Patents

Literature

41results about How to "Good shape recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shape memory fiber prepared with shape memory polyurethane and its prepn process

InactiveCN1706997AGood shape recoveryLarge temperature adjustment rangeMonocomponent synthetic polymer artificial filamentNatural fiberMelt spinning

The present invention relates to one kind of shape memory fiber prepared with shape memory polyurethane and its preparation process. The shape memory polyurethane is prepared with material including one hydroxyl containing polymer, chain expander, diisocyanate and blocking agent in the molar ratio of 1 to 1-3 to 2.4-4.8 to 0.8-1.6. The preparation process of the shape memory fiber includes the following steps: preparing shape memory polyurethane with excessive isocyanate; adding blocking agent to obtain blocked shape memory polyurethane; and melt spinning to obtain shape memory fiber. The shape memory fiber of the present invention has very wide temperature regulating range, practical elasticity, strength and shape memory performance and comfortable hand feeling, is easy to spin alone or together with synthetic fiber and natural fiber, and may find wide application in clothing, biomedical material and other fields.

Owner:THE HONG KONG POLYTECHNIC UNIV

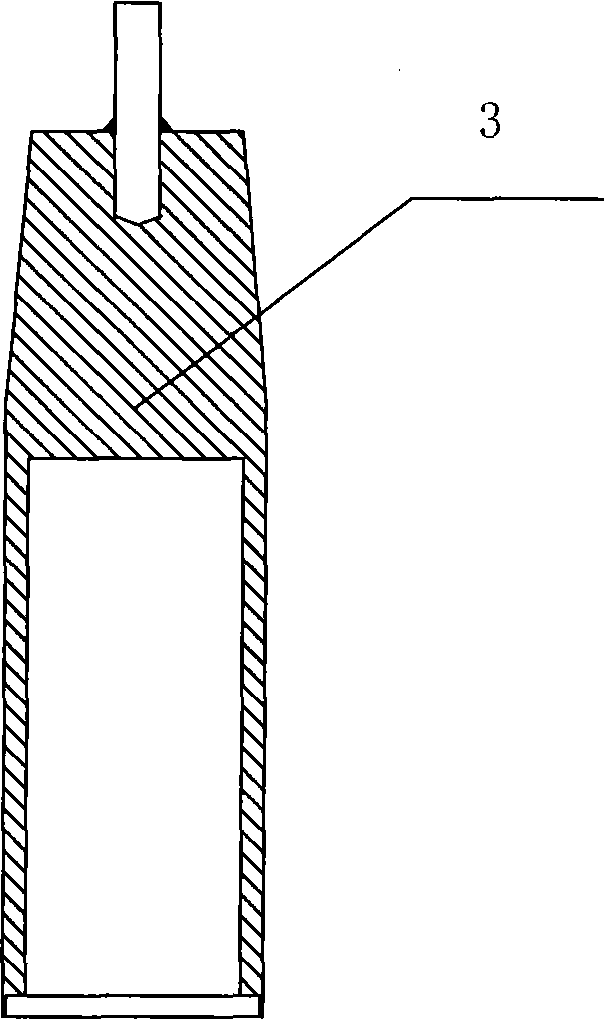

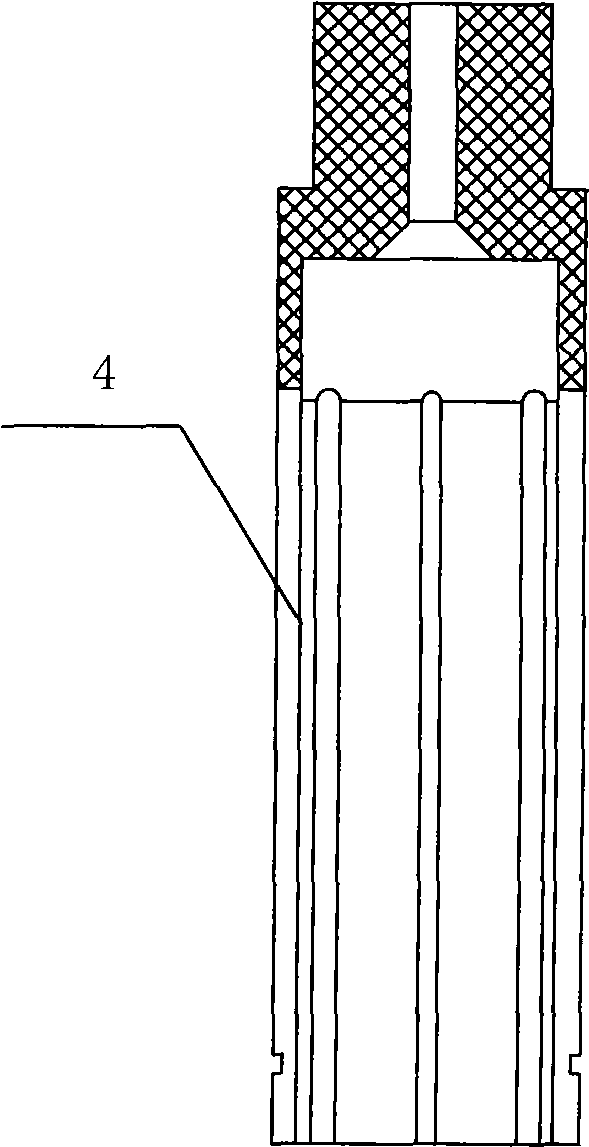

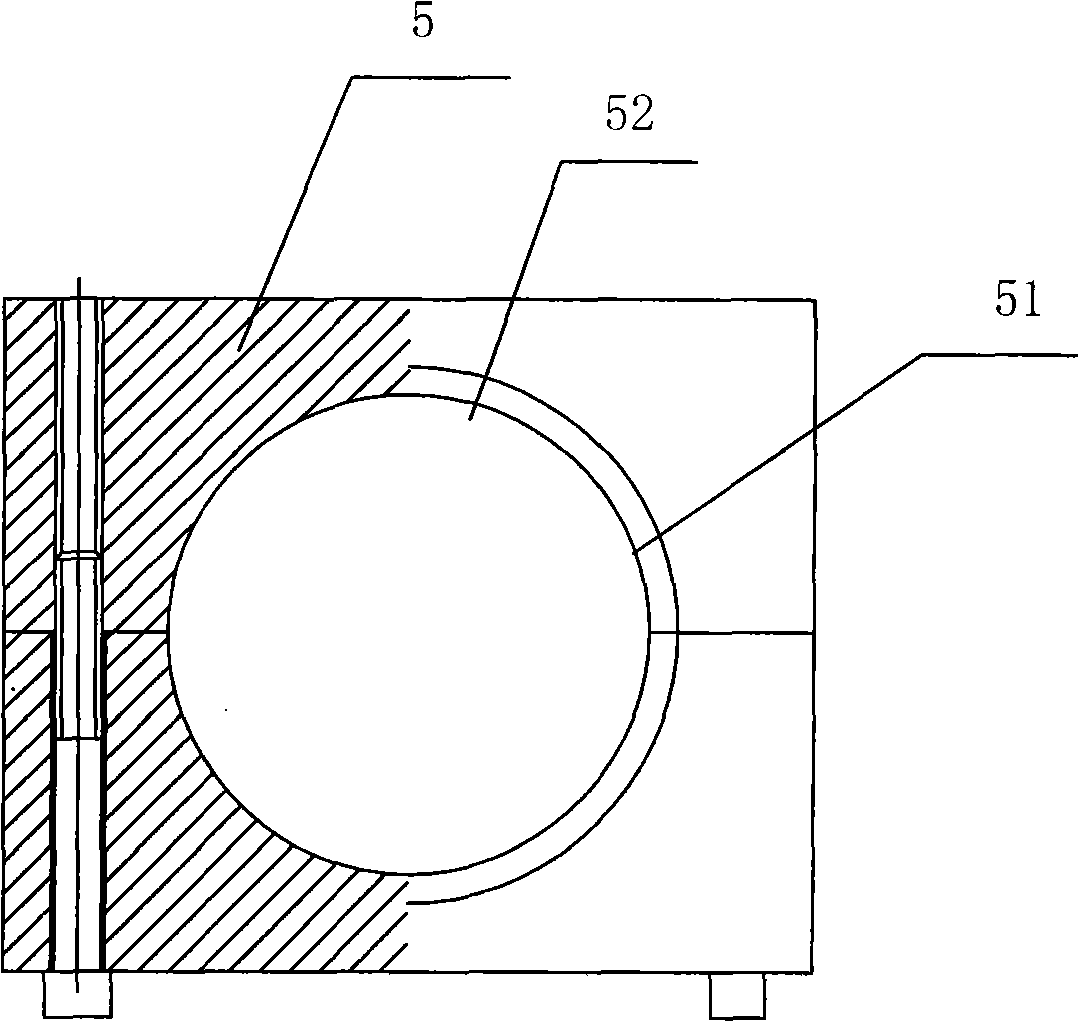

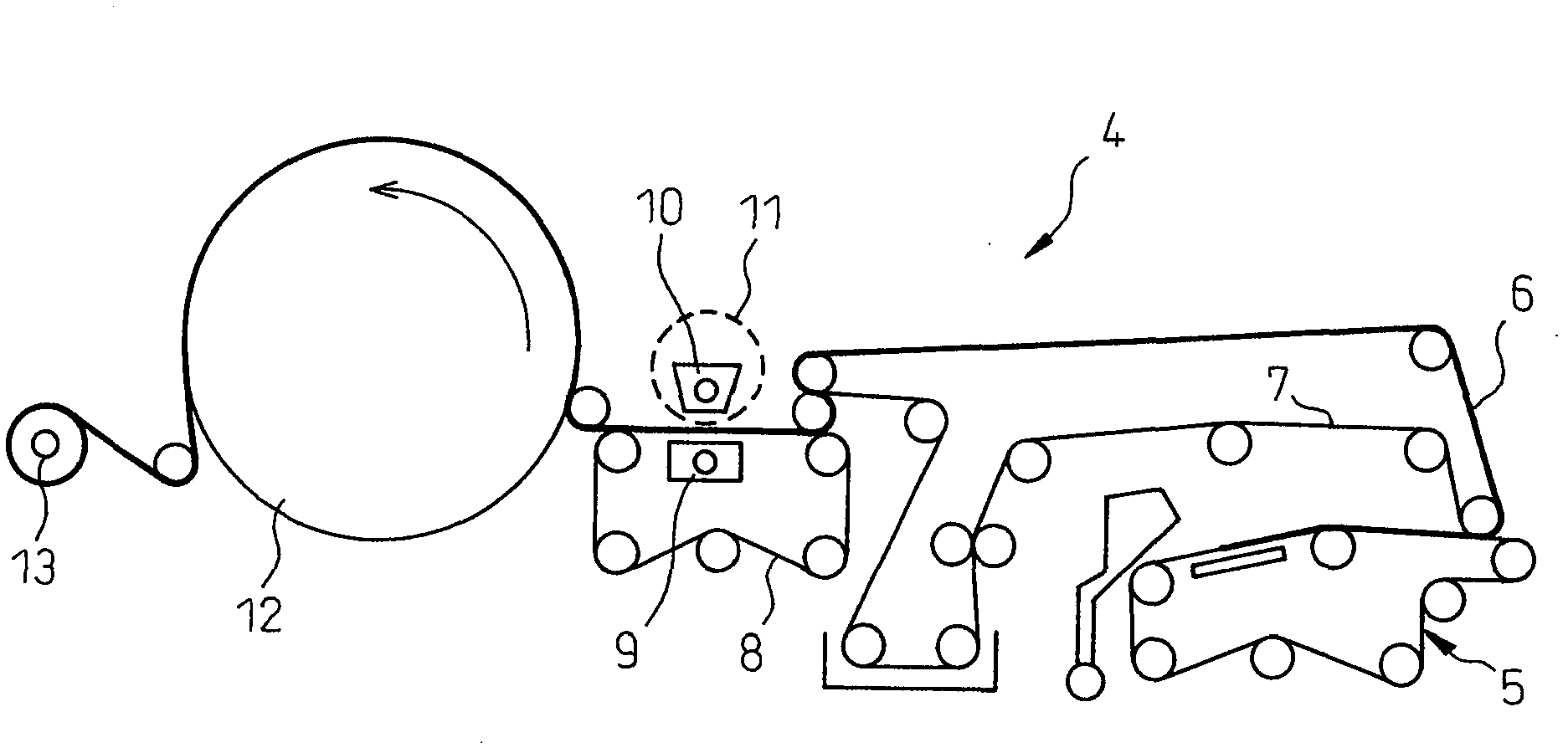

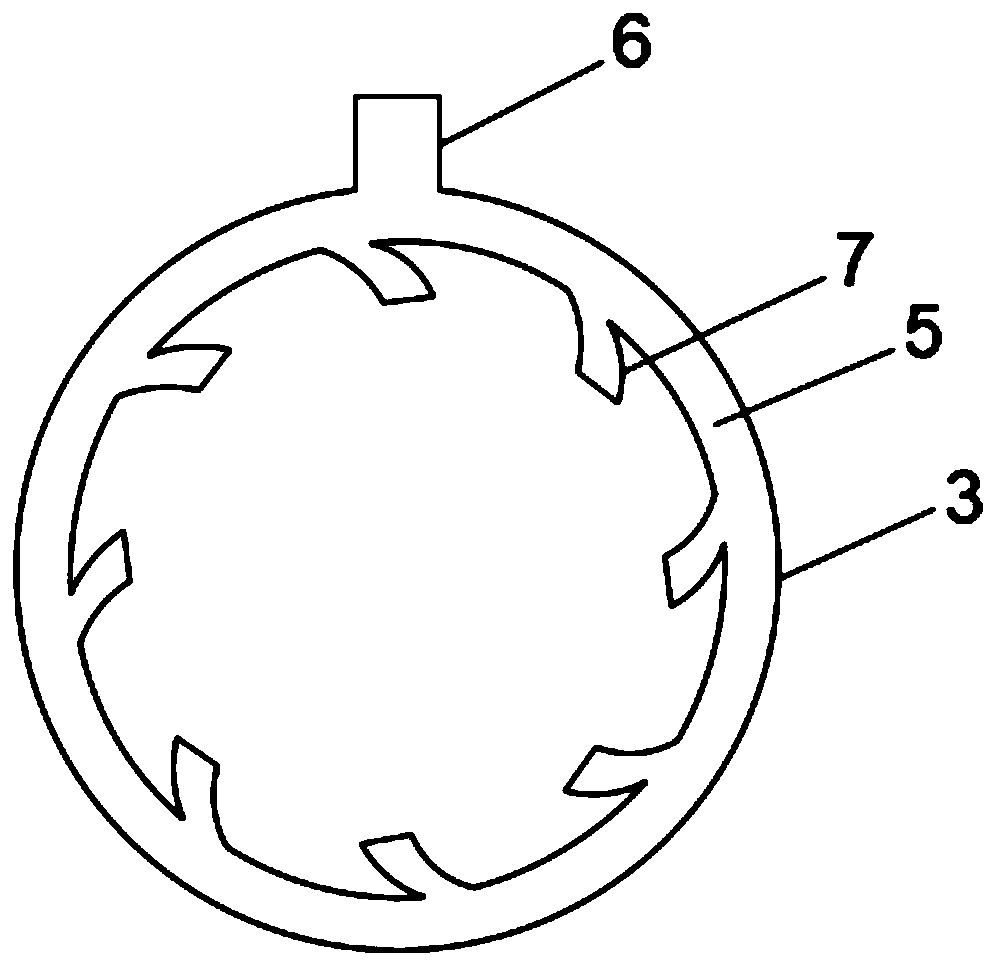

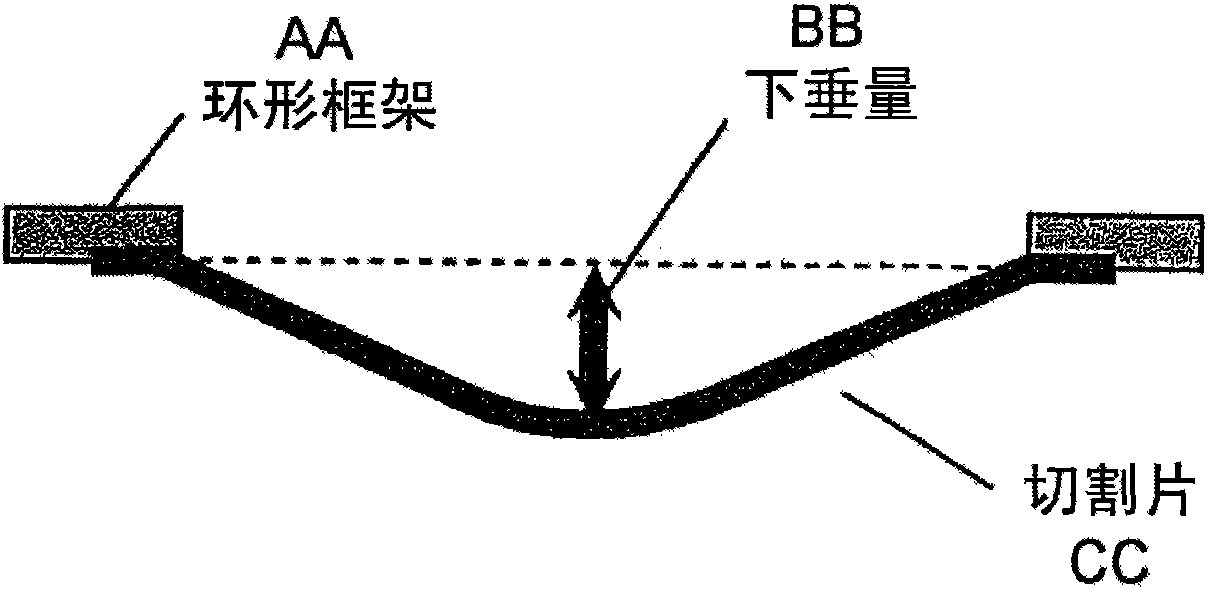

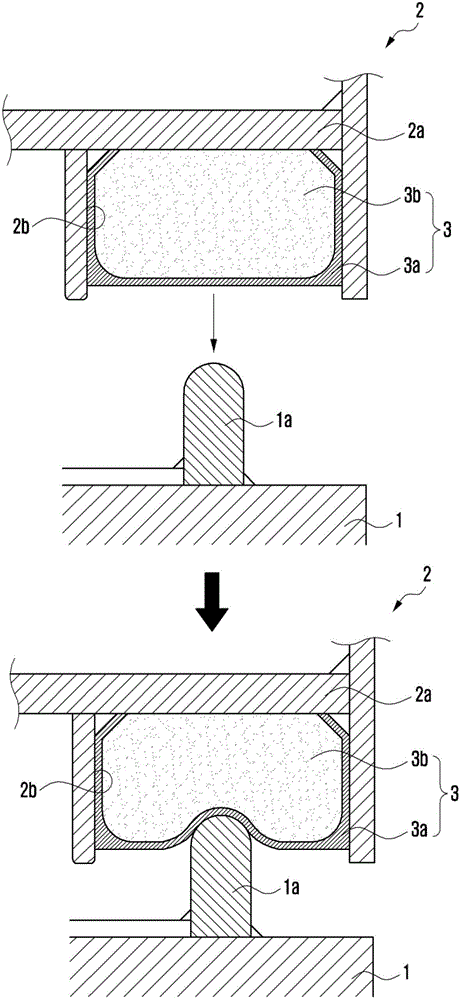

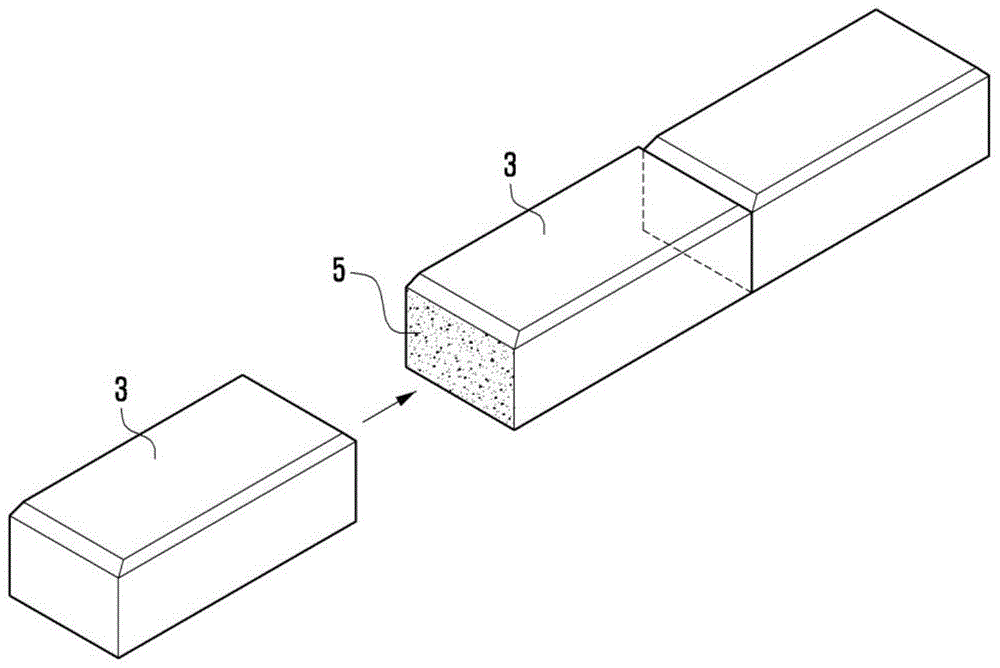

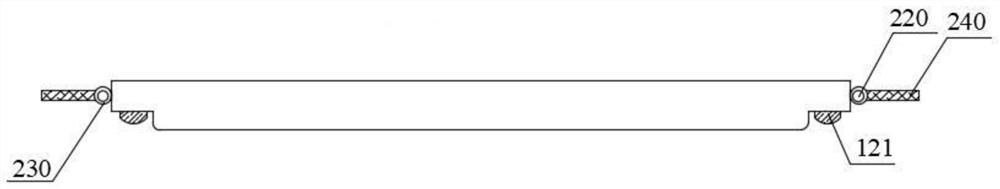

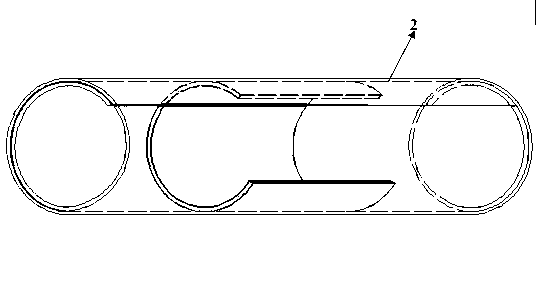

Method for assembling inelastic sealed ring and assembling device for implementing the method

