Laser welding packing barrel and welding technology thereof

A laser welding and welding process technology, applied in the field of packaging, can solve the problems of increasing the production cost of packaging materials, reducing the cost of goods purchased by consumers, and reducing the utilization rate of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 2

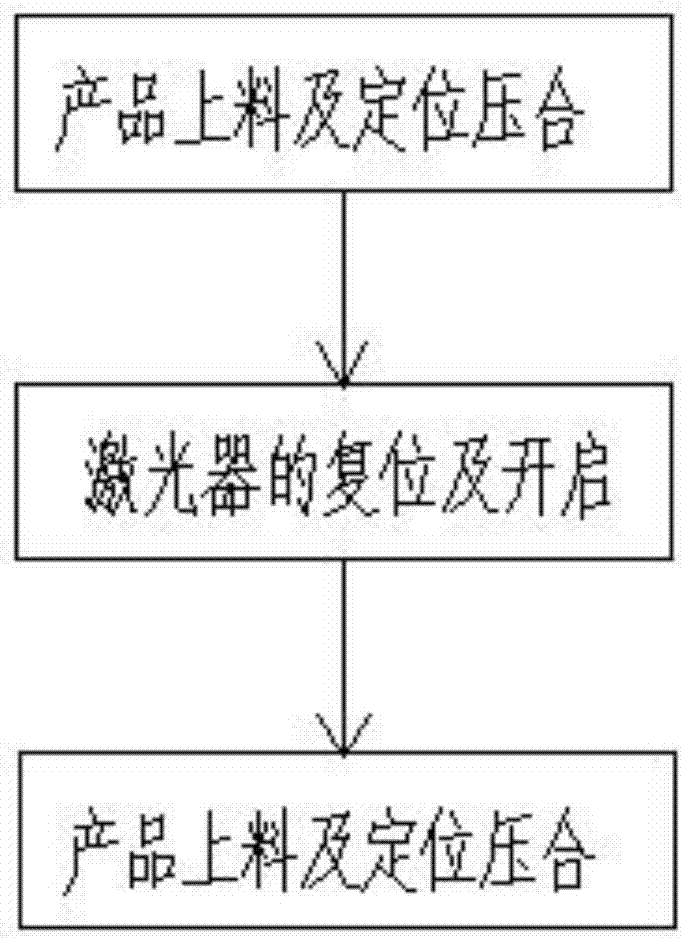

[0043] A welding process for laser welding packaging drums, comprising:

[0044] Product loading and positioning and pressing: After the steel plate raw materials to be welded are folded and docked, they are fixed on the welding workbench with clamping fixtures. Among them, the steel plate to be processed adopts butt welding, that is, the steel plate to be welded does not need to be overlapped when coiled. The butt welding method makes the welding seam smooth, avoids the occurrence of high welding seam, and ensures that there will be no dead corners when the end curling of the packaging barrel after welding is formed, so as to avoid packaging leakage accidents.

[0045] Resetting and opening of the laser: move the laser head of the laser to the starting position, turn on the shielding gas and the laser, the laser head starts to move, and welds the two ends of the rolled steel plate together. Among them, since no welding material is used in the laser welding process, the steel...

specific Embodiment example 3

[0052] A welding process for laser welding packaging drums, comprising:

[0053]Product loading and positioning and pressing: After the steel plate raw materials to be welded are folded and docked, they are fixed on the welding workbench with clamping fixtures. Among them, the steel plate to be processed adopts butt welding, that is, the steel plate to be welded does not need to be overlapped when coiled. The butt welding method makes the welding seam smooth, avoids the occurrence of high welding seam, and ensures that there will be no dead corners when the end curling of the packaging barrel after welding is formed, so as to avoid packaging leakage accidents.

[0054] Resetting and opening of the laser: move the laser head of the laser to the starting position, turn on the shielding gas and the laser, the laser head starts to move, and welds the two ends of the rolled steel plate together. Among them, since no welding material is used in the laser welding process, the steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com