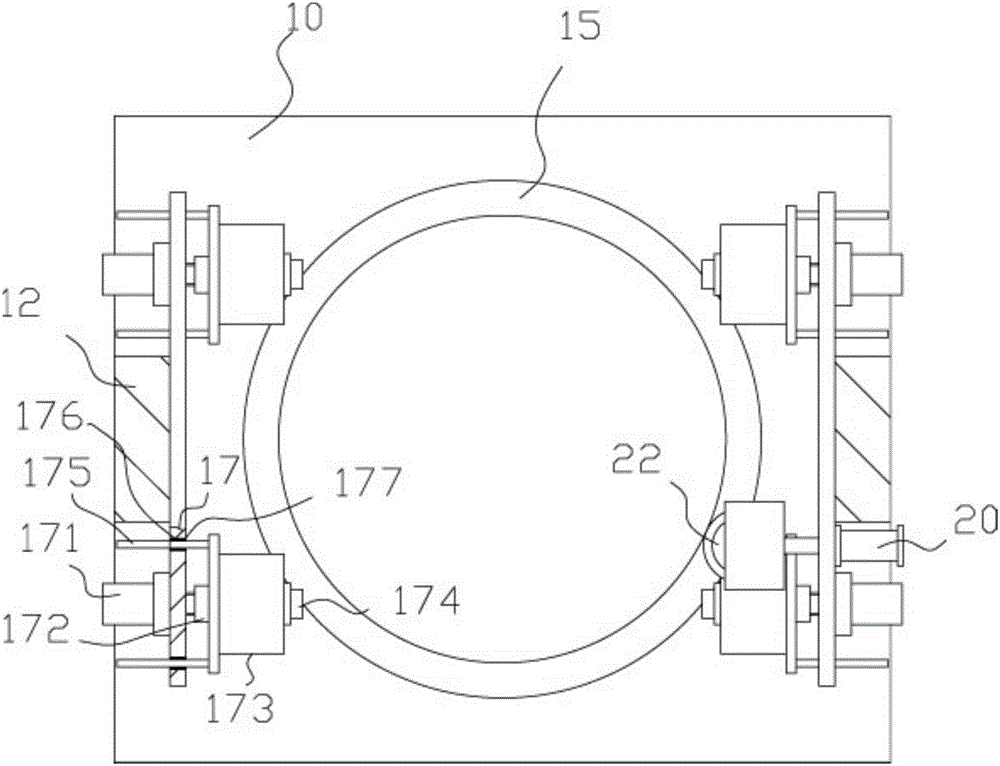

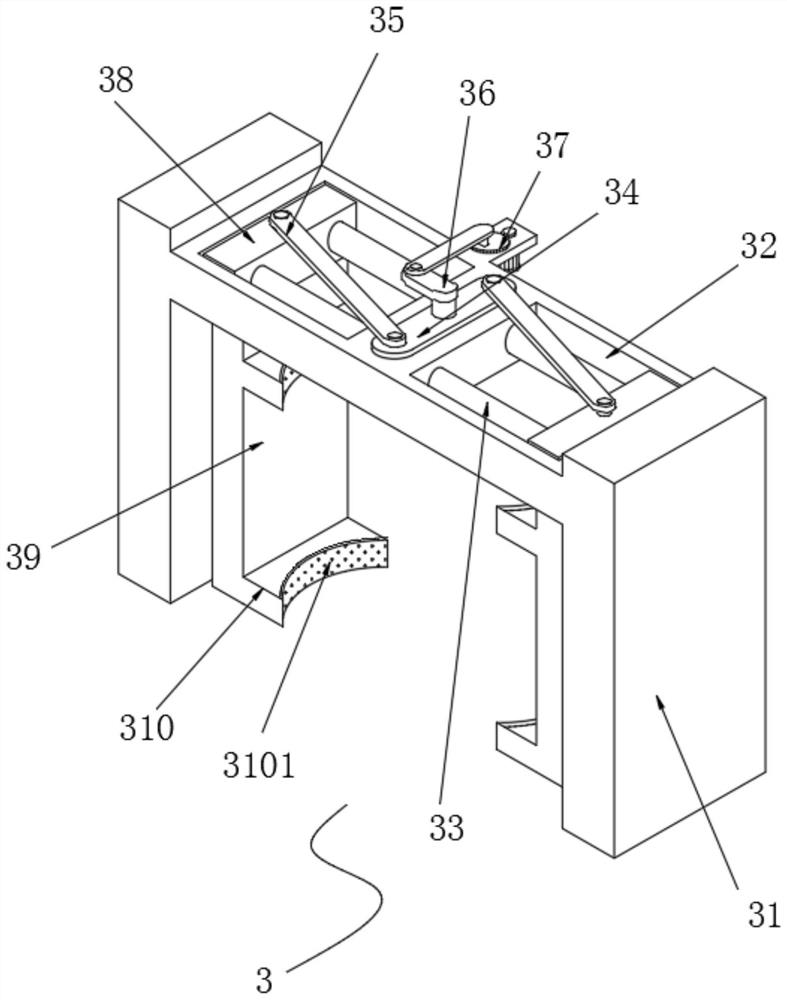

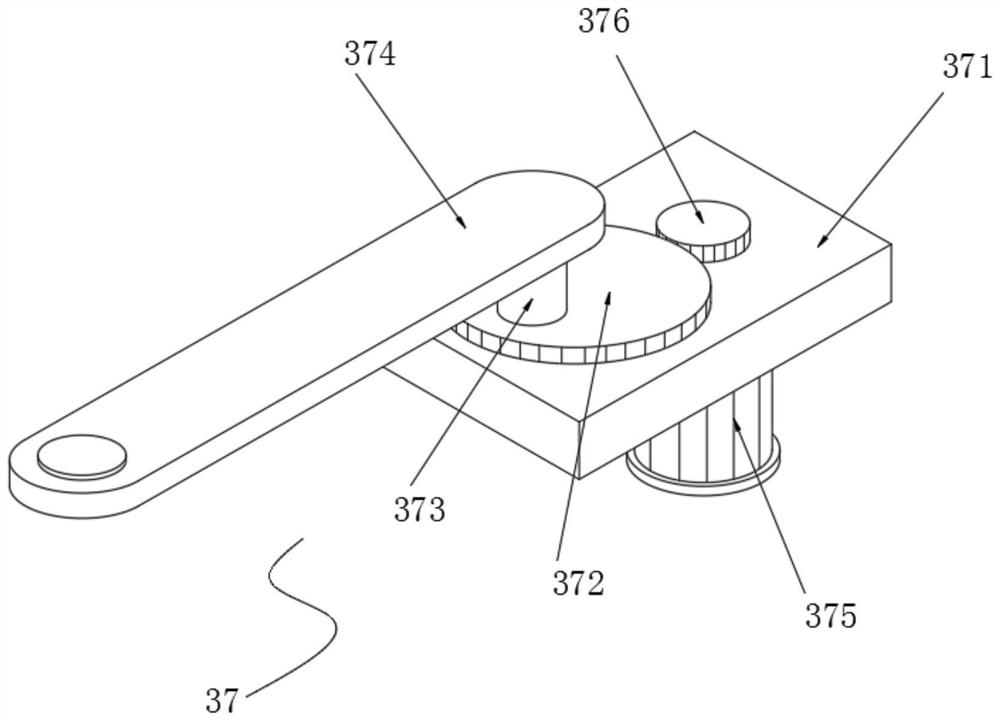

Rotating gluing mechanism for cylinder packaging barrel

The invention discloses a rotating gluing mechanism for a cylinder packaging barrel. The rotating gluing mechanism comprises a clamping frame. A lower clamping cylinder is fixed to the middle portion of the bottom face of a top plate of the clamping frame. Vertical plates are fixed to the edge portion of the top plate of the clamping frame. An upper plate body is fixed to the top ends of the two vertical plates. An upper clamping cylinder is fixed to the middle portion of the top face of the upper plate body. Drive devices are arranged on the left side and the right side of the top plate of the clamping frame. A push rod of the lower clamping cylinder is inserted in and sleeved with a stepped hole formed in the bottom face of the middle portion of the top plate of the clamping frame. A circular groove is formed in the middle portion of the top plate of the clamping frame. The bottom face of the circular groove communicates with the stepped hole. A lower clamping plate is inserted in and sleeved with the circular groove and presses and leans on the bottom face of the circular groove. The end portion of a push rod of the lower clamping cylinder is hinged to the bottom face of the lower clamping plate. A lower clamping groove is formed in the top face of the lower clamping plate. Drive rollers of the drive devices correspond to the outer side wall of the lower clamping plate. The rotating gluing mechanism can fix and clamp the cylinder packaging barrel, automatically rotates, automatically smears glue liquid and saves time and labor.

Owner:江苏彪发化妆品有限公司

Inkjet printing device for surfaces of vegetable oil packaging barrels

ActiveCN110802947ADry fastGuarantee the quality of sprayingDispersed particle filtrationPrintingVegetable oilEngineering

The invention relates to the field of processing of vegetable oil packaging barrels, and particularly discloses an inkjet printing device for the surfaces of vegetable oil packaging barrels. The inkjet printing device comprises a box body, a supporting cover is erected in the box body, and a telescopic air cylinder for adjusting the height of the position of the supporting cover in the box body isinstalled on a top plate of the box body; a rotating disc is rotationally arranged at the opening in the bottom end of the supporting cover in a sealing manner, and an air blowing port for discharging air in the supporting cover is formed in one side of the rotating disc; an inkjet printing gun is fixedly installed on the bottom surface of the middle of the supporting cover through a support, andan inkjet printing head is arranged on the inkjet printing gun; the opening of the air blowing port faces the bottom end of the inkjet printing head; and an air heater for introducing air into the supporting cover is further installed on the box body. According to the inkjet printing device, after inkjet printing is performed through the inkjet printing head, marks formed by inkjet printing can be rapidly dried by air blown by the air blowing port so that the inkjet printing quality of the marks can be guaranteed.

Owner:安徽省含山县华康调味品厂

Novel wire and cable packaging drum

The invention discloses a novel wire and cable packaging drum. The novel wire and cable packaging drum structurally comprises a right supporting arm, a fixed base, a speed adjusting rotary knob, a control cabinet, a motor base, a power supply conducting wire, a rotating encoder, an energy supply motor, a motor protective case, a right fixed disc, a cable drum, a left fixed disc and a left supporting arm, wherein the rotating encoder is provided with an electric connecting hole, an induction lamp, a machine body and an electric detection rod; the electric connecting hole is embedded in the center of the surface of the right side of the machine body; and the induction lamp is horizontally fixed above the electric connecting hole and is electrically connected with a circuit board in the machine body. According to the novel wire and cable packaging drum, the arranged rotating encoder can electronically detect the length of cables and wires wound by the drum, people do not need to measure the length specially, labor intensity of people is reduced, besides, electronically measured data is more accurate, and efficiency is higher.

Owner:安徽星博电气科技有限公司

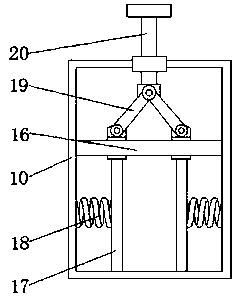

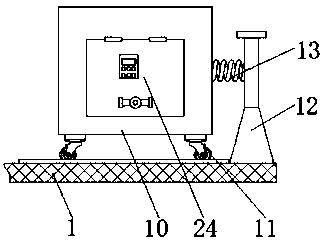

Quantitative packaging device for industrial glue production

The invention discloses a quantitative packaging device for industrial glue production. The quantitative packaging device comprises a horizontal stabilizing plate, wherein the left side of the horizontal stabilizing plate is fixedly connected with a vertical plate, the right side of the vertical plate is fixedly connected with a horizontal top plate, the surface of the horizontal top plate is slidably connected with a filling telescopic rod through a movable sleeve, the left side of the top of the horizontal stabilizing plate is fixedly connected with a rotating motor box, the bottom of the inner wall of the rotating motor box is fixedly connected with a rotating motor through a motor seat, and the top end of the output shaft of the rotating motor is fixedly connected with an active shaftthrough a coupling. The invention relates to the technical field of glue production. The quantitative packaging device for industrial glue production can stably shake the entire external device of a packaging barrel when the industrial glue is quantitatively packed, so that the glue in the packaging barrel is shaken evenly, which effectively prevents the glue in the packaging barrel from being layered during the filling, and improves the overall use effect of industrial glue.