InactiveCN101474737AReduce the probability of breakageGood shape recoveryMetal working apparatusFailure rateEngineering

The invention discloses a method for assembling an unelastic seal packingring and an assembly device for implementing the method. The assembly method is as follows: fixing work pieces, sheathing a guide cylinder on a rotating shaft, sheathing a seal packingring on the cylindrical guide cylinder, sheathing a cylinder on the guide cylinder, pushing the seal packingring into a seal groove on the rotating shaft, retracting the cylinder, taking down the guide cylinder, clipping the seal packingring by a clip, causing the seal packingring to be reset in a dual rectangular way, and withdrawing the clip, thereby accomplishing the assembly of the seal packingring. The unelastic seal packingring assembly device for implementing the method is characterized by comprising a workbench (1), a work piece clamp seat (11), a guide post (3), a push ring cylinder(4) and the clip(5), and has the advantages of great reduction of tensile failure rate of the unelastic seal packingring, favorable shape restoration of the seal packingring, high assembly efficiency and favorable seal effect.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

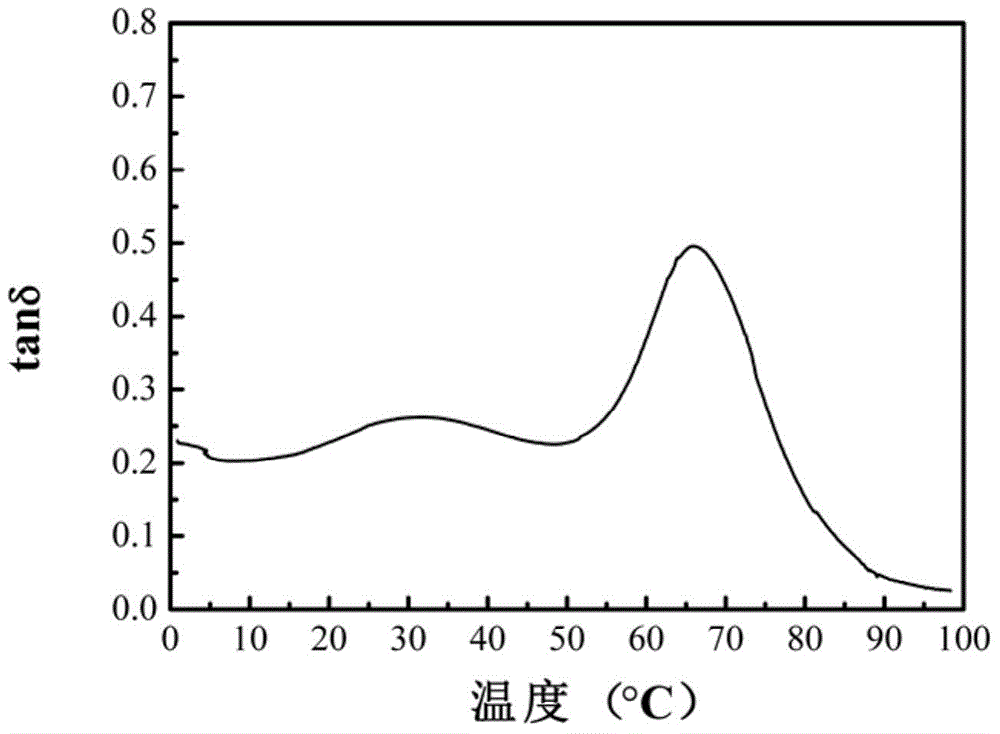

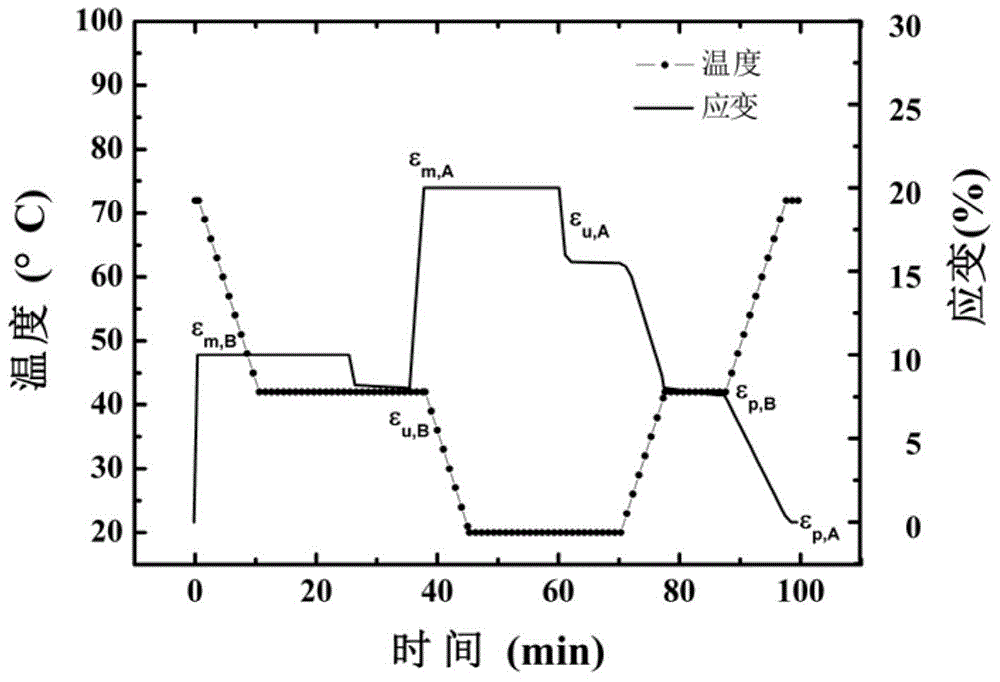

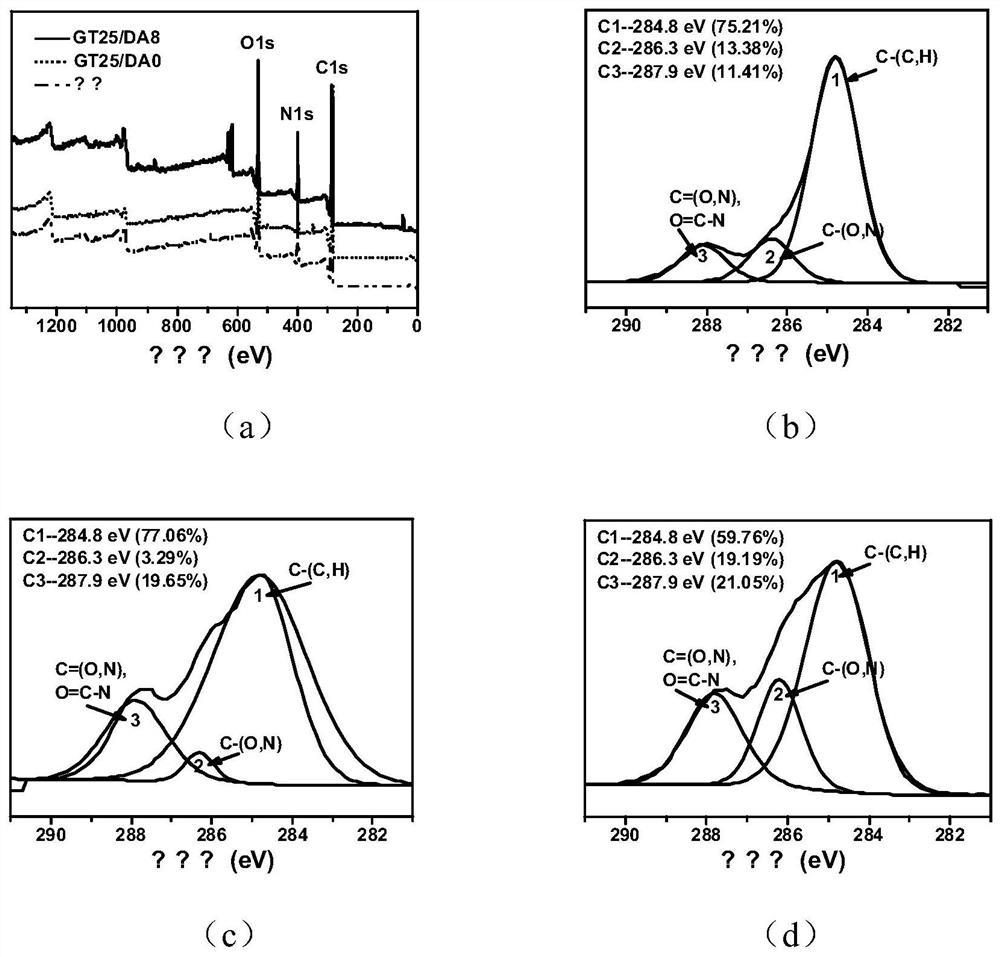

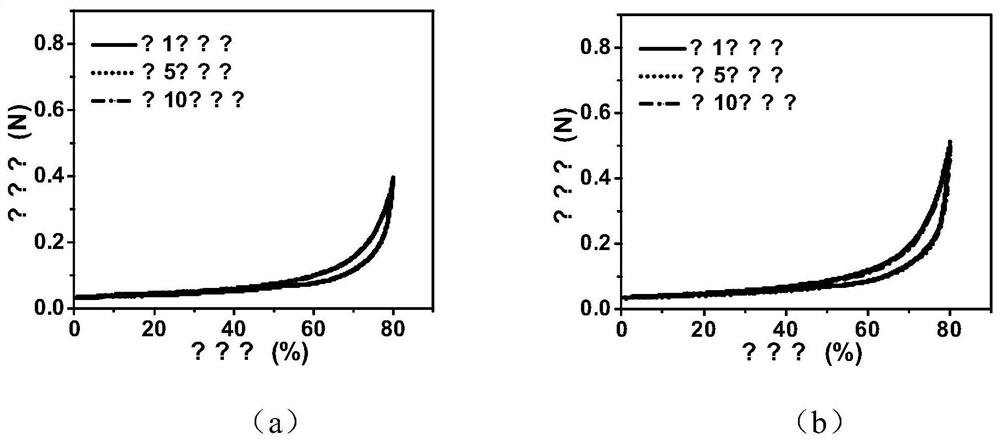

Preparation method of triple shape memory composite material

ActiveCN104893250AHigh elongation at breakThe triple shape memory effect does not existEpoxyPolyethylene glycol

The invention discloses a preparation method of a triple shape memory composite material. The method comprises two processes, namely, modification of a double shape memory material and preparation of the triple shape memory composite material. Firstly, the double shape memory material is modified, low-molecular-weight PEG (polyethylene glycol) and epoxy resin are mixed in different proportions, the GTT (glass transition temperature) of the double shape memory material is decreased, the low-molecular-weight PEG dispersed nano-silica and epoxy resin are mixed in different proportions, the GTT of the double shape memory material is increased, the double shape memory material with the low GTT and the double shape memory material with the high GTT are stacked, and the triple shape memory composite material is prepared. The method has the advantages that the technology is simple, preparation conditions are mild, the prepared material has the good shape memory effect and the like.

Owner:ZHEJIANG SCI-TECH UNIV

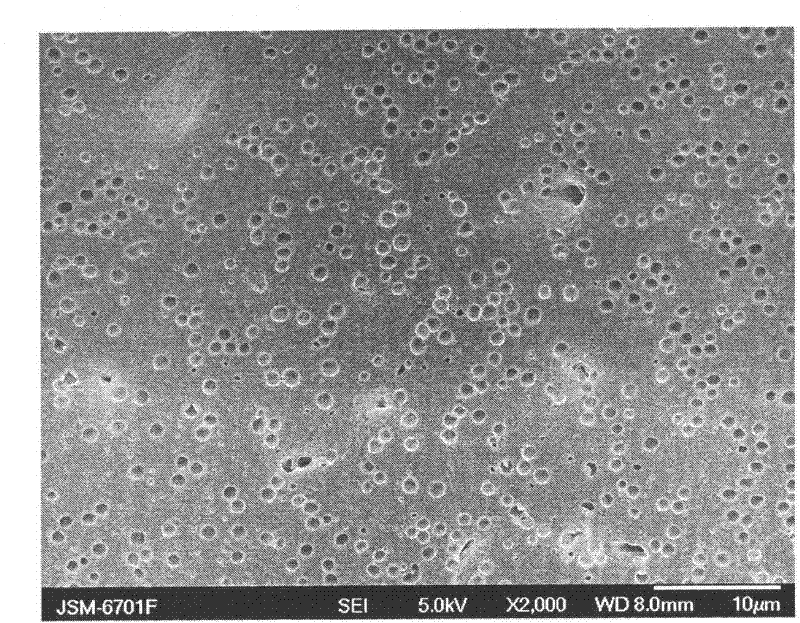

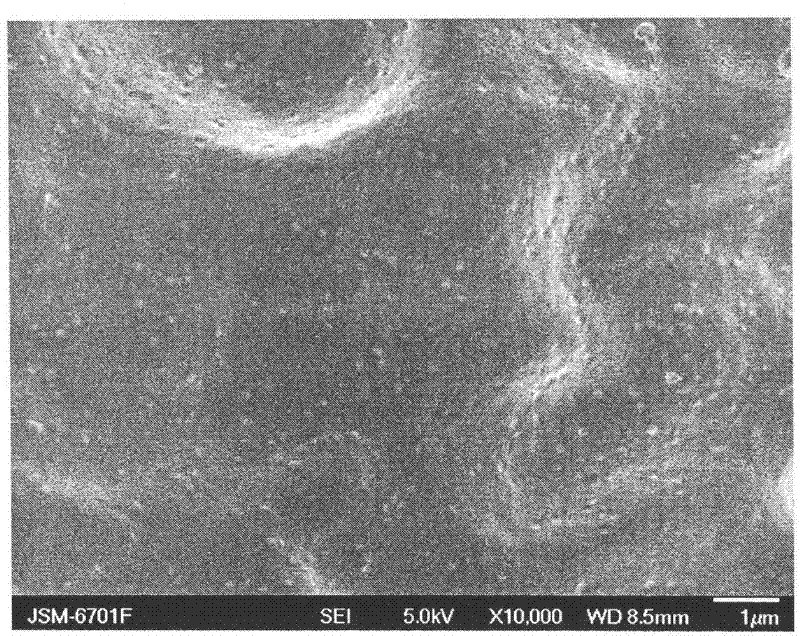

Silica cross-linking shape memory polymer material

The invention discloses a silica cross-linking shape memory polymer material, characterized by using silica as a cross-linking point, forming a SiO2@polymer spherical polymer in which silica is used as the shell of the core polymer through surface grafting of a polymer, and connecting polyisocyanate with the terminal hydroxy of the polymer to obtain a polymer having a cross-over network structure, wherein the soft segment is a polymer whose surface is grafted by silica, and the hard segment comprises silica and a urethane chain segment. The silica cross-linking shape memory polymer material has the advantages of regular structure, high mechanical strength, stable shape memory performance, and high shape memory fixation rate and shape memory recovery rate, and can be applied for materials in medical science and other aspects.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

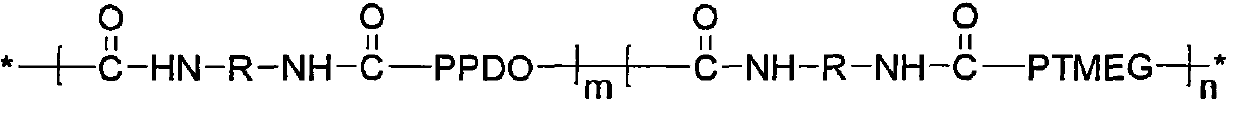

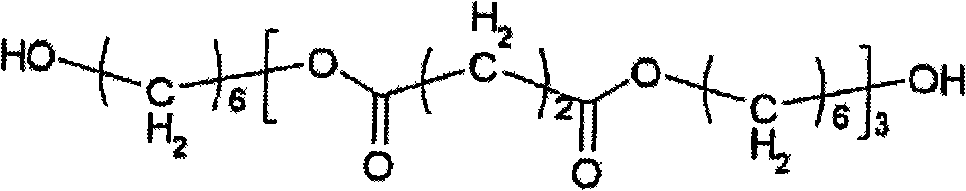

Poly (p-dioxanone)/polytetrahydrofuran multi-block copolyether ester with shape memory function and preparation method thereof

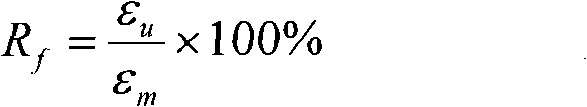

The invention discloses poly (p-dioxanone) / polytetrahydrofuran multi-block copolyether ester with shape memory function. The repetitive structure of the copolyether ester is shown in the specification, the intrinsic viscosity is 0.54-3.5dl / g, the shape fixed rate Rf is 82.6-100% and the shape recovery rate Rr is 84.9-100%. The invention also discloses a preparation method of the multi-block copolyether ester. The multi-block copolyether ester provided by the invention simultaneously has the advantages of shape memory function, controlled thermal transition temperature, controlled molecular weight, biodegradability, etc and has wide application prospect. The preparation method provided by the invention is simple, convenient and mature and has easily controlled process.

Owner:SICHUAN UNIV

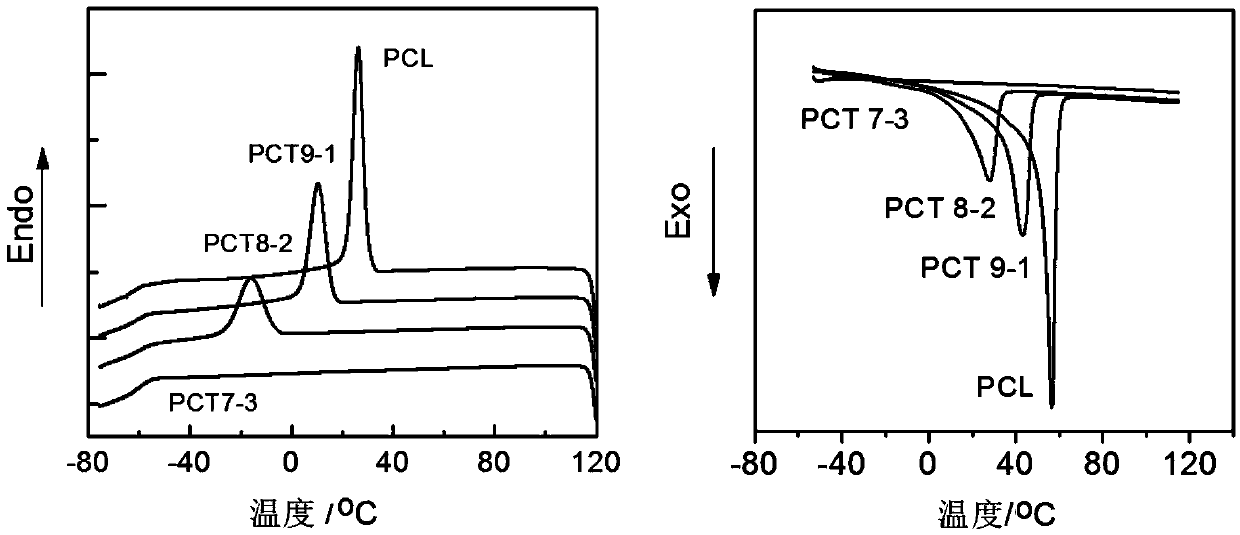

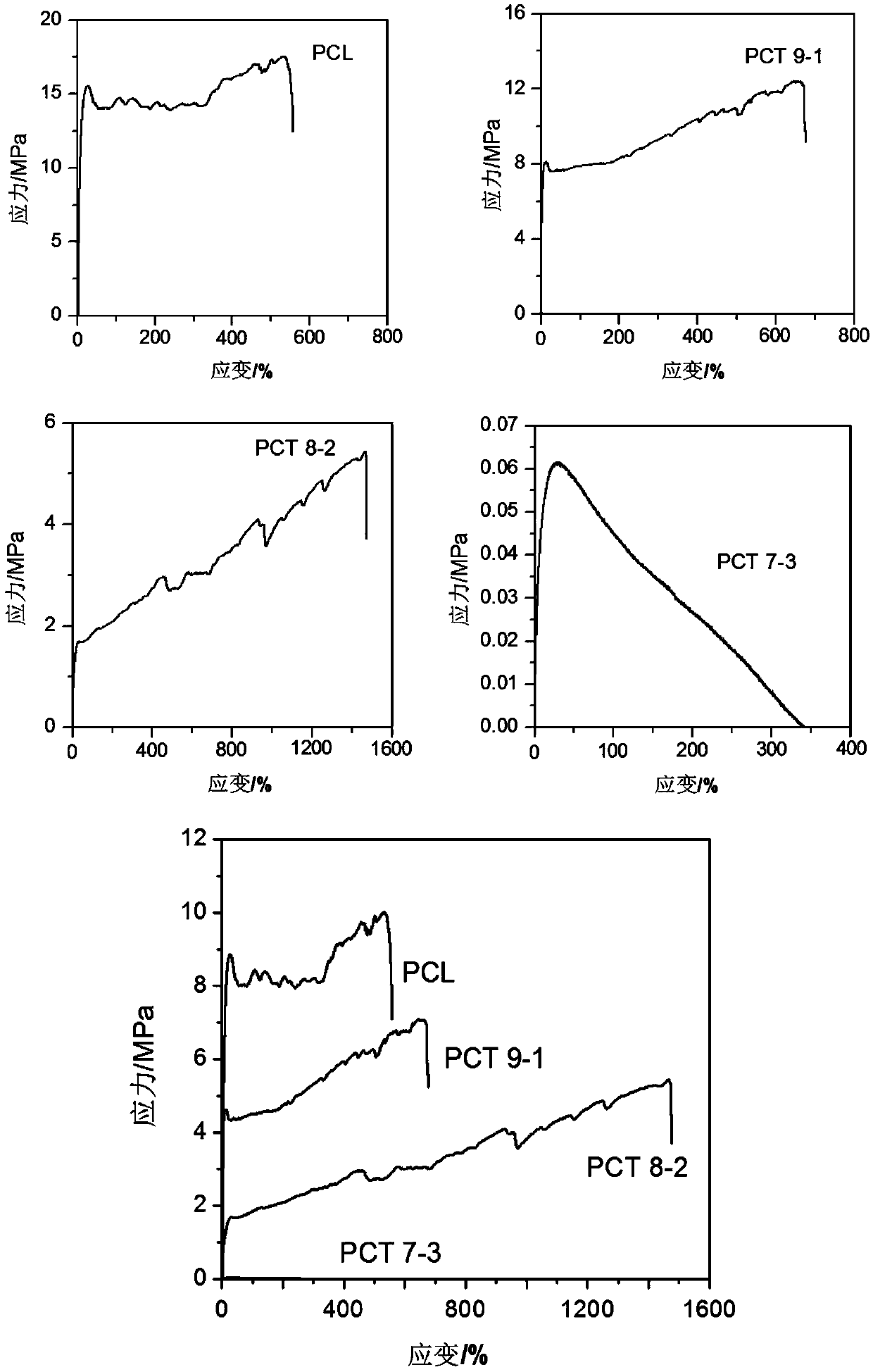

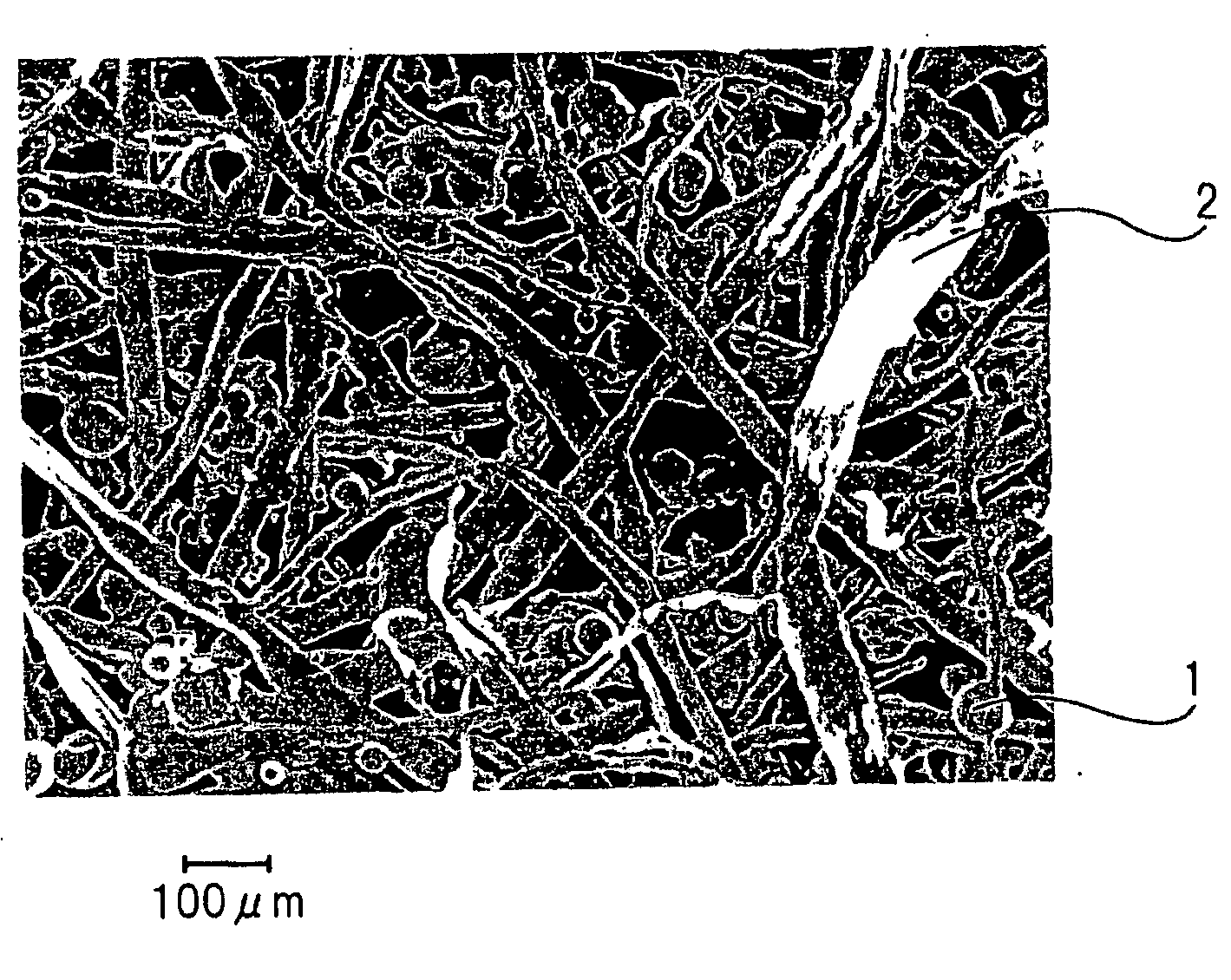

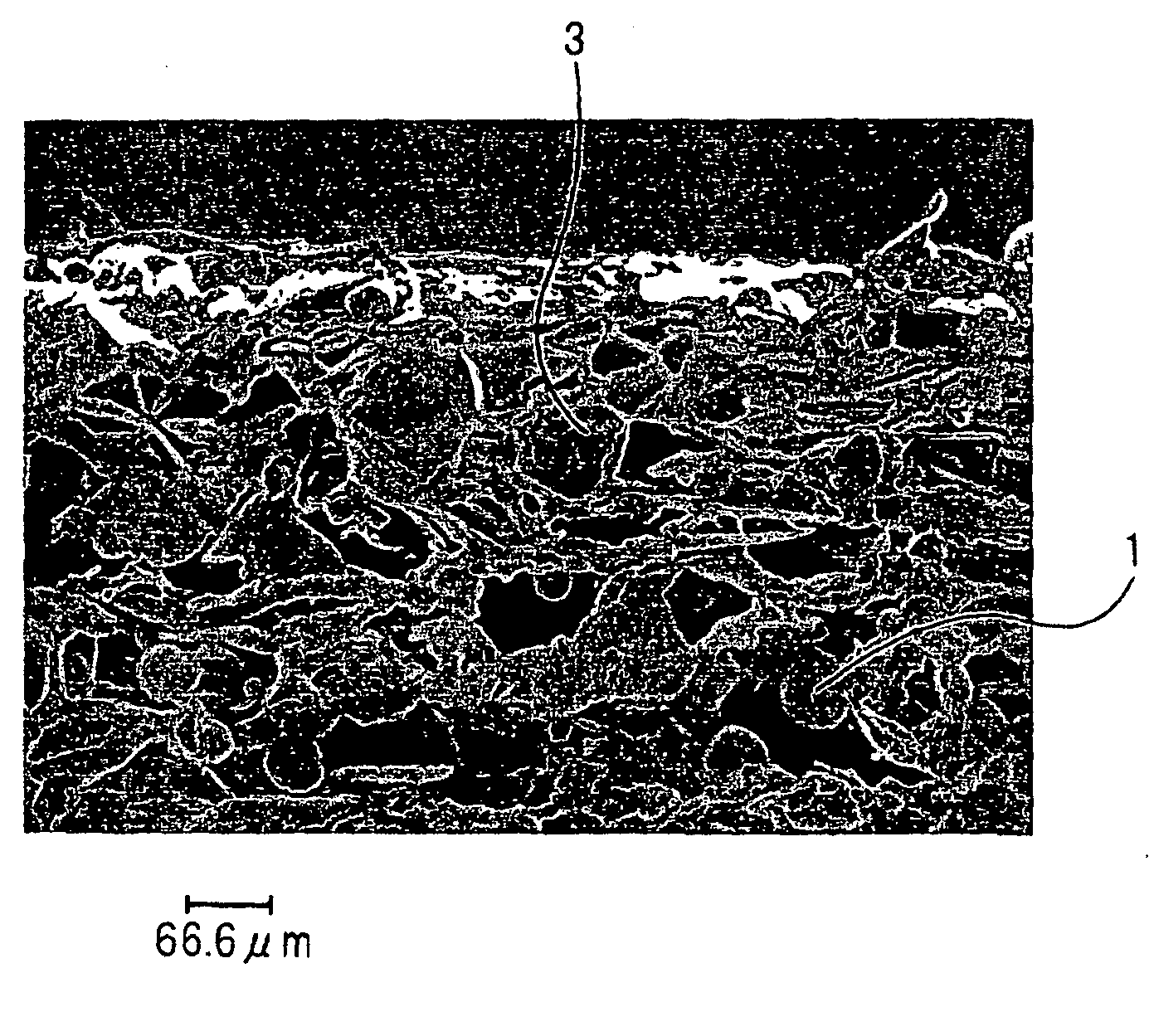

Preparation and application of linear biodegradable polyester elastomer with controllable elasticity and shape memory effect

InactiveCN105504248AMeet biomechanical needsHigh viscoelasticitySuture equipmentsPharmaceutical delivery mechanismElastomerTissue repair

The invention discloses preparation and application of a linear biodegradable polyester elastomer with a controllable elasticity and shape memory effect. The linear biodegradable polyester elastomer with the controllable elasticity and shape memory effect is formed by conducting copolymerization on a caprolactone monomer containing a lateral cyclic ether structural unit and caprolactone, wherein the molar ratio of the caprolactone monomer containing the lateral cyclic ether structural unit to the caprolactone is 5:95-25:75, and the structural formula can be found in description. The viscoelasticity of the linear biodegradable polyester elastomer with the controllable elasticity and shape memory effect is remarkably improved, the elongation at break can reach 1600% and above, the elastomer can be dissolved in a conventional organic solvent, a three-dimensional porous support can be constructed conveniently through a construction technology of the porous support such as, electrostatic spinning, three-dimensional printing and phase separation, tissue engineering blood vessel scaffold materials, myocardial patches, nervous tissue engineering scaffold materials and the like are prepared, and the preparation and application of the linear biodegradable polyester elastomer can be widely applied to the fields of soft tissue engineering scaffolds, tissue repair and regenerative medicine.

Owner:JINAN UNIVERSITY

Absorbent laminated sheet

InactiveCN102573736ASuitable for diffusionImprove diffusivityAbsorbent padsBandagesWrinkle skinEngineering

Owner:UNI CHARM CORP

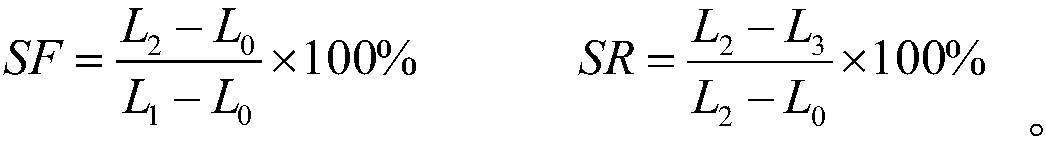

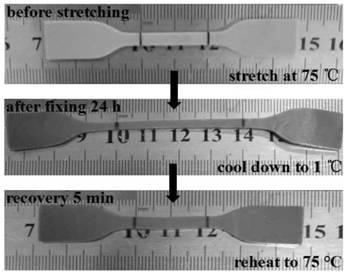

Preparation method of shape memory high polymer material based on thermoplastic vulcanizate

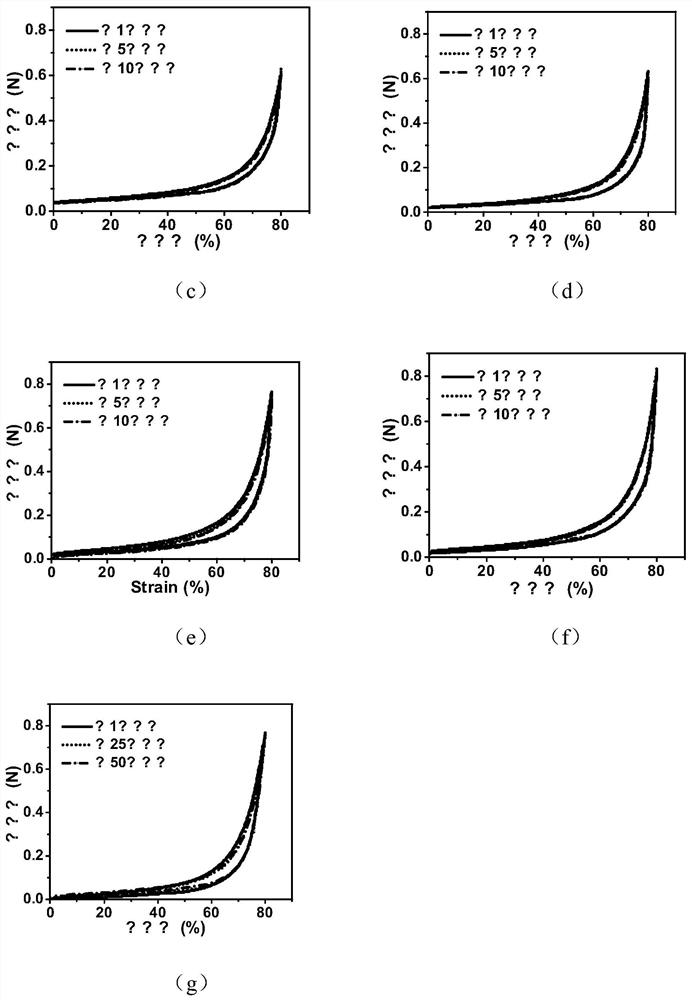

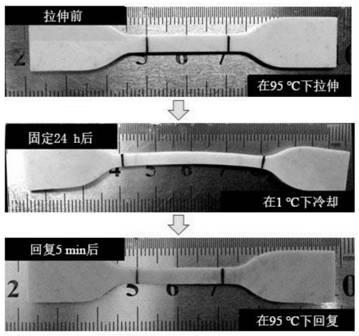

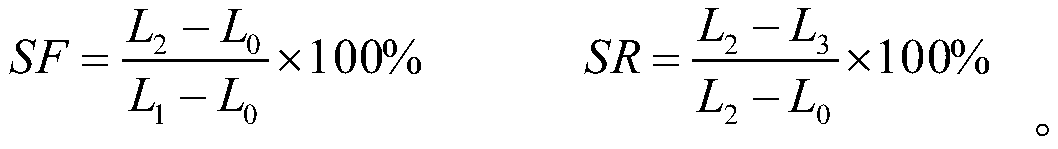

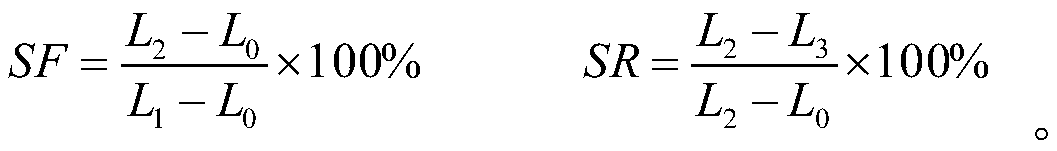

A preparation method of a shape memory high polymer material based on thermoplastic vulcanizate comprises steps as follows: (1) a sample of ethylene-vinyl acetate copolymer / nitrile rubber thermoplastic vulcanizate is fixed on a simple tensile fixture and preheated; (2) external force is applied, so that the preheated thermoplastic vulcanizate sample deforms and then is soaked in an ice-water mixture to be set, and the distance between scale marks is recorded; (3) external force is removed, the sample is naturally placed at the room temperature for 24 hr, and the distance between scale marks isrecorded; (4) the thermoplastic vulcanizate sample in (3) is put in a heating temperature, and the distance between scale marks is recorded; (5) the SF (shape fixed rate) and the SR (shape recovery rate) of the thermoplastic vulcanizate are calculated. The prepared shape memory high polymer material based on thermoplastic vulcanizate has the advantages of being low in hardness, good in flexibility, easy to form, recyclable and low in switch temperature and is expected to be applied to sensors and self-assembly equipment.

Owner:QINGDAO UNIV OF SCI & TECH

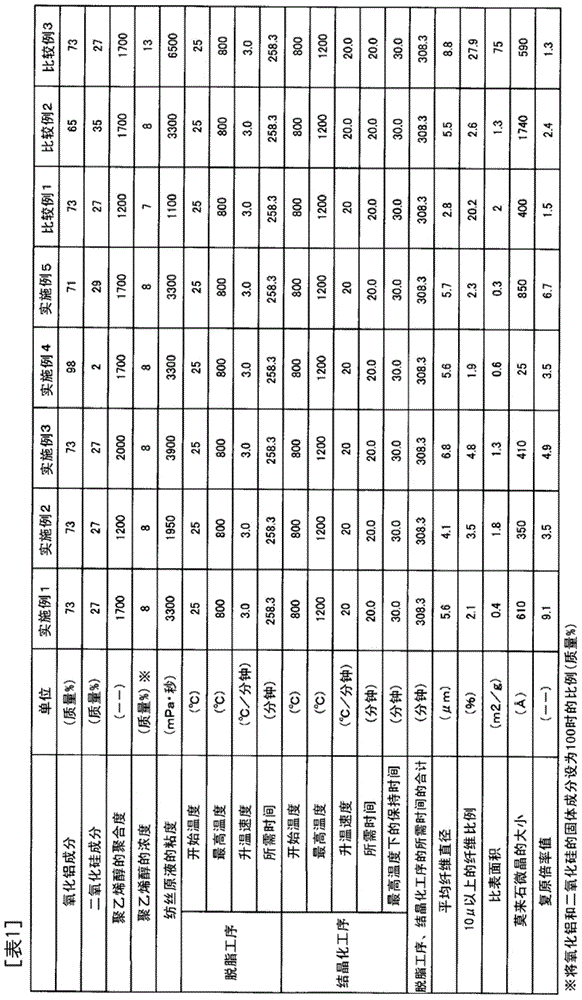

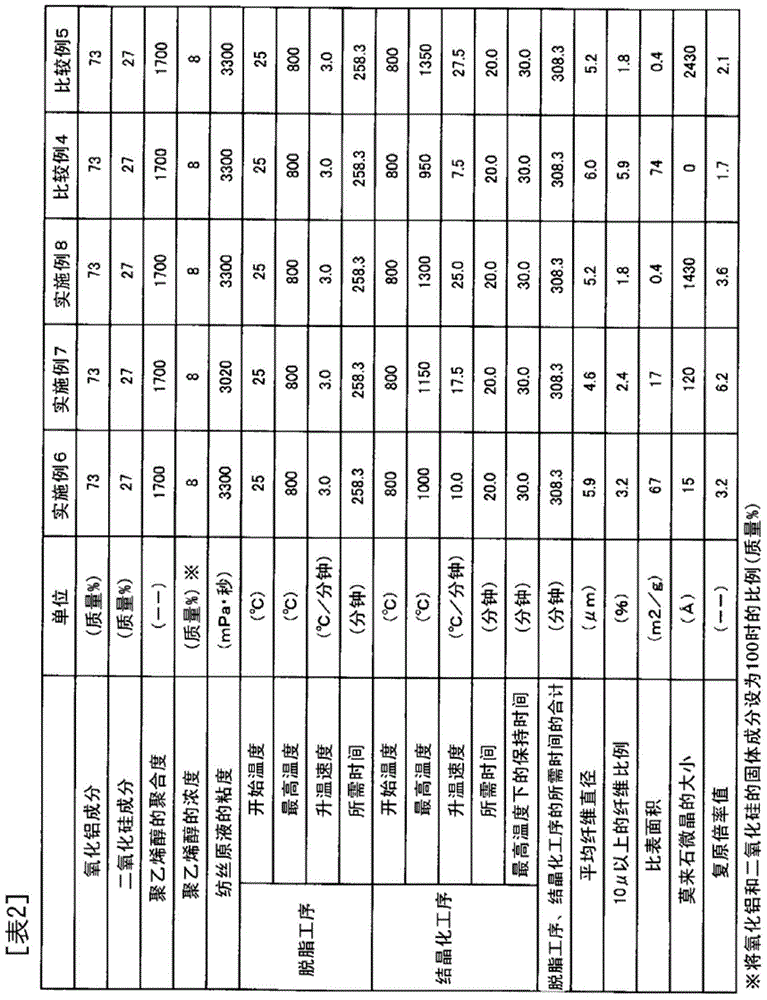

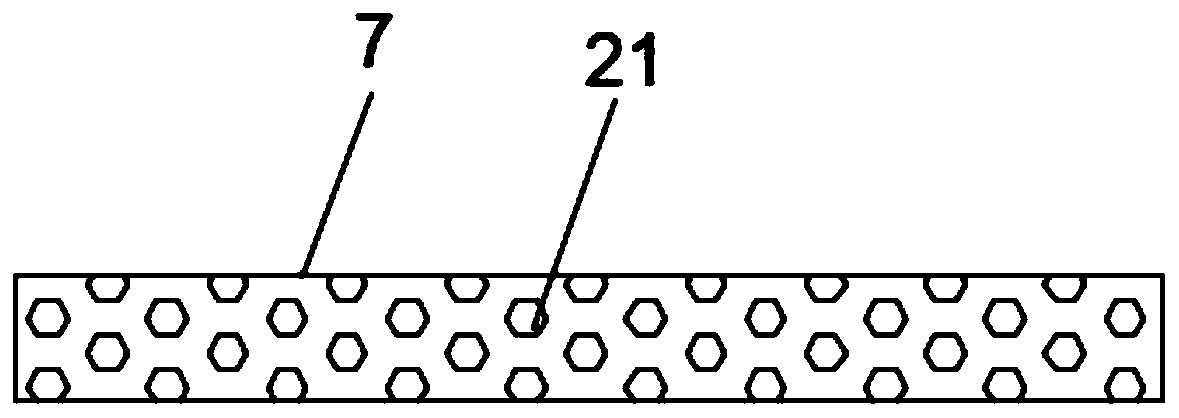

Alumina fiber and alumina fiber aggregate

InactiveCN105051272AGood shape recoveryStay flexibleInorganic material artificial filamentsNon-woven fabricsHoneycombMullite

The purpose of the present invention is to provide an alumina fiber, and an alumina fiber aggregate constituted from such fiber, that even in harsh usage environments maintains elasticity over long periods of time and can secure a honeycomb carrier. The alumina fiber has an alumina content of 70%-98% by mass, a silica content of 2%-30% by mass, an average fiber diameter of 3.0-8.0 µm or less, and a ratio of fibers with fiber diameters exceeding 10 µm of 5% or less in terms of number of fibers. The size of mullite crystallites contained in each fiber is 10-1500 Å. By using such fibers to form the alumina fiber aggregate, problems with a retainer material for a honeycomb carrier for an automobile are solved.