Owner:安徽省明睿合成材料有限公司

Novel energy collecting primer

The invention discloses a novel energy collecting primer. A priming body is arranged at a central axis position close to a priming point of a detonator hole of the primer, is an independent explosive unit, is arranged in a capsule by using penthrite or hexogen and sealed; charge quantity of each priming body is not less than 10g; 3 to 8 cambered closed energy collecting semicircular grooves are uniformly distributed on the outer wall of the primer; and the grooves are closed in the outer wall of a packaging drum. The invention has the advantages that: a low-charge primer has the same priming effect as a high-charge primer, the charge quantity is obviously reduced, and cost is also reduced.

Owner:云南燃二化工有限公司

Food plastic packaging barrel molding and blanking mechanism

PendingCN111056328AGood shape recoveryFully contactedConveyorsControl devices for conveyorsCold airPlastic packaging

The invention discloses a food plastic packaging barrel molding and blanking mechanism. The mechanism comprises a mounting base, a cooling channel is arranged above the mounting base, and an air cooler is arranged on the cooling channel; a conveyor belt device is horizontally arranged in the cooling channel in a penetrating mode, a vertical blocking piece is installed on the upper edge at the upper end of a guide channel, an obliquely-placed collecting box is arranged on one side at the lower end of the guide channel, and a vibration counter and an alarm are installed on a limiting baffle. According to the invention, plastic packaging barrels can be cooled in the cooling channel before cartonning to ensure a good molding recovery state, cold air in the refrigeration channel forms a circulating state and is in full contact with the surfaces of the plastic packaging barrels, so that the cooling efficiency is greatly improved; the plastic packaging barrels are laid down through the blocking piece, and sequentially falls into the obliquely-arranged collecting box along the guide channel and are stacked in sequence, full box monitoring is conducted through the vibration counter and thealarm, the operation is easy, the falling and cartonning efficiency is high, manpower is saved, and the working efficiency is improved.

Owner:界首市佳宝包装材料有限公司

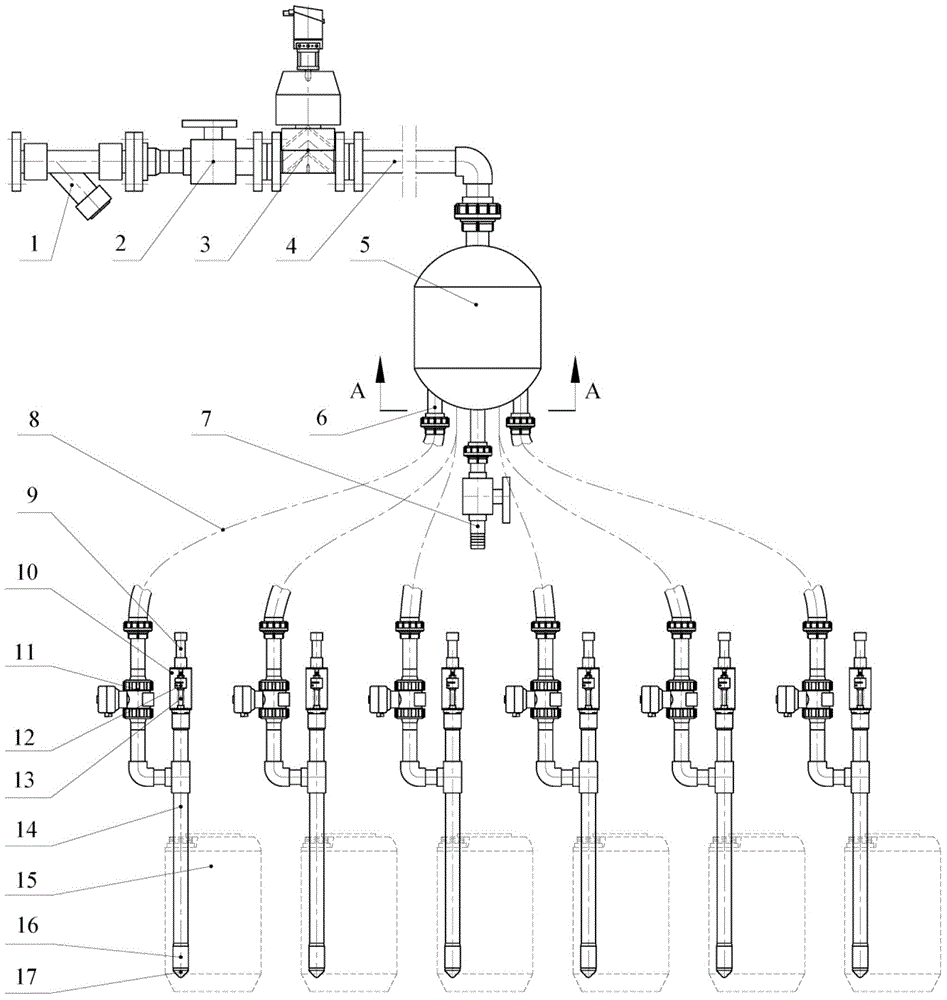

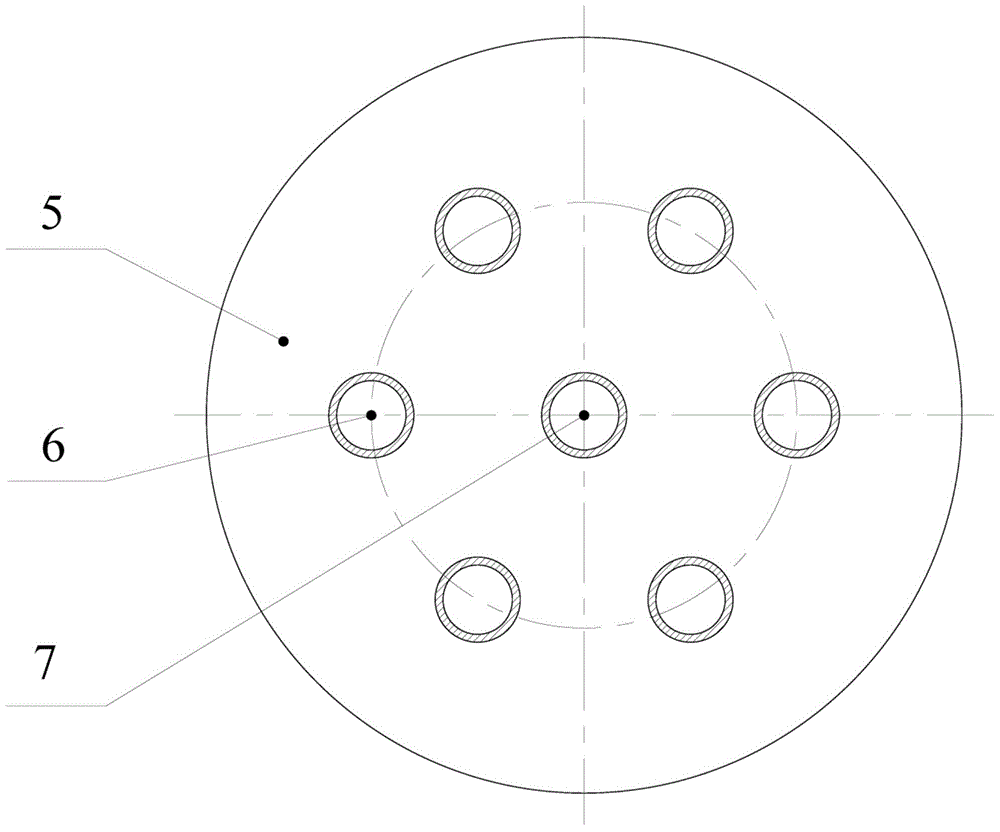

Corrosive solution filling system

InactiveCN104973552ACorrosion resistanceSimple structureBarrels/casks fillingStrong acidsEngineering

The invention relates to a corrosive solution filling system which comprises a liquid inlet pipeline, a liquid distribution tank, a liquid distribution pipeline, a cleaning liquid discharge pipe and a filling valve; one end of the liquid inlet pipeline is communicated with the upper end of the liquid distribution tank; a filter, a manual valve and an electric diagram are sequentially arranged from the upstream end of the liquid inlet pipeline to the connecting end of the liquid distribution tank; the upper end of the cleaning liquid discharge pipe is communicated with the lowest point at the bottom of the liquid distribution tank, and a valve is arranged at the lower end of the cleaning liquid discharge pipe; and the upper end of the liquid distribution pipeline is communicated with the bottom of the liquid distribution tank, and the lower end of the liquid distribution pipeline is connected with a filling device. According to the invention, all parts of components, in contact with material, are made from homopolymerized polypropylene or polytetrafluoroethylene, and the texture can resist corrosion of liquids with strong acid with pH value approaching 0 and strong base with pH value approaching 14. The corrosive solution filling system has the advantages of being simple in structure, convenient to operate, low in cost and the like, and is applicable to automatic filling machines under the liquid level of small and medium packaging barrels in the field of chemical engineering.

Owner:BEIJING AREOSTANARD NEW TECH +2

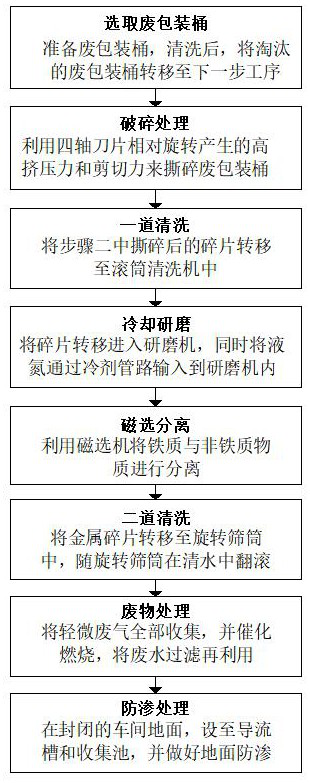

Two-stage crushing and cleaning process for waste packaging materials

InactiveCN112439767AEasy to recycleReduce pollutionSolid waste disposalDirt cleaningParticulatesWaste treatment

The invention discloses a two-stage crushing and cleaning process for waste packaging materials. The two-stage crushing and cleaning process comprises the following steps of waste packaging barrel selection, crushing treatment, primary cleaning, cooling and grinding, magnetic separation, secondary cleaning, waste treatment and anti-seepage treatment. According to the two-stage crushing and cleaning process, a shredder is used for crushing treatment and primary crushing is carried out, so that some impurities such as particulate matters and dust on the surface are removed; then liquid nitrogenis used for cooling and is matched with a grinding machine for cold treatment, so that the embrittlement of adhesive materials and the separation of fragments are realized, the treatment is more perfect, the recycling of subsequent fragments is facilitated, and the utilization rate is improved; and in the treatment process, a gas collecting hood is used for being matched with a suction pump to collect waste gas completely, then ROC is used for catalytic combustion, a vacuum pump is used for directly sucking waste water into a waste water collecting pool, flocculation precipitation and steam flotation separation are carried out after cotton pressing and filtering, and recycling is carried out after ceramic filtering, so that air pollution is reduced, and water resources are saved.

Owner:湖州金洁静脉科技有限公司

Mixed paint assembly equipment for construction

The invention discloses a mixed paint assembly equipment for construction, comprising a main body. The main body comprises an outer casing, the right side of the outer casing is provided with a discharge port, the top of the outer casing is provided with an accommodating port, the upper end of the main body is provided with a feeding box, the feeding box is connected with the outer casing in a matched mode, the middle part of the outer casing is provided with a charging component and a power component, the power component is connected with the charging component in a matched mode, and the charging component is connected with the outer casing in a matched mode; the feeding box comprises a box body, the bottom end of the box body is provided with a feeding tube and a supporting column, the feeding tube extends into the outer casing and is slidably connected with the outer casing, the feeding tube is connected with the charging assembly in a matched mode, and the supporting column is disposed between the outer casing and the box body. The problem in the existing equipment that there is an error in the amount of paint in each drum during the loading process, and after the paint is loaded, the open packaging drum needs to be manually transported to the packing place and packaged, and the paint is exposed to the air and may cause solidification of the surface of the paint during transportation is solved.