Owner:DENKA CO LTD

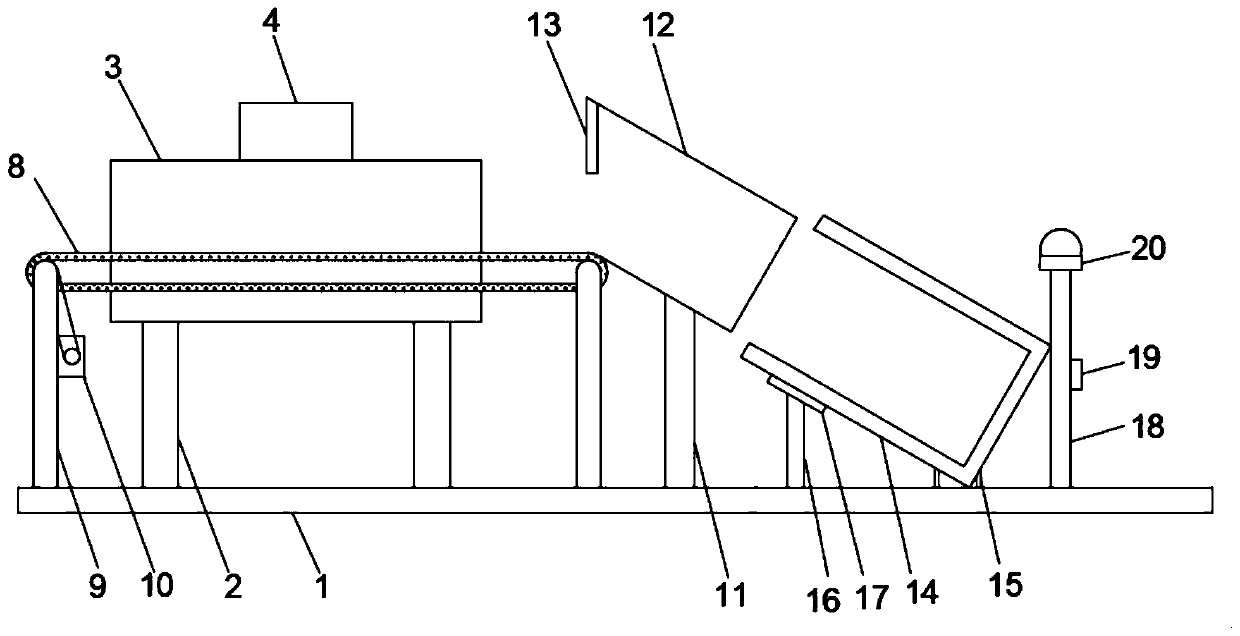

Food plastic packaging barrel molding and blanking mechanism

PendingCN111056328AGood shape recoveryFully contactedConveyorsControl devices for conveyorsCold airPlastic packaging

The invention discloses a food plastic packaging barrel molding and blanking mechanism. The mechanism comprises a mounting base, a cooling channel is arranged above the mounting base, and an air cooler is arranged on the cooling channel; a conveyor belt device is horizontally arranged in the cooling channel in a penetrating mode, a vertical blocking piece is installed on the upper edge at the upper end of a guide channel, an obliquely-placed collecting box is arranged on one side at the lower end of the guide channel, and a vibration counter and an alarm are installed on a limiting baffle. According to the invention, plastic packaging barrels can be cooled in the cooling channel before cartonning to ensure a good molding recovery state, cold air in the refrigeration channel forms a circulating state and is in full contact with the surfaces of the plastic packaging barrels, so that the cooling efficiency is greatly improved; the plastic packaging barrels are laid down through the blocking piece, and sequentially falls into the obliquely-arranged collecting box along the guide channel and are stacked in sequence, full box monitoring is conducted through the vibration counter and thealarm, the operation is easy, the falling and cartonning efficiency is high, manpower is saved, and the working efficiency is improved.

Owner:界首市佳宝包装材料有限公司

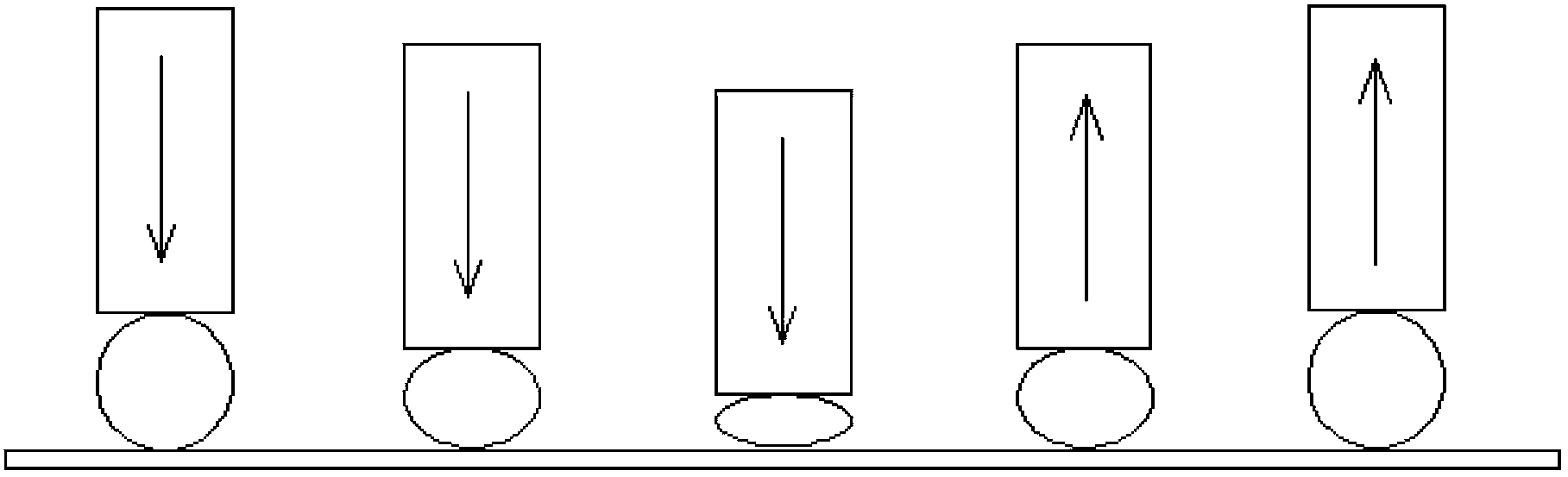

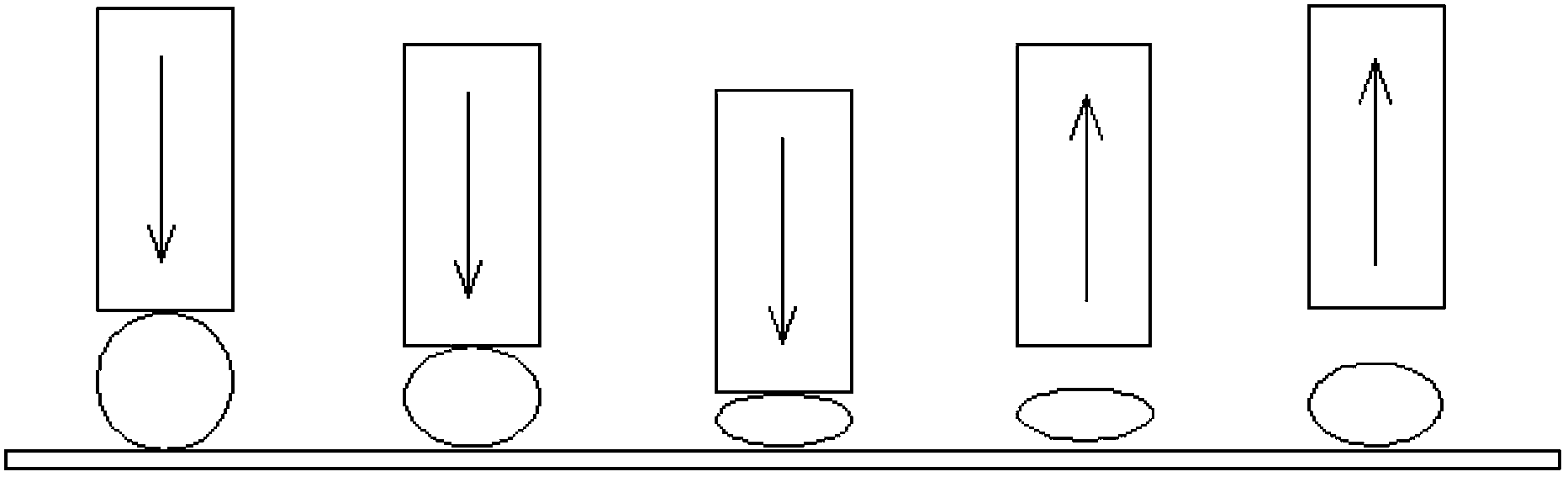

Biodegradable cryogel dressing as well as preparation method and application thereof

ActiveCN111905144AGood shape fixationExcellent shape recovery performanceAntibacterial agentsAerosol deliveryChemical compoundBiocompatibility

The invention discloses a biodegradable cryogel dressing as well as a preparation method and application thereof, and belongs to the technical field of biomedical materials. Amino compounds are selected as main components, and the selected amino compounds have good biocompatibility and can be degraded in organisms. Therefore, the amidation reaction of amino and carboxyl in the amino compound is catalyzed by EDC hydrochloride and NHS to form a basic network structure of the cryogel. The cryogel dressing is holes communicating with each other in a free state, compared with the cryogel dressing in a shape free state, the cryogel dressing in a shape fixed state is a collapsed and closed hole, but a cryogel dressing sample still keeps an undamaged network structure. The preparation method disclosed by the invention is simple and low in cost, the biodegradable cryogel dressing is easy to carry and biodegradable, and the prepared cryogel dressing can be used for quickly stopping bleeding andhas huge potential in serving as a novel hemostatic for promoting wound healing.

Owner:XI AN JIAOTONG UNIV

Preparation method for shape memory material based on thermoplastic vulcanized rubber

InactiveCN110308053AStrong adhesionImprove toughnessMaterial strength using tensile/compressive forcesIce waterPolymer science

The invention relates to a preparation method for a shape memory material based on thermoplastic vulcanized rubber. The preparation method comprises the following steps: (1) fixing a sample strip of ethylene-acrylic acid copolymer / chloroprene rubber blended type thermoplastic vulcanized rubber on a simple stretching clamp, and then preheating the sample strip; (2) applying external force to enablethe preheated sample strip of the thermoplastic vulcanized rubber to deform, afterwards, quickly immersing the sample strip in an ice water mixture for shaping, and recording the distance between scale lines; (3) removing the external force, naturally standing for 24 hours at the room temperature, and recording the distance between the scale lines; (4) arranging the thermoplastic vulcanized rubber in the step (3) in a heating environment, and recording the distance between the scale lines; and (5) calculating the shape fixed rate (SF) and the deformation recovery rate (SR) of the thermoplastic vulcanized rubber. The shape memory material based on the thermoplastic vulcanized rubber prepared by the invention has the advantages of being low in hardness, good in flexibility, easy to shape, recyclable and low in switch temperature and is expected to be applied to sensors and self-assembly equipment.

Owner:QINGDAO UNIV OF SCI & TECH

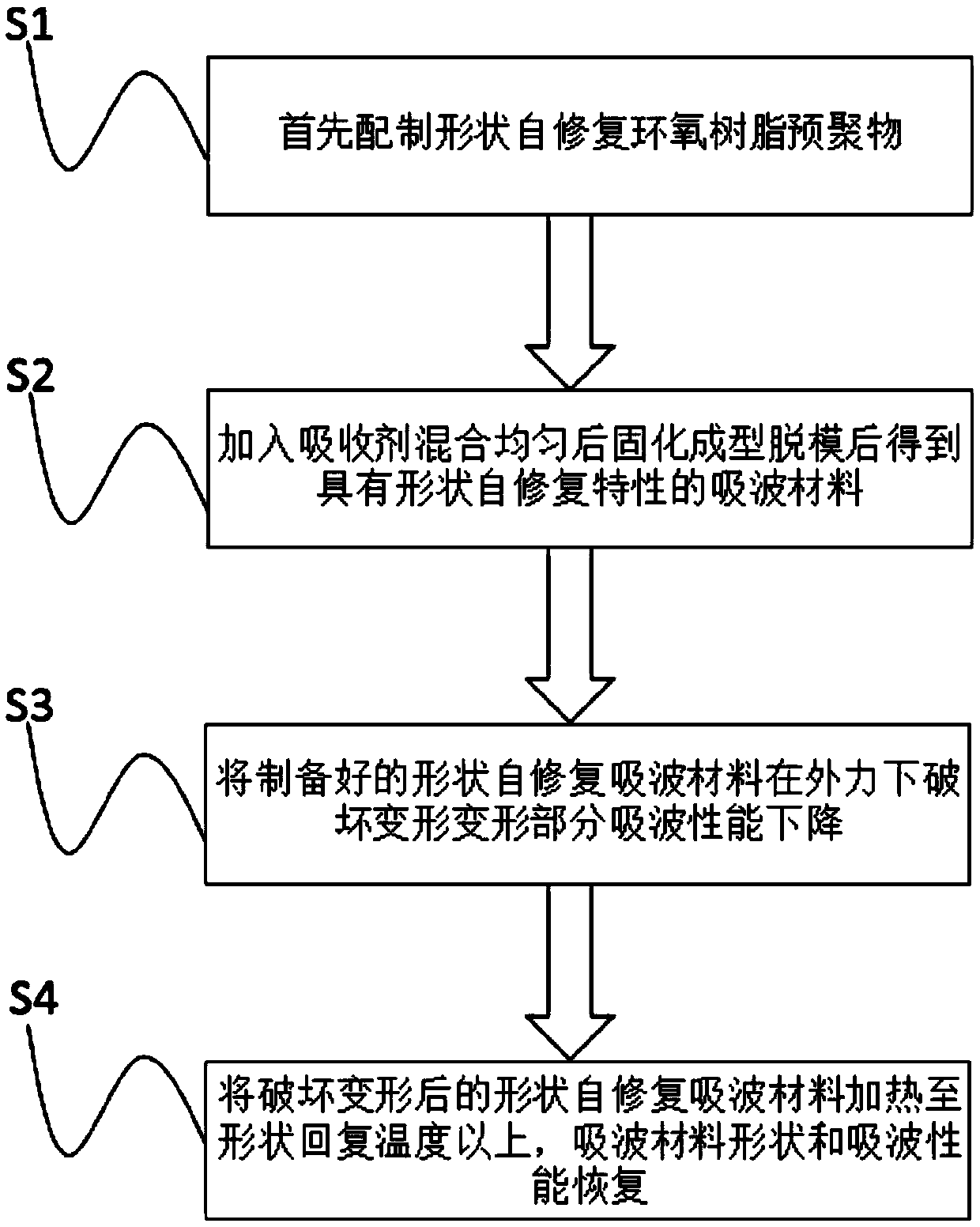

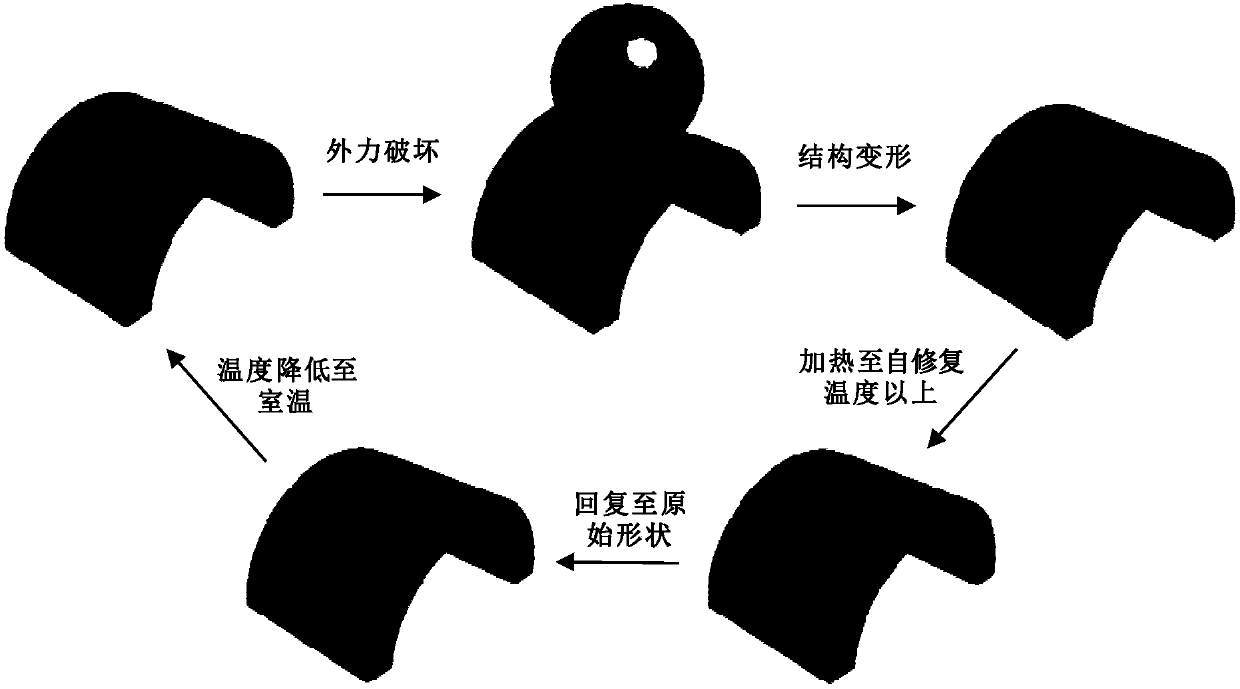

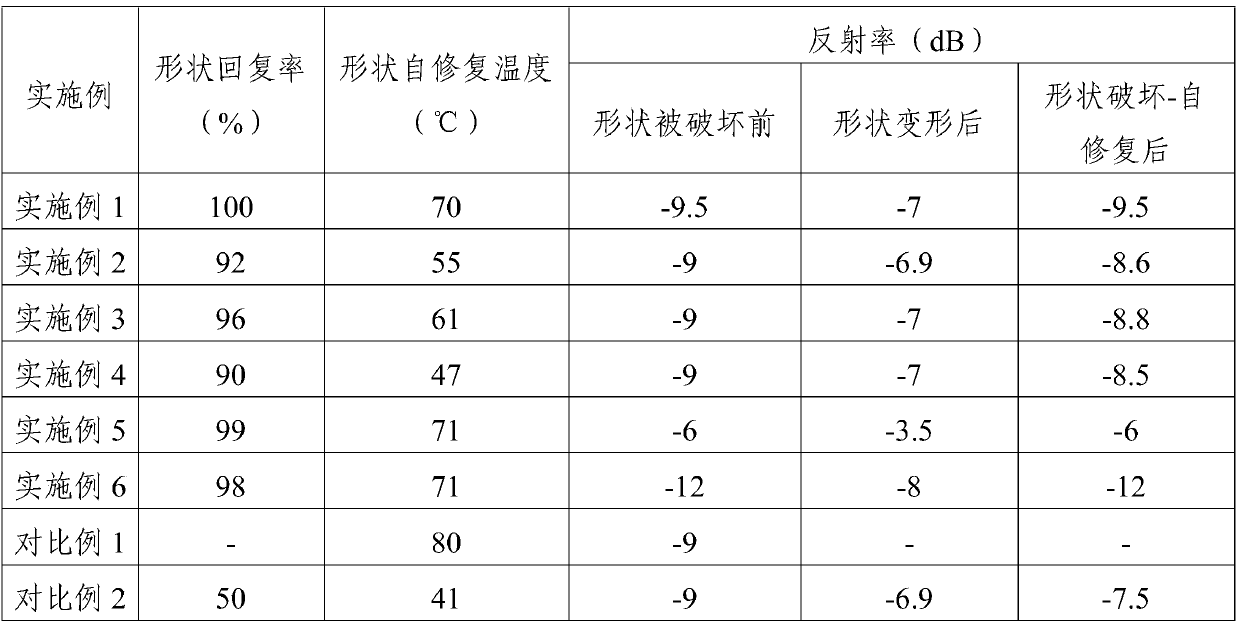

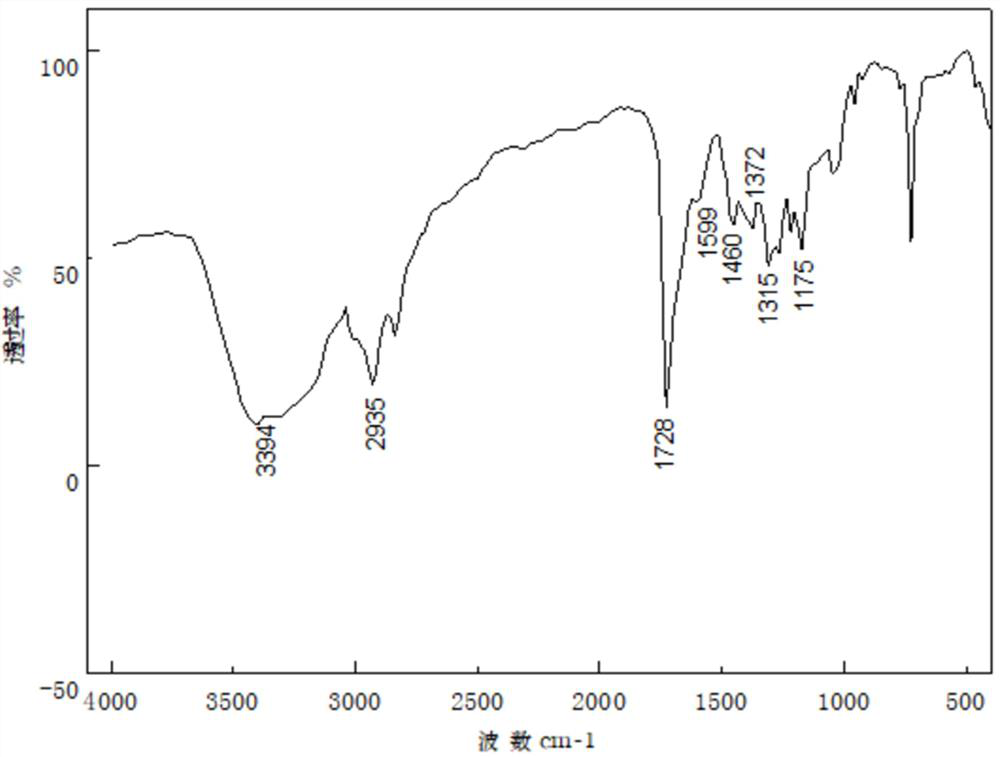

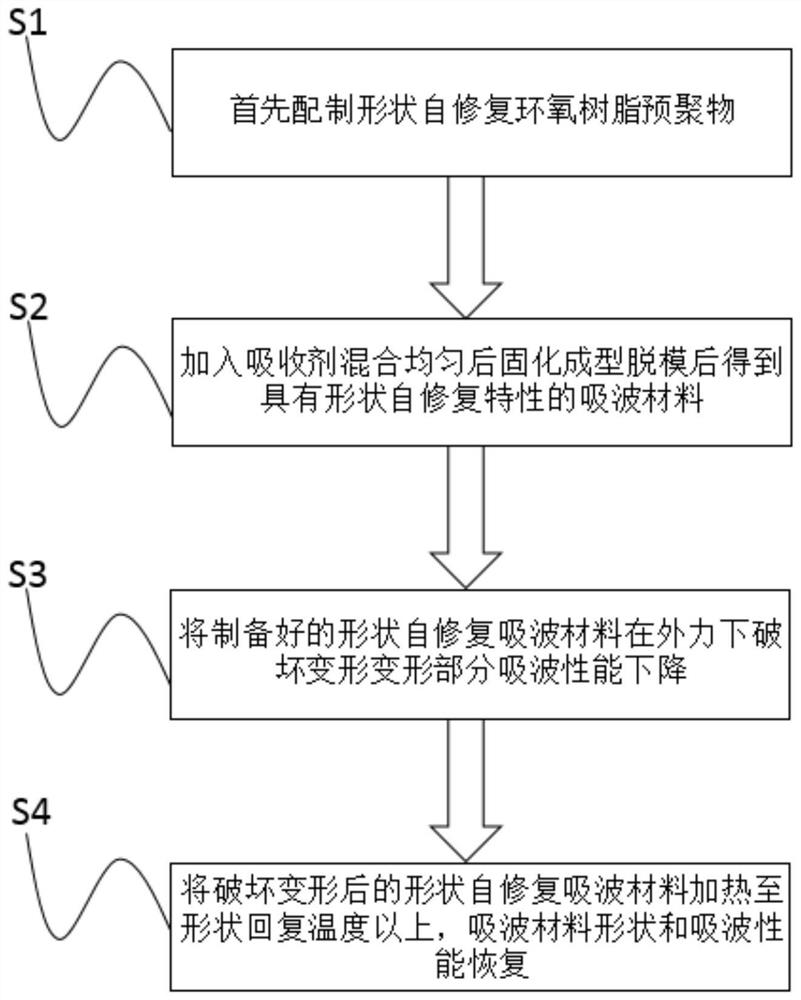

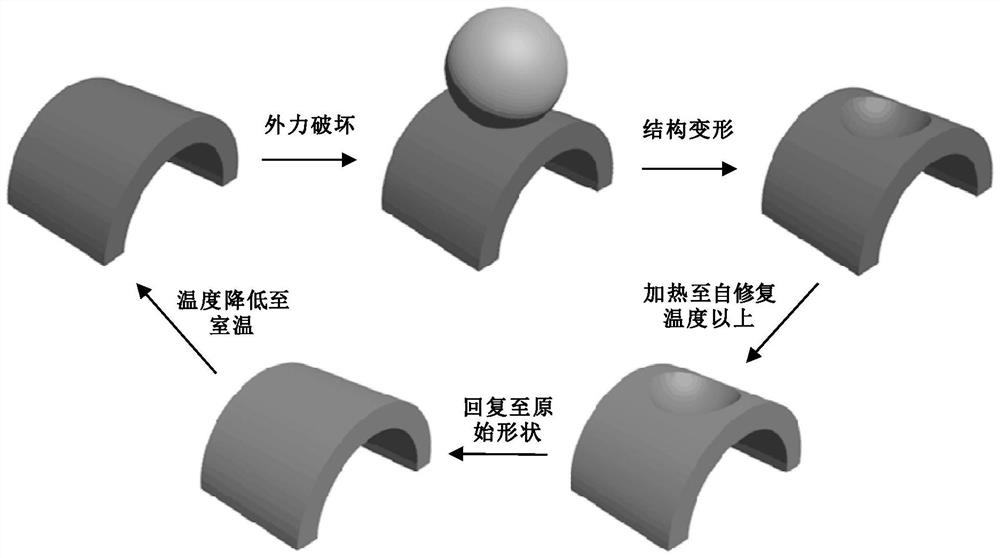

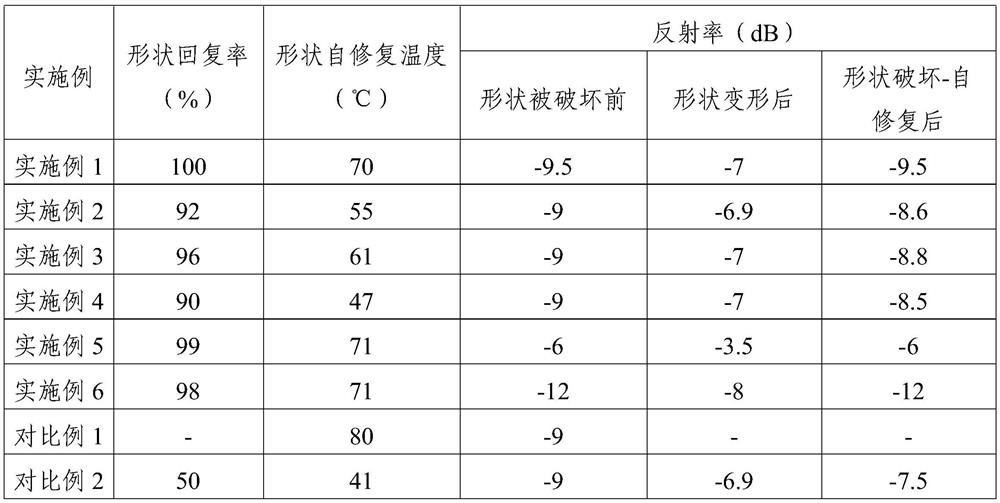

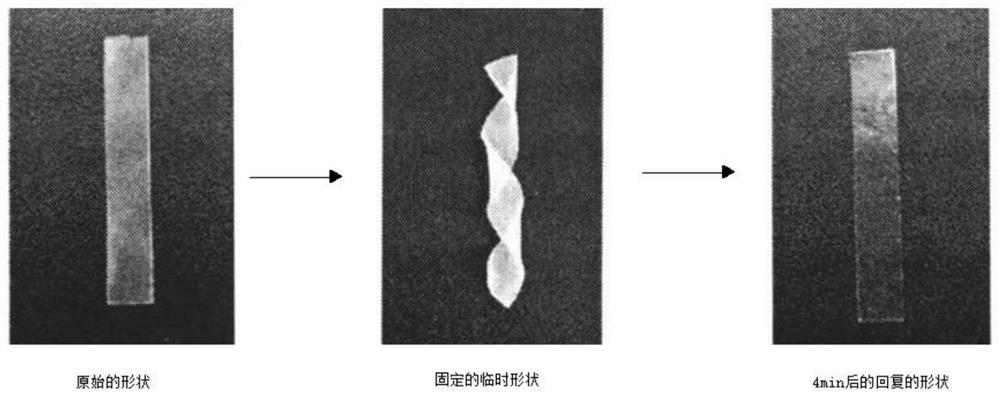

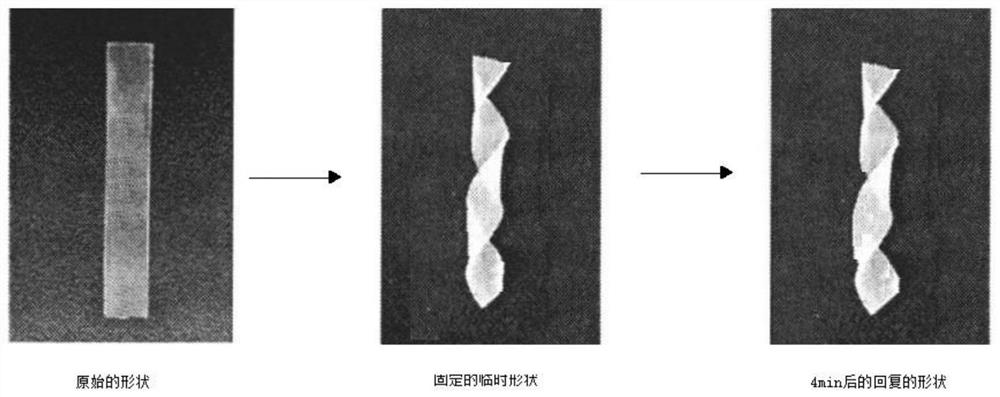

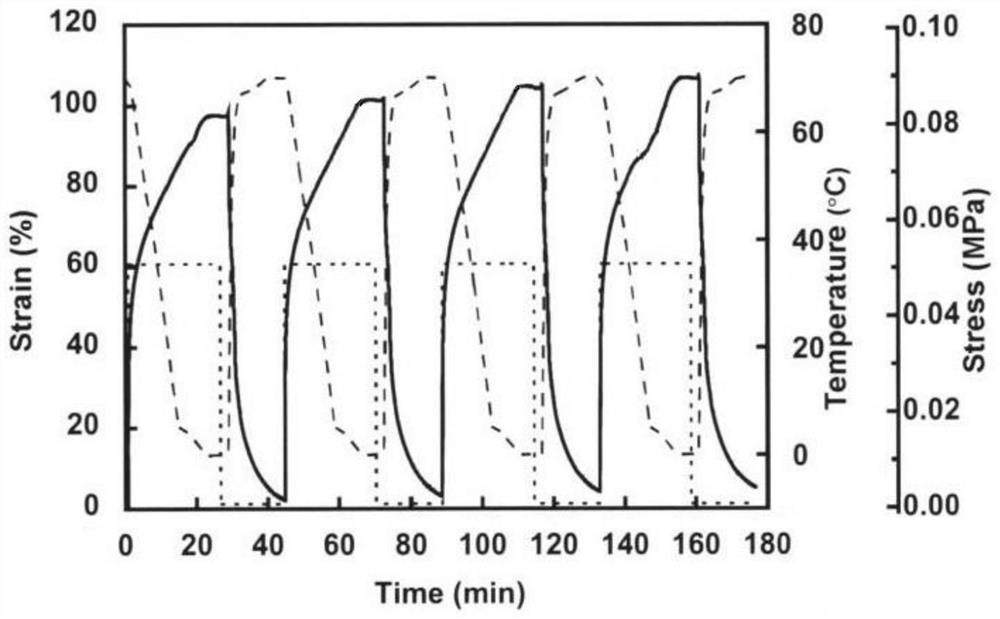

Shape self-repairing wave-absorbing material and preparation method thereof

ActiveCN109666262AShape self-healing performance optimizationExcellent shape self-healing performanceEpoxyCarbon fibers

The invention relates to a shape self-repairing wave-absorbing material and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing a resin matrix, a toughening agent and a curing agent of which a mass ratio is 1:(0.02-0.33):(0.01-0.017), to obtain a resin prepolymer, wherein the resin matrix is selected from a group formed by epoxy resin, polyurethane resin, polystyrene resin and polynorbornene resin; (2) adding an absorbent selected from a group formed by ferrite powder, carbonyl iron powder, conducive carbon black, carbon fibers, silico carbide fibers, carbon nano tubes and graphene to the obtained resin prepolymer, and uniformly stirring, to obtain shape self-repairing wave-absorbing resin; and (3) curing the shape self-repairing wave-absorbing resin in more than two different temperature stages, preparing the shape self-repairing wave-absorbing material. The wave-absorbing material is endowed with shape self-repairing performance through the method, and a requirement of wave-absorbing performance recovery can be satisfied after the wave-absorbing material is damaged to be deformed by an external force.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

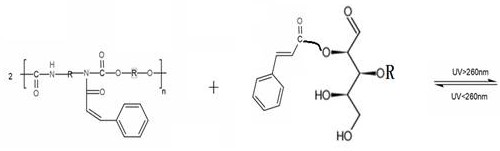

Preparation method of shape-restorable polyurethane material

InactiveCN111848899ATo achieve photoreversible effectGood shape recoveryPolymer sciencePtru catalyst

The invention discloses a preparation method of a shape-restorable polyurethane material. The preparation method comprises the following steps of adding polyol into a reaction kettle, performing heating while stirring, conducting vacuumizing, carrying out reaction for a period of time, then performing cooling, introducing high-purity nitrogen to standard atmospheric pressure, adding isocyanate anda photochemical assistant, performing heating to carry out reaction for a period of time, conducting vacuumizing, and introducing nitrogen to standard atmospheric pressure to obtain a prepolymer reaction solution; uniformly mixing 1, 4-butanediol, diamine and a catalyst, quickly adding the mixture into prepolymer reaction liquid under the protection of nitrogen, performing quick stirring, then pouring the mixture into a Teflon mold, performing pressure curing and demolding when the reaction liquid becomes gel, and performing post-curing on the obtained product, thereby obtaining the shape-restorable polyurethane material. The shape-restorable polyurethane material obtained by the invention can achieve the effects of photoinduced memory shape restoration and thermoinduced memory shape restoration at the same time.