Owner:芜湖露盾新材料科技有限公司

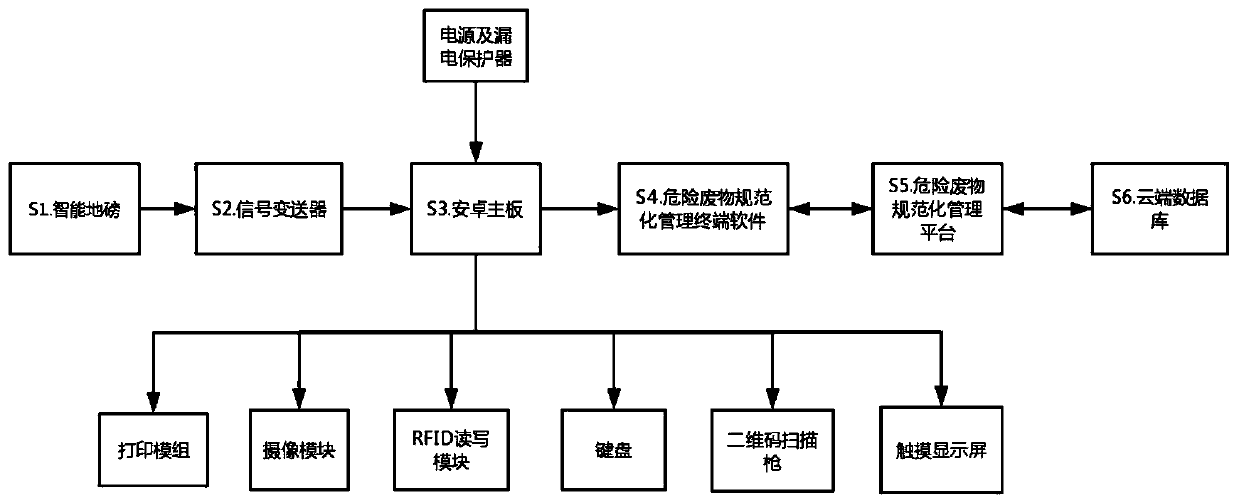

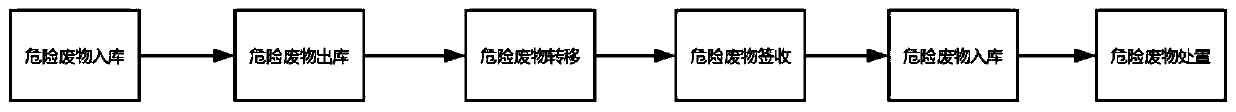

Hazardous waste full-life-cycle intelligent management terminal system

PendingCN111260222AThe whole process is safe and controllableFull cycle safety and controllableResourcesUSBTerminal system

The invention discloses a hazardous waste full-life-cycle intelligent management terminal system which comprises the following steps: S1, firstly, an intelligent wagon balance is responsible for weighing a packaging bag or a packaging barrel filled with hazardous waste and transmitting the packaging bag or the packaging barrel to a signal transmitter; S2, the signal transmitter receives a signal sent by the intelligent wagon balance, and the signal is read by the Android mainboard through a serial interface according to a Modbus protocol; S3, the Android mainboard is connected with the printing module through a serial interface and connected with an RFID read-write module, a keyboard, a two-dimensional code scanning gun and a camera module through USB ports; S4, the hazardous waste processed by the Android mainboard is transmitted to hazardous waste standardized management terminal software; S5, a hazardous waste standardized management platform realizes intelligent supervision of hazardous waste standardized management terminal equipment; S6, a cloud database is responsible for storing authentication data of the hazardous waste standardized management terminal. The beneficial effects of the invention are that the system can record the information of all links from the generation, storage, transportation to the treatment of the hazardous wastes in the whole life cycle.

Owner:神彩科技股份有限公司 +1

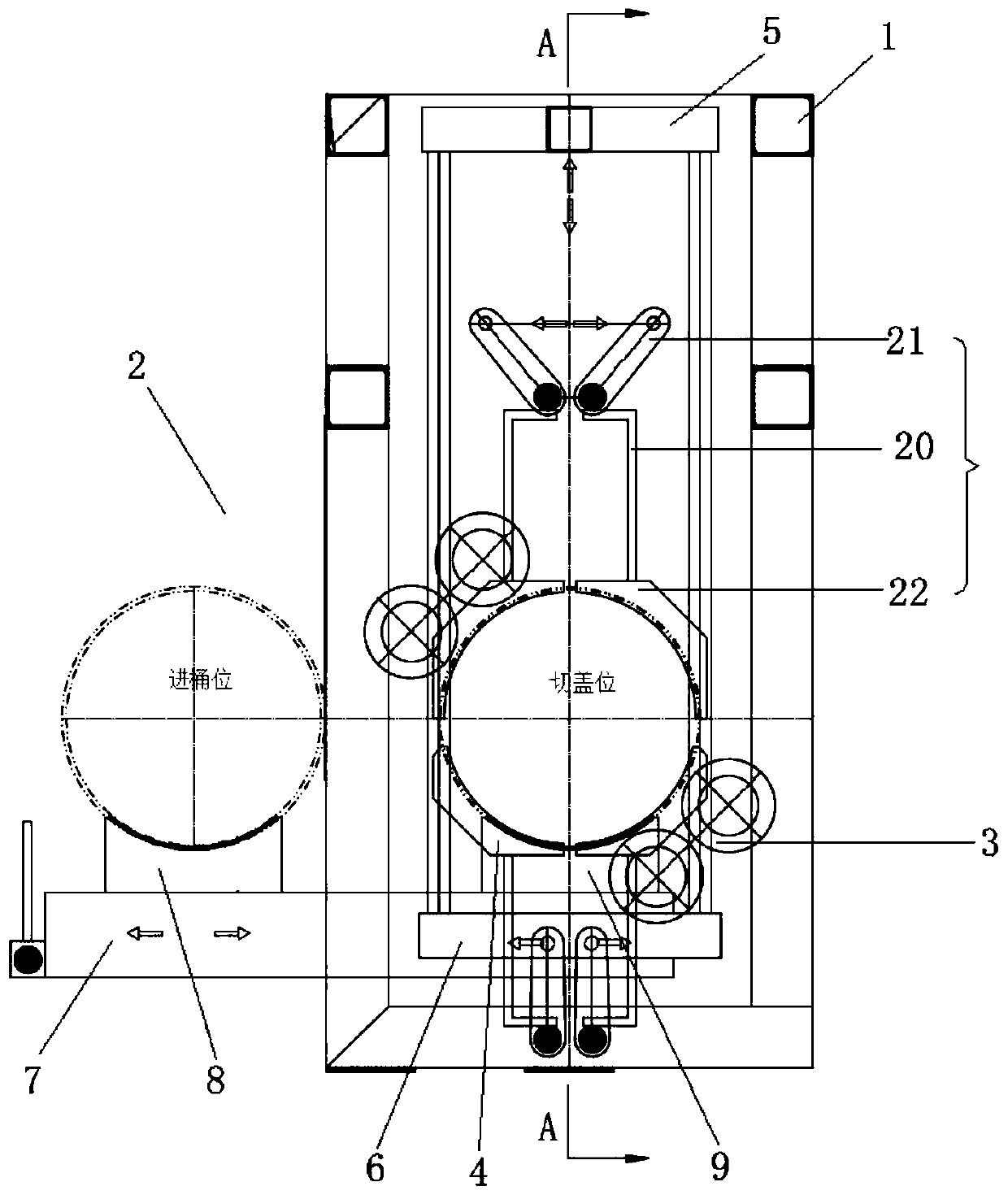

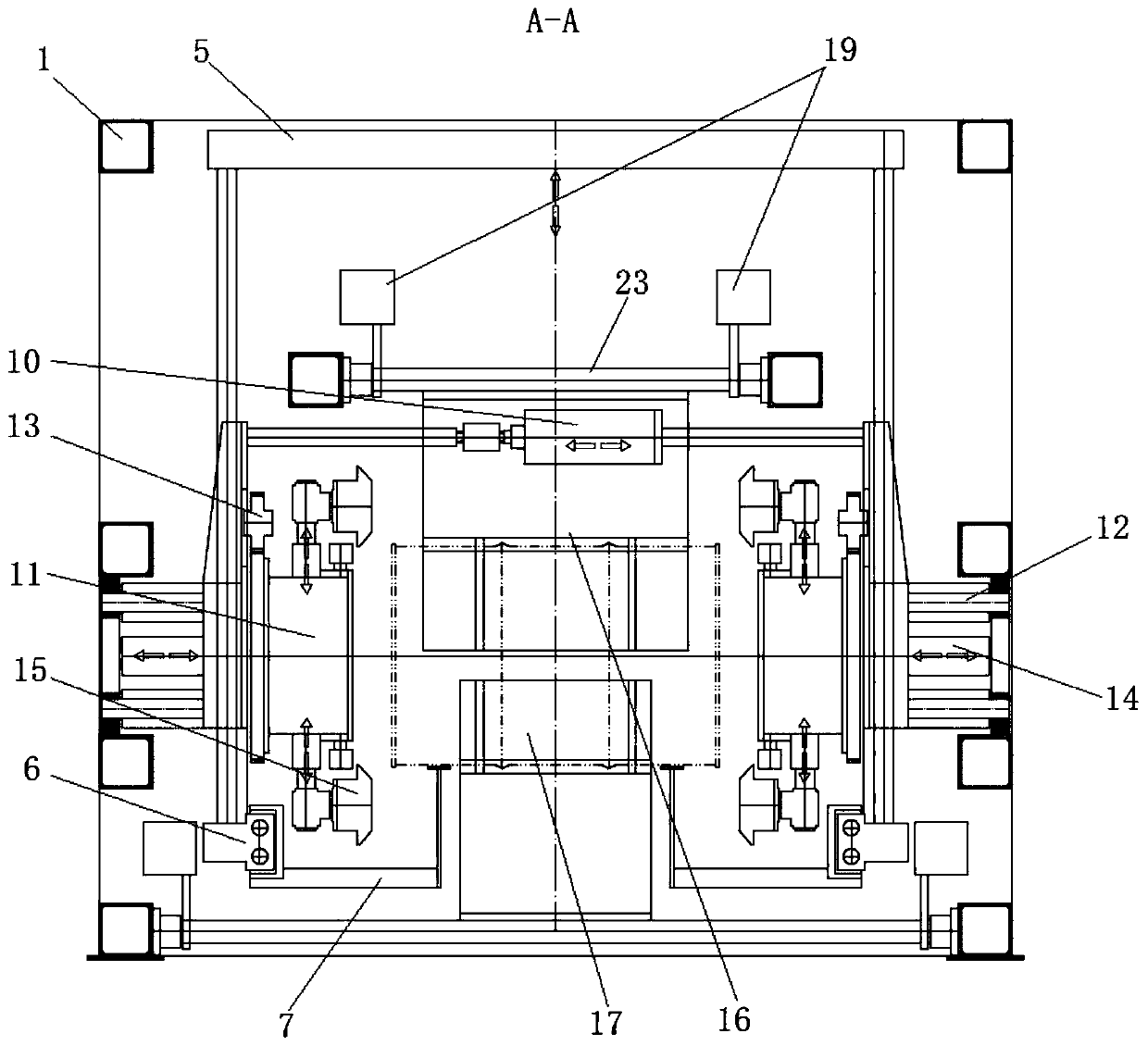

Full-automatic packaging barrel cover-cutting machine

PendingCN111376326AIntegrity guaranteedEnsure orderSolid waste disposalMetal working apparatusStructural engineeringIndustrial engineering

The invention discloses a full-automatic packaging barrel cover-cutting machine. The full-automatic packaging barrel cover-cutting machine comprises an integral frame, a barrel feeding and conveying mechanism, a cover cutting assembly and a barrel holding mechanism. The barrel feeding and conveying mechanism, the cover cutting assembly and the barrel holding mechanism are all installed on the integral frame, and the barrel feeding and conveying mechanism is used for conveying a packaging barrel to be cut to the cover cutting mechanism. The full-automatic packaging barrel cover-cutting machineis a device for cutting off a barrel cover of the barrel bottom of a waste packaging barrel, the barrel bottom and the barrel cover are automatically cut off by two sets of cutting tools on a barrel cover cutting mechanism, and the integrity of the barrel skin is ensured conveniently; the barrel and a barrel plate do not fall in the whole process of cutting, the order and hygiene of the productionsite and the operating environment of the workers can be ensured, and the full-automatic packaging barrel cover-cutting machine is conducive to the simultaneous operation of exhaust gas collection, noise control and collection of residual hazardous waste liquid in the barrel; and in addition, an integral box-type closed structure and a low-speed shear structure are adopted, and the full-automaticpackaging barrel cover-cutting machine is environmentally friendly, safe and reliable and has no noise and no secondary pollution. Full-automatic control is achieved on the premise of ensuring the safety of production equipment and the operating workers, and practicability of equipment operation is improved.