Owner:东阳市前途工业设计有限公司

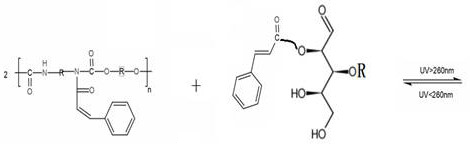

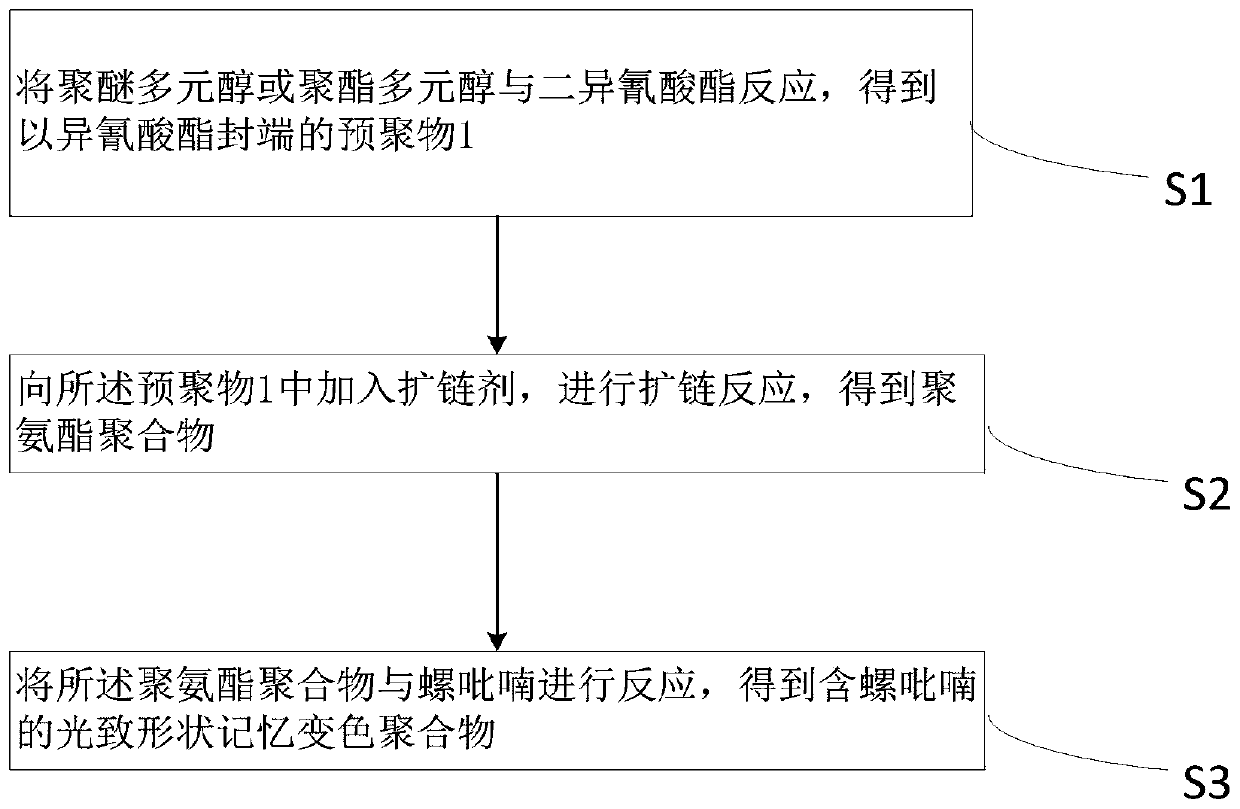

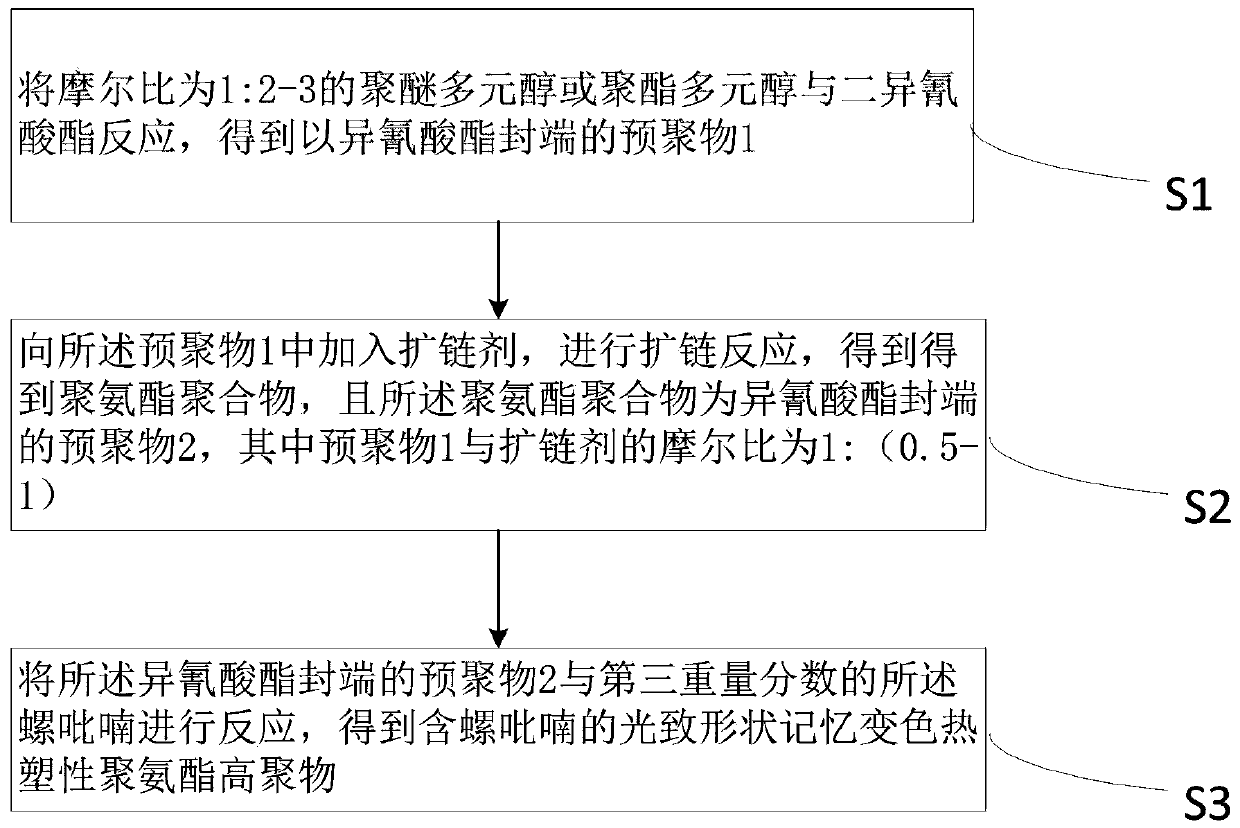

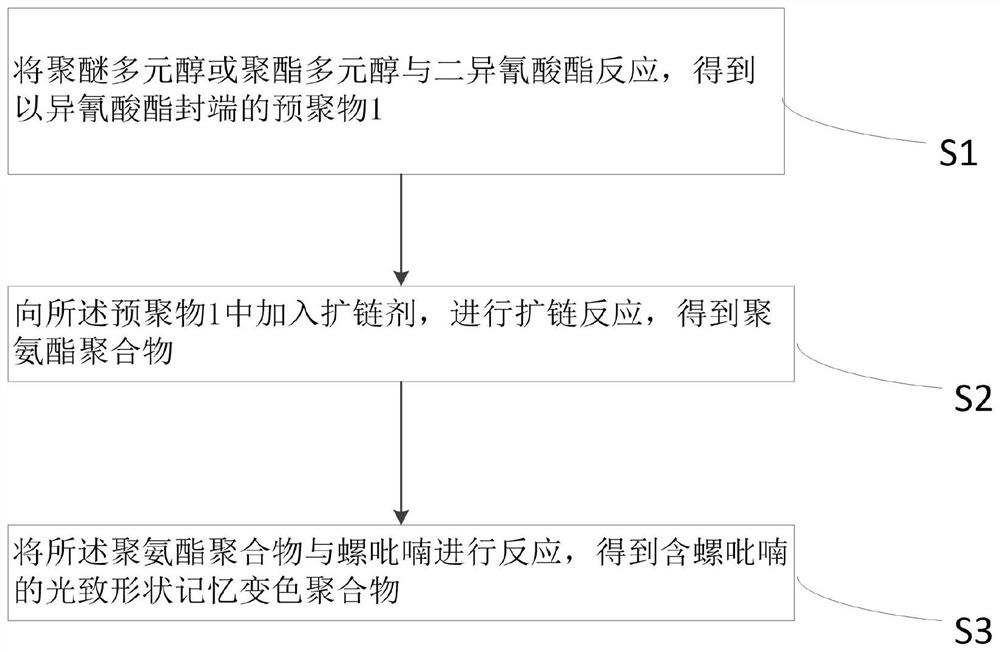

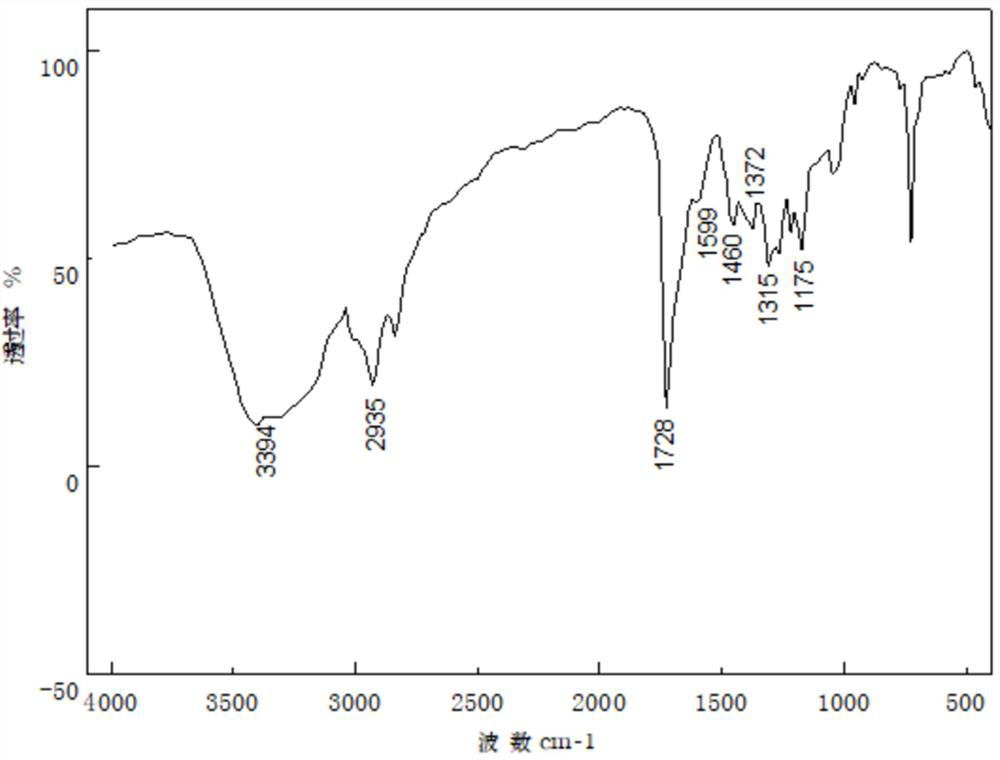

Spiropyrane-containing photoinduced shape memory discoloration polymer and preparation method thereof

ActiveCN111269384AGood shape fixationPhotoplasticizing effectTenebresent compositionsPrepolymerPolyester

The invention provides a spiropyrane-containing photoinduced shape memory discoloration polymer and a preparation method thereof, and belongs to the technical field of functional polymer preparation.The preparation method of the spiropyrane-containing photoinduced shape memory discoloration polymer comprises the following steps: reacting polyether polyol or polyester polyol with diisocyanate to obtain an isocyanate-terminated prepolymer 1; adding a chain extender into the prepolymer 1, and carrying out a chain extension reaction to obtain a polyurethane polymer; and reacting the polyurethanepolymer with spiropyrane to obtain the spiropyrane-containing photoinduced shape memory discoloration polymer. The spiropyrane-containing photoinduced shape memory discoloration polymer gives consideration to a photoinduced shape memory effect and a photoinduced discoloration effect, i.e., the spiropyrane-containing photoinduced shape memory discoloration polymer has very good shape fixing rate, shape recovery rate and discoloration rate, and can be widely applied to the fields of information storage, counterfeiting prevention, flexible camouflage robots and the like.

Owner:HARBIN INST OF TECH

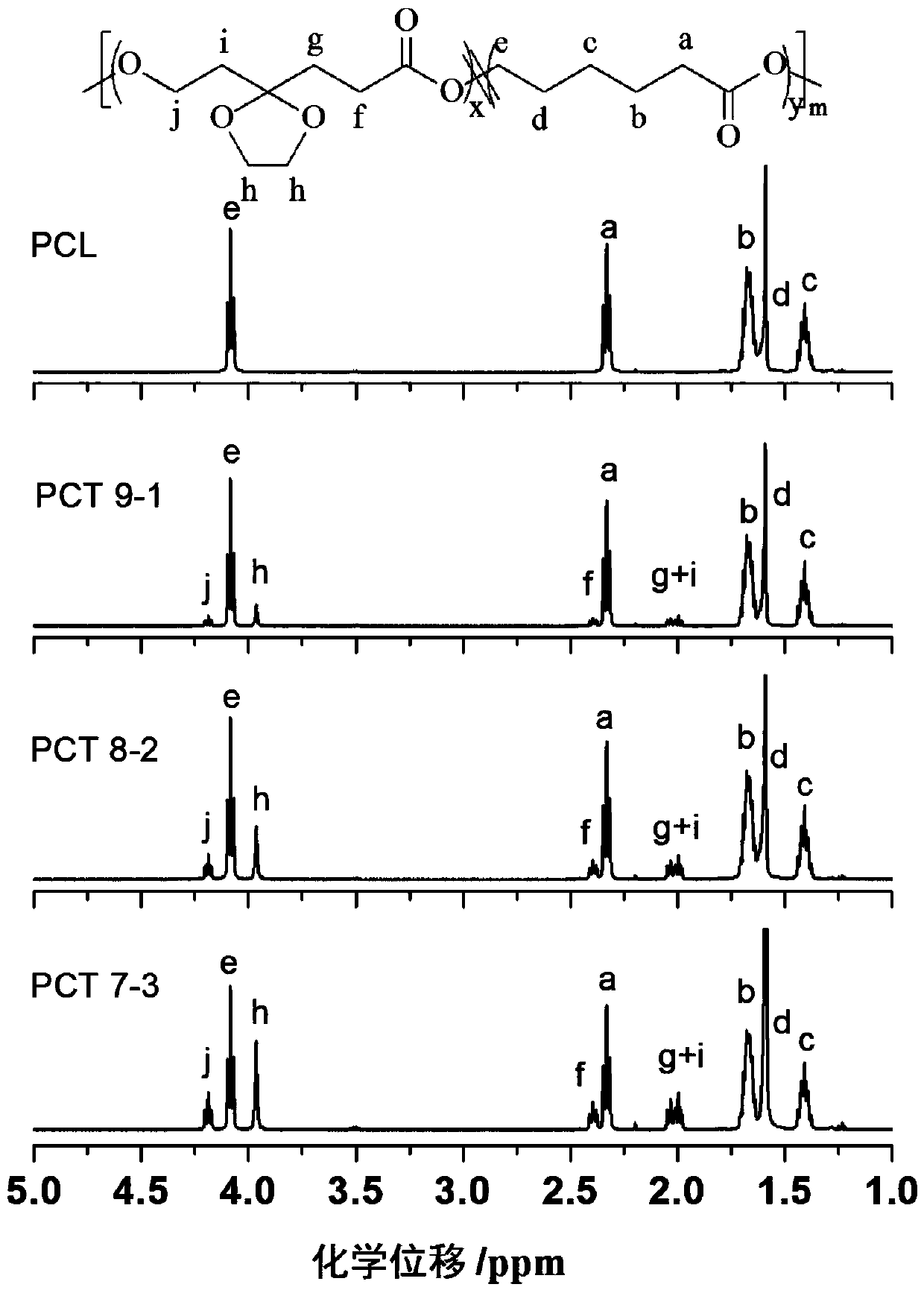

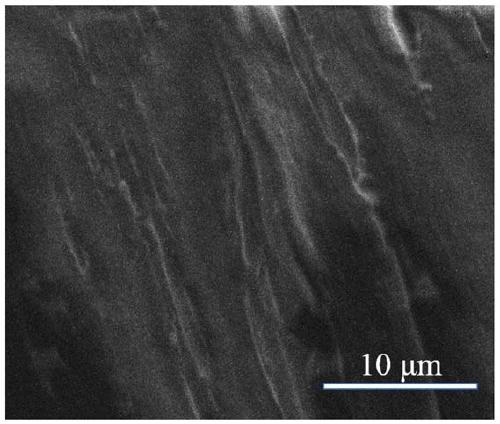

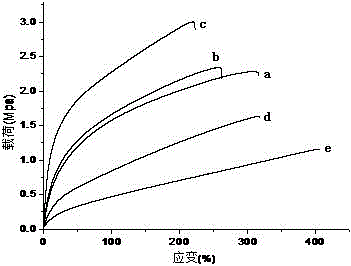

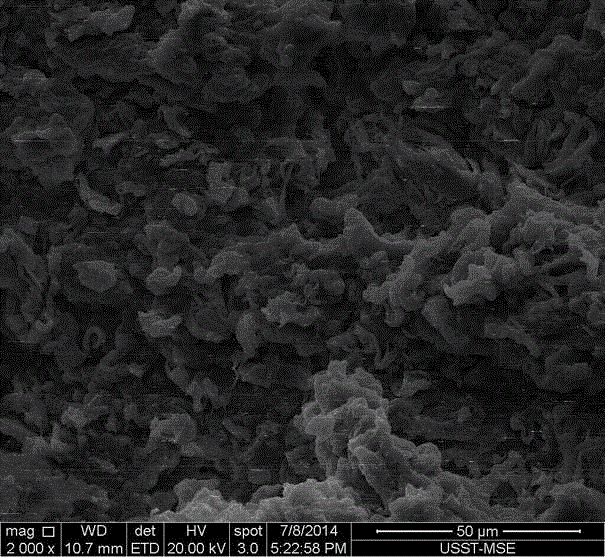

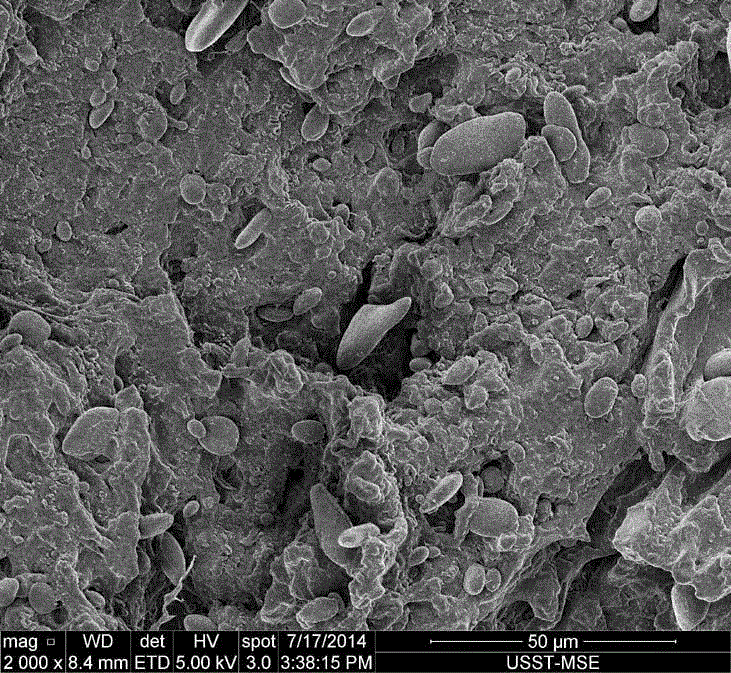

Preparation method of polymer nanocomposite with shape memory

The invention discloses a preparation method of a polymer nanocomposite with shape memory. According to the preparation method, a polystyrene-polyethylene / butane-polystyrene triblock copolymer SEBS is melt-blended with polycaprolactone PCL, and grafted maleic anhydride SEBS-g-MA and nano organic montmorillonite OMMT are added to modify a shape memory polymer composite so as to control the shape memory and deformation restoration capabilities of the polymer nanocomposite. The preparation method comprises the following steps: uniformly mixing the SEBS with extending oil at a mass ratio of 1:1 and placing for 24 h to obtain oil extended SEBS; blending the oil extended SEBS with the polycaprolactone PCL; adding the grafted maleic anhydride SEBS-g-MA and the nano organic montmorillonite OMMT and uniformly stirring to obtain a premixed sample; placing the premixed sample in a banburying chamber of a torque rheometer and carrying out melt-blending at 195 DEG C and 120 rpm for 15 min; and carrying out hot briquetting on the prepared sample in a hot press to obtain the polymer nanocomposite with shape memory. The preparation method provided by the invention is simple; the material has shape memory and favorable restoration rate and can be repeatedly used.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

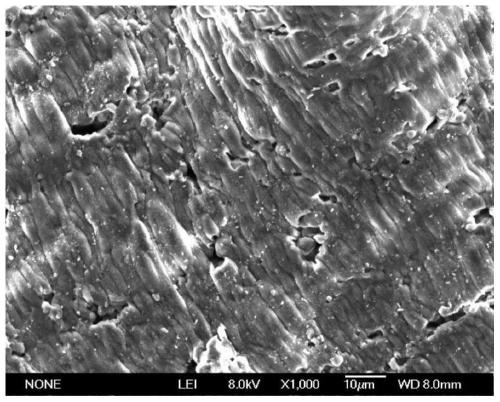

Laser dicing sheet and method for manufacturing chip body

ActiveCN101568994AAvoid damageGood shape recoverySolid-state devicesSemiconductor/solid-state device manufacturingWafer dicingEngineering

The present invention aims to prevent cutting of a dicing sheet, damage to a chuck table and fusion bonding of a dicing sheet to a chuck table by laser light during laser dicing. Specifically disclosed is a laser dicing sheet which is characterized by being composed of a base made of a polyurethane acrylate and an adhesive layer formed on one side of the base.

Owner:LINTEC CORP

A preparation method of shape memory polymer material based on thermoplastic vulcanizate

A preparation method of a shape memory high polymer material based on thermoplastic vulcanizate comprises steps as follows: (1) a sample of ethylene-vinyl acetate copolymer / nitrile rubber thermoplastic vulcanizate is fixed on a simple tensile fixture and preheated; (2) external force is applied, so that the preheated thermoplastic vulcanizate sample deforms and then is soaked in an ice-water mixture to be set, and the distance between scale marks is recorded; (3) external force is removed, the sample is naturally placed at the room temperature for 24 hr, and the distance between scale marks isrecorded; (4) the thermoplastic vulcanizate sample in (3) is put in a heating temperature, and the distance between scale marks is recorded; (5) the SF (shape fixed rate) and the SR (shape recovery rate) of the thermoplastic vulcanizate are calculated. The prepared shape memory high polymer material based on thermoplastic vulcanizate has the advantages of being low in hardness, good in flexibility, easy to form, recyclable and low in switch temperature and is expected to be applied to sensors and self-assembly equipment.

Owner:QINGDAO UNIV OF SCI & TECH

Memory high molecular material and preparation method thereof

The invention relates to a memory polymer material and a preparation method thereof. The memory polymer material comprises the following raw materials in parts by weight: 3-5 parts of rubber powder, 2-5 parts of petroleum ether, 1-6 parts of surfactant, 0.5-5 parts of 1.8 parts of n-butanol, 1-6 parts of acetic acid, 0.8-1.5 parts of sodium stearate, 1-2.5 parts of N-N-dimethylamide DMF, 10-15 parts of 2,4-toluene diethylcyanate, 0.8-2.5 parts of polynorbornene, 0.2-1.5 parts of polycaprolactone, 0.3-1.5 parts of polyethylene wax, 1.8-2.5 parts of maleic anhydride, 0.6-2 parts of silane coupling agent, 0.5-1.5 parts of zinc oxide, 0.7-1.5 parts of silicon oxynitride, 0.7-2.3 parts of epoxidized soybean oil. The memory polymer material of the invention has good thermal stability, elasticity, wear resistance, aging resistance, shape recovery rate and tensile strength.

Owner:桂林市漓江机电制造有限公司

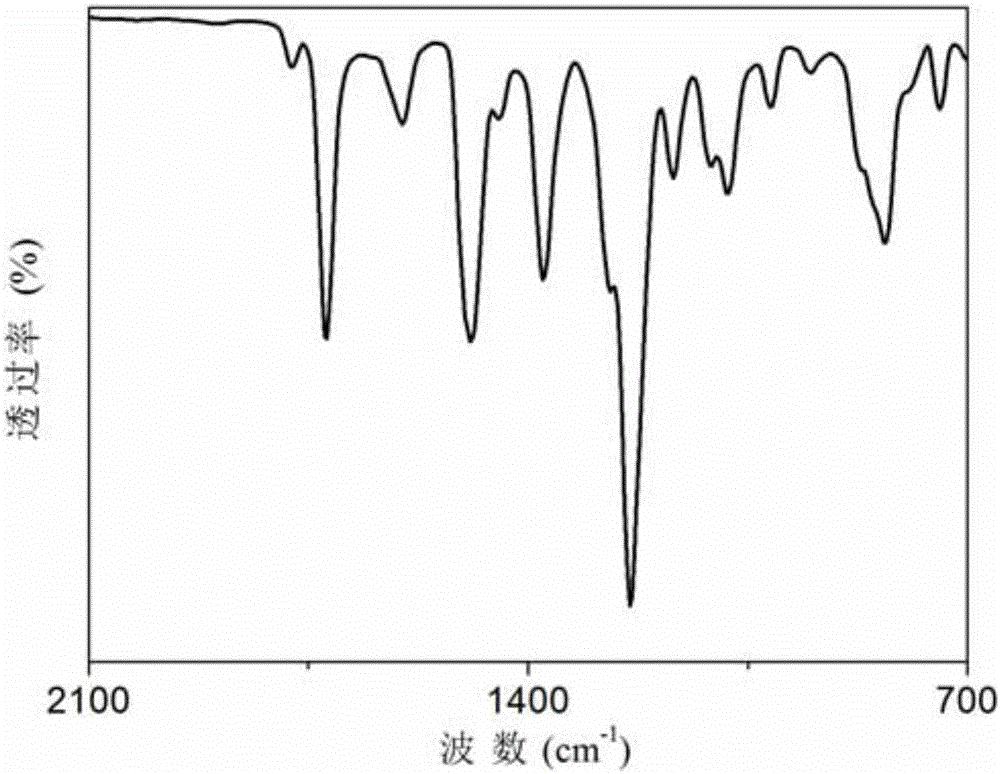

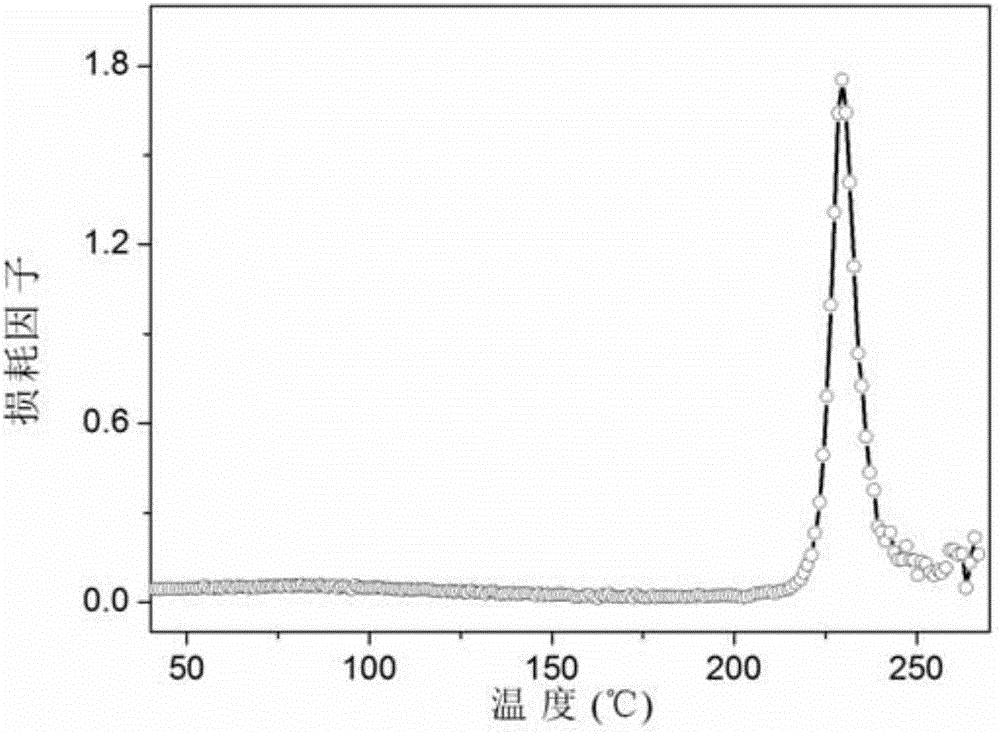

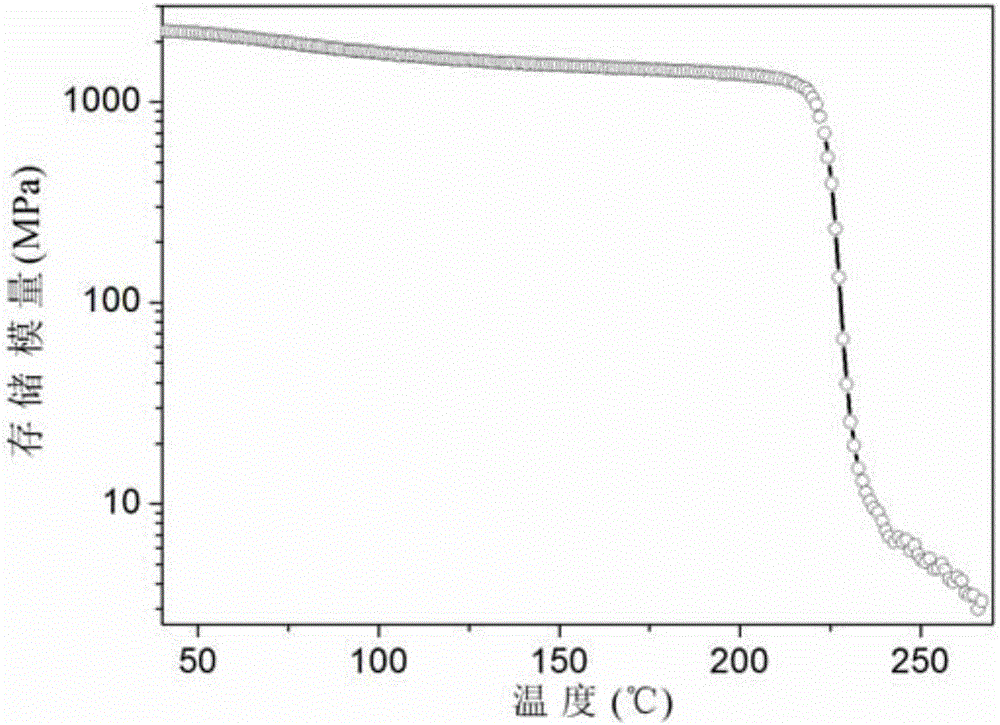

High-temperature-resistant long-service-life shape memory polyimide and preparation method thereof

The invention provides high-temperature-resistant long-service-life shape memory polyimide and a preparation method thereof, and relates to polyimide and a preparation method of the polyimide. The invention aims at solving the problem that no long-service-life shape memory polyimide with the Tg exceeding 230 DEG C and the use times exceeding thousands of times exists in the prior art. The high-temperature-resistant long-service-life shape memory polyimide has a structural formula shown as the accompanying drawing. The preparation method comprises the following steps of 1, preparing a diamine solution; 2, preparing anhydride end sealing molecular weight polyamic acid; 3, preparing bubble-free viscous sol-gel; 4, performing gradient temperature rise to obtain the high-temperature-resistant long-service-life shape memory polyimide. By using the method, the high-temperature-resistant long-service-life shape memory polyimide can be obtained.

Owner:哈尔滨哈船融阳材料科技有限公司

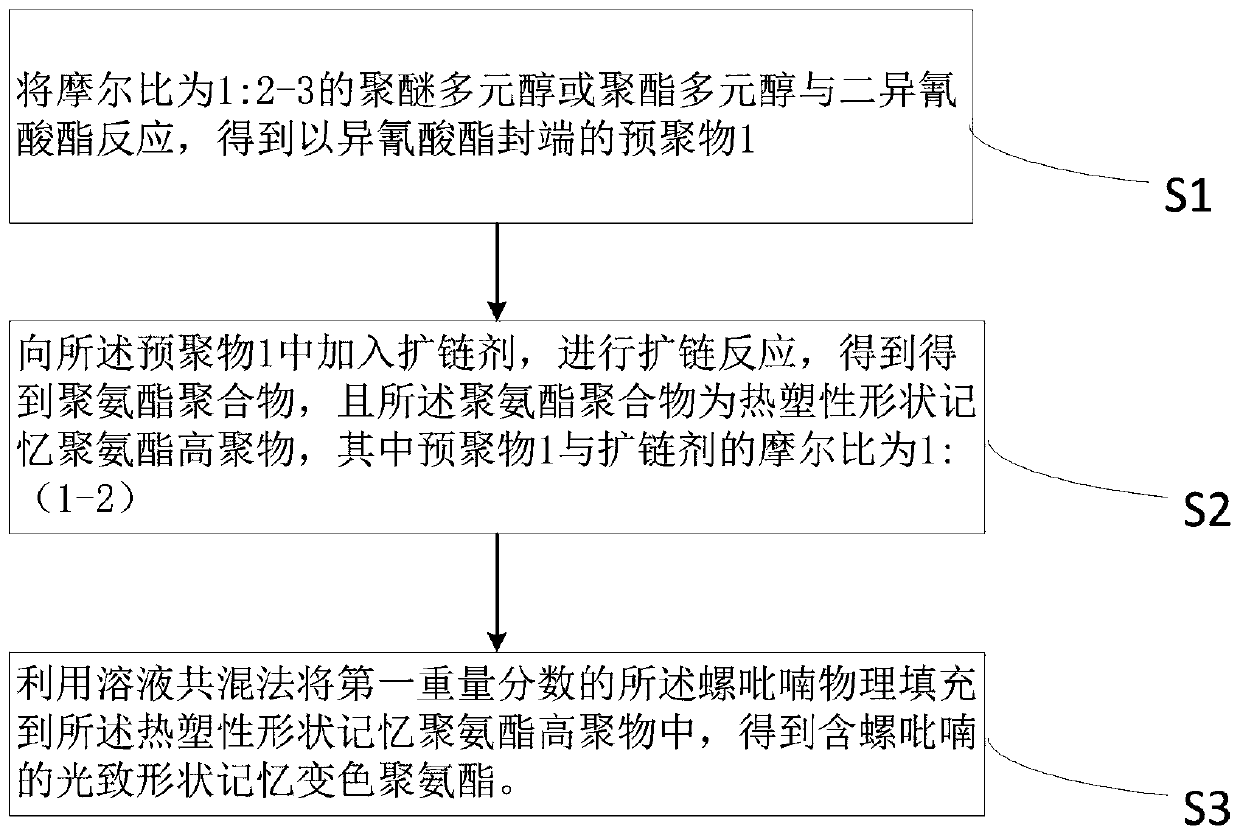

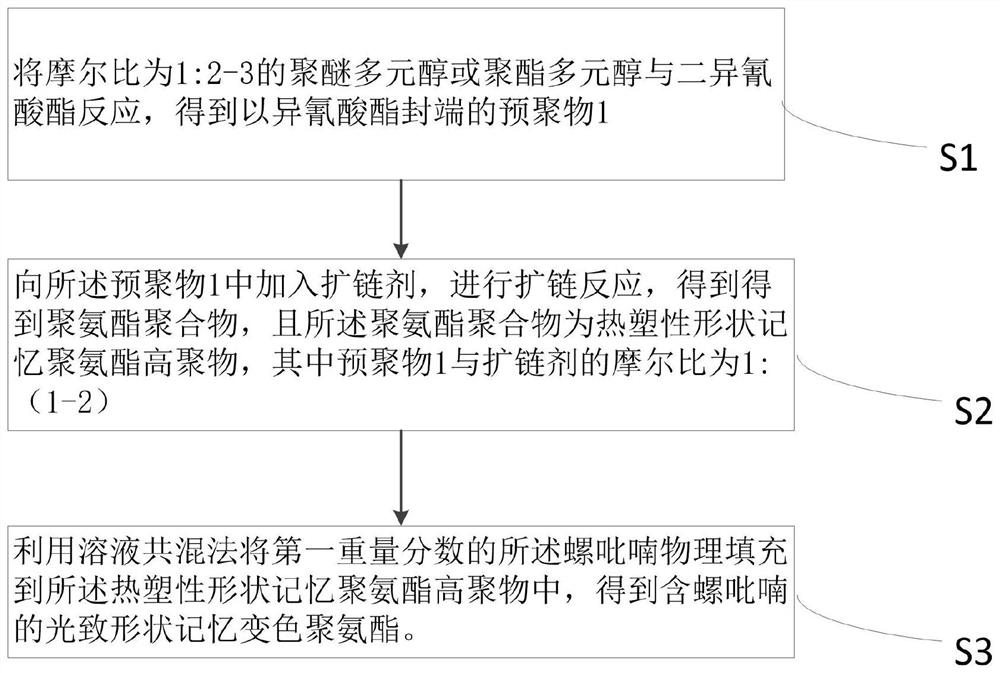

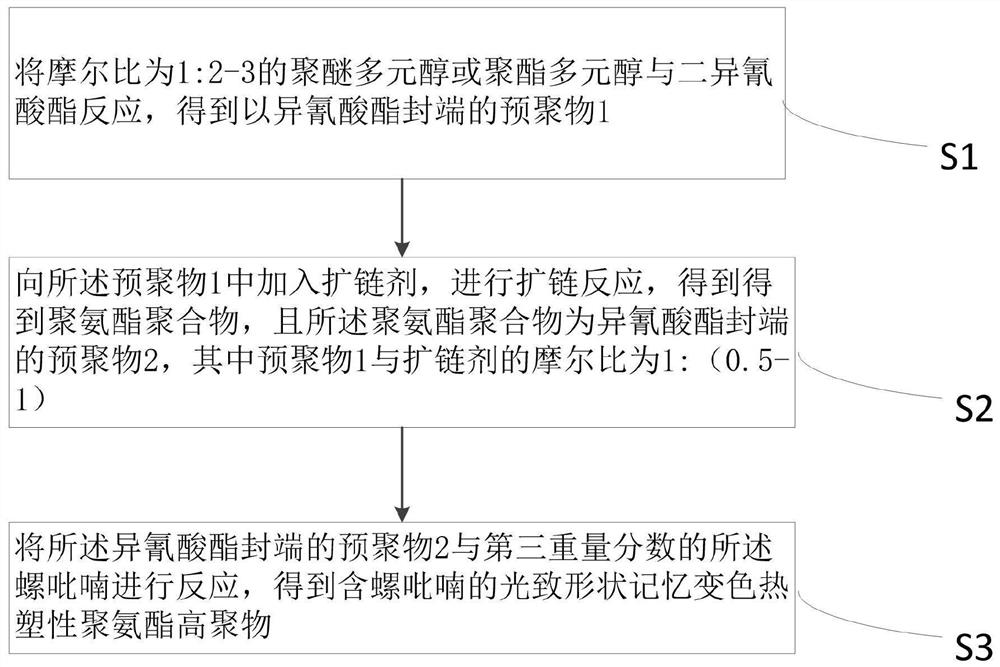

A kind of photoinduced shape memory color changing polymer containing spiropyran and preparation method thereof

ActiveCN111269384BPhotoplasticizing effectRealization of photoplasticizing effectTenebresent compositionsPolyesterPolymer science

The invention provides a spiropyran-containing photo-induced shape memory color-changing polymer and a preparation method thereof, belonging to the technical field of functional polymer preparation. The preparation method of the spiropyran-containing photo-induced shape memory color-changing polymer comprises the following steps: The polyether polyol or polyester polyol is reacted with diisocyanate to obtain a prepolymer 1 terminated with isocyanate; a chain extender is added to the prepolymer 1, and a chain extension reaction is carried out to obtain a polyurethane polymer; The polyurethane polymer reacts with the spiropyran to obtain the photo-induced shape memory color-changing polymer containing the spiropyran. Compared with the prior art, the spiropyran-containing photochromic polymer of the present invention has both the photoinduced shape memory effect and the photochromic effect, that is, the spiropyran-containing photochromic photochromic polymer has excellent performance. The shape fixation rate, shape recovery rate and discoloration rate can be widely used in information storage, anti-counterfeiting, flexible camouflage robots and other fields.

Owner:HARBIN INST OF TECH

Preparation method of unsaturated lignocellulose material for polyurethane shape memory material

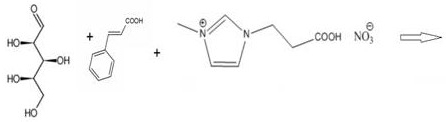

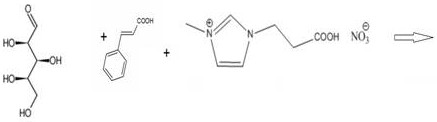

The invention discloses a preparation method of an unsaturated lignocellulose material for a polyurethane shape memory material. The preparation method comprises the following steps of: by mass, uniformly stirring 30-50 parts of lignocellulose, 59-80 parts of cinnamic acid, 5-12 parts of a D001 resin catalyst, 200-320 parts of water and 0.03-0.2 part of 1-carboxyethyl-3-methylimidazole nitrate, controlling the temperature to be 70-80DEG C, conducting stirring for 3-7h, conducting evaporation and drying, and then grinding the mixture into 50-70mesh powder, thus obtaining the unsaturated lignocellulose material.

Owner:东阳市前途工业设计有限公司

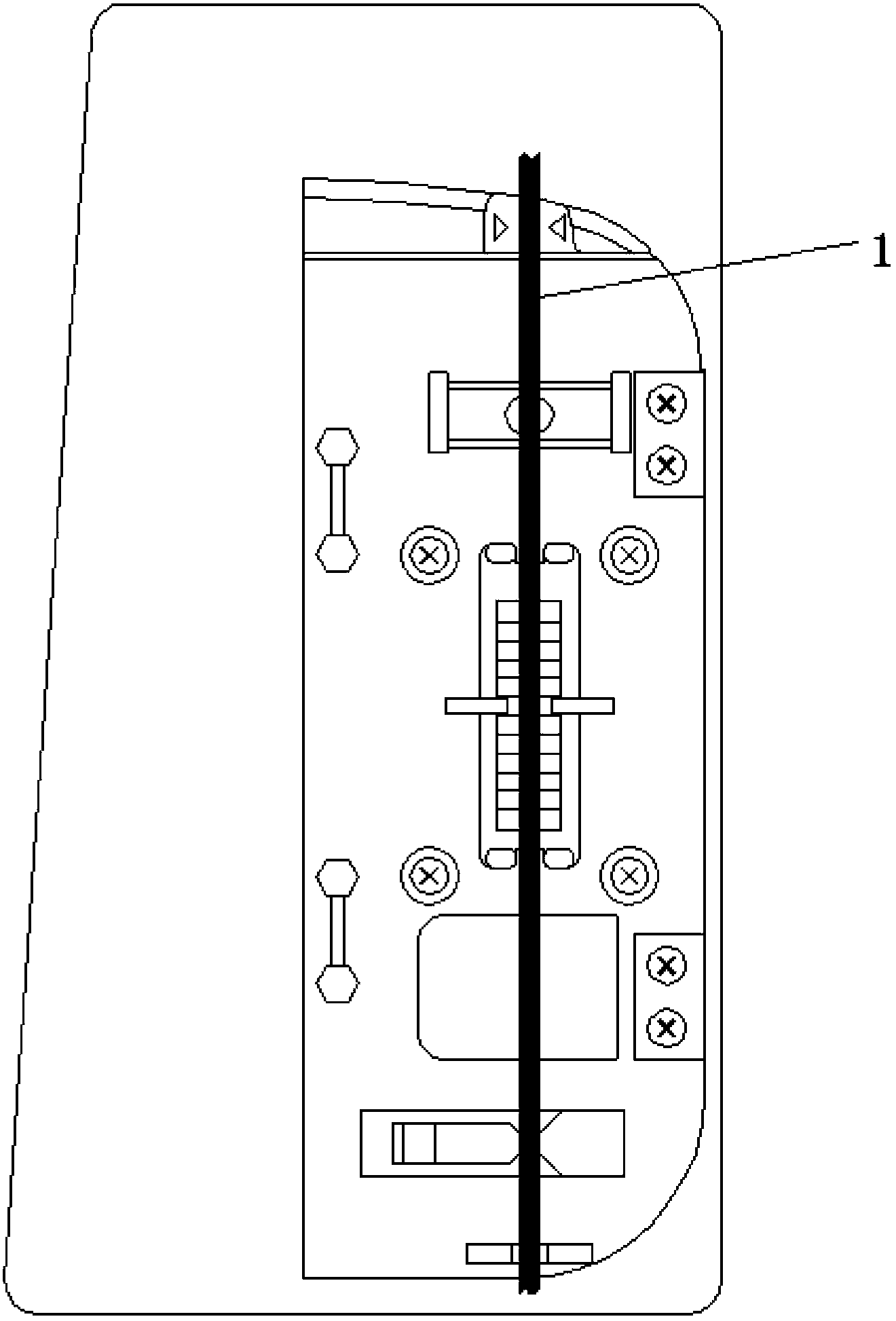

Medical infusion pump

The invention relates to a medical infusion pump which comprises a support housing, wherein an infusion tube is arranged in the support housing; the support housing in the length direction of the infusion tube is set as the longitudinal direction; and the support housing in the radial direction of the infusion tube is set as the transverse direction. The medical infusion pump is characterized in that the medical infusion pump further comprises at least three pressure fingers arranged in the longitudinal direction, wherein straight tooth structures are arranged on the two transverse sides of part or the whole of the pressure fingers; a pair of support shafts is longitudinally and fixedly arranged on the two sides of each straight tooth structure; the support shafts are rotationally connected with a plurality pairs of linked power-assisted arms; a round tooth structure is arranged at one end of each linked power-assisted arm; the round tooth structures are correspondingly meshed with the straight tooth structures; when the pressure fingers are far away from the infusion tube, the round tooth structures drive one corresponding pair of linked power-assisted arms to rotate inwards, and when the pressure fingers are the furthest from the infusion tube, transverse space between centers of head parts of a pair of linked power-assisted arms is equal to or approximately equal to the outer diameter of the infusion tube; and when the pressure fingers are close to the infusion tube, a pair of linked power-assisted arms rotates outwards, and the heads of the linked power-assisted arms depart from the infusion tube.