Owner:谭德庆

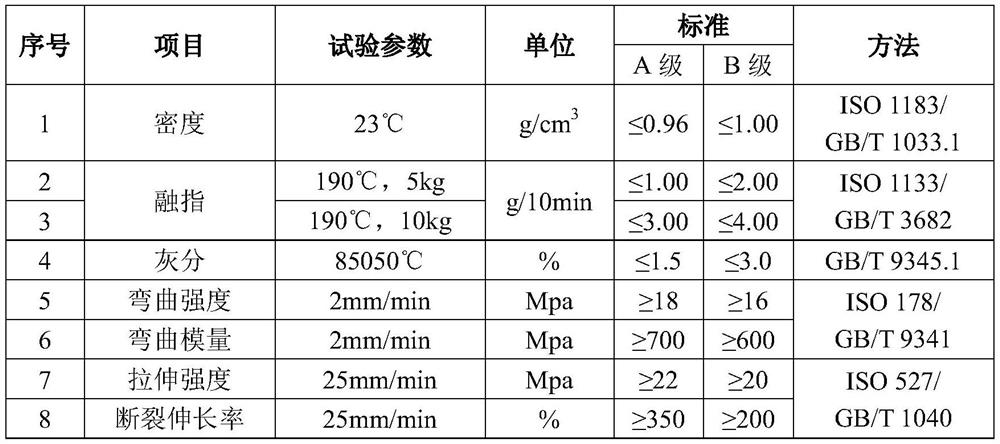

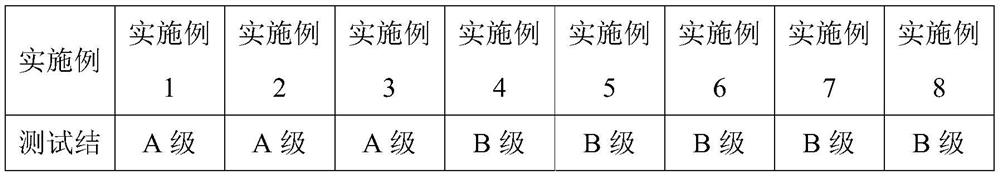

Modified regenerated polyethylene corrugated pipe material and preparation method thereof

The invention relates to the field of waste plastic regeneration technologies and pipe preparation methods, in particular to a modified regenerated polyethylene corrugated pipe material and a preparation method thereof. The modified regenerated polyethylene corrugated pipe material is at least prepared from the following preparation raw materials: 60 to 90 parts of a regenerated polyethylene material, 5 to 20 parts of a filler, 1 to 5 parts of a heat stabilizer, 1 to 5 parts of a flame retardant and 1 to 3 parts of other auxiliary agents. The corrugated pipe material prepared from a recycled polyethylene material of a plastic packaging barrel overcomes the problem of resource waste of the plastic packaging barrel, realizes resource utilization and decreases environmental pollution; and therecycled polyethylene material is used as a base material, and is compounded with a certain amount of the filler, the flame retardant, the heat stabilizer and other auxiliary agents to prepare the corrugated pipe material with excellent flame retardancy and mechanical properties, so the production cost of the corrugated pipe is greatly lowered.

Owner:上海睿聚环保科技有限公司

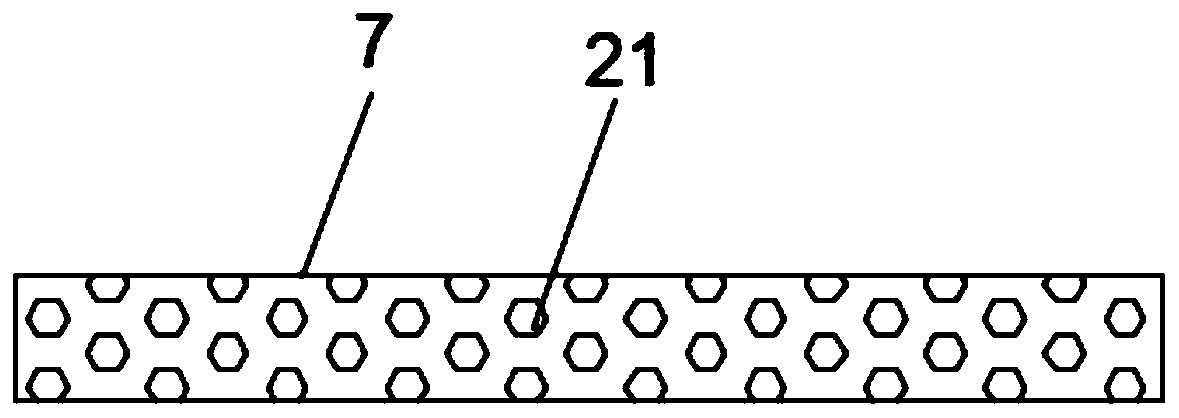

Translation downward-sliding barrel discharging device of particle barrel washing machine

PendingCN114056913ASimple structureLow failure rateConveyorsHollow article cleaningEngineeringMechanical engineering

The invention relates to translation downward-sliding barrel discharging device of a particle barrel washing machine; the device is formed by combining a barrel raking device (4), a translation conveyor (5), a barrel pushing device (6) and a downward sliding way (7), a cleaned packaging barrel (3) is raked into the translation conveyor (5) by the barrel raking device (4), the translation conveyor (5) translates the packaging barrel (3) to the upper end of the downward sliding way (7), the packaging barrel (3) is pushed into the downward sliding way (7) by the barrel pushing device (6), and the packaging barrel (3) falls onto a conveying belt (8) along the downward sliding way to be carried away; the mode of sliding out the barrel in a translation mode is relatively simple in structure, low in failure rate and easy to manufacture and maintain, the reliability is improved, and the production requirement is met.

Owner:徐捷

Automatic electrolyte filling machine and control system

PendingCN113148930AAchieve filling efficiencyAchieve sealingCapsBarrels/casks fillingControl systemEngineering

The invention provides an automatic electrolyte filling machine and a control system. The automatic electrolyte filling machine comprises a workbench, a rotating disc, a barrel feeding device, a filling structure and a sealing device. The workbench is provided with a feeding station, a filling station and a sealing station; the rotating disc can rotate relative to the workbench; the feeding station, the filling station and the sealing station are sequentially arranged in the circumferential direction of the rotating disc; the rotating disc is provided with a plurality of first through holes used for containing packaging barrels; the barrel feeding device is located at the feeding station, and the barrel feeding device is used for putting the packaging barrels into the first through holes; the filling structure is located at the filling station, and the packaging barrels are filled with electrolyte through the filling structure; and the sealing device is located at the sealing station and used for sealing openings of the packaging barrels. The automatic electrolyte filling machine has the advantages of being high in automation degree and filling efficiency and capable of replacing manual labor.

Owner:珠海光瑞新材料有限公司

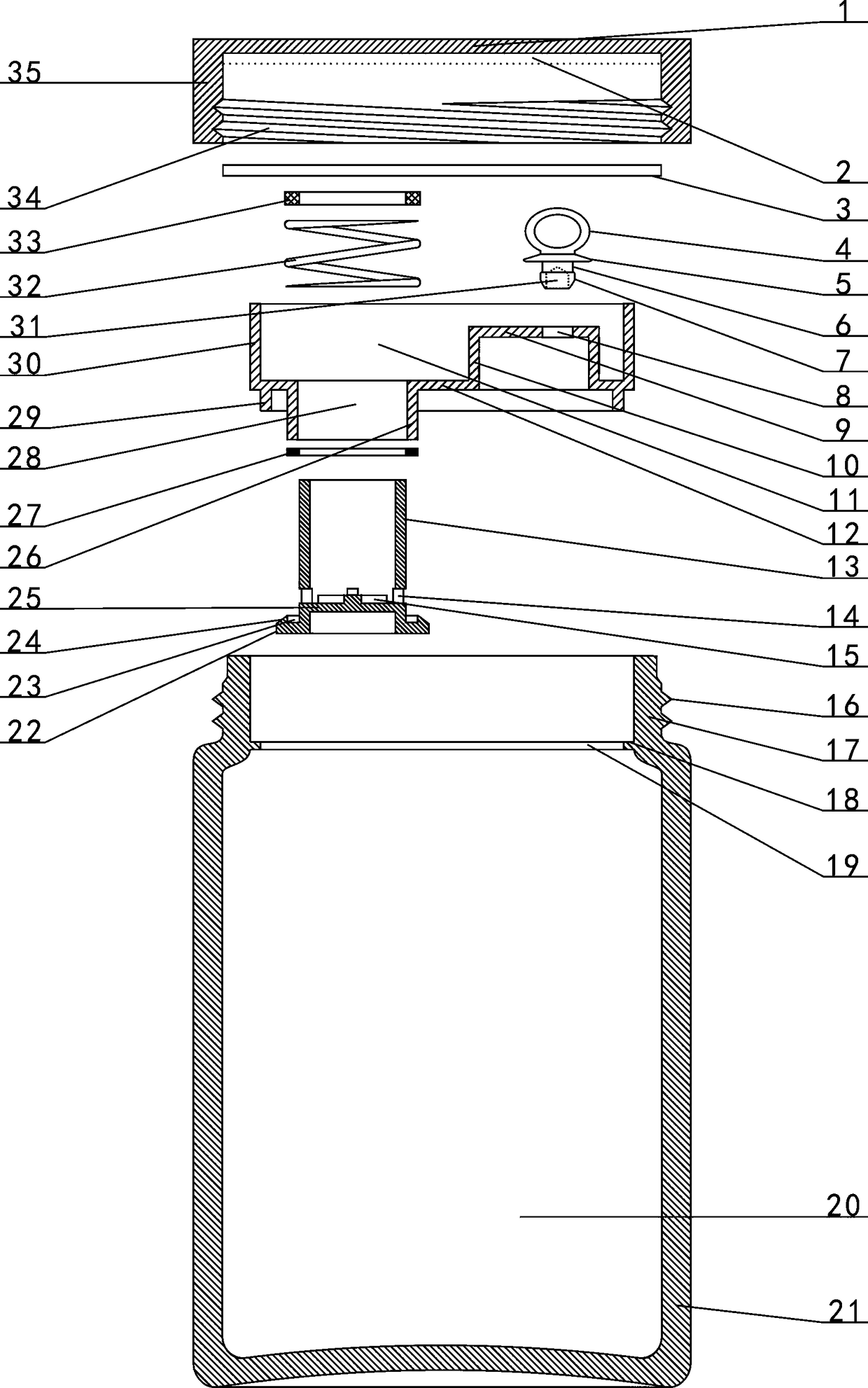

Chemical liquid raw material small packing barrel

PendingCN108996018ALess exposure to air qualityStorage convenience and quality assuranceClosure with auxillary devicesSealingEngineeringBottle

The invention discloses a chemical liquid raw material small packing barrel, and relates to a small packing barrel. An upper cover (35) is arranged on a bottle opening (17); an inner projection ring (19) is arranged at the lower part of the inner wall of the bottle opening; the lower part of a base plate (12) of the inner cover is pressed at the upper part of the inner projection ring; a lower projection pipe (26) is arranged on the lower surface of the base plate; the lower part of a lifting cylinder (13) is inserted in the lower projection pipe; a sealing ring (27) is arranged on the lower end edge of the lifting cylinder; a lock ring (33) is arranged on the upper end edge of the lifting cylinder; two ends of a spring (32) are ejected to the lock ring and the base plate; a projection baris arranged on the upper surface of a lower plate (25) in the lifting cylinder; at least one filling hole (14) is formed near the base plate; an outer orifice of the filling hole is as high as or higher than the sealing ring; a pouring hole (8) is formed in the base plate; and the pouring hole is closed by a sealing piece (5). By use of an automatic closing structure of the lifting cylinder and closing of the pouring hole by the sealing piece, the air contact in filling is reduced.

Owner:HENAN ZT LEAGUE CHEM

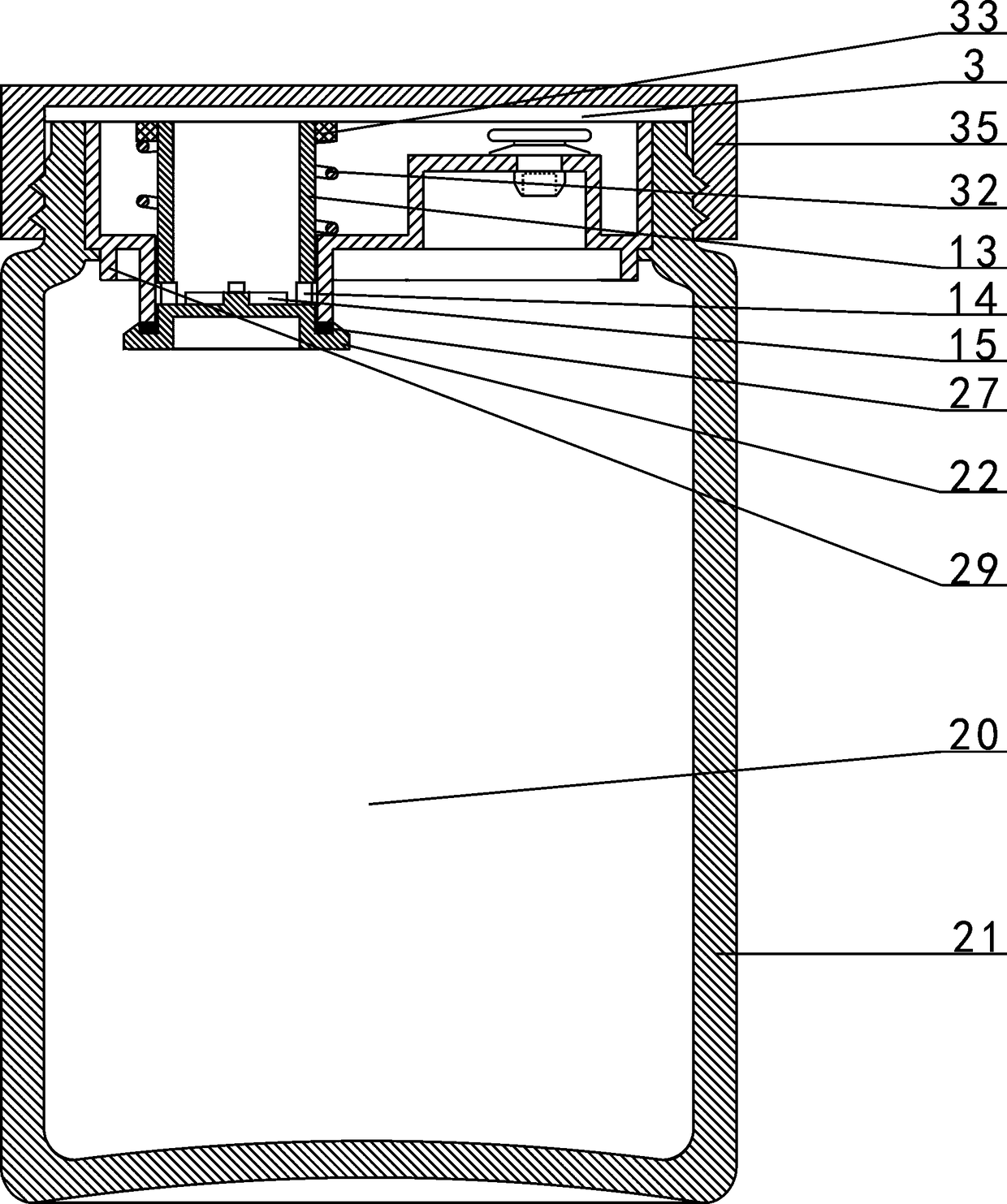

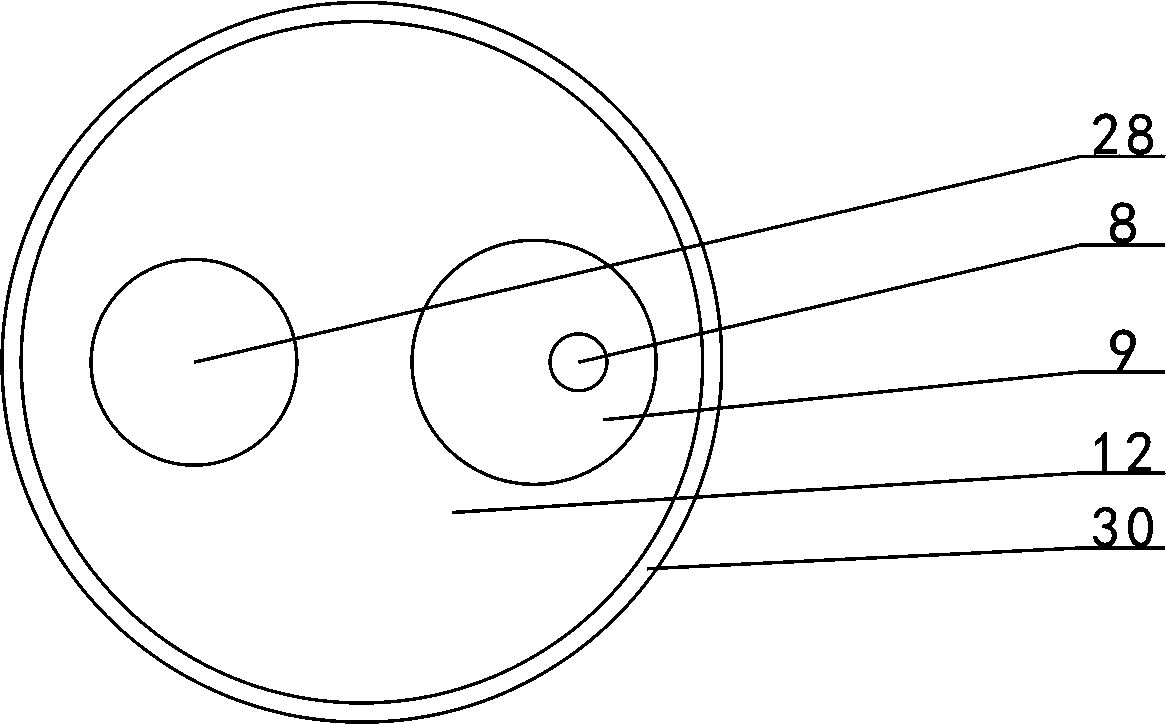

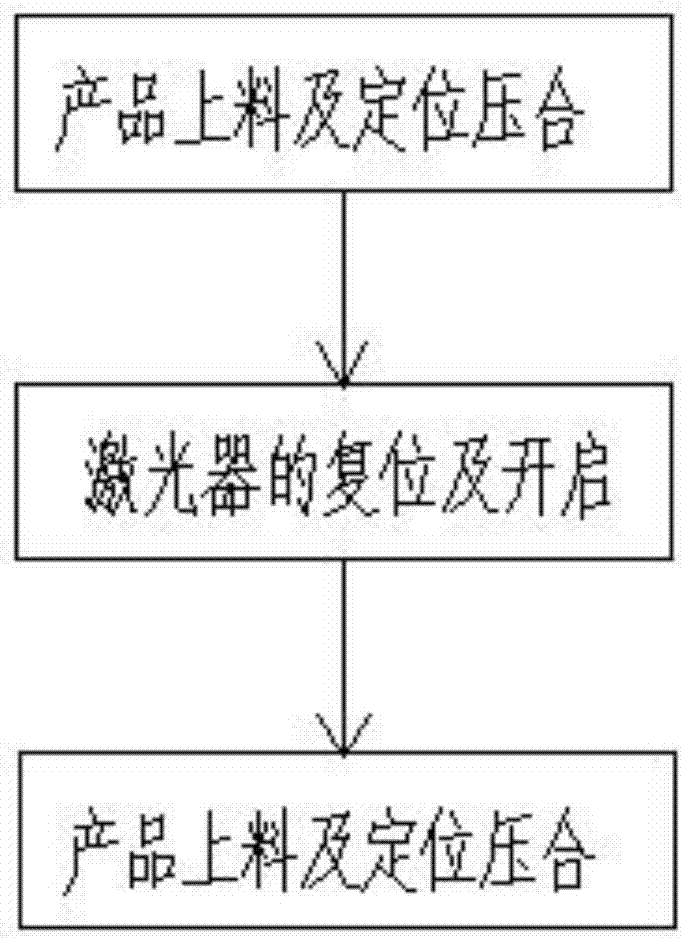

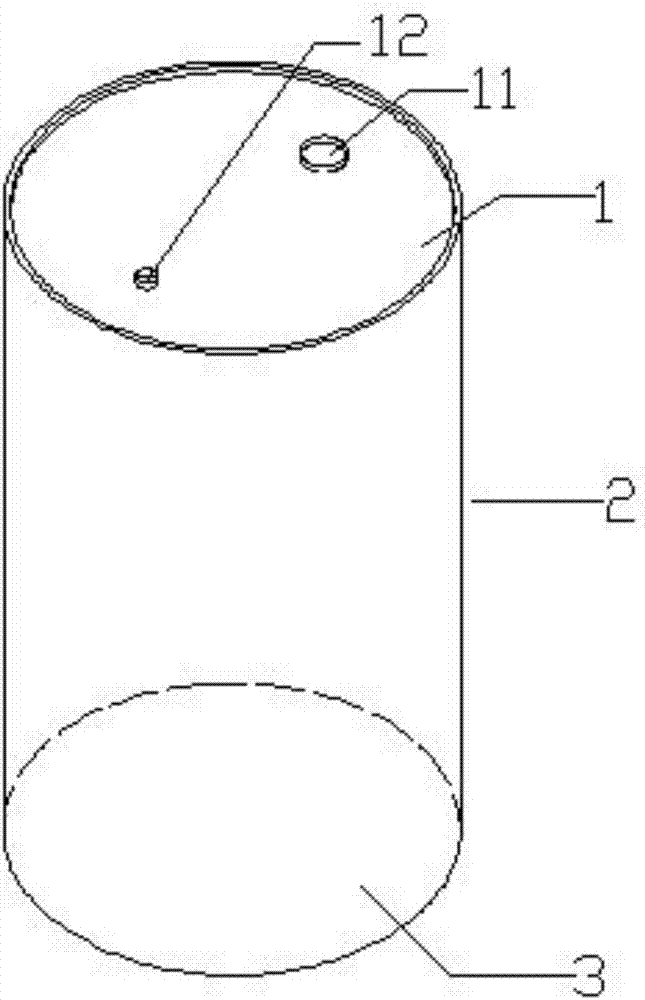

Laser welding packing barrel and welding technology thereof

PendingCN107284795AReduce manufacturing costEasy to operateRigid containersLiquid productButt welding

The invention provides a laser welding packing barrel and a welding technology thereof. The welding technology of the laser welding packing barrel comprises the following steps of feeding a product, positioning and laminating the product, resetting and starting a laser, shutting off the laser and discharging the product. The welding technology has the beneficial effects that no high welded joints are generated by setting laser parameters and replacing traditional overlap welding with butt welding to ensure that no dead angles are left at the end during hemming of the packing barrel to cause liquid leakage; the width of the welded joints is kept to be about 3mm, so that the appearance of the packing barrel is not affected; sheet materials used according to the technology are steel plates subjected to roll coating by special manufactures, so that spray coating is not needed after welding; no benzene hydrocarbon is generated; and environment pollution is avoided. The packing barrel formed by welding according to the welding technology comprises an upper cover body, a barrel body and a lower cover body, wherein the lower cover body is connected to the bottom end of the barrel body in a fastening closed manner; the upper end opening of the barrel body is connected to the upper cover body in a fastening closed manner or is detachably connected to the upper cover body, and the fastening closed connection and the detachable connection respectively correspond to the packaging of solid products and liquid products; meanwhile, a coating printed at the outer side of the packing barrel has an anti-fake label so as to facilitate fair competition and protect the rights and interests of manufactures and consumers.