Owner:上海雷恩医疗器械有限公司

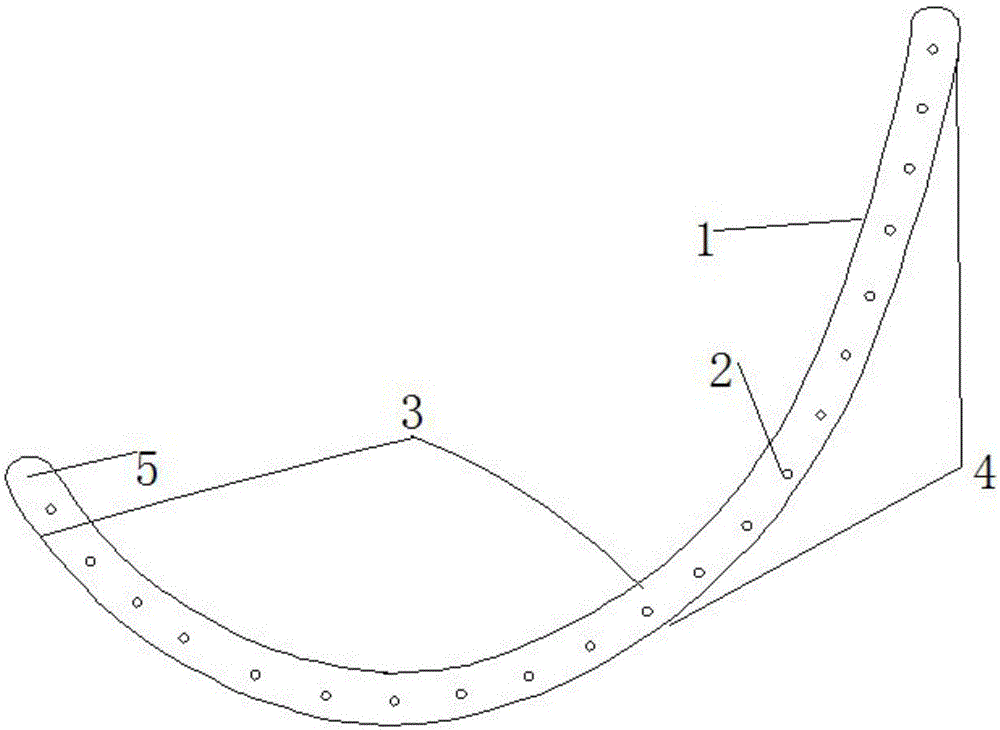

Improved bra underwires, processing method thereof and bra product provided with same

InactiveCN106307645AGood rubber elasticityImprove water resistanceBrassieresEconomic benefitsThermoplastic polyurethane

The invention relates to the technical field of underwear and in particular discloses a kind of improved bra underwires. The improved bra underwires are formed by injecting modified thermoplastic polyurethane elastomer into a mould and then carrying out integral moulding, and relatively dense grooves are accordingly formed in the front and back of the underwires from one end to the other end, so that an inner layer and an outer layer of a bra cup can be closely embedded into the grooves to be connected and fixed with the underwires after being sequentially subjected to glue spraying, cold laminating and mould pressing. The invention also discloses a processing method of the improved bra underwires and a bra product applying the underwires. The improved bra underwires disclosed by the invention is low in cost, a one-time moulding manufacturing process is adopted, environmental protection is realized, resource is greatly saved, and the grooves in the underwires are closely embedded with a bra body, so that the formed bra has good fixity and washing resistance, is difficult to deform, can replace expensive like products and has extremely high marketing value and good economic benefit.

Owner:何斌

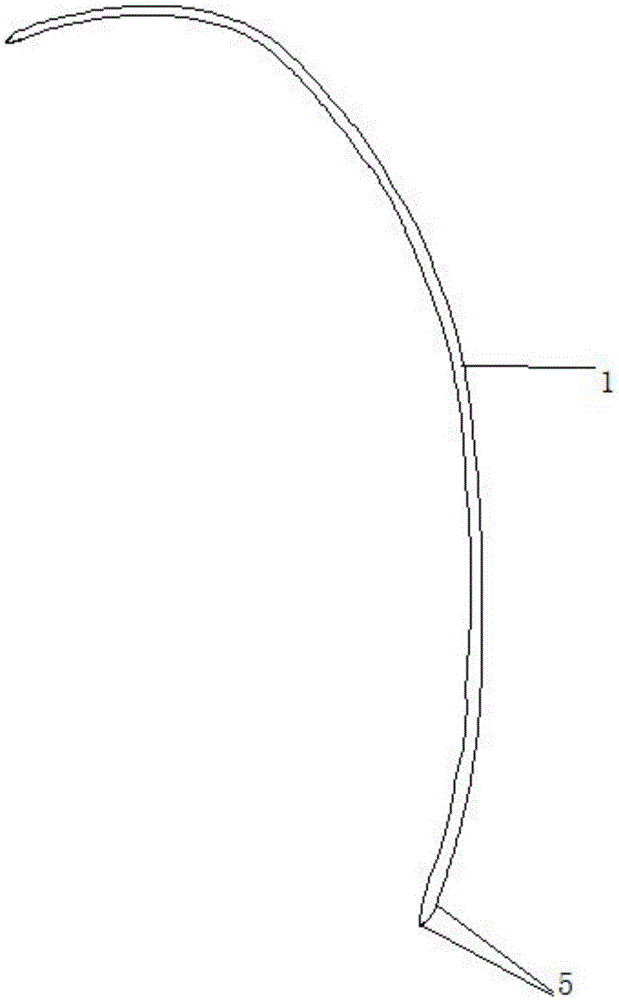

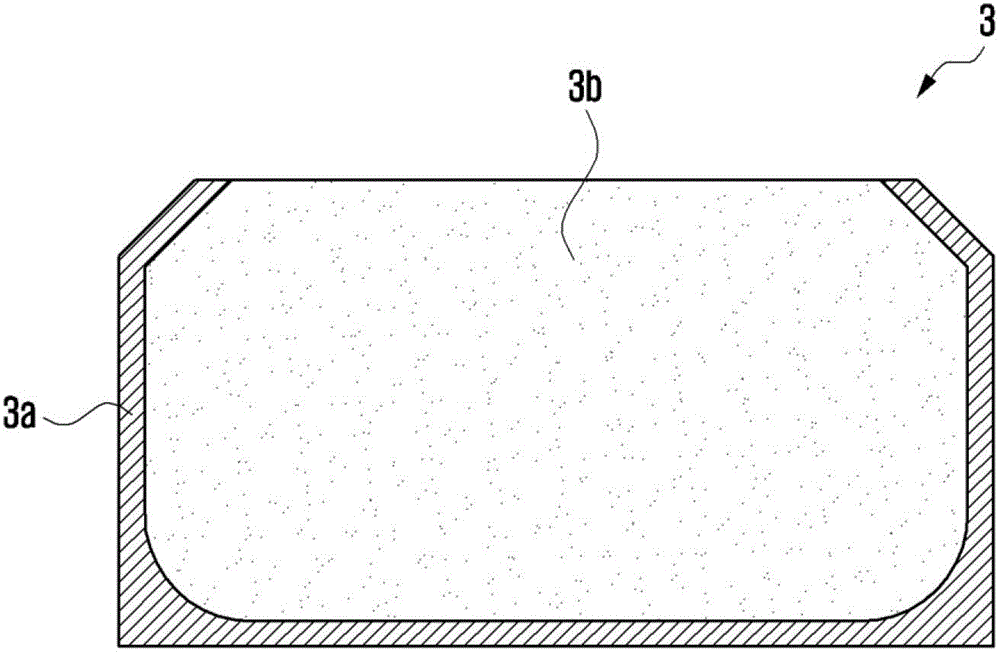

Sealing material for hatch cover and manufacturing method thereof

ActiveCN103362424BGood shape recoveryShorten the timeEngine sealsSealingRubber materialVulcanization

The invention relates to a packing material for a hatch cover, and more specifically relates to a packing material for a hatch cover, which is hollow inside and thus can elastically absorb loads. The packing material for a hatch cover is characterized by comprising a first part and a second part. The first part is formed into an outer frame with a hollow inside, any one face of the upper face and the lower face is open, is made of a first rubber material, and performs elastic deformation with combination with a pressure lever of the hatch cover. The second part is formed inside the first part and is made of a second rubber material. The second part has the following forms by comprising more than two hollow structures and more than one post between the hollow structures. Therefore, according to the packing material, a shape restoration ratio can be improved through the hollow structures inside the packing material; the packing material is made by a continuous vulcanization method and can have stable cross sections, and the time for manufacturing process can be shortened when the continuous vulcanization method is compared with conventional injection moulding methods.

Owner:HS R & A

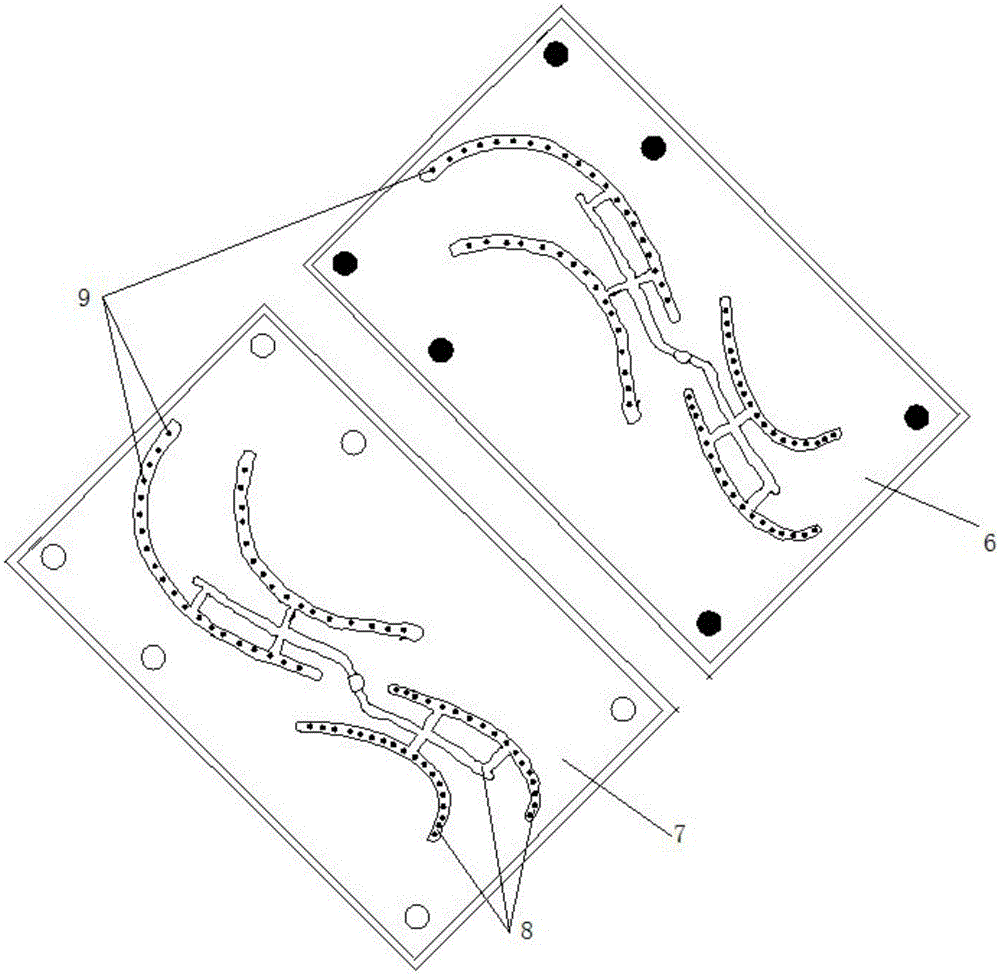

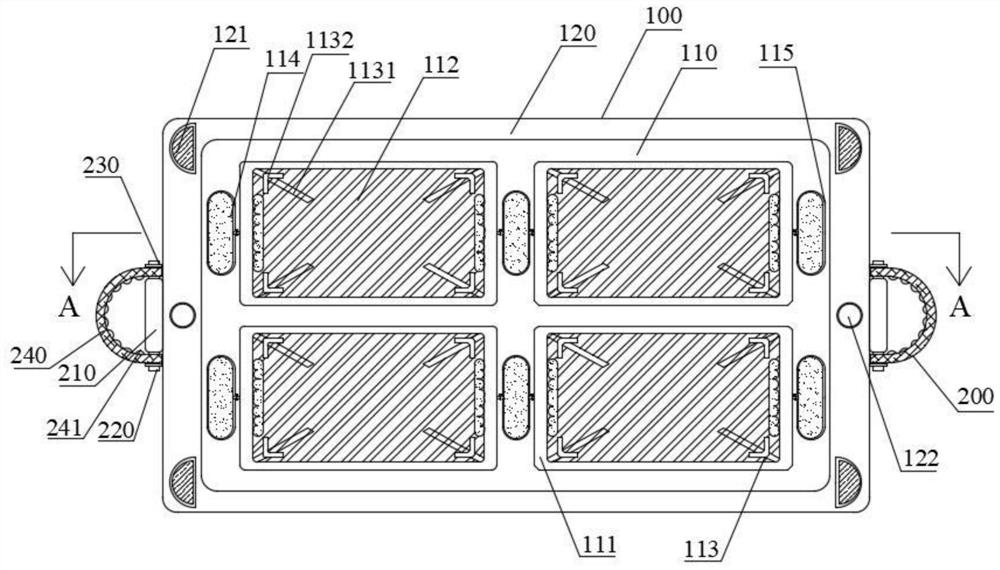

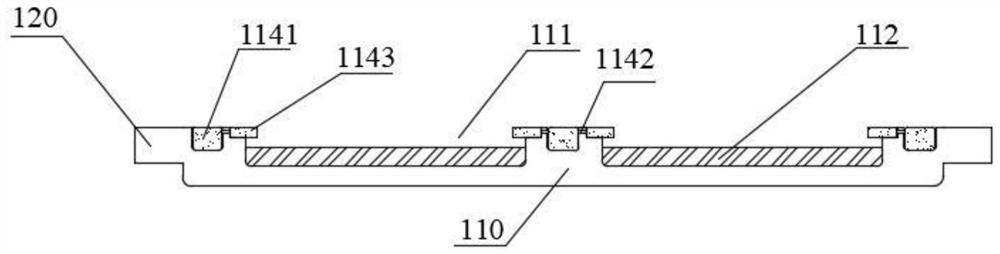

Material storage tray of LCD (liquid crystal display) and production process of material storage tray

ActiveCN113942747AVibration reliefReduce vibrationDomestic articlesContainers to prevent mechanical damageLiquid-crystal displayEngineering

The invention discloses a material storage disc of an LCD and a production process of the material storage disc, and relates to the technical field of display screen storage equipment. The material storage disc comprises a material storage disc body, the material storage disc body comprises a material storage area in the center and a stacking area arranged on the outer edge of the material storage area, adjustable fastening mechanisms are arranged at the positions, located on vibration buffering pads, in liquid crystal display screen containing cavities, and air bag vibration reduction mechanisms used for relieving shaking of the LCD are arranged in the material storage area. According to the material storage disc, stable clamping and fixing of the LCD are achieved, meanwhile, shaking and vibration generated in the taking, placing and carrying processes are relieved, and the stability of the LCD in the material storage process is improved. The production process comprises the steps of material preparation of the material storage disc body, injection molding, cooling demolding, installation of the adjustable fastening mechanisms, installation of the air bag vibration reduction mechanisms and installation of handheld parts, harsh conditions are not needed, the strength, elasticity, ventilation and heat dissipation performance of the material storage disc are guaranteed, and the material storage disc is suitable for large-scale production.

Owner:蚌埠市高远光电有限公司

A shape self-repairing wave-absorbing material and its preparation method

ActiveCN109666262BShape self-healing performance optimizationExcellent shape self-healing performancePolymer sciencePolystyrene

The invention relates to a shape self-repairing wave-absorbing material and a preparation method thereof. The method includes: (1) uniformly mixing a resin matrix, a toughening agent and a curing agent with a mass ratio of 1:(0.02-0.33):(0.01-0.017) to obtain a resin prepolymer, and the resin matrix is selected from epoxy A group consisting of resin, polyurethane resin, polystyrene resin and polynorbornene resin; (2) adding ferrite powder, carbonyl iron powder, conductive carbon black, carbon fiber, silicon carbide to the obtained resin prepolymer fiber, carbon nanotubes and graphene and stir evenly to obtain a shape self-repairing absorbing resin; (3) curing the shape self-repairing absorbing resin at two or more different temperature stages to obtain a shape self-repairing absorbing resin Repair the absorbing material. The method of the invention endows the wave-absorbing material with shape self-repairing performance, and can meet the requirement of recovering the wave-absorbing performance of the wave-absorbing material after being damaged and deformed by an external force.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method and application of bio-based polymer capable of recovering high strain

The preparation method comprises the following steps: (1) preparation of bio-based polyol: mixing peanut shell powder with a liquefying reagent, starting condensate water and a stirrer, heating a constant-temperature oil bath pan to 135-145 DEG C, slowly dropwise adding a catalyst, starting timing after the catalyst is completely added, and stopping the reaction; after reacting for 2-3 hours, quickly cooling to room temperature to obtain bio-based polyol; and (2) preparation of the bio-based polymer: mixing the bio-based polyol, the sieved peanut shell powder, deionized water and a catalyst I to obtain the bio-based polymer. According to the preparation method and application of the bio-based polymer capable of recovering the high strain, the preparation method is reasonable, the peanut shells are used as the raw material to prepare bio-based polyol, energy consumed in the production process is low, carbon emission is reduced, and the prepared bio-based polymer is high in strain, low in modulus and high in recovery rate. The shape fixing rate, the shape recovery rate and the cycling stability are good, and the application prospect is wide.

Owner:江苏时代铭阳生物新技术研究院有限公司

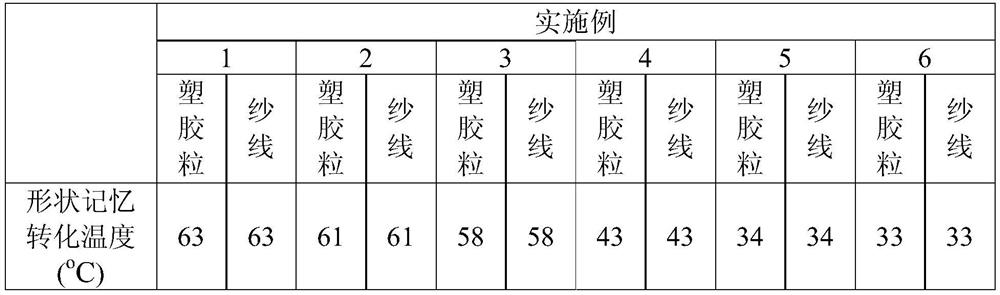

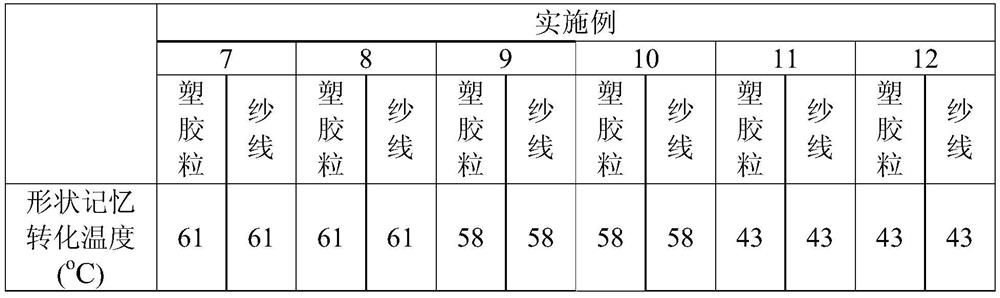

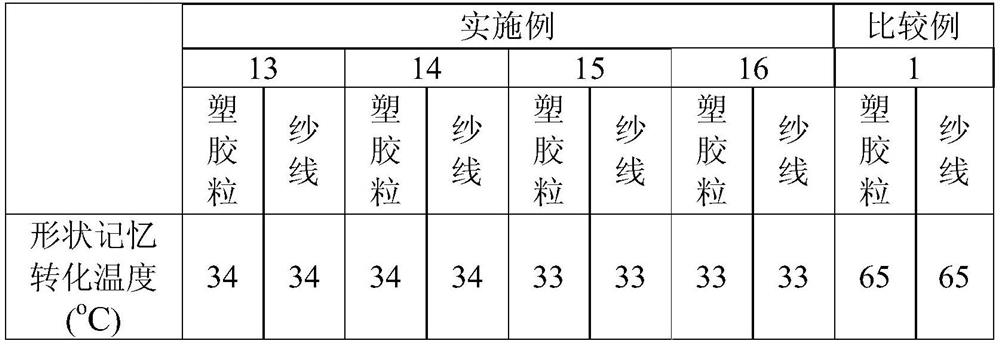

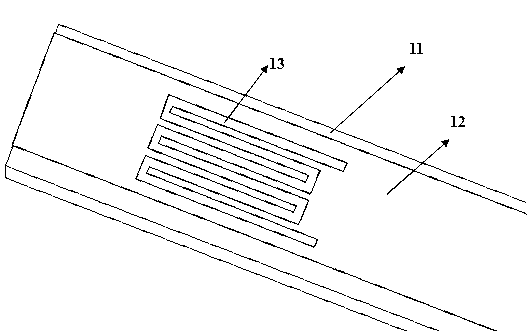

Plastic pellets and yarn

The invention provides a plastic particle and a yarn, the plastic particle includes shape-memory polyurethane, polyurethane and a polyurethane-type dispersant, wherein the shape-memory polyurethane is formed by the following steps: polymerizing a diisocyanate and a polyol to form a polymer, and The polymer is polymerized with a chain extender to form shape memory polyurethane. The yarn is made of the plastic pellets. The plastic particles and yarns have shape memory properties, and have good shape fixation rate, shape recovery rate, textile processability and textile applicability.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Cardiovascular blood flow velocity sensor

InactiveCN102370476BImprove flexibilityGood biocompatibilityBlood flow measurementCardiovascular stentBlood flow

The invention relates to a cardiovascular blood flow velocity sensor, which comprises a cardiovascular bracket and a flow velocity sensor. The cardiovascular bracket is a tubular film. The flow velocity sensor is on the inside surface of the tube wall of the cardiovascular bracket. The flow velocity sensor comprises a substrate, the surface of which is coated with a coat. An electrode is arrangedat the upper side of the substrate. According to the cardiovascular blood flow velocity sensor disclosed by the invention, the production process is simple; the cardiovascular blood flow velocity sensor has good biocompatibility, higher mechanical flexibility and corrosion resistance and excellent self-expansion property; the cardiovascular blood flow velocity sensor is beneficial to working in human body stably for a long time; the real-time measurement of cardiovascular flow velocity is realized; and the problems urgently needed to be solved in clinic are solved.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com