Owner:苏州固安包装材料有限公司

Conveying device for shield tail sealing grease processing and using method of conveying device

PendingCN113428618AGuaranteed neatnessEasy cap handlingConveyor partsStructural engineeringMechanical engineering

The invention discloses a conveying device for shield tail sealing grease processing and a using method of the conveying device and relates to the technical field of shield tail grease processing. The conveying device comprises a concave base, a conveying belt is arranged in the concave base, and an alignment assembly is arranged between the upper surfaces of the two sides of the concave base. A blocking piece is arranged at the position, located behind the alignment assembly, of the upper surface of one side of the concave base, the alignment assembly comprises a concave plate, and the lower surfaces of the two sides of the concave plate are fixedly connected to the upper surfaces of the two sides of the concave base correspondingly. According to the device, by arranging the alignment assembly, when packaging barrels filled with grease are conveyed on the conveying belt, under the work of a transmission assembly, two push plates can move, the moving distances of the two push plates are the same, the packaging barrels can be pushed to the middle position, and therefore all the conveyed packaging barrels can be conveyed on the same straight line, the packaging barrel conveying regularity is guaranteed, and then follow-up cover sealing treatment on the packaging barrels is facilitated.

Owner:武汉市华鼎成新材料有限公司

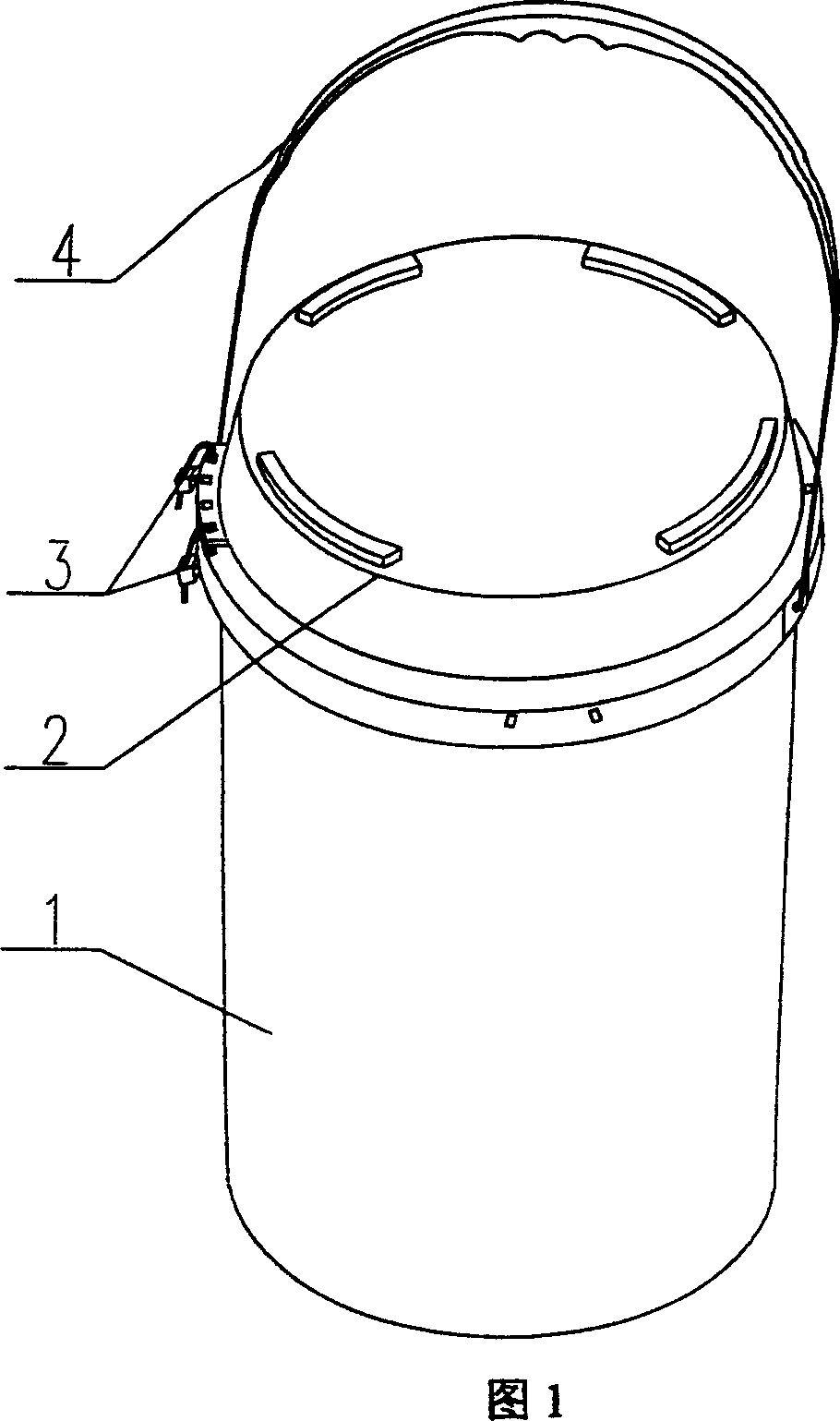

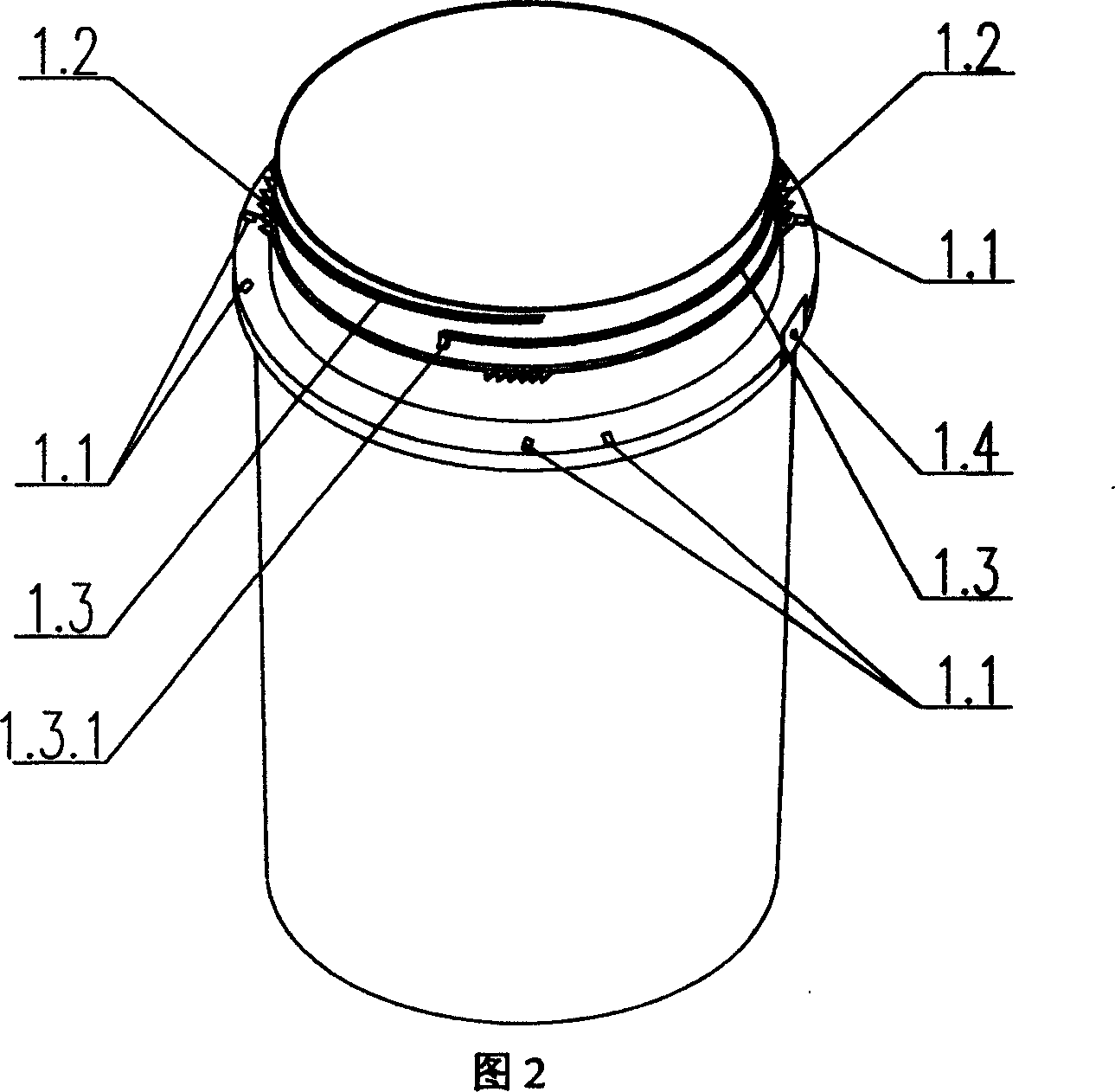

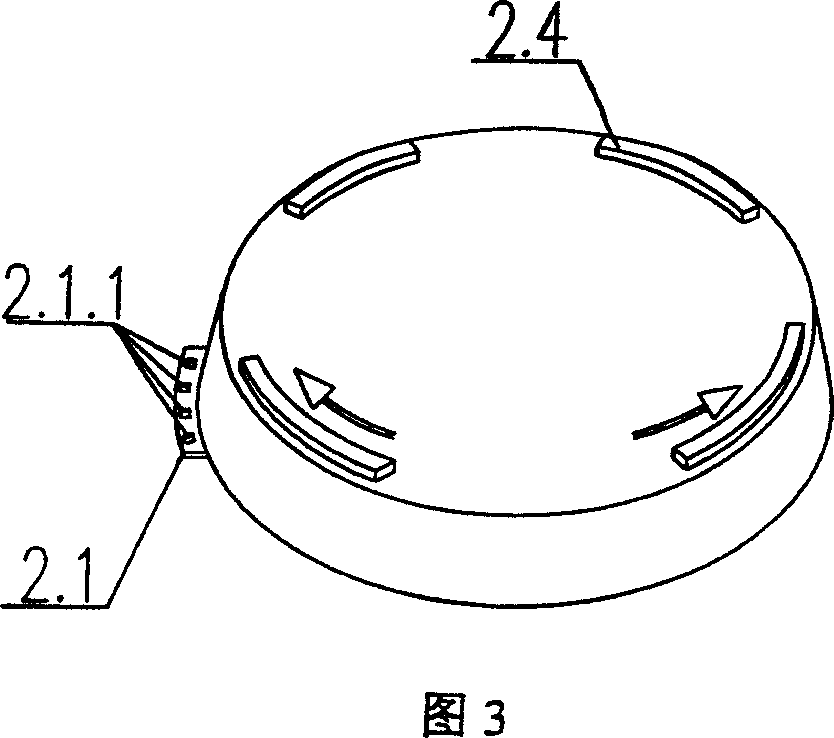

Three-counterfeit-proof plastic barrel

InactiveCN1919695AImprove anti-counterfeiting functionClamping mechanismLocking devicesPlastic packagingStructural engineering

The invention discloses a three-false proof plastic packing barrel, which consists of barrel bulk (1) and barrel lid (2), wherein the periphery of barrel bulk (1) possesses multiple spiral locking screws (1.3) with baffle block (1.3.1) on the end part of locking screw (1.3), multiple groups of saw tooth (1.2) are distributed on the external wall of barrel (1) under spiral locking screw evenly, multiple spiral locking screws (2.3) on the periphery of barrel mate multiple spiral locking screws (2.3), one group of locked saw tooth (2.2) is set on the inner wall of barrel lid (2) under multiple spiral locking screw (1.3), which mates multiple saw teeth (1.2) on the external wall of barrel (1).

Owner:江阴市鑫宝铁塑制品有限公司

Egg sorting and packaging device

InactiveCN112173218AShorten the timeImprove work efficiencyPackaging eggsAvicultureAnimal scienceEngineering

The invention discloses an egg sorting and packaging device, and relates to the technical field of egg packaging devices. The egg sorting and packaging device comprises a sorting assembly, a conveyingtable, a separating and pushing assembly and egg packaging barrels, wherein the sorting assembly and the conveying table are located on the same horizontal plane and are distributed side by side; theegg packaging barrels are obliquely clamped on the sorting assembly at a certain angle; a plurality of first telescopic adjusting rods are fixedly connected to the surface of a supporting plate in alinear distribution mode; and spring dynamometers are fixedly connected to the tops of the first telescopic adjusting rods. According to the egg sorting and packaging device, eggs are conveyed to thesorting assembly one by one through the conveying table; and the eggs pass through guide plates through air discharged from an air outlet pipeline, egg partition plates are pushed by second telescopicadjusting rods to fall into barrel openings of the egg packaging barrels from L-shaped straight barrels, when the eggs pass through the corresponding guide plates, the guide plates are pressed to rotate, the eggs fall into oval grooves in the egg partition plates and slide into the corresponding egg packaging barrels along with the partition plates, and therefore the eggs can be sorted and packaged.

Owner:安徽鳌鸟信息科技有限公司

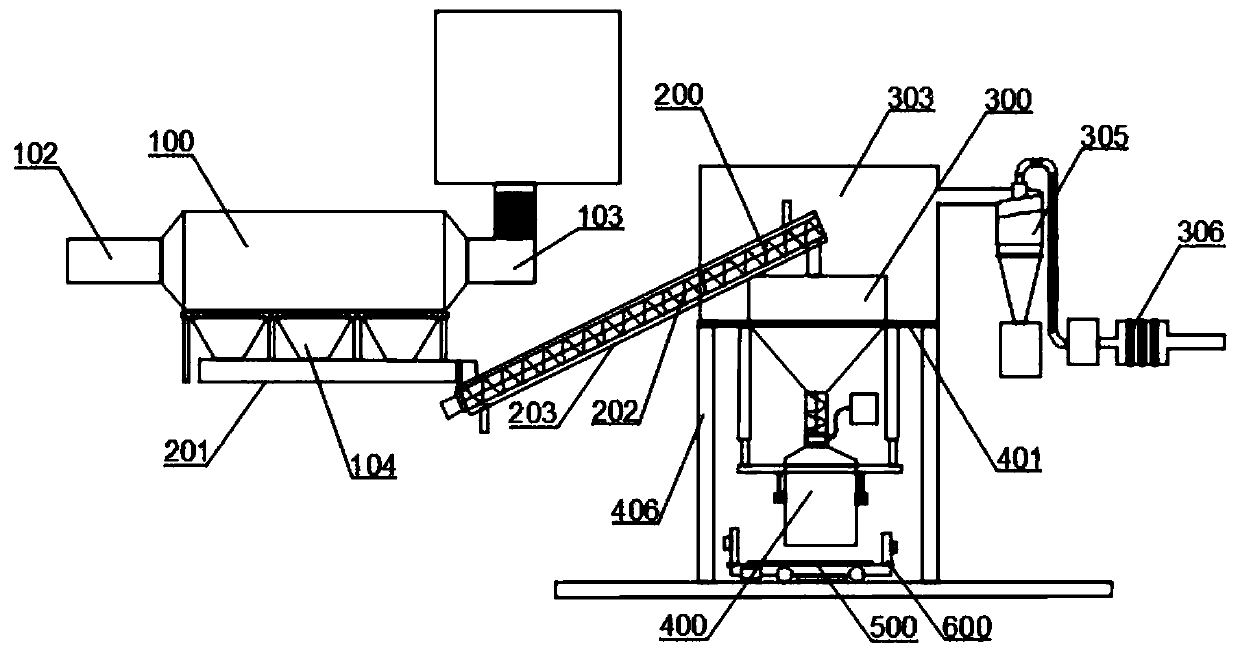

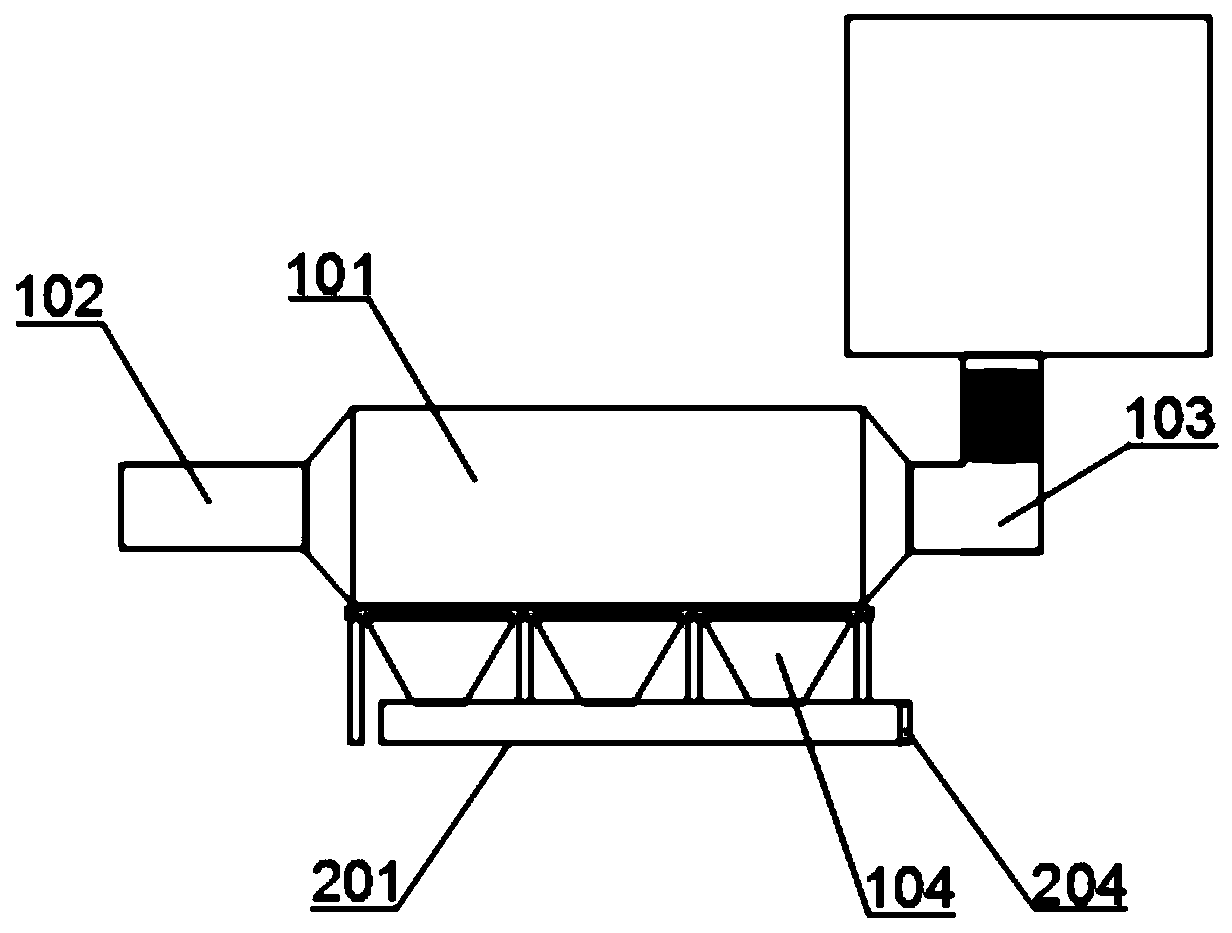

High-temperature smoke cooling, metering and packaging integrated device and process method thereof

PendingCN111470280AMeet the basic conditions for baggingTroubleshoot Connection Sealing IssuesSolid materialLoading/unloadingEngineeringProcess engineering

The invention provides a high-temperature smoke cooling, metering and packaging integrated device. The high-temperature smoke cooling, metering and packaging integrated device comprises a smoke collecting device, a smoke cooling and conveying system, a packaging device, a single-barrel weighing device and a smoke conveying device. According to the high-temperature smoke cooling, metering and packaging integrated device, the temperature of high-temperature smoke can be directly reduced from 180 DEG C to 60 DEG C and is lower than the highest tolerance temperature of bagging, and the basic packaging condition is met; the problem of connection sealing between a discharging opening and a packaging barrel is solved, the problem of smoke flying is solved, and the environmental risk is eliminated; the problem that the weight of a single barrel cannot reach the export sales weight is solved; single-bag metering is achieved, material calculation is facilitated, and real-time adjustment is facilitated; transfer transportation of a small truck is omitted, the production cost is saved, and the post risk coefficient is reduced; and a smoke kneading machine is omitted, equipment is reduced, andpollution sources are reduced.

Owner:YIMEN COPPER CO LTD

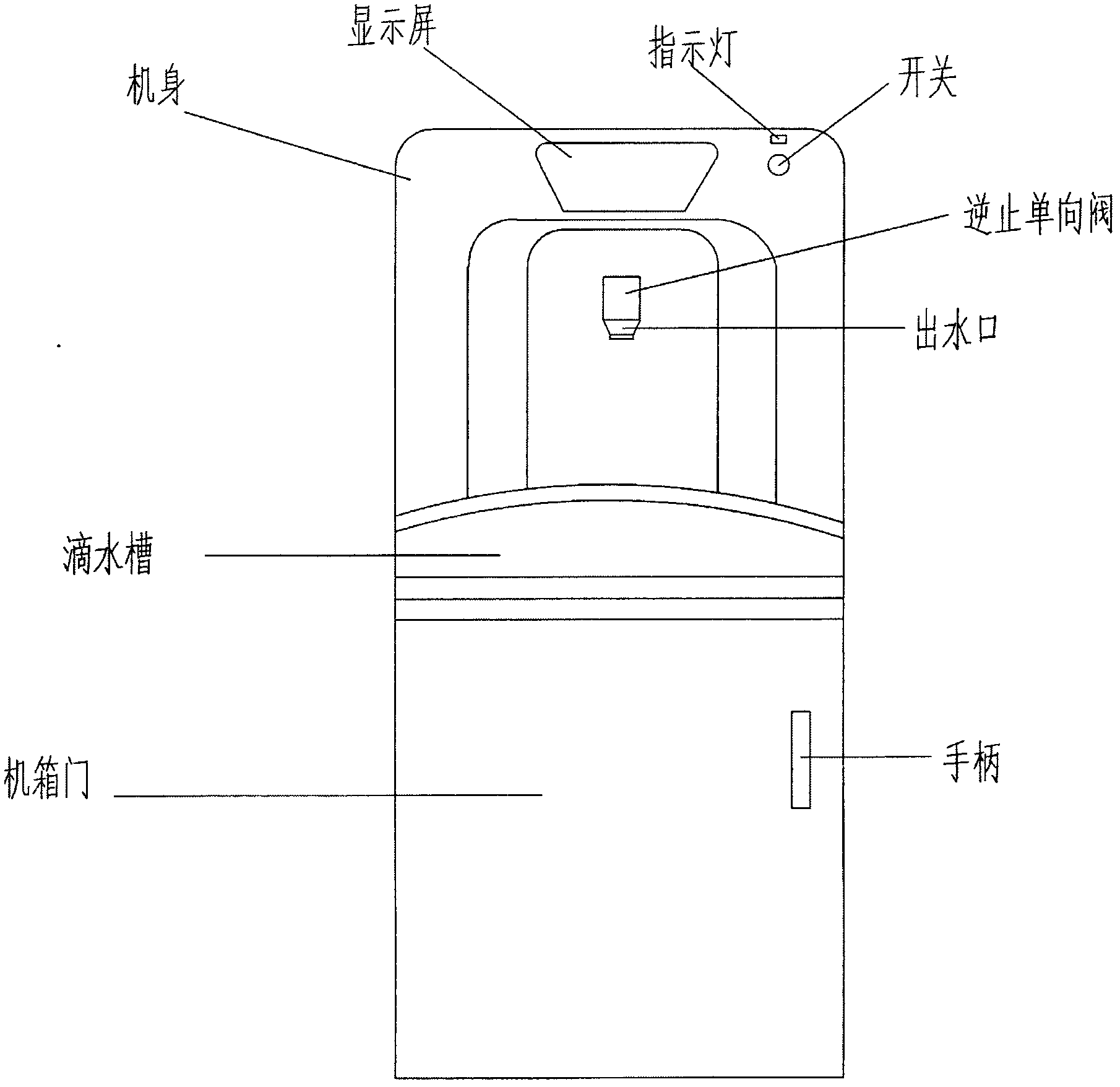

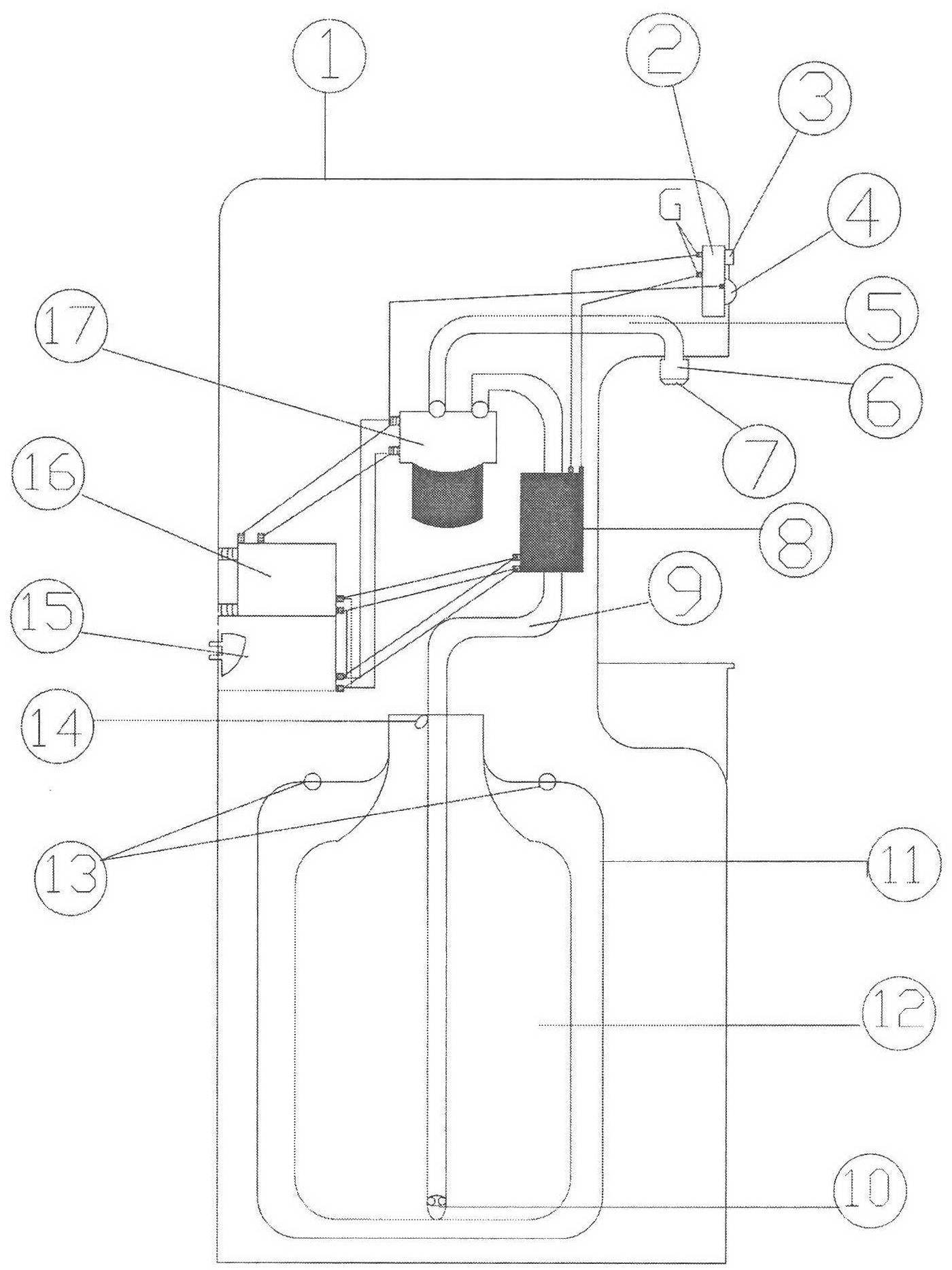

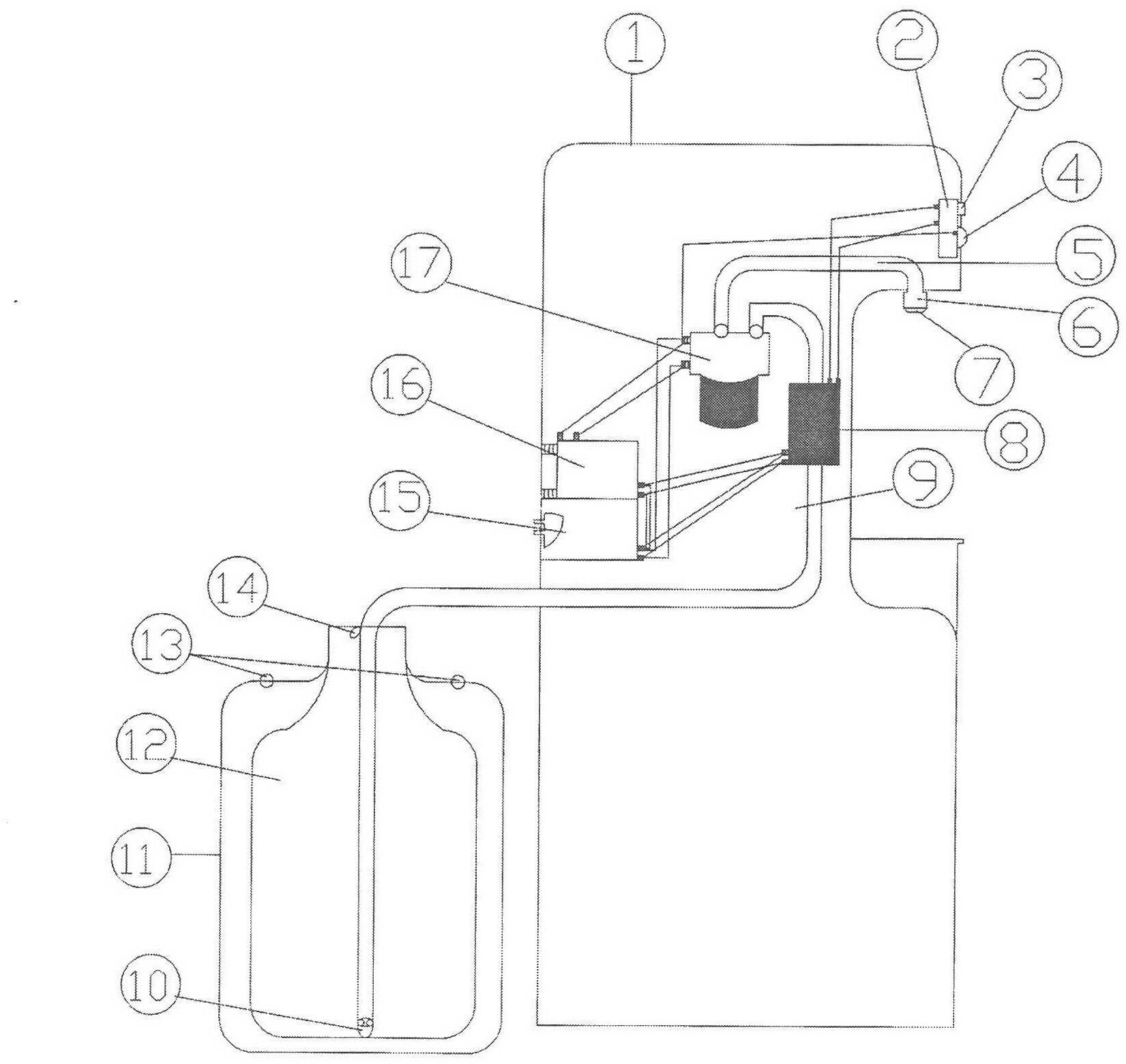

Electric fresh keeping liquid extractor

The invention relates to a liquid extractor, which comprises a machine casing, a liquid container, a storage battery, a charging transformer, a liquid inlet pipeline, a liquid outlet pipeline, an electric liquid pumping pump, a liquid quality on-line monitor, a circuit control main board and a stroke switch and is characterized in that the container is a ZL201020565098.2 patent germ-proof packaging barrel, the barrel is placed at the inner bottom of the machine casing or beside the outside of a liquid extractor casing in a way that a barrel opening is upward, the liquid inlet pipeline is a path extending to the container for pumping the liquid, and a liquid conveying pipeline is indirectly communicated with the liquid inlet pipeline and directly extends to a liquid outlet arranged outside the machine casing. The direct current electric liquid pumping pump is provided with two small holes: i.e. an outlet and an inlet, and is communicated with the liquid inlet pipeline and the liquid conveying pipeline. The liquid quality on-line monitor is arranged on the liquid inlet pipeline, an optical wave or electric conductivity detector is adopted for detecting the quality of liquid flowing in the pipeline, and the detected liquid quality purification value can be displayed onto a liquid extractor display screen in real time.

Owner:GUANGXI LUOSHI TECH

Intelligent acceptance method for livestock and poultry frozen raw materials

ActiveCN112129392AEasy to check and acceptAvoid stickingPackagingWeighing apparatus with automatic feed/dischargeAnimal scienceEngineering

The invention discloses an intelligent acceptance method for livestock and poultry frozen raw materials. A base, a connecting pipe, a rotating shaft, a second gasket and a third gasket are included; afixing frame is welded to the bottom of the inner side of the base, and a first spring is fixed to the inner side of the fixing frame; the connecting pipe communicates with an air bag, and a sleeve head is fixed to the right side of the upper portion of the connecting pipe; a connecting plate is welded to the inner side of the sleeve head; supporting columns are welded to the rear side of the upper portion of the base, and upper transverse rods are arranged on the rear sides of the upper ends of the supporting columns; gravity sensors are arranged above the upper transverse rods; a hook is arranged on the outer side of the rotating shaft, and a gear is further fixed to the outer side of the rotating shaft; and a rack is arranged on the right side of the gear. An intelligent acceptance device for the livestock and poultry frozen raw materials is provided with the first spring and a sliding block, the phenomenon that when the livestock and poultry frozen raw materials fall on the innerside of a packaging barrel, the packaging barrel is damaged can be effectively avoided through the first spring and the sliding block, a certain buffering function is achieved, and meanwhile the service life of the packaging barrel is prolonged.

Owner:HUNAN JIAPIN JIAWEI BIOTECHNOLOGY CO LTD

High-strength hazardous article packaging plastic barrel and production method

PendingCN113372649AUnique formulaReasonable structureCans/barrels/drumsPackage recyclingPolypropyleneMechanical engineering

A high-strength hazardous article packaging plastic barrel comprises a barrel body and a barrel cover or only comprises the barrel body, the barrel body is a conical barrel body or a straight barrel body, reinforcing ribs are arranged on the barrel wall, the outer wall of a barrel opening is in threaded connection with the barrel cover, and when only the barrel body is arranged, the outer wall of the barrel opening is free of threads; the barrel body and the barrel cover are formed by injection molding of plastics formed by uniformly mixing, by weight, 70 parts of polypropylene resin, 302 parts of polypropylene, 2.5 parts of polyethylene resin, 5 parts of PHDE and 3 parts of a pigment; two ring ribs are arranged below the external threads of the barrel body, two barrel lifting seats are arranged between the ring ribs, buckling holes are formed in the barrel lifting seats and used for pressing connection of the barrel lifting seats, a ring groove matched with the barrel opening edge is formed in the inner side of the barrel cover, internal threads matched with the barrel body are arranged on the outer side of the ring groove, and a barrel cover outer ring rib and a barrel cover inner ring rib are arranged on the inner side of the ring groove; and barrel cover radial ribs are arranged between the barrel cover outer ring rib and the barrel cover inner ring rib and are connected with the cover top plate into a whole. The packaging barrel meeting the packaging, transporting and storing requirements of dangerous goods can be produced, and the packaging barrel is novel in structure, high in strength and toughness, resistant to falling, impact and corrosion.

Owner:建水县建芸塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